Patents

Literature

101results about How to "Smooth slip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

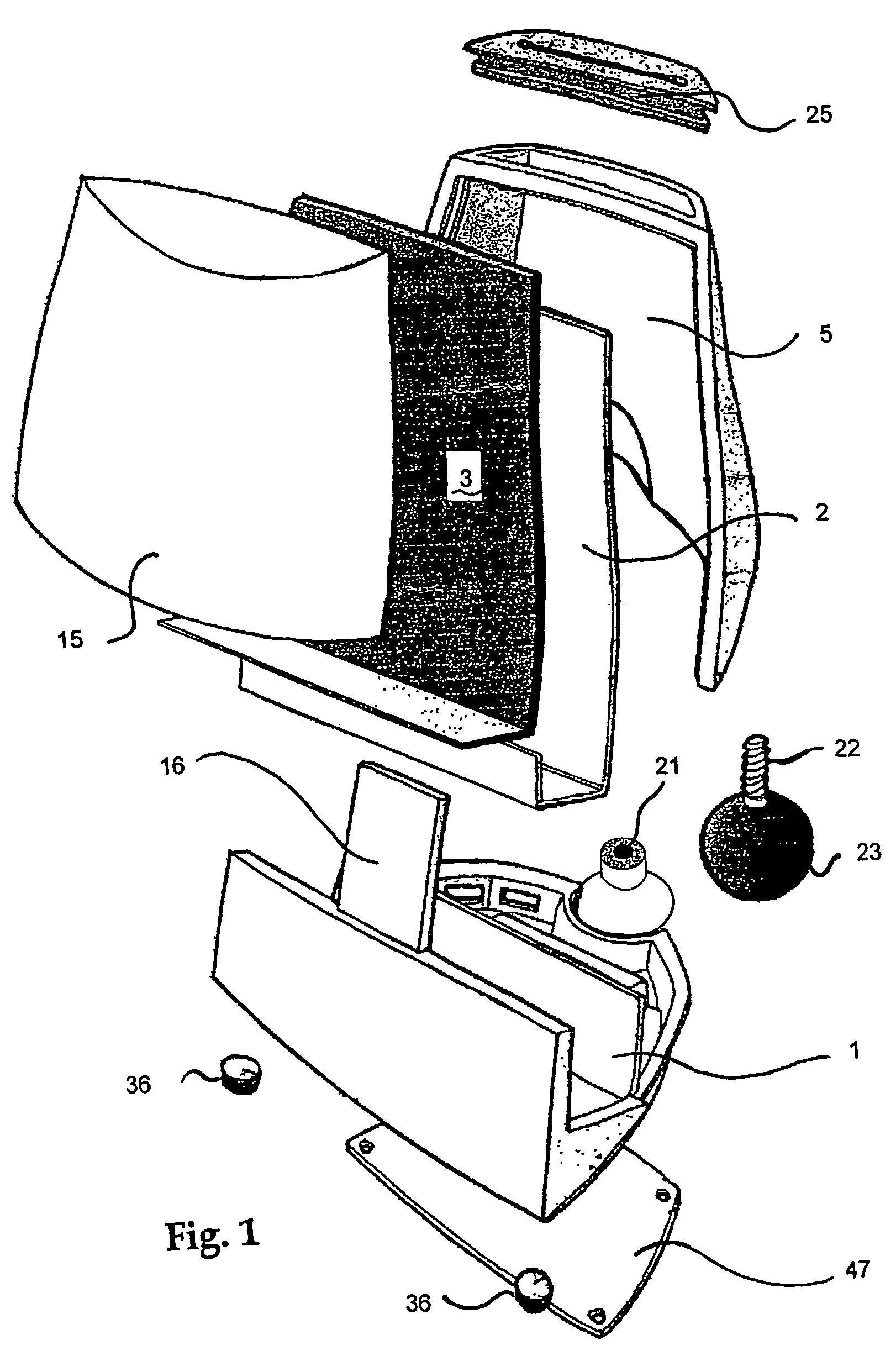

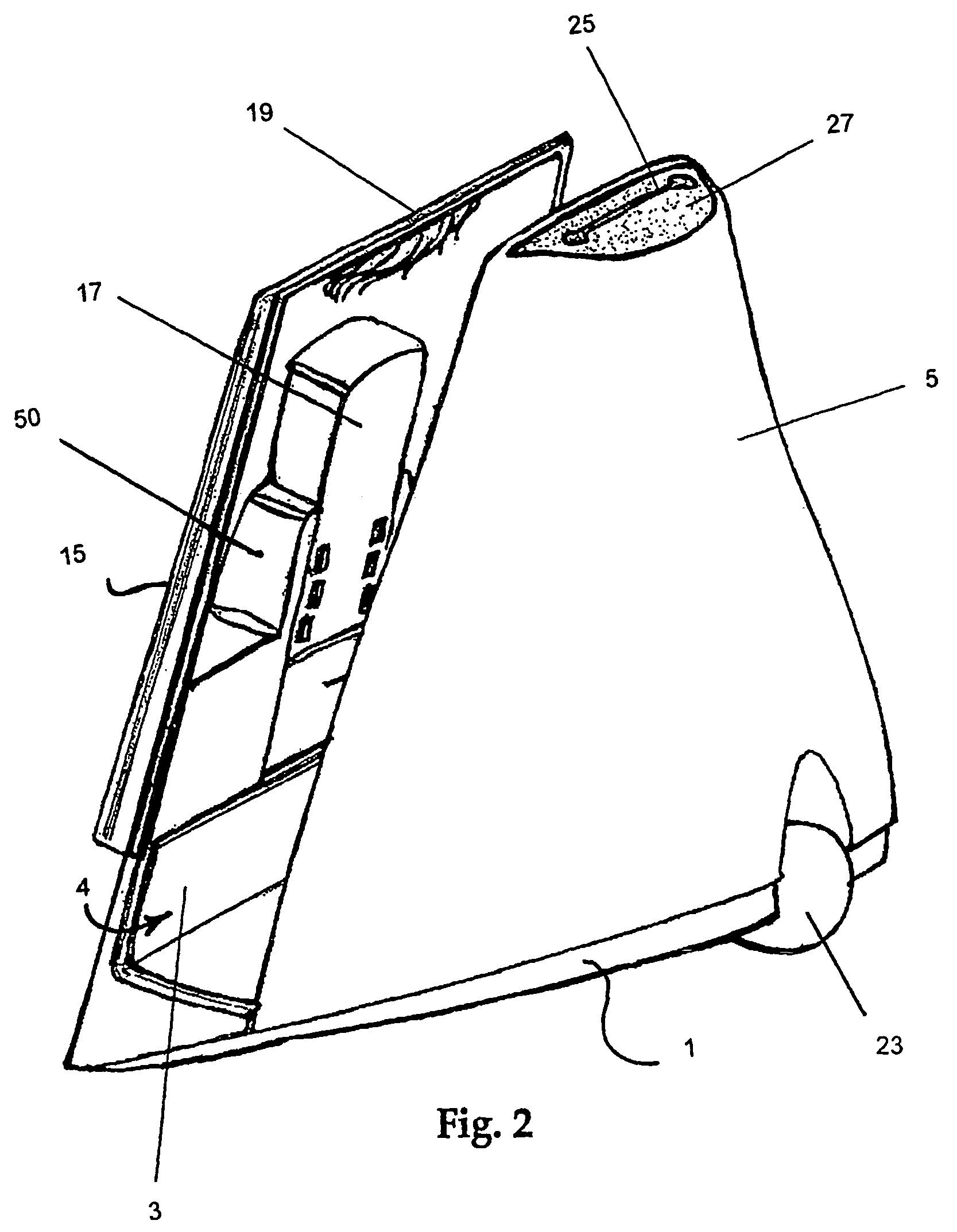

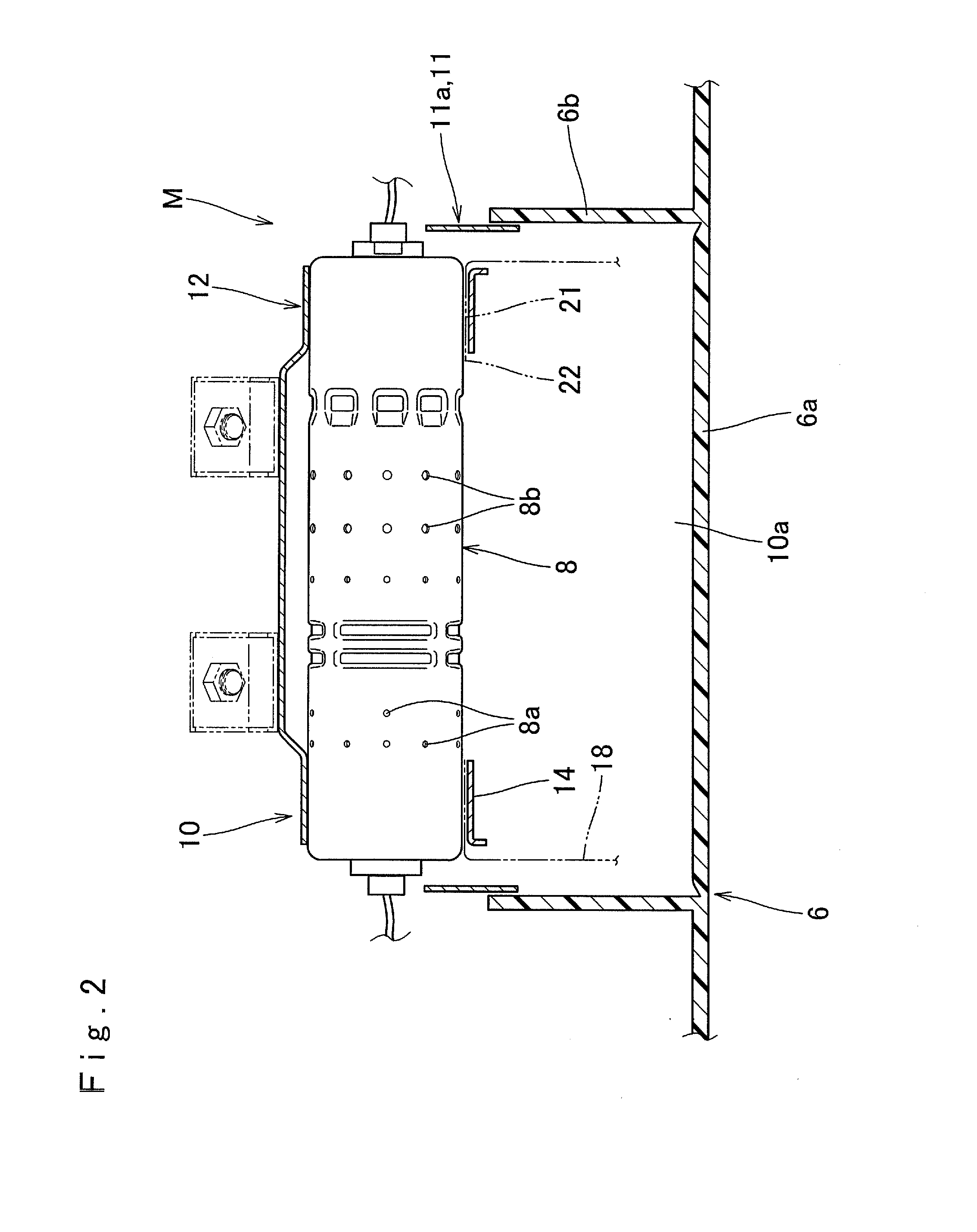

Vertical docking station

InactiveUS20050162824A1Easy to cleanEasy and quick connectionDigital data processing detailsCooling/ventilation/heating modificationsDocking stationElectric power transmission

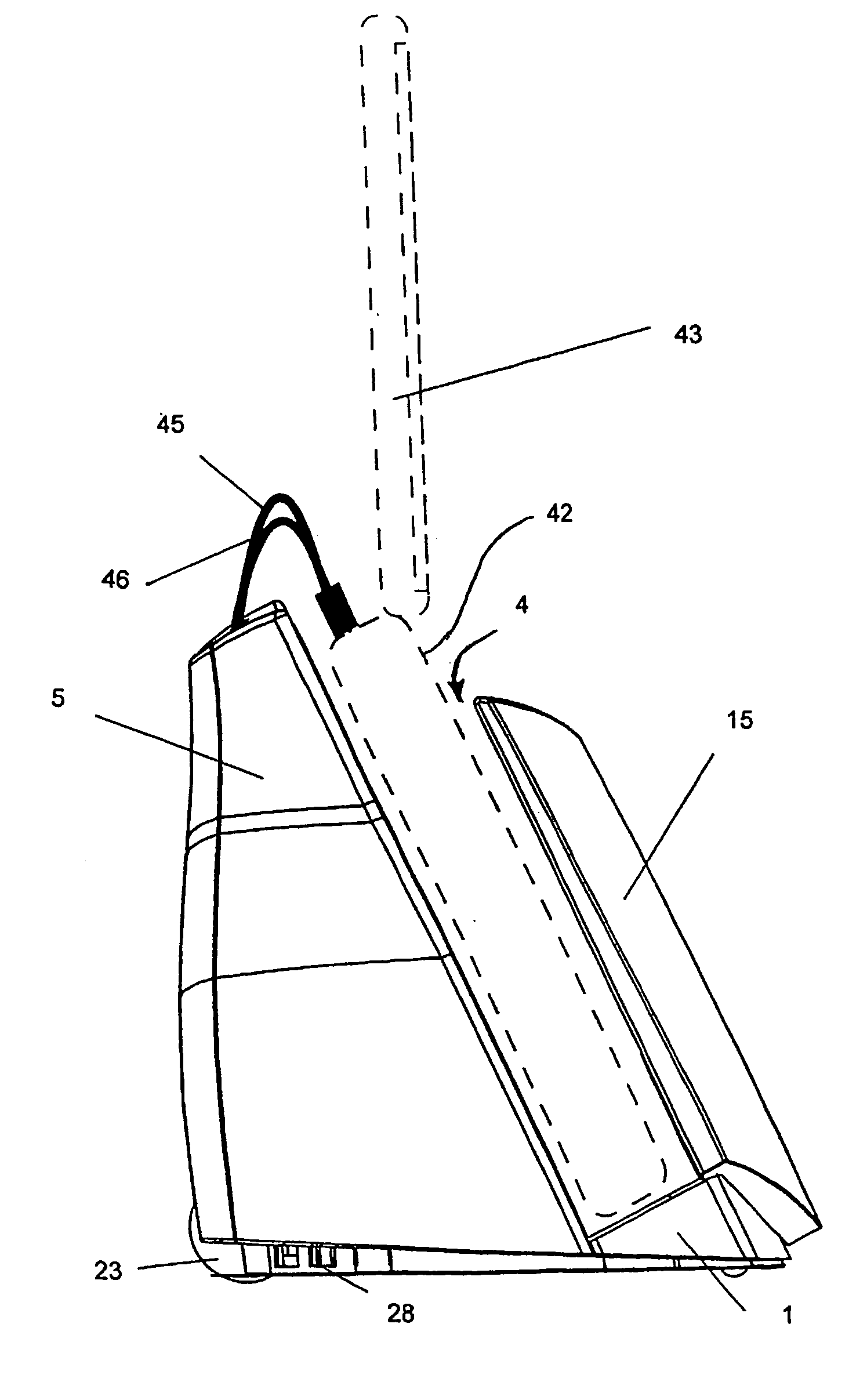

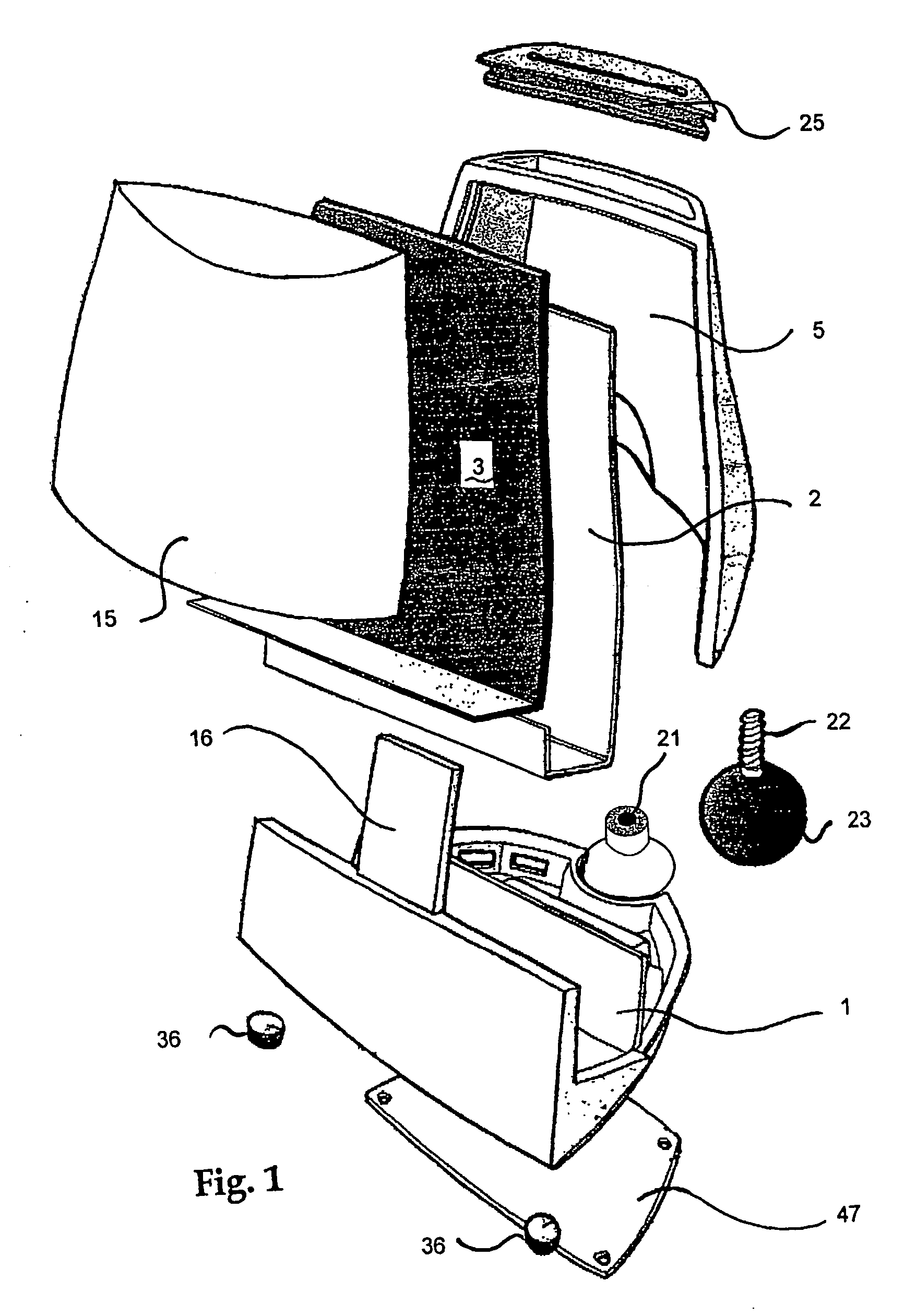

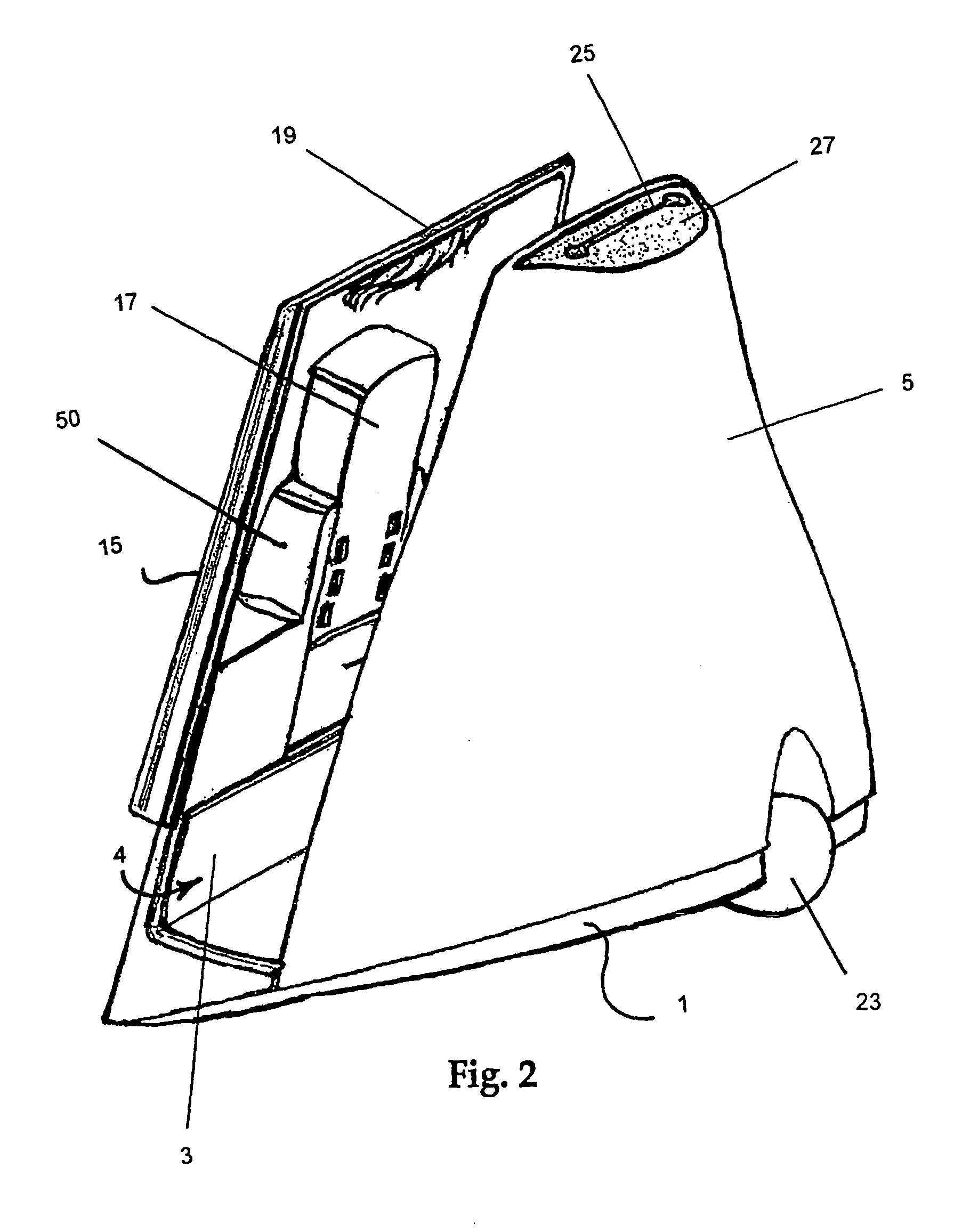

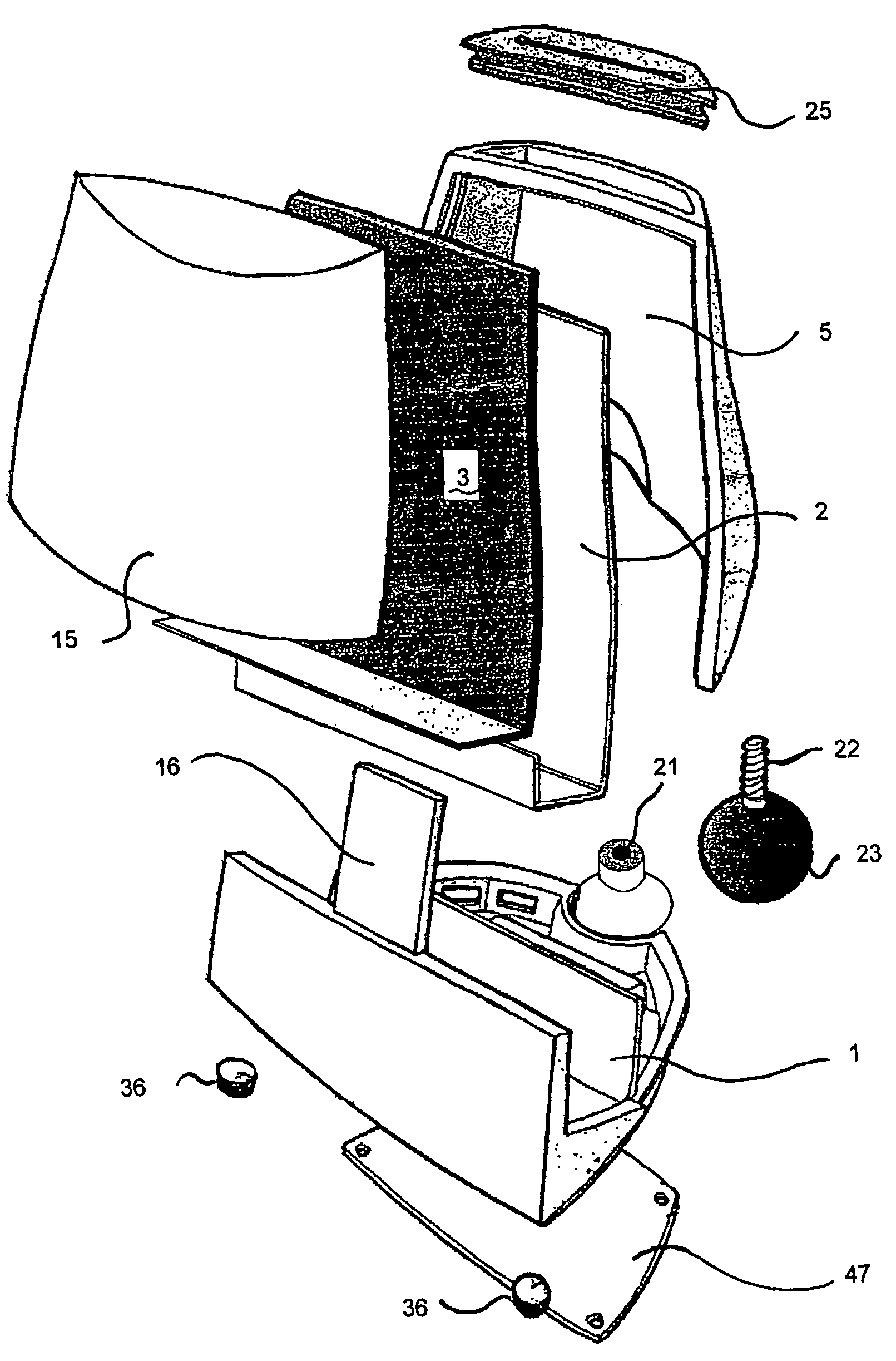

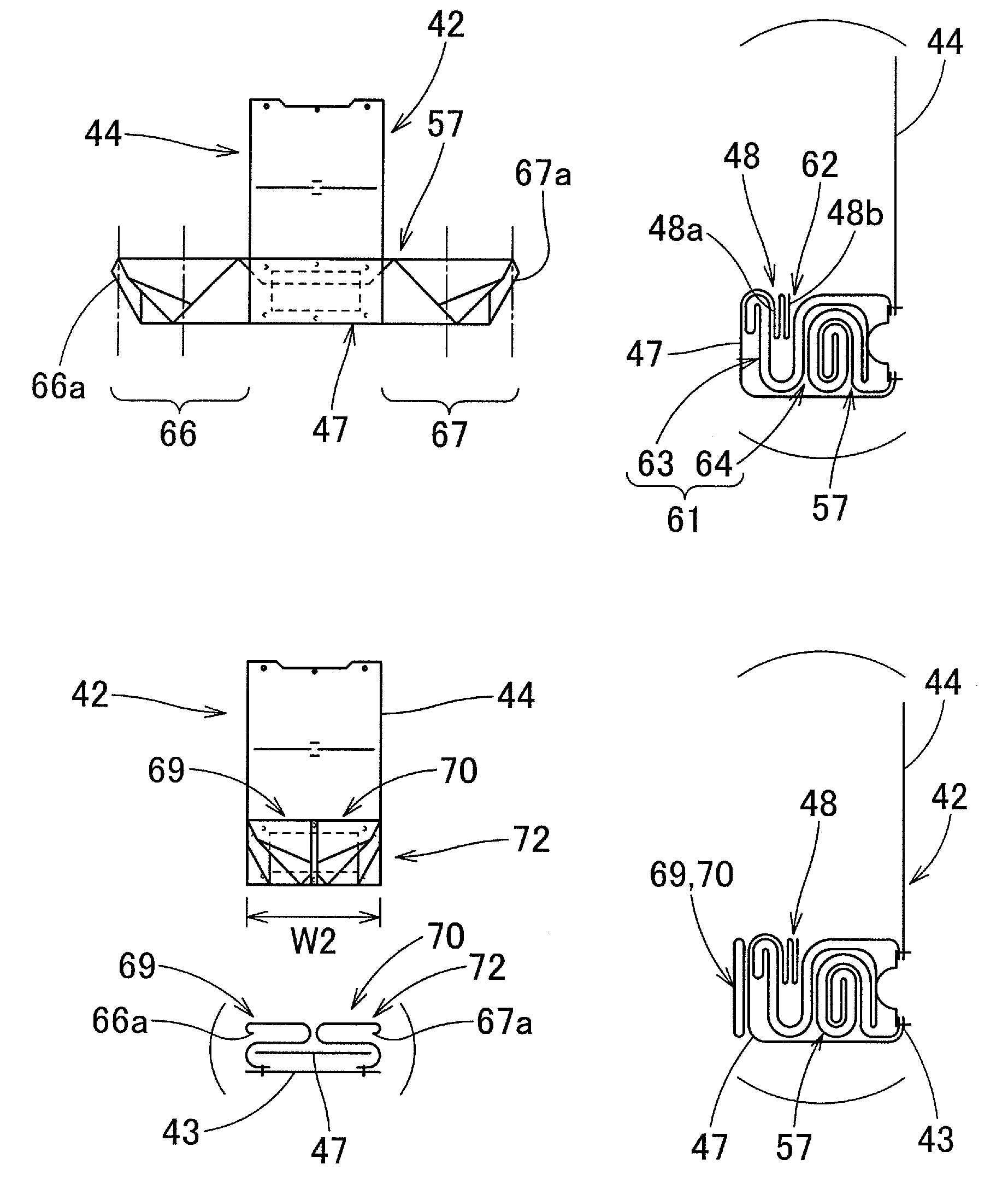

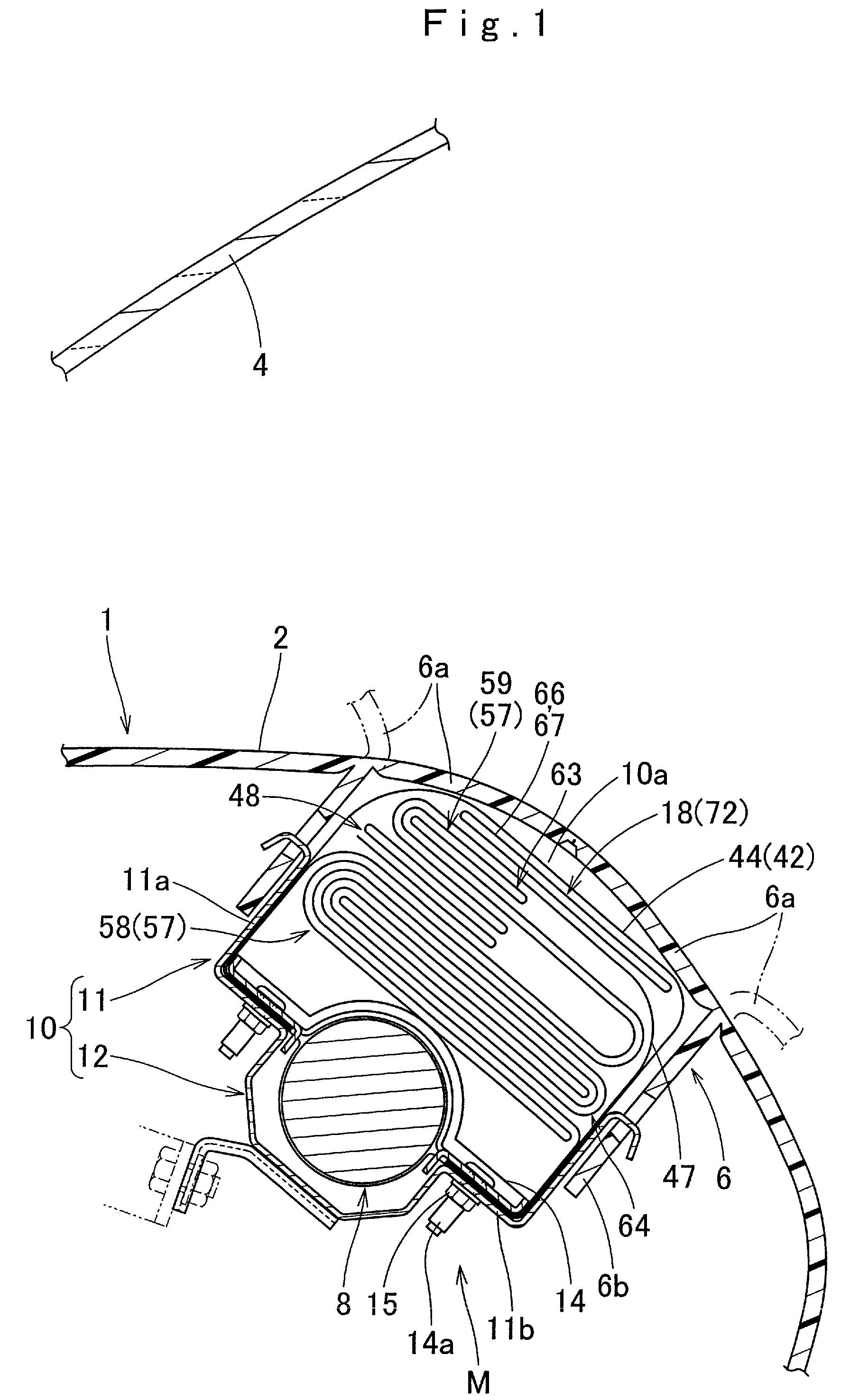

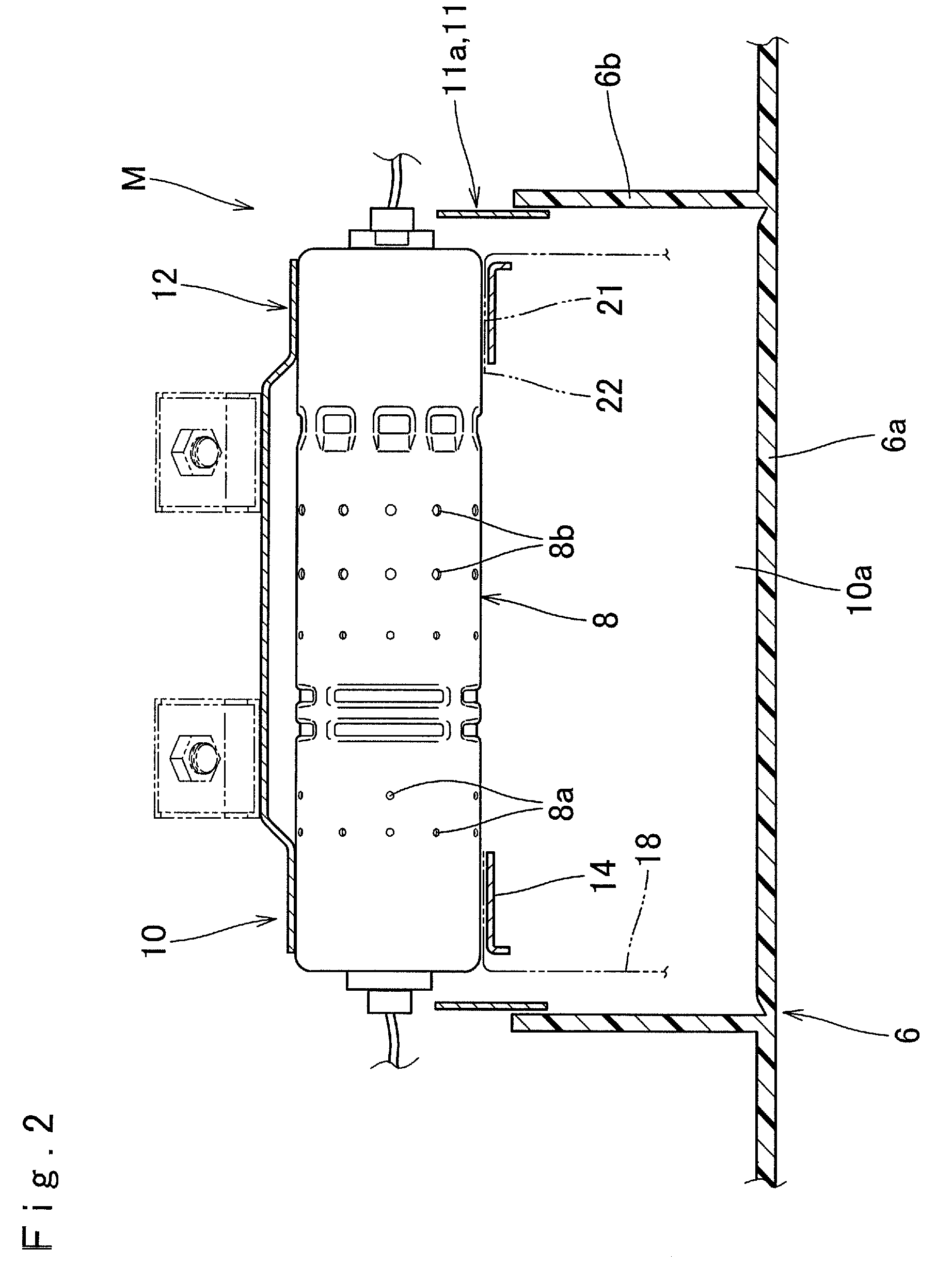

A docking station, serving as a digital hub and cable management platform, support a laptop computer (42) in an upright position with the laptop screen (43) in a comfortable viewing position relative to the working position of the user. The laptop (42) is positioned in an upright slot (4) in the docking station, with the connection ports easily seen and accessed. The surface of the laptop slot (4) is lined with non-slip surface (3) to ease insertion and control of the laptop (42) as it is lowered into the slot (4). An adjustable front cover (15) defining the front boundary of the slot (4) covers the keyboard of the mobile computer (42) so that the user does not need to view two keyboards, and the appearance of the docked laptop (42) is clean and aesthetic. Wireless data and power transmission into the laptop (42) is provided while the laptop (42) is in the slot (4) so that the laptop (42) can be used in the docking station without a need for cable connections (45, 46) at all.

Owner:THOMPSON

Vertical docking station

InactiveUS7679902B2Easy and quick connectionEasy storage managementDigital data processing detailsCooling/ventilation/heating modificationsDocking stationElectric power transmission

A docking station, serving as a digital hub and cable management platform, support a laptop computer (42) in an upright position with the laptop screen (43) in a comfortable viewing position relative to the working position of the user. The laptop (42) is positioned in an upright slot (4) in the docking station, with the connection ports easily seen and accessed. The surface of the laptop slot (4) is lined with non-slip surface (3) to ease insertion and control of the laptop (42) as it is lowered into the slot (4). An adjustable front cover (15) defining the front boundary of the slot (4) covers the keyboard of the mobile computer (42) so that the user does not need to view two keyboards, and the appearance of the docked laptop (42) is clean and aesthetic. Wireless data and power transmission into the laptop (42) is provided while the laptop (42) is in the slot (4) so that the laptop (42) can be used in the docking station without a need for cable connections (45, 46) at all.

Owner:THOMPSON

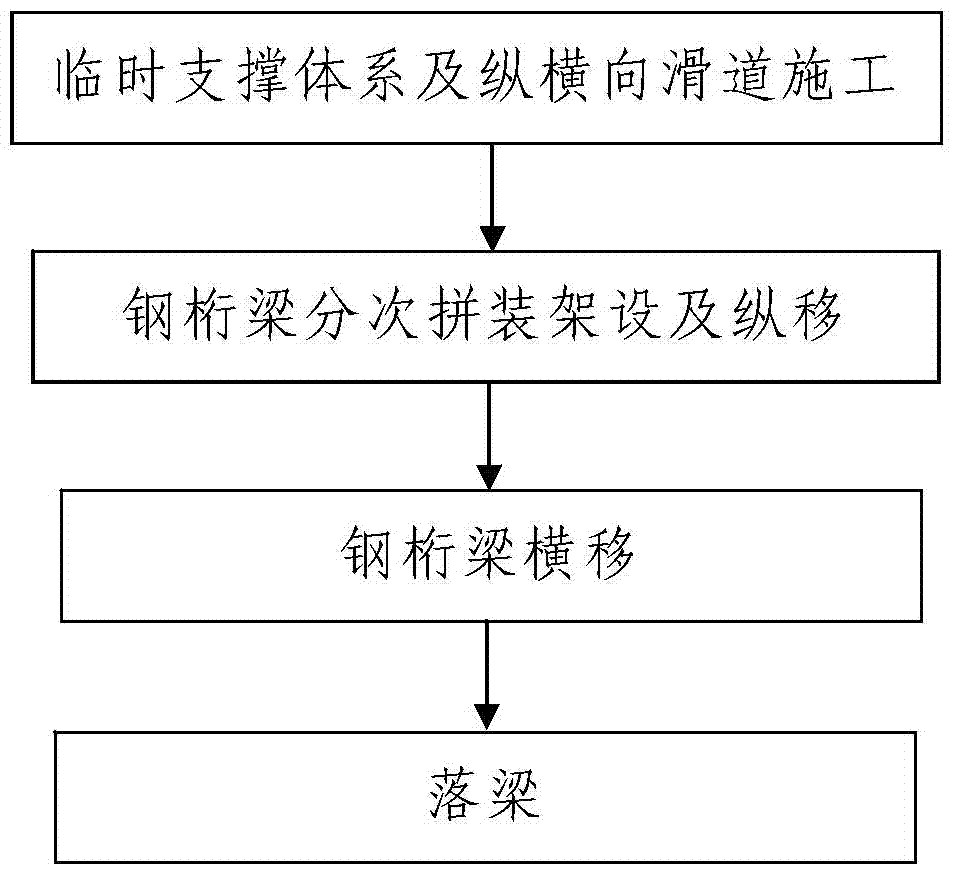

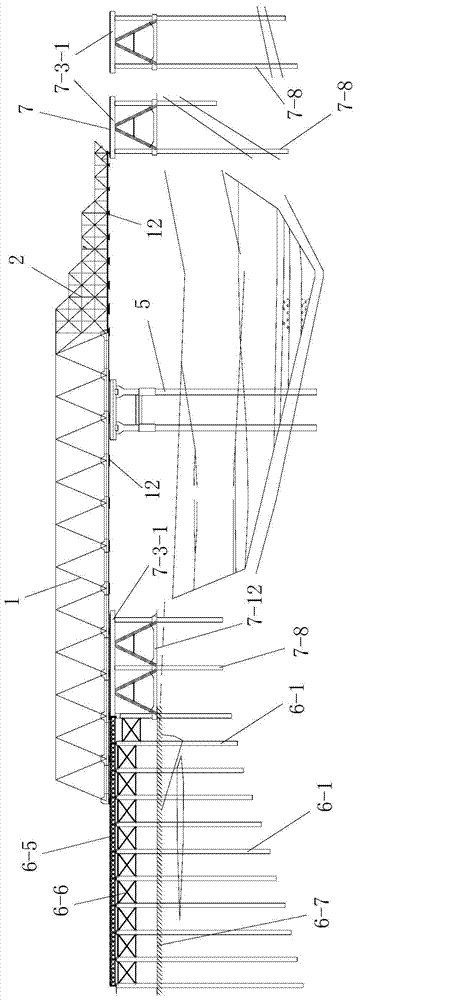

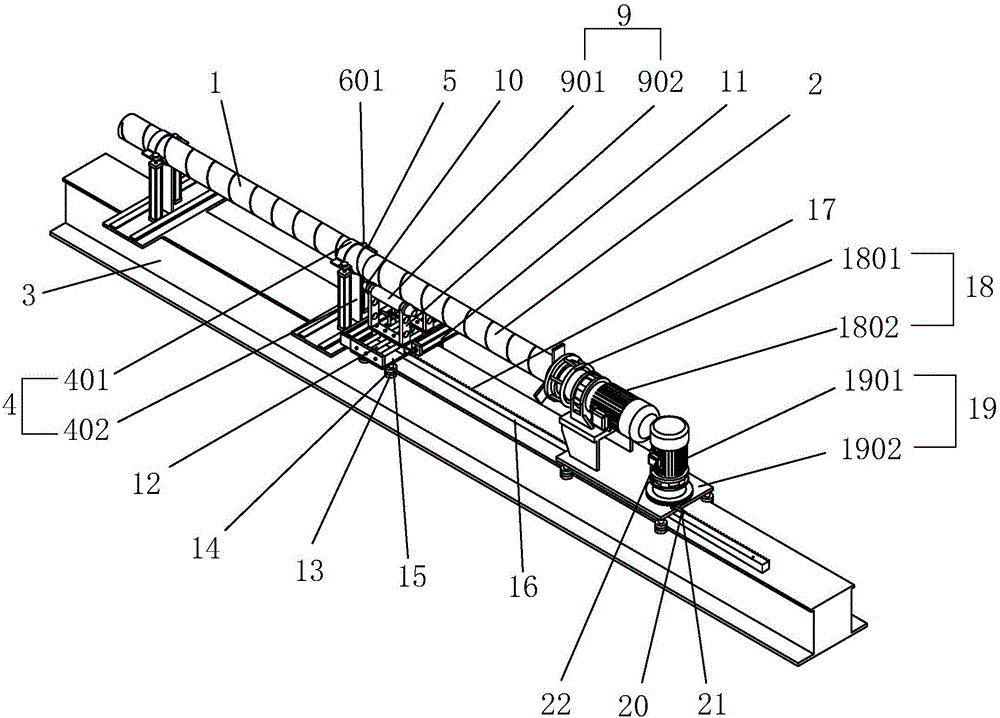

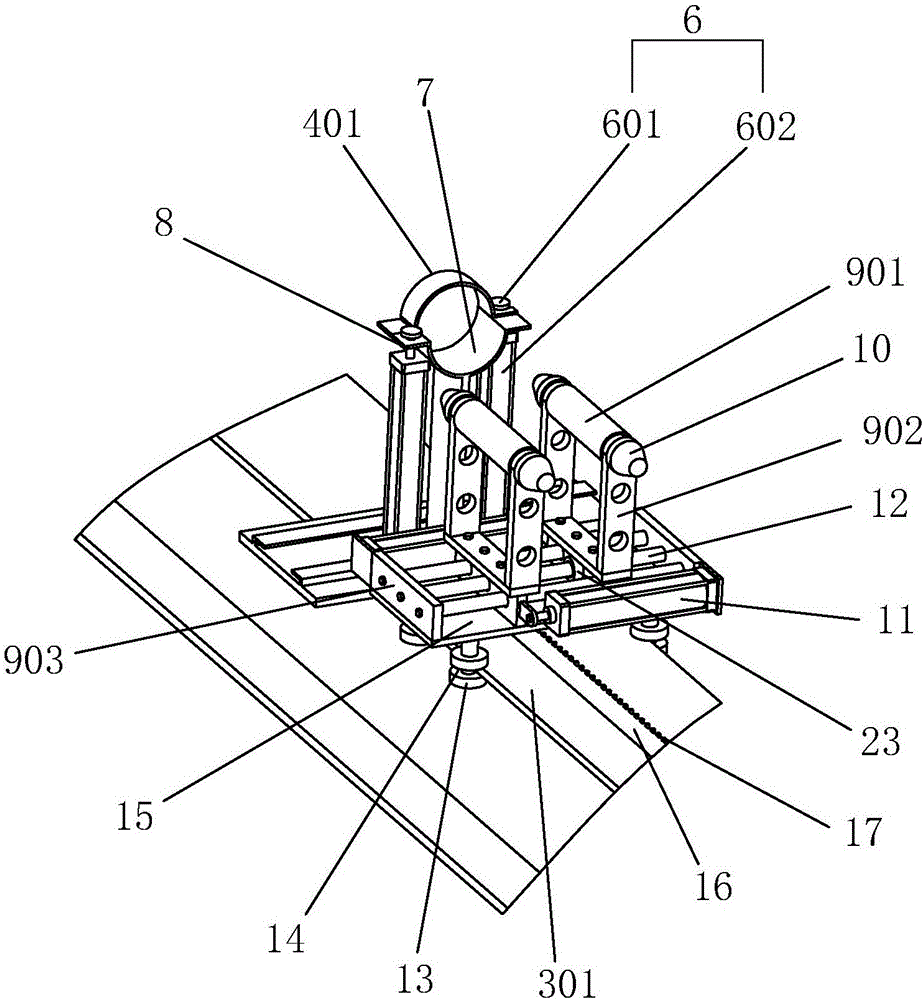

Steel truss girder assembling, erecting and construction process

ActiveCN103614969AThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

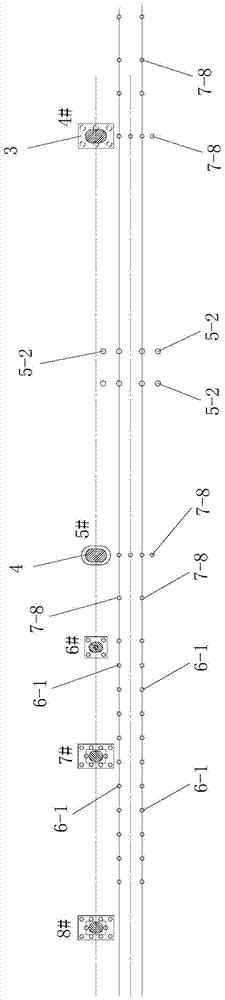

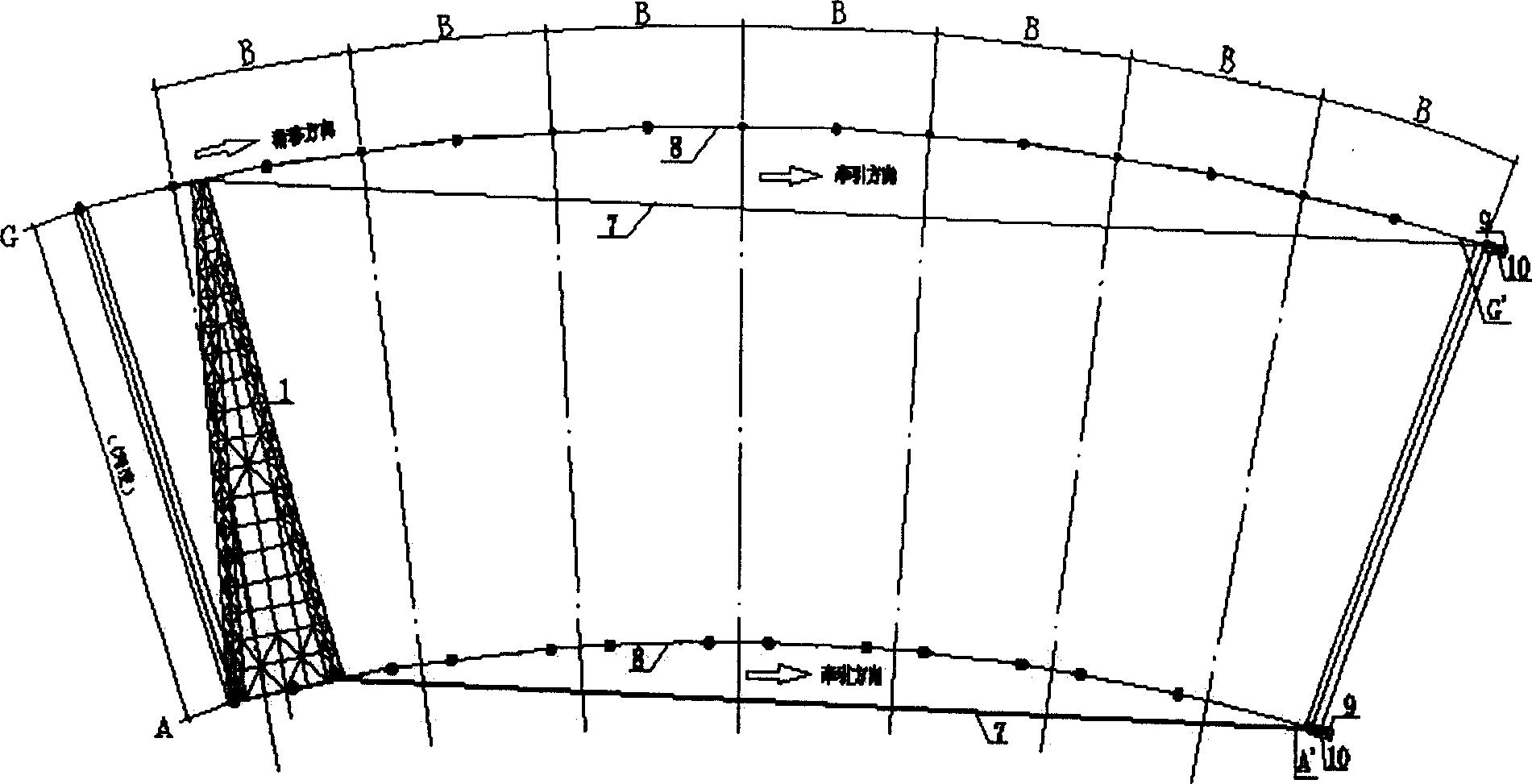

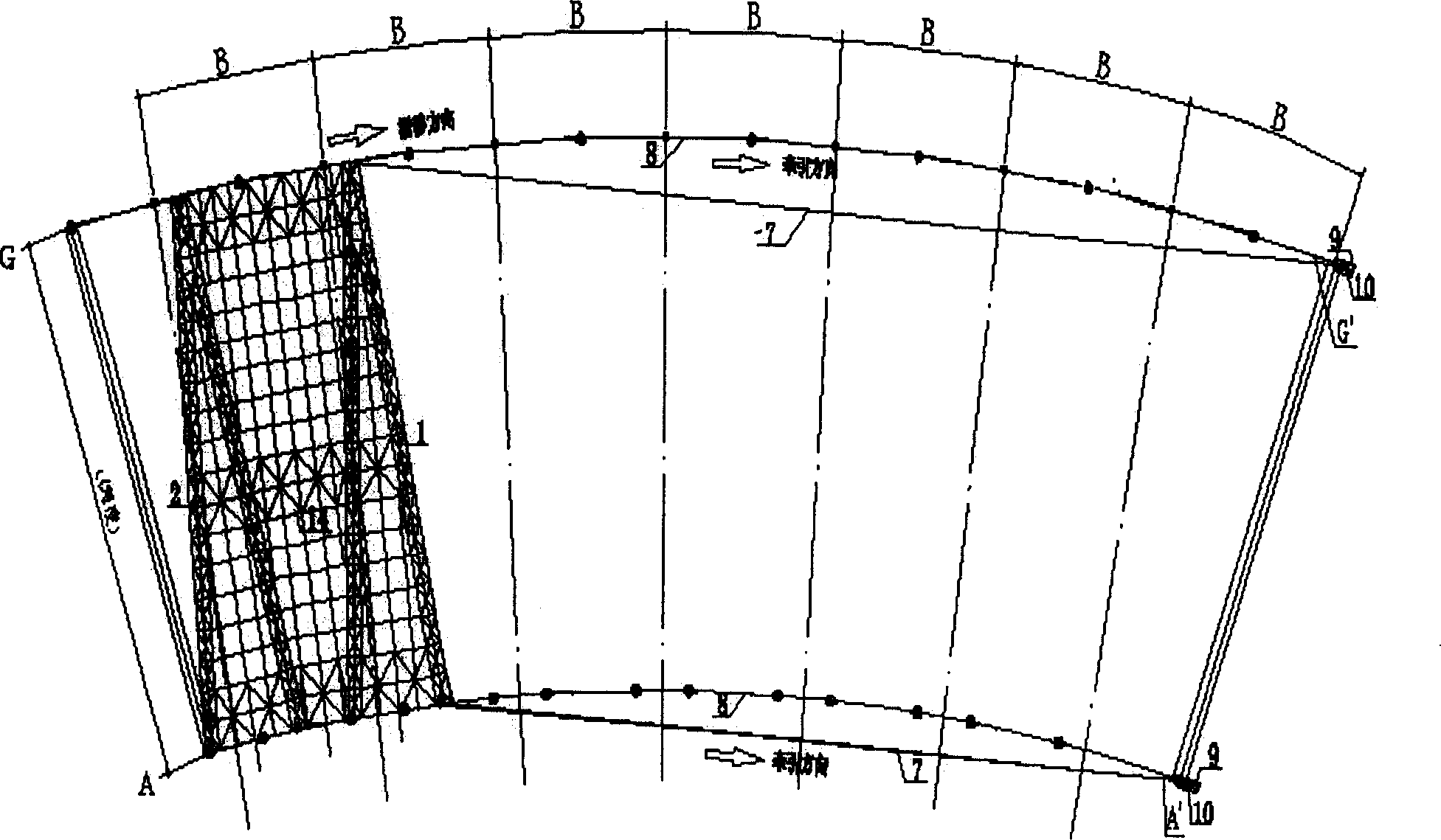

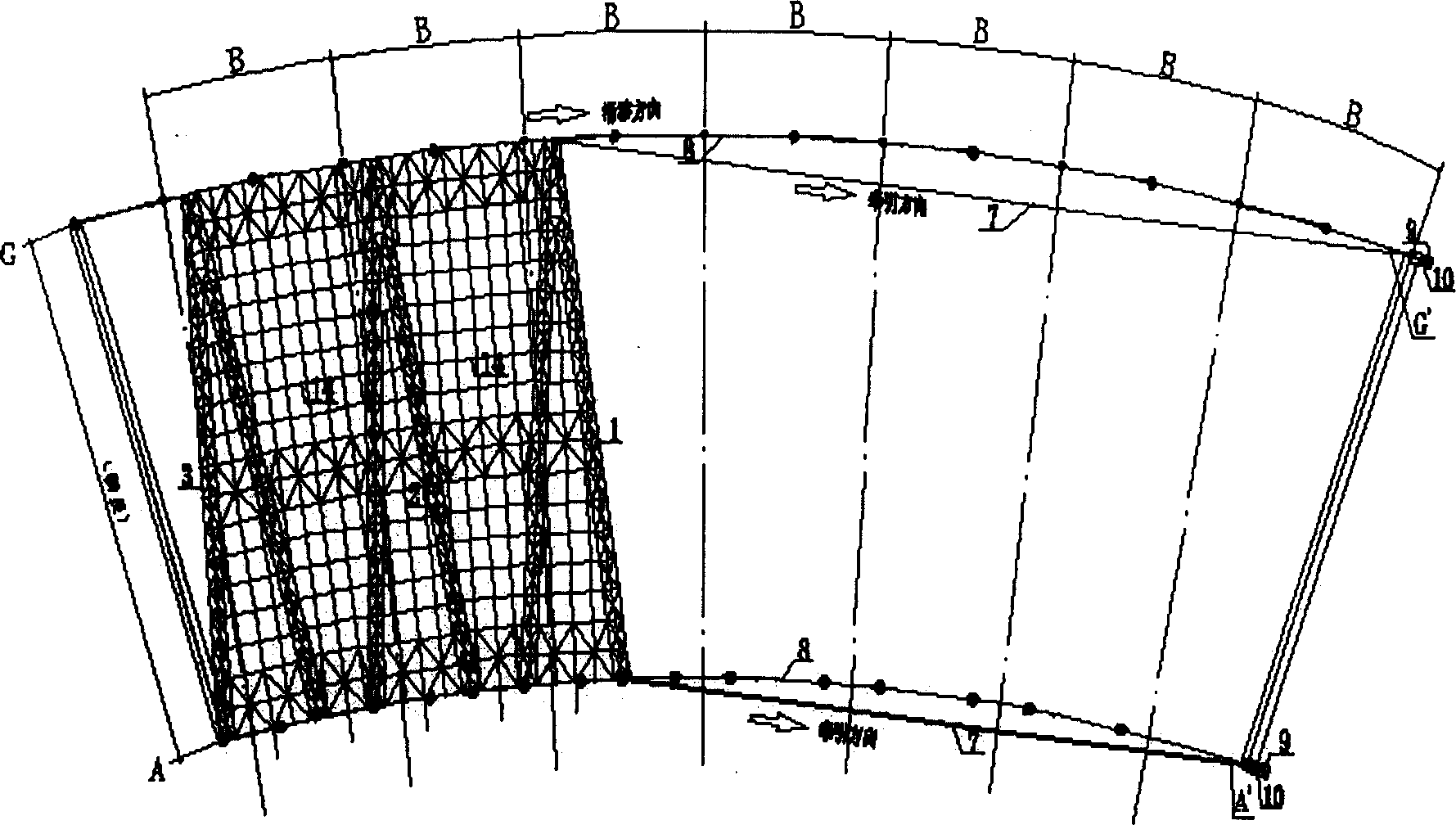

Steel-structure truss high-altitude arc sliding installing method

InactiveCN1584263ASolve the difficulty that cannot be hoisted in placeLow costBuilding material handlingWhole bodyEngineering

The present invention relates to a high-level arc-line slide-moving installation method of steel structure truss. In the concrete, on the concentric curved steel beams respectivley positioned on two ends of the truss to be installed the sipways are respectively set, each of two ends of the truss is equipped with slipper respectively. A hydraulic traction equipment can be used for pulling the slipper and making it be moved along the slipway from far end place of two slipways. After the first main truss is hoisted to high level and assembled into one whole body, the slipper can be forwards slide-moved by one truss width, then the second main truss can be assembled and connected with member between trusses, and can be slide-moved by one truss width, so that the above-mentioned steps can be circulated until several truss units are assembled into a whole body unit, then the whole body unit can be slide-moved into the designed plane position.

Owner:上海拜特钢结构设计有限公司

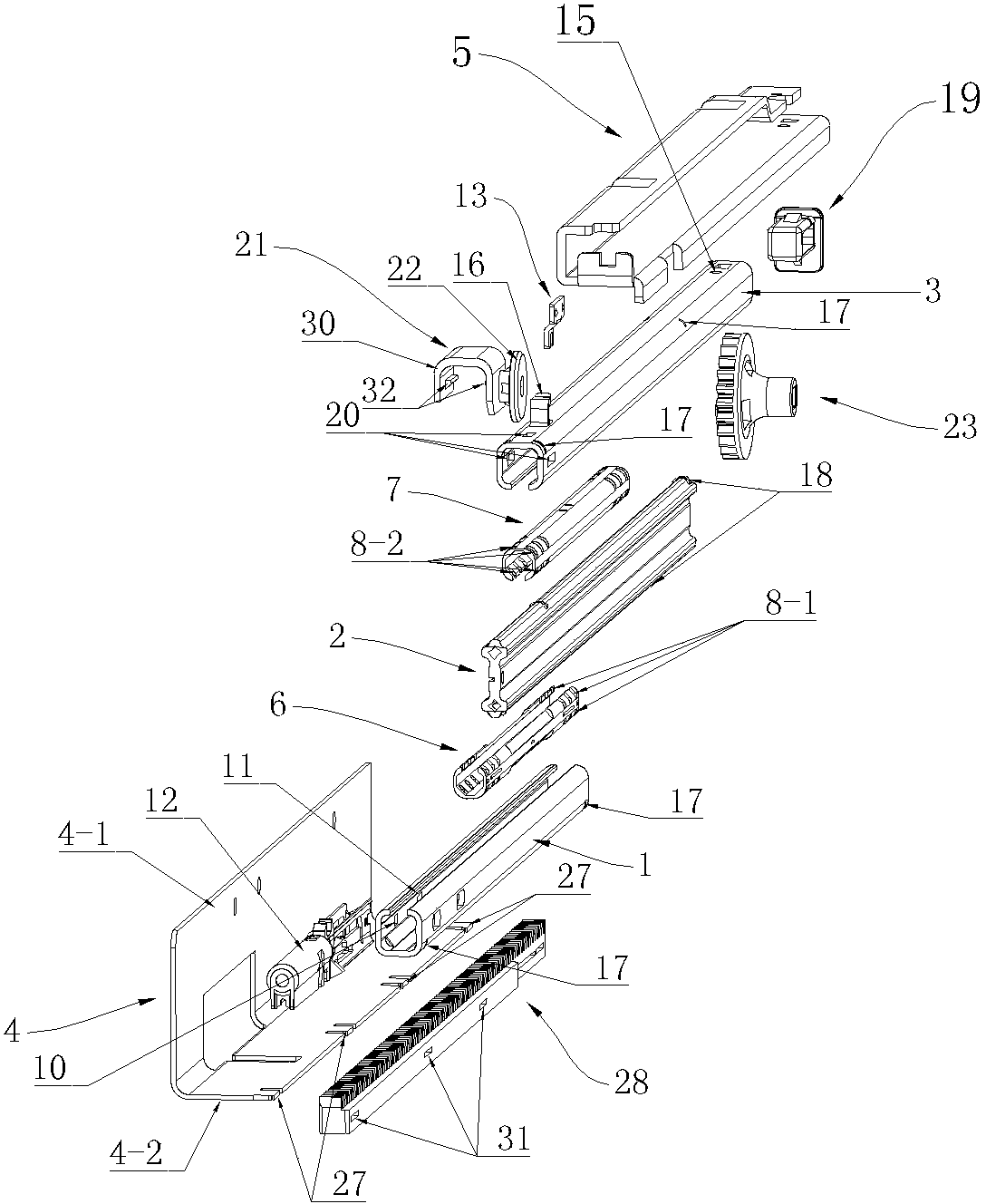

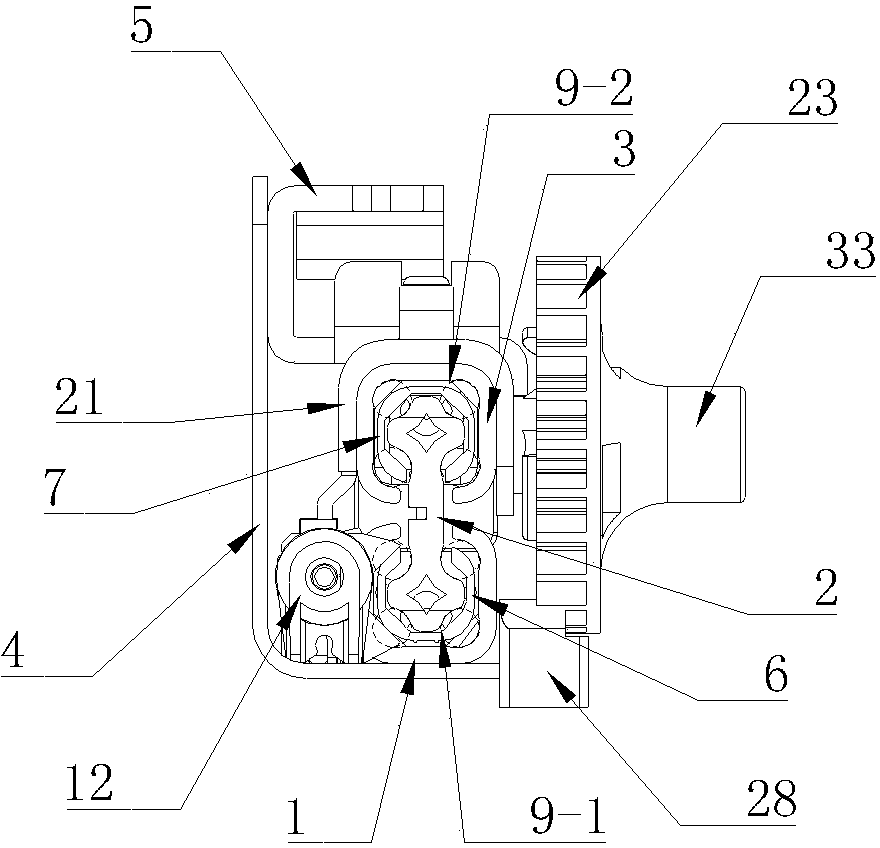

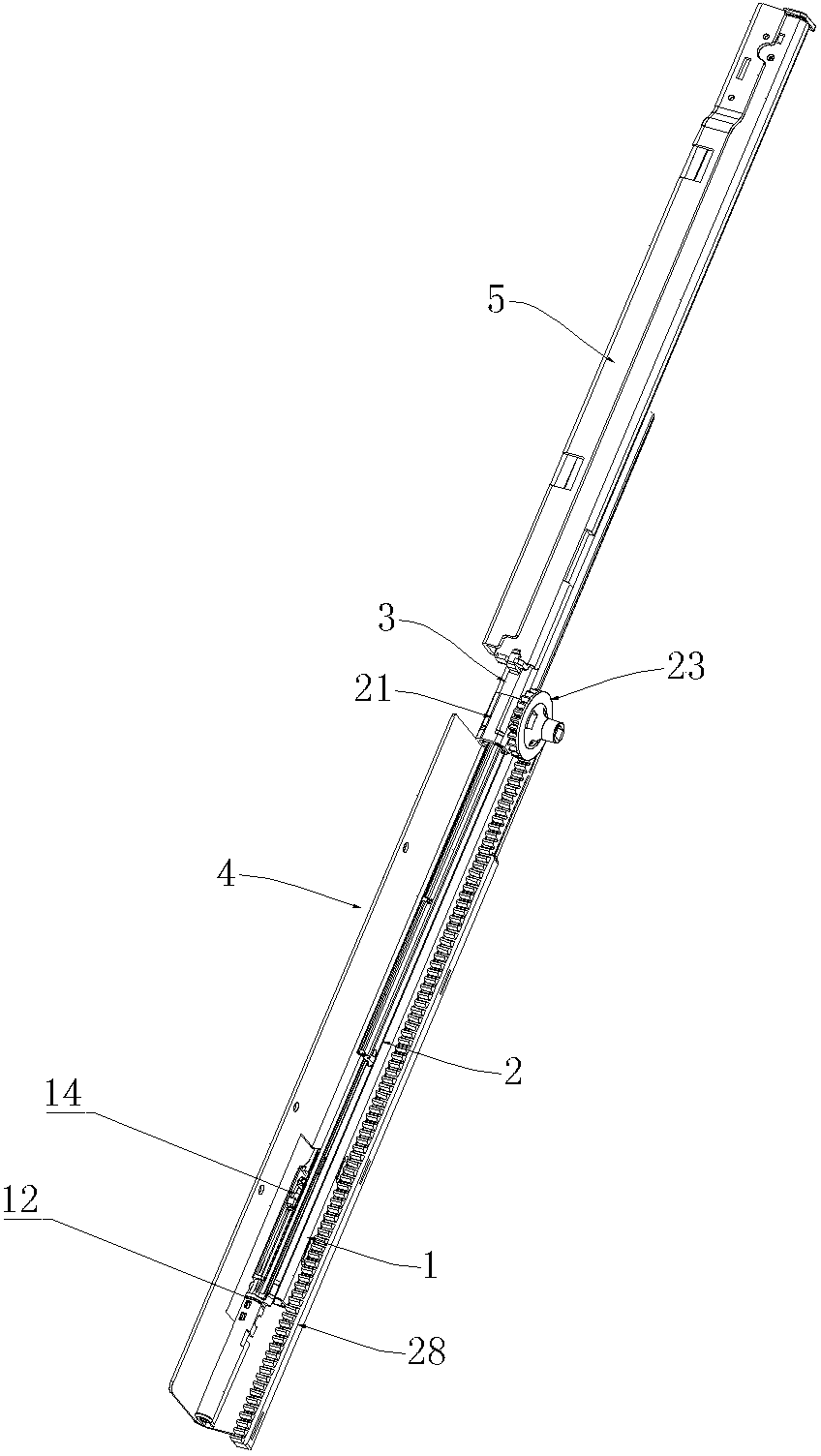

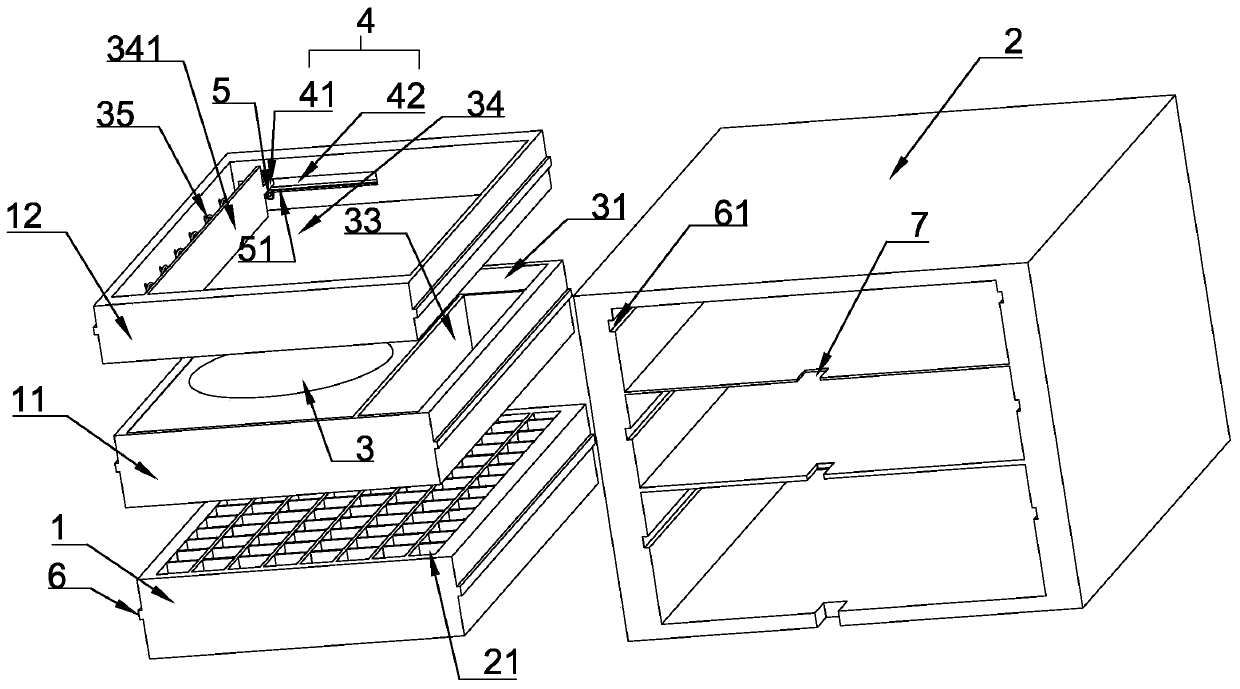

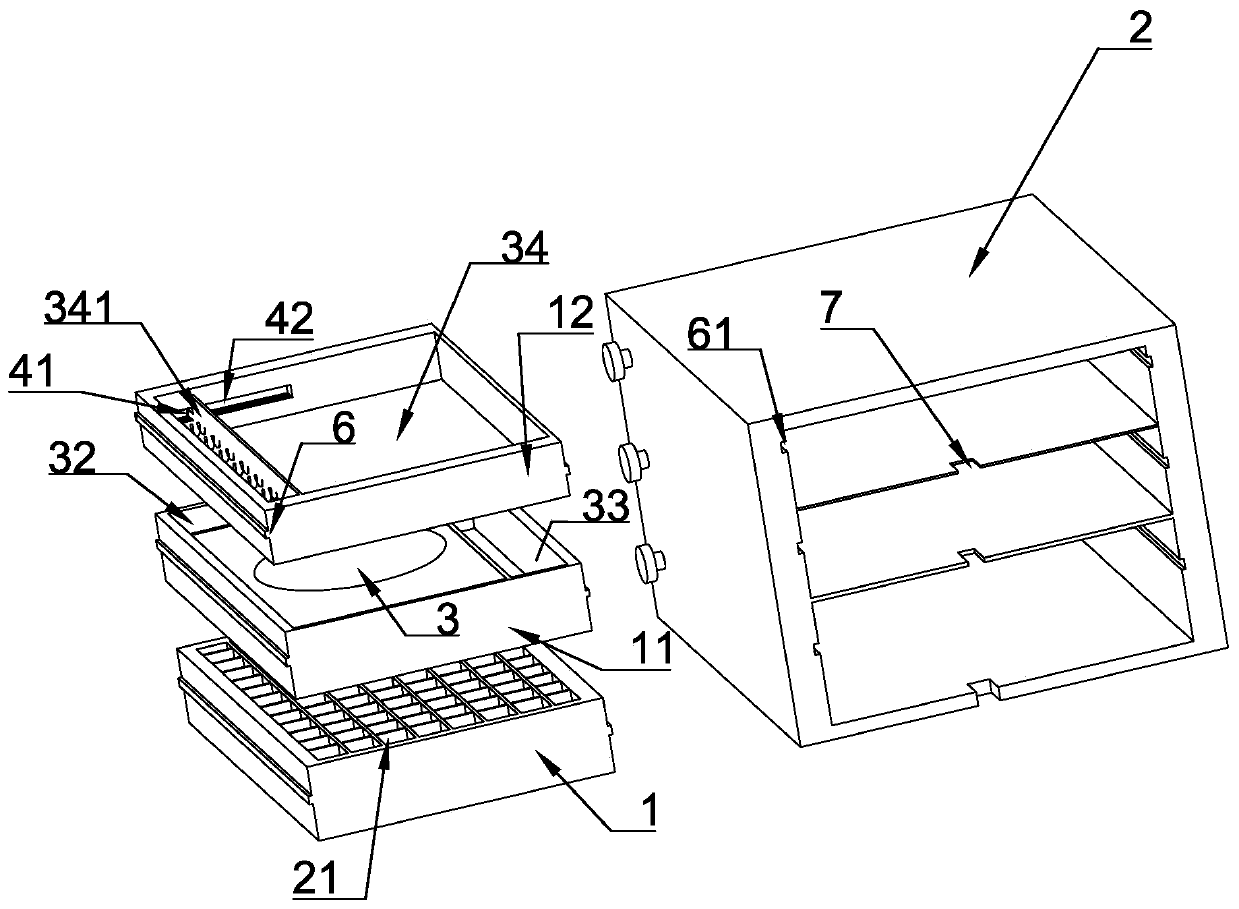

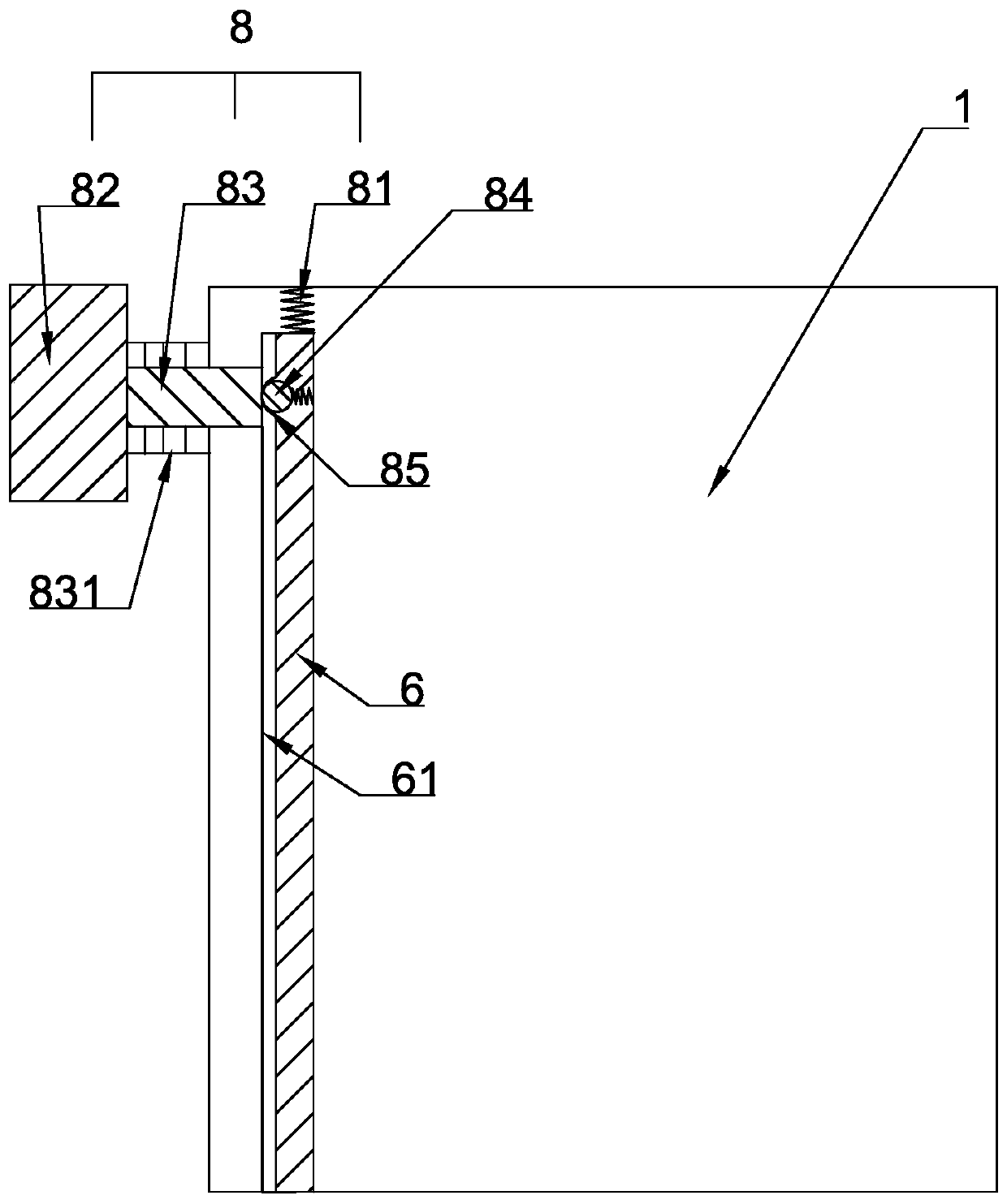

Three-section type hidden sliding rail mechanism

ActiveCN103919375ASmooth slipLinear bearingsLighting and heating apparatusMechanical engineeringRack and pinion

Owner:WUXI HAIDAER PRECISION SLIDES CO LTD

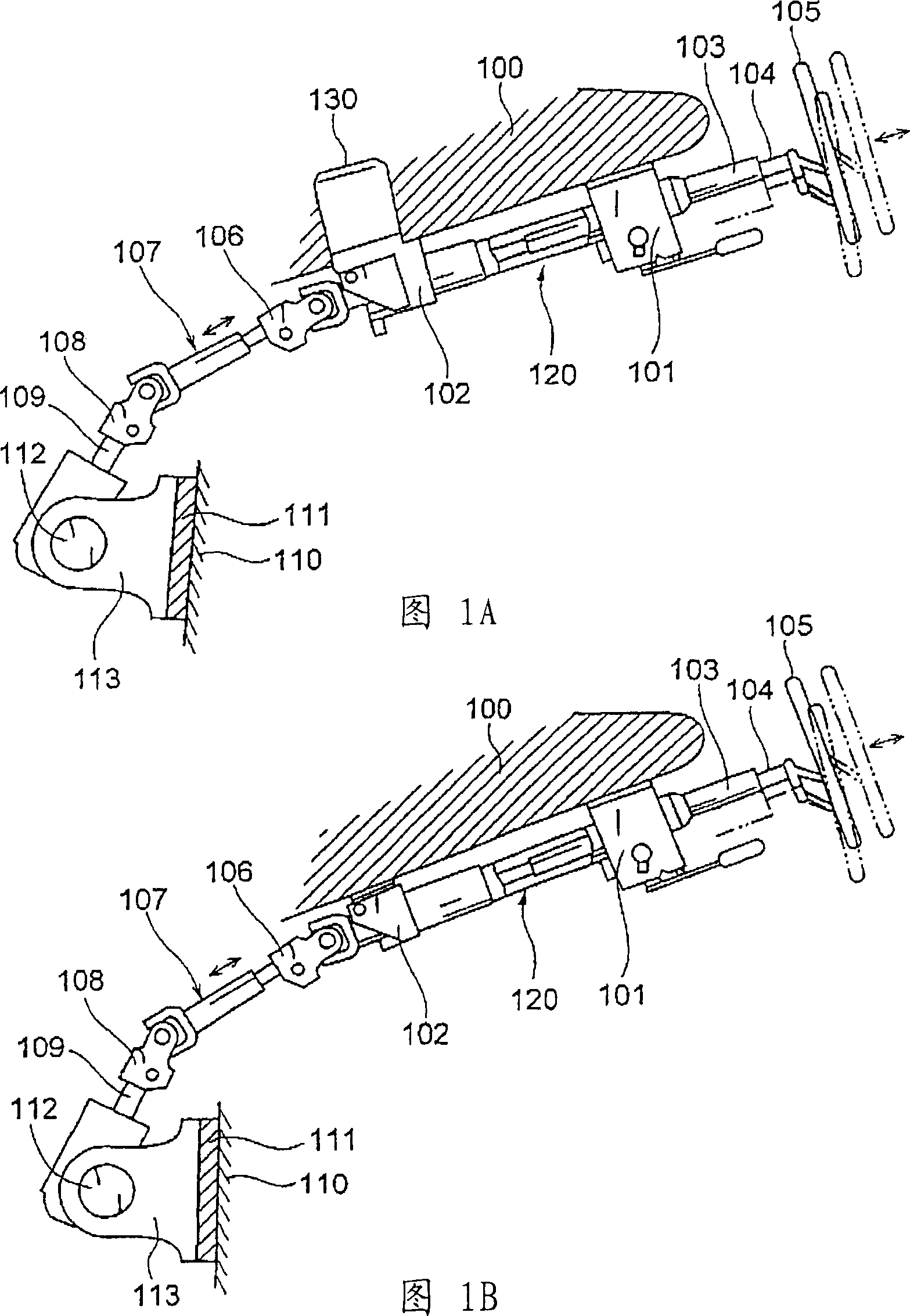

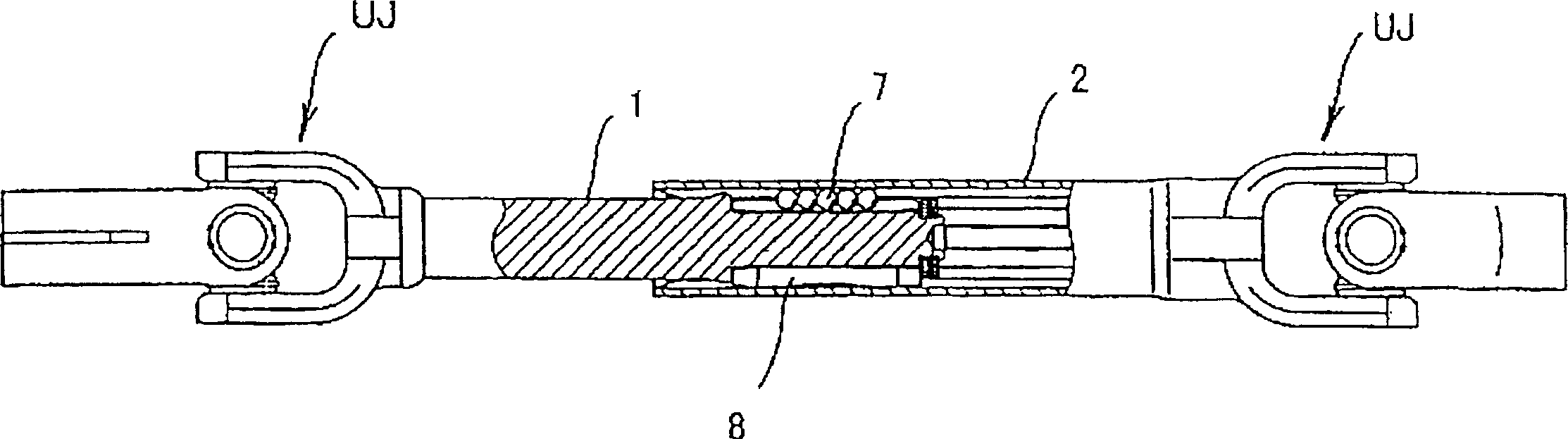

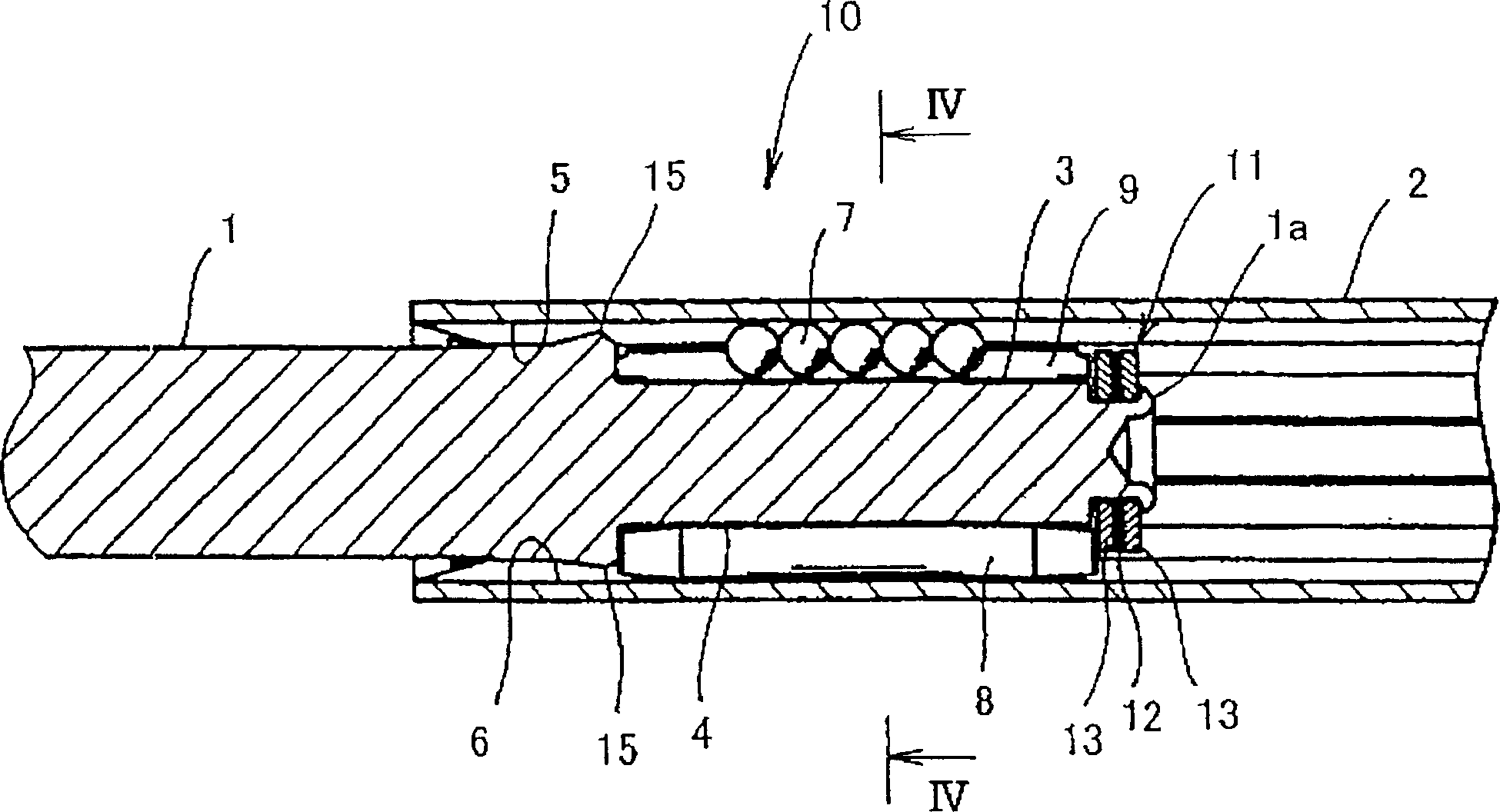

Telescopic shaft

A surface hardening treatment is applied to an inner peripheral surface of a female shaft 2, thereby forming a hard layer Ha thereon. Surface harness of the hard layer is 400 Hv or more. The thickness of the hard layer Ha is 10 m to 100 m, and for example gas nitrocarburizing treatment is performed as the surface hardening treatment. A surface hardening treatment is also applied to an outer surface of each cylindrical member 8 by a heat treatment, thereby forming a hard layer Hb thereon. With this construction, the inner peripheral surface of the female shaft is prevented from deformation and wear under a high contact pressure, so that the smooth sliding movement can be obtained.

Owner:NSK LTD

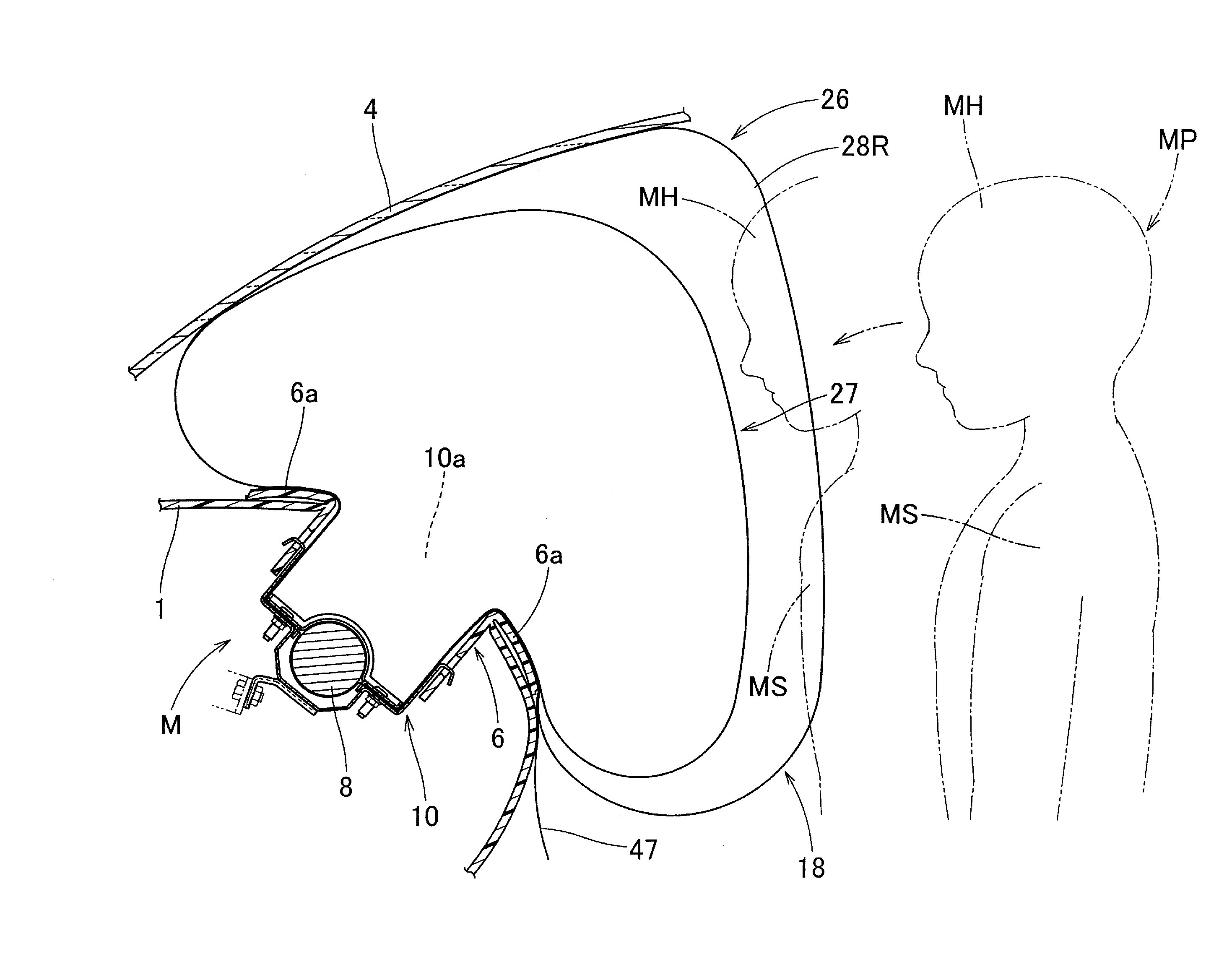

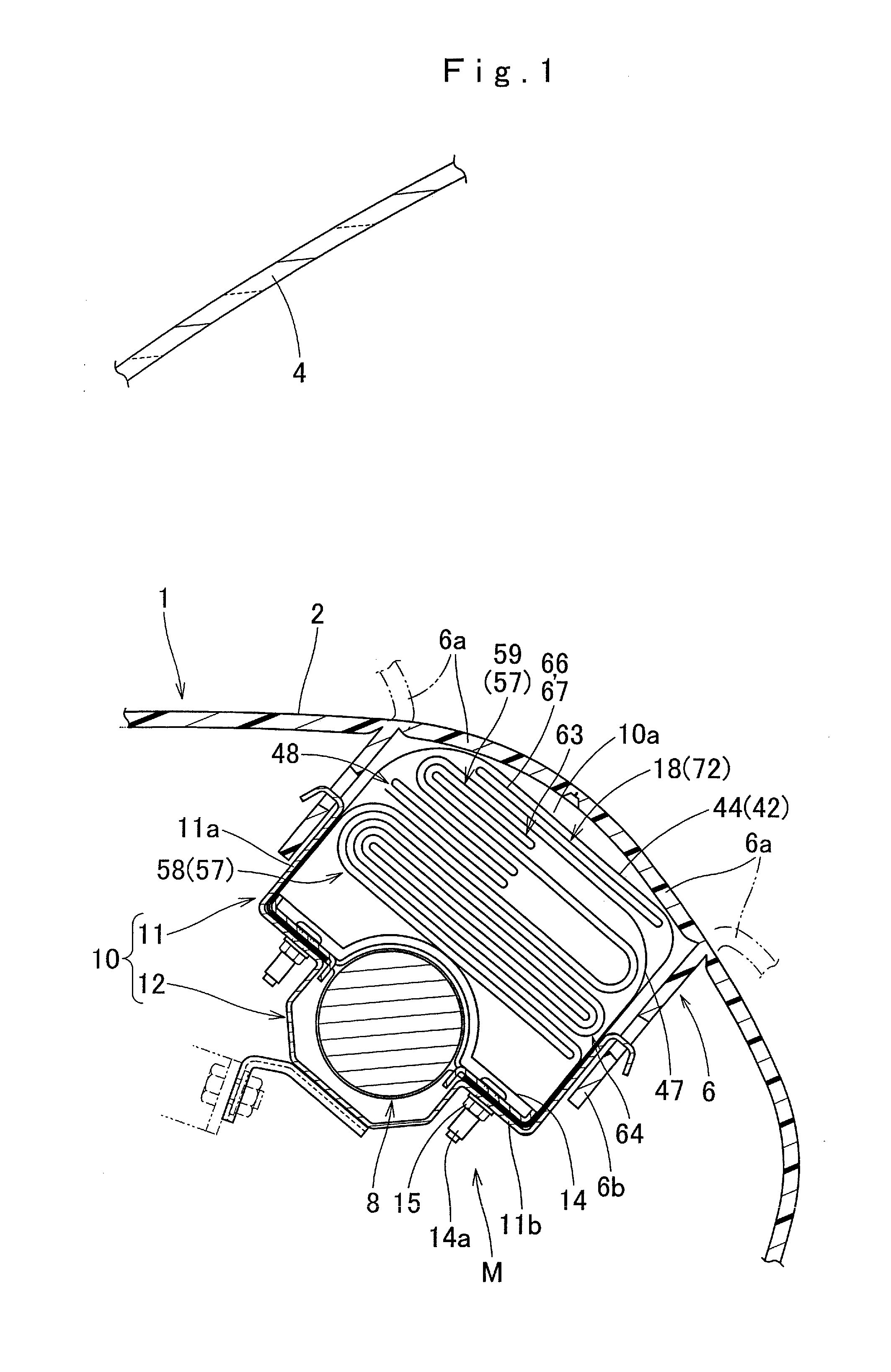

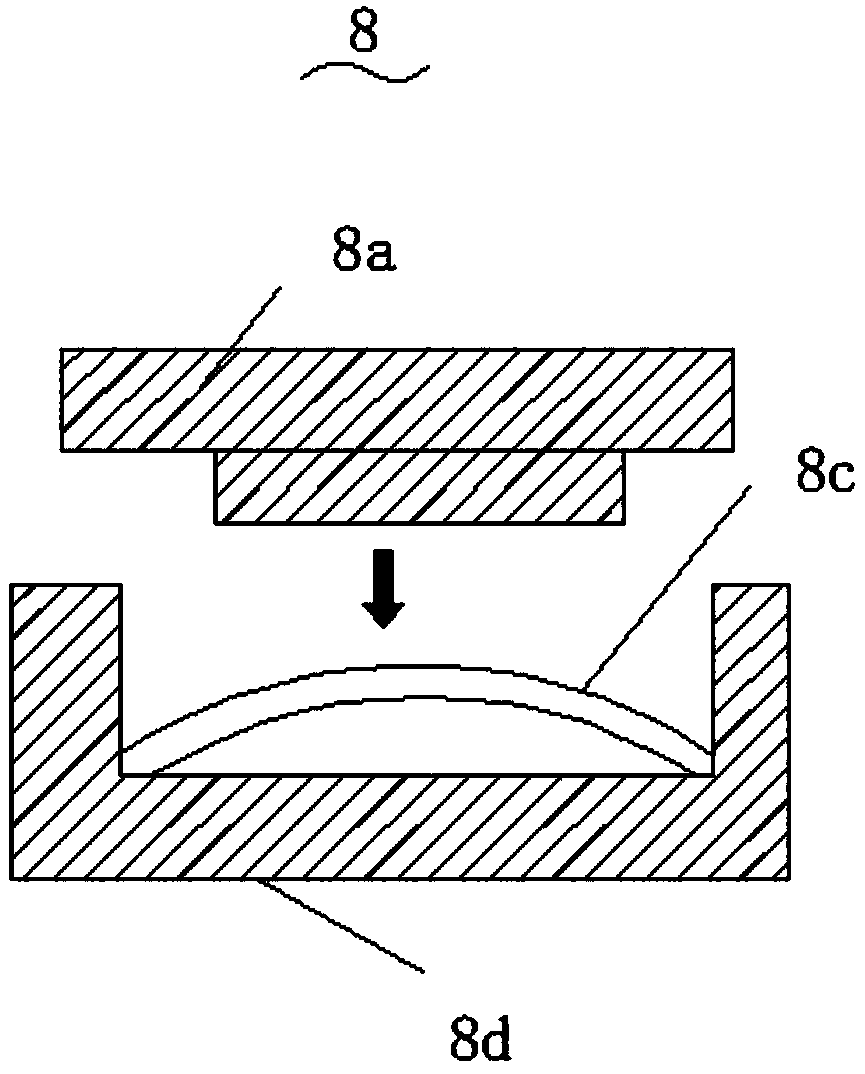

Airbag apparatus for a front passenger's seat

ActiveUS20130001937A1Suppression problemReduced dimensionPedestrian/occupant safety arrangementEngineeringInitial phase

An airbag apparatus for a front passenger's seat is disclosed. The apparatus includes a wrapping member that wraps up an airbag in a folded-up configuration. The wrapping member includes a joint portion that is secured to an airbag housing or its vicinity together with the airbag, a main body that extends forward from the joint portion and a cover portion that extends rearward from the joint portion for deployment between the airbag and an out-of-position object in an initial phase of airbag deployment. During a folding process of the airbag, the cover portion is wrapped around a front-rear contracted bag, and a leading end of the cover portion is tucked down between an upper folded portion and a lower folded portion of the front-rear contracted bag.

Owner:TOYODA GOSEI CO LTD

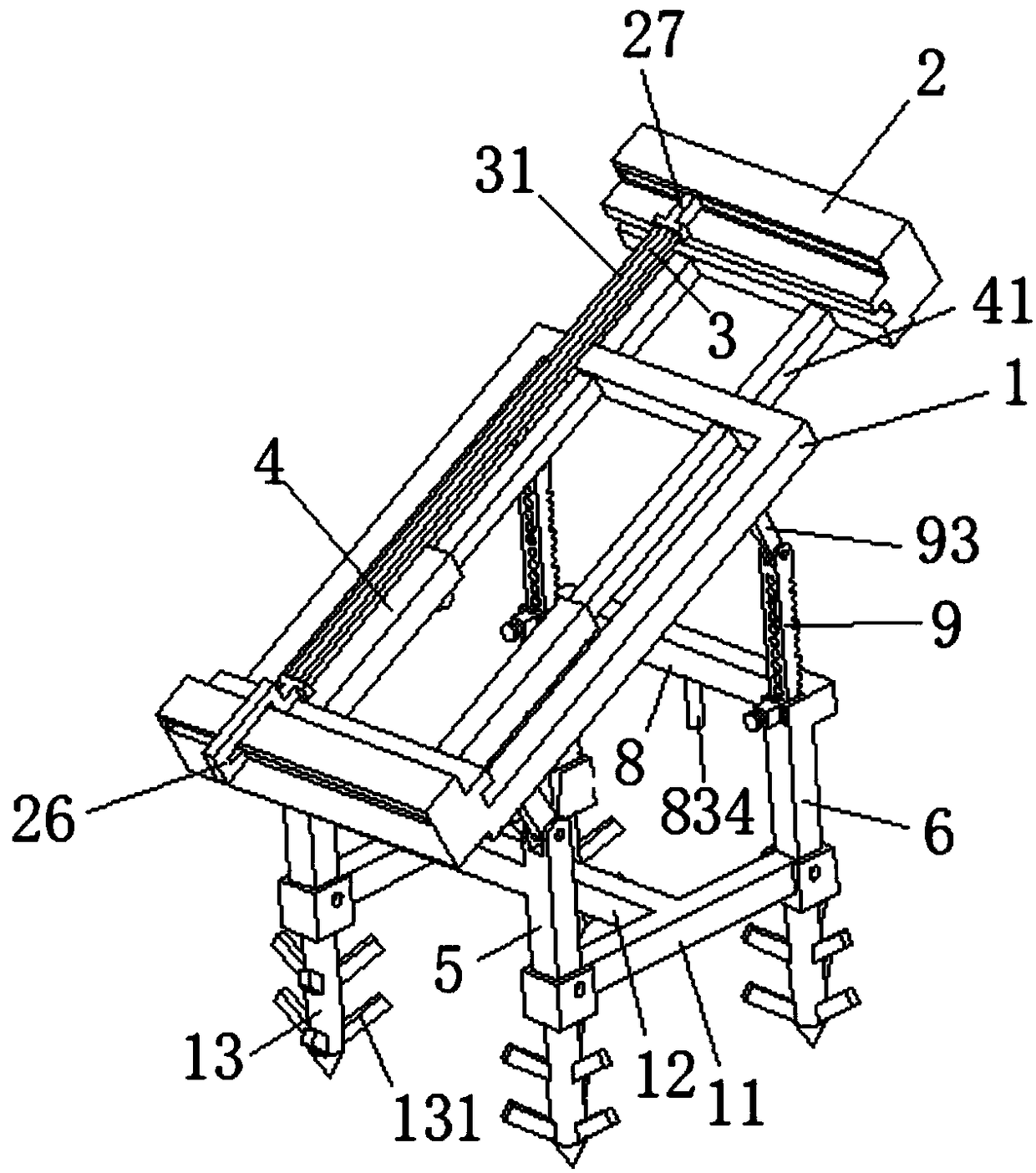

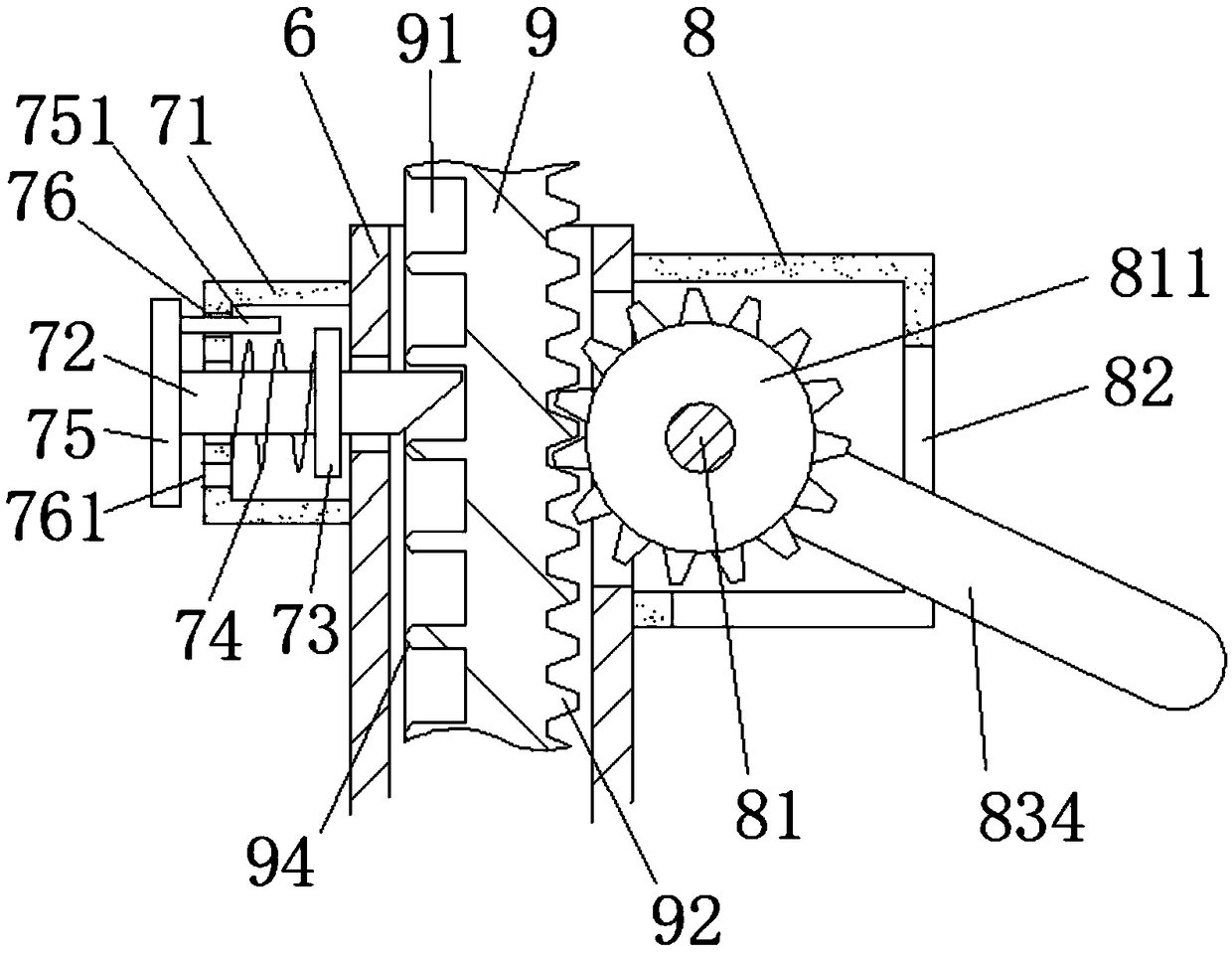

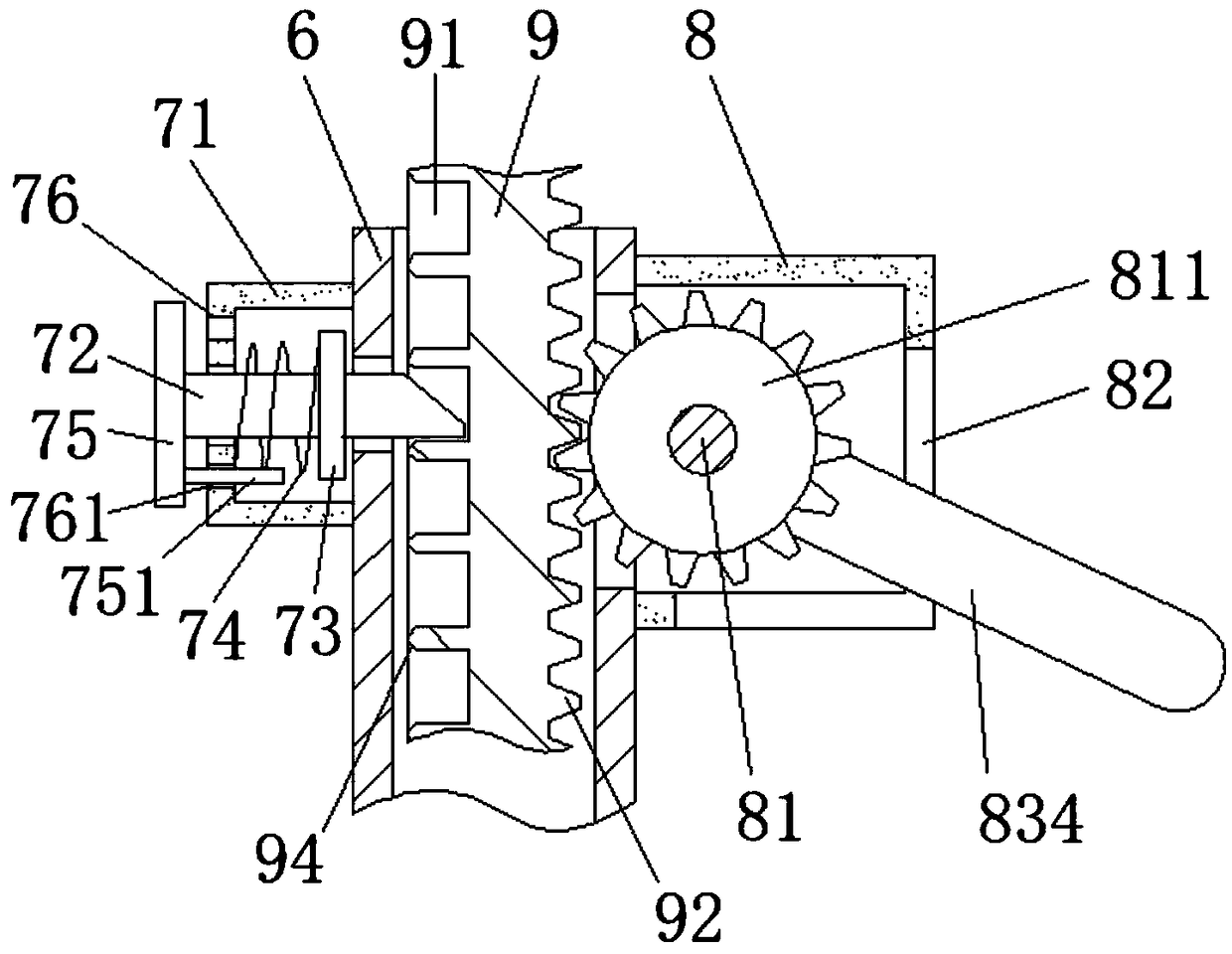

Installation support for solar photovoltaic battery component

ActiveCN109450353AImprove energy conversion effectEasy to adjustPhotovoltaic supportsPhotovoltaic energy generationMechanical engineeringPhotovoltaics

The invention discloses an installation support for a solar photovoltaic battery component. At least two regulating holes are arranged in a telescopic rod in a length direction of the telescopic rod;a second support tube is provided with insertion rods inserted into the regulating holes; a second spring is arranged between a limiting plate and a positioning shell; one end, far from a rotary disc,of the insertion rod is a wedge; the telescopic rod is provided with teeth; a gear is arranged in the second shell in a rotating manner; a rotary shaft of the gear is provided with a ratchet; the rotary shaft is further provided with a rotary cylinder with a pawl in a rotating manner; the rotary cylinder is provided with a pull rod for pulling the pawl to release from the ratchet; a mobile rod isinserted in one end of a guide sleeve; one end of the mobile rod stretches out of a placement rack; and ends, back to each other, of the guide sleeve and the mobile rod are provided with L-shaped plates. Due to match of the insertion rods, regulating holes, teeth, gear, ratchet and pawl, the telescopic rod is displaced, so that a worker can regulate degree of inclination of the placement rack conveniently, and power generation efficiency of a photovoltaic battery panel is improved; further, the mobile rod that is inserted and can slide can be used for installing different sizes of photovoltaic battery panel, so that the installation support is very convenient.

Owner:SUZHOU VOCATIONAL UNIV

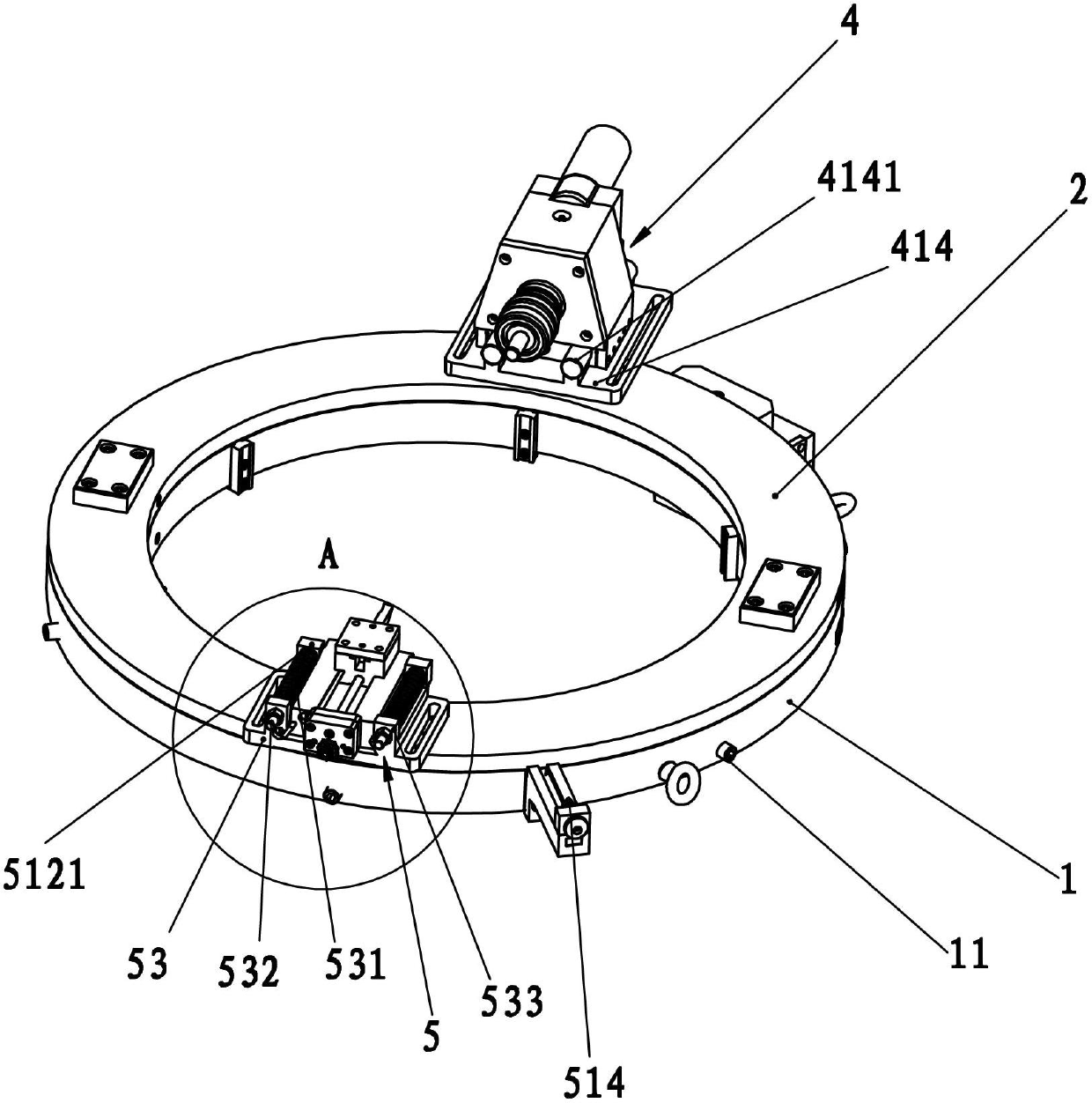

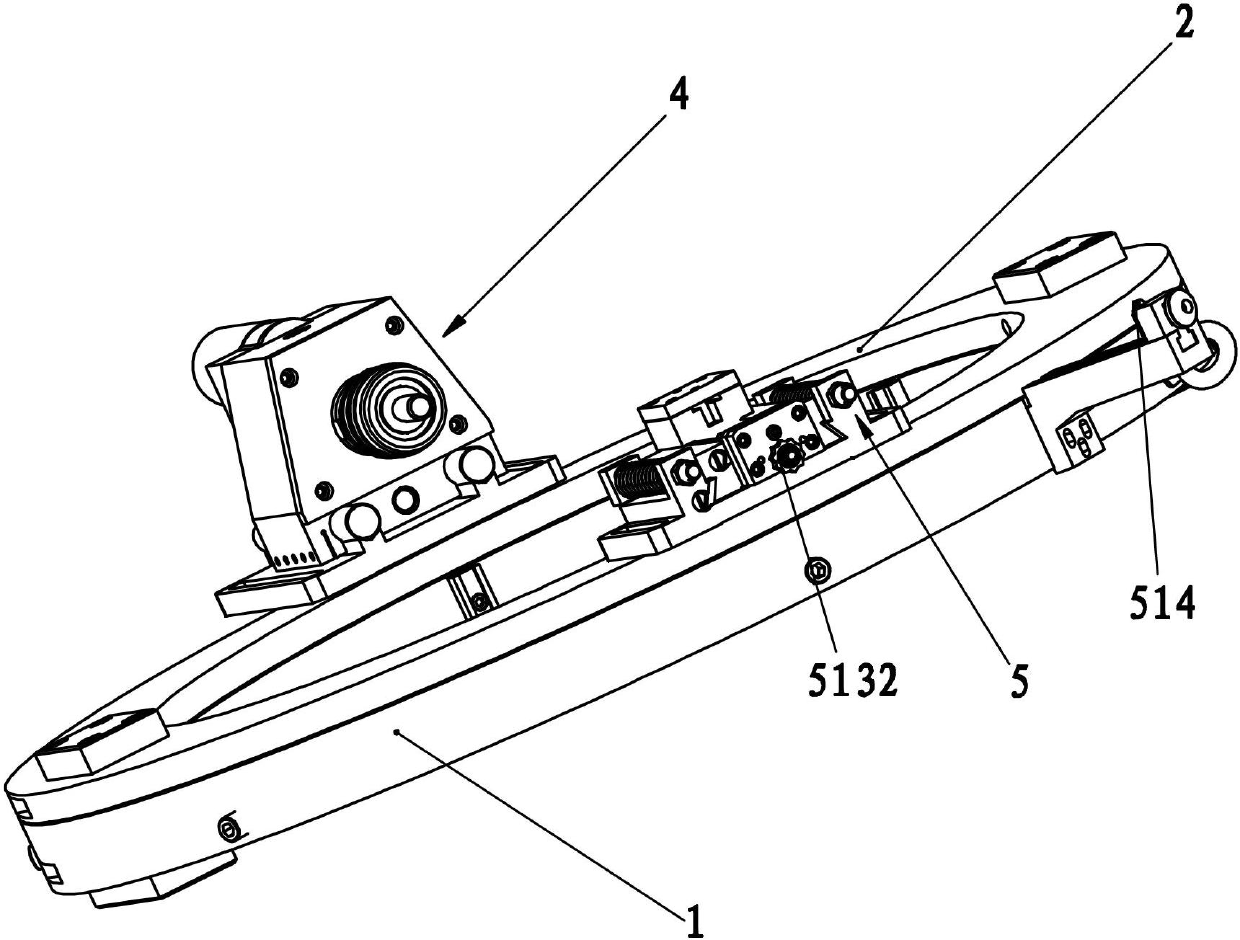

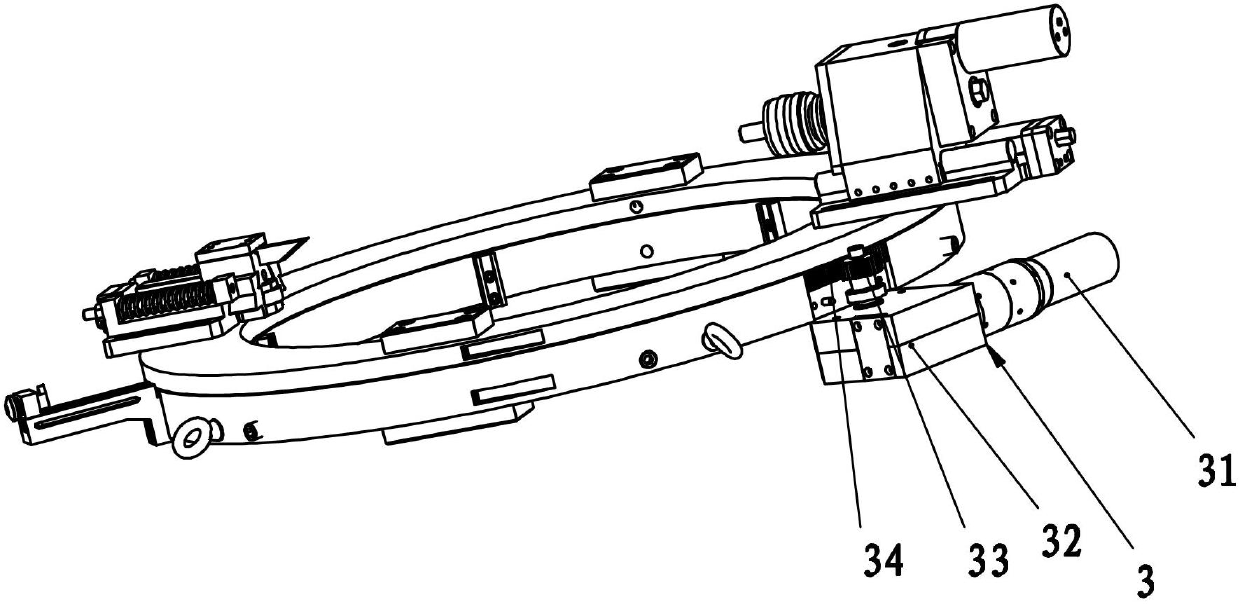

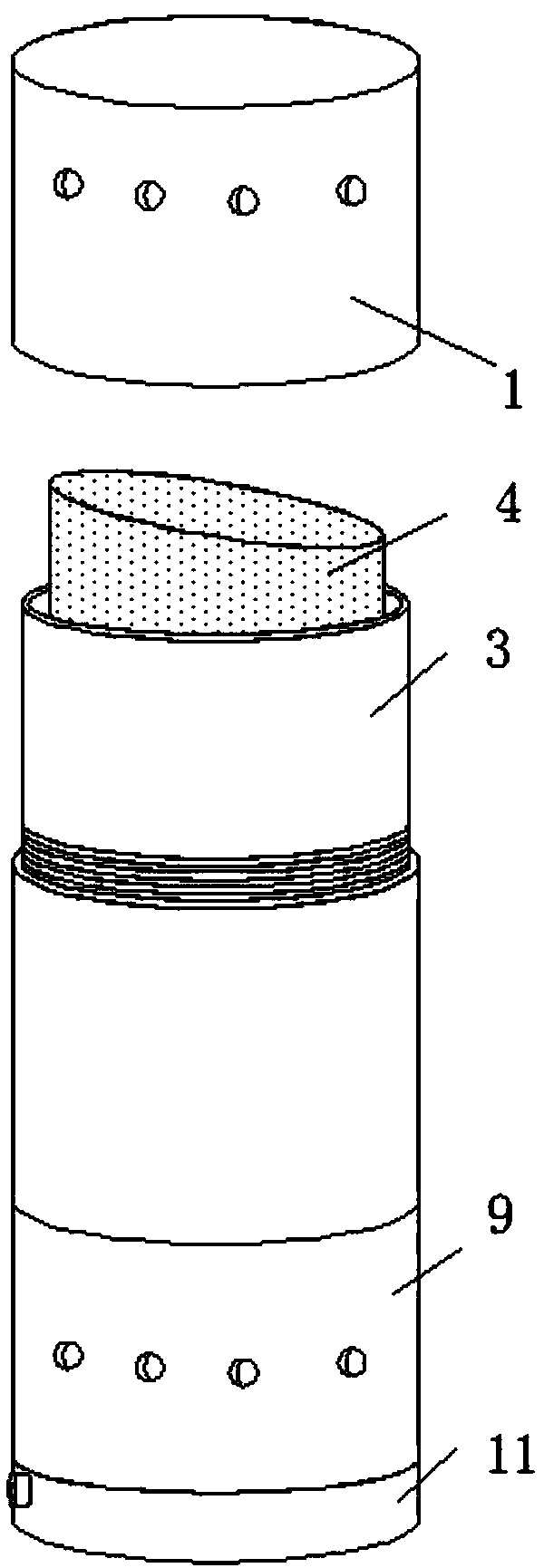

Multifunctional cylindrical cutting and beveling machine

ActiveCN102653055AEasy to moveImprove cutting effectOther manufacturing equipments/toolsMotor driveThick wall

The invention relates to a cutting and beveling machine for beveling, cutting, milling and drilling a steel pipe and particularly relates to the cutting and beveling machine for beveling, cutting, milling and drilling a large-size circular or oval thick-wall steel pipe. The invention provides the following technical scheme that a multifunctional cylindrical cutting and beveling machine is characterized in that a cutting device comprises a propelling mechanism and a cutting and rotating mechanism, wherein the cutting and rotating mechanism comprises a base, a cutting drill bit knife holder, a transmission part and a motor; an output shaft of the motor drives the cutting drill bit knife holder to rotate through the transmission part; a screw rod of the propelling mechanism can push the base to slide; and a beveling knife mounting frame in a beveling mechanism can slide along the rotation of the screw rod in a progressing mechanism. With the adoption of the scheme, the invention provides the novel cutting and beveling machine for rapidly beveling, cutting, milling and drilling the large-size circular or oval thick-wall steel pipe to overcome the disadvantages in the prior art.

Owner:ZHEJIANG AOTAI MACHINE MFG

Airbag apparatus for a front passenger's seat

ActiveUS8608195B2Reduced dimensionReduce in quantityPedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYODA GOSEI CO LTD

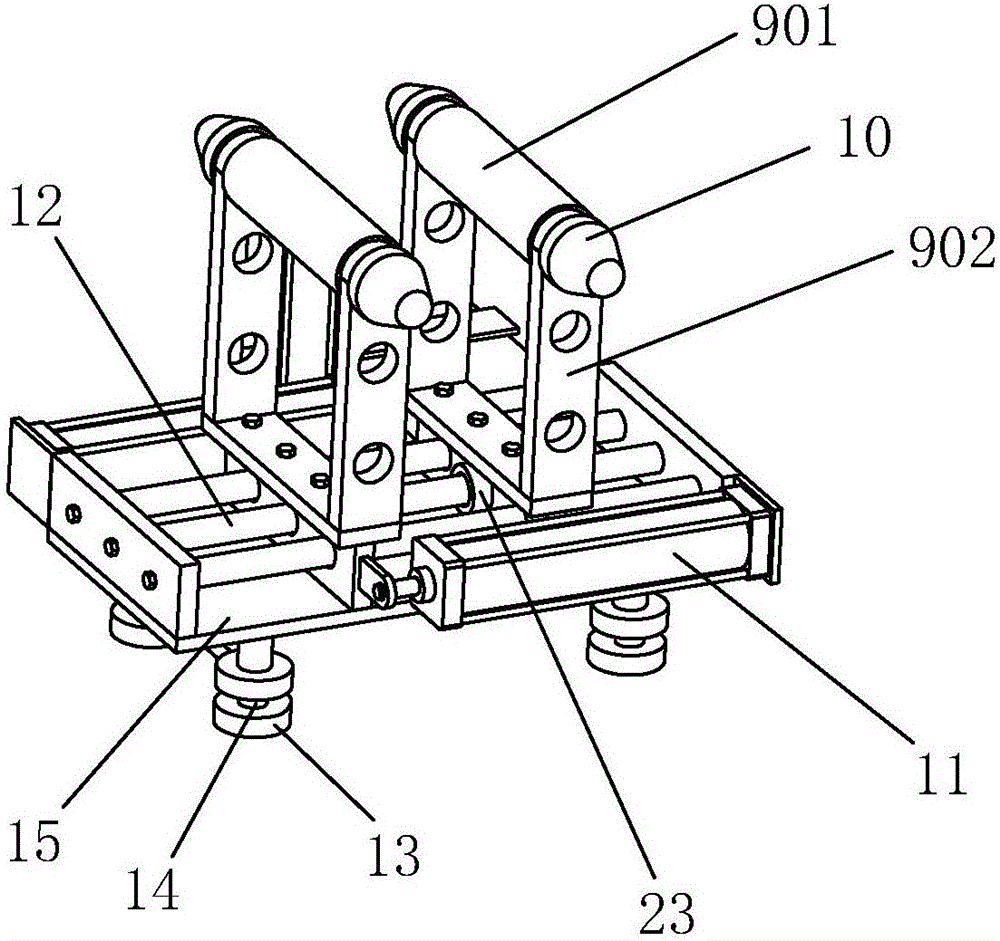

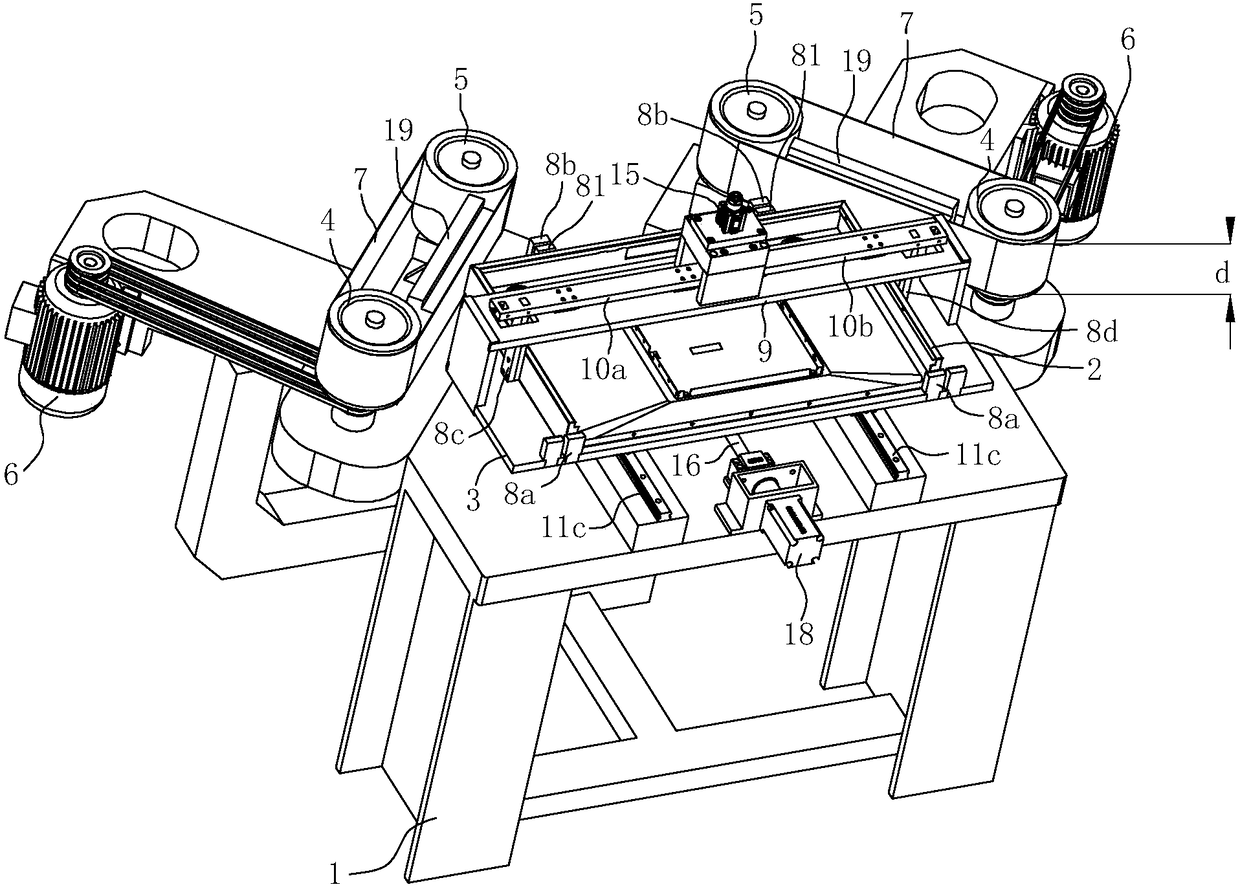

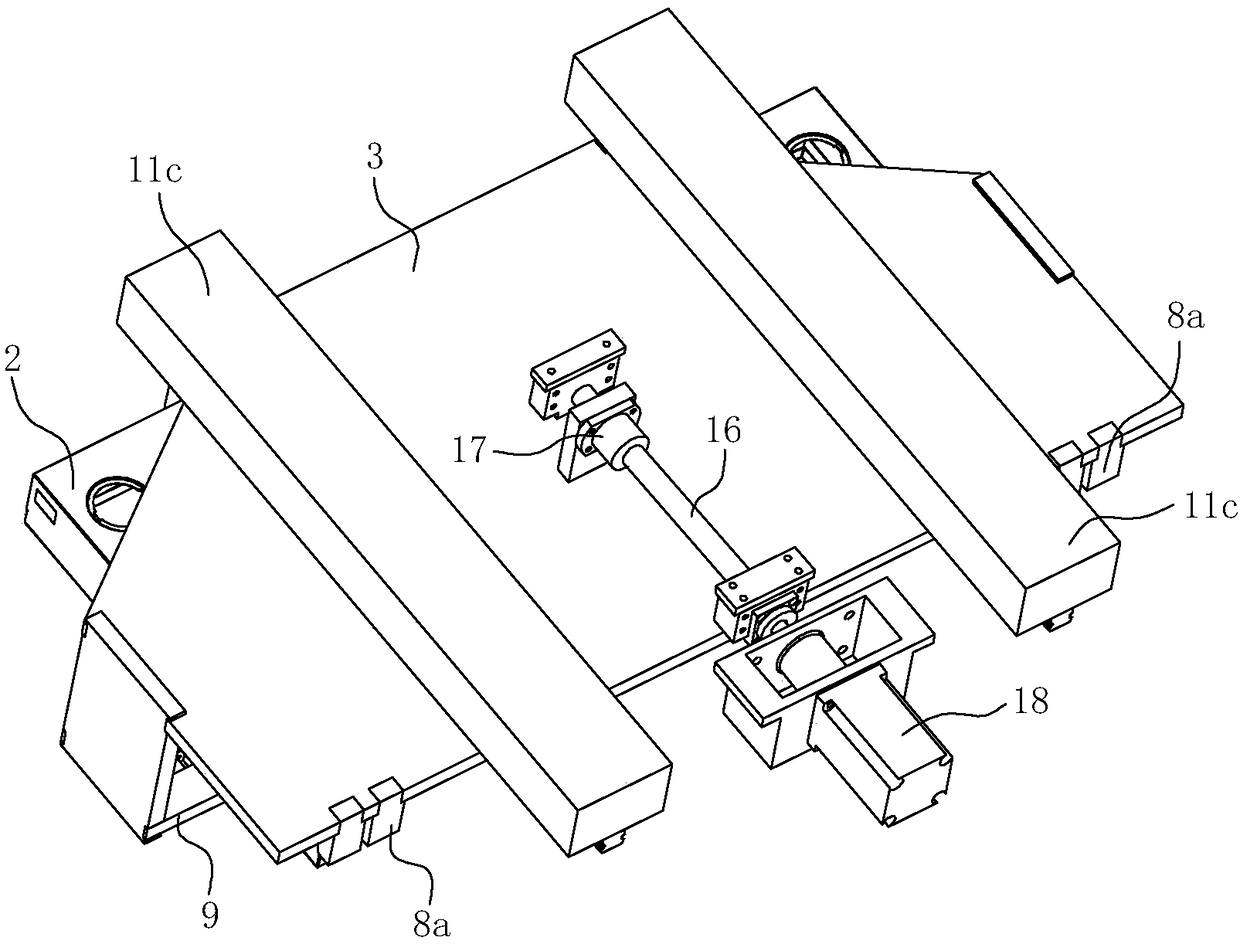

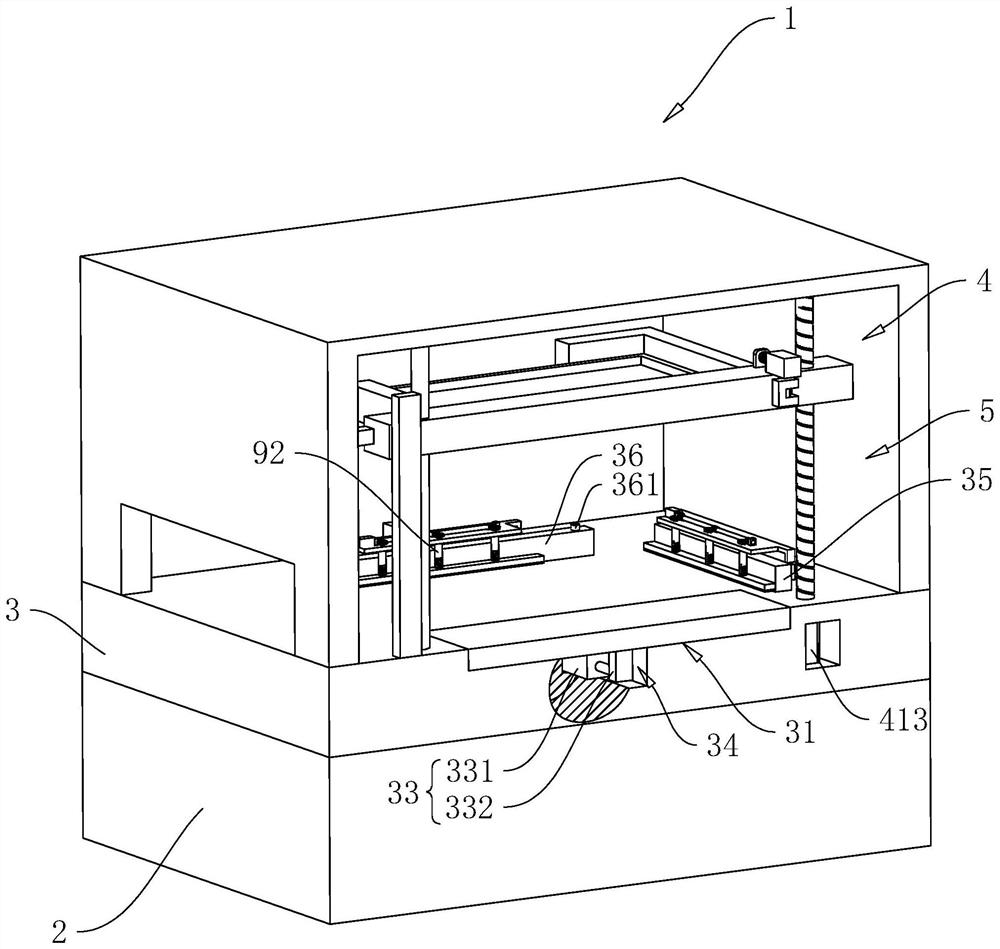

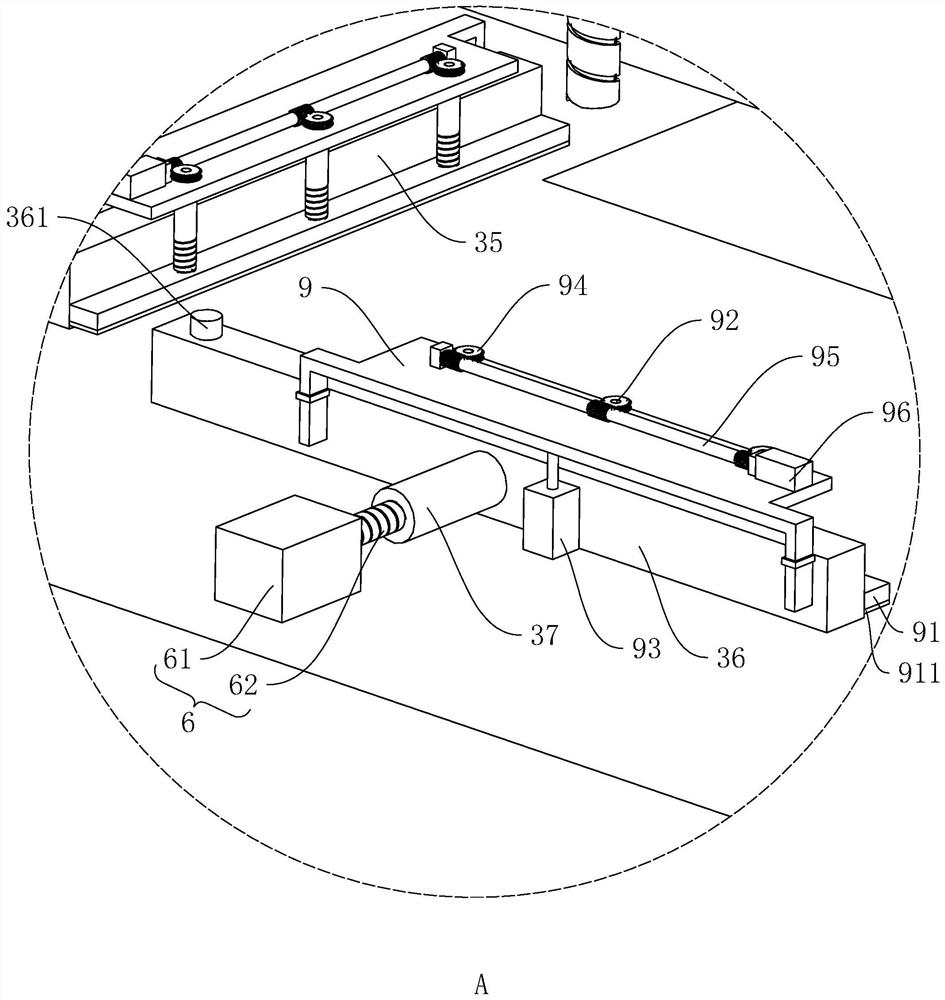

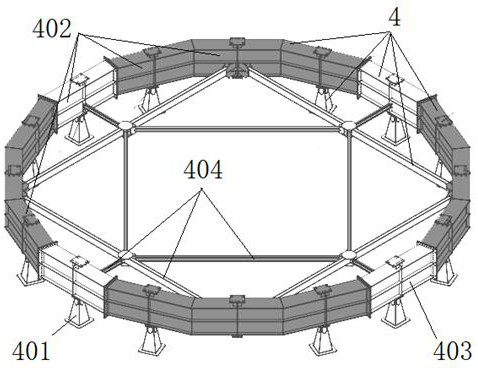

Assembly equipment for double-layer spiral duct

ActiveCN106002171ARealize transmissionSmooth slipMetal working apparatusEngineeringMechanical engineering

The invention discloses assembly equipment for a double-layer spiral duct. The assembly equipment is characterized in that a rack is included, the rack is provided with a containing part used for containing and fixing an outer spiral duct body and a pushing device used for pushing an inner spiral duct body into the outer spiral duct body, the rack is provided with at least one pair of supporting assemblies which axially slide along the outer spiral duct body and a first driving part used for driving the supporting assemblies to relatively slide to support the inner spiral duct body, and the two supporting assemblies play a supporting role on the inner spiral duct body, so that the axis of the inner spiral duct body and the axis of the outer spiral duct body always keep collinear. The two supporting assemblies can slide back to back to be away from the inner spiral duct body, the condition that the supporting assemblies cause interference to penetration of the inner spiral duct body is avoided, therefore, the inner spiral duct body is smoothly pushed into the outer spiral duct body, and assembly is smoother and more efficient.

Owner:SUZHOU ZHAOHE ENVIRONMENT & ENERGY TECH CO LTD

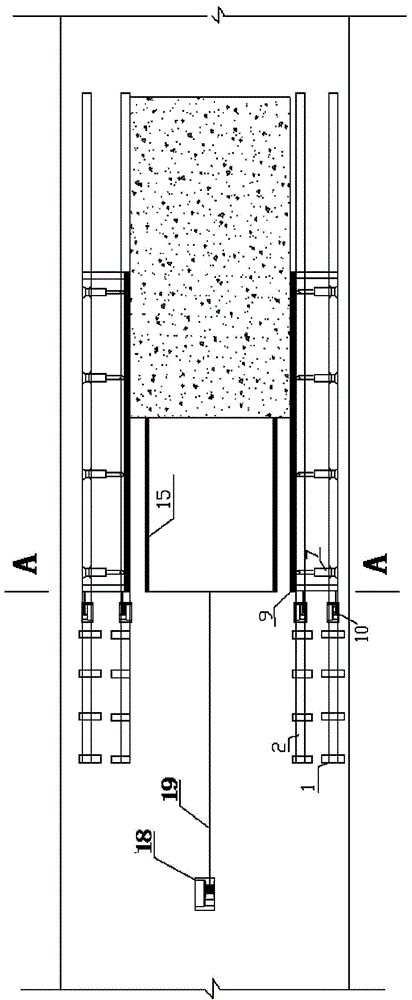

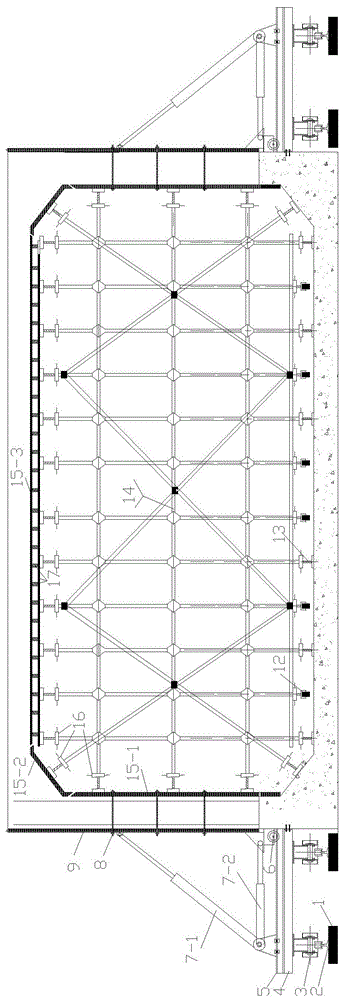

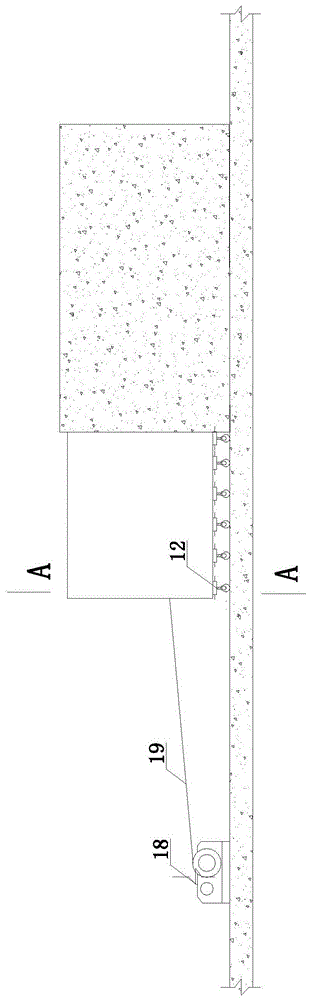

Box culvert slip form construction device and method

ActiveCN106120584AAvoid duplicate installationsReduce workloadGround-workTraction systemArchitectural engineering

The invention discloses a box culvert slip form construction device and method. The box culvert slip form construction device comprises an outer mold, an inner mold and a full support; the outer mold is pulled by an outer mold traction system to slide on tracks; and the integral structure formed by the inner mold and the full support slides under traction of an inner mold traction system. During use, a foundation and a culvert body are firstly constructed, then, the integral structure formed by the full support and the inner mold is pulled and made to slide in place, and the position of the inner mold is adjusted to complete installing of the inner mold; then, the outer mold is made to slide in place, and installing of the outer mold is completed; wall body and culvert cover concrete is poured between the outer mold and the inner mold; and finally, demolding of the inner mold and the outer mold is performed, and the integral structure formed by the inner mold and the full support and the outer mold are made to slide to a next segment of box culvert to take their positions. By means of the box culvert slip form construction device and method, the integral structure formed by the inner mold and the full support can slide and the outer mold can slide as a whole, repeated installing of a formwork and a support is avoided, operation is quite easy, the workload for installing and detaching the formwork is reduced, the mechanical degree is high, the construction speed is high, and the construction period is greatly shortened.

Owner:MCC5 GROUP CORP SHANGHAI

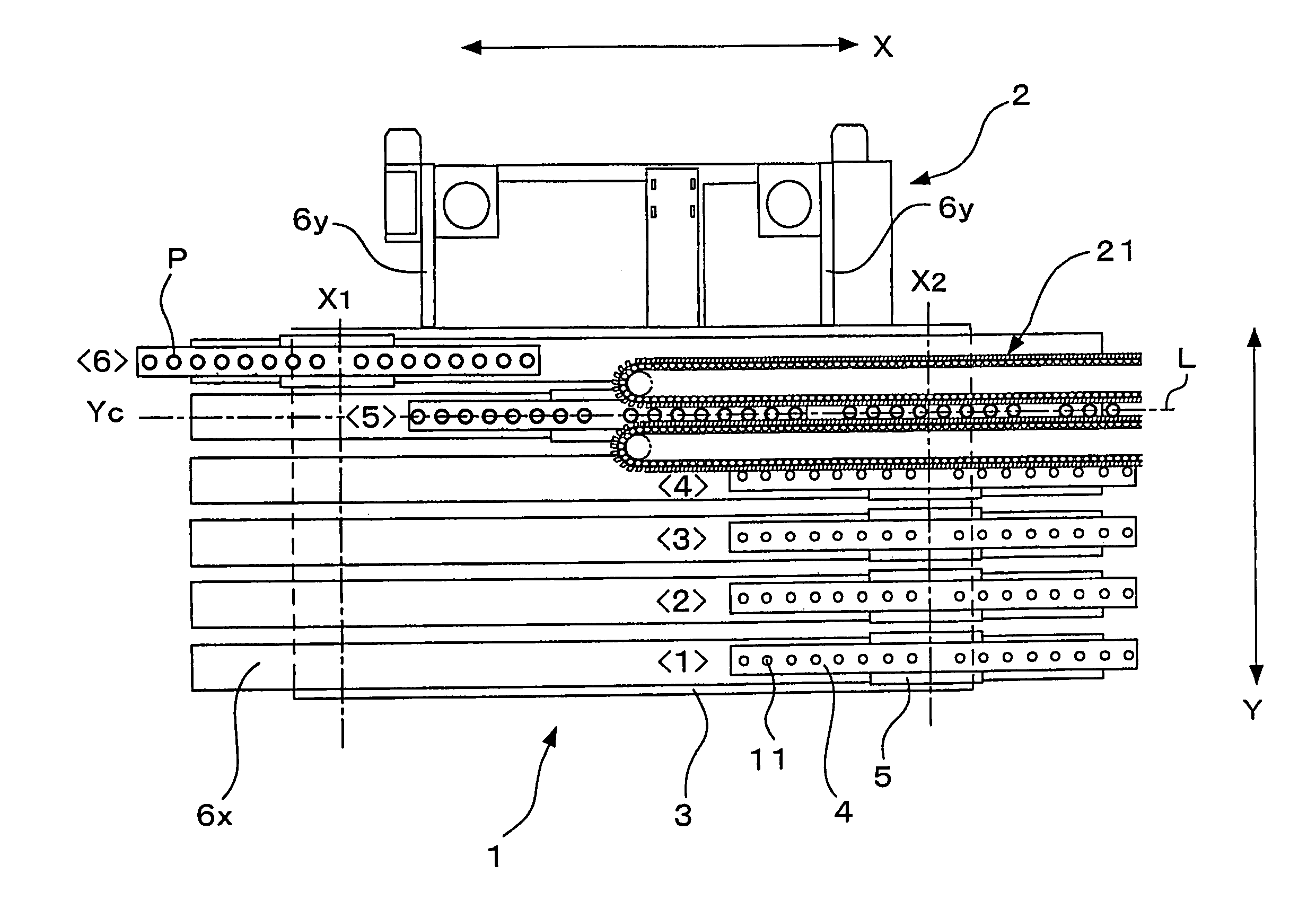

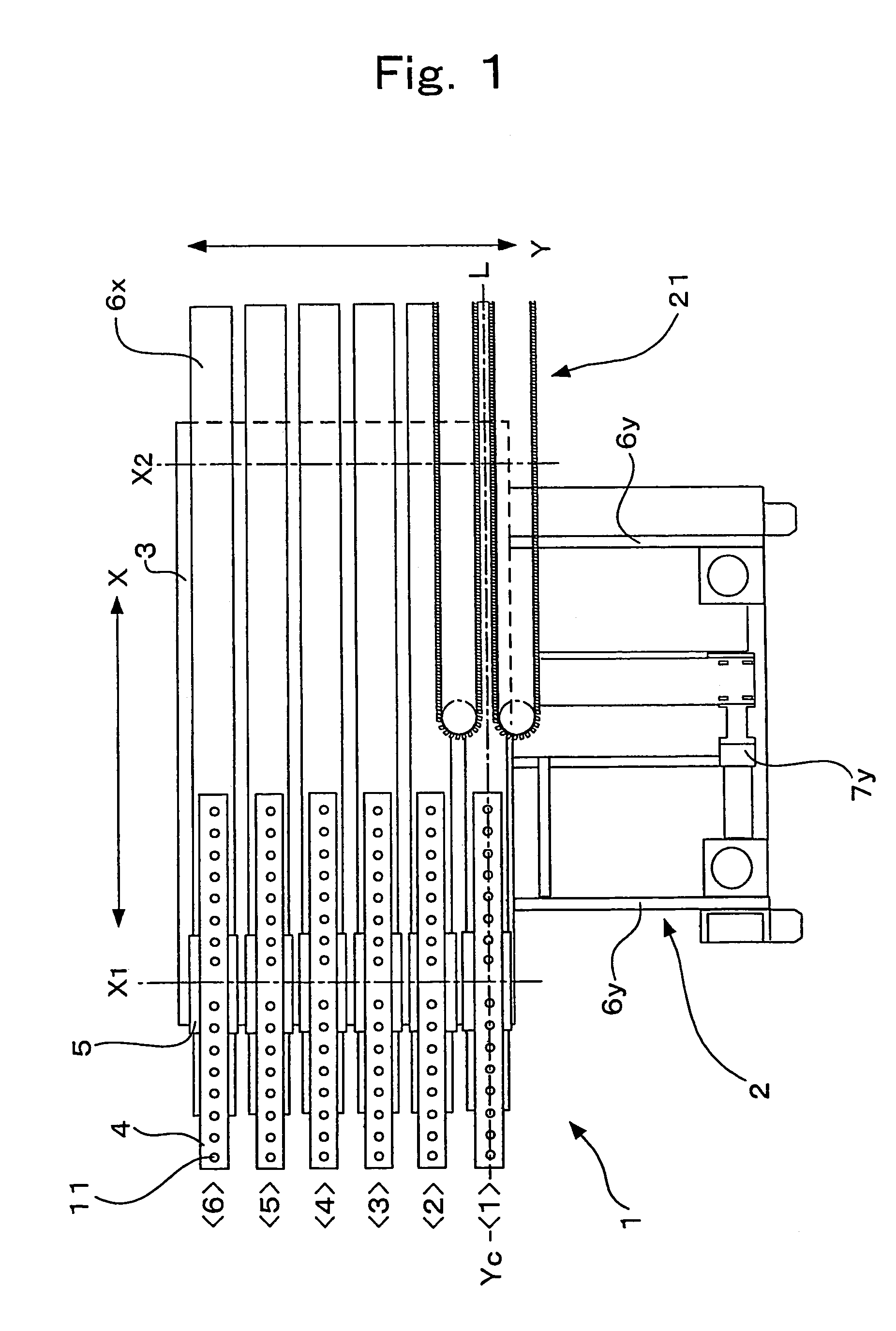

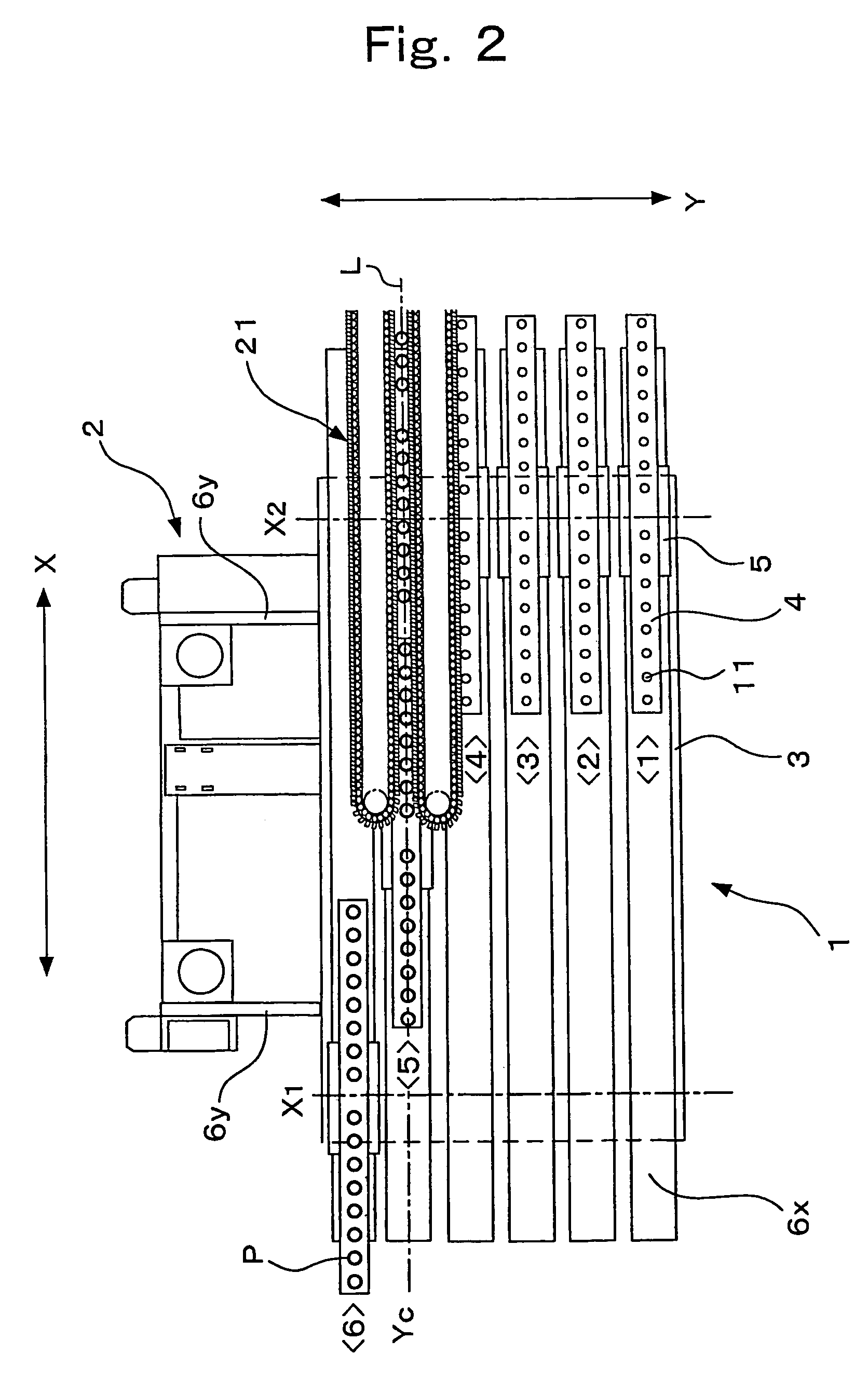

Preform conveying device

An object of this invention is to provide a preform conveying device of high production efficiency under the technical theme of aligning the plurality of preforms in single rows at high speed, while eliminating contact of individual preforms with other preforms and minimizing the chances of contact with device parts.In a state in which a plurality of preforms are aligned vertically and laterally, preforms are received in a manner partitioned in vertical row units, and by putting a conveying line, formed along the direction of a vertical row of preforms, in an inclined orientation in which the downstream side is raised, positioning the upstream end of the conveying line above a preform receiving part, and moving the vertical row unit of preforms that is positioned along the conveying line in the vertical row direction at substantially the same speed as the conveying speed of the conveying line, the respective preforms of the vertical row unit are transferred in a state in which each is sandwiched by the conveying line and this is carried out successively for each vertical row unit to supply the plurality of preforms to a blow molding machine or other subsequent process side upon aligning them in single rows.

Owner:YOSHINO KOGYOSHO CO LTD +1

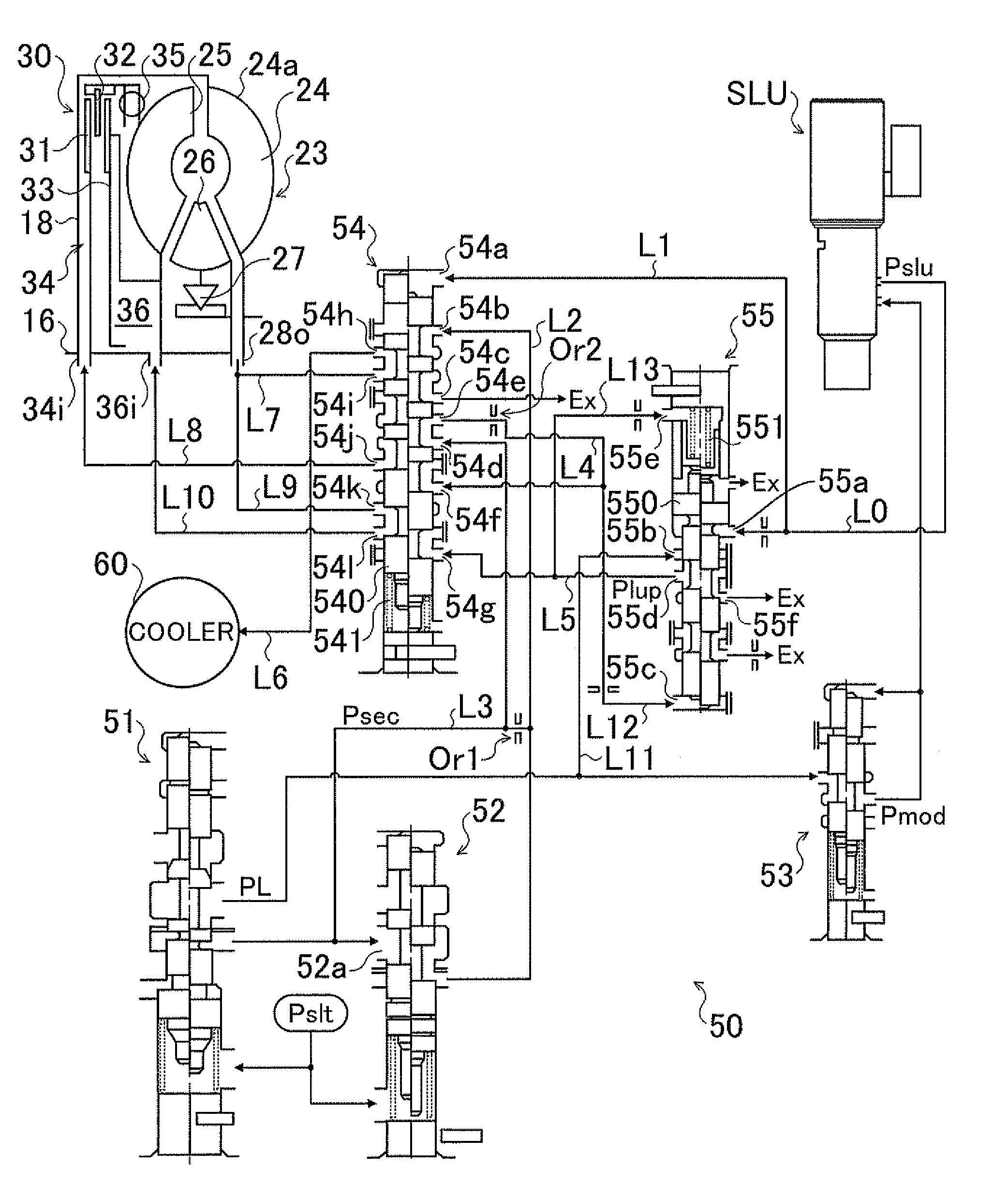

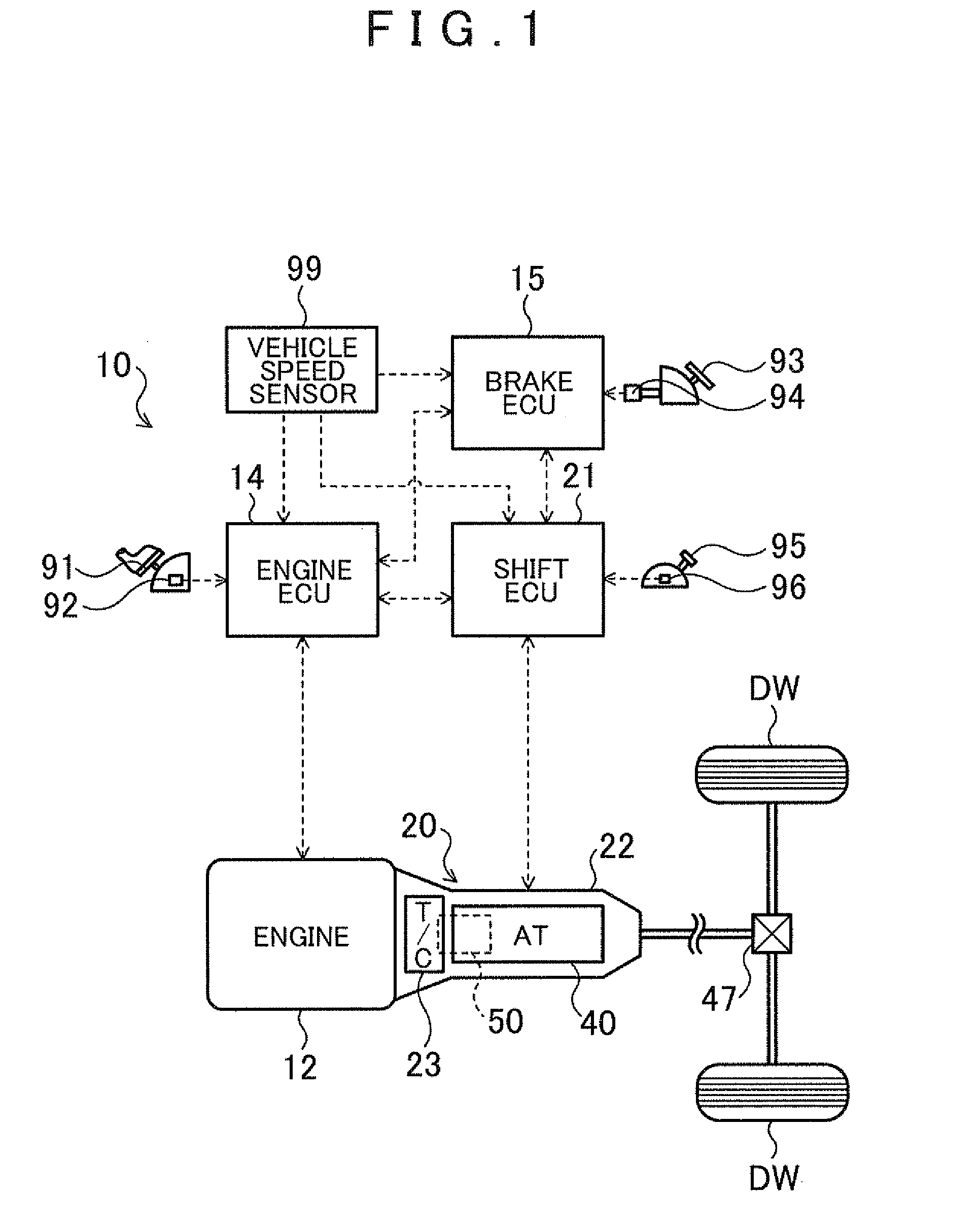

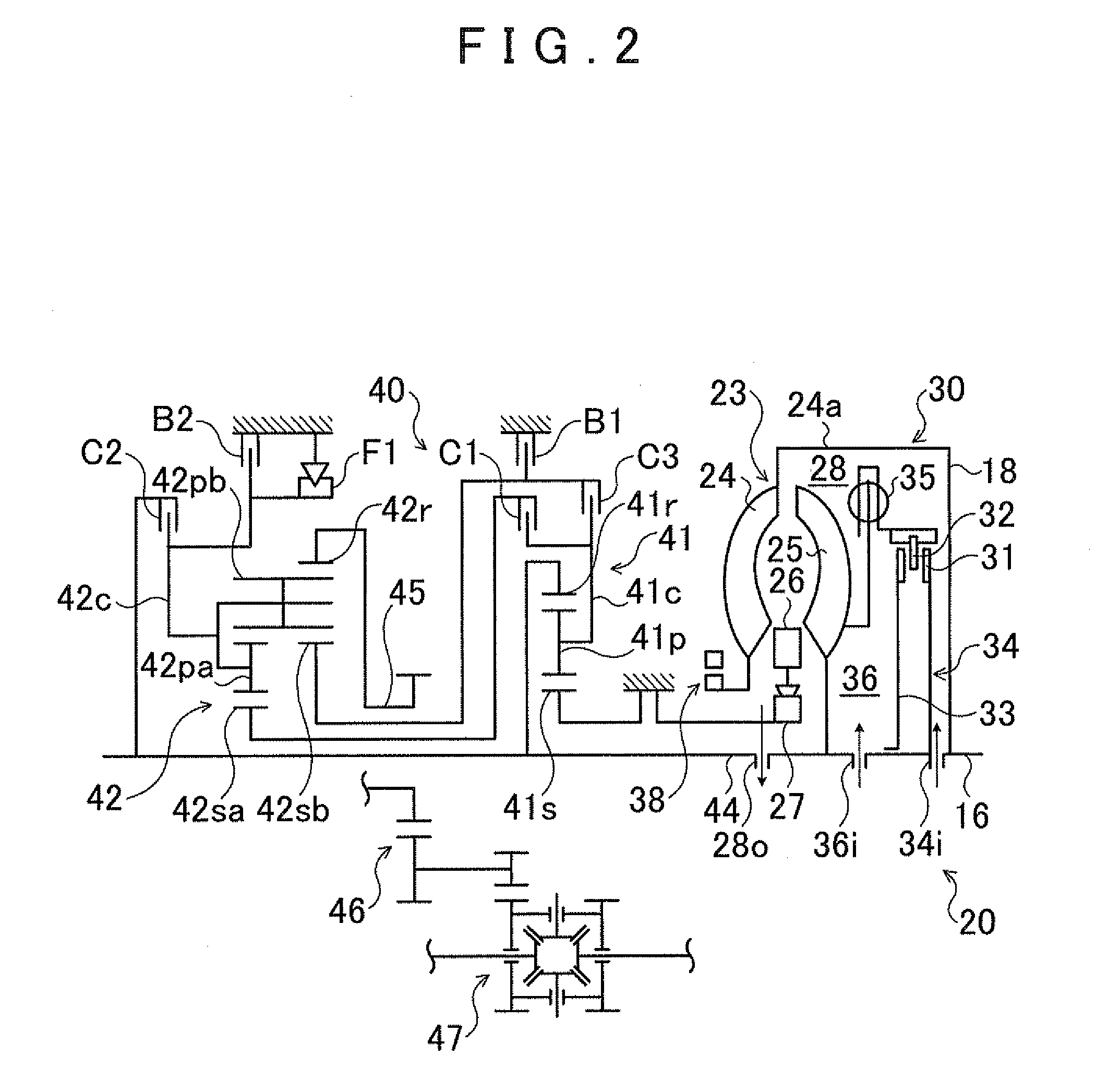

Hydraulic control device

InactiveUS20120241272A1InhibitionIncrease pressureRotary clutchesFluid actuated clutchesEngineeringPiston

A hydraulic control device controls a hydraulic pressure in an engagement side oil chamber defined on one side of a piston that configures a hydraulic clutch, and a hydraulic pressure in a back-pressure side oil chamber defined on the other side of the piston. The hydraulic control device includes a line pressure generating valve that generates a line pressure by adjusting a hydraulic pressure from an oil pump; a secondary pressure generating valve that generates a secondary pressure, which is a hydraulic pressure supplied to the back-pressure side oil chamber, by adjusting a hydraulic pressure from the line pressure generating valve so as to be lower than the line pressure; and a clutch engagement pressure generating valve that generates a clutch engagement pressure, which is a hydraulic pressure supplied to the engagement side oil chamber, by adjusting the line pressure from the line pressure generating valve.

Owner:AISIN AW CO LTD

Cutting radius adjusting mechanism of circumference cutter

The invention relates to a cutting radius adjusting mechanism of a circumference cutter. The circumference cutter comprises a base and a cutter body arranged on the base, wherein the cutter body comprises a cutting blade and a power device for driving the cutting blade to rotate and move; the cutter body further comprises a horizontal slide plate which is arranged on the base in a horizontal sliding manner, wherein the cutting blade and the power device are arranged on the horizontal slide plate to horizontally move along with the horizontal slide plate; a locking plate mechanism which is used for selectively permitting or blocking horizontal sliding of the horizontal slide plate is arranged on the base. According to the cutting radius adjusting mechanism, the adjustment of the cutting radius of the circumference cutter is realized by adjusting the horizontal slide plate; the radius adjusting mechanism is simple in structure, easy and convenient to adjust, so that the application range of the circumference cutter is expanded; moreover, the circumference cutter is strong in integrity, small in size, good in stability, and easy and convenient to adjust.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

Tiling device and automatic transfer arrangement machine

PendingCN113264220AReduce the frequency of manual feedingImprove efficiencyPackagingDe-stacking articlesStructural engineeringMechanical engineering

The invention discloses a tiling device and discloses an automatic transfer arrangement machine with the tiling device. The tiling device comprises a feeding mechanism and a tiling mechanism, the feeding mechanism comprises a material bin and a material pushing part located on one side of the material bin, the material bin accommodates vertically stacked magnetic sheets, and the material pushing part is used for pushing the magnetic sheets to the other side of the material bin; and the tiling mechanism is located on the side, away from the material pushing part, of the material bin and comprises a material carrying table and a power assembly driving the material carrying table to be away from and close to the material bin, and the material carrying table is used for supporting the magnetic sheets from the material bin. According to the tiling device, the magnetic sheets can be automatically tiled and arranged, and the magnetic sheets can be tiled more orderly.

Owner:肇庆高峰机械科技有限公司

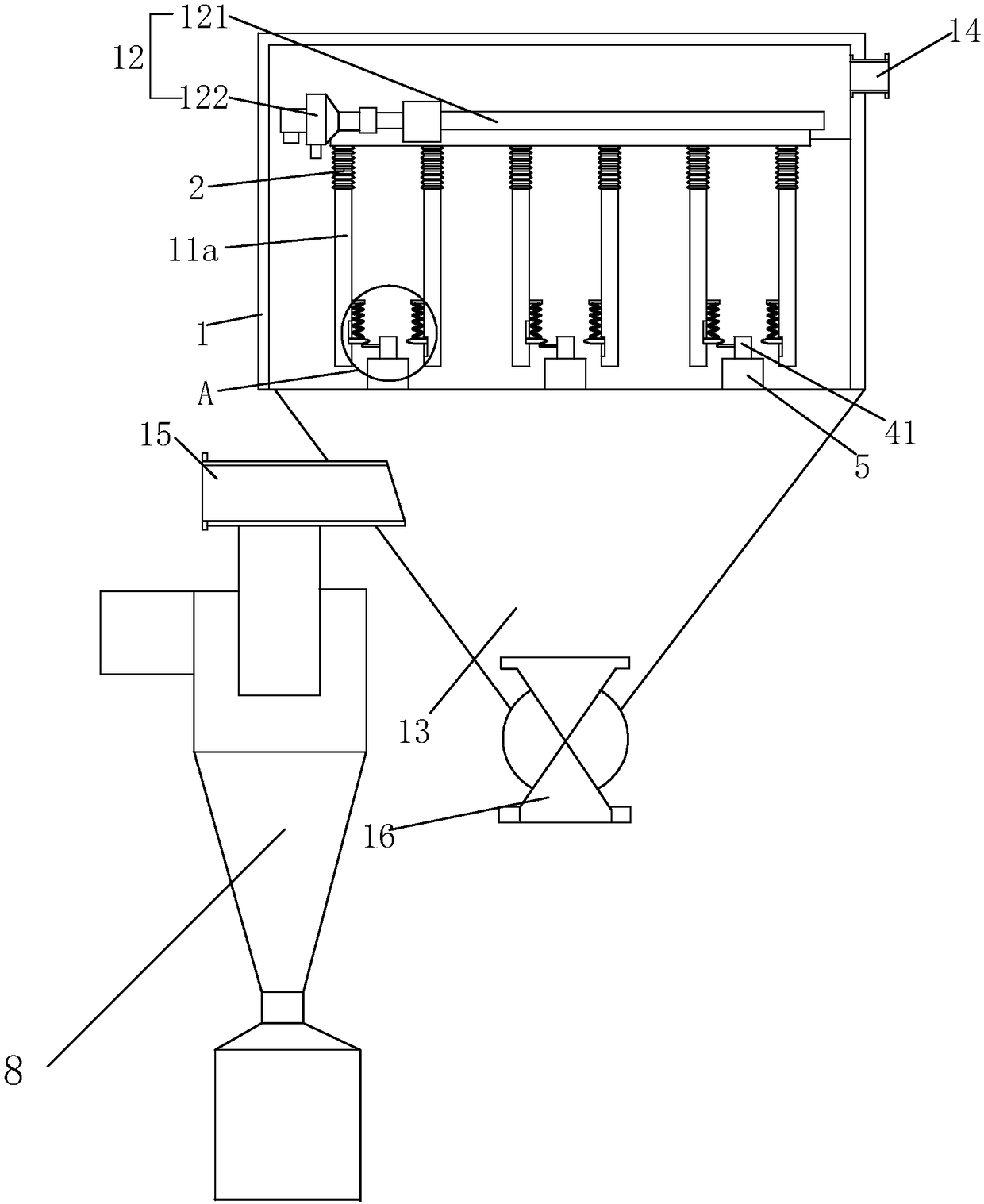

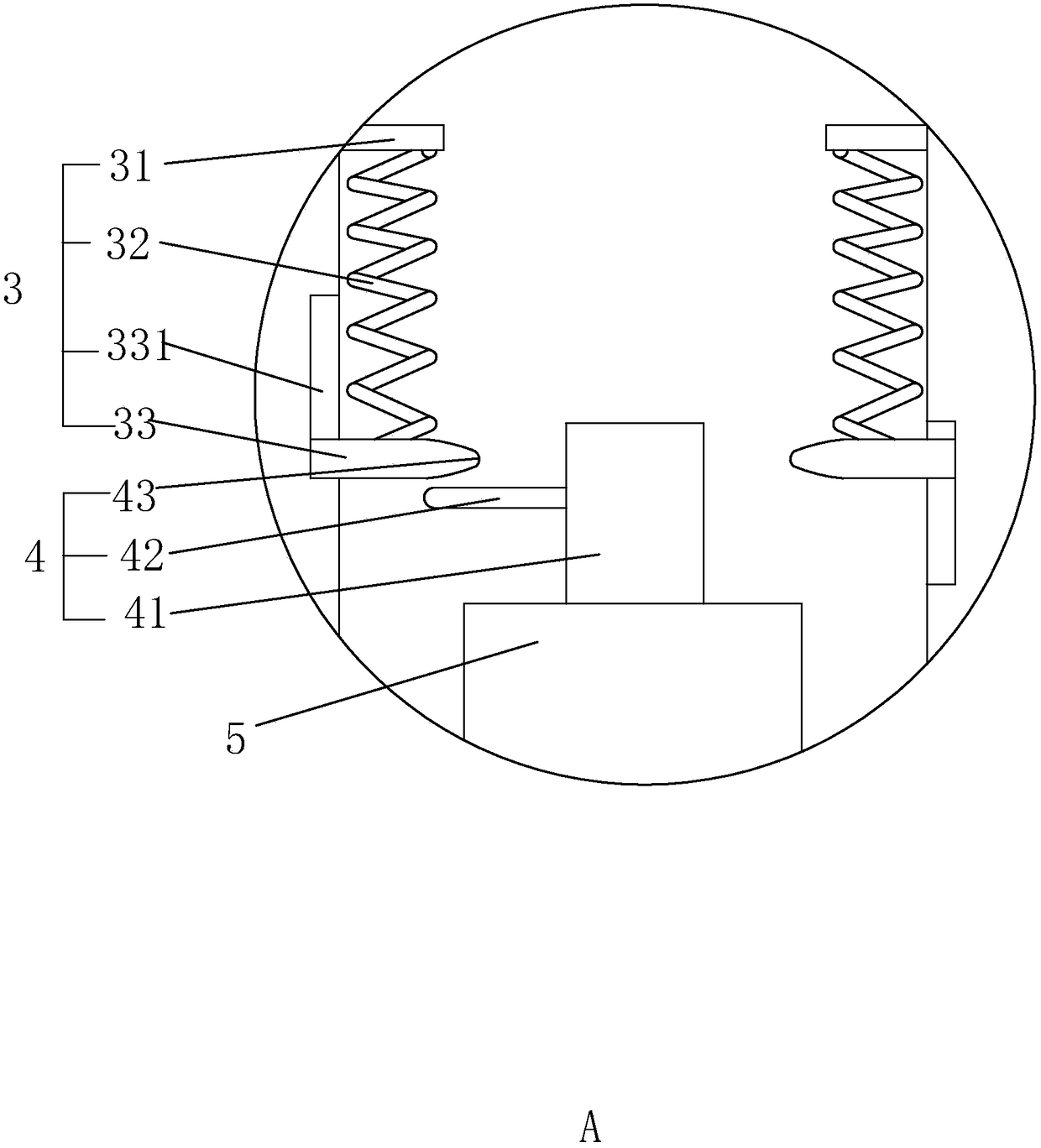

Bag-type dust collector with prepositioned cyclone separator

PendingCN108939724ACleared smoothlyAvoid collisionDispersed particle filtrationTransportation and packagingControl systemBaghouse

The invention discloses a bag-type dust collector with a prepositioned cyclone separator. The bag-type dust collector comprises a machine body, wherein a plurality of filter elements are arrayed in the machine body, a dust cleaning control system is arranged in the machine body located above the filter elements, the filter elements arrayed along the vertical direction of the dust cleaning controlsystem form a set of filter assembly, a dust hopper for storing dust is arranged in the machine body located below the filter elements, upper ends of the filter elements are fixedly connected with corrugated pipes separately, the ends, far away from the filter elements, of the corrugated pipes are fixedly connected with the dust cleaning control system separately, auxiliary vibration devices are separately arranged on the filter elements and comprise connecting plates arranged on external walls of the filter elements close to middle-lower parts, the connecting plates are fixedly connected witha set of filter assembly simultaneously, telescopic springs are fixedly arranged at bottoms of the connecting plates, the ends, far away from the connecting plates, of the telescopic springs are fixedly connected with slipping working plates, the slipping working plates are arranged on the external walls of the filter elements in a slipping manner and are located below the connecting plates, anda driving device for controlling the telescoping of the telescopic springs is arranged on the dust hopper.

Owner:JIANGSU RUIJIE ENVIRONMENTAL ENG SCI & TECH

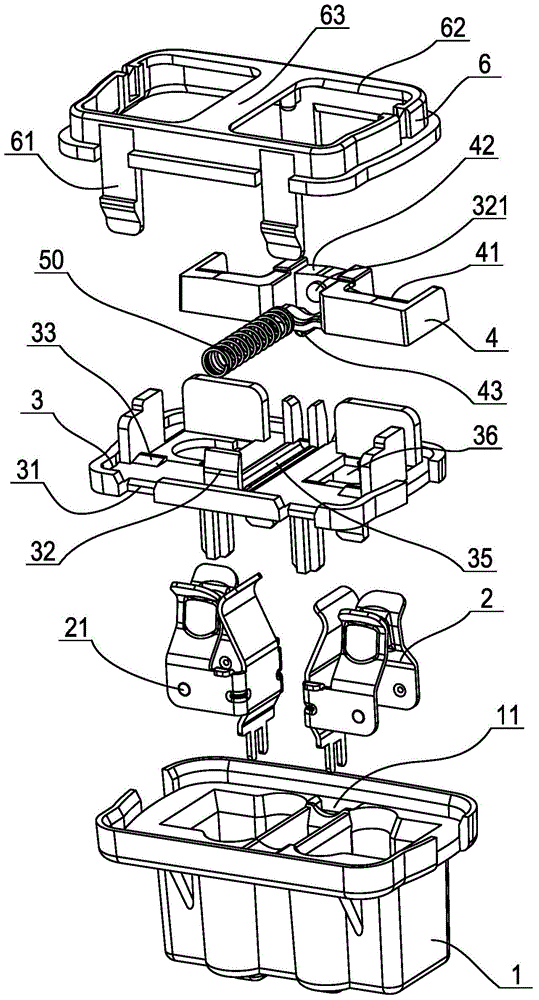

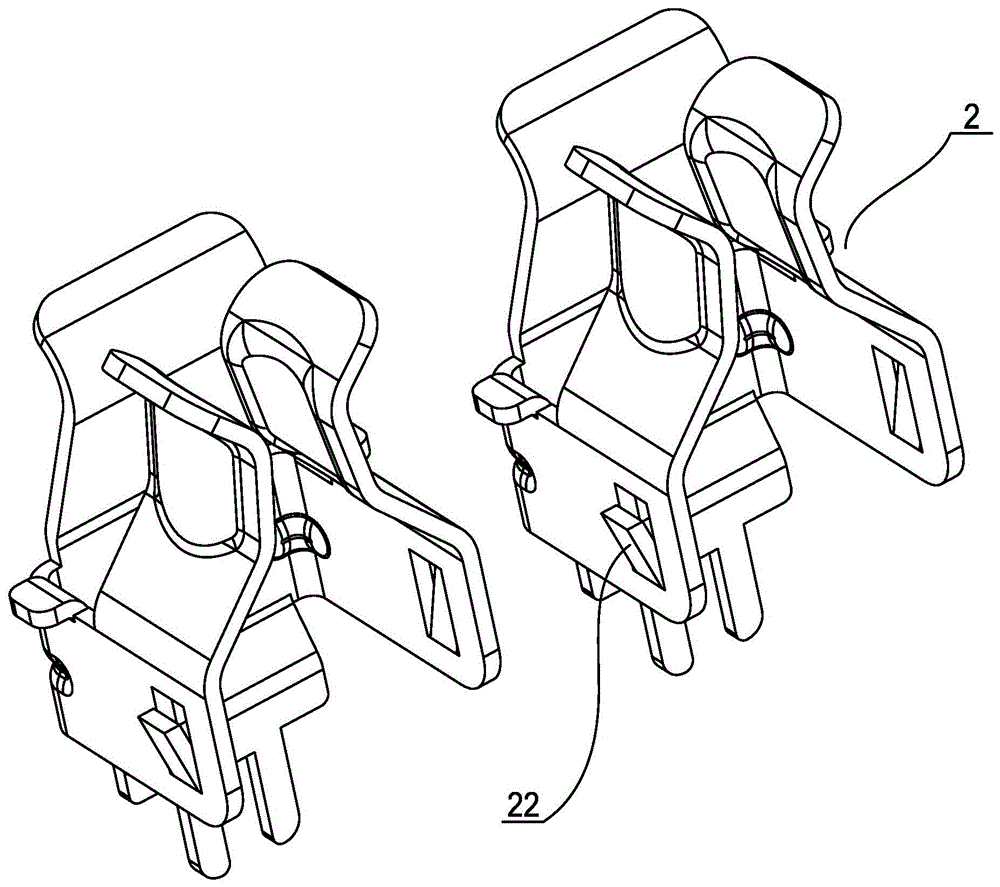

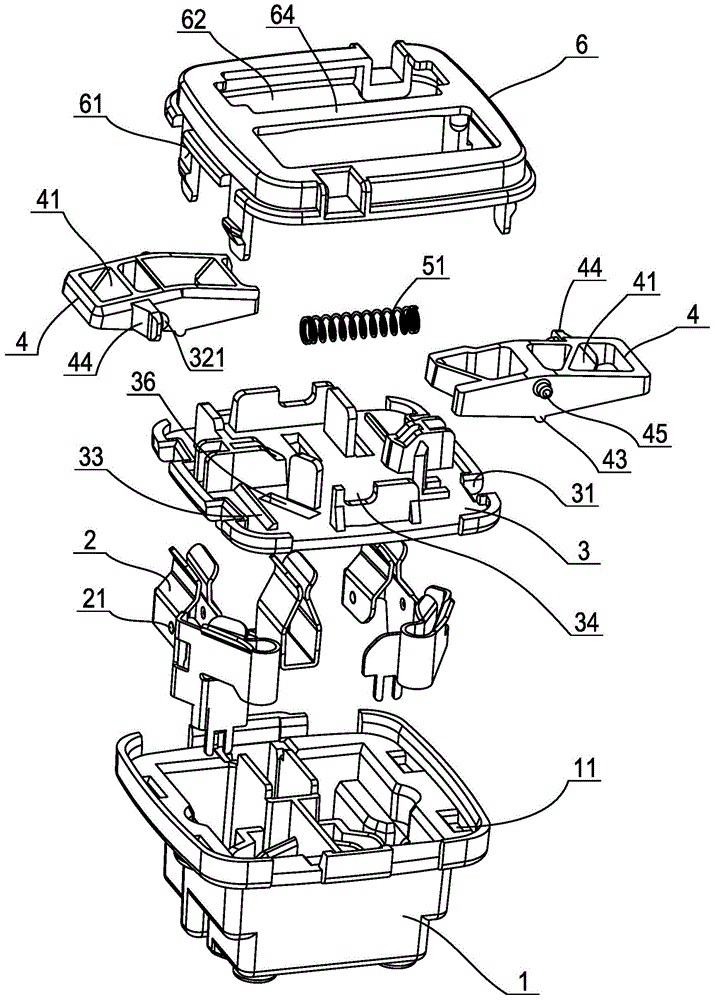

Socket module with protective door and socket

ActiveCN105048155APrevent looseningPrevent loosening and fallingCoupling device detailsEngineeringElectrical and Electronics engineering

Owner:BULL GRP CO LTD

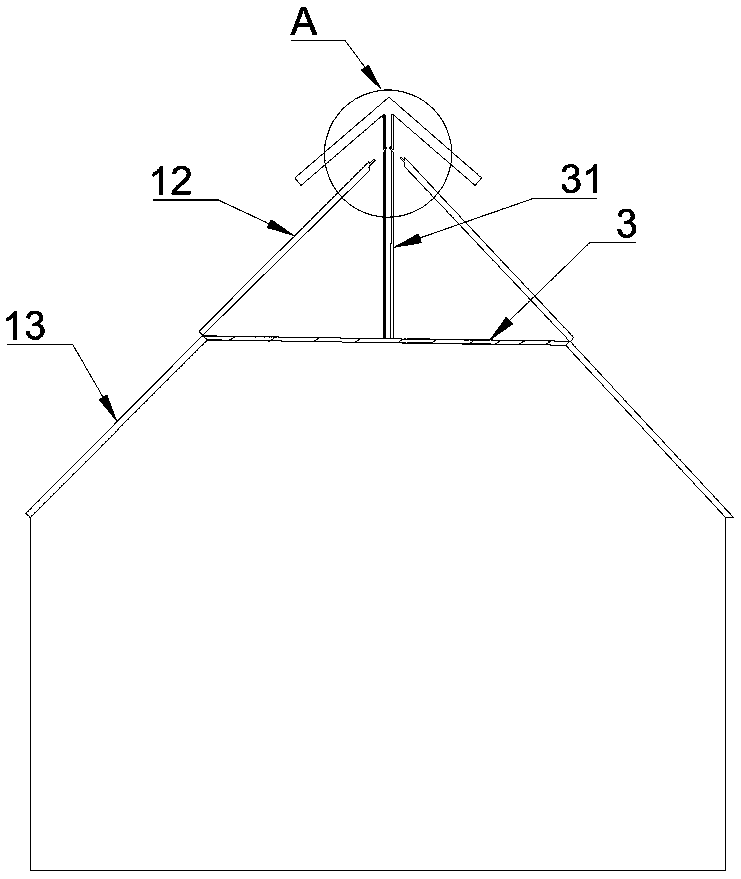

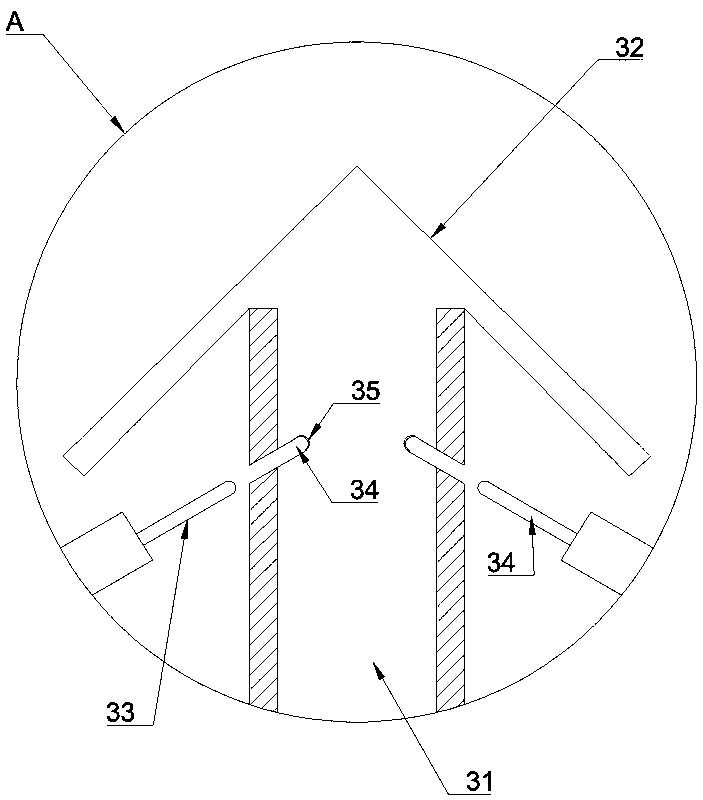

Novel environment-friendly energy-saving roof

The invention discloses a novel environment-friendly energy-saving roof. According to the technical scheme, the roof comprises a roof beam and house columns arranged on the four sides of the house andplaying a support role, the roof beam is composed of two intersected inclined panels, overturning panels are connected with the house columns, the inclined panels and the overturning panels form a triangular structure, the inclined panels can slide downwards in the inclined length direction, driving assemblies used for driving the inclined panels to slide downwards are arranged on the inclined panels, and overturning assemblies used for overturning the overturning panels are arranged on the overturning panels. The driving assemblies are respectively arranged at the joints of the two inclinedpanels and the column bodies, and the driving assemblies comprise sliding rails arranged on the inclined panels and sliding ways arranged on the house columns, the sliding rails are matched with the sliding ways, and driving mechanisms are arranged on the sliding rails and used for driving the sliding ways to slide in the length direction of the sliding rails. The roof can be opened to allow sunlight to irradiate in and can achieve natural ventilation.

Owner:WENZHOU LUCHENG THE FIRST CONSTR ENG CO LTD

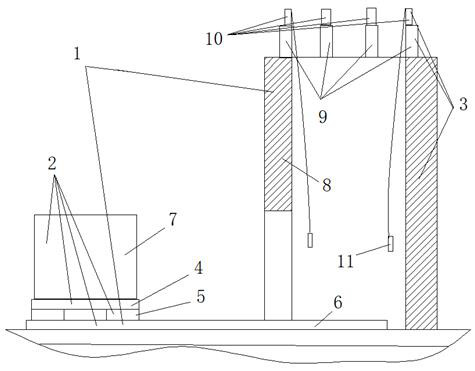

Steel truss girder multi-point traction type incremental launching construction system and construction method thereof

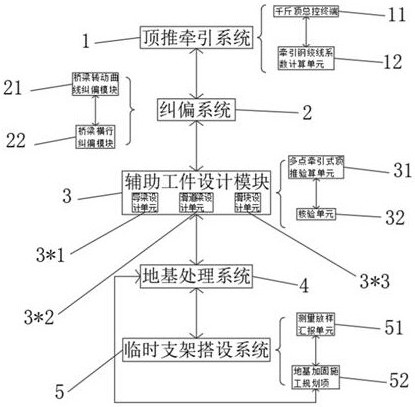

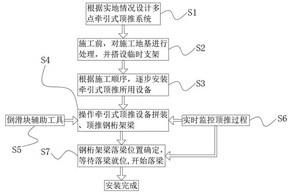

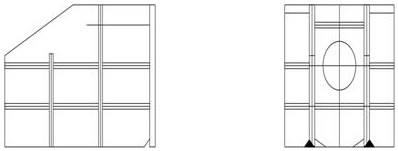

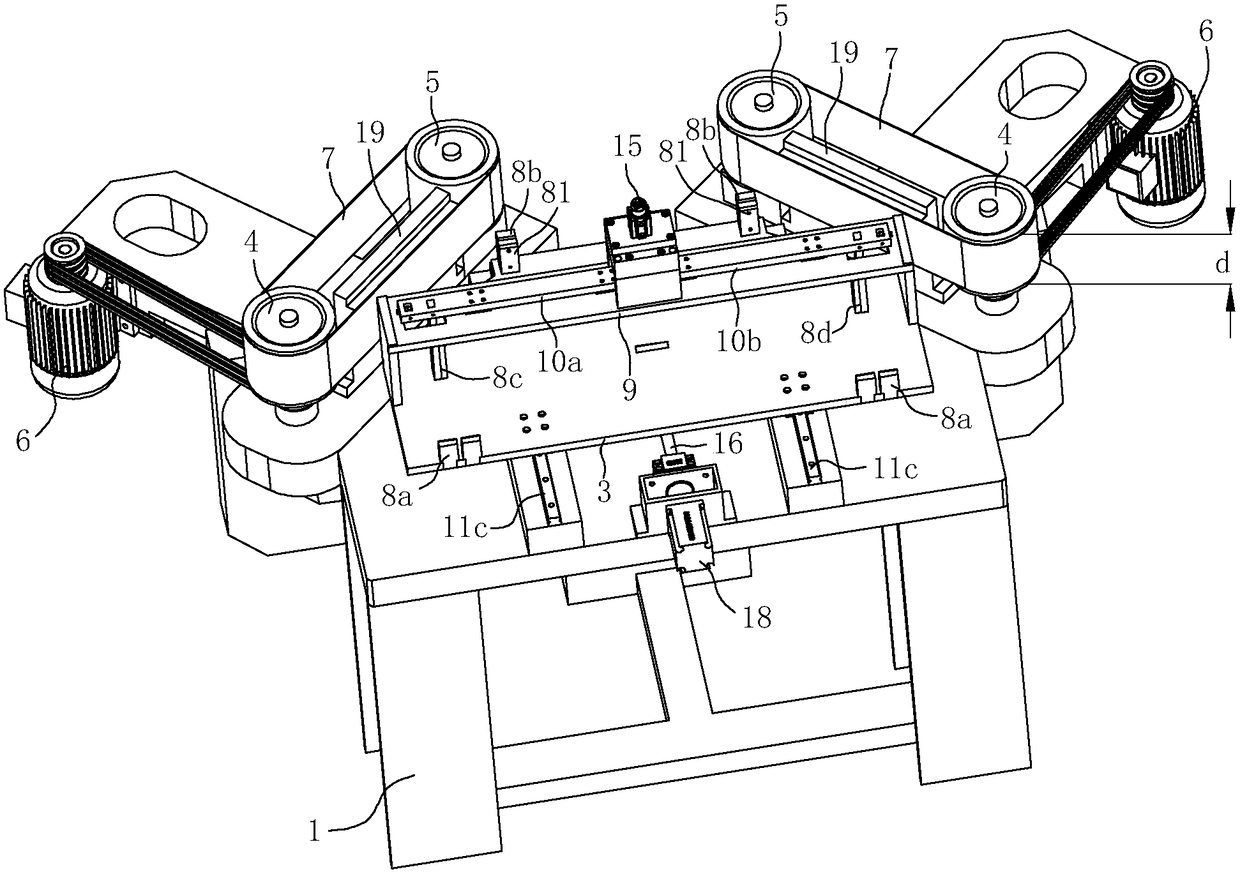

PendingCN113622316ADoes not affect normal trafficReasonable forceBridge erection/assemblyArchitectural engineeringJackscrew

The invention relates to the technical field of constructional engineering, in particular to a steel truss girder multi-point traction type incremental launching construction system and a construction method thereof.The steel truss girder multi-point traction type incremental launching construction system comprises an incremental launching traction system used for steel truss girder engineering traction general control, instrument allocation and sub-package type issuing of engineering tasks; The system further comprises a jack master control terminal and a traction steel strand coefficient calculation unit. The jack master control terminal is used for controlling a plurality of continuous jacks to synchronously pull and move forwards, and providing a power source for a steel truss girder to reach a design coordinate; The traction steel strand coefficient calculation unit is used for calculating the optimal number of strands of traction steel strands and is responsible for connecting each jack. The steel truss girder and the support are stressed more reasonably by adopting multi-point traction, overlarge stress of a single point is avoided. Meanwhile, the multi-point traction girder body is stable in sliding, the advancing track of the curve bridge is easier to control. The problems that the rigidity of the bottom surface of the lower chord of the steel truss girder is changed, the bearing force is not uniform, and the curved bridge pushing advancing track is not easy to control are solved.

Owner:ANHUI HIGHWAY BRIDGE ENG CO LTD

Corner grinding machine tool

InactiveCN109382732AImprove grinding efficiencyRealize automatic grinding processBelt grinding machinesGrinding feedersMachine toolEngineering

The invention relates to a corner grinding machine tool. The tool is characterized by comprising a rack, a platform used for placing a to-be-ground workpiece, a platform driving mechanism and two grinding mechanisms, wherein the platform is arranged above the table top of the rack, and the positioning structure used for positioning the to-be-ground workpiece on the platform is arranged on the platform; the platform driving mechanism is used for driving the platform to horizontally slide back and forth; the two grinding mechanisms are arranged on the left side and the right side of the rear part of the rack and correspond to two grinding corners of the to-be-ground workpiece respectively; each grinding mechanism comprises a driving belt wheel and a driven belt wheel, an abrasive belt is obliquely arranged between each driving belt wheel and the corresponding driven belt wheel, and the width of each abrasive belt is larger than the height of the grinding corners of the to-be-ground workpiece. The corner grinding machine tool can be used for grinding the two side corners of the to-be-ground workpiece at the same time, and the tool can precisely grind the workpiece with the corners meeting design requirements. The corner grinding machine tool can be used for automatically grinding the two side corners of the to-be-ground workpiece at the same time, and can precisely grind the workpiece with the corners meeting the design requirements.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

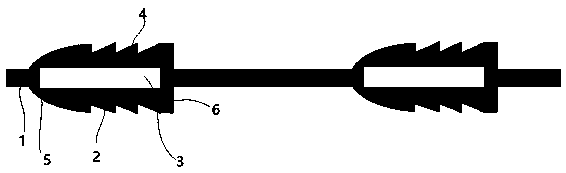

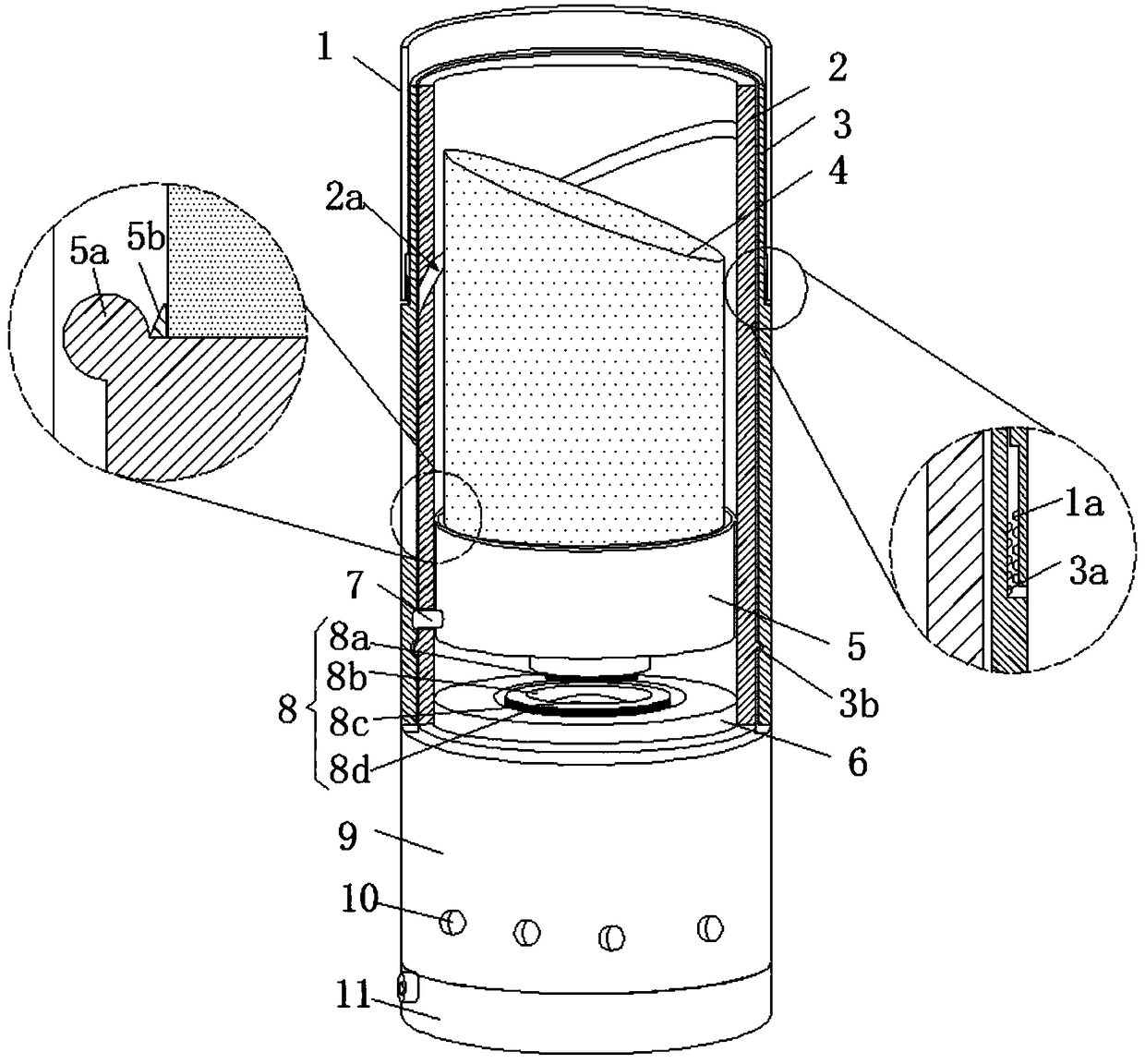

Knotting-free surgical suture line

ActiveCN107890360ARelieve painSmooth slipSuture equipmentsSurgical needlesRight triangleGeneral surgery

The invention relates to the technical field of surgical suture lines, in particular to a knotting-free surgical suture line. The knotting-free surgical suture line comprises a first portion and a second portion distributed in a spaced mode, the width of the section of the first portion is uniform, the width of the section of the second portion is larger than that of the first portion, the first end of the second portion is in arc smooth transition with the first portion, the edge of the second end of the second portion is perpendicular to the axial direction of the surgical suture line, a sawtooth portion is arranged between the two ends of the second portion, the sawtooth portion is provided with a plurality of sawteeth with right triangle sections, the right-angle sides of the sawteethare close to the second end of the second portion and are perpendicular to the axis direction of the surgical suture line, and the inclined edges of the sawteeth are close to the first end of the second portion; a long-strip-shaped hole is formed in the center inside the second portion. Compared with a traditional surgical suture line, the surgical suture line has the advantages of being free of knotting, capable of easily penetrating through muscles and low in production cost, can shorten the knotting time in the surgical suture process and relieves patient's pain.

Owner:NANTONG HOLYCON MEDICAL DEVICES

Alignment printing technology

The invention relates to an alignment printing technology. The alignment printing technology comprises the steps that S1, a screen plate for silk-screen printing is manufactured according to a pattern provided by a client; S2, dye for printing is blended according to the silk screen plate pattern; S3, the screen plate and the dye are mounted on a printing device, and the pattern is printed on the printing stock through a printing device; and S4, the printed material after printing is dried and then stored. The printing device is provided with an alignment mechanism used for positioning the printing stock. The alignment printing technology has the beneficial effects that when a worker places the printing stock on the workbench for printing, the printing stock is aligned through the alignment mechanism, so that the worker does not need to consume additional printing stock to conduct trial printing so as to check the positioning of the printing stock before batch printing, and the printing cost is reduced.

Owner:杭州鸿运彩印包装有限公司

Method for storing cosmetic lipstick paste

ActiveCN108606452ASmooth slipAvoid cloggingPackaging toiletriesPackaging cosmeticsEngineeringLipstick

The invention belongs to the technical field of cosmetics, and particularly relates to a method for storing cosmetic lipstick paste. The method comprises the following steps that S1, the lipstick paste is put into a paste storage box; S2, the paste storage box contains cooling liquid; S3, the paste storage box is put into a packaging machine for packaging. According to the paste storage box used in the method, the side walls of an inner sleeve and an outer sleeve are provided with spirally corresponding sliding grooves, the movement of a hole formed by the outer sleeve and the inner sleeve isachieved by rotating the outer sleeve, the side wall of a base is fixedly provided with a connecting column, the base is driven to move through the movement of the hole, and therefore the stable sliding movement of the paste on the base is achieved; a bump is arranged at the outer edge of the top of the base, a triangular support plate is arranged between the bump and the paste, a containing groove is formed between the support plate and the bump, and the paste can be preliminarily collected after being melt at the high temperature.

Owner:SHANDONG HUANGSHENGTANG PHARMA CO LTD

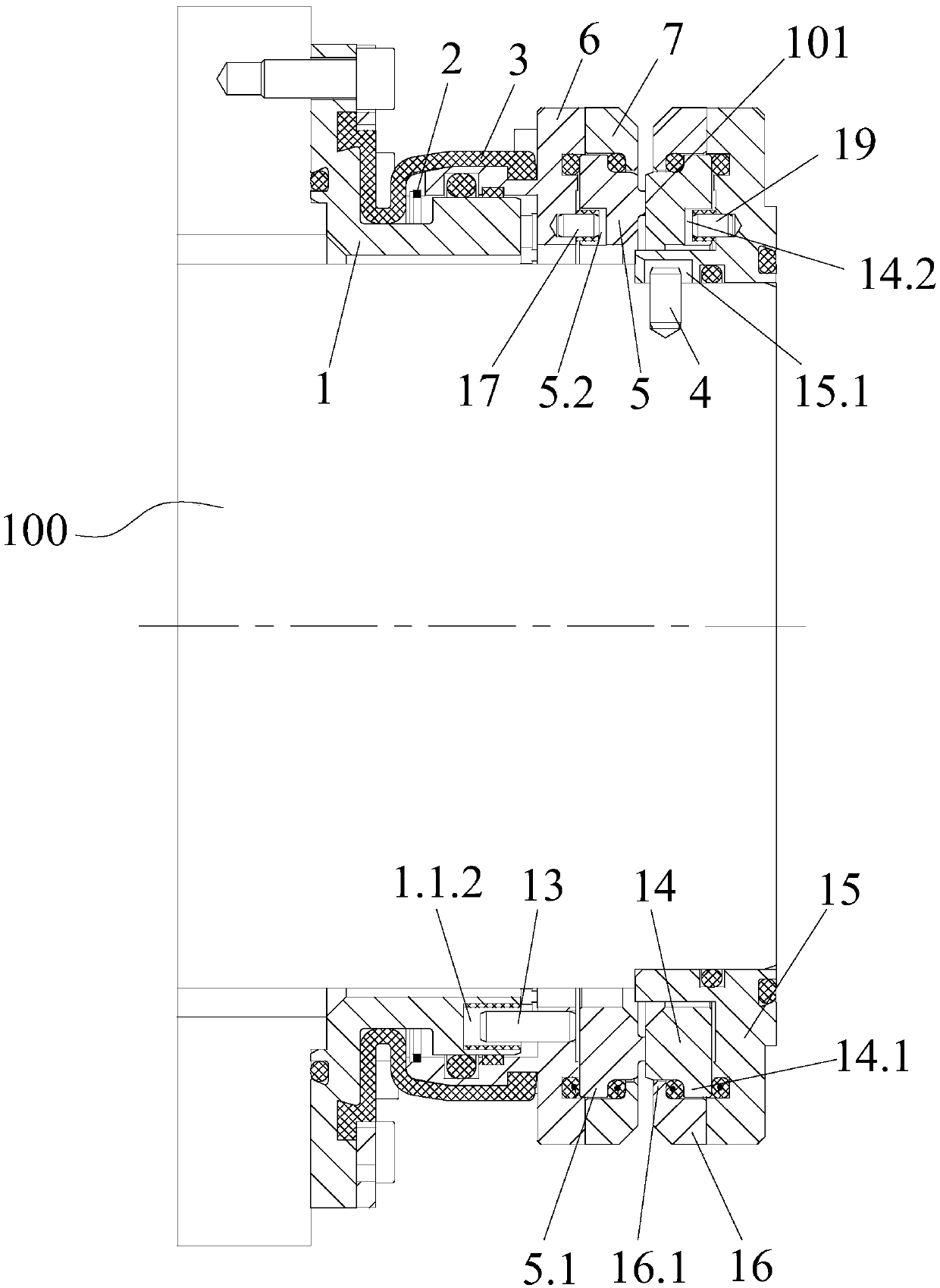

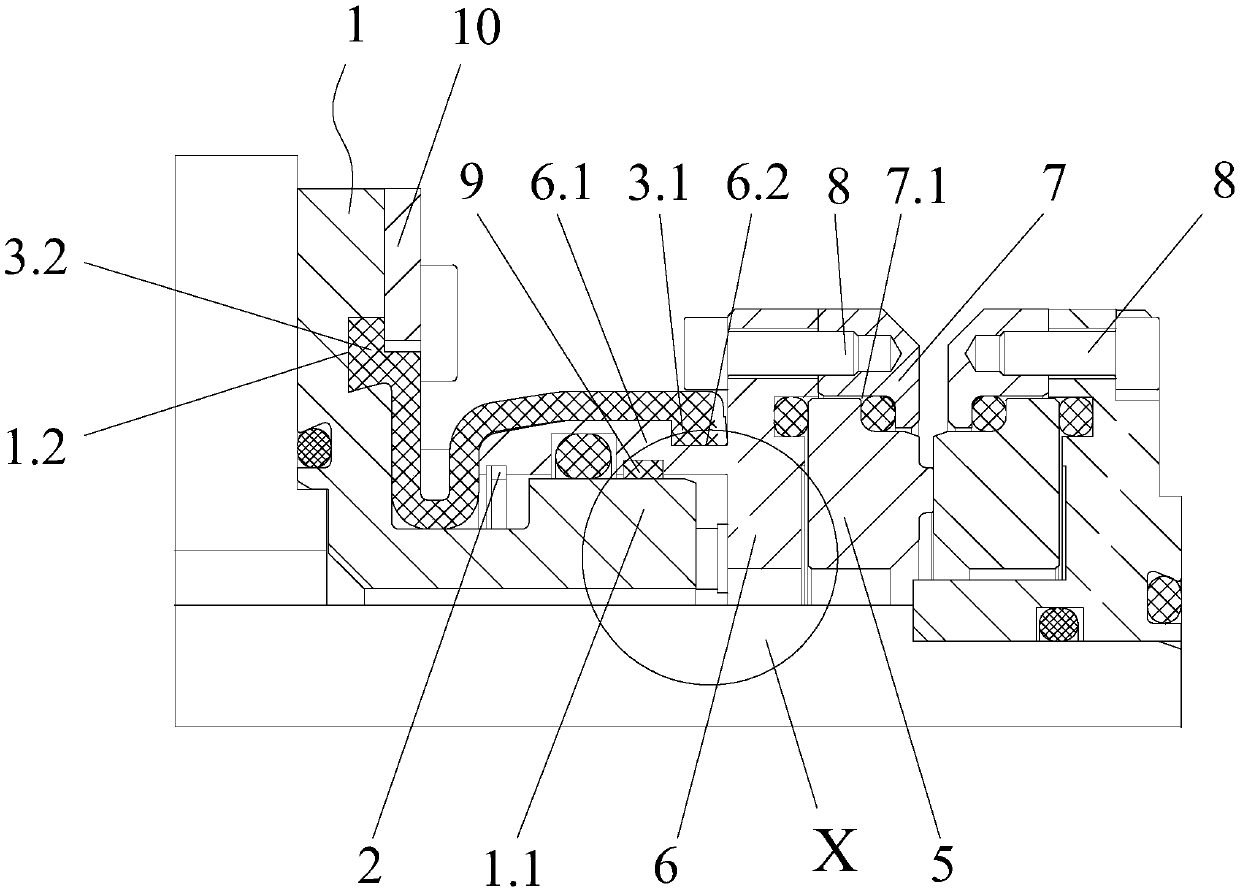

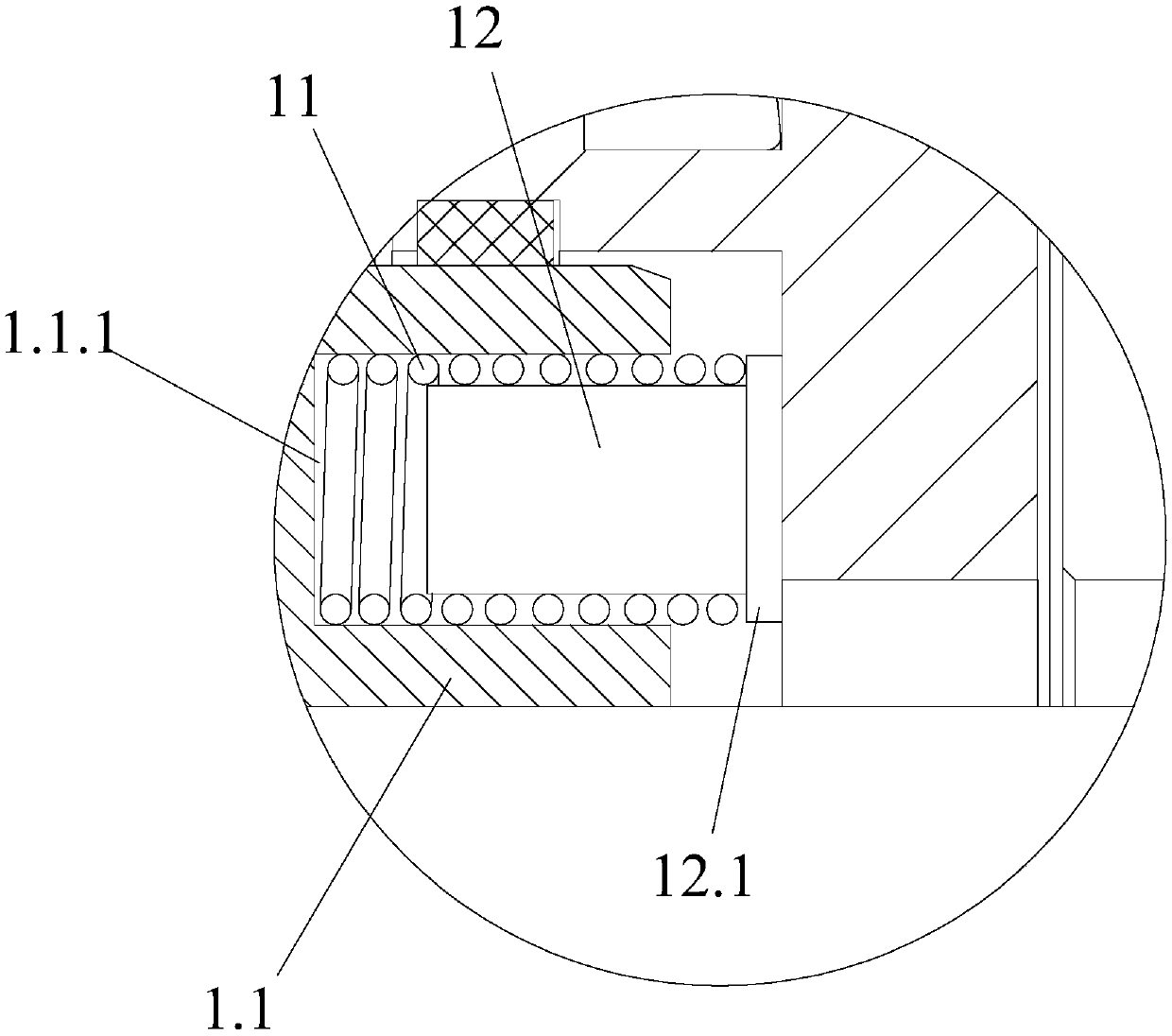

Mechanical sealing device for water jetting propeller pump

The invention discloses a mechanical sealing device for a water jetting propeller pump. The mechanical sealing device comprises a mounting flange, a static ring assembly and a dynamic ring assembly which are sequentially arranged on a rotating shaft in a sleeving manner, a mounting shaft is arranged at the end, close to the static ring assembly, of the mounting flange, one end of the static ring assembly is installed on the mounting shaft in sliding, sealed and sleeving manners, an elastic compensating component is arranged between the end surface of the static ring assembly and the end surface of the mounting shaft, and a limit retaining spring is further arranged on the static ring assembly to be used for preventing the static ring assembly from leaving the mounting shaft; the exterior of the end, close to the mounting shaft, of the static ring assembly is sleeved with a rubber corrugated pipe, and the other end of the rubber corrugated pipe is connected to the mounting flange; and the dynamic ring assembly and the rotating shaft in driven connection through a transmission pin, and the friction surface of the dynamic ring assembly is attached to the other end face of the static ring assembly to form a sealed grinding surface. The mechanical sealing device for the water jetting propeller pump has the advantages of being simple in structure and good in sealing performance and being capable of effectively preventing sediment from entering a sealing seat, damaging the sealing ring and destroying the sealing surface.

Owner:洛普兰机械设备(宁波)有限公司

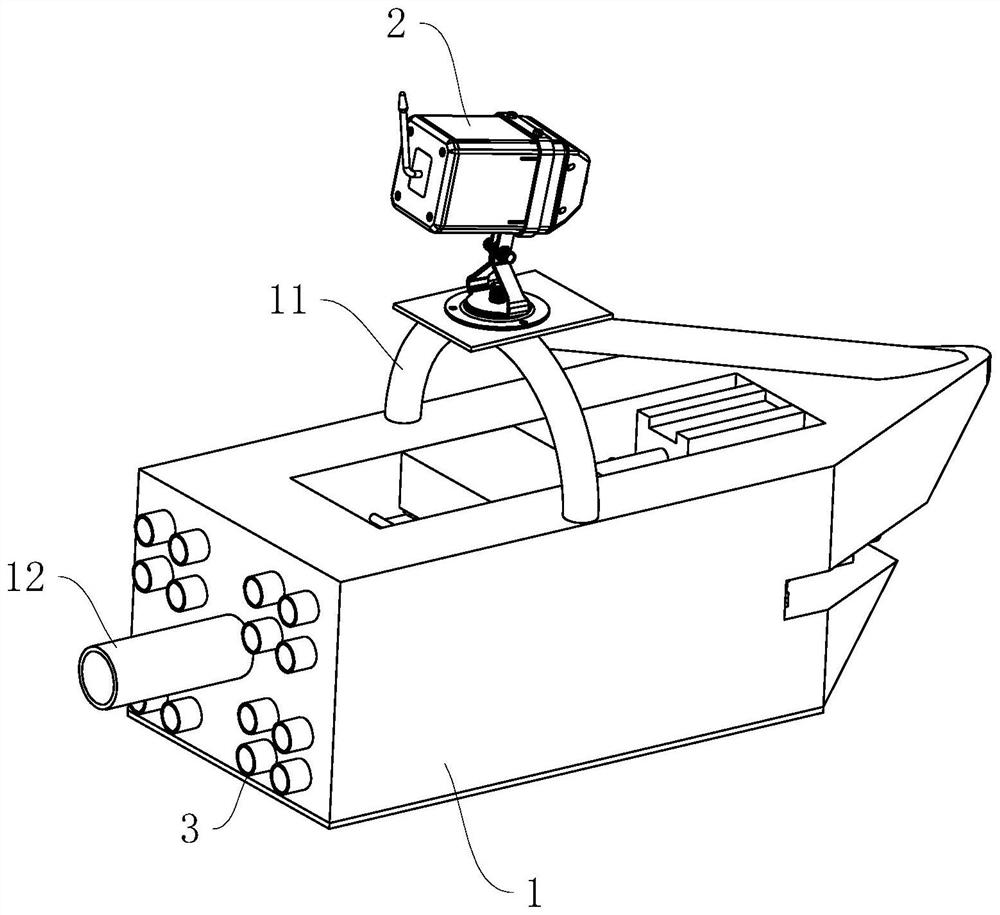

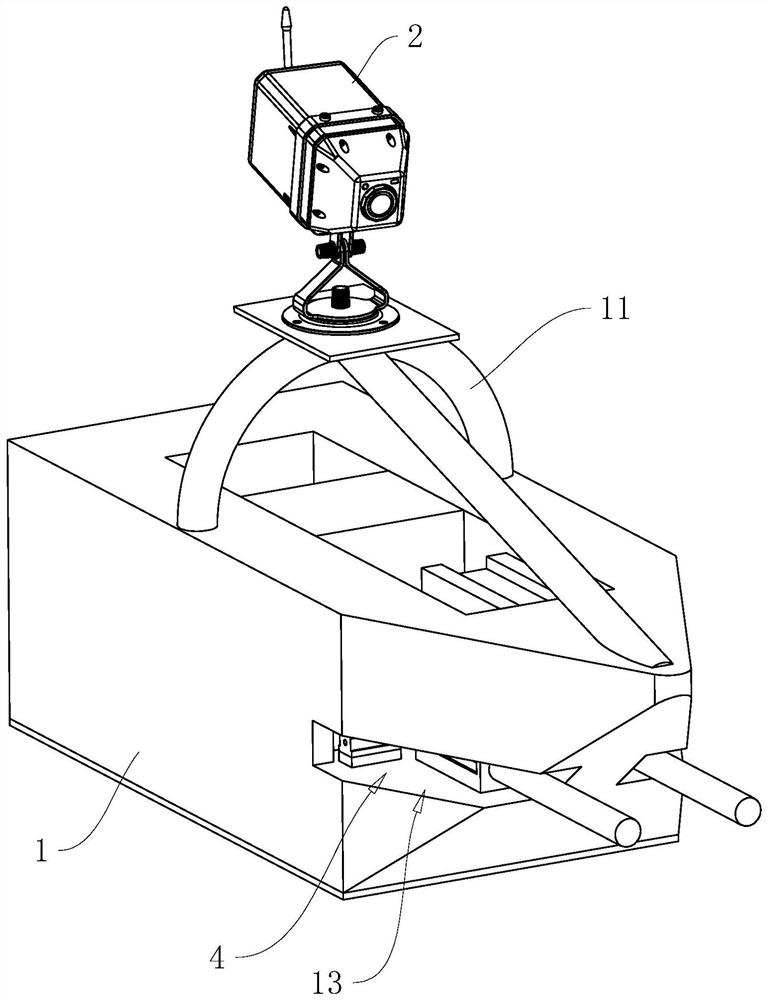

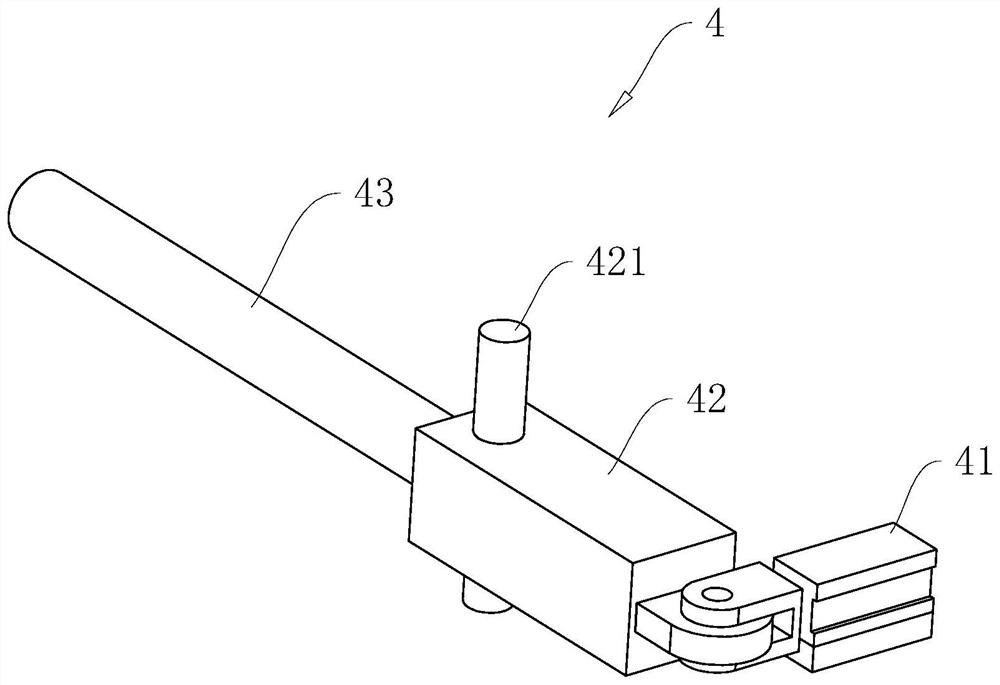

Intelligent pipeline dredging trolley

The invention relates to an intelligent pipeline dredging trolley, and belongs to the technical field of pipeline cleaning. The device comprises a trolley body, a camera mounted at the top of the trolley body and a dredging nozzle arranged at the tail of the trolley body; an obstacle removing mechanism is installed on the head portion of the trolley body and comprises a pushing hydraulic cylinder fixedly connected with the trolley body, a horizontal hydraulic cylinder located in the trolley body and a shifting rod used for shifting obstacles, and a piston rod of the pushing hydraulic cylinder is rotationally connected with the horizontal hydraulic cylinder. An included angle is formed between the pushing hydraulic cylinder and the horizontal hydraulic cylinder, the horizontal hydraulic cylinder is rotationally connected into the trolley body, a piston rod of the horizontal hydraulic cylinder is fixedly connected with a shifting rod, and the end, away from the horizontal hydraulic cylinder, of the shifting rod extends out of the trolley body. Sludge blocks in front of the trolley body are pushed away through the obstacle removing mechanism, so that the trolley body can still run in the pipeline when being blocked by the sludge blocks.

Owner:浙江上鑫生态建设有限公司

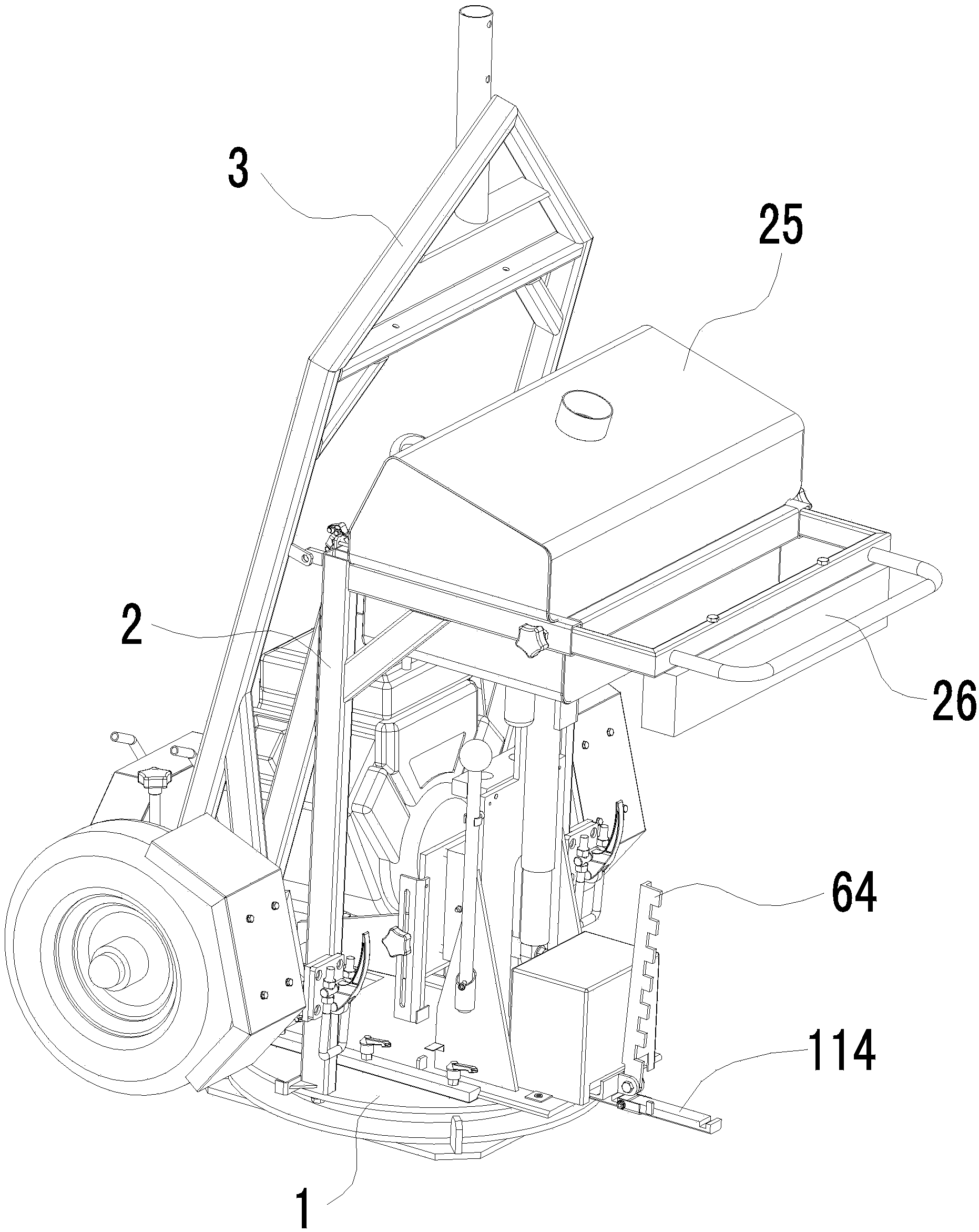

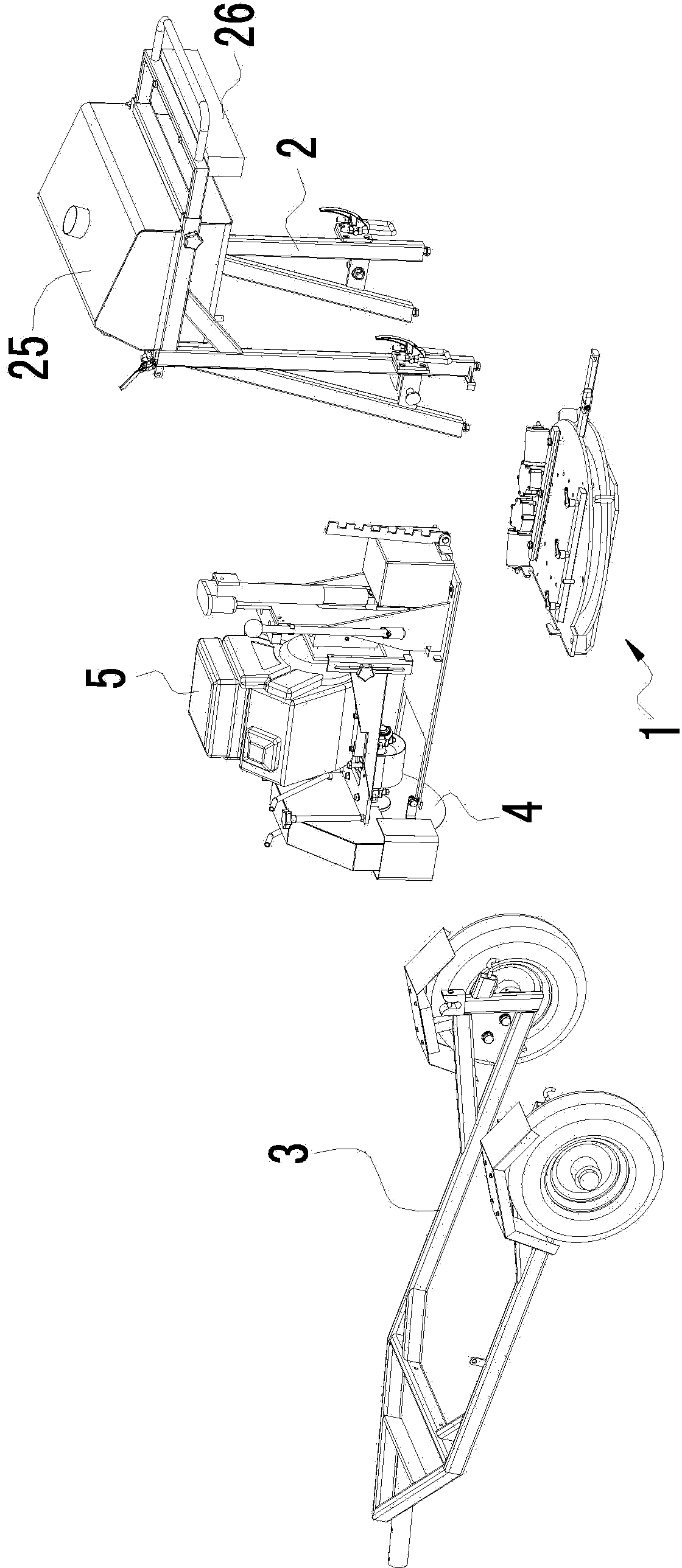

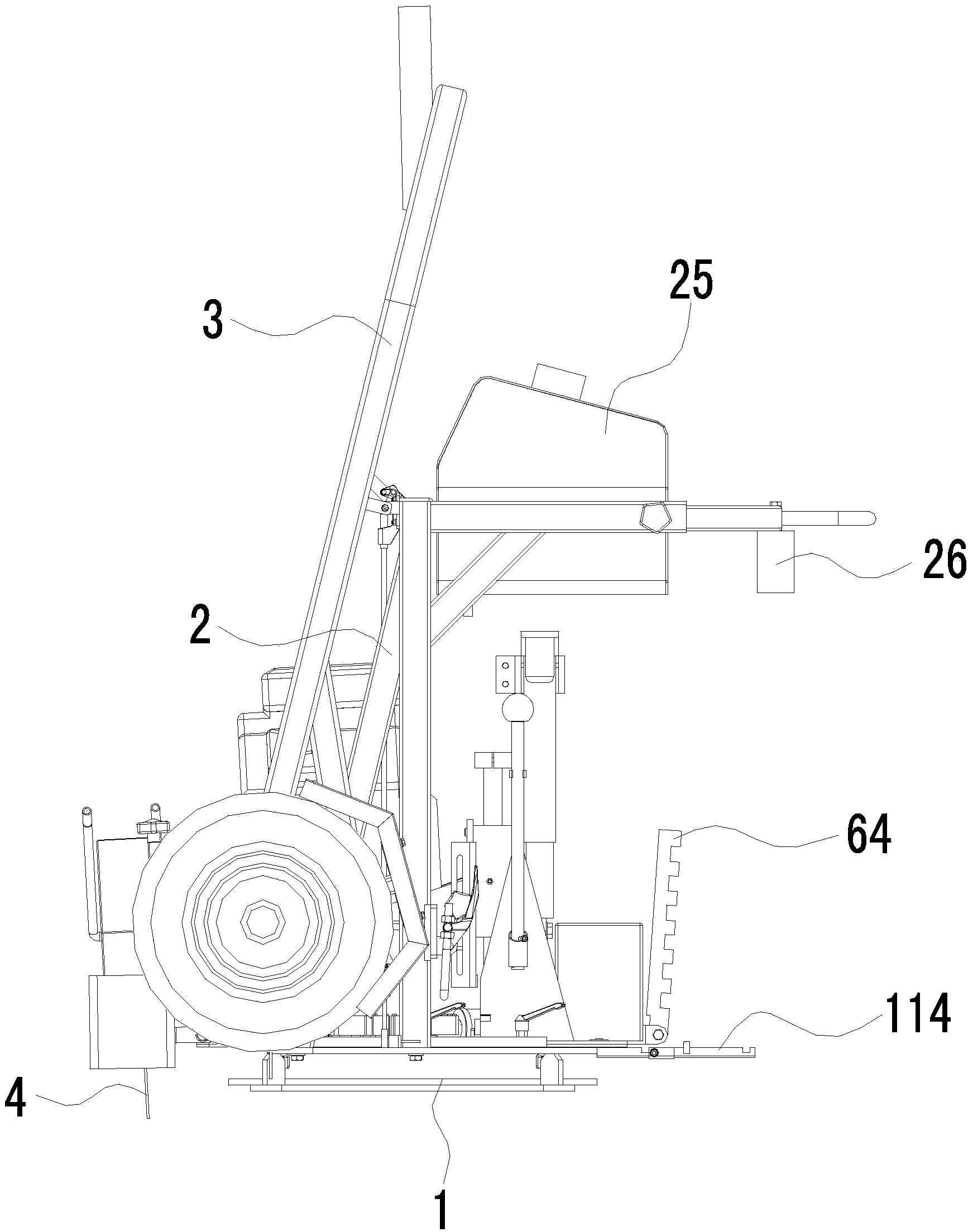

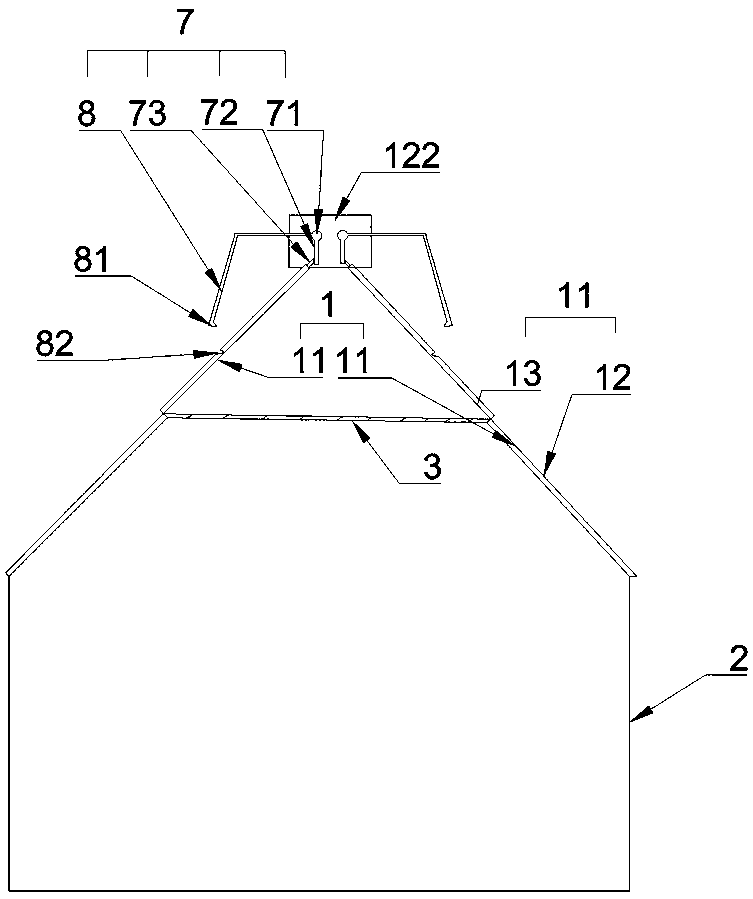

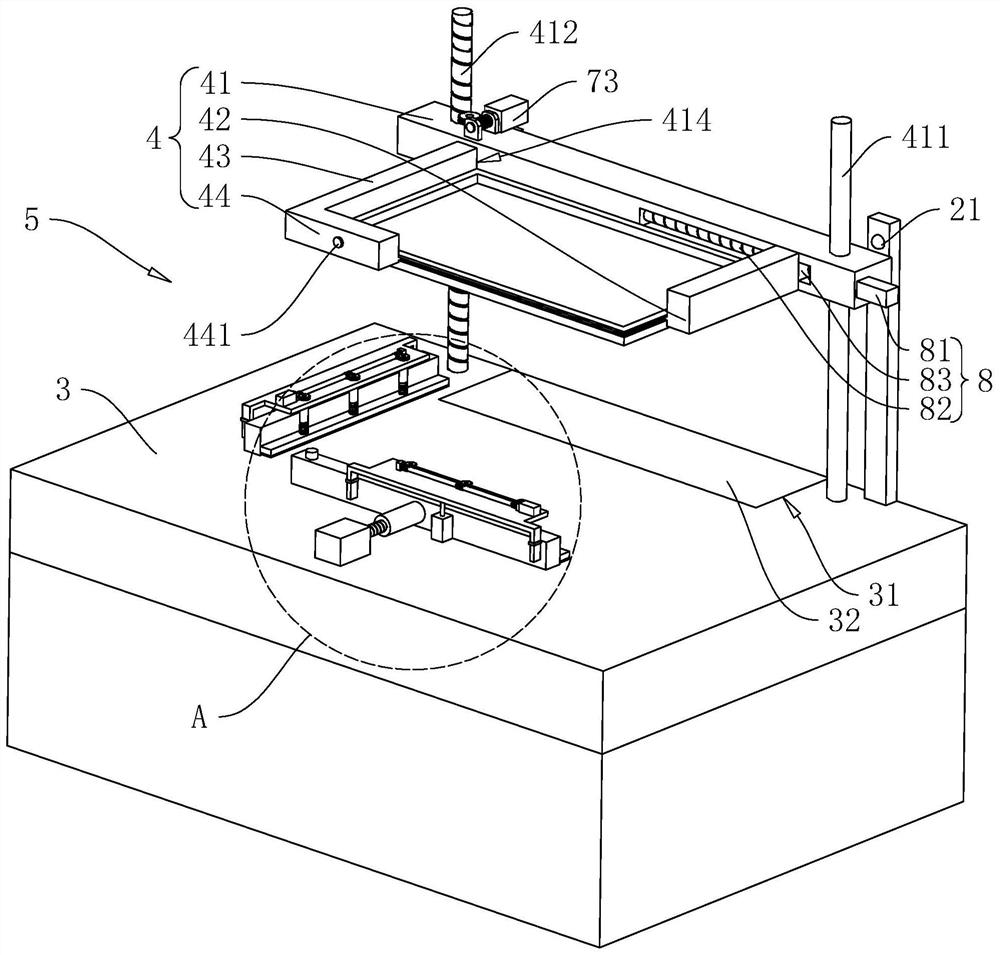

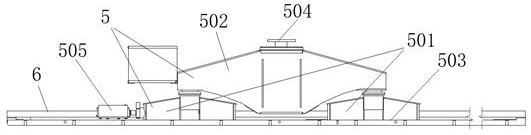

Megawatt tower type photo-thermal power generation heat collector mounting method and mounting system device

ActiveCN112429666ASave installation timeImprove installation qualitySafety devices for lifting equipmentsSolar thermal energy generationThermodynamicsCollector device

The invention discloses a megawatt tower type photo-thermal power generation heat collector mounting method and mounting system device. The method is characterized in that at first, a heat absorptiontower is built on the ground at a tower type photo-thermal power generation heat collector mounting position, and according to the size of the tower type photo-thermal power generation heat collector,an internal space for tower type photo-thermal power generation heat collector hoisting is reserved in the heat absorption tower; then, the tower type photo-thermal power generation heat collector isintegrally assembled on the ground; the assembled tower type photo-thermal power generation heat collector integrally slides to the center in the heat absorption tower from an assembly site by sliding devices through a sliding channel; and finally, the megawatt tower type photo-thermal power generation heat collector is integrally hoisted from the bottom of the heat absorption tower to the top ofthe heat absorption tower by using gantries and a hydraulic crane at the top of the heat absorption tower, and integrally mounted by using a support frame. According to the method, the megawatt tower-type photo-thermal power generation heat collector is assembled on the ground at first, and is integrally hoisted to the tower top from the interior of the heat absorption tower so that the construction period can be effectively shortened, a large amount of aloft work can be reduced, and the safety construction can be greatly guaranteed.

Owner:HUNAN THERMAL POWER CONSTR CO LTD OF CHINA ENERGY ENG GRP +1

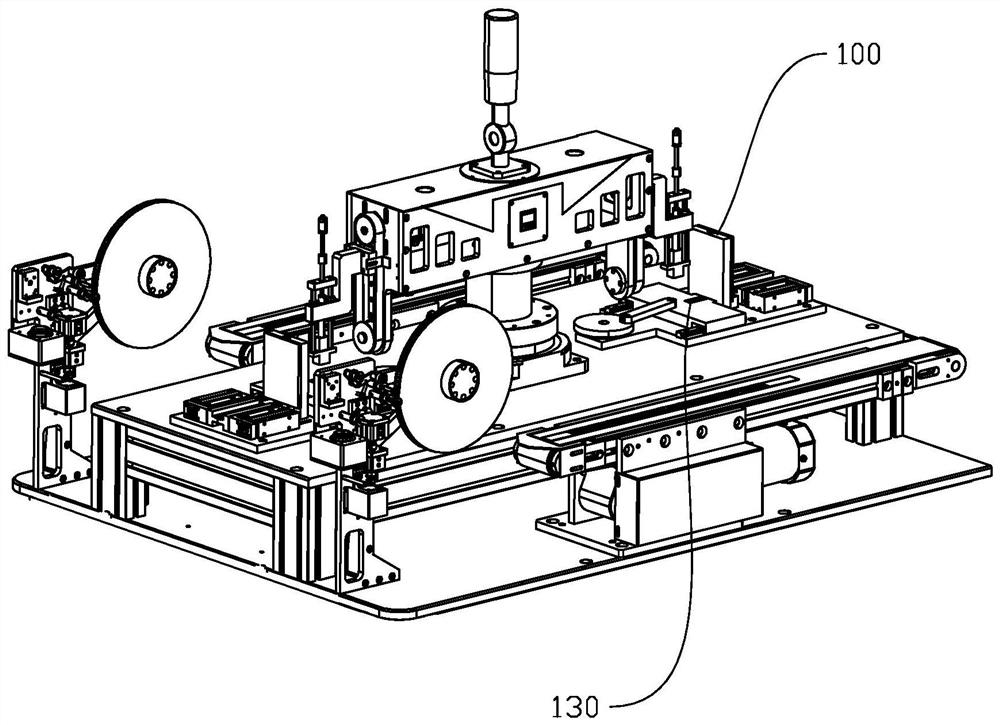

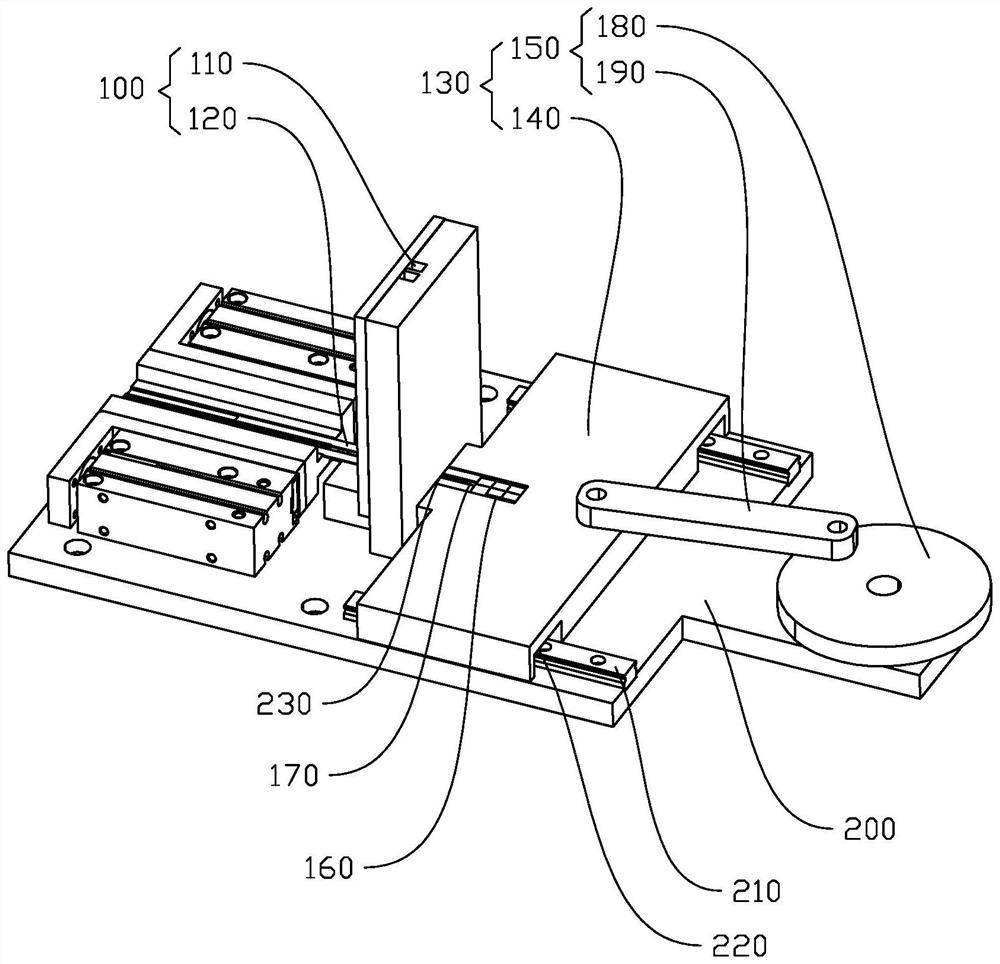

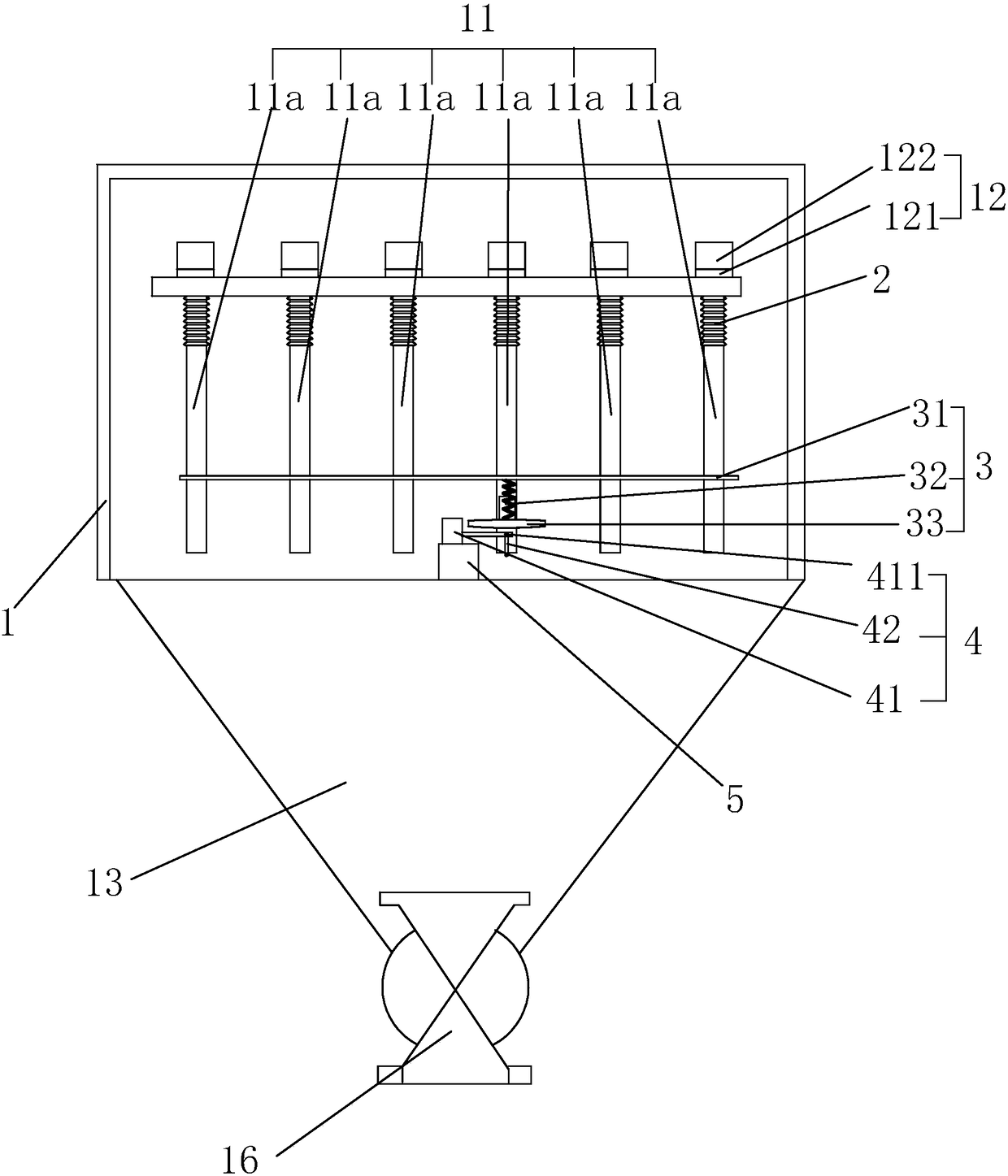

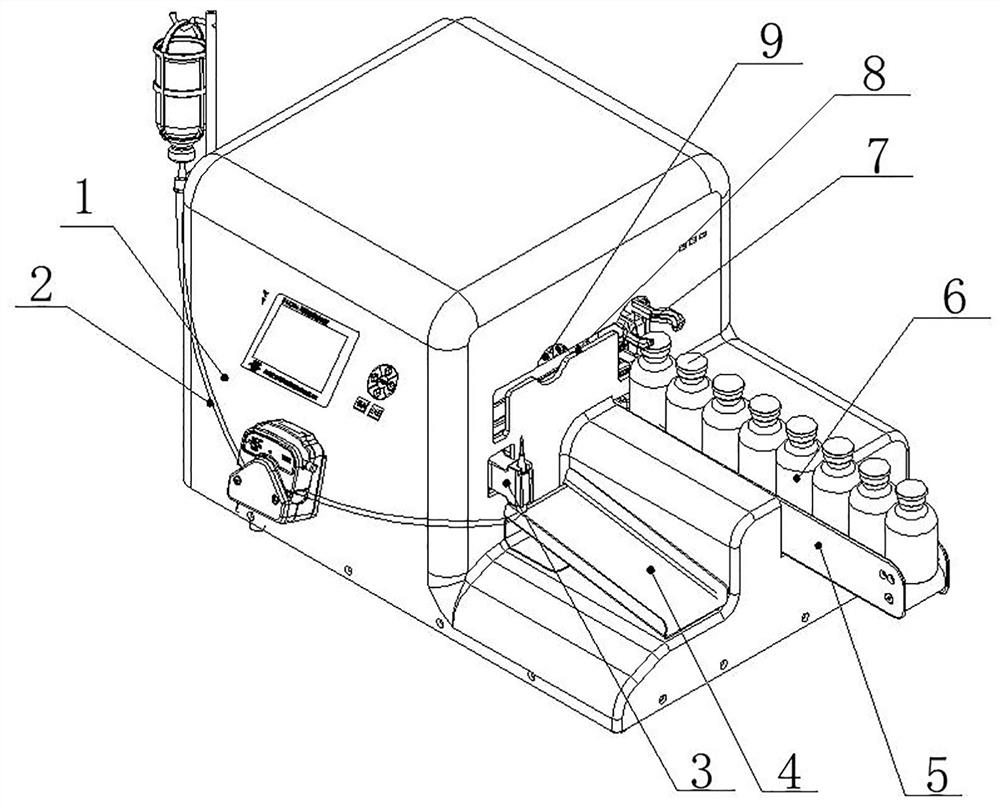

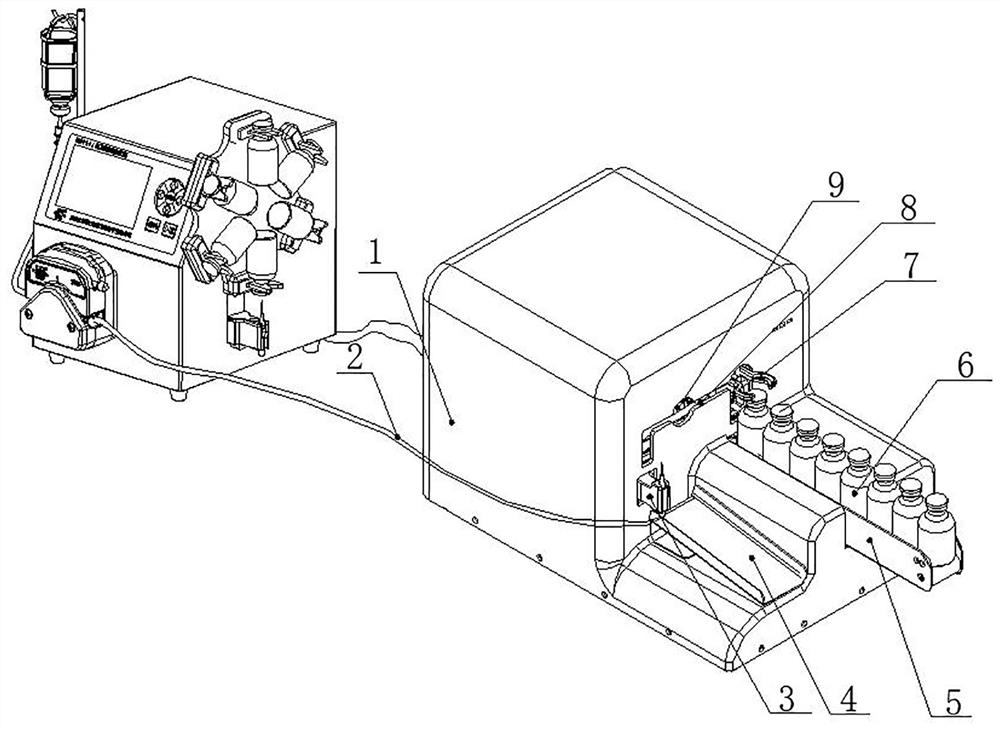

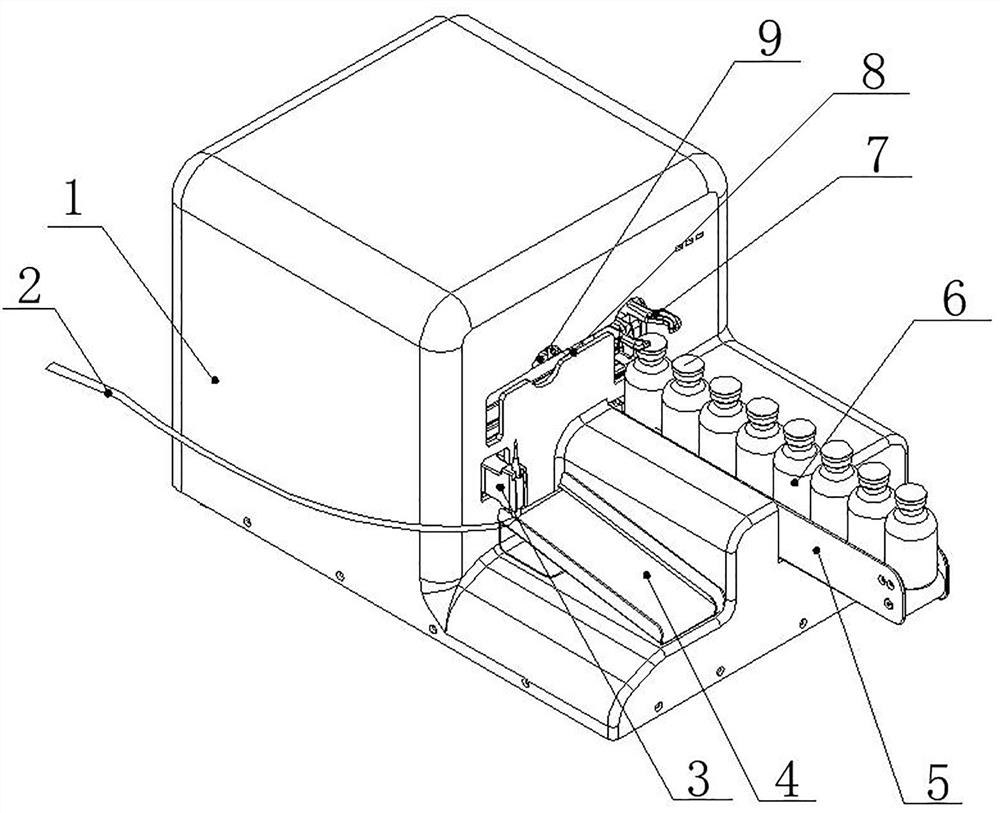

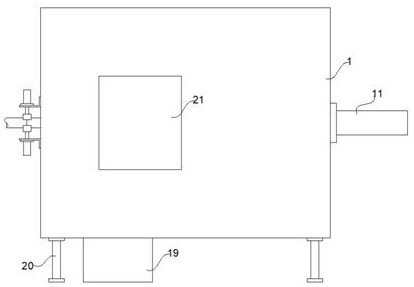

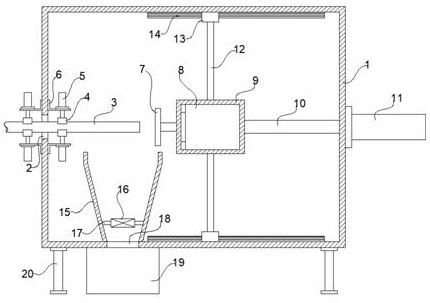

Automatic and continuous medicine dispensing device and medicine dispensing method for multiple medicine bottles

PendingCN113526116AImprove work efficiencySave human effortConveyorsPharmaceutical containersProcess engineeringDispensing medications

The invention belongs to the technical field of medicine dispensing, and discloses an automatic and continuous medicine dispensing device and medicine dispensing method for multiple medicine bottles so as to solve the problem that automatic and continuous medicine dispensing cannot be achieved in the prior art. The medicine dispensing device comprises a medicine liquid pumping mechanism, and one end of the medicine liquid pumping mechanism is connected with a motor liquid bottle. The medicine dispensing device further comprises a medicine bottle conveying mechanism arranged on the side of a machine shell, a puncturing mechanism connected with the medicine liquid pumping mechanism and a medicine bottle clamping mechanism arranged in the machine shell. The medicine bottle clamping mechanism can move vertically and horizontally under driving of a power device, the medicine bottle clamping mechanism can clamp or loosen medicine bottle bodies, and the medicine bottle clamping mechanism is used for taking medicine bottles in cooperation with the medicine bottle conveying mechanism and achieving puncturing in cooperation with the puncturing mechanism. The automatic and continuous medicine dispensing device and medicine dispensing method can achieve the actions of automatic medicine bottle conveying, bottle taking, puncturing, bottle abandoning and the like and cooperate with an automatic pumping mechanism, the working efficiency is improved, manpower is saved, and continuous medicine dispensing of multiple medicine bottles can be achieved under mutual cooperation of the medicine bottle conveying mechanism, the medicine bottle clamping mechanism, the puncturing mechanism and the medicine liquid pumping mechanism.

Owner:LANZHOU WENHE MEDICAL EQUIP RES & DEV CO LTD +1

Grinding equipment for PVC pipe port

PendingCN113649876AClamp firmlySimple structureGrinding carriagesGrinding drivesHydraulic cylinderElectric machinery

The invention discloses grinding equipment for a PVC pipe port. The grinding equipment comprises a grinding box and a grinding insertion hole, the grinding insertion hole is formed in the side wall of the grinding box, a PVC pipe is connected into the grinding insertion hole in an inserted mode, clamping mechanisms are symmetrically arranged on the inner side and the outer side of the grinding insertion hole, each clamping mechanism comprises arc-shaped clamping sleeves symmetrically arranged on the upper side and the lower side, the arc-shaped clamping sleeves on the upper side and the lower side clamp and fix the PVC pipe, the arc-shaped clamping sleeves are fixedly connected to the telescopic tail ends of air cylinders, the air cylinders are connected with the grinding box through L-shaped supporting plates, grinding discs are correspondingly arranged at the port positions of the PVC pipe and fixedly connected to the output end of a grinding motor, the grinding motor is installed in a motor shell, the motor shell is fixedly connected with the tail end of a telescopic rod, the telescopic rod is integrally connected with a hydraulic cylinder, and the hydraulic cylinder is fixedly installed on the outer wall of the grinding box. By the adoption of the technical scheme, and the grinding equipment is simple in structure, convenient to assemble and install, stable and efficient in grinding treatment and uniform in grinding treatment.

Owner:六安市强盛塑胶有限公司

Transportation device for wood movable-type printing device

PendingCN109775084AReduce contact areaIncrease contact areaDrawer-and-shell containersMovable typeEngineering

The invention discloses a transportation device for a wood movable-type printing plate. According to the technical scheme, the transportation device is characterized in that a first storage groove, asecond storage groove and a third storage groove are included, wherein a storage box surrounds the outer portions of the first storage groove, the second storage groove and the third storage groove; storage cavities for containing movable types and filling blocks are evenly distributed in the first storage groove; the first storage groove is internally provided with a circular groove for containing inkstone, a first square groove for containing a transverse brush, a second square groove for containing a vertical brush and a three-dimension groove for containing a plurality of partition strips;the third storage groove is provided with a containing groove for containing wood boards, a telescopic plate is arranged in the containing groove, the face, opposite to the containing groove, of thetelescopic plate is provided with a telescopic spring, one end of the telescopic spring is fixedly connected with the telescopic plate, and the other end of the telescopic spring is fixedly connectedwith the groove wall of the containing groove; the position, close to the end portion, of the telescopic plate is provided with an auxiliary device for assisting telescopic plate sliding; and by meansof the device, a wood movable-type printing tool can be protected against damage in the transportation process.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com