Patents

Literature

187results about How to "Improve turning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

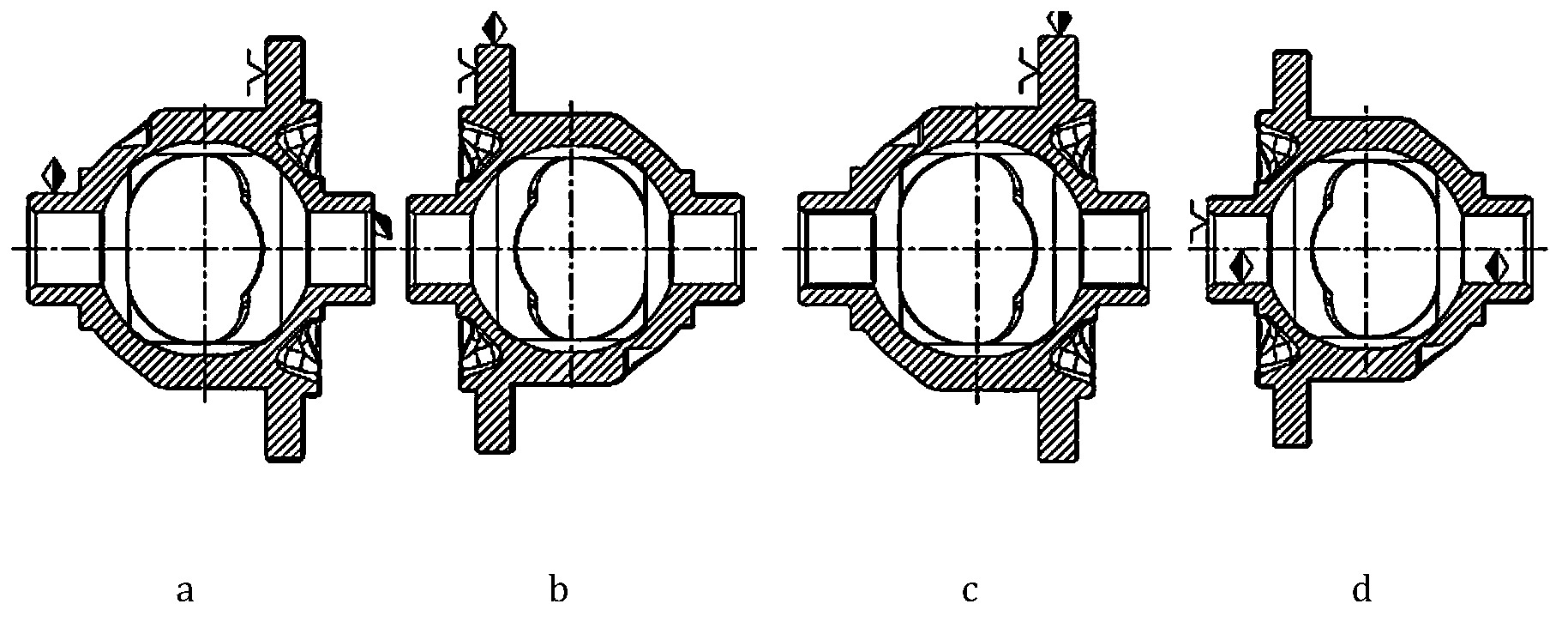

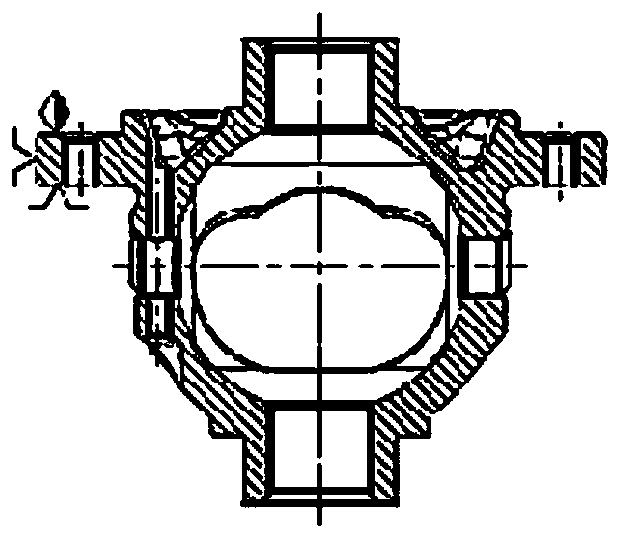

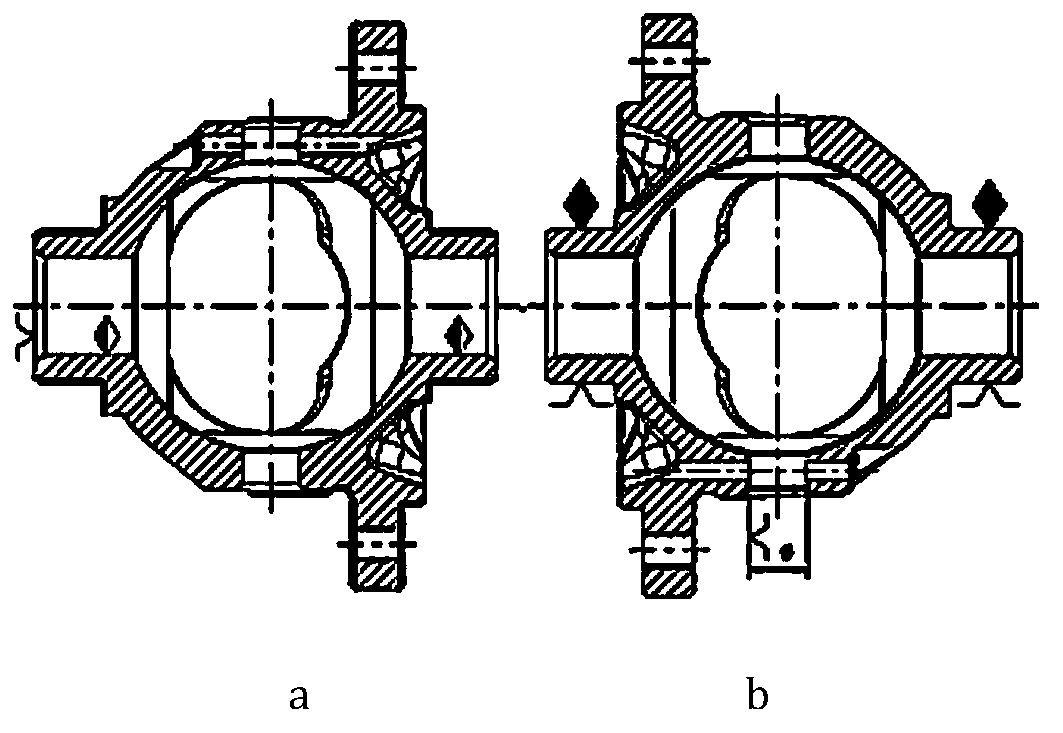

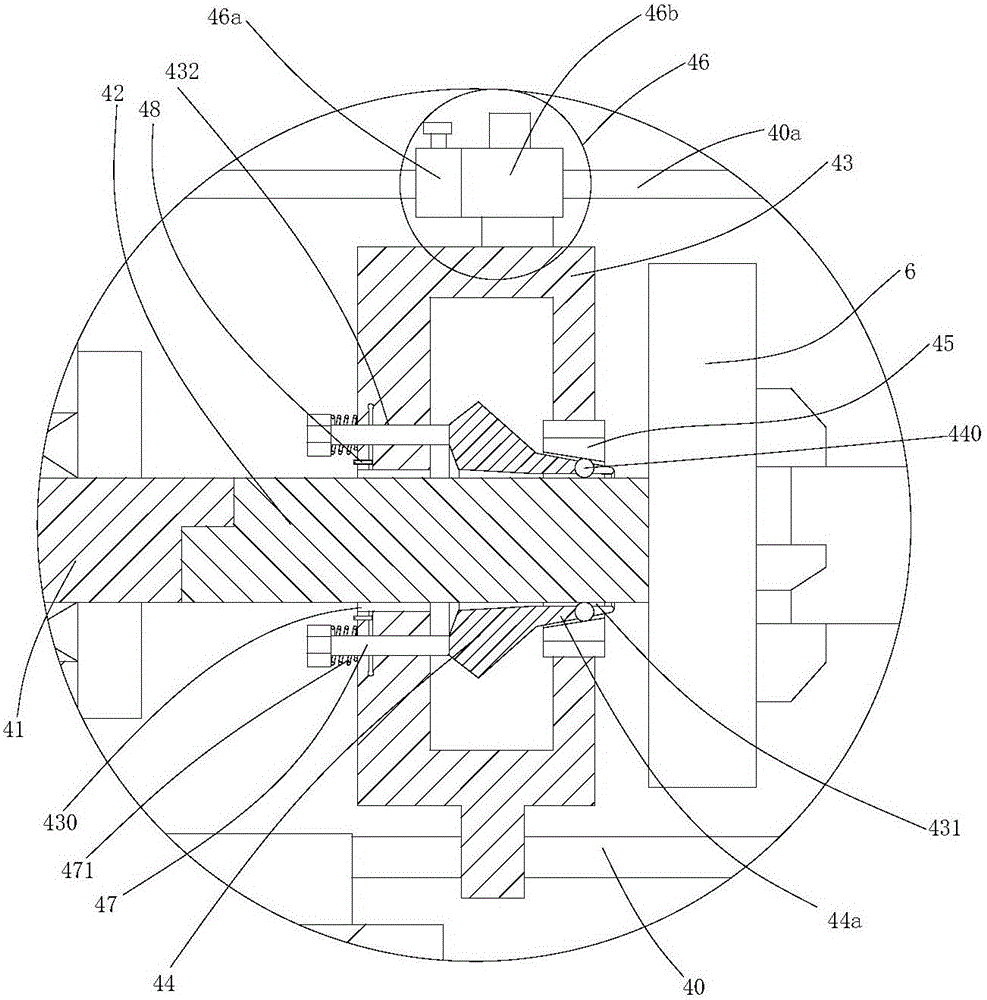

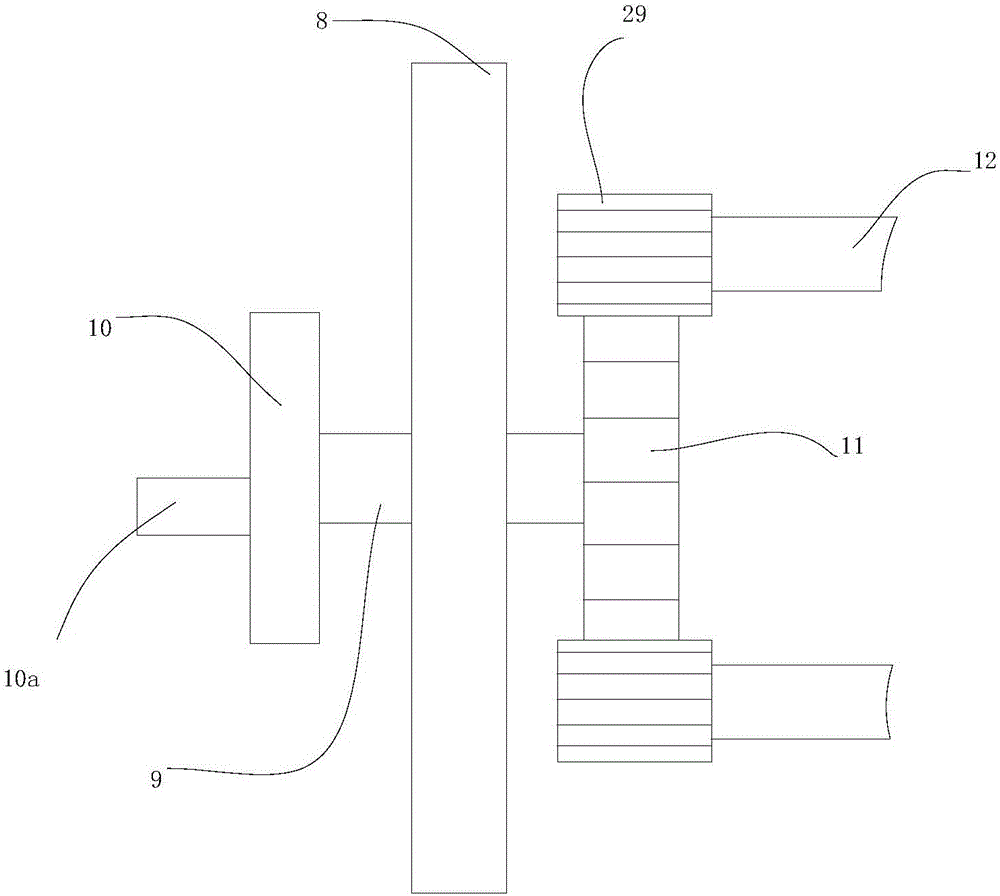

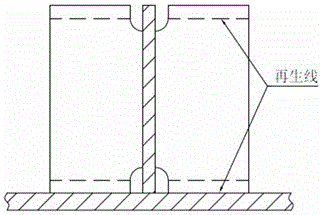

Device and process for machining differential housing

ActiveCN103753322ARealize batch production processingRealize inputWork clamping meansExpansion mandrelsNumerical controlCar manufacturing

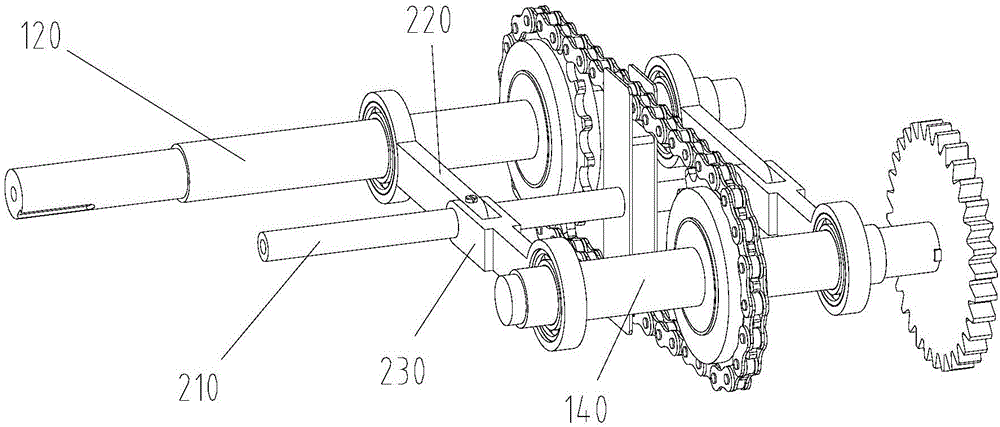

The invention belongs to the technical field of automobile manufacturing and discloses a device and process for machining a differential housing. The device is composed of a rotary jig, an internally-expanding lathing jig and a spherical surface lathing jig, wherein the rotary jig is arranged on a machining center and comprises an operation part with the two ends arranged on the machining center through rotating assemblies, and the internally-expanding lathing jig and the spherical surface lathing jig are arranged on a common numerically-controlled lathe. Synchronous machining of two parts can be achieved through the high-precision rotary jig when the machining center is used for machining various axial inner holes, and therefore efficiency is higher; a high-precision numerically-controlled indexing table is applied to the jigs, rotating accuracy is as high as 20'' or higher, and precision of the critical size of a product is better guaranteed; the parts can be automatically clamped and dismounted by the jigs through numerical control programs, and therefore labor can be saved.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

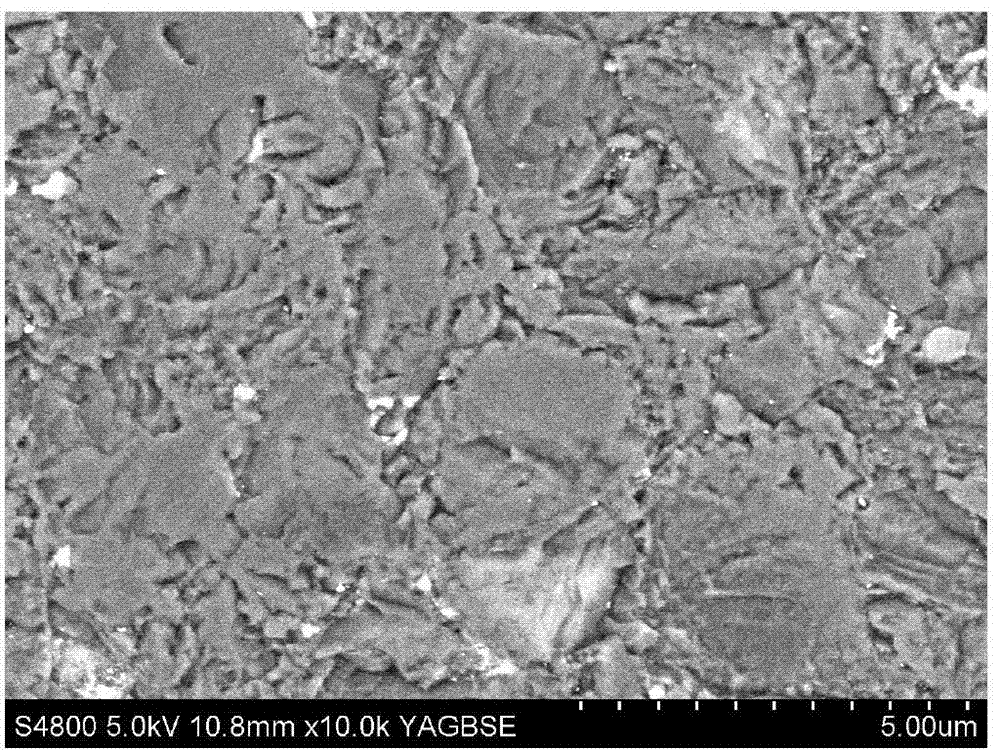

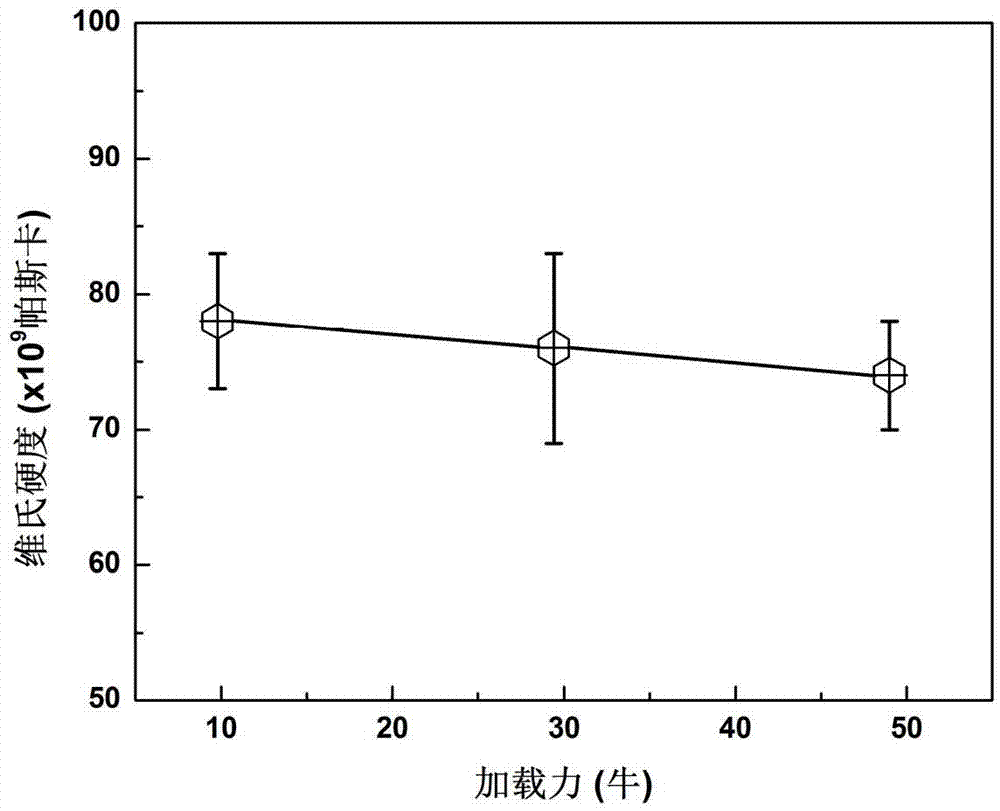

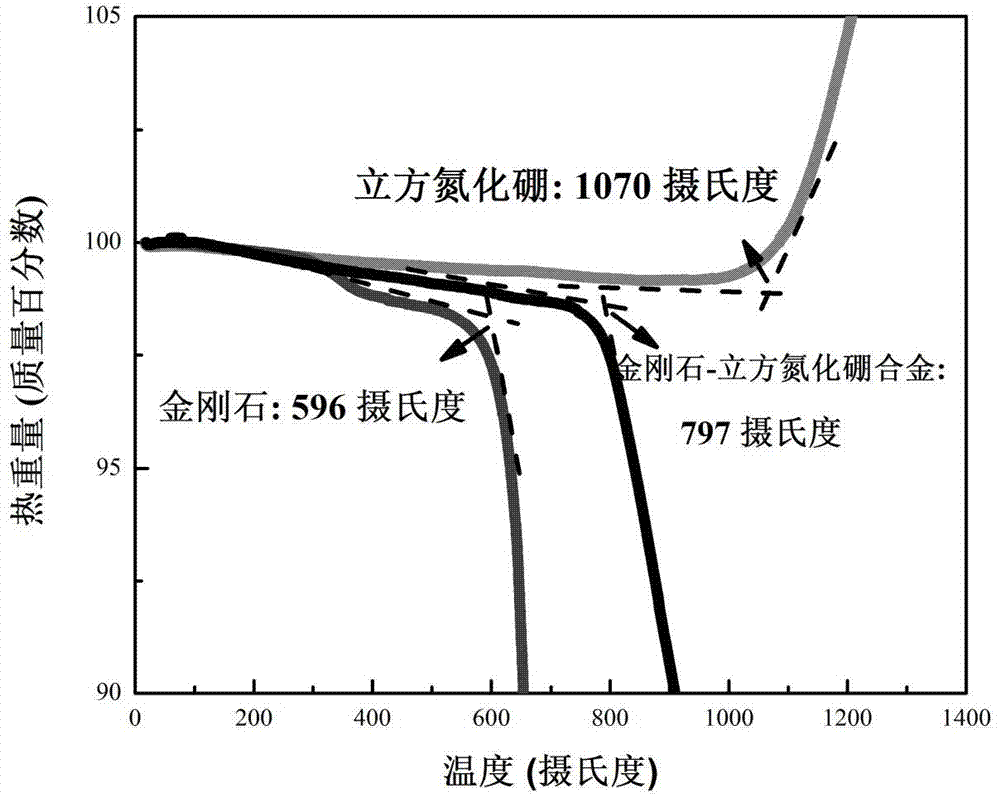

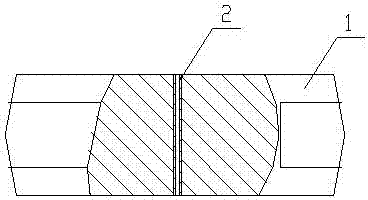

Diamond-cubic boron nitride type universal superhard cutter material, cutter and preparation method of material

InactiveCN104759240AHigh hardnessImprove thermal stabilityUltra-high pressure processesSuperhard materialAlloy

The invention discloses a diamond-cubic boron nitride type universal superhard cutter material, a cutter and a preparation method of the material. The material is characterized in that diamond and cubic boron nitride are used as raw materials, the pre-treatment and the forming are performed on the raw materials to obtain a blank; the blank assembled with a sintering unit is arranged in a high temperature and high pressure device, wherein the intensity of pressure is 7-25GPa, the temperature is 1000-2700 DEG C, the sintering solution strengthening lasts for 10s-30min, the sizes of obtained crystal grains are uniform, and interfaces of the crystal grains are tight and closed; the compact-structure diamond-cubic boron nitride type universal superhard cutter material which is high in atomic density, is in a three-dimensional network shape and has strong covalent bonds can be formed by boron atoms, carbon atoms and nitrogen atoms at the crystal interfaces between the diamond and the cubic boron nitride. The universal superhard material is processed into a cylinder with the same height; two ends of the cylinder are polished and finished and then are processed to be in triangular cylinder shapes with the side lengths and the thicknesses of 2-3mm, the processed cylinder and a steel alloy base body are welded under the vacuum degree being 1*10<-3>Pa at the temperature being 800 DEG C, and then the laser processing is performed, so that the superhard alloy cutter in which the radius of the circular arc of the knife point is 0.4-0.8mm is obtained.

Owner:SICHUAN UNIV

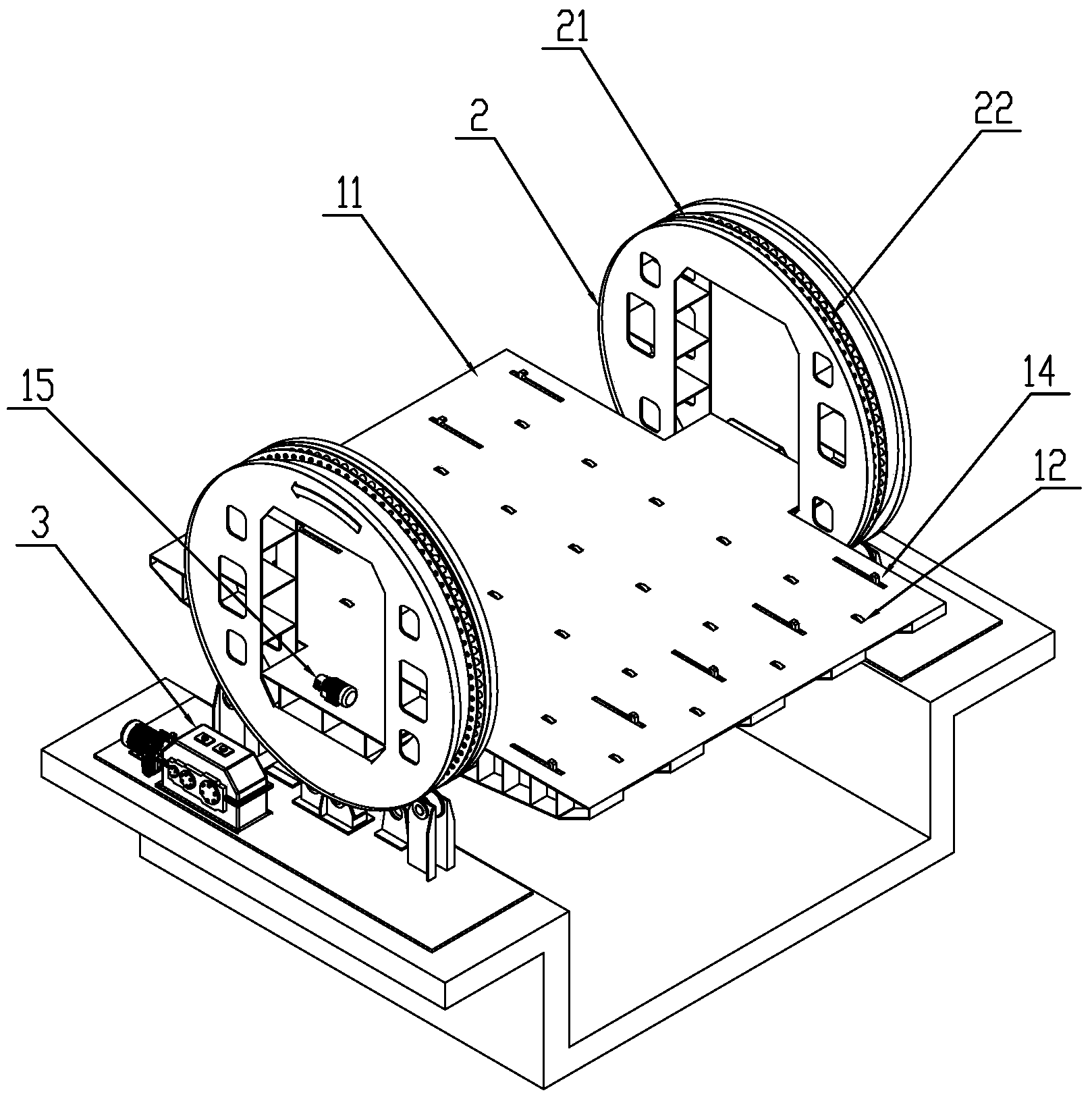

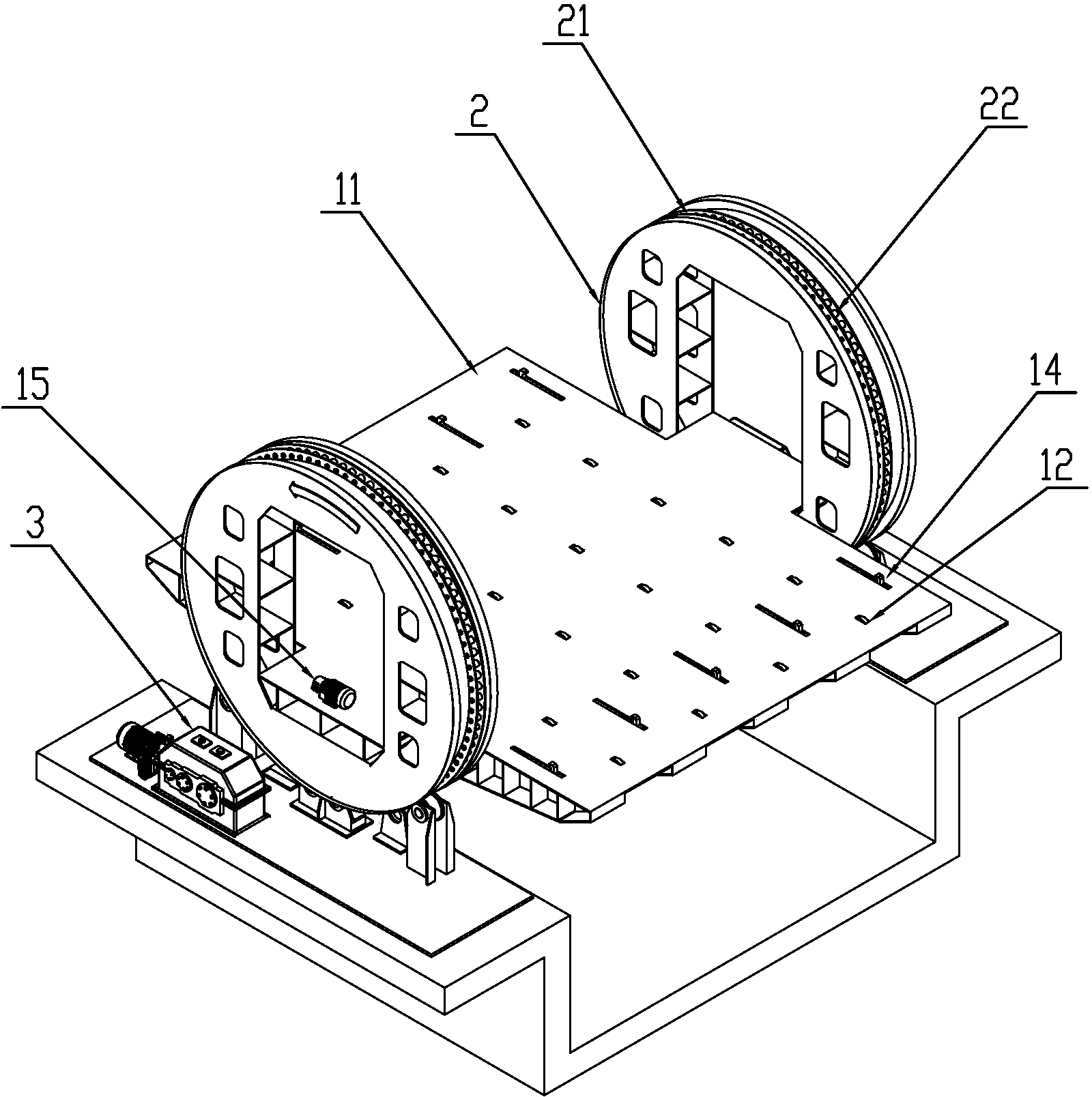

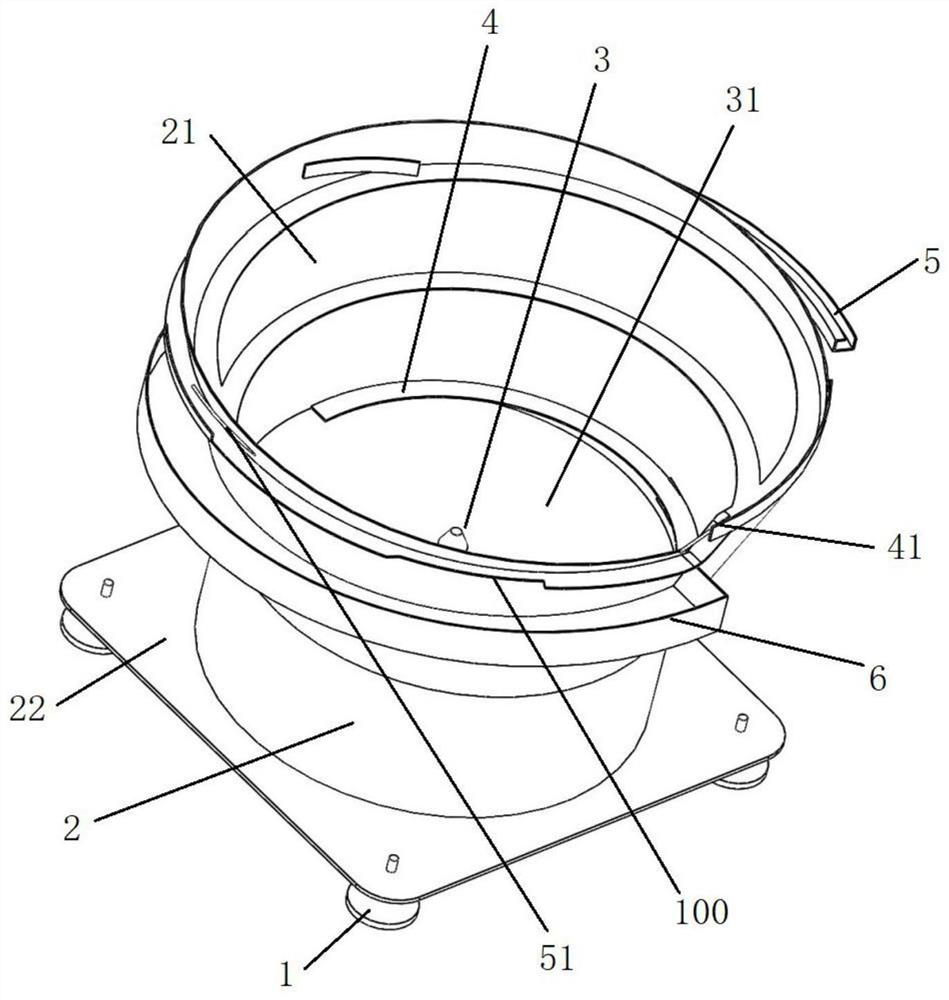

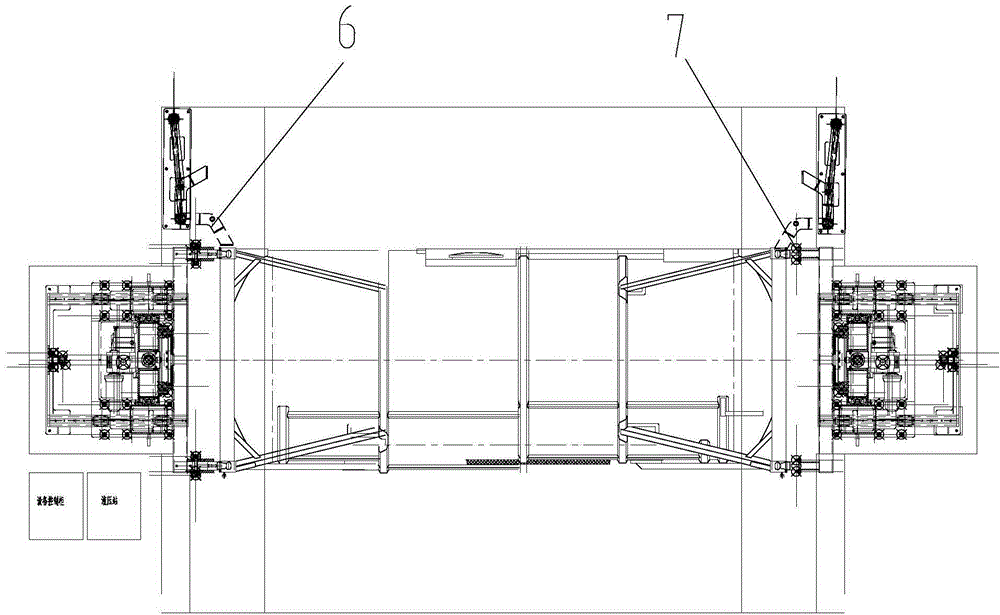

Lift roller based hull block turning equipment during ship construction

ActiveCN103661799AImprove build accuracyReduce secondary transportVessel partsEngineeringMechanical engineering

The invention discloses lift roller based hull block turning equipment during ship construction. The turning equipment comprises a rotary table (11). Two sides of the rotary table (11) are fixed on rotary rings (21) used for overturning respectively. The rotary table (11) comprises an electromagnet adsorption component and a plane attached to a hull block. Each rotary ring (21) rotates together with an outer side driving gear (33). Grooves are formed in the plane, attracted to the hull block, of the rotary table (11) at intervals. Lift roller components (12) are arranged in the grooves. Each lift roller component (12) comprises a track (123) perpendicular to the plane of the rotary table (11). Roller carriers (124) with rollers (121) are arranged in the tracks (123). Lift roller hydraulic oil cylinder components (122) are connected to the lower sides of the roller carriers (124). Rotary shafts of the rollers (121) are connected with roller driving motor components. By the turning equipment, construction cost of the hull block is greatly reduced, and construction efficiency is improved.

Owner:DALIAN SHIPBUILDING IND

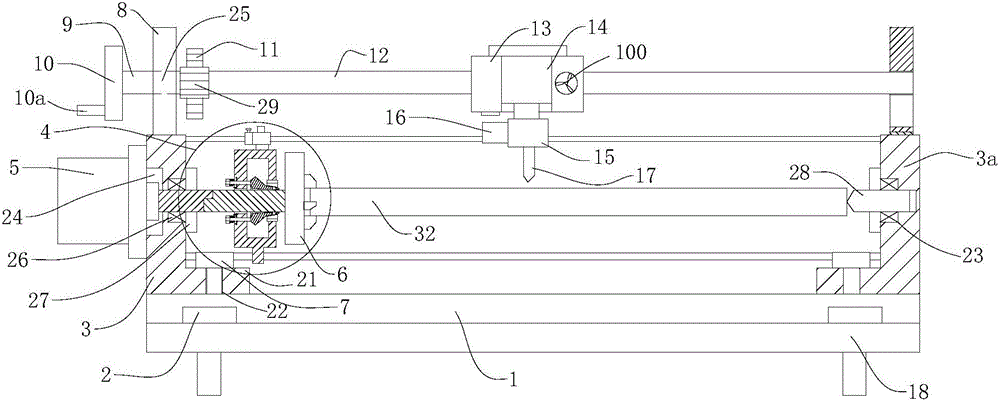

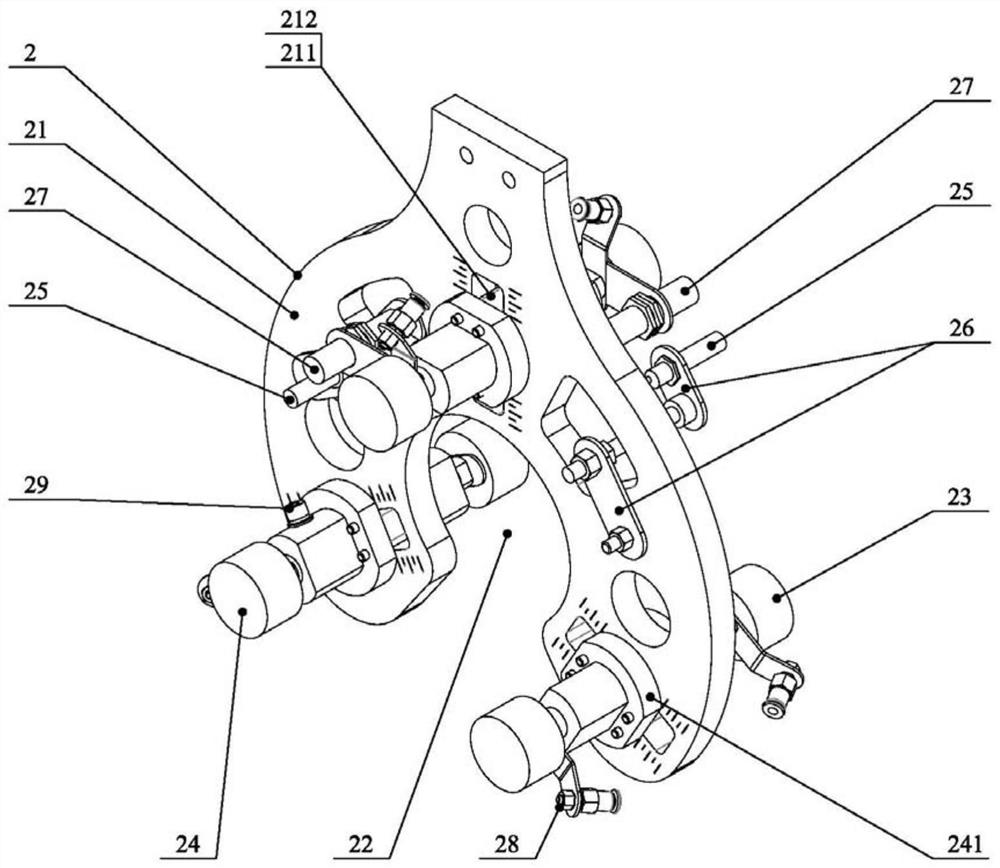

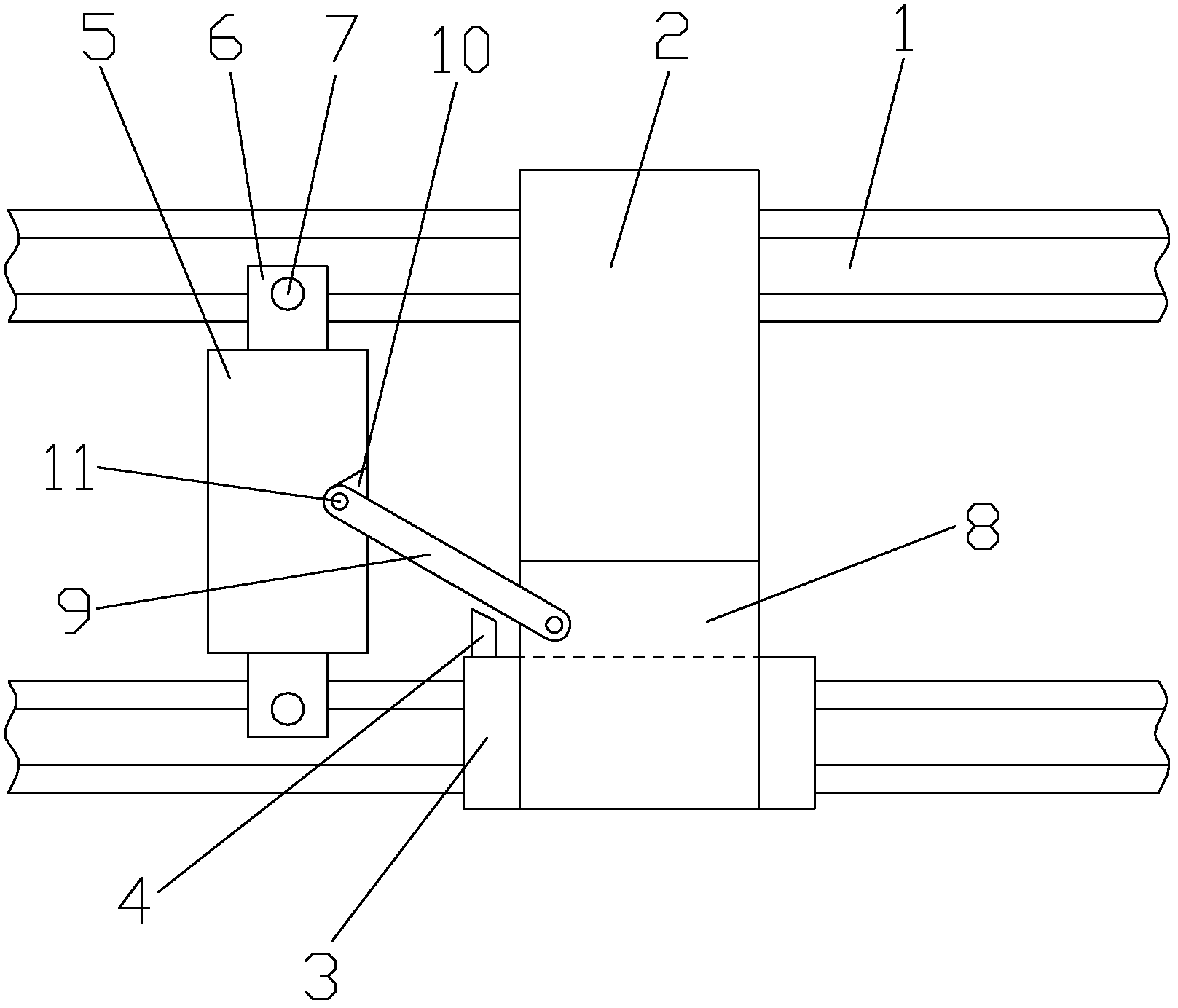

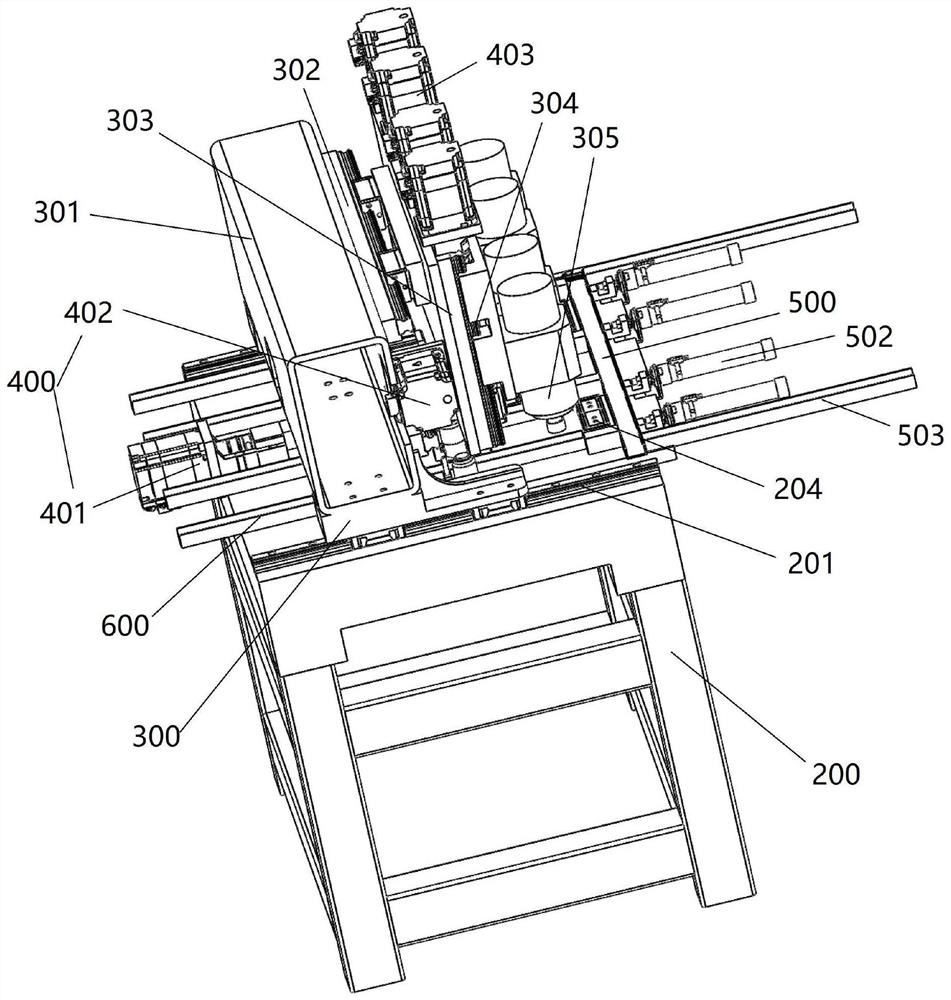

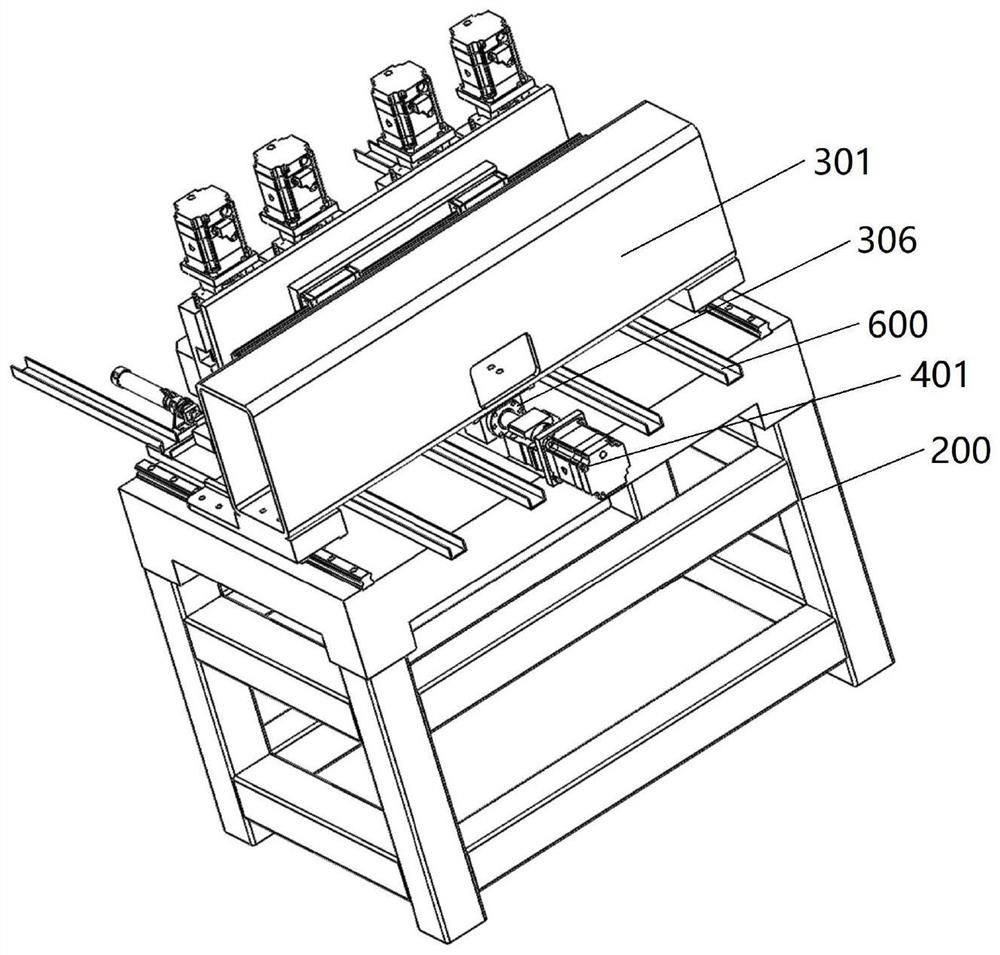

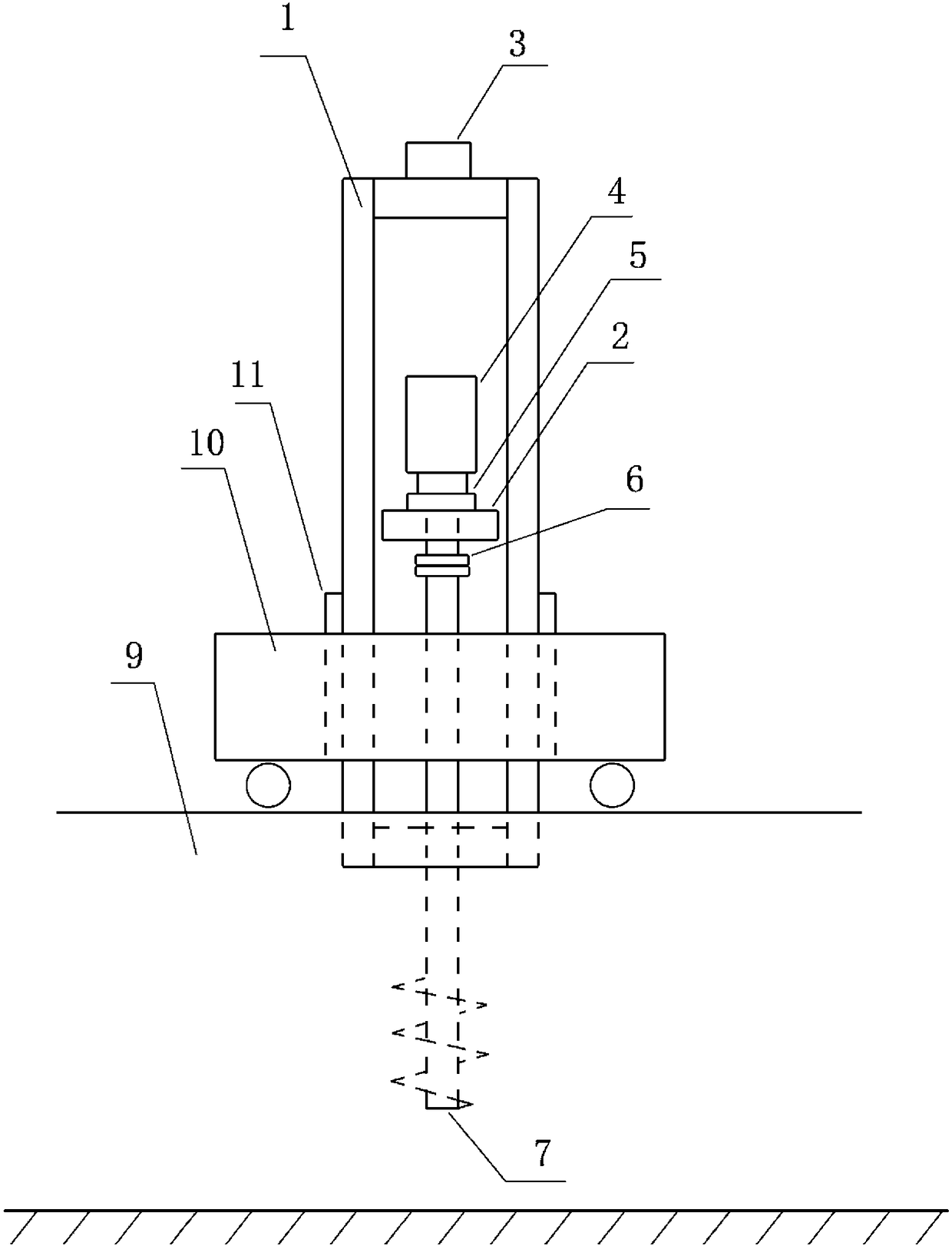

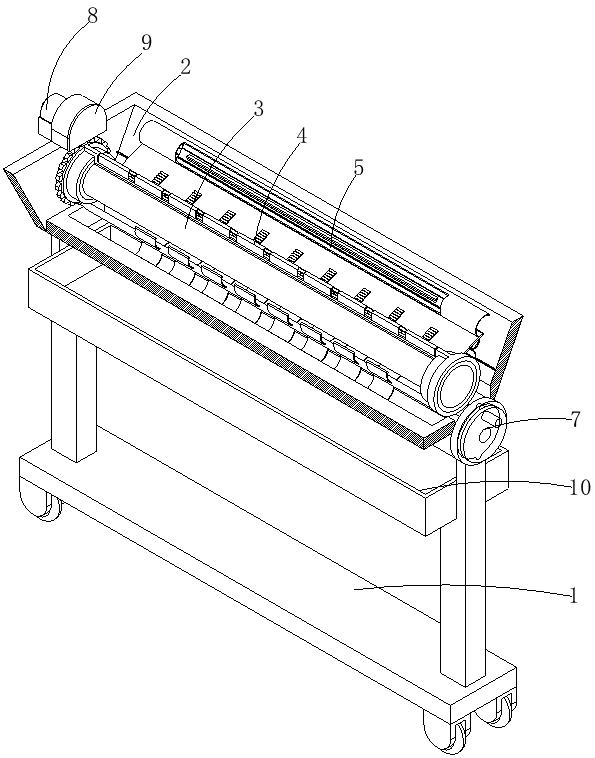

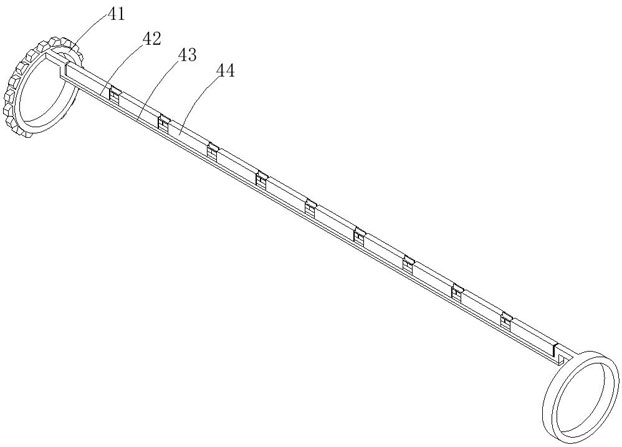

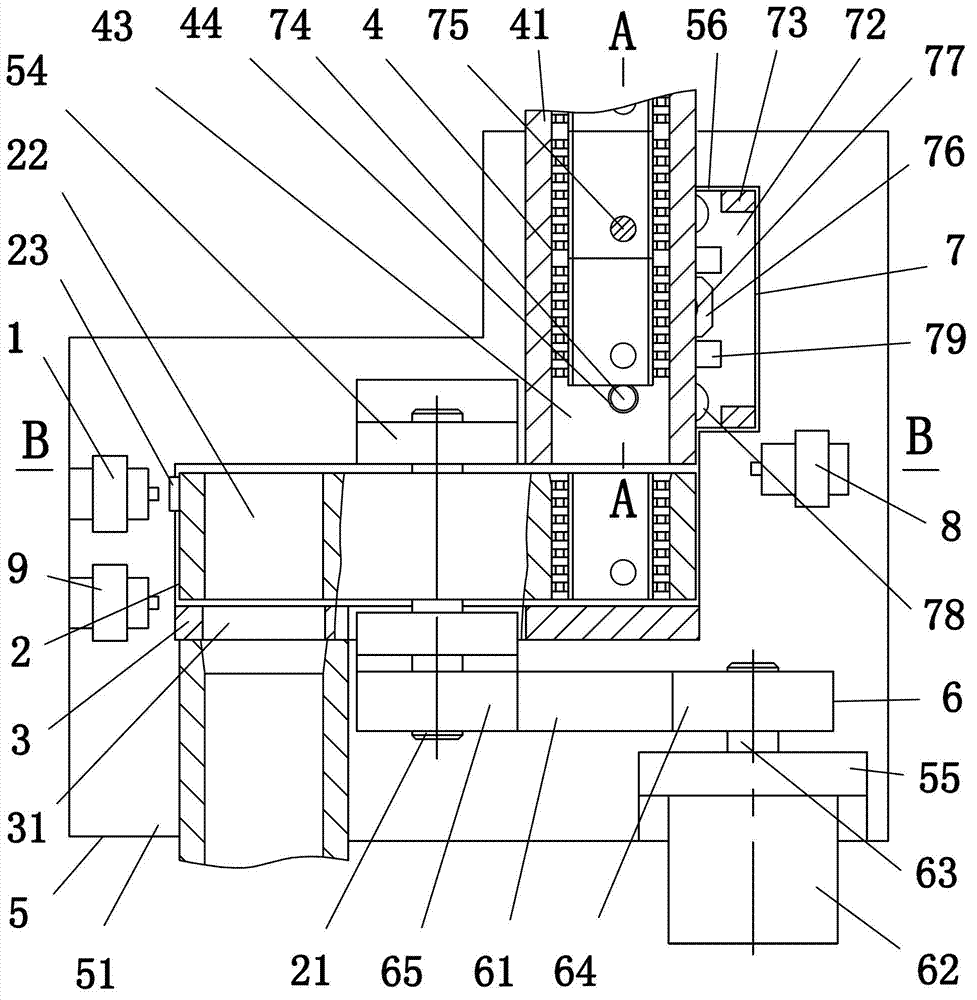

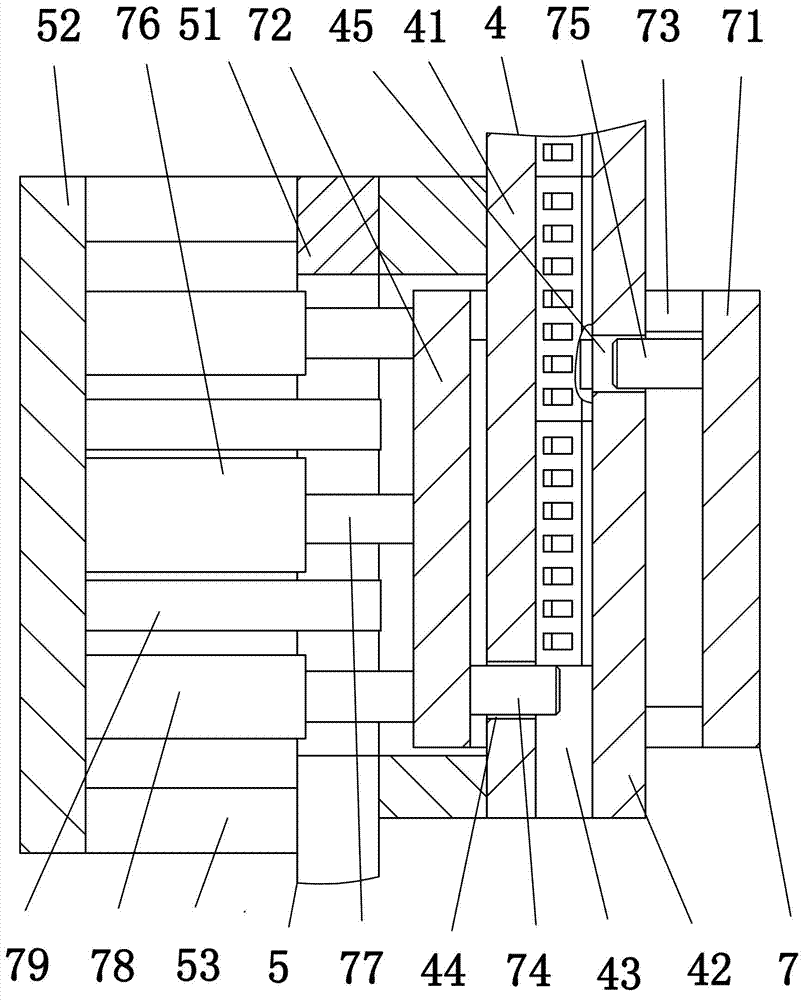

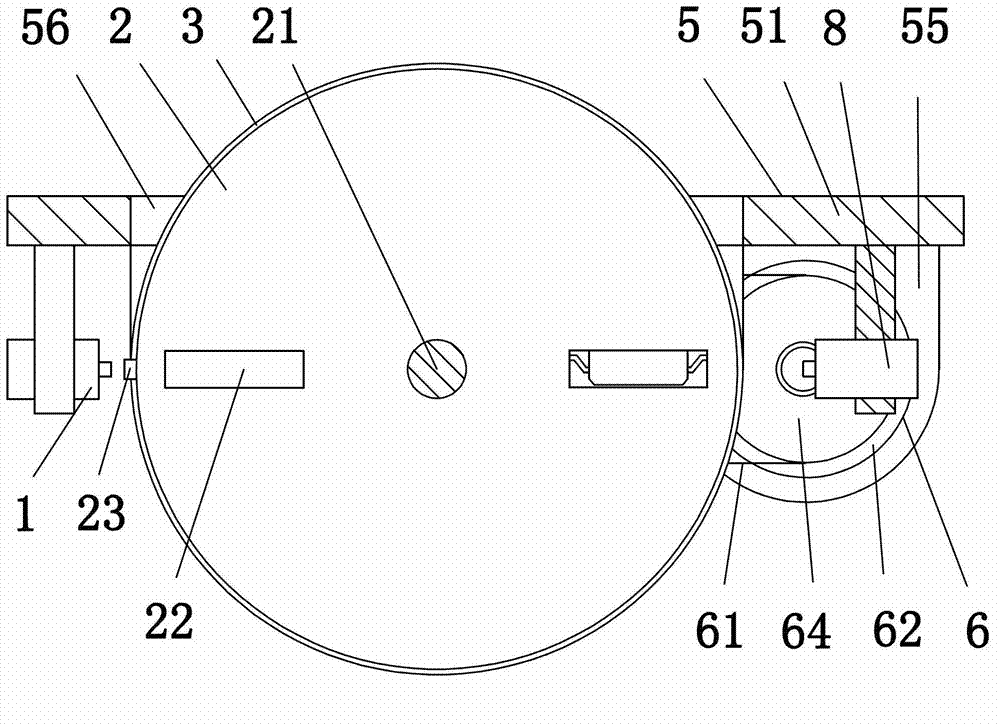

Turning equipment

ActiveCN106270560AReduce the probability of breakageImprove turning efficiencyAuxillary equipmentTurning machinesEngineeringKnife holder

The invention provides turning equipment which can be used for turning workpieces with different length and is high in process accuracy and efficiency. The turning equipment comprises a base, a left frame, a right frame and a turning mechanism, and the turning mechanism comprises a moving mechanism and a turning assembly. The moving mechanism comprises a group of a screw seat, a rotary shaft, a hand wheel, a handle, a screw gear and a moving mechanism driven gear which are fixed on the left frame and the right frame respectively and a group of screws which are arranged in parallel. The turning assembly comprises a knife holder, an oil cylinder, a knife rest, a turning motor and a turning tool, the knife rest is assembled on the screws, the oil cylinder is arranged on the knife holder, the knife rest is connected to the output end of the oil cylinder, and the turning motor and the turning tool are mounted on the knife rest. The turning equipment cannot only adaptively adjust the processed installation positions so as to adapt to the workpieces with different length but also can reduce the probability that the surface accuracy of the turning workpieces is low and the fracture probability is high due to ununiform stress in the workpiece turning process.

Owner:浙江科锦机电有限公司

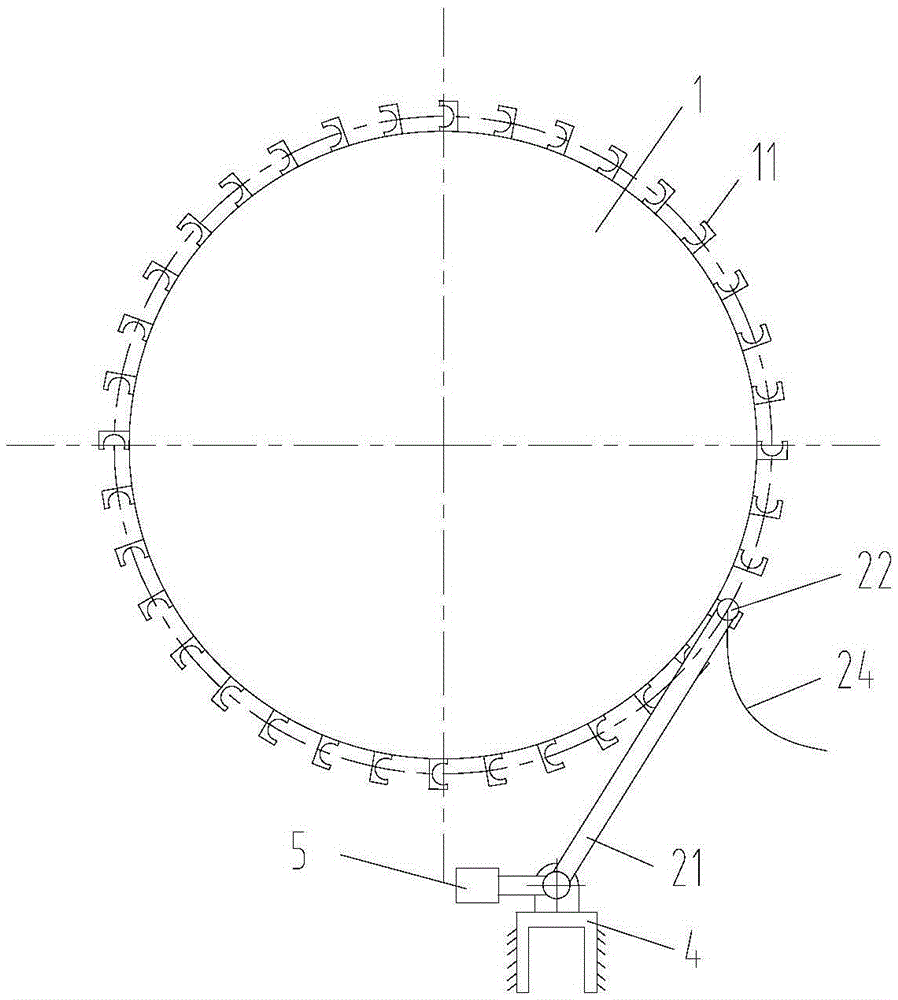

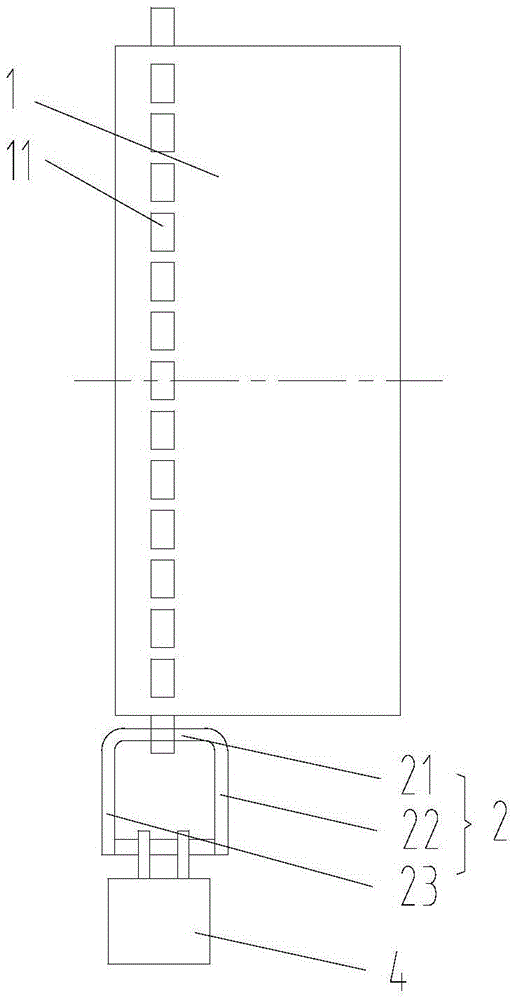

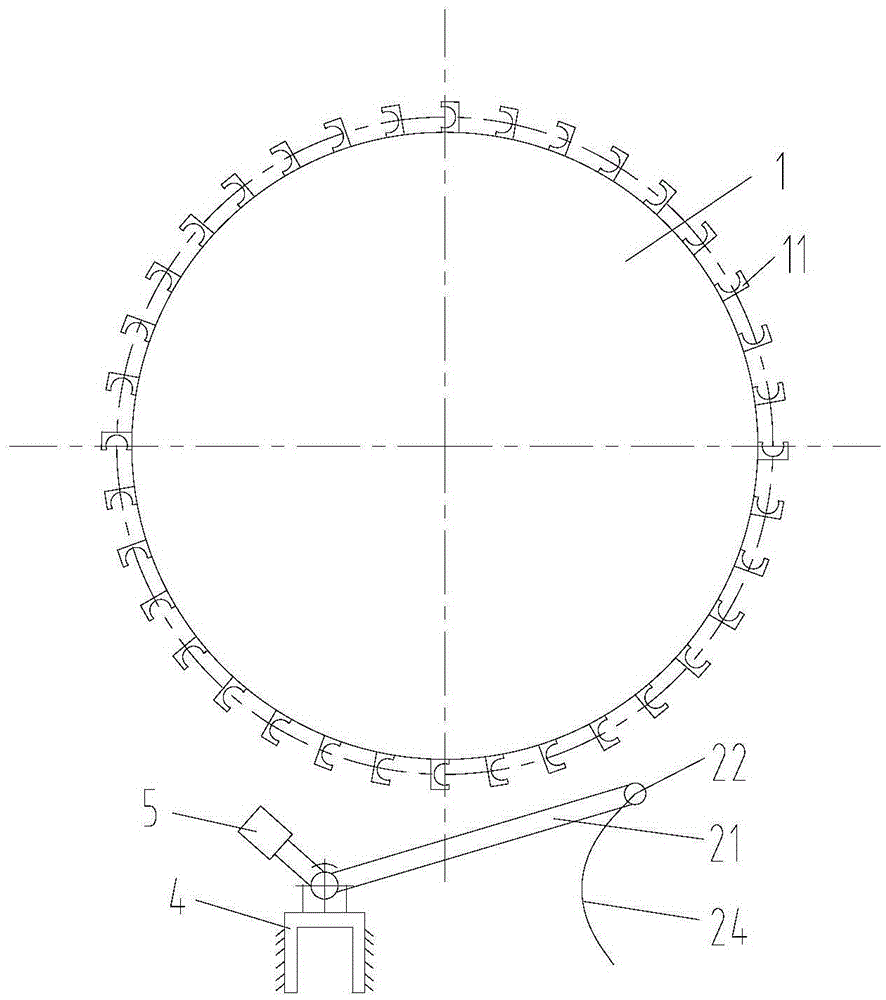

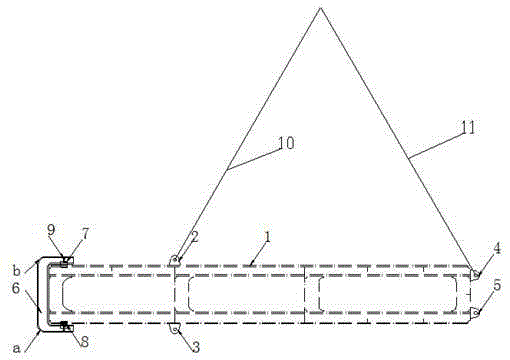

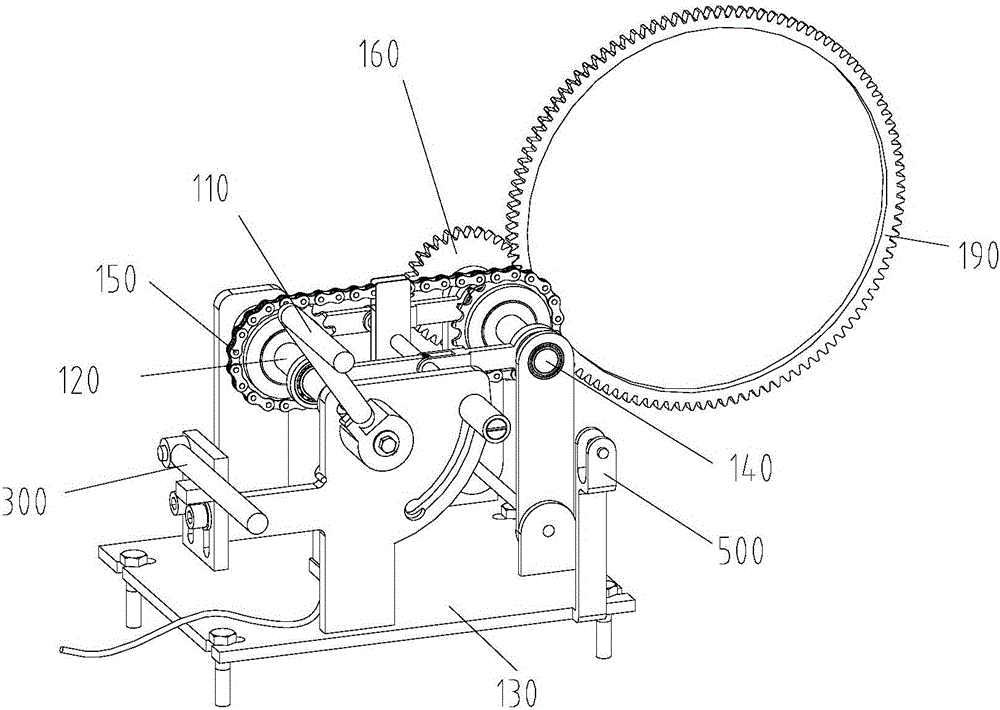

Wind turbine generator set impeller turning device and turning method

ActiveCN105673349ASimple structureImprove turning efficiencyWind motor assemblyWind energy generationAutomotive engineeringNacelle

The invention provides a wind turbine generator set impeller turning device and turning method. A wind turbine generator set comprises an electric generator, a tower drum, a machine room, a yawing mechanism and a rotor. The machine room is arranged on the tower drum and can rotate around the axis direction of the tower drum. The yawing mechanism is connected between the machine room and the tower drum. The rotor is connected to the machine room and can rotate around the axis direction of the electric generator. The wind turbine generator set impeller turning device comprises a pulling part. The first end of the pulling part is connected to a fixed platform. The second end of the pulling part is detachably connected with the rotor. When the machine room is driven by the yawing mechanism to rotate, the pulling part makes the rotor rotate. According to the wind turbine generator set impeller turning device, an additional power source is not needed, so that the structure is simple, the turning efficiency is improved, and the turning cost is reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

Turning processing method of wheel groove milling cutter

The invention discloses a turning processing method of a wheel groove milling cutter and relates to a turning processing method, in particular to a turning processing method of a wheel groove milling cutter. The turning processing method aims to solve the problem that coincident axial size of a molded line of the wheel groove milling cutter cannot be guaranteed by the existing processing method. The turning processing method comprises the following steps that the wheel groove milling cutter is processed on an engine lathe; then the wheel groove milling cutter is installed on a turning fixture, and the molded line of the wheel groove milling cutter is semi-finished by using a 55 DEG rhombic turning tool blade on a numerically controlled lathe; then the molded line of the wheel groove milling cutter is finished by using a 35 DEG rhombic turning tool blade; and after processing, the wheel groove milling cutter is taken from the turning fixture. The turning processing method is used for the turning wheel groove milling cutter.

Owner:HARBIN TURBINE

Touchdown turning process of subsection

InactiveCN104528525AAvoid damageReduce loadWelding/cutting auxillary devicesAuxillary welding devicesLong axisEngineering

The invention relates to a touchdown turning process of a subsection. During turning, a first steel wire rope and a second steel wire rope are respectively connected with a first lug on the side of a long shaft and a second lug on the side of a short shaft on the same side of the subsection; the first steel wire rope is released slowly by retracting and releasing of the first and second steel wire ropes; meanwhile, a third steel wire rope is connected with the other third lug positioned on the short shaft of the subsection to ensure that the third lug is stressed and a lower foot point of a touchdown turning protective sleeve touches down; then, when the foothold point of the touchdown turning protective sleeve touches down, the touchdown turning protective sleeve slowly rotates to ensure that the subsection is vertical; finally, the second steel wire rope is released slowly, and a fourth lug on the side of the other long shaft is connected with a fourth steel wire rope and the fourth lug is stressed; an upper foot point of the turning protective sleeve touches down and rotates, the subsection keeps flat, and the turning of the subsection is completed. The touchdown turning process of the subsection has the advantages that the cost is reduced and the turning efficiency is increased.

Owner:华泰重工(南通)有限公司

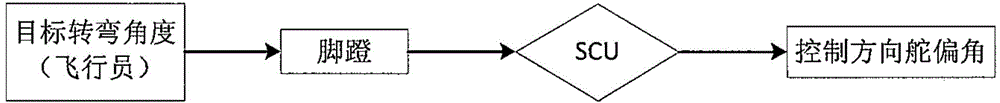

Airplane front wheel turning control system and airplane front wheel turning control method

ActiveCN104085528AImprove turning efficiencyEfficient corneringActuated automaticallyAirplaneDeflection angle

The invention provides an airplane front wheel turning control system which comprises a turning control unit, a turning control valve and a turning acting cylinder, wherein the turning control unit reads an airplane current state parameter through a sensor or bus and calculates a front wheel deflection angle required by reaching a target turning angle; the turning control valve receives a command from the turning control unit; and the turning acting cylinder makes a corresponding movement according to the command received from the turning control unit so as to output a corresponding pressure to the turning acting cylinder to complete deflection of a front wheel. The invention further provides an airplane front wheel turning control method, which uses the airplane front wheel turning control system.

Owner:COMAC +1

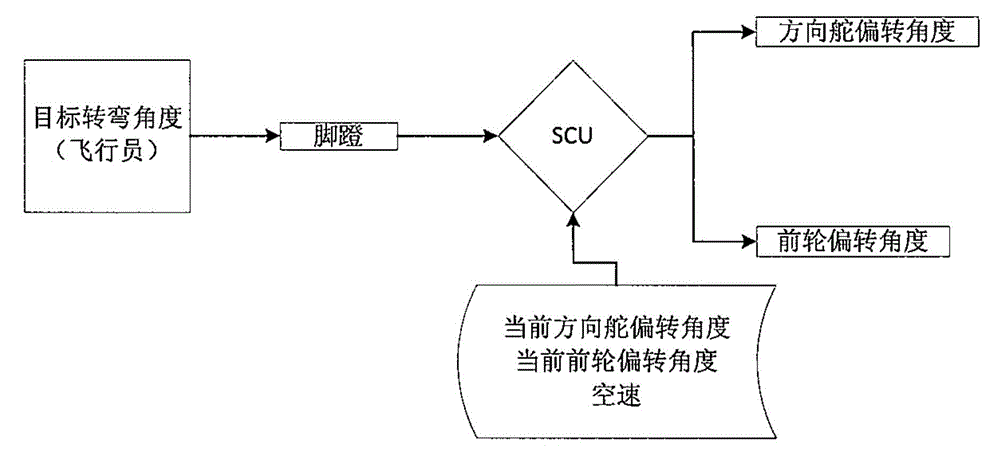

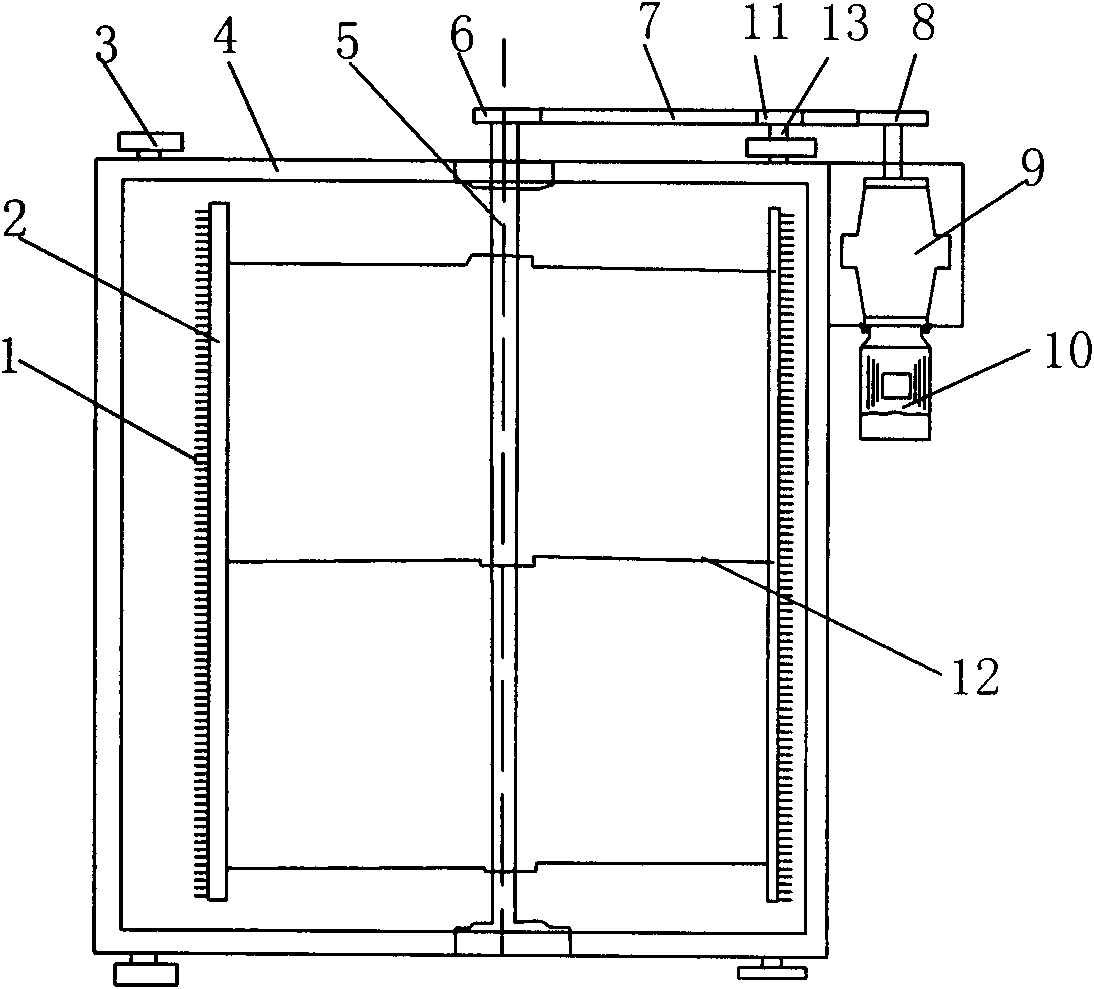

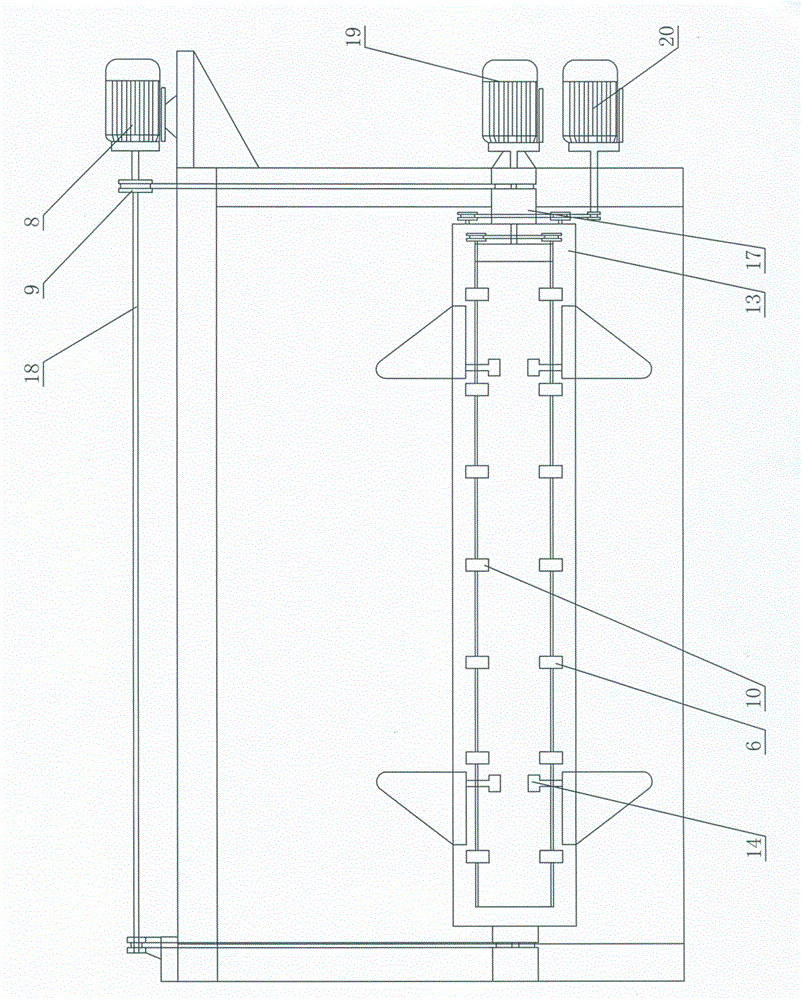

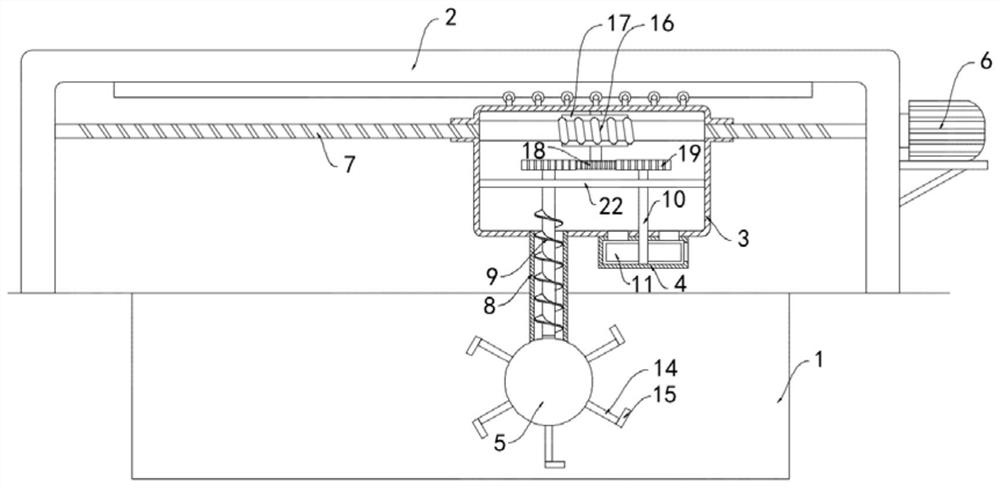

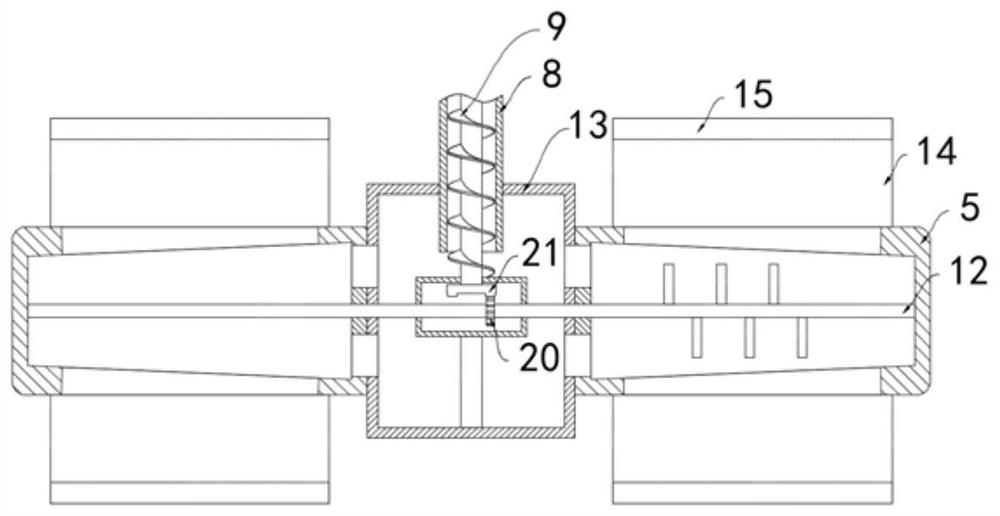

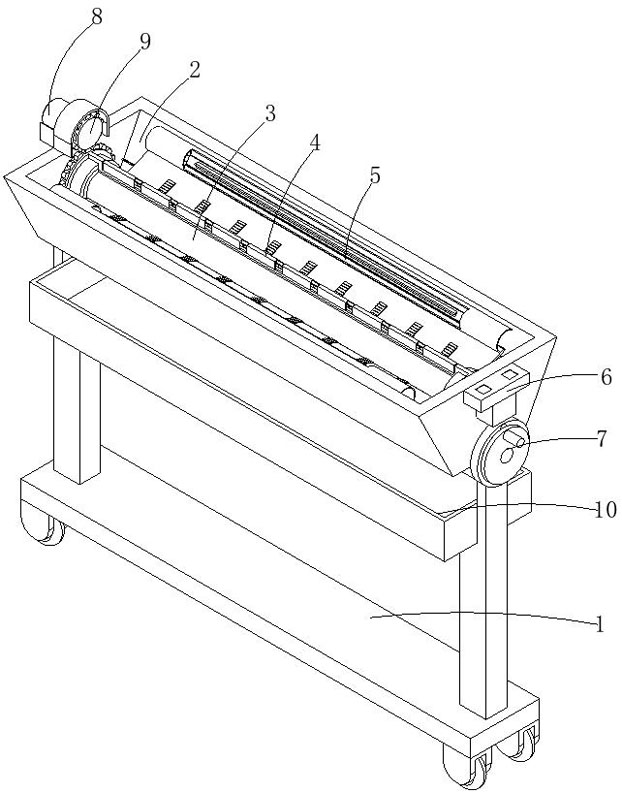

Chicken manure fermenting and turning machine

InactiveCN101913917AImprove turning efficiencyReduce labor costsClimate change adaptationExcrement fertilisersEngineeringMechanical engineering

The invention discloses a chicken manure fermenting and turning machine which comprises a framework [4], a turning wheel [12] and a driving device, wherein the framework [4] is provided with a plurality of roller wheels [3] which are flexibly connected on the framework [4] through a roller wheel spindle [13], a rotatable turning wheel spindle [5] is arranged in the framework [4], the turning wheel [12] is fixed on the turning wheel spindle [13], the outer circle of the turning wheel [12] is fixed with a plurality of turning plates [2] parallel to the center line of the turning wheel, and each turning plate [2] is fixed with turning teeth [1] for turning chicken manure; and the driving device drives the roller wheels and the turning wheel to rotate. The invention realizes mechanical chicken manure turning, raises the turning efficiency and lowers the labor cost.

Owner:铜陵正强禽业有限责任公司

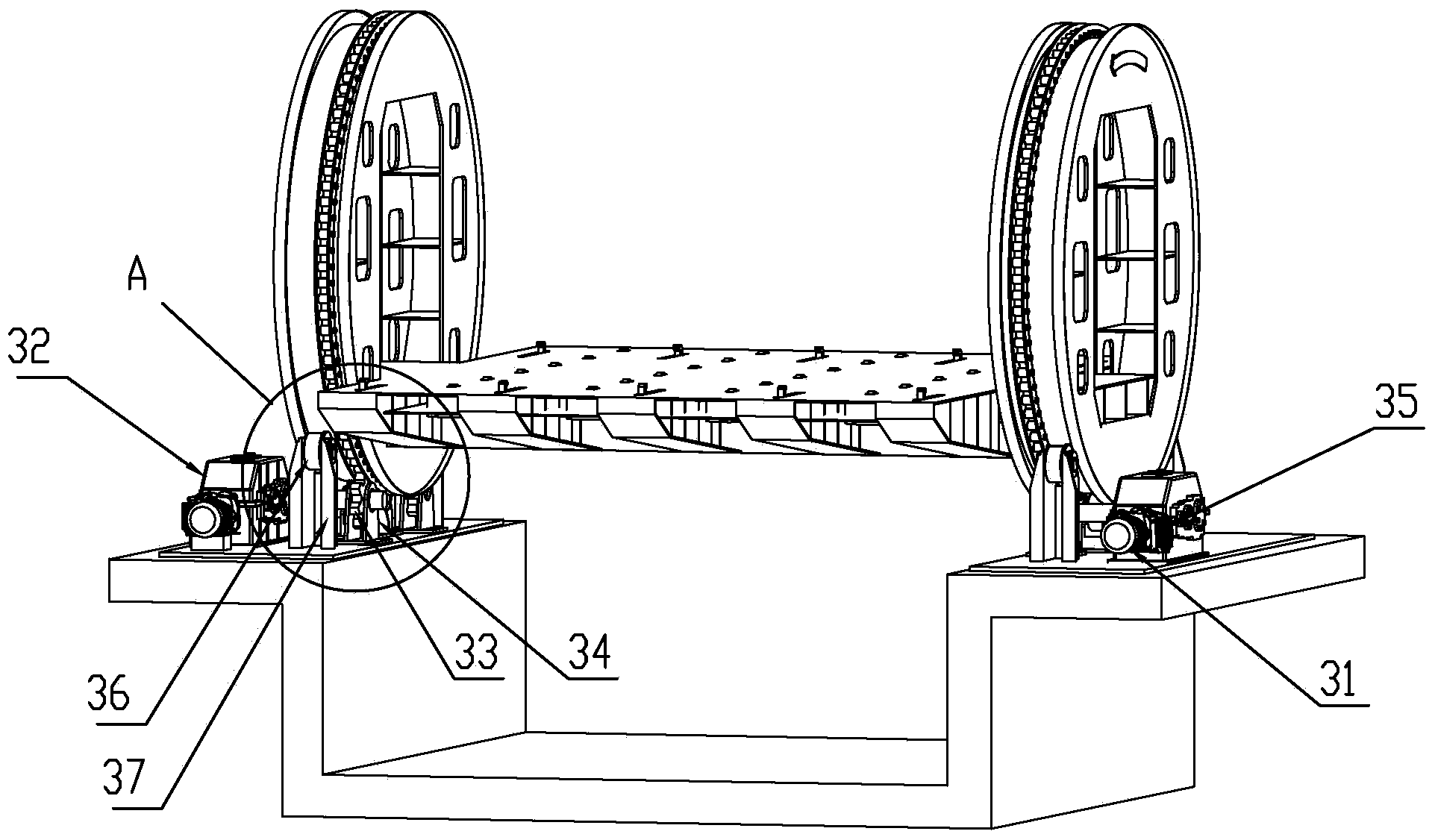

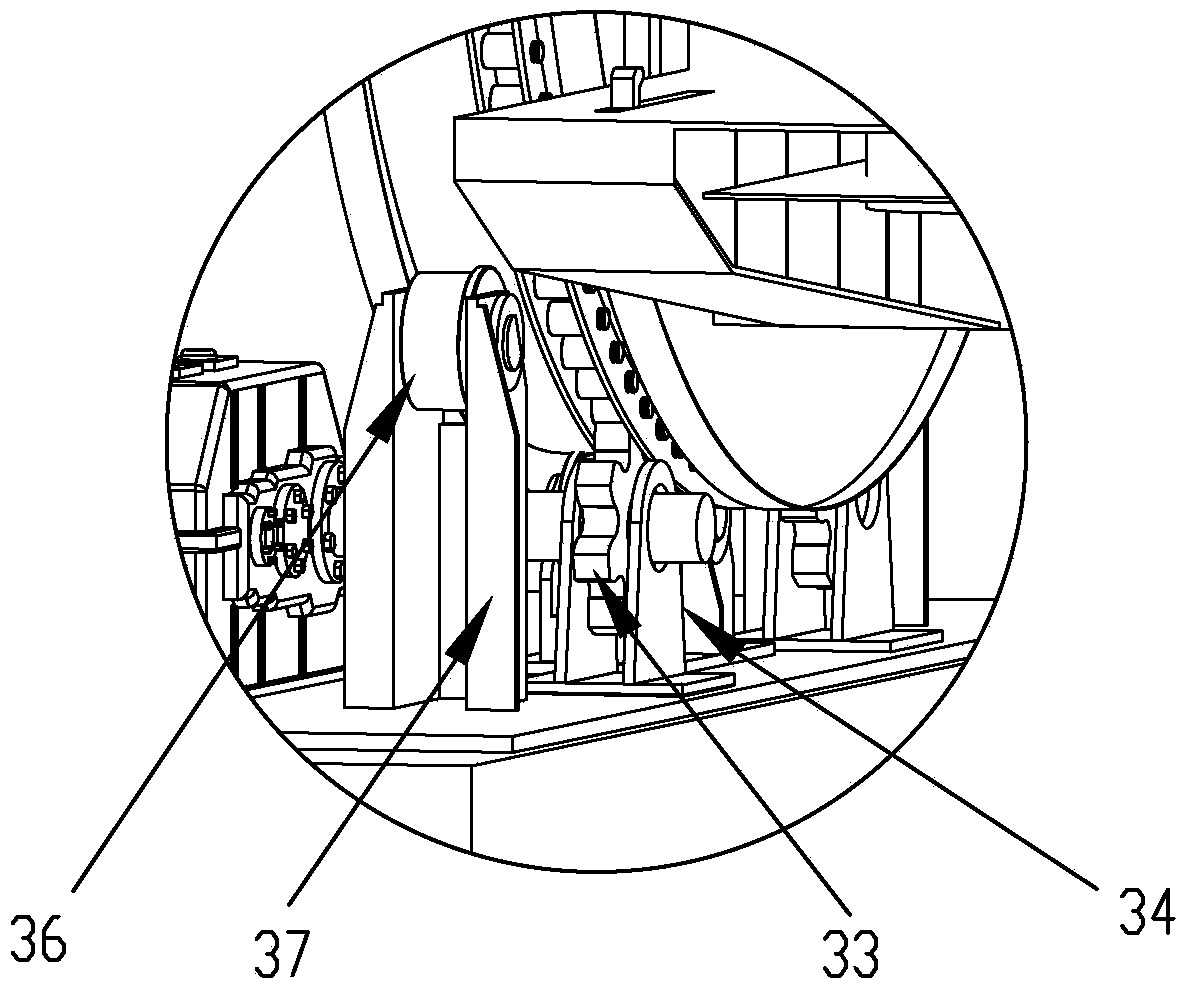

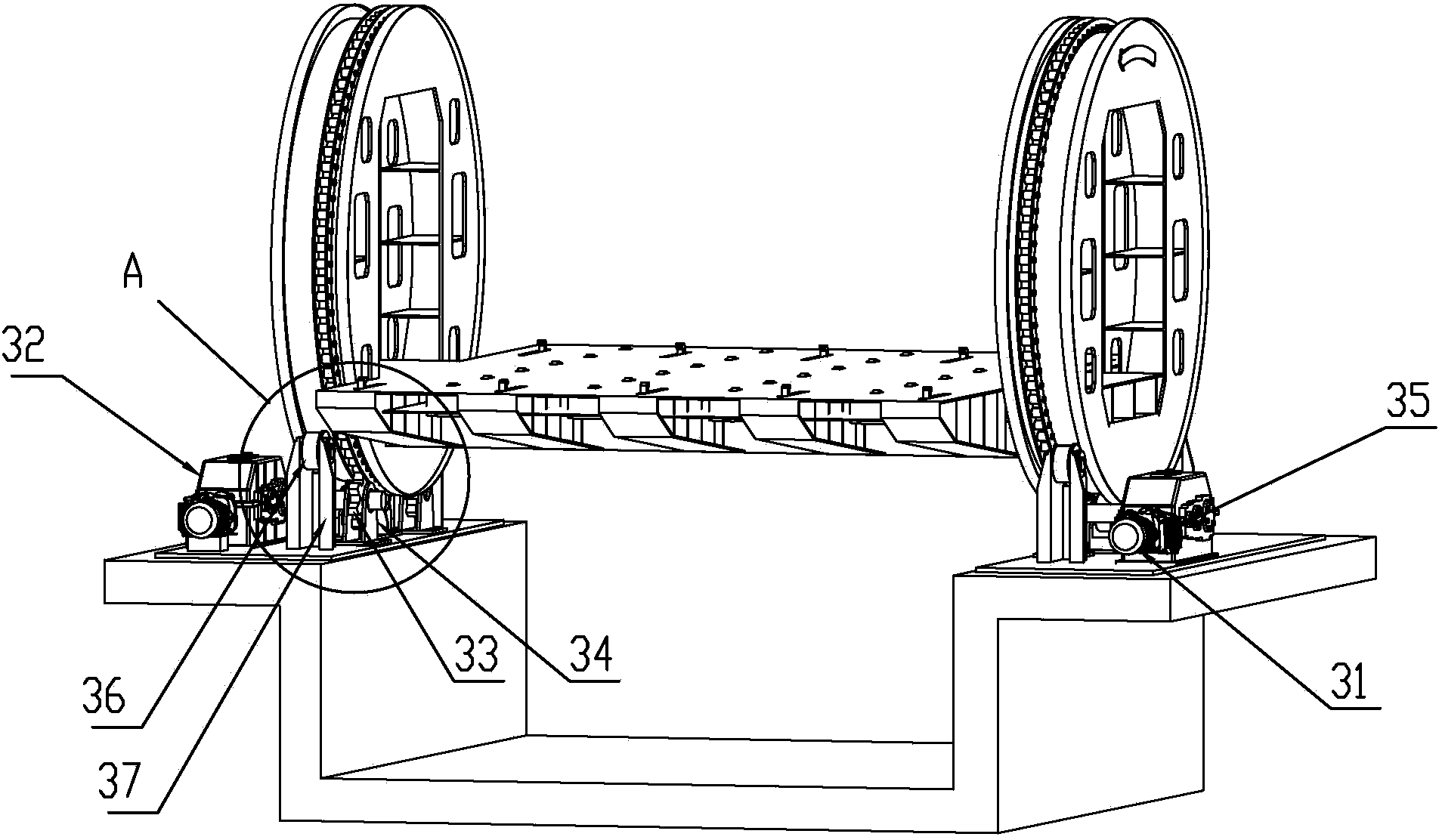

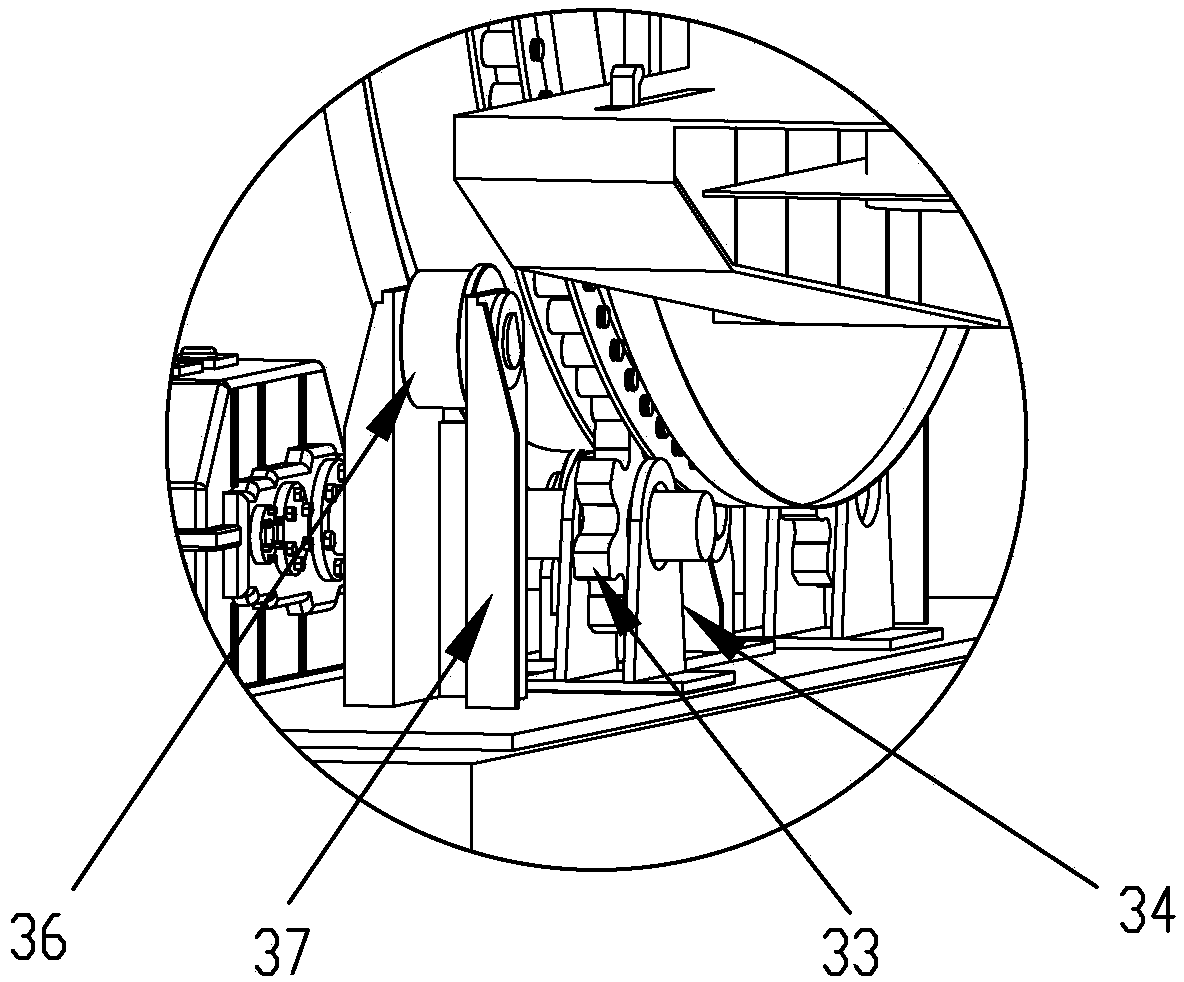

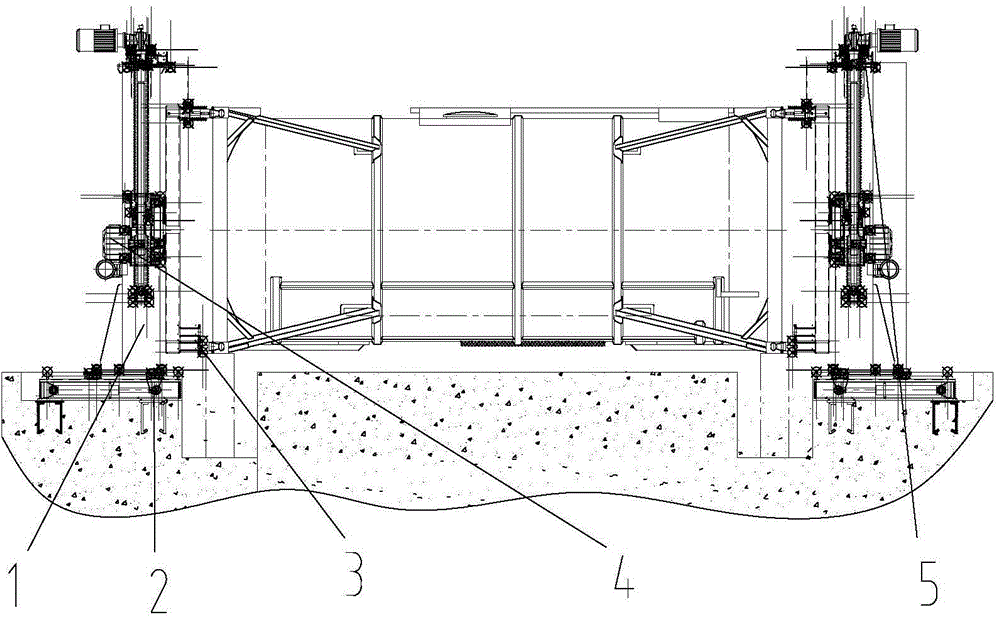

Hull block turning equipment provided with clamping and protecting mechanisms during ship construction

ActiveCN103661800AImprove build accuracyReduce secondary transportVessel partsEngineeringMechanical engineering

The invention discloses hull block turning equipment provided with clamping and protecting mechanisms during ship construction. The hull block turning equipment comprises a rotary table (11). Two sides of the rotary table (11) are fixed on rotary rings (21) used for overturning respectively. The rotary table (11) comprises an electromagnet adsorption component and a plane attached to a hull block. Each rotary ring (21) rotates together with an outer side driving gear (33). Wide slots are formed at the edge, contacting with the hull block, of the rotary table (11). Movable clamping components are arranged in the wide slots. Each movable clamping component comprises a track frame component which is perpendicular to the plane of the rotary platform and moves outwards parallelly to the plane of the rotary platform. Clamping claws are arranged in the track frame components. Each clamping claw is provided with a hydraulic component for moving the claws in two directions. By the hull block turning equipment, construction cost is greatly reduced, and construction efficiency is improved.

Owner:DALIAN SHIPBUILDING IND

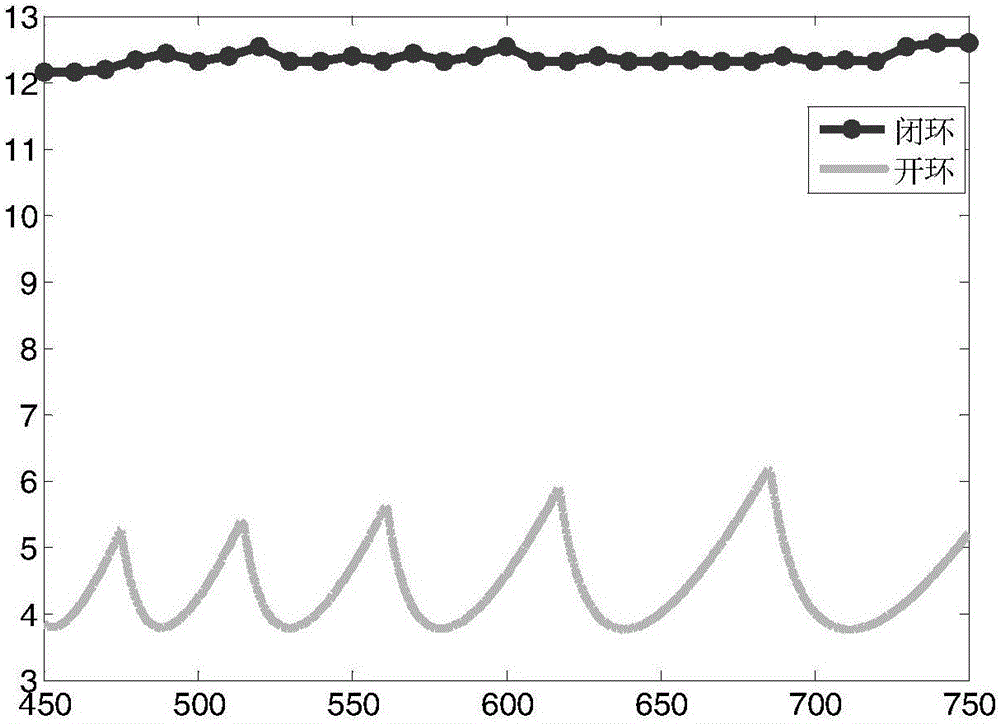

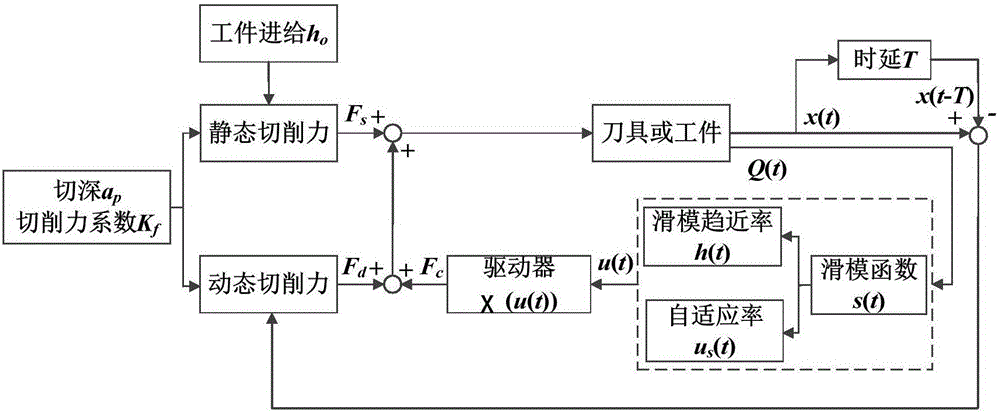

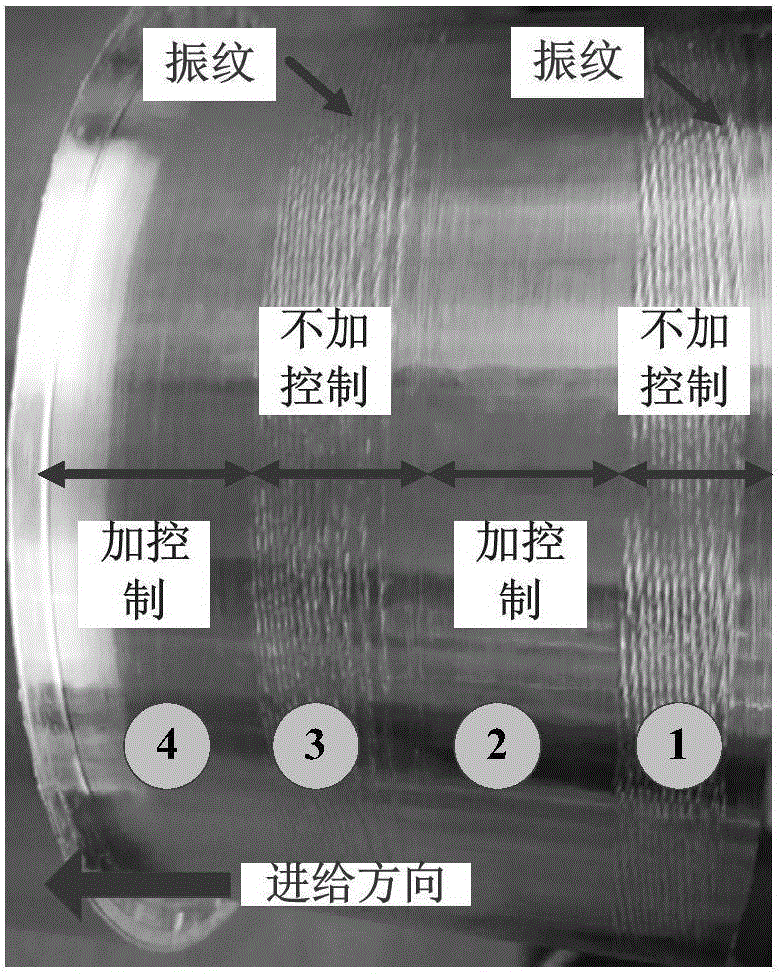

Chatter active control method under driver saturation without model parameters

ActiveCN105700476AGuaranteed surface qualityImprove robustnessProgramme controlComputer controlSelf adaptiveAdaptive control

The invention discloses a chatter active control method under driver saturation without model parameters, and relates to the field of machining automation. According to the technical scheme, the characteristic that the upper bound of the model parameters and the upper bound of interference can be estimated online by utilizing the self-adaptive control rate is utilized, the self-adaptive boundary layer control rate is designed by adopting the Liapunov function, and robustness and effectiveness of the method are further enhanced by utilizing the sliding mode reaching rate so that chatters are suppressed by changing the intrinsic characteristic of a machine tool through a driver, the beneficial effects that the whole lathing process can still be maintained to be stable in lathing work under the conditions of no model parameters, driver saturation and high cutting depth can be achieved, and thus the surface quality of workpieces can be guaranteed and lathing efficiency can also be enhanced.

Owner:SHANGHAI JIAO TONG UNIV

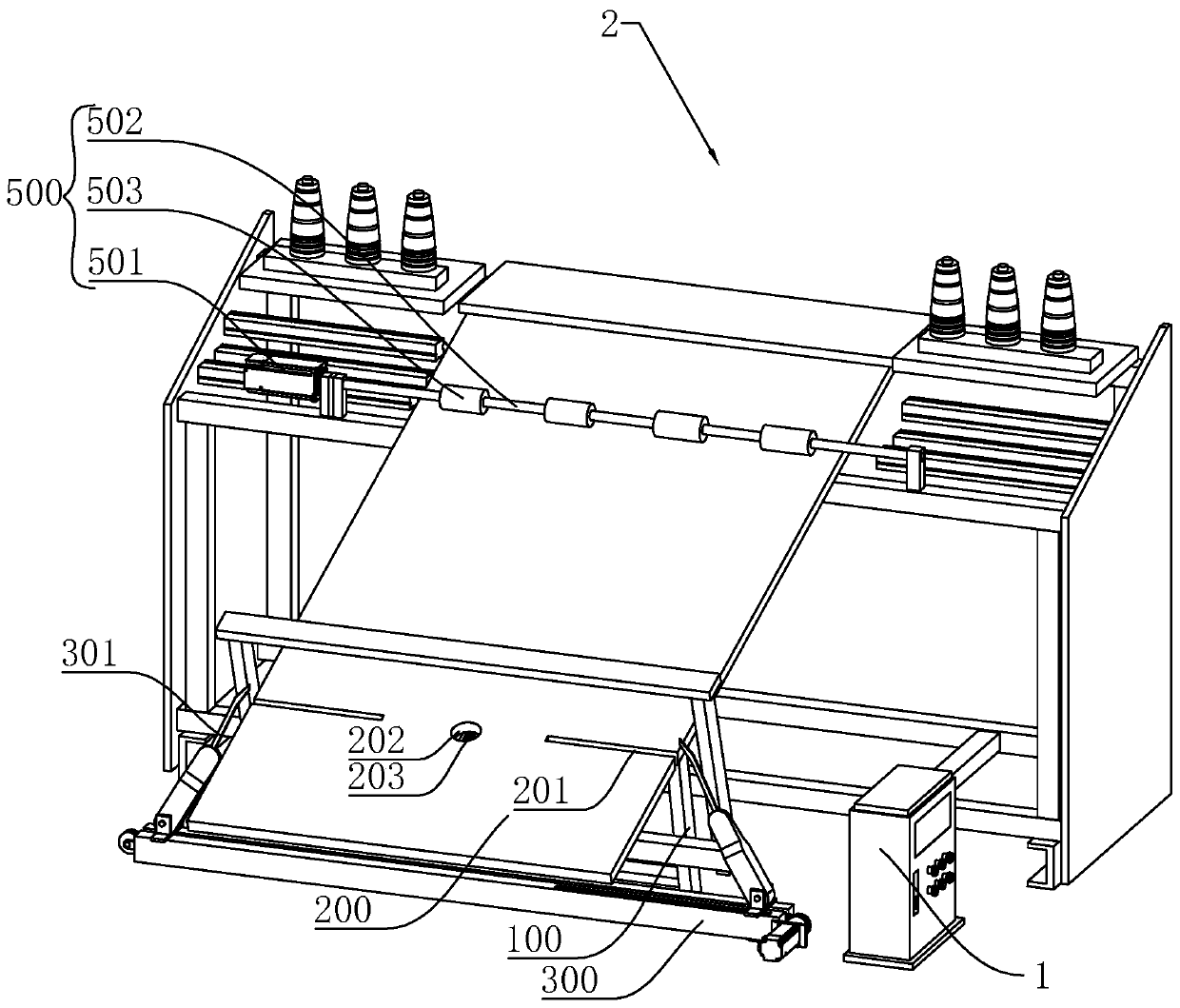

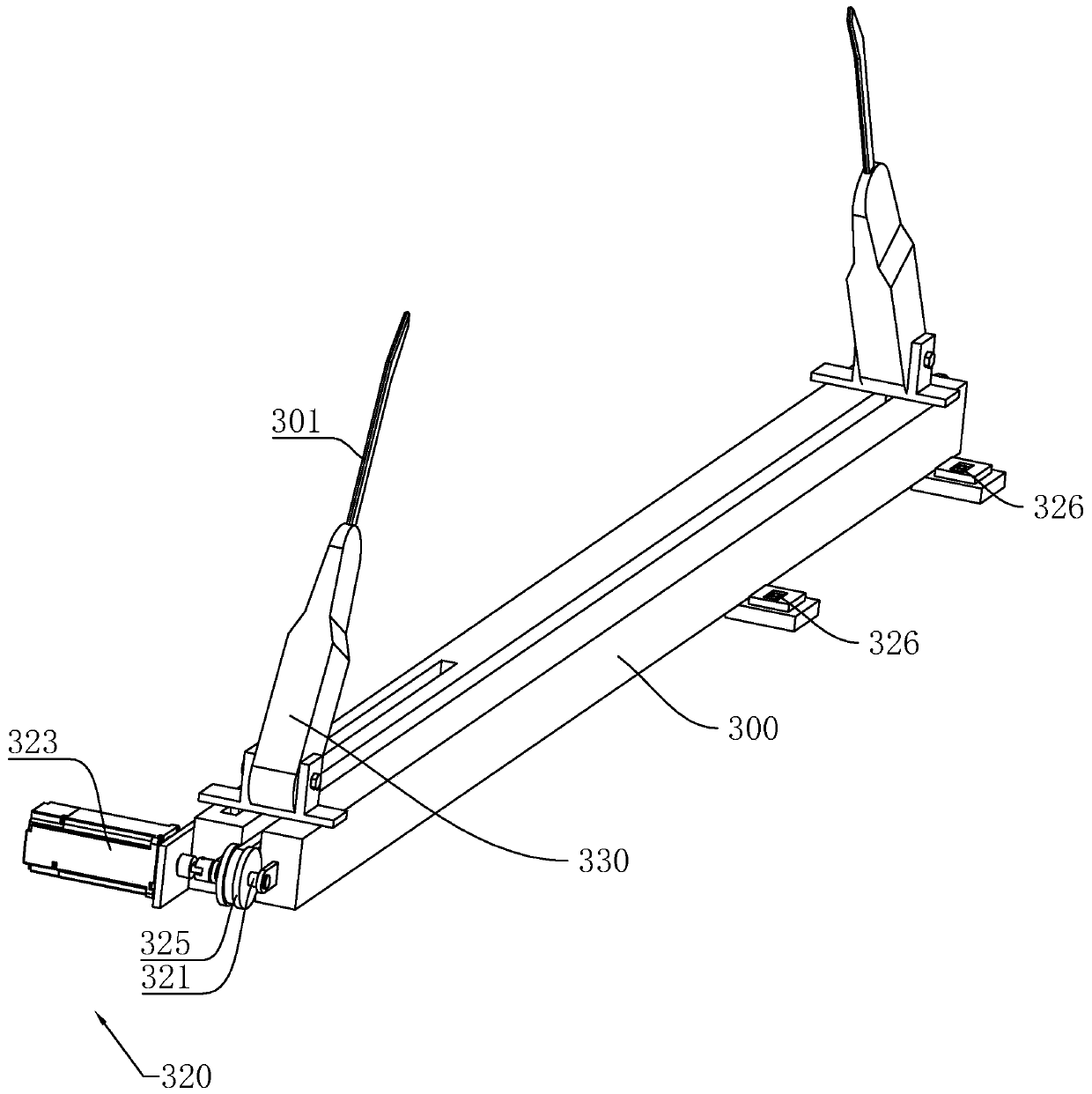

Pillow sleeve edge cutting turning production line

ActiveCN109778445AImprove work efficiencySave human effortMechanical cleaningPressure cleaningProduction lineEngineering

The invention discloses a pillow sleeve edge cutting turning production line, belongs to the technical field of pillow sleeve production equipment, and aims at providing the pillow sleeve edge cuttingturning production line. The production line is characterized by comprising a pillow sleeve edge cutting device, a pillow sleeve turning accommodation device and a control box, and the pillow sleeveturning accommodation device is located on the next working position of the pillow sleeve edge cutting device; the pillow sleeve edge cutting device comprises an edge cutting supporting frame, the edge cutting supporting frame is provided with an obliquely arranged working panel, the working panel is provided with two cutting grooves which are formed in the same line, the cutting grooves are formed in the direction perpendicular to the proceeding direction of the pillow sleeve, an edge cutting sliding rail which is arranged in the length direction of the cutting grooves is arranged on the edgecutting supporting frame, cutters are arranged on the two sides of the edge cutting sliding rails and driving mechanisms which are used for performing reciprocating sliding in the cutting grooves arearranged on the two sides of the edge cutting sliding rails. By arranging various kinds of sensors, automatic pillow sleeve accommodating is achieved, manual operation is reduced, and the automationlevel is higher.

Owner:无锡市维娅娜纺织品有限公司

Method for turning over subsections and overall section

InactiveCN105836595ASimple structureSave installation timeLoad-engaging elementsGravity centerWorkload

The invention discloses a method for turning over in subsections and total sections. According to the method, B-type lifting rings of corresponding tonnage are selected according to the weight center of gravity of the subsections and the total section, and B-type suspension rings with lighter weight are installed on the rebates of the subsections and the total section. Lifting ring, pull the turning tooling to the position of the segmental and general segmental rings, when the center line of the tooling connecting ear plate hole and the segmental and total segmental ring holes is basically on the same straight line, insert the connecting pin, screw on the fastening nut, Insert the cotter pin. When the section and the total section need to turn over, connect the hook to the lifting part structure and tighten it slowly, so that the active top plate of the tooling can be attached to the installation plane of the lifting ring. After turning over the subsection and the total section, loosen the hook, pull out the connecting pin, remove the tooling, and recycle it. The invention greatly reduces the installation time of turning over suspension rings, reduces the workload of welding and cutting and grinding of suspension rings, improves the turning efficiency of sections and total sections, and saves costs.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

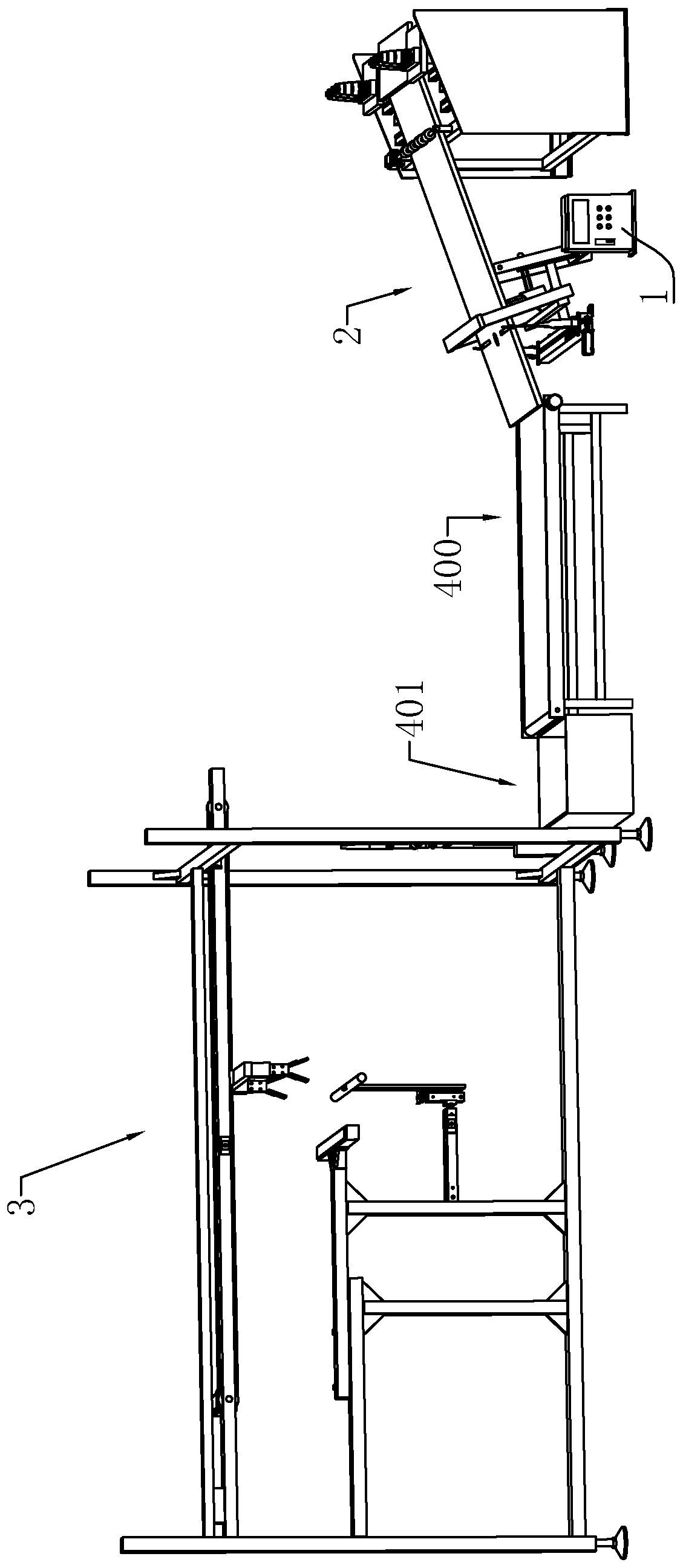

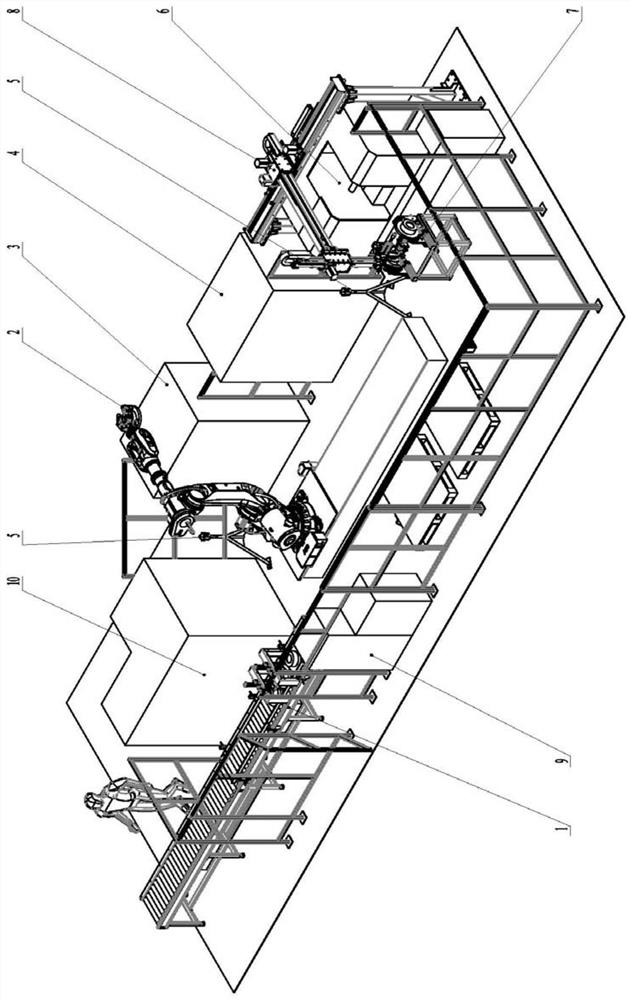

Brake disc machining robot feeding and discharging production line and production method

ActiveCN112296723AHigh degree of automationIncrease productivityMetal working apparatusPositioning apparatusNumerical controlProduction line

The invention discloses a brake disc machining robot feeding and discharging production line and a production method. The brake disc machining robot feeding and discharging production line comprises an auxiliary feeding system, a first numerical control machine tool, a second numerical control machine tool, a machining center, a grinding machine tool, an auxiliary turnover mechanism, an auxiliarytransfer mechanism, a truss manipulator, a mechanical clamping jaw, an industrial robot and a control cabinet, wherein the industrial robot comprises a ground rail, a robot body arranged on the groundrail, a robot arm connected to the robot body and a robot jig connected to the tail end of the robot arm; the control cabinet controls the robot body, the robot arm and the robot jig to act; and under the control of the control cabinet, a brake disc sequentially finishes the machining process on the first numerical control machine tool, the second numerical control machine tool, the machining center and the grinding machine tool. The production line has high automation degree, production efficiency and percent of pass of products. According to the production method, the brake disc machining efficiency can be further improved, and the enterprise production cost is reduced.

Owner:青岛智研自动化设备有限公司

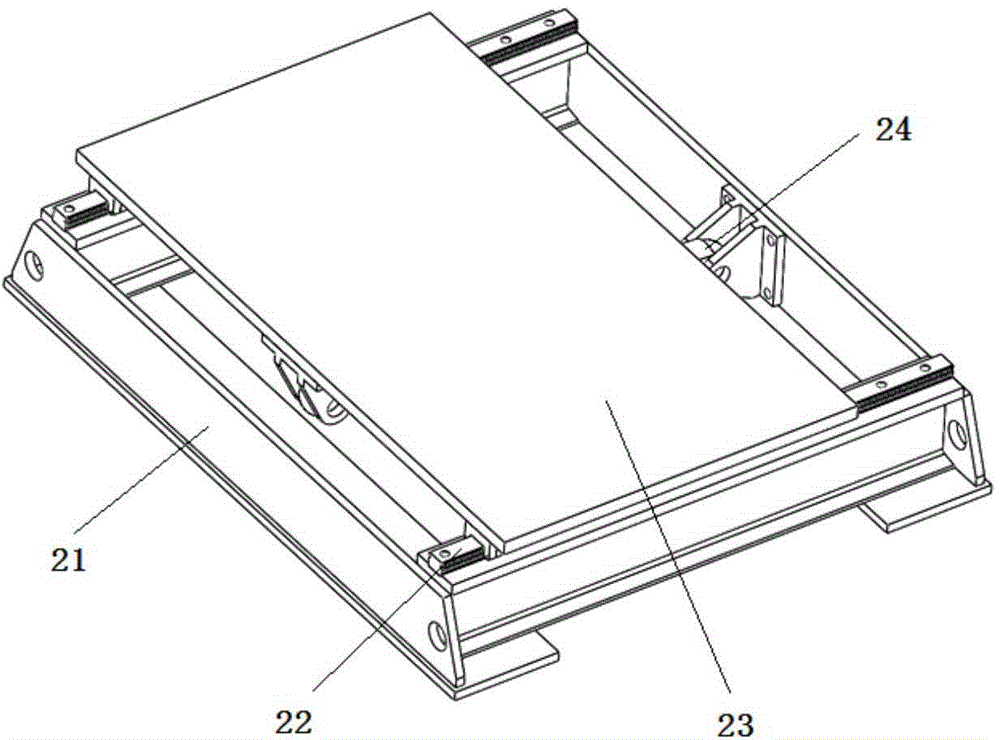

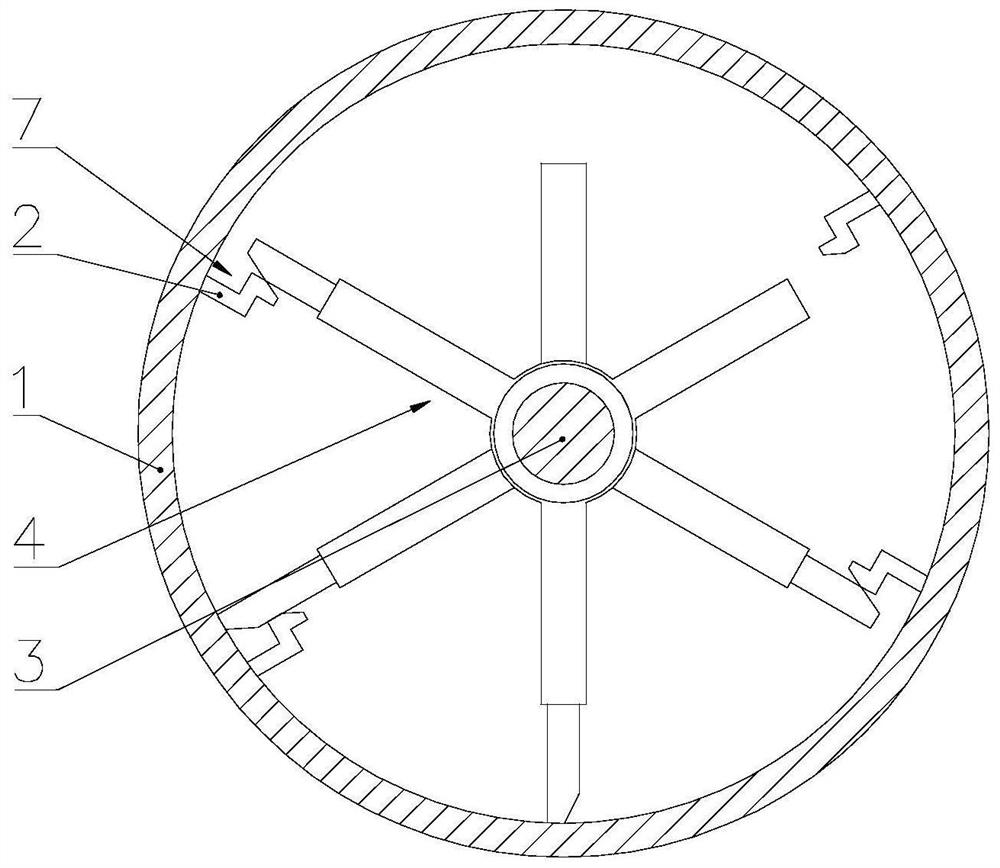

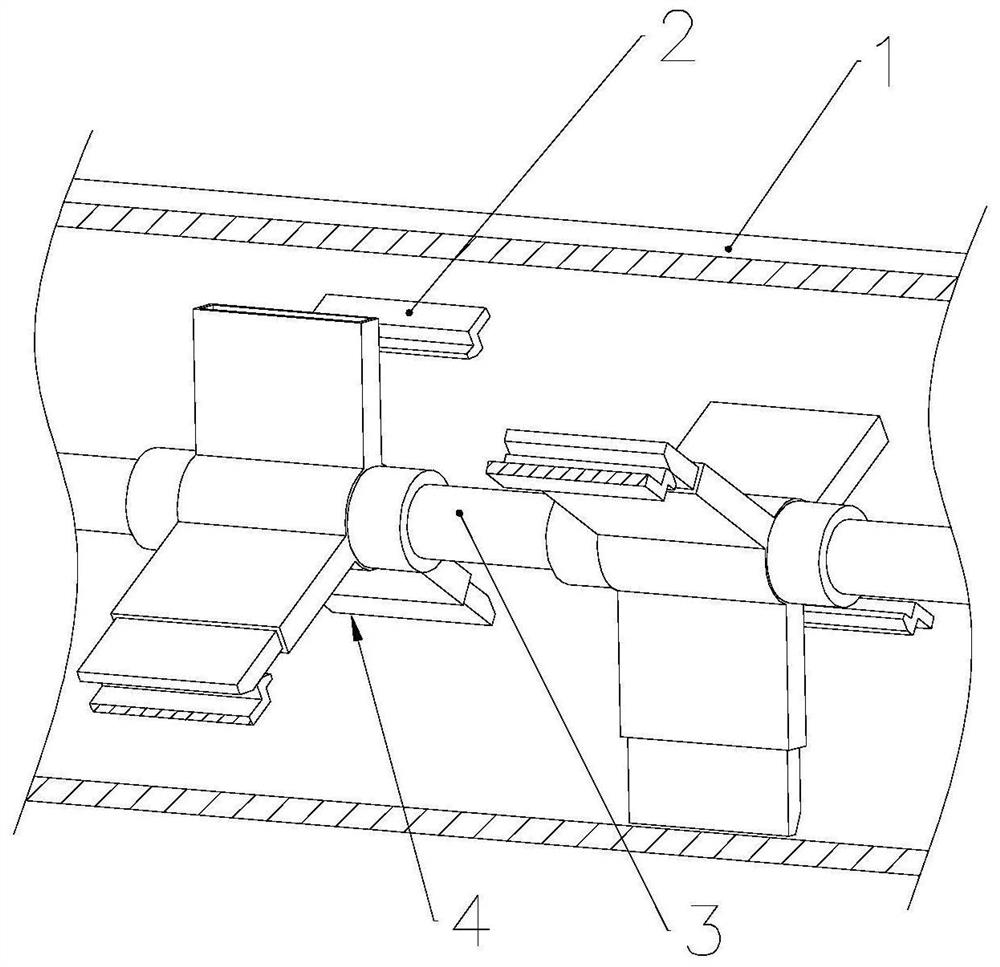

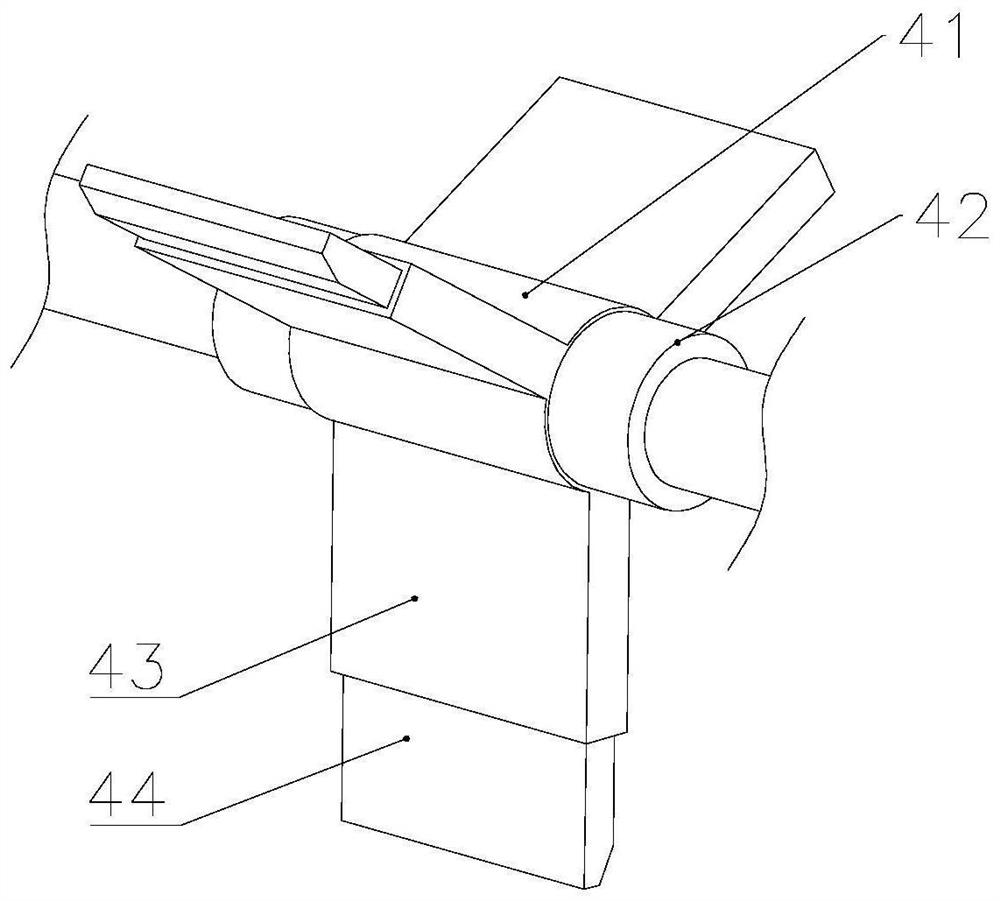

Dovetail groove turning device

InactiveCN103521783ATurning realizedImprove processing efficiencyFeeding apparatusLarge fixed membersHigh volume manufacturingEngineering

The invention provides a dovetail groove turning device, and belongs to the technical field of machine tool components. The dovetail groove turning device solves the problem that when an existing lathe is used for machining an annular dovetail groove, machining efficiency is not high, and the dovetail groove is not suitable for mass production. The dovetail groove turning device comprises a big carriage plate, wherein the big carriage plate is provided with small carriage plates arranged in an inclining mode and a driving mechanism which can drive the small carriage plates to move in a reciprocating mode in the inclining direction of the small carriage plates. A tool assembly is arranged on the small carriage plates. The tool assembly comprises two forming tools of a rod shape, wherein the two forming tools are both arranged in parallel in the inclining direction of the small carriage plates, and a gap for a workpiece to pass through is formed between the outer ends of the two forming tools. The dovetail groove turning device has the advantages of being simple in structure, high in machining efficiency and the like.

Owner:玉环市佳颂自动化科技有限公司

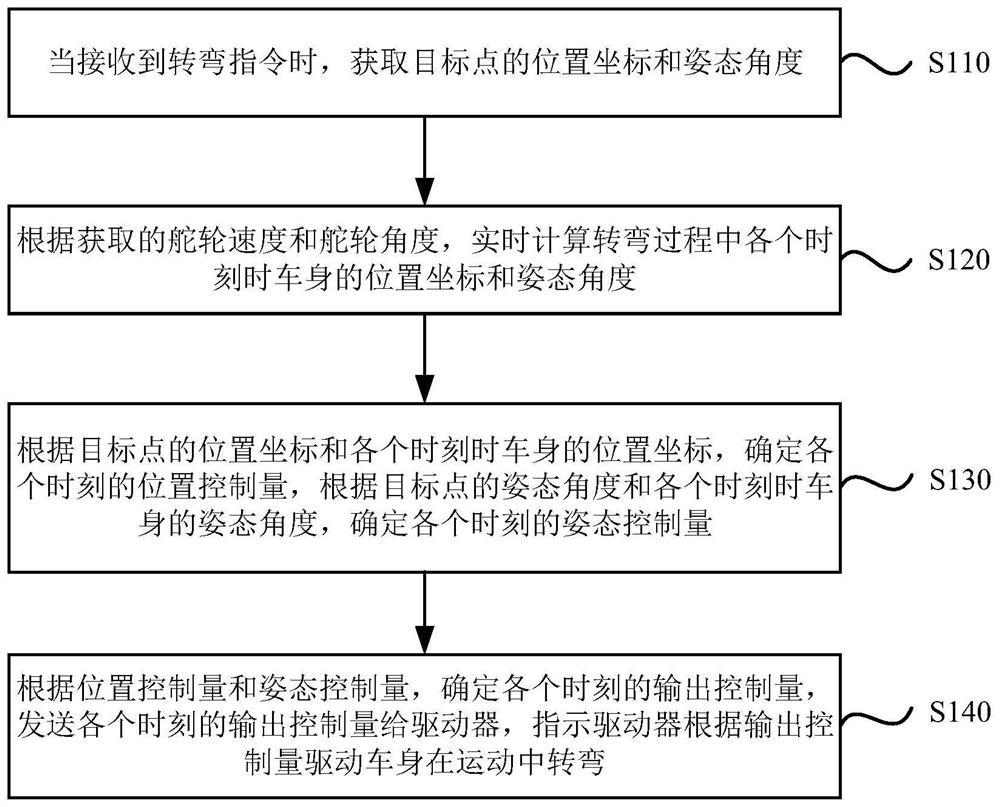

Turning control method, device and system of unmanned mobile device and storage medium

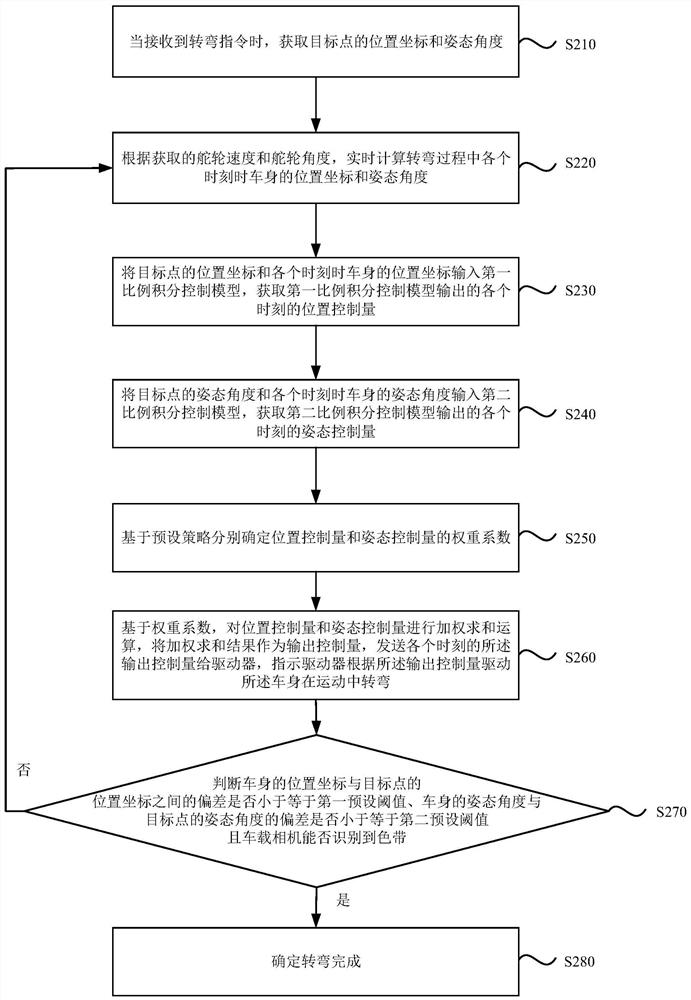

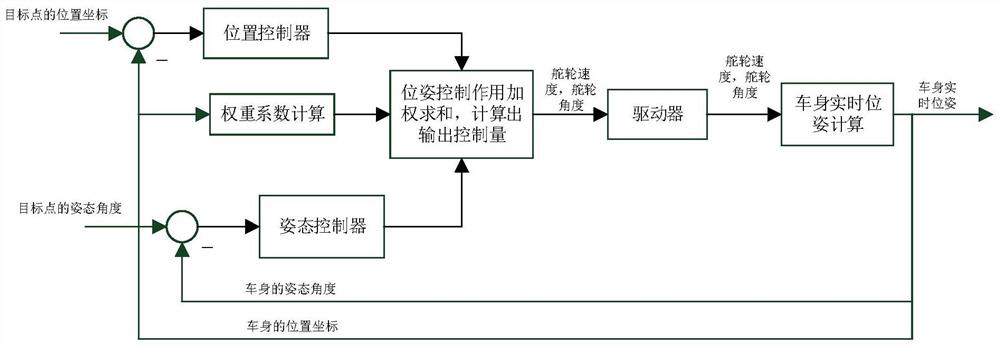

ActiveCN111966101AAvoid parkingSimplify the turning processPosition/course control in two dimensionsVehiclesSteering wheelAttitude control

The embodiment of the invention discloses a turning control method, device and system of an unmanned mobile device and a storage medium. The method comprises the steps that when a turning instructionis received, acquiring the position coordinate and the posture angle of a target point; according to the obtained steering wheel speed and steering wheel angle, calculating position coordinates and attitude angles of the vehicle body at each moment in the turning process in real time; determining the position control quantity of each moment according to the position coordinates of the target pointand the position coordinates of the vehicle body at each moment, and determining the attitude control quantity of each moment according to the attitude angle of the target point and the attitude angle of the vehicle body at each moment; and according to the position control quantity and the attitude control quantity, determining the output control quantity of each moment, sending the output control quantity of each moment to a driver, and indicating the driver to drive the vehicle body to turn in motion according to the output control quantity. By calculating the position coordinates and theattitude angle of the vehicle body in real time, the position coordinates and the attitude angle are respectively controlled, the turning time is shortened, and the turning efficiency is improved.

Owner:国以贤智能科技(上海)股份有限公司

Method for overturning precast concrete column with bent structure

InactiveCN107304630AThe structure of the spreader device is simpleEasy to makeBuilding material handlingManufacturing qualityPrecast concrete

The invention relates to a method for overturning a precast concrete column with a bent structure. The method is characterized by comprising the following steps: a) embedding a welding steel pipe (2) into the precast concrete column; b) processing two overturning hangers for the precast concrete column with the bent structure; c) penetrating a threaded end of a hanger (7) through the welding steel pipe (2) embedded in the precast concrete column with the bent structure; d) binding a hanging steel wire rope in the hanging lugs (11) at the top ends of two hangers and using a crane for hoisting; and e) placing three sleepers (10) on the ground at uniform interval, placing the precast concrete column with the bent structure onto the sleepers, loosening a nut, drawing out the hangers and completing the overturning of the precast concrete column. The method for overturning the precast concrete column with the bent structure provided by the invention has the advantages of simple structure of the hanger device, convenience in manufacturing, capability of increasing the overturning efficiency of the precast concrete column with the bent structure and capability of reducing the manufacturing quality risk of the precast concrete column with the bent structure.

Owner:MCC5 GROUP CORP SHANGHAI

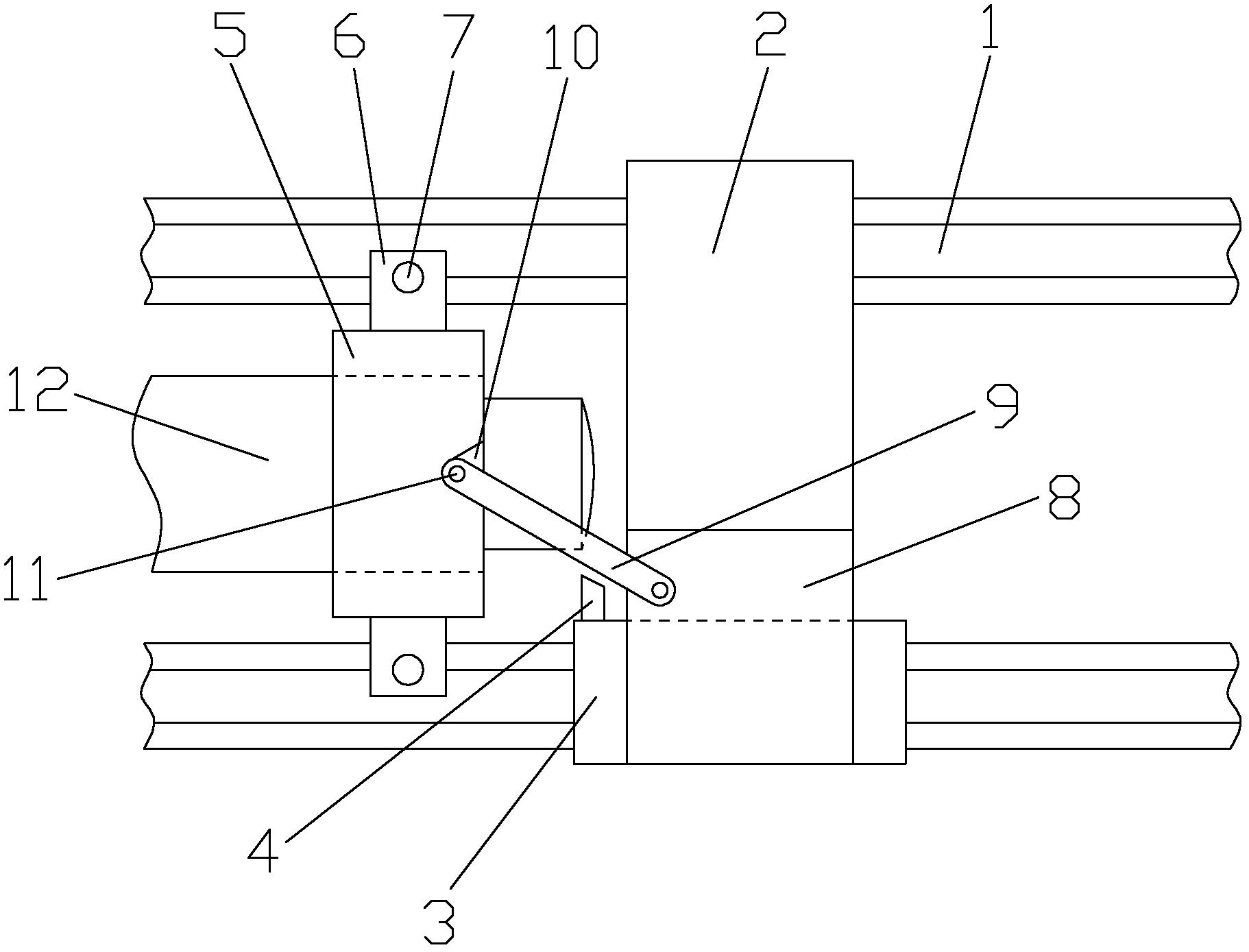

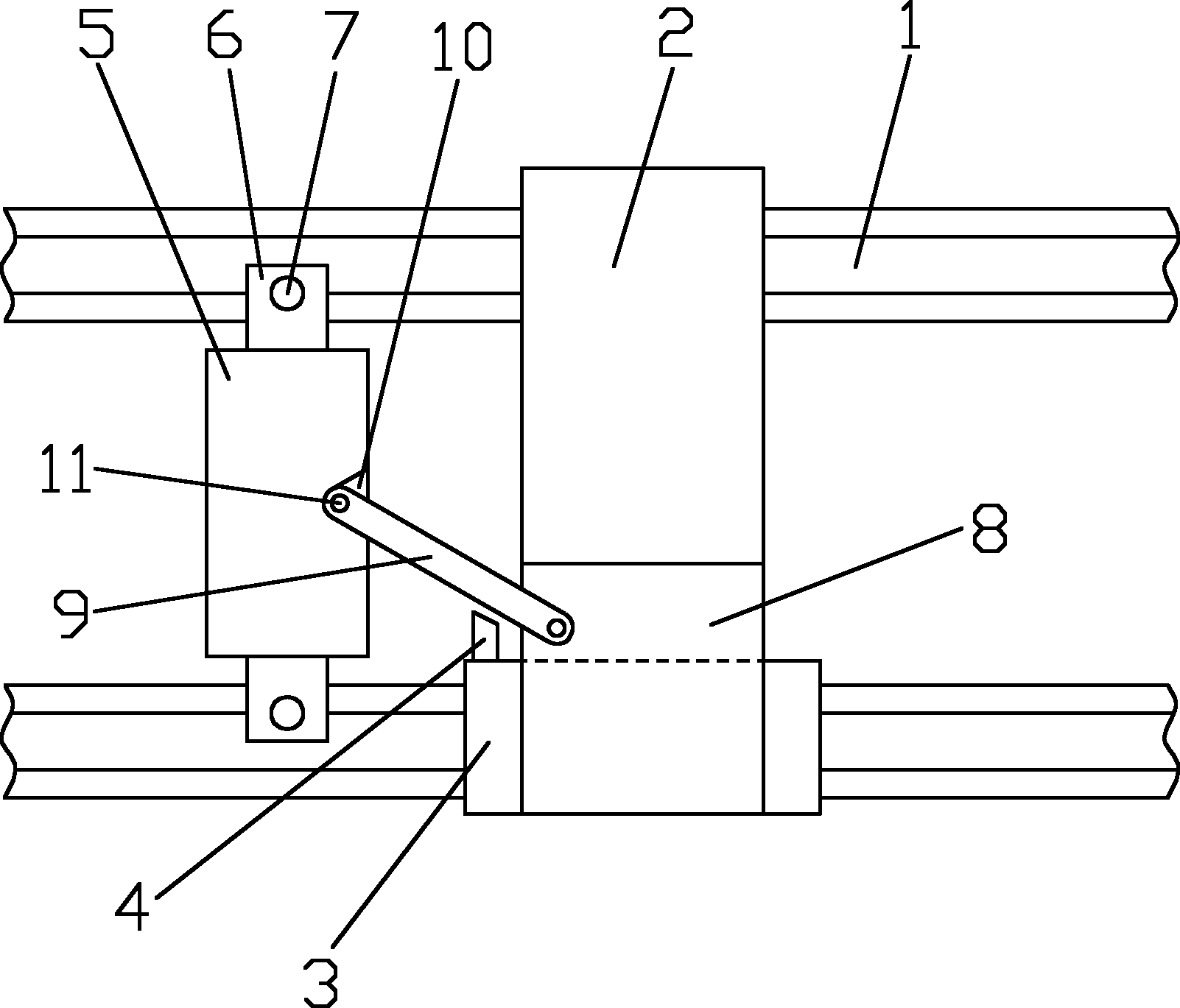

Steel plate overturning mechanism

InactiveCN106185265ARealize automatic deliverySimple and safe operationConveyorsConveyor partsSheet steelEngineering

Owner:瓯星机械设备有限公司

Arc turning device

The invention discloses an arc turning device which comprises a turning machine guide track, a sliding plate, a tool holder and a turning tool, wherein the sliding plate is arranged on the turning machine guide track, the tool holder is arranged on the sliding plate in a way of being capable of moving up and down along the sliding plate, the turning tool is arranged on the tool holder, a work piece fixing block is arranged at the left end of the turning machine guide track, a fixed block is arranged on the sliding plate and connected with the tool holder, a connecting rod is hinged on the upper end face of the fixed block, a fan-shaped groove is formed on the work piece fixing block, and the other end of the connecting rod is arranged in the fan-shaped groove through a pin. According to the arc turning device, a work piece requiring arc turning passes through the work piece fixing block and is tightly clamped on the three-claw chuck of the tool, the sliding plate is released to slide freely on the turning machine guide track, and during turning, after setting the longitudinal feed, the connecting rod drives the tool holder make a circumferential motion, so as to turn an arc. The turning mode is easy to operate, the labor intensity is reduced, the turning efficiency is increased, and the quality of arc turning is improved.

Owner:SUZHOU GUANGFU METALLURGY CASTING

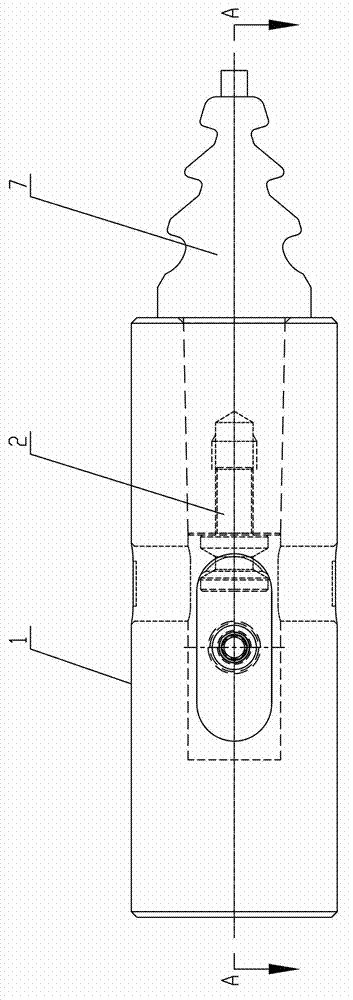

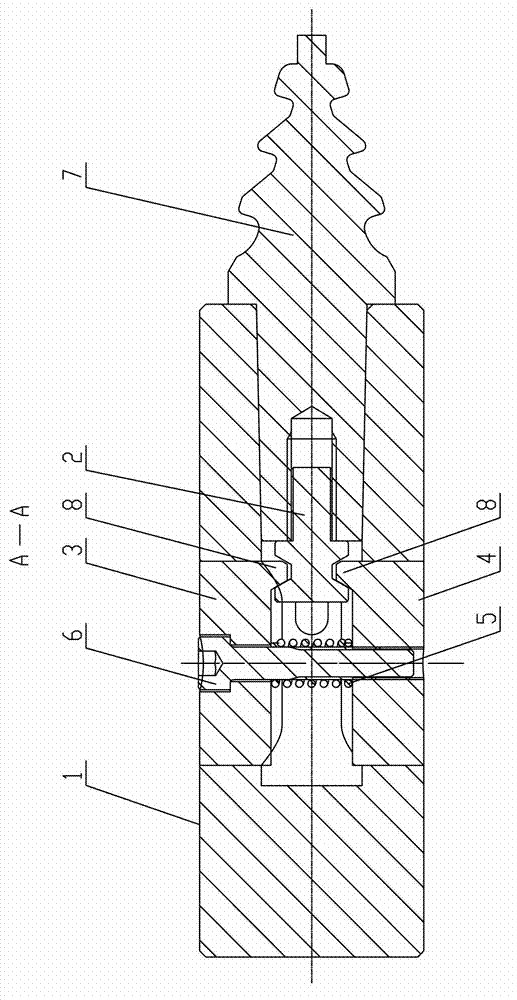

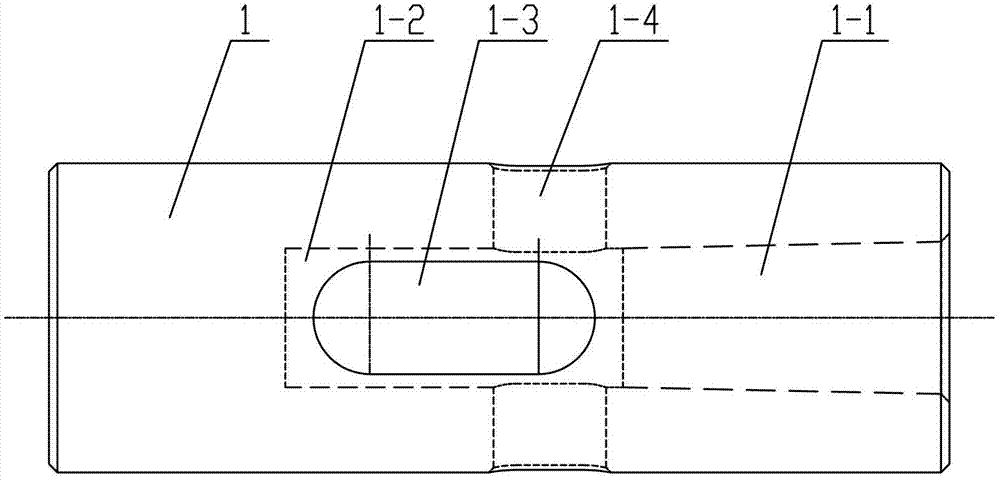

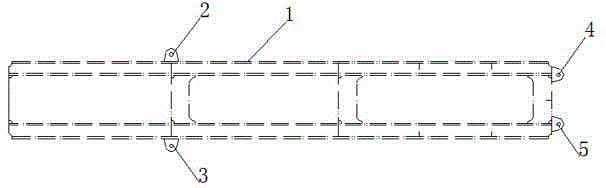

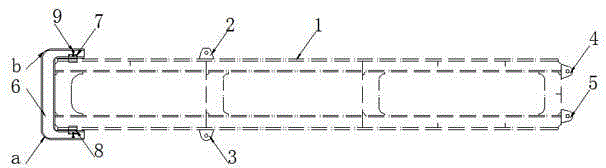

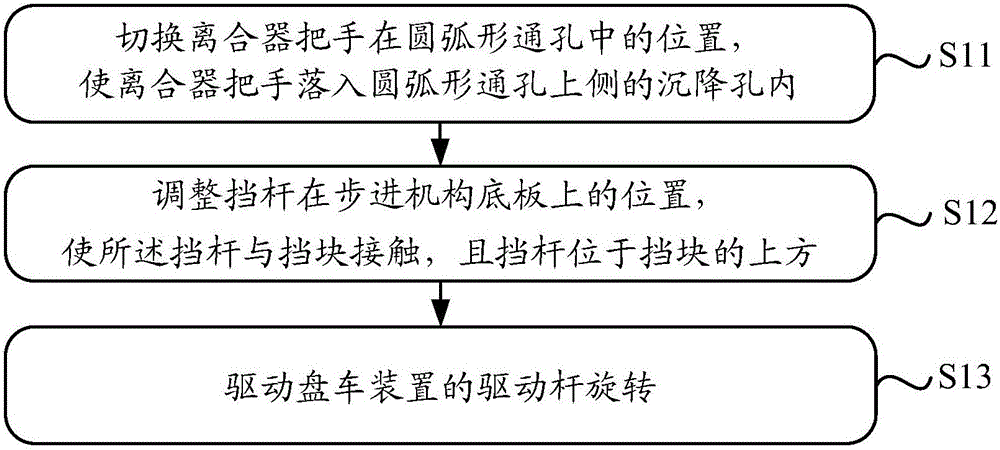

Operation method for barring gear of tablet press

The invention discloses an operation method for a barring gear of a tablet press. The tablet press can be barred by operating the barring gear, and then the barring efficiency of the tablet press can be improved. The barring gear comprises a clutch handle, a machine frame, a stepping mechanism and a drive rod; the machine frame comprises a bottom plate and vertical plates vertically connected to the bottom plate, and the vertical plates are provided with arc-shaped through holes; the stepping mechanism comprises a stop rod, a stop block and a stepping mechanism bottom plate. The operation method comprises the steps of switching the positions of the clutch handle in the arc-shaped through holes so that the clutch handle can fall into settling holes in the upper sides of the arc-shaped through holes; adjusting the position of the stop rod on the stepping mechanism bottom plate so that the stop rod can make contact with the stop block and can be located above the stop block; driving the drive rod of the barring gear to rotate.

Owner:北京新龙立智能科技有限公司

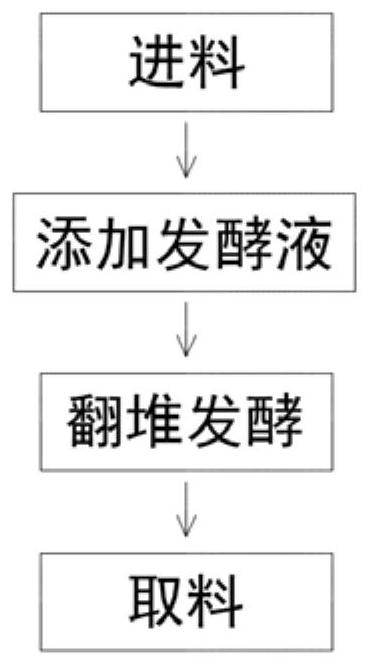

Fermentation turning method of aerobic microbial fertilizer

InactiveCN112341252AAchieve horizontal slidingTurn over evenlyBio-organic fraction processingExcrement fertilisersBiotechnologyAgricultural science

The invention belongs to the technical field of microbial fertilizer production, and particularly relates to an aerobic microbial fertilizer fermentation turning method. The method mainly comprises the following steps: S1, performing feeding: feeding human and animal excreta, sawdust, bran coat, soybean meal and water into a fermentation tank to obtain a base material; S2, adding fermentation liquor, and uniformly spraying the fermentation liquor to the surface of the base material; S3, performing turning and fermenting: keeping the temperature of the base material at 40 DEG C and 50 DEG C, frequently stirring and turning the base material, and continuously fermenting for 9-15 days; S4, performing material taking: taking out the fermented microbial fertilizer from the fermentation tank, and carrying out the next drying and granulation process; fermentation turning equipment used in the fermentation turning process of the aerobic microbial fertilizer comprises a fermentation tank, a supporting frame, a driving box, a turning box and a stirring cylinder. Fertilizers are in full contact with air in the turning and throwing process, growth and fermentation of aerobic bacteria are facilitated, meanwhile, heat in a fertilizer pile can be rapidly dissipated, the fertilizers can make full contact with the air, and the temperature of the fertilizer pile is prevented from being too high.

Owner:武汉木兰山水生态农业发展有限公司

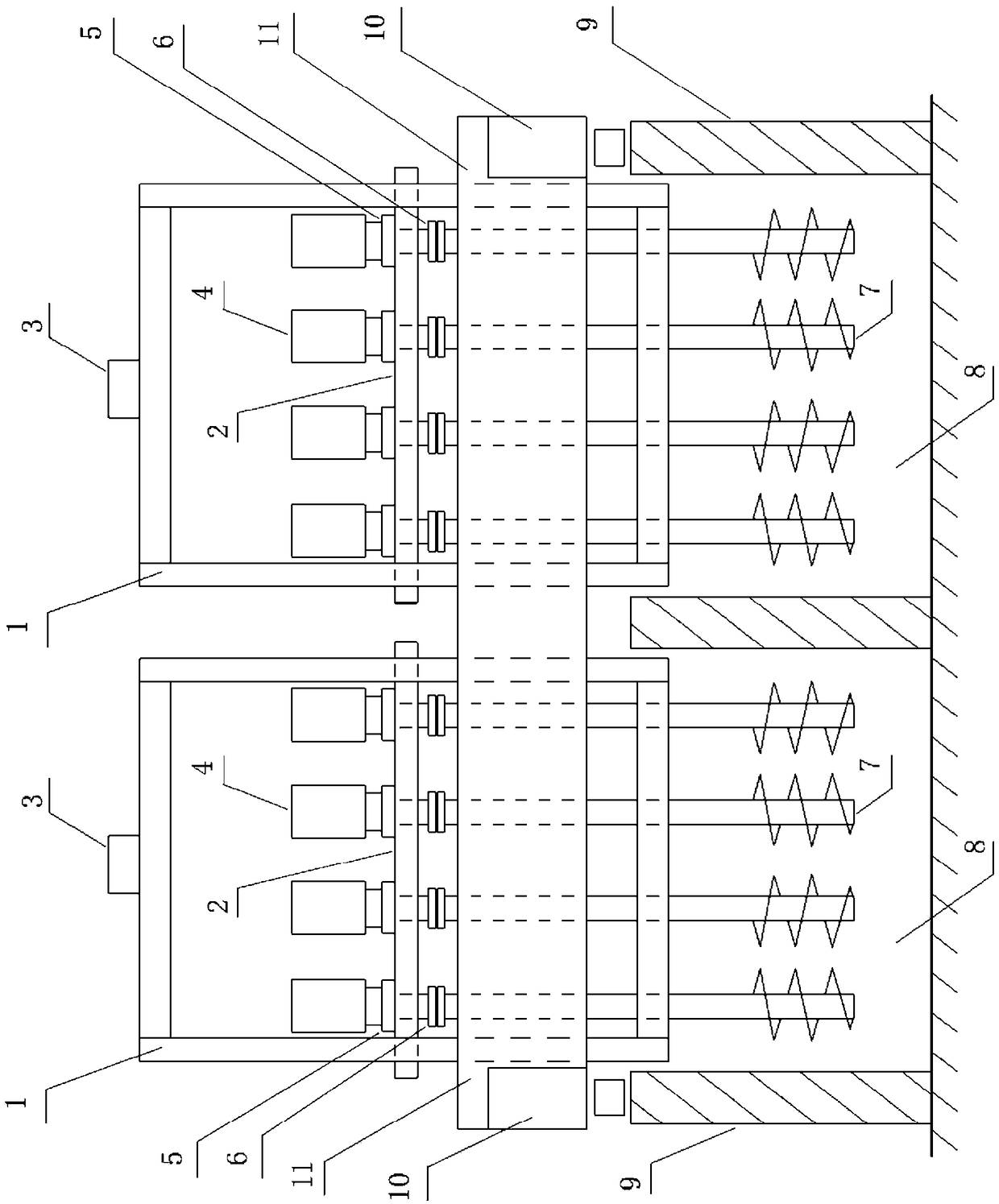

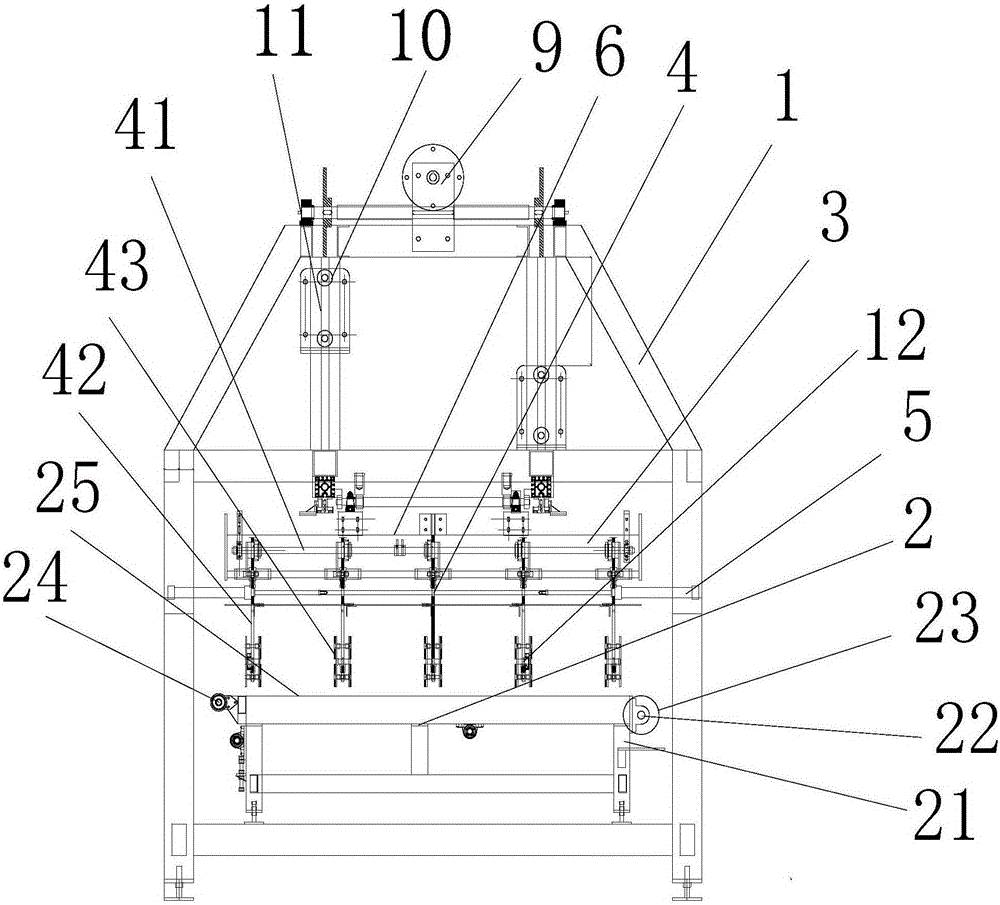

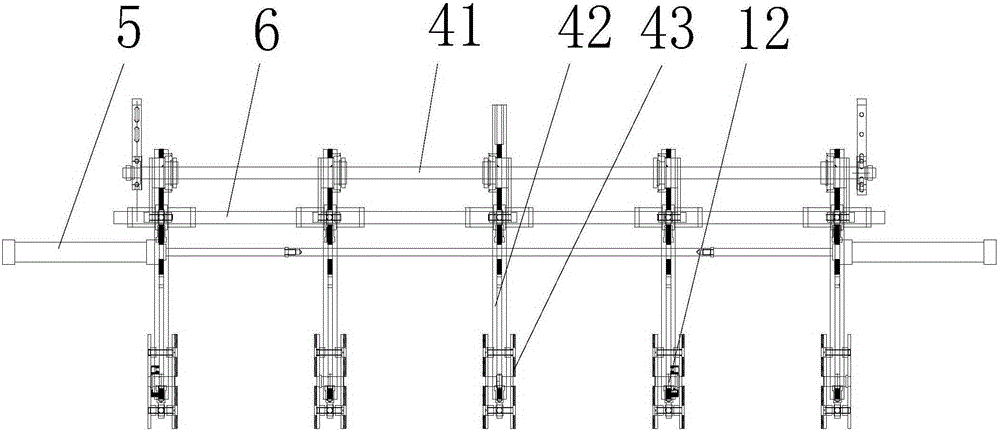

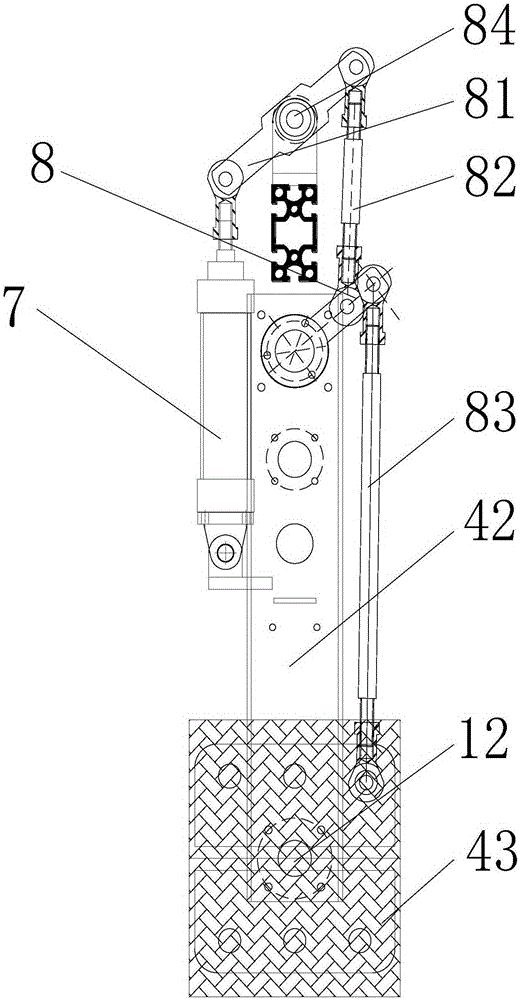

Multi-line parallel automatic machining production line capable of automatically turning materials

PendingCN112027595AReduce displacementReduce deformation errorControl devices for conveyorsJigging conveyorsManufacturing lineManufacturing engineering

The invention discloses a multi-line parallel automatic machining production line capable of automatically turning materials. The multi-line parallel automatic machining production line comprises a feeding system, a conveying line, a machining system and a discharging system, wherein the machining system involves a machining table and a movable portal frame, an X-axis guide rail is arranged on themachining table, a Y-axis guide rail is arranged on an upper beam of the movable portal frame, a mounting plate is arranged on the Y-axis guide rail, a plurality of sets of Z-axis guide rails are arranged on the mounting plate, machining heads are arranged on the plurality of Z-axis guide rails, a plurality of machining stations are arranged on the machining table, the conveying line comprises aconveying rail and a driving system for driving the materials to move in the conveying rail, the conveying rail is arranged parallel to the plurality of machining stations, and material output channels are formed in the positions corresponding to the plurality of machining stations; the multi-line parallel automatic machining production line further comprises a calibrating system for calibrating all the machining heads at a time, and the discharging system is connected with the feeding system through an automatic material turning device; and the multi-line parallel automatic machining production line further comprises a PLC control system for controlling each part to operate.

Owner:王杰

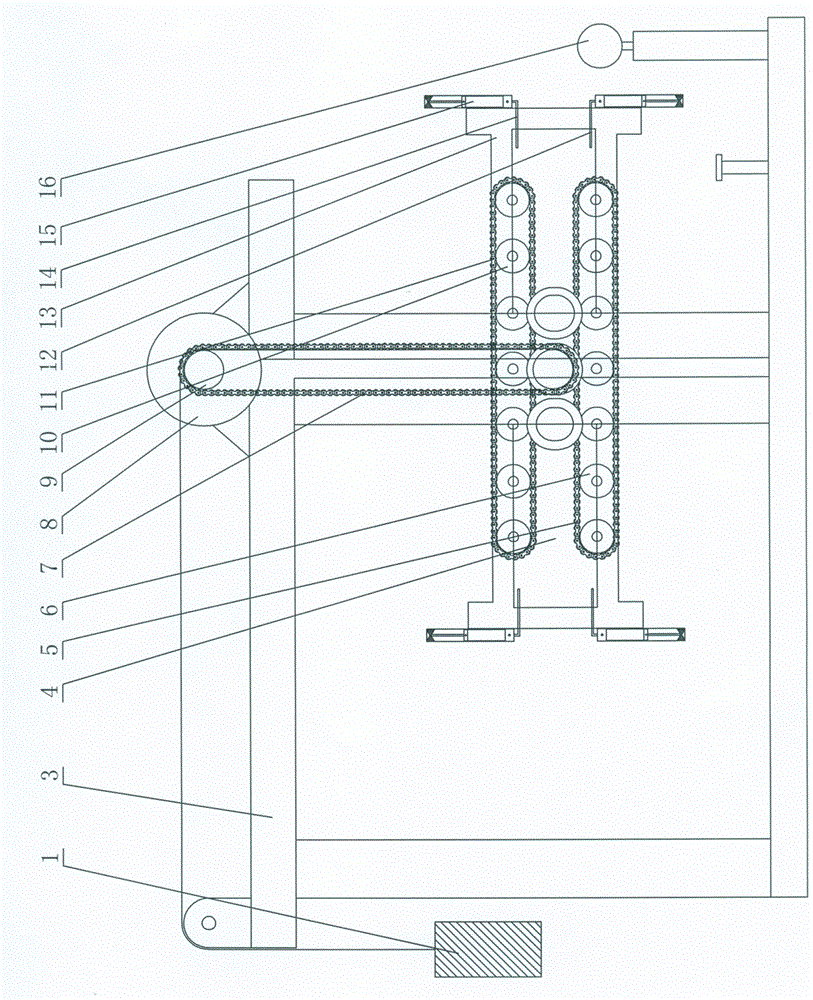

Lifting type spiral turning drill hole turning machine

InactiveCN109485474AImprove mechanical stressImprove adaptabilityClimate change adaptationExcrement fertilisersFailure rateStress conditions

The invention discloses a lifting type spiral turning drill hole turning machine with a groove type fermentation compost turning function. The machine is formed by combining two systems of a track type moving beam frame and a lifting type spiral drilling machine, wherein the movement of the moving beam frame and the drilling and turning and throwing of the spiral drilling machine are preformed ina time-sharing manner; and a spiral drill bit vertically lifts and drills holes to lift materials at the lower layer of the compost to the surface layer of the compost, and thus the mixing and aeration of the materials at each layer of the compost are realized, and the purpose of turning over the compost is achieved. The machine has the advantages that the mechanical stress condition of the turning machine is improved, the operation load is reduced, the failure rate can be reduced, and the turning efficiency is improved; the adjustment of the turning interval and the turning frequency is facilitated, and different turning frequencies can be implemented for different intervals and different fermentation stages of multi-groove fermentation composts; the adaptability to long-span and deep composting, continuous composting and different composting materials is good; and large-scale continuous composting automatic turning operation is convenient to realize.

Owner:金文虎

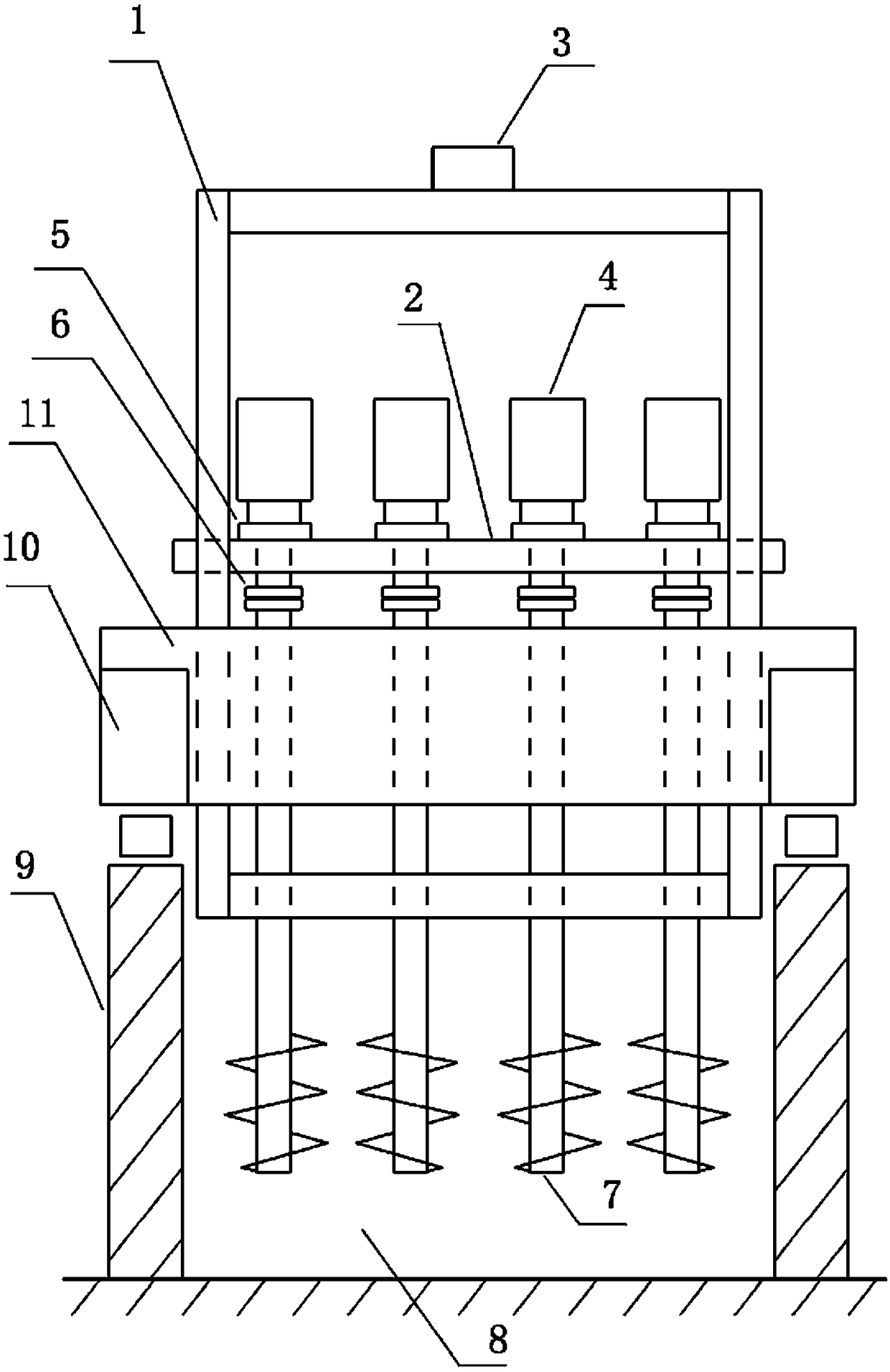

Automatic overturning device applied to tank container

ActiveCN104925721AImprove turning efficiencyReduce labor intensityLifting devicesHoisting equipmentsControl systemFixed frame

The invention discloses an automatic overturning device applied to a tank container. The automatic overturning device comprises racks, bases, overturning fixing frames, workpiece correcting systems, workpiece insertion hole locking systems, overturning transmission systems, lifting driving systems, a safety system, a hydraulic system and a control system. Assembling work is carried out with the tank container located at an ideal position through the cooperation of the clamping, lifting and overturning movement of an assembling position changing machine on the tank container and a tank container conveying line, the workpiece overturning efficiency can be greatly improved, the labor intensity of workers can be relieved, the production efficiency can be improved, the safety of the workers is ensured, and the automatic overturning device is an ideal device for carrying out overturning movement on various tank container and the same types of components.

Owner:成都焊研威达科技股份有限公司

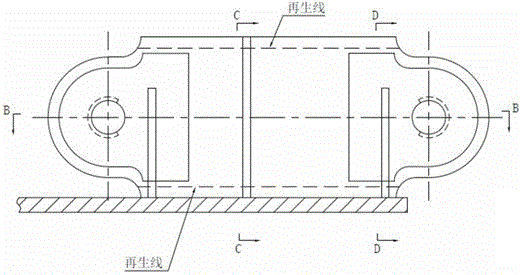

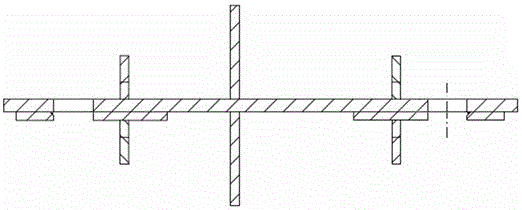

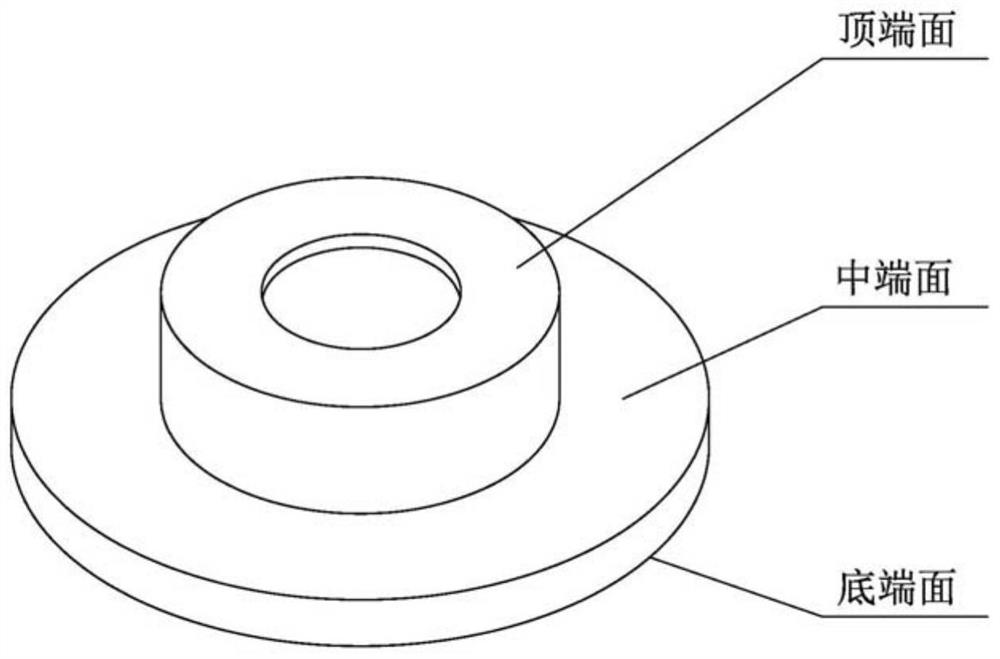

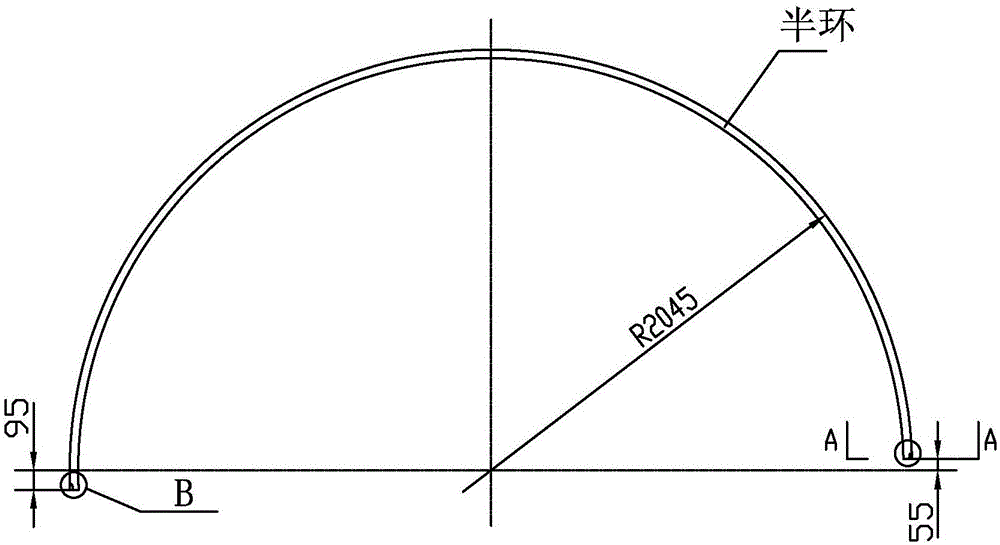

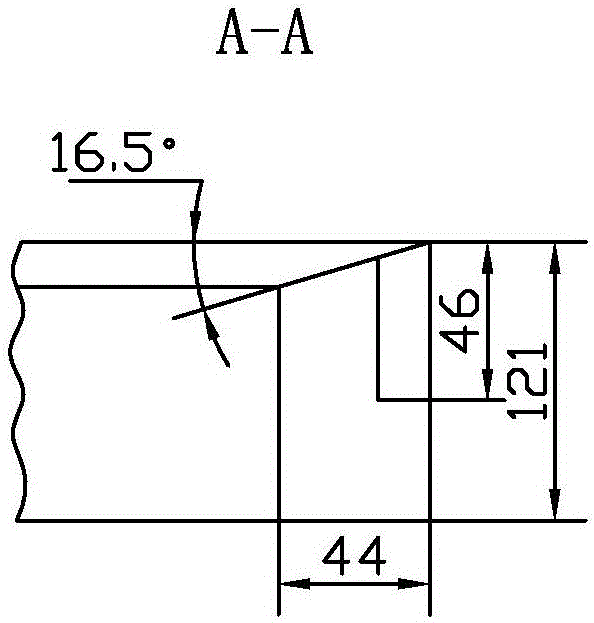

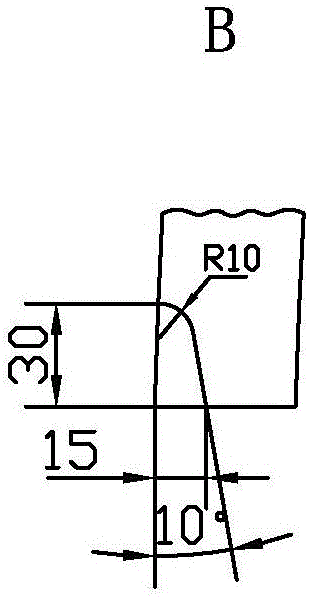

Nuclear power semi-ring machining method

The invention belongs to the field of machining and relates to a machining method, in particular to a nuclear power semi-ring machining method. The problems that according to an existing technological scheme, the machining precision of a nuclear power semi-ring cannot be guaranteed, the working difficulty is increased for subsequent welding, and the welding quality is lowered are solved. The machining method specifically comprises the steps that firstly, a semi-ring blank is formed through casting; secondly, the surface of the semi-ring is turned by 121 mm on a vertical lathe, and the two planes are turned to 122 mm; thirdly, an inner hole, the outer circle line and two end face lines are marked on the semi-ring, and a line is marked in the position 55 mm away from the right side according to the dimension of 95 mm; fourthly, the two end faces of the semi-ring are milled on a boring mill, and the two end faces of the semi-ring are machined according to the dimension of 95mm; fifthly, the standard inner hole of the semi-ring is turned on the vertical lathe, and the volume of the outer circle is 3-5 mm; sixthly, tie bars are welded to the semi-ring in a matched mode by a bench worker; and seventhly, the tie bars are welded through electric welding.

Owner:HARBIN TURBINE

Overhead green brick turnover equipment used for hollow brick production

ActiveCN105329648AImprove turning efficiencySimple structureConveyor partsBrickProgrammable logic controller

The invention provides overhead green brick turnover equipment used for hollow brick production, and relates to the technical field of mechanical equipment for hollow brick production. The overhead green brick turnover equipment comprises a bracket, a transport unit and a turnover mechanism for turning over and steering green hollow bricks, wherein the transport unit is mounted below the bracket; the turnover mechanism is mounted on the bracket; the transport unit and the turnover mechanism are controlled by a PLC (programmable logic controller) and a servo mechanism to cooperatively work; the turnover mechanism is an overhead turnover mechanism for vertically rotating the green hollow bricks in air by 90 degrees. The overhead green brick turnover equipment provided by the invention is high in green brick turnover efficiency for hollow bricks, is small in floor space, relatively low in manufacturing cost and simple in structure, and has a wide market prospect.

Owner:CHONGQING ZHUOGONG TECH

Purple light LED light-emitting device

ActiveCN113701090AReduce the frequency of cleaningAvoid overheating damageLighting support devicesLighting heating/cooling arrangementsEngineeringLight tube

The invention discloses a purple light LED light-emitting device, and relates to the technical field of LEDs. The device comprises a movable frame, a light reflecting groove plate is movably installed at the top of the movable frame, a purple light LED lamp tube is fixedly installed in the light reflecting groove plate, a cleaning device is arranged on the outer side of the purple light LED lamp tube, heat dissipation devices are arranged on the front face and the back face of the inner wall of the light reflecting groove plate, and an adjusting device is arranged on the right side of the light reflecting groove plate. A gear is matched with a gear ring arranged on the outer side of a left circular ring, so that the gear drives the circular ring to rotate clockwise, the circular ring drives a U-shaped frame to rotate clockwise, the U-shaped frame drives a cleaning brush to rotate, the cleaning brush cleans the outer side of the purple light LED lamp tube, therefore the problem that in an area with much dust, the brightness and the irradiation rate of the purple light LED lamp are reduced due to the fact that dust is attached to the purple light LED lamp tube is solved, and then the frequency of manually cleaning the purple light LED lamp tube is reduced.

Owner:张家港奇点光电科技有限公司

Integrated circuit turning device and control method

ActiveCN102774634AImprove turning efficiencySimple structureElectronic circuit testingControl devices for conveyorsTest equipmentEmbedded system

The invention relates to the field of integrated circuit test equipment and aims at providing an integrated circuit turning device and a control method. The integrated circuit device has high integrated circuit turning efficiency, is favorable for the organization of integrated circuit test flow line operation and comprises a rotating seat, a rotating driving mechanism, a baffle plate, a feeding rail and a base, wherein the rotating seat is provided with a rotating shaft and at least two integrated circuit accommodating through holes distributed in the circumferential direction, the baffle plate is provided with a material discharge through hole, the rotating shaft is pivoted with the base, the feeding rail and the baffle plate are respectively positioned at the two opposite sides of the rotating seat and are fixedly connected with the base, the rotating driving mechanism is respectively and fixedly connected with the rotating seat and the base, the integrated circuit turning device is provided with a material conveying mechanism and a rotating angle detecting mechanism, the material conveying mechanism is used for controlling the feeding rail to convey materials to the rotating seat, and the rotating angle detecting mechanism is used for detecting the rotating angle of the rotating seat. The integrated circuit turning device has the advantages that the integrated circuit turning efficiency is high, in addition, the flow line operation of the integrated circuit test can be favorably organized, and in addition, the control method is simple and practical.

Owner:HANGZHOU CHANGCHUAN TECH CO LTD

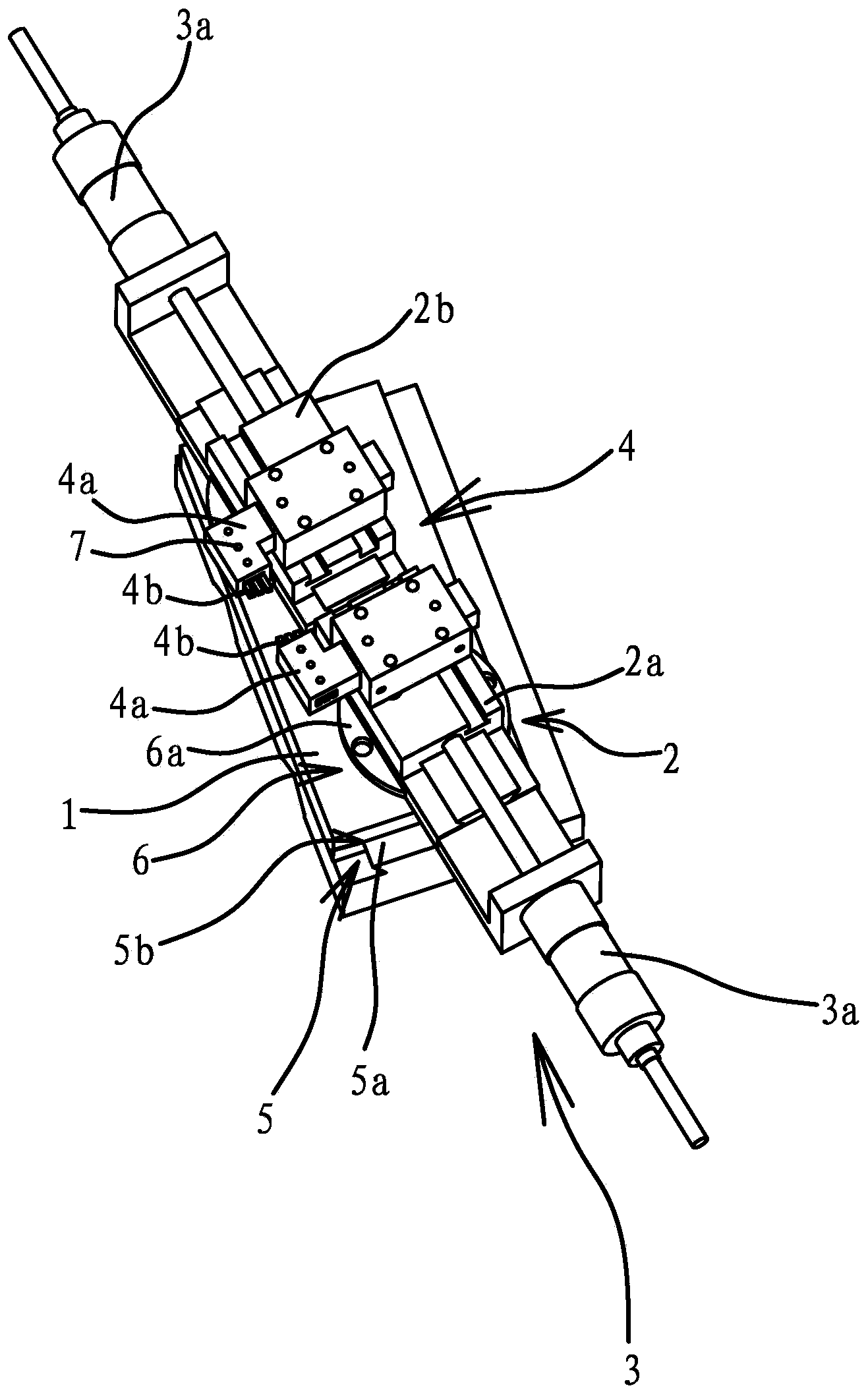

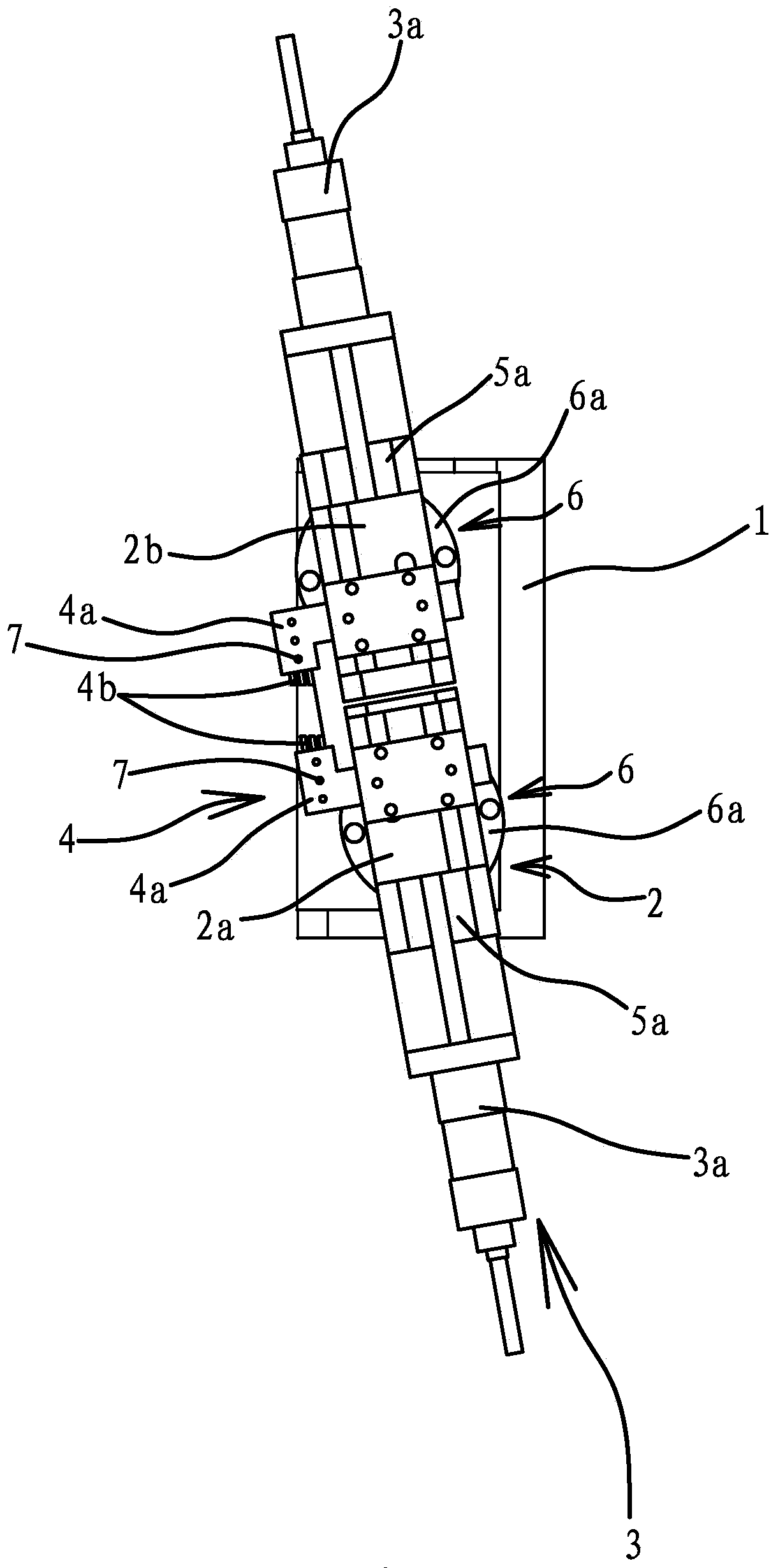

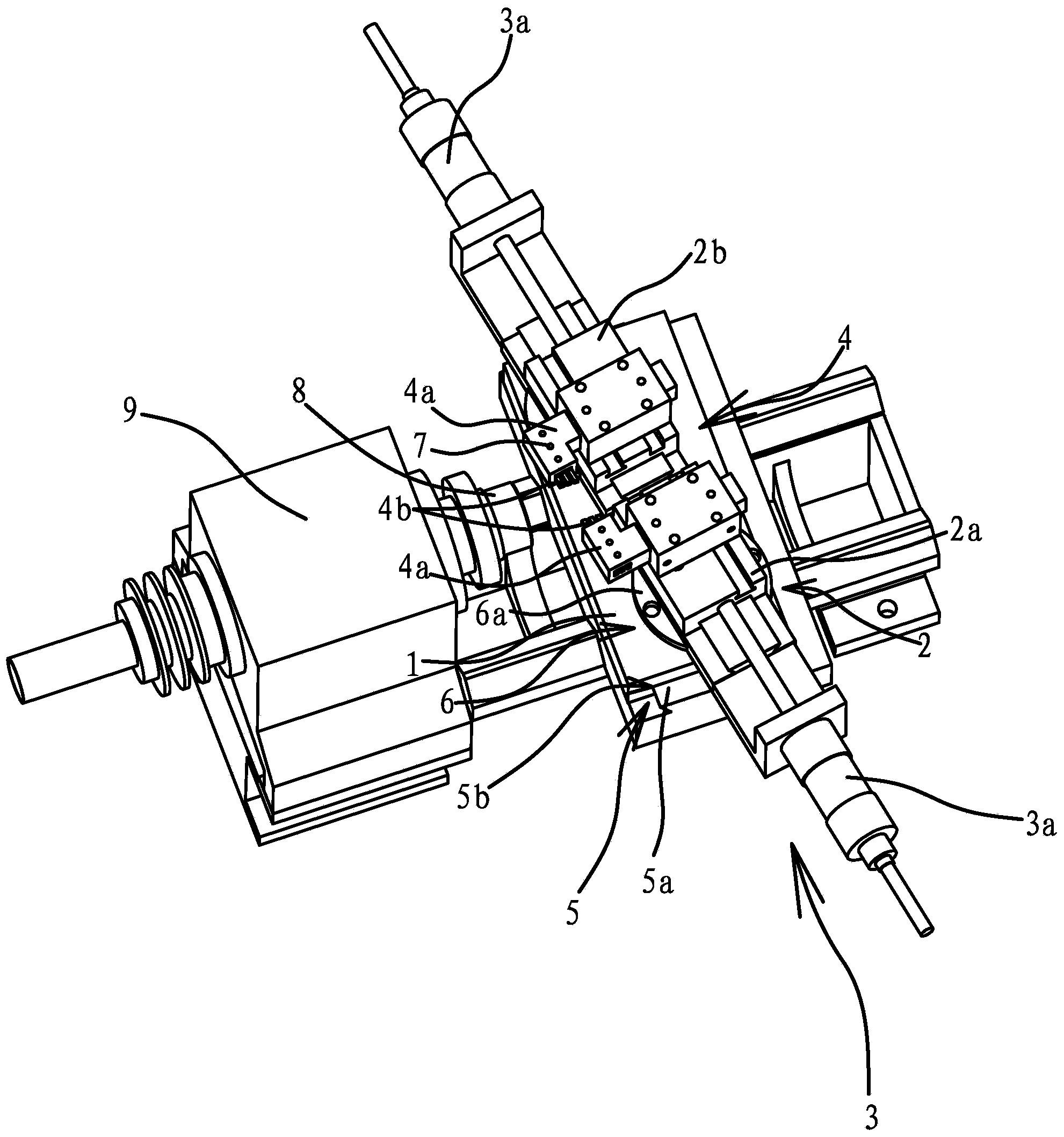

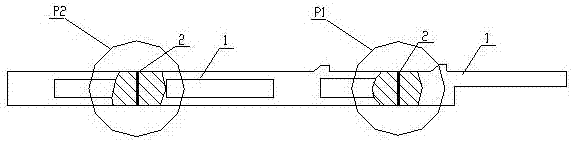

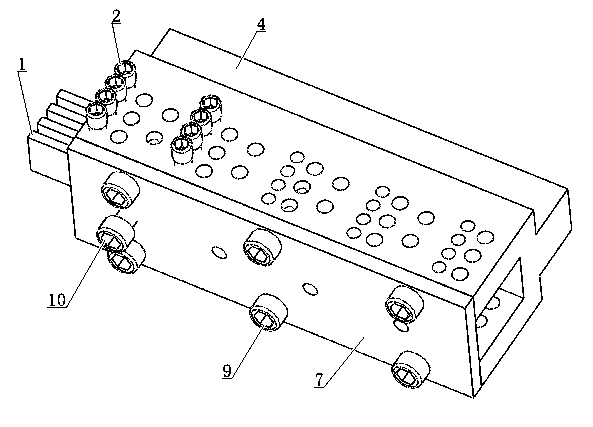

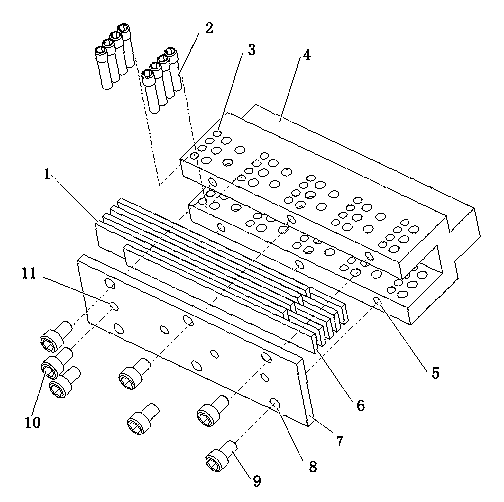

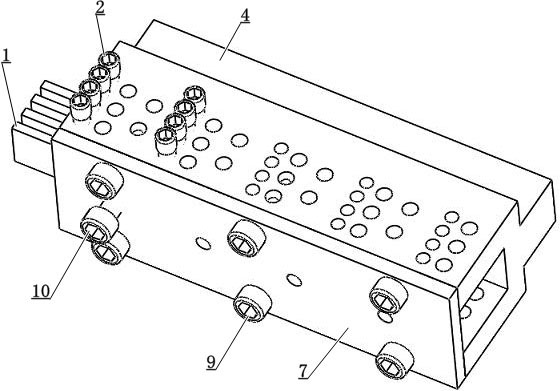

Multi-knife lathe tool clamp

The invention discloses a multi-knife lathe tool clamp. The lathe tool clamp comprises lathe tool blades 1, a compression bolt 2, a lathe tool clamp body 4, a knife-padding sheet 6, a laterally pressing plate 7, a bolt 9 and a laterally pressing bolt 10, and is characterized in that the laterally pressing plate 7 is arranged on the side surface of the lathe tool clamp body 4 through a hole 8 and a screw thread hole 5 by using the bolt 9; the lathe tool blades 1 and the knife-padding sheet 6 are arranged in a long groove in the lathe tool clamp body 4; and after the laterally pressing bolt 10 pre-tightens the lathe tool blades 1 through a screw thread hole 11 in the laterally pressing plate 7 in a laterally pressing way, the lathe tool blades 1 are tightly pressed by the compression bolt 2, and the compression bolt 2 is tightly locked. The lathe tool blades are clamped by the lathe tool clamp and cut a workpiece simultaneously, so that the production efficiency is improved through cutting by the lathe tool blades, and the requirements of low consumption and high efficiency on the production technology are met by a reasonable machining process.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

Rotary kiln with material turning function

PendingCN113465365ATurnover continuesStretch out fastRotary drum furnacesCharge manipulationEngineeringMechanical equipment

The invention belongs to the technical field of mechanical equipment, and relates to a rotary kiln with a material turning function. The rotary kiln comprises a kiln head, a roller and a kiln tail, wherein the roller is obliquely arranged on the kiln head and the kiln tail, the rotary kiln further comprises a mounting shaft and a material turning mechanism, a linkage part is arranged on the inner wall of the roller and is used for driving the material turning mechanism to perform material turning operation, the material turning mechanism comprises a rotating ring sleeve and two limiting sliding seats, three telescopic frames are arranged on the rotating ring sleeve, telescopic baffles are arranged in the telescopic frames, a secondary propelling assembly is arranged in a mounting groove, a sealing cover is arranged at the inner side end of each telescopic baffle, the telescopic frames communicate with the rotating ring sleeve, the two limiting sliding seats are arranged on the mounting shaft at intervals, a pop-up assembly is arranged on the right lower side wall of the mounting shaft, the mounting shaft is mounted on the kiln head and the kiln tail, the mounting shaft and the roller are coaxial, and the material turning mechanism is rotationally arranged on the mounting shaft. According to the rotary kiln, the dangerous waste can be continuously turned over, so that the dangerous waste is uniformly heated in the roller.

Owner:高邮市环创资源再生科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com