Assembly equipment for double-layer spiral duct

A technology of spiral air duct and assembly equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as downward offset, installation resistance of inner spiral air duct, affecting the progress of double-layer spiral air duct assembly, etc. , to achieve the effect of ensuring assembly quality and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

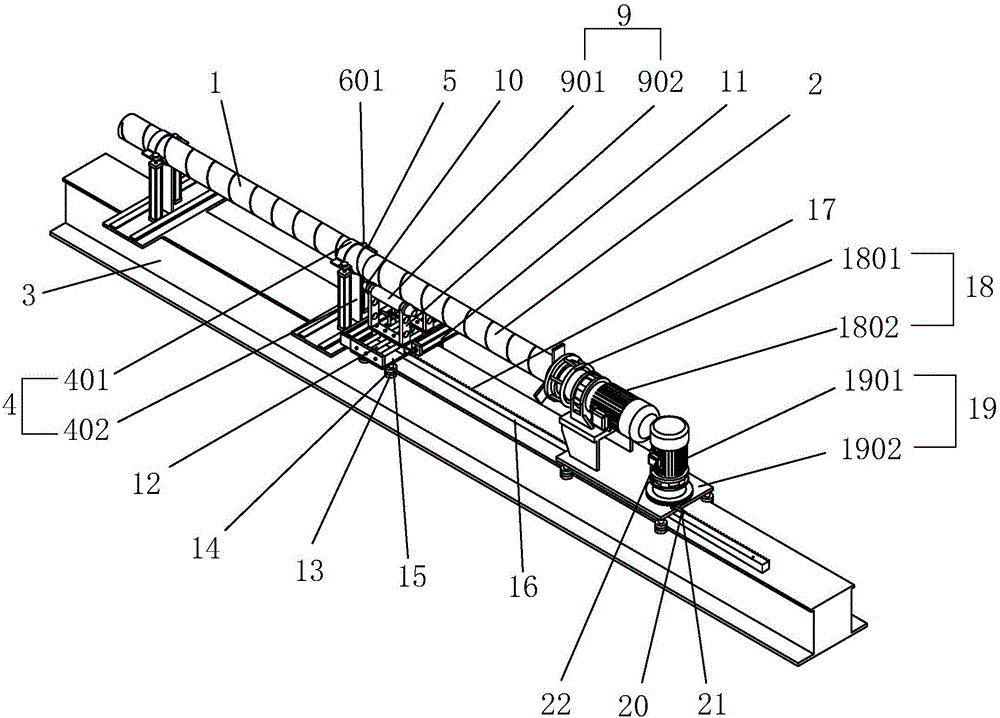

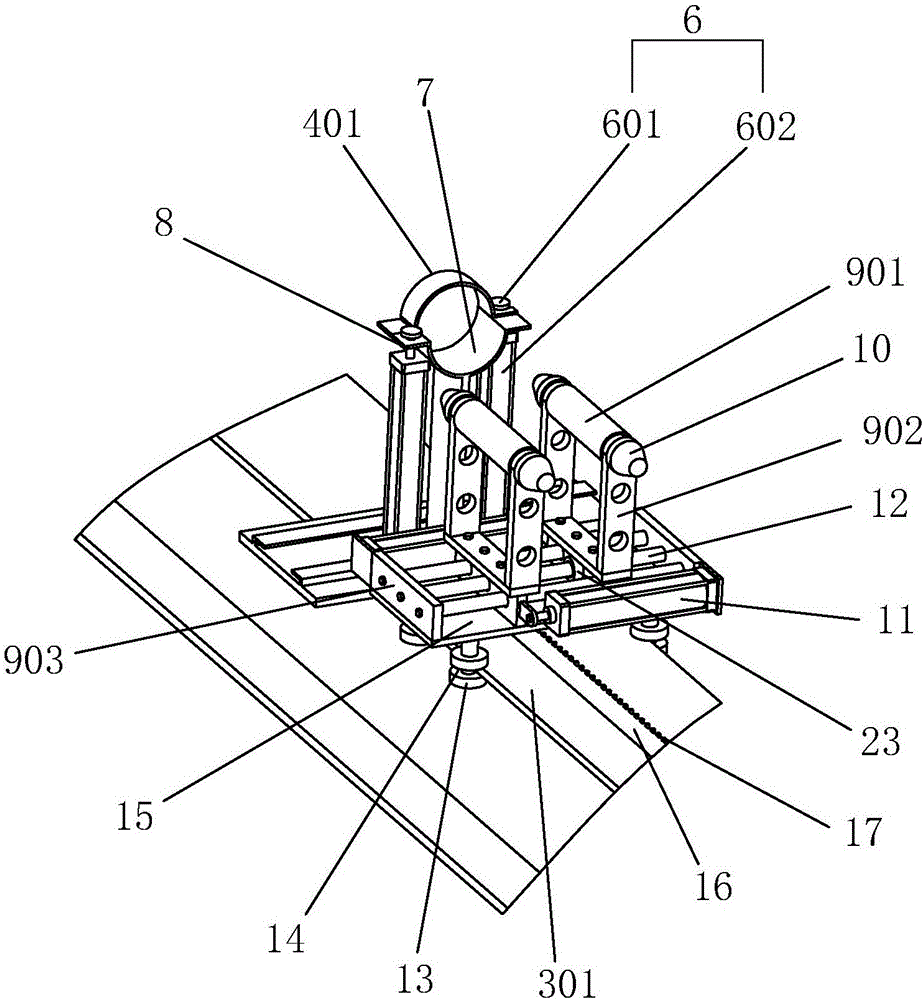

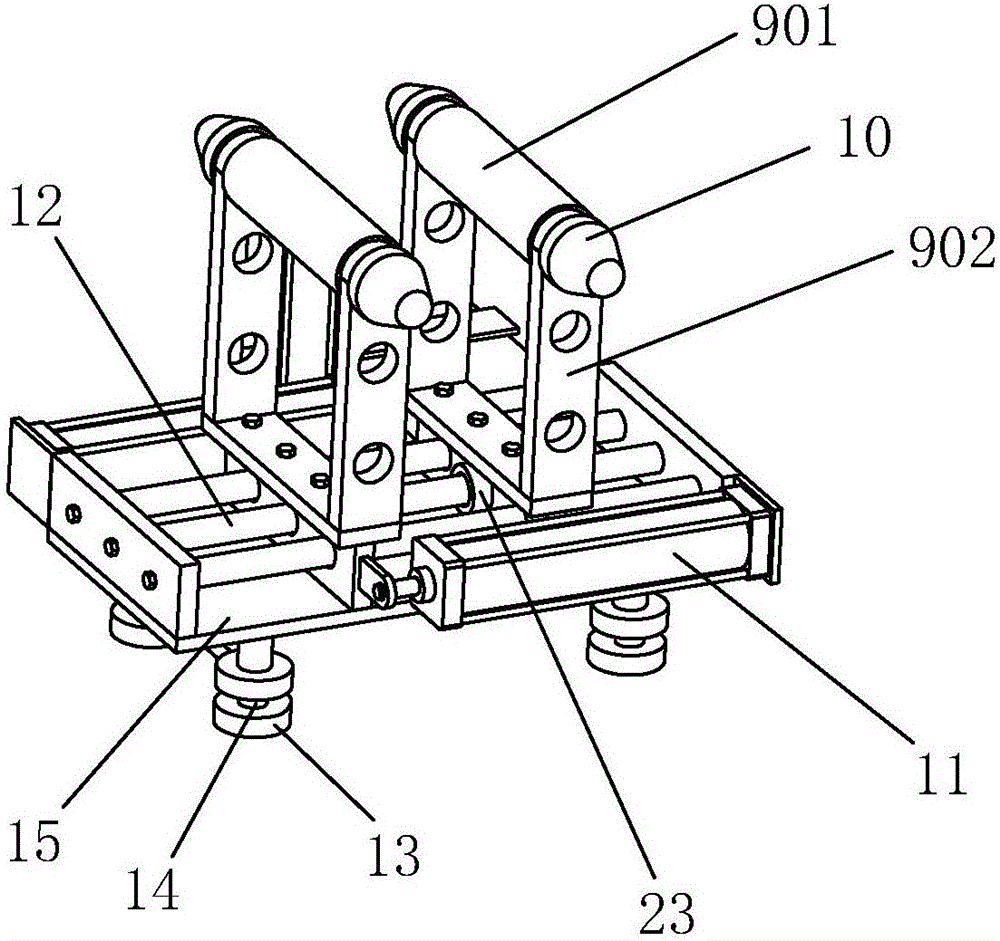

[0036] Embodiment 1: A kind of assembly equipment of double-layer spiral air duct, such as Figure 1 to Figure 3 As shown, it includes a frame 3, the frame 3 is a frame body in the shape of a cuboid, and the frame 3 is provided with a placement part 4 for placing and fixing the outer spiral air duct 1, and the placement part 4 includes a The placement frame 402 and the fixed ring 401 that are attached to the outer wall, the placement frame 402 is fixedly installed on the frame 3, the upper end of the placement frame 402 is recessed from top to bottom to form a placement groove 7, the inner wall of the placement groove 7 is connected to the outer spiral air duct 1 The outer pipe wall of the pipe is attached to prevent the outer spiral air pipe 1 from rolling in the axial direction. The shape of the fixed ring 401 is a semi-annular body, and one end of the semi-annular body is rotationally connected with the upper end surface of the placement frame 402. In this implementation In...

Embodiment 2

[0043] Embodiment 2: A kind of assembly equipment of double-layer spiral air duct, such as Image 6 As shown, the difference from Embodiment 1 is that on the basis of Embodiment 1, an elastic sleeve 28 is sleeved on the fixing ring 401, and an elastic gasket 27 is provided on the inner wall of the placement groove 7, and the elastic sleeve 28 and the elastic The gaskets 27 are made of elastic rubber material and have a certain degree of elasticity. Place the outer spiral air duct 1 in the fixing ring 401 and the placement groove 7. By setting the elastic sleeve 28 and the elastic gasket 27, the pressing block 601 is avoided. When the pressure is too high during the pressing down process, the fixed ring 401 may crush the outer spiral air duct 1, and the elastic sleeve 28 and the elastic gasket 27 play a role in buffering the pressure, which greatly improves the product quality of the outer spiral air duct 1 during the assembly process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com