A box culvert sliding form construction device and method

A technology of construction device and construction method, applied in the field of culvert construction, can solve the problems of inability to meet construction requirements, high labor intensity, low work efficiency, etc., and achieves time-saving, labor-saving, high degree of mechanization, and reduced workload for mold installation and mold removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

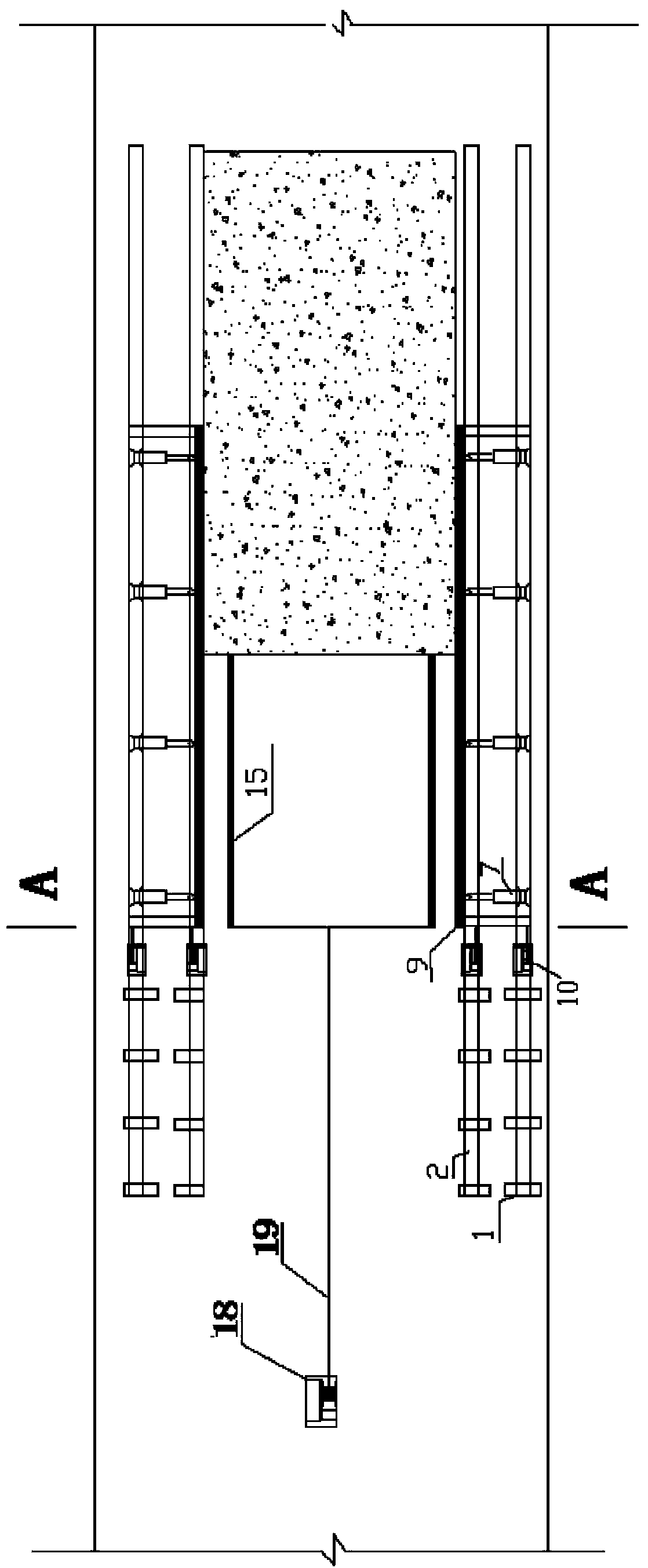

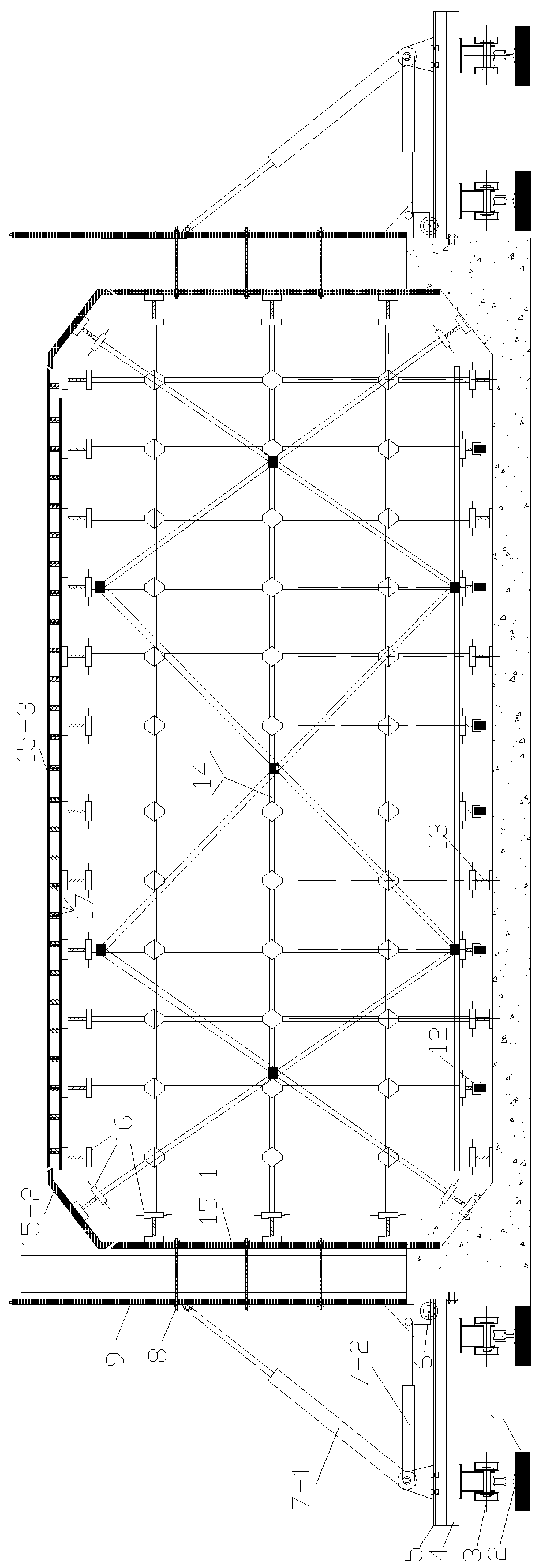

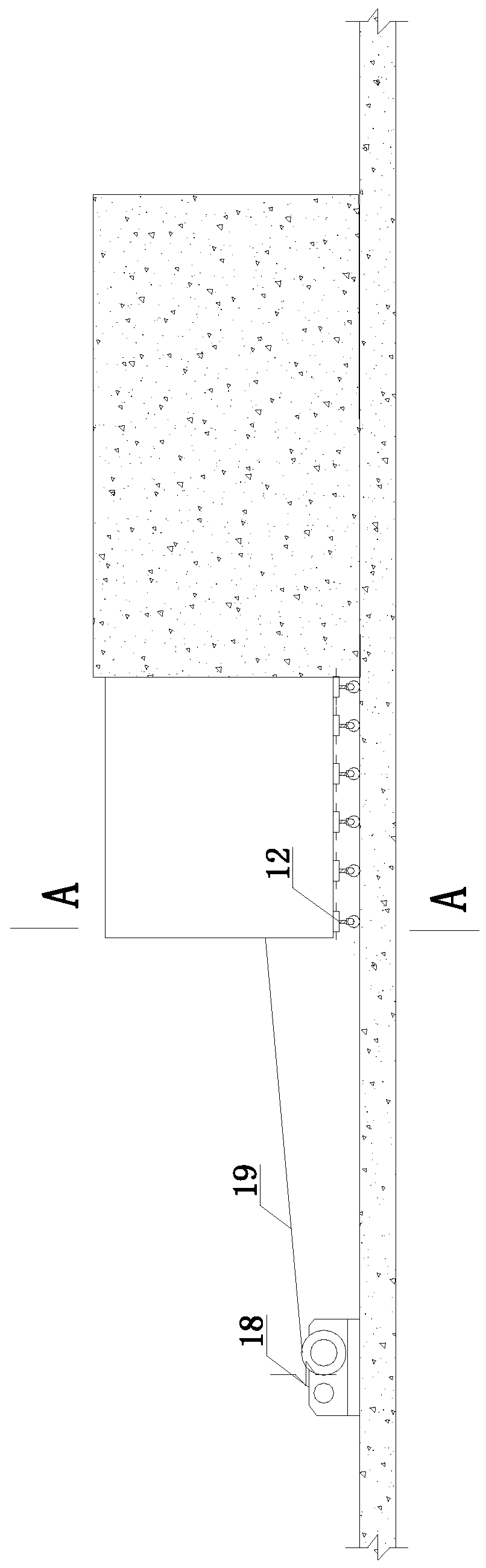

[0038] A box culvert slipform construction device, such as figure 1 , figure 2 As shown, it includes an outer mold 9, an inner mold 15, and a full-wall bracket 14. The outer mold 9 is pulled by the outer mold traction system to slide on the track. The whole slides under the traction of the internal model traction system.

[0039] Inner mold 15 adopts combined steel mold, and combined steel mold comprises side mold 15-1, cornea 15-2 and bamboo plywood bottom mold 15-3, and side mold 15-1 is assembled in full hall support 14 both sides, and bamboo plywood bottom mold 15-3 is assembled on the top of the full hall support 14, and the cornea 15-2 is assembled between the side mold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com