Fermentation turning method of aerobic microbial fertilizer

A technology of microbial fertilizer and heap turning, which is applied in the field of fermentation and turning of aerobic microbial fertilizers, can solve the problems of slow fermentation efficiency, high temperature, poor turning effect, etc. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

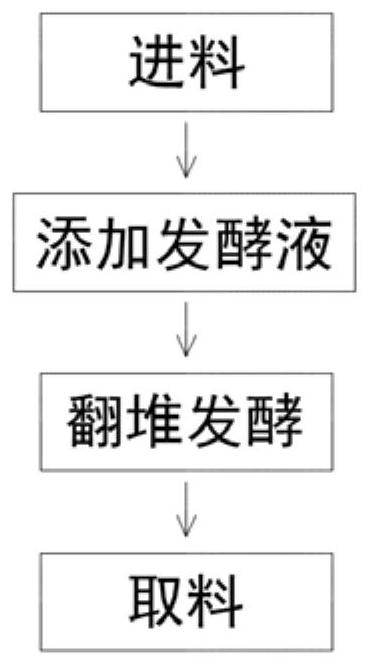

[0028] Such as Figure 1-4 Shown, a kind of fermenting turning method of aerobic microbial fertilizer mainly comprises the following steps:

[0029] S1 Feed, human and livestock manure, sawdust, rice bran, soybean meal, and water are put into the fermentation tank 1 to obtain the base material;

[0030] S2 adding fermented liquid, evenly spraying the fermented liquid onto the base material surface;

[0031] S3 Turn over and ferment, keep the temperature of the base material at 40°C-50°C, and frequently stir and turn the base material, and continue to ferment for 9-15 days;

[0032] S4 taking material, taking out the fermented microbial fertilizer from the fermentation tank 1, and carrying out the next drying and granulation process;

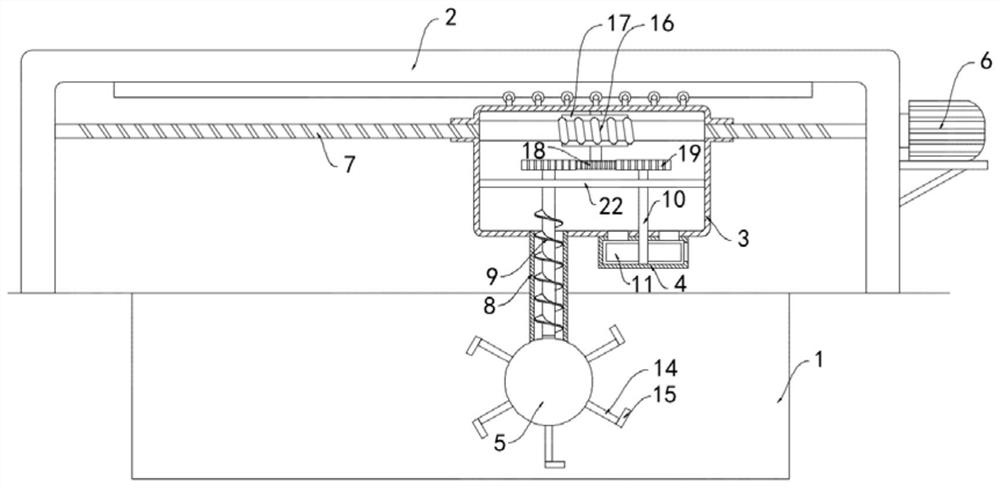

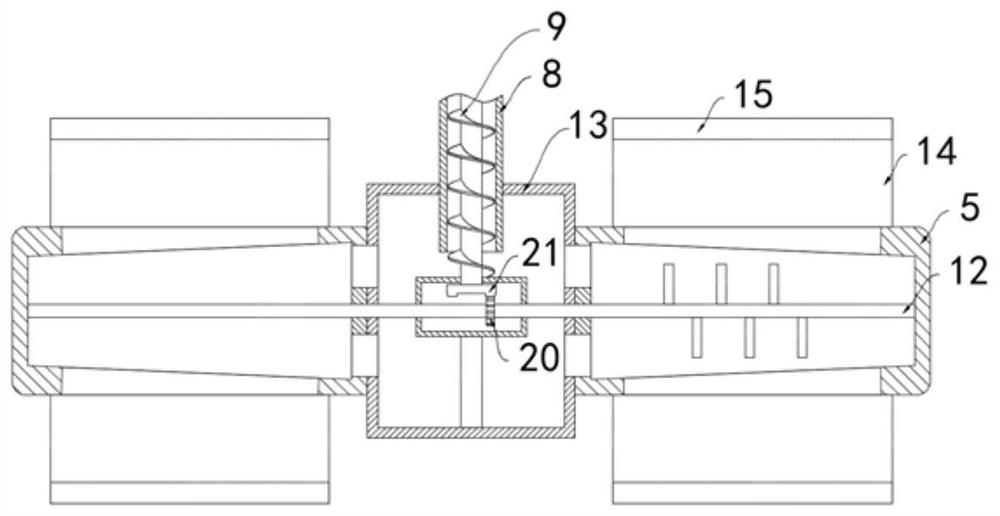

[0033] The fermentation and composting equipment used in the fermentation and composting process of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com