Tensile sliding rubber support

A rubber bearing and anti-tension technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of increasing installation costs, vertical tension of beam end supports, and no vertical pull-out resistance of sliding rubber bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

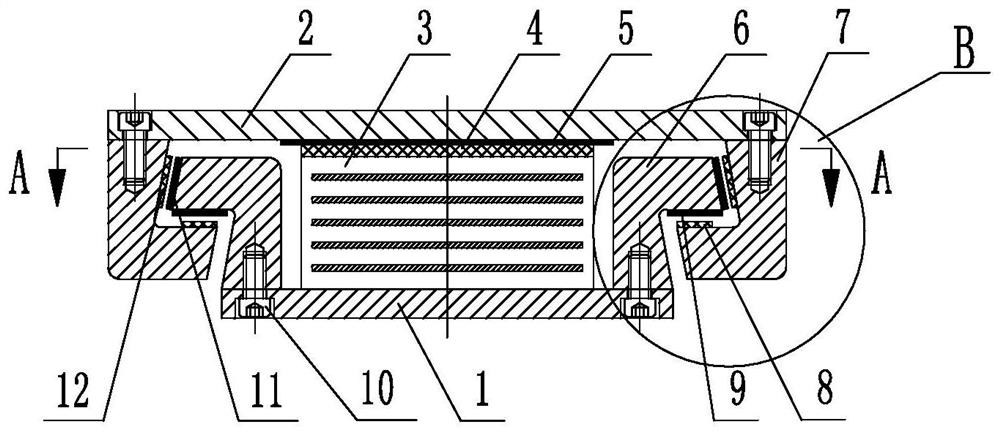

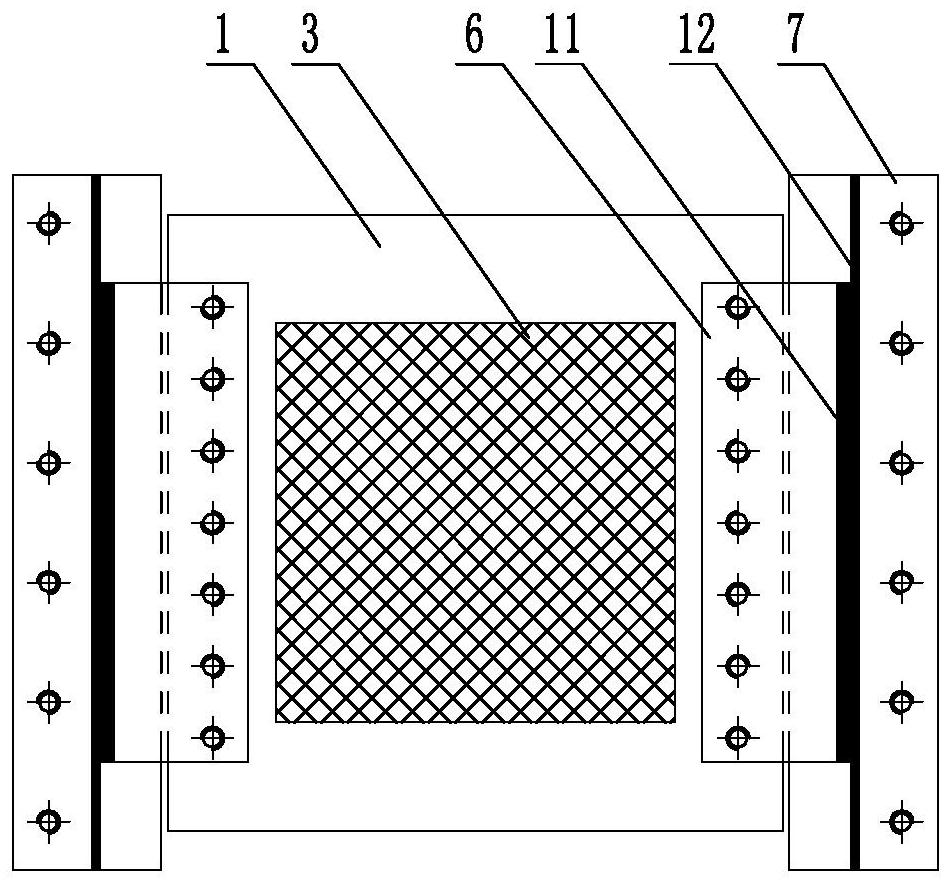

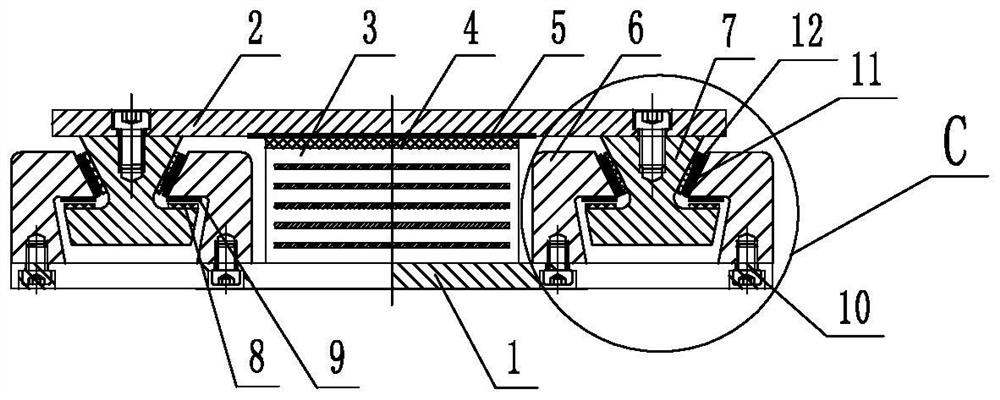

[0048] A tensile sliding rubber bearing, comprising a bearing body 3 and an upper steel plate 2 and a lower steel plate 1 connected up and down the upper steel plate 2 and a lower steel plate 1, and a tensile mechanism and a sliding mechanism are arranged between the upper steel plate 2 and the lower steel plate 1: the The tensile mechanism includes a left tensile mechanism and a right tensile mechanism. The left tensile mechanism and the right tensile mechanism are symmetrically arranged between the upper and lower steel plates on the left and right sides of the support body. The left and right tensile mechanisms have the same structure. It includes an upper tensile steel part and a lower tensile steel part, the upper tensile steel part is connected with the upper steel plate, the lower tensile steel part is connected with the lower steel plate, the lower end of the upper tensile steel part is connected with the upper end of the lower tensile steel part Interlocking to form a ...

Embodiment 2

[0059] A tensile sliding rubber support, the basic structure of which is basically the same as that of Embodiment 1, including a support body 3 and an upper steel plate 2 and a lower steel plate 1 connected up and down the upper steel plate 2 and the lower steel plate 1. Tensile mechanism and sliding mechanism:

[0060] The tensile mechanism includes a left tensile mechanism and a right tensile mechanism symmetrically arranged between the upper steel plate and the lower steel plate on the left and right sides of the support body. The left and right tensile mechanisms have the same structure, including upper tensile steel parts and The lower tensile steel part, the upper tensile steel part is connected with the upper steel plate, the lower tensile steel part is connected with the lower steel plate, and the lower end of the upper tensile steel part is buckled with the upper end of the lower tensile steel part to form a tensile mechanism ;

[0061] The upper tensile steel piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com