Two-tool cathodic electrolytic milling system and method for processing complex thin walls

A tool cathode and processing method technology, applied in the fields of electrolytic machining and grinding, can solve the problems of large machining error and long machining time, and achieve the effects of reducing feed error, improving machining accuracy and shortening machining time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

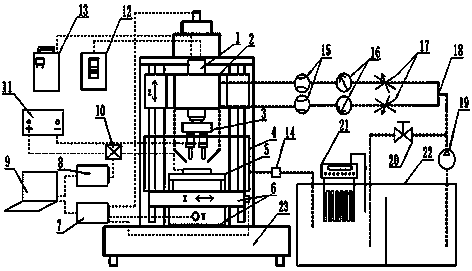

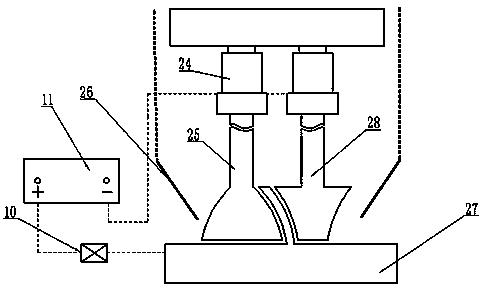

[0013] according to figure 1 As shown, the overall schematic diagram of the dual-cathode feed electrolytic grinding and milling system consists of the following parts: In the spindle system of the machine tool, the frequency converter 12 can control the speed of the electric spindle 1, the water cooler 13 can cool the electric spindle 1, and the spindle fixture 2 The electric spindle 1 can be clamped and fixed, and the double-joint transmission mechanism 3 realizes the rotation of one electric spindle 1 driving two water-stop chucks 24; in the electrolyte circulation system, the shunt tee 18 can evenly divide the electrolyte into two circuit, the two external nozzles 26 pass through the hole of the main shaft fixture 2 and are always aimed at their respective processing areas, and the two pressure gauges 16 and flowmeters 15 can monitor the pressure and flow of their respective circuits; in motion control and data In the acquisition system, the computer 9 controls the X-Y-Z th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com