Alignment printing technology

A counterpoint printing and technology technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of consumption and increased screen printing costs, and achieve the effect of cost reduction and slip stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-4 The application is described in further detail.

[0042] The embodiment of the present application discloses an alignment printing technology, including the following steps:

[0043] S1. Make a screen printing screen for the pattern provided by the customer;

[0044] S2, deploying dyes for printing according to the screen screen pattern;

[0045] S3, install the screen plate and the dye on the printing device 1, and print the pattern on the substrate through the printing device 1;

[0046] S4. Dry and store the printed substrate after printing.

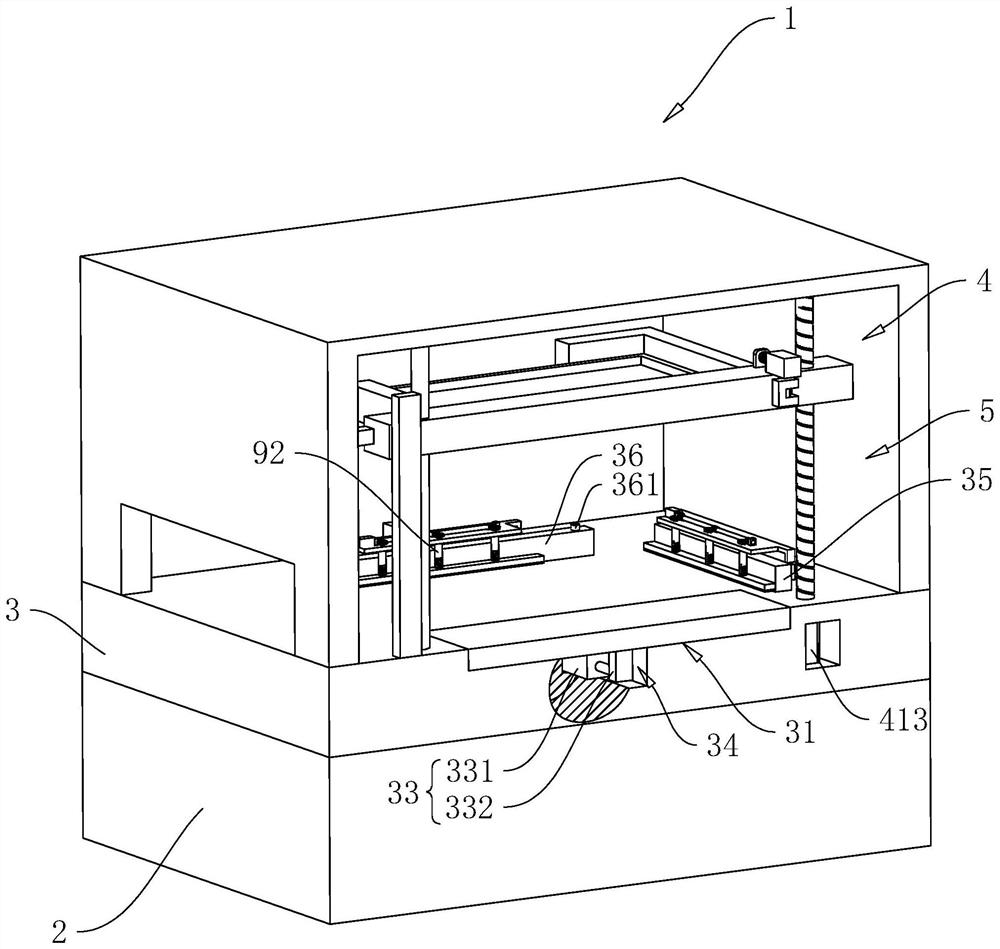

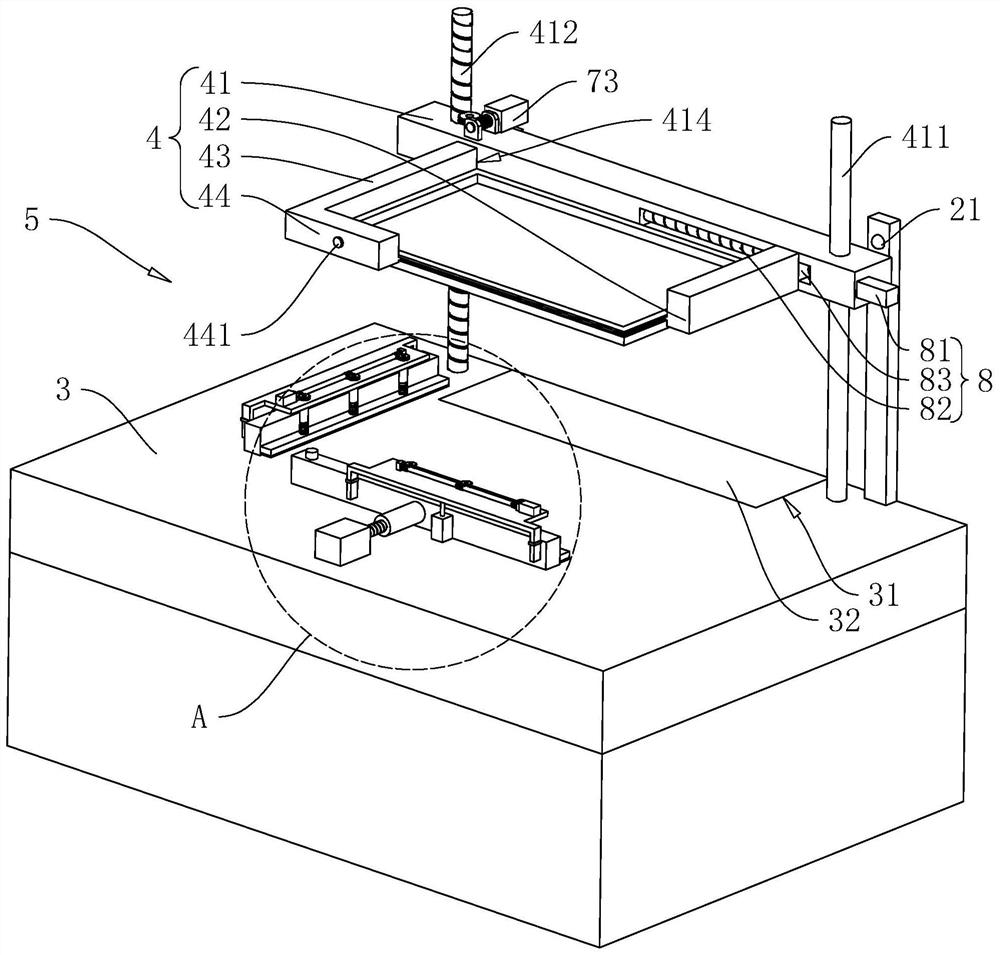

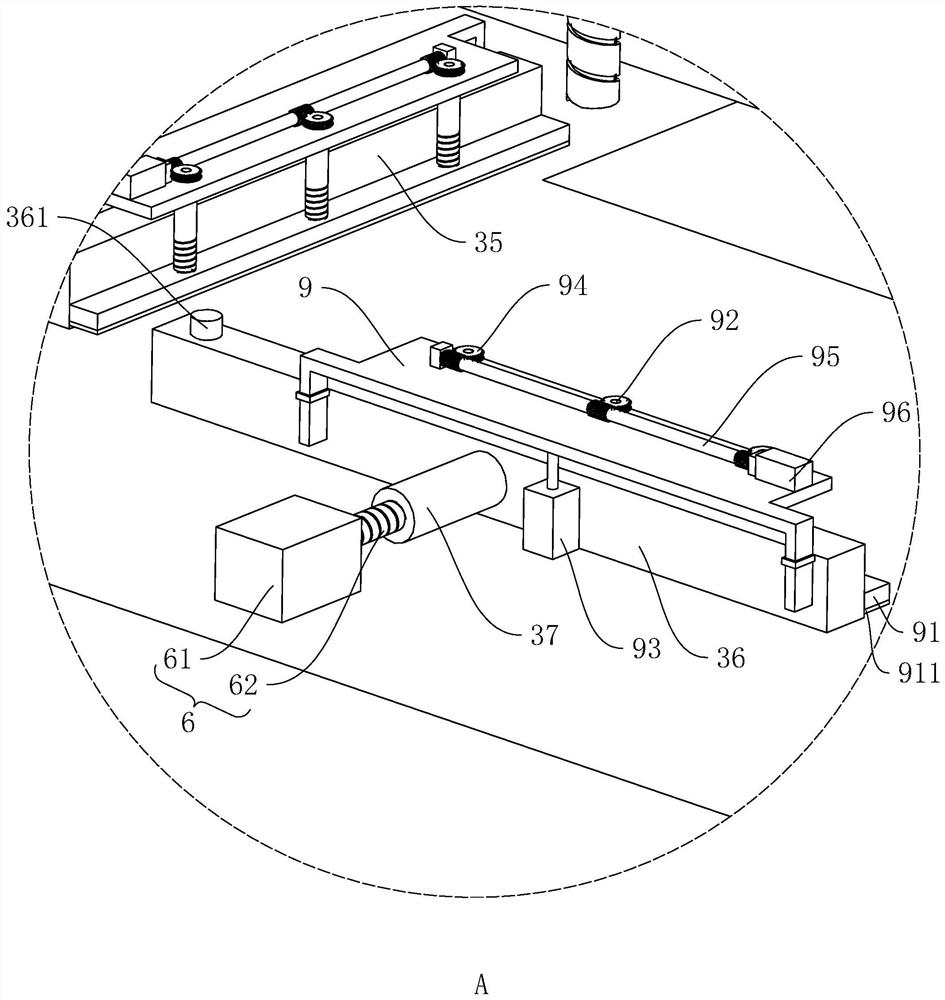

[0047] refer to figure 1 and figure 2 , the printing device 1 in S3 includes a frame 2 placed on the ground, on which a workbench 3 in the shape of a cuboid is fixedly installed, and the top wall of the workbench 3 is horizontal. One side of the top wall of the workbench 3 is provided with an installation groove 31, the installation groove 31 penetrates the side wall of the workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com