Cutting radius adjusting mechanism of circumference cutter

A technology of radius adjustment and cutting machine, applied in the direction of road, road repair, road, etc., can solve the problems of large area of filling new material, consumption of new filling material, inconvenient vehicle traffic, etc., achieving less circular deviation, high work efficiency, Overall strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

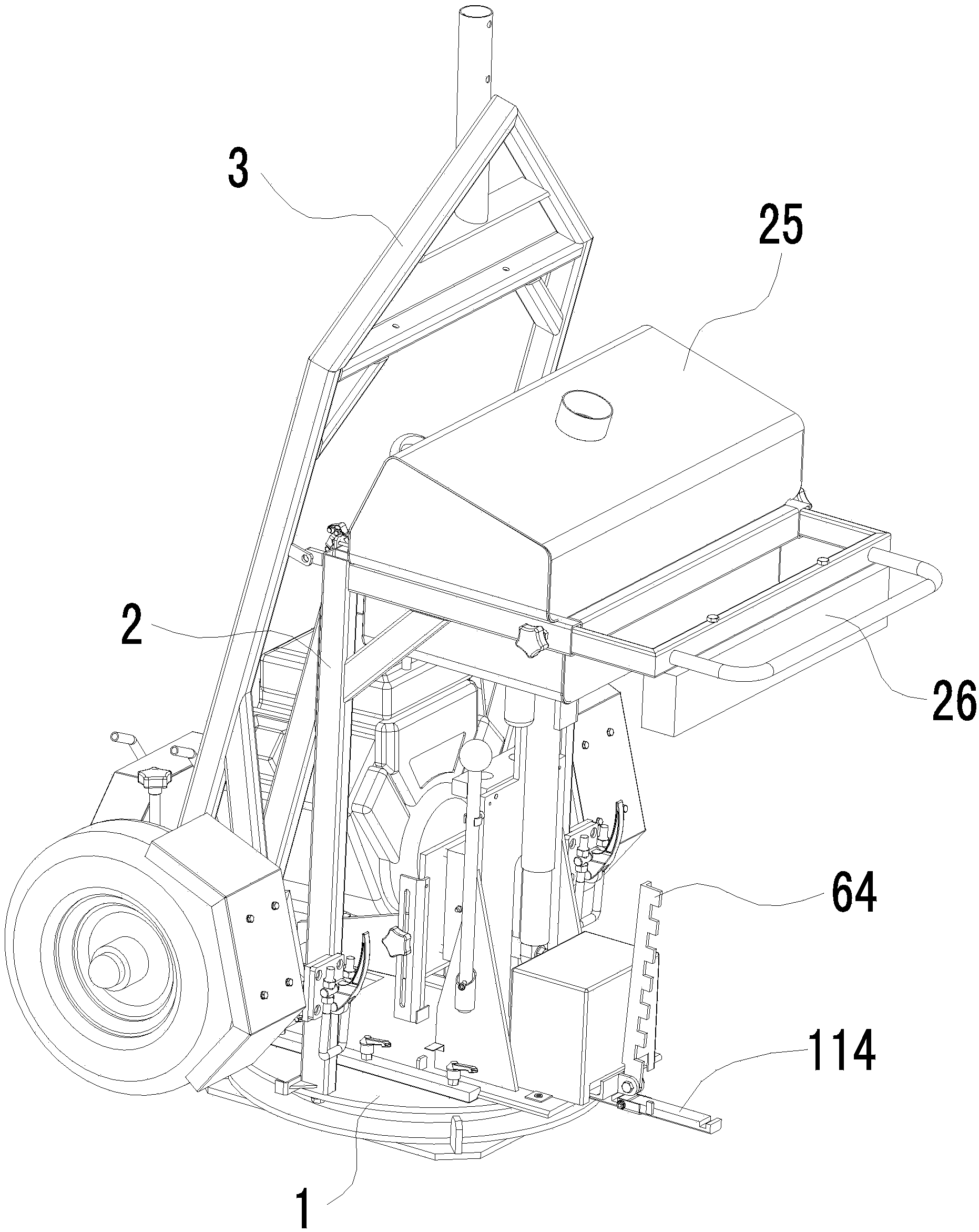

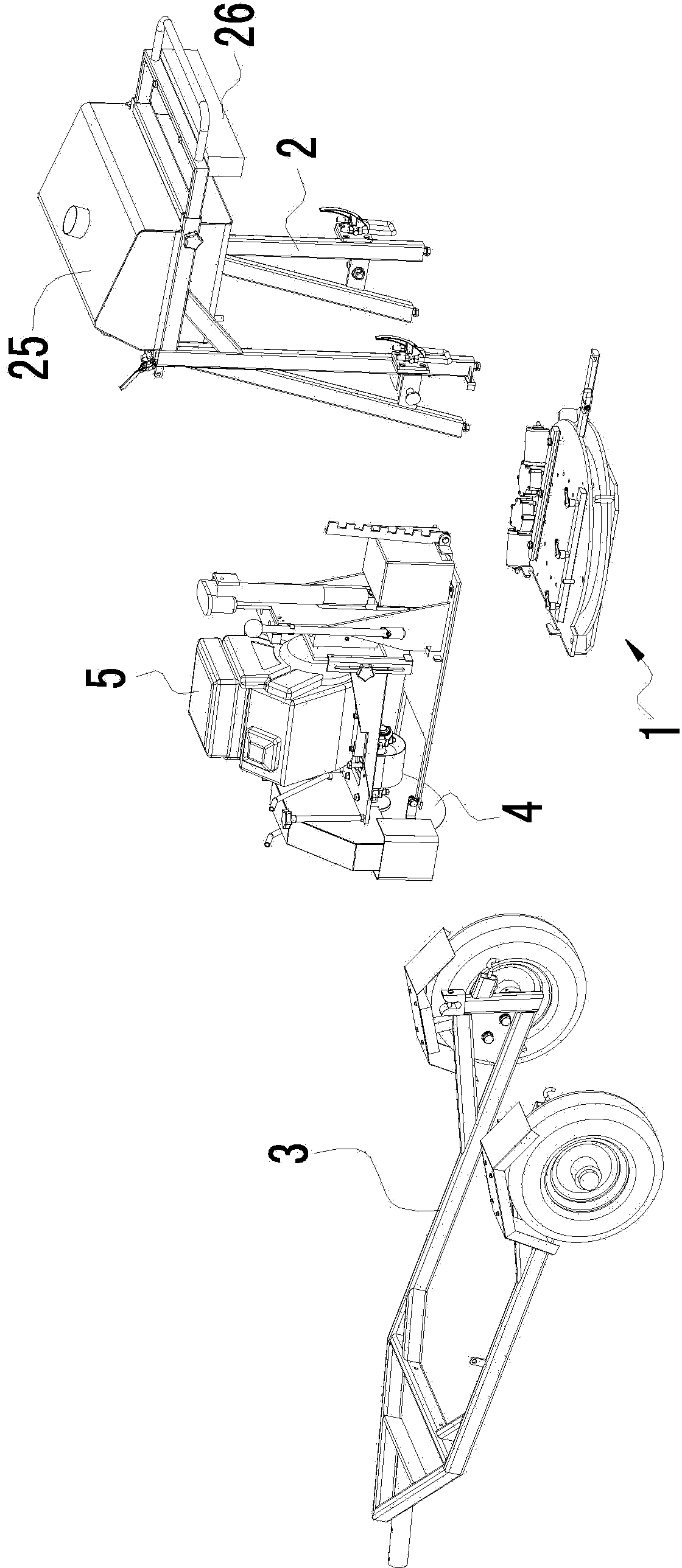

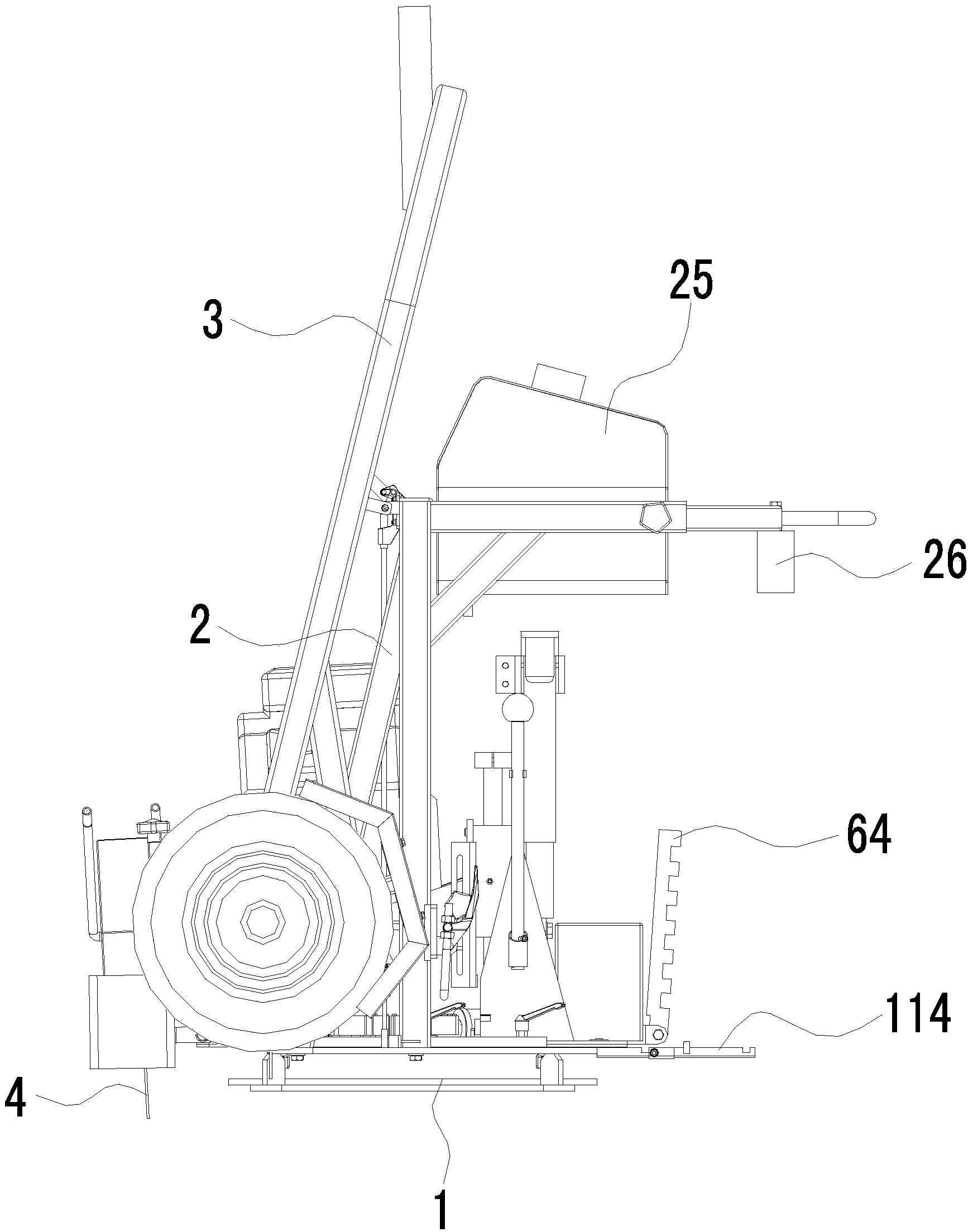

[0045] Such as Figure 1 to Figure 17 As shown, a cutting radius adjustment mechanism of a circular cutting machine, the circular cutting machine includes a base 1 and a cutting machine body installed on the base 1, the cutting machine body includes a cutting piece 4 and a power device that drives the cutting piece 4 to rotate 5. The body of the cutting machine also includes a horizontal sliding plate 6 mounted on the base 1 in a horizontally slidable manner. The cutting piece 4 and the power unit 5 are installed on the horizontal sliding plate 6 and follow the horizontal sliding plate 6 to move horizontally. The base 1 is equipped with There is a locking plate mechanism that selectively allows or prevents the horizontal slide plate 6 from sliding horizontally.

[0046] The base 1 is provided with two parallel and spaced apart horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com