Multifunctional cylindrical cutting and beveling machine

A bevel cutting, multi-functional technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of blade replacement, troublesome replacement, easy to tilt, etc., to achieve stable sliding, good cutting effect, and stable movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

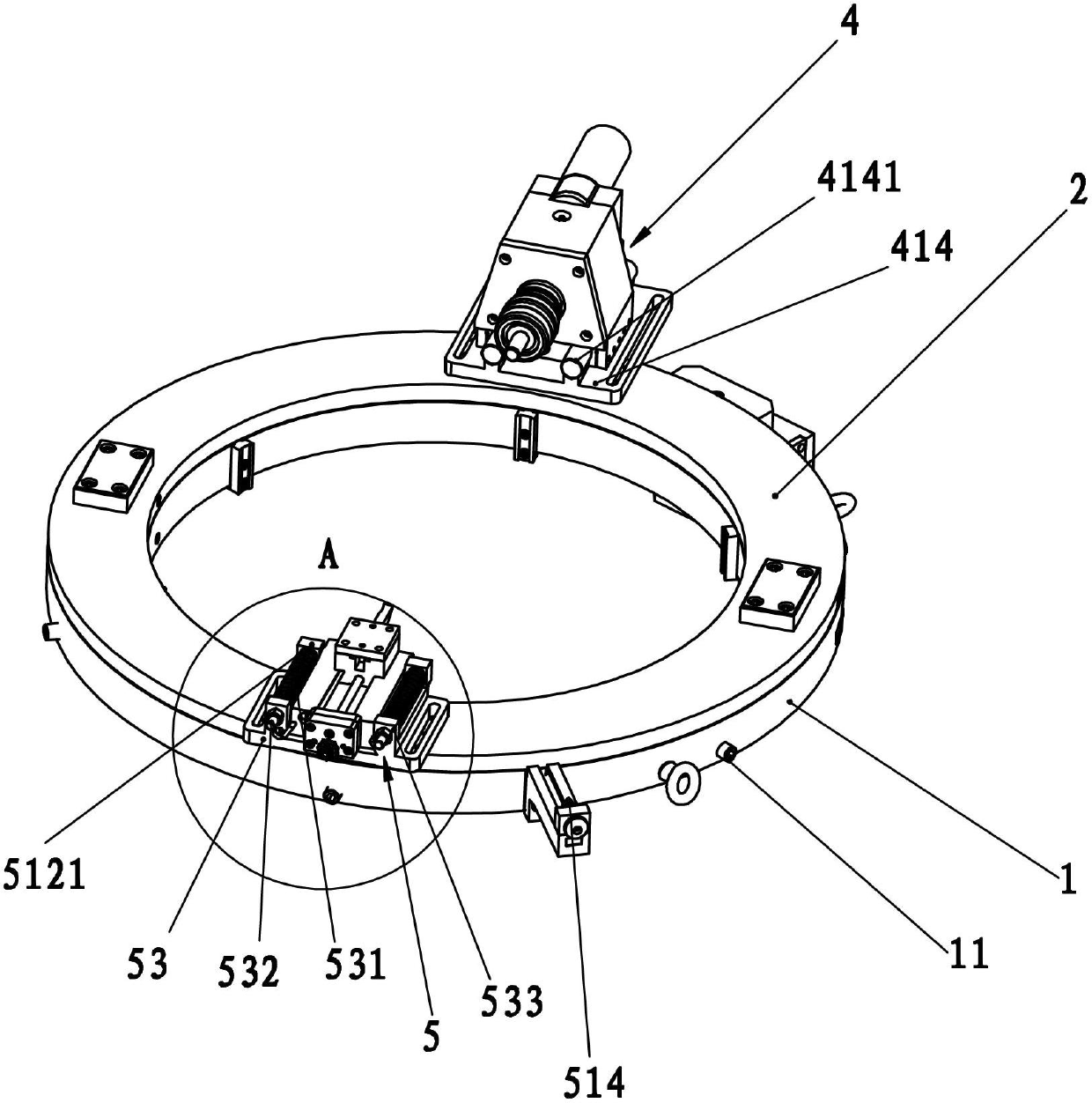

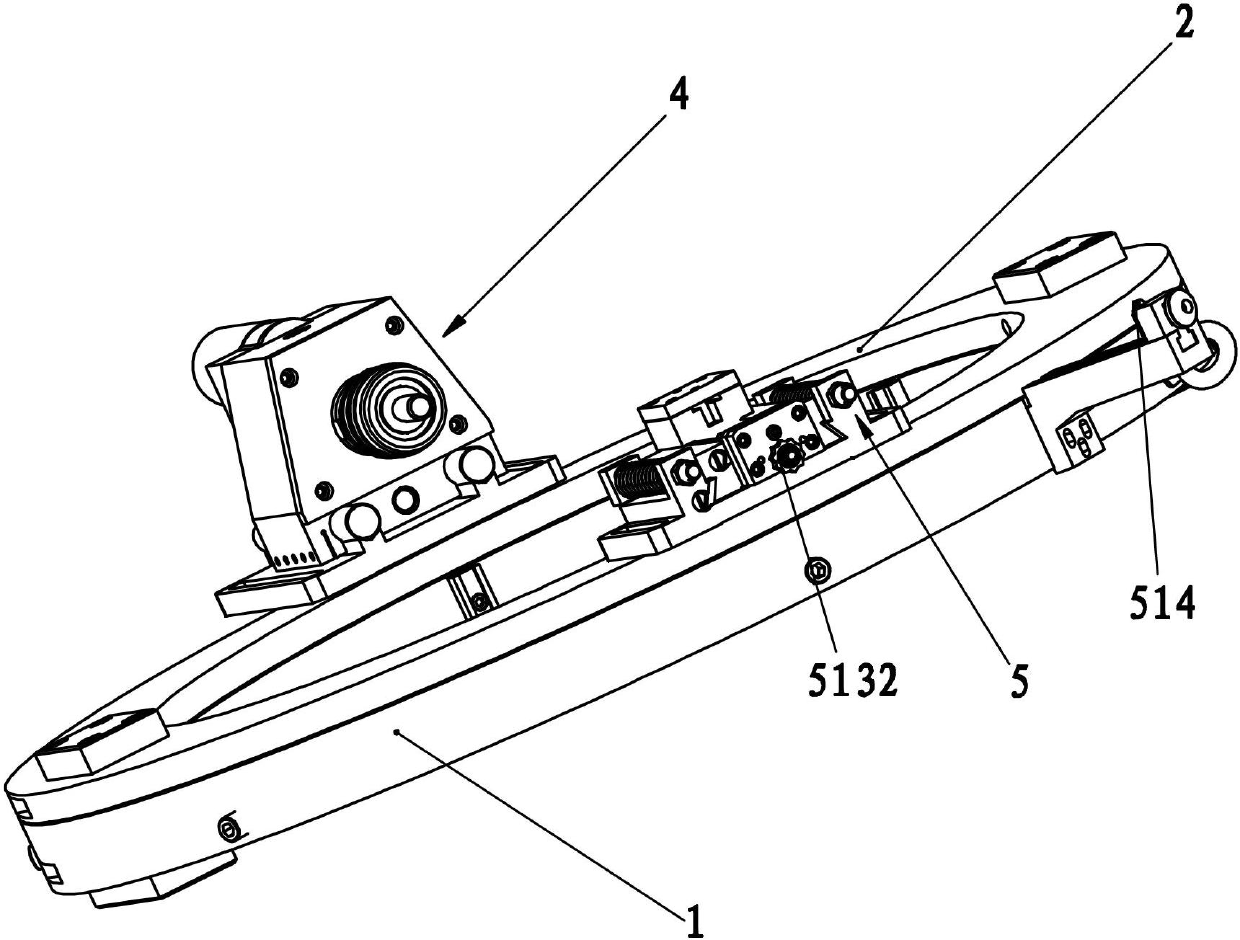

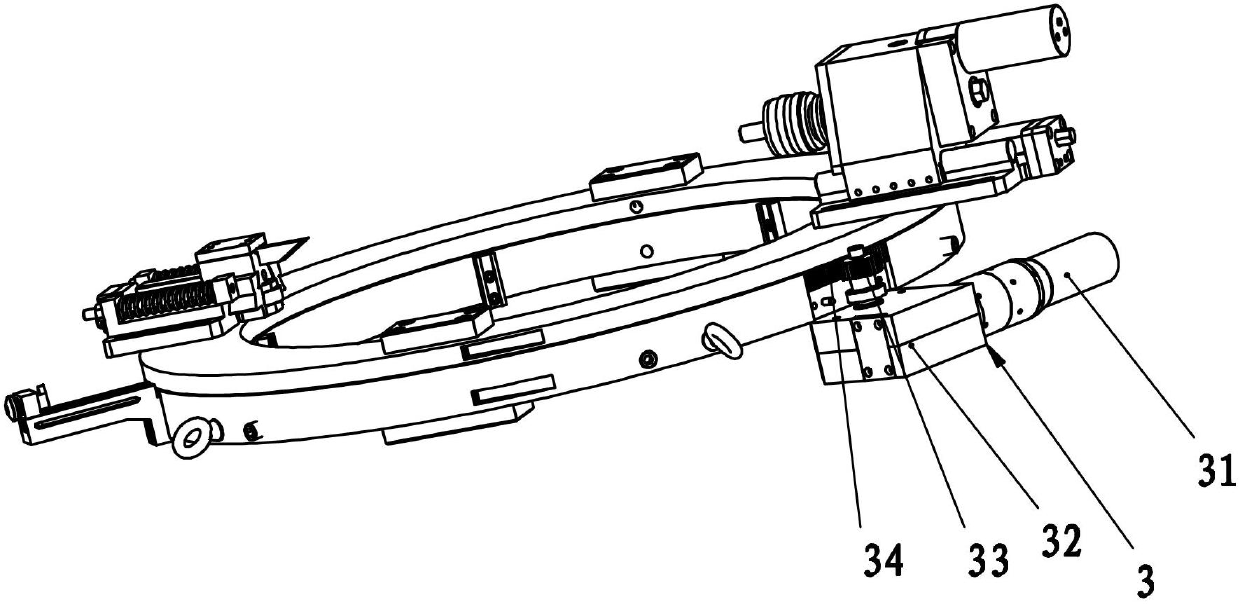

[0021] Such as figure 1 — Image 6 As shown, a multifunctional cylinder cutting and beveling machine includes a fixed disk 1 and a rotating disk 2. The fixed disk 1 is provided with a fixing bolt 11 that can realize fixed cooperation with the cylinder. The fixed disk 1 Between the rotating disk 2, there is a rotating device 3 that can realize the mutual rotation of the fixed disk 1 and the rotating disk 2. The rotating disk 2 is detachably provided with a cutting device 4 and a tracking groove device 5. In the embodiment of the present invention Among them, the cutting device 4 includes a propulsion mechanism 41 and a cutting rotation mechanism 42, wherein the cutting rotation mechanism 42 includes a base 421, a cutting bit holder 422, a transmission part 423 and a motor 424, and the output shaft of the motor 424 passes through the transmission part 423 Drive the cutting bit holder 422 to rotate, the cutting bit holder 422, the transmission part 423 and the motor 424 are dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com