Touchdown turning process of subsection

A process and ground technology, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve problems such as no identical or similar technical solutions found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

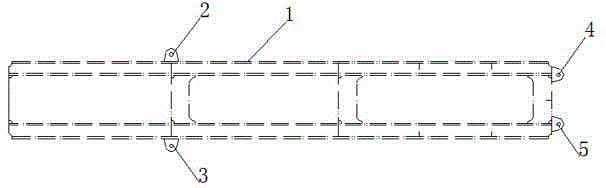

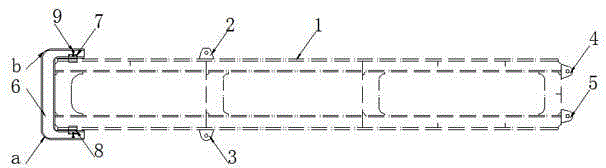

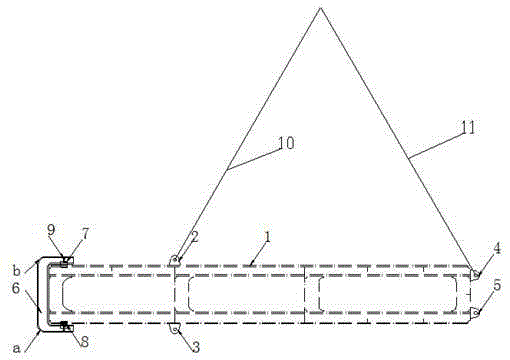

[0018] like figure 1 As shown, the present invention discloses a technique for standing up on the ground in section 1, and the structure involved in the section includes section 1, a pair of first lifting lugs 2 and fourth lifting lugs respectively arranged on the sides of the two major axes of section 1. Lifting lug 3 , a pair of second lifting lug 4 and third lifting lug 5 arranged on the same minor axis side of segment 1 .

[0019] When turning over in the above subsection 1, the supporting force of the ground is used to reduce the lifting load of the crane, so as to achieve the purpose of turning over. The specific steps are as follows:

[0020] (1) Production of protective cover for turning over on the ground: I-shaped steel is used, and the I-shaped steel is bent into a U-shaped structure that matches the end of the segment to complete the production of protective cover for turning over on the ground;

[0021] (2) Install the turn over protective cover: such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com