Patents

Literature

124results about How to "Play a bearing role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geothermal energy collecting pile foundation and construction method thereof

ActiveCN102995627ARealize transmissionPlay a bearing roleOther heat production devicesGeothermal energy generationReinforced concreteHeat conducting

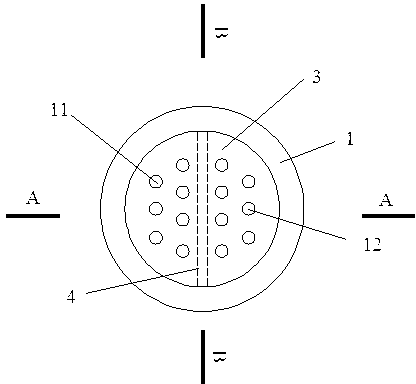

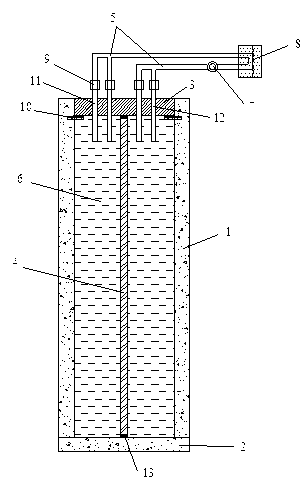

The invention discloses a geothermal energy collecting pile foundation which comprises a tubular pile, heat conduction liquid, a spreader plate, a cover plate, a bottom plate, heat conduction pipes, a collector and the like, wherein the bottom of the pile is completely closed by adopting reinforced concrete, the reinforced concrete cover plate is arranged on the top of the pile, a plurality of holes are arranged in the cover plate, the spreader plate is arranged in a cavity in the tubular pile, a plurality of holes are arranged in the locations, close to the bottom, of the spreader plate, the cavity of the tubular pile is filled with the heat conduction liquid, the heat conduction pipes penetrate through the holes in the cover plate and extend in the heat conduction liquid in the cavity of the tubular pile, and the heat conduction pipes are connected with the collector and form a circulating channel with the cavity of the tubular pile. The invention also discloses a construction method of the pile. The construction method comprises the following technical steps of: constructing the tubular pile in a foundation, excavating pile core soil, making the bottom plate, installing the spreader plate, installing the cover plate, installing the heat conducting pipes, injecting the heat conducting liquid and the like. The geothermal energy collecting pile foundation has the advantages of simple and convenience for construction, no influence on the stress of the tubular pile body, convenience for examination and maintenance, wide application range and low construction cost, and is an energy saving and emission reduction pile with economy and high efficiency.

Owner:HOHAI UNIV +1

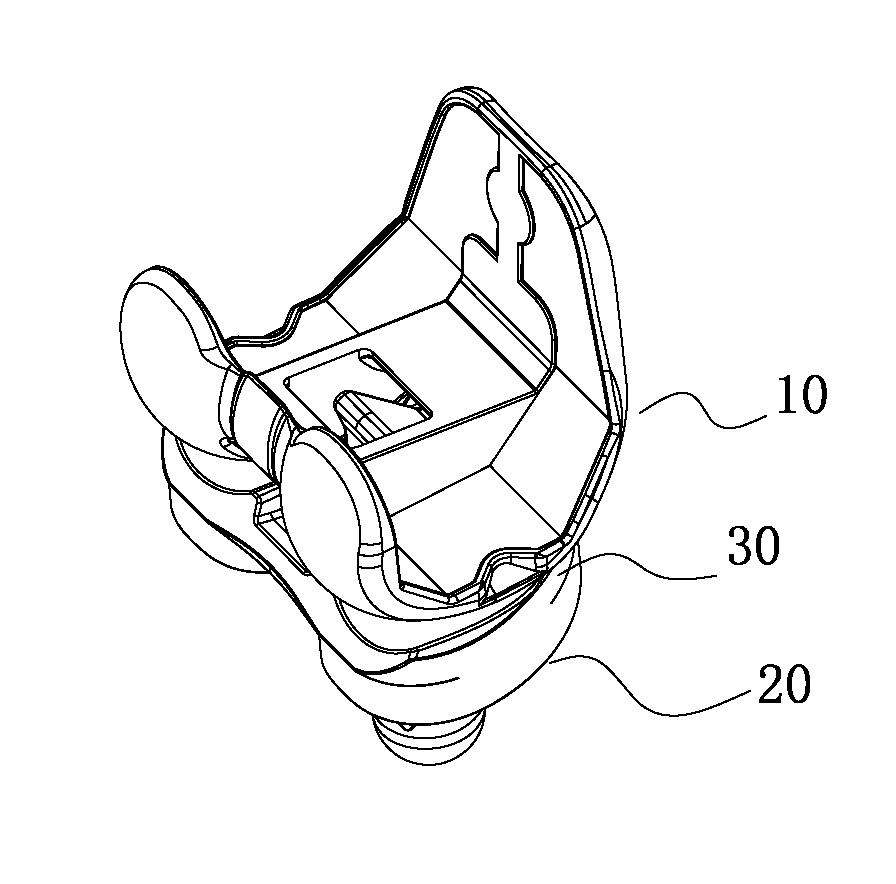

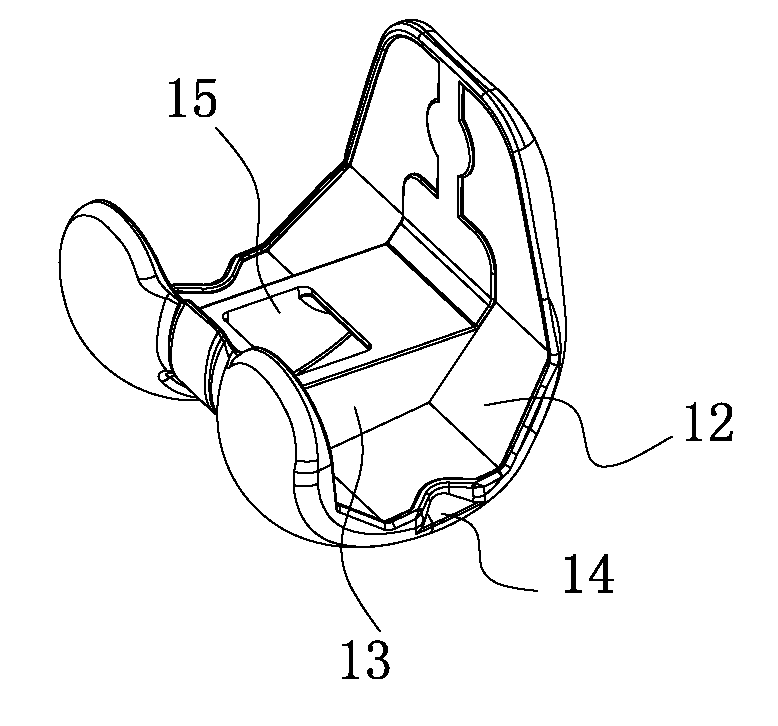

Artificial knee joint

InactiveCN102793594AIn line with the characteristics of daily behavior sportsReduce stressJoint implantsKnee jointsTibiaFEMORAL CONDYLE

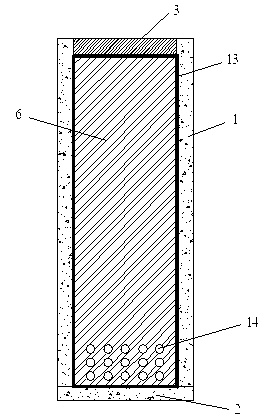

The invention relates to an artificial knee joint. The artificial knee joint comprises a femoral condyle prosthesis, a tibial platform prosthesis and a joint gasket, wherein the femoral condyle prosthesis is movably placed on the tibial joint surface of the joint gasket through the femoral joint surface after being assembled; a projection in the middle of the joint gasket extends into a square hole in the middle of the femoral condyle prosthesis to limit the motion range of the knee joint and prevent the dislocation of the joint; a protrusion part of the joint gasket is movably mounted on a profiled groove of the femoral condyle prosthesis; and a gibbosity part of the joint gasket is movably mounted on a middle circular groove of the tibial platform prosthesis. Due to the adoption of the structure, the technical problem of mismatching of anatomic forms of the conventional artificial knee joint product and the oriental knee joint due to different anatomic forms of the oriental knee joint and the occidental knee joint is solved. The artificial knee joint is suitable for the orientals or the oriental patients requiring total knee arthroplasty.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

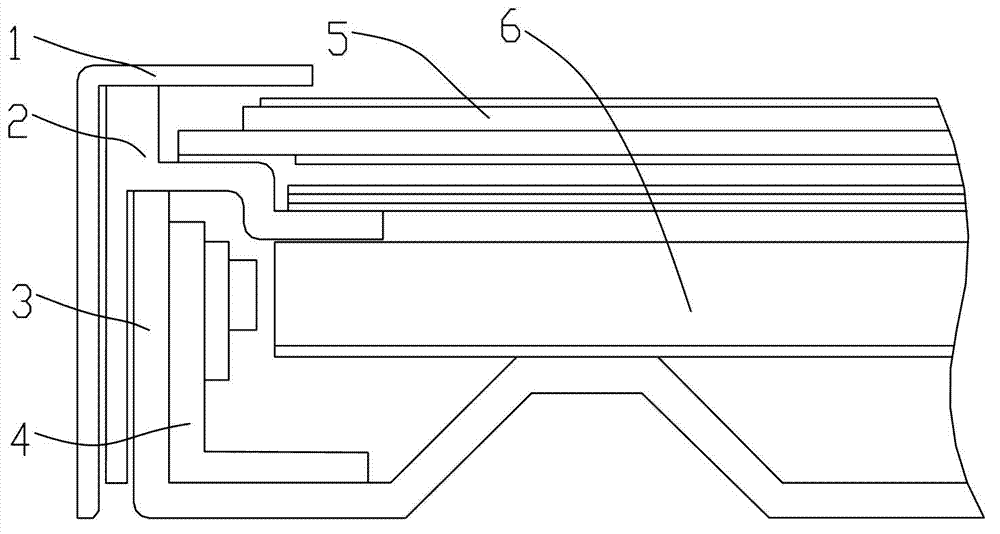

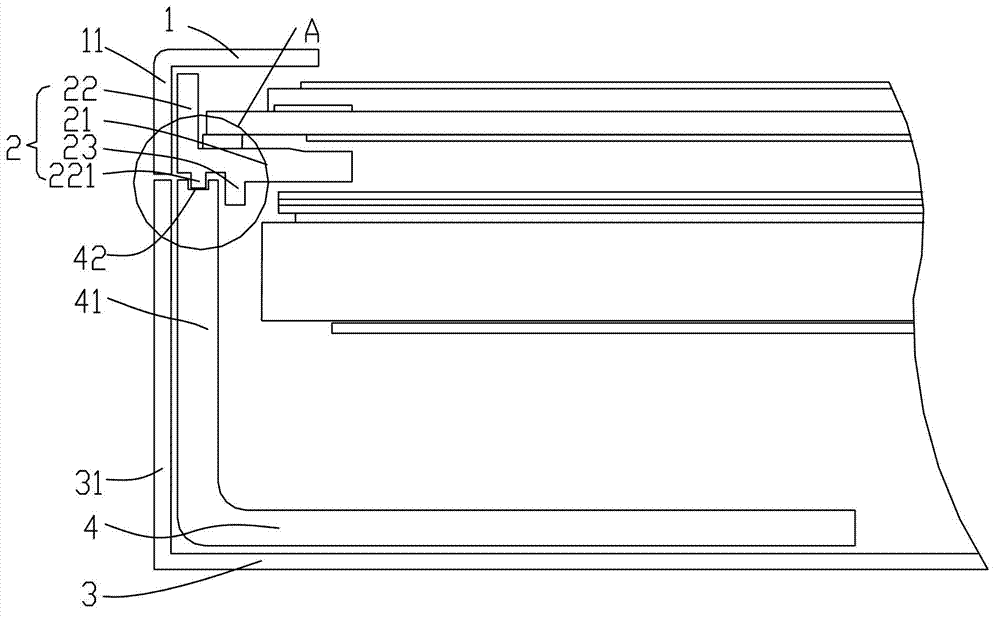

Liquid crystal display module and liquid crystal display device

ActiveCN102819131AImprove torsion resistanceAvoid deformationLighting heating/cooling arrangementsRack/frame constructionLiquid-crystal displayEngineering

The invention belongs to the field of liquid crystal display, and specifically relates to a liquid crystal display module and a liquid crystal display device. A liquid crystal display panel comprises a middle frame, a backboard and a light source heat dissipation part, wherein the light source heat dissipation part is fixed on the backboard, the middle frame comprises a horizontal wall and a vertical wall, the light source heat dissipation part comprises one vertical wall, the middle frame is corresponding to the light source heat dissipation part in an up-down form, and the vertical wall of the middle frame and the vertical wall of the light source heat dissipation part are correspondingly provided with mutually matched holding structures. For the liquid crystal display module disclosed by the invention, based on the up-down corresponding relation of the middle frame and the light source heat dissipation part, the mutually matched holding structures are correspondingly arranged on the vertical wall of the middle frame and the vertical wall of the light source heat dissipation part, so that the middle frame and the light source heat dissipation part are located in the vertical direction, the anti-torsion performance of the middle frame can be increased, and the middle frame is not prone to deformation when bearing the liquid crystal display panel, thereby playing a better role in bearing.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

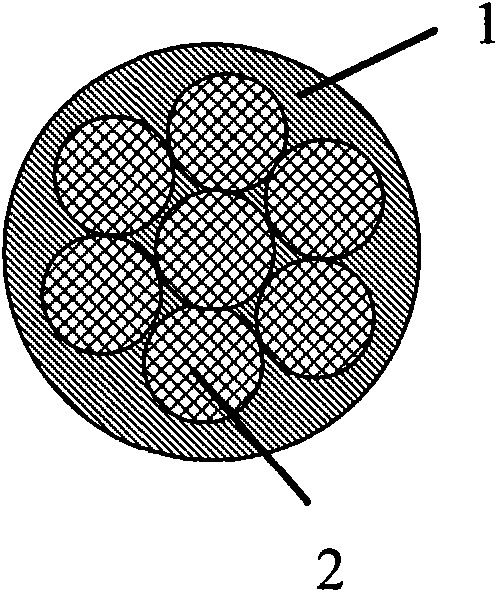

Reinforced cable core and manufacturing method thereof

InactiveCN101727998AExtended service lifePrevent Galvanic CorrosionNon-insulated conductorsConductive materialCarrying capacityElectrical conductor

The invention discloses a reinforced cable core and a manufacturing method thereof. The reinforced cable core comprises a fiber reinforced core and a metallic sheath, wherein the fiber reinforced core is coated by the metallic sheath. The reinforced cable core of the invention not only has the advantages of low density, low expansion coefficient, high tensile strength and the like, but also has the functions of improving the current carrying capacity of a cable, shielding an inner fiber composite structure to avoid the electrical erosion between a fiber and an aluminum conductor, protecting the surface of a fiber composite material and reducing the mechanical performance loss caused by surface damage. Compared with reinforced cable cores with other structures, which are formed by only fiber composite cores, the reinforced cable core of the invention not only plays a role of bearing but also can further improve the current carrying capacity of the cable.

Owner:SHANGHAI ELECTRIC CABLE RES INST

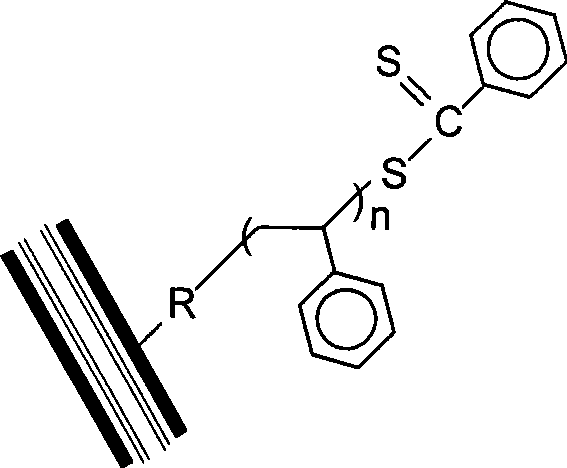

Preparation of multi-arm carbon nano-tube lubricant additive

InactiveCN101469143AGood anti-wear performanceEasy to prepareAdditivesPigment treatment with non-polymer organic compoundsLubricationCarbon nanotube

The invention discloses a method for preparing a multi-arm carbon nanotube lube additive. Through solid load of a chain transfer agent on the surface of a multi-arm carbon nanotube, the method carries out active polymerization on different monomers to obtain functionalized multi-arm carbon nanotubes modified by different polymers. The preparation process is simple and easy to operate; the prepared multi-arm carbon nanotube lube additive has good thermal stability and mechanical stability, and can greatly improve dispersion of the carbon nanotube in lube. The lube additive utilizes the rigid carbon nanotube as a nuclear structure and plays a role in bearing; long-chain macromolecule plays a role in abrasion reduction due to the flexibility and viscoelasticity of the macromolecule and realizes the conversion from sliding friction to rolling friction microscopically; therefore, the lube additive shows excellent abrasion resistance and is expected to solve the problem of lubrication of a mechanical material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

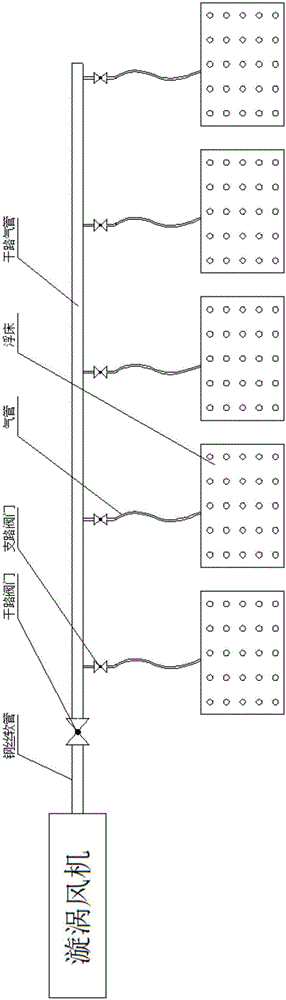

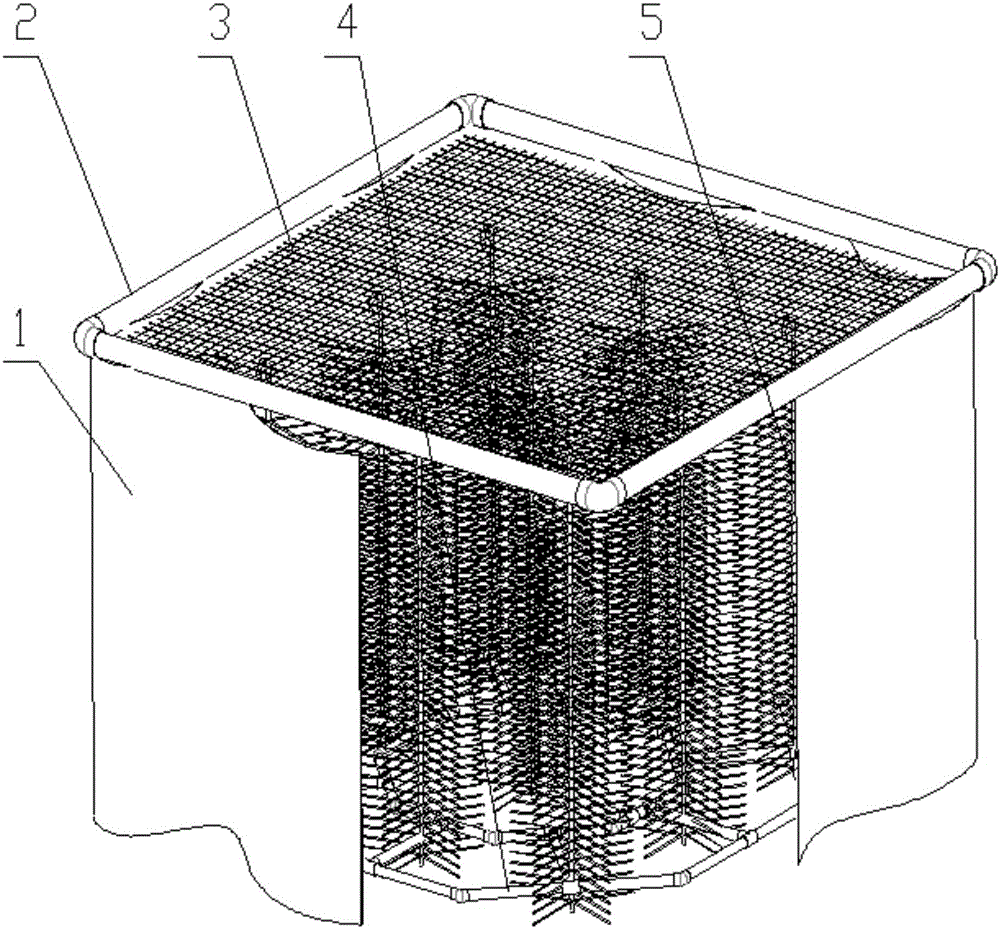

Simple ecological floating bed and system for aquaculture pond

ActiveCN105110478ASimple structureLow costSustainable biological treatmentBiological water/sewage treatmentAeration systemWater quality

The invention relates to a simple ecological floating bed for an aquaculture pond. The simple ecological floating bed comprises a PVC pipe frame of a rectangular structure, a fence is arranged in the middle of the PVC pipe frame, an elastic filtering material is hung on the lower portion of the fence, aquatic plants are planted on the upper portion of the fence, waterproof canvas is hung on the lower portion of the PVC pipe frame, an aeration coiler is arranged in a space surrounded by the waterproof canvas and provides an aerobic environment for the elastic filtering material through aeration water lifting and oxygenation, and lifted water is discharged from a gap between the PVC pipe frame and the canvas. The simple ecological floating bed is simple in structure, so that cost is lowered substantially; the simple ecological floating bed is ingenious in structural design, and the fence has multiple functions; the simple ecological floating bed is especially suitable for being used in a large water area for building an ecological floating bed system having high requirements on economic efficiency and in-situ regulating water quality of pond aquaculture; the technical problem that building of ecological floating beds in the large water area is high in cost and difficult to implement is solved; an aeration system is compact in design and achieves an integral designing objective.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

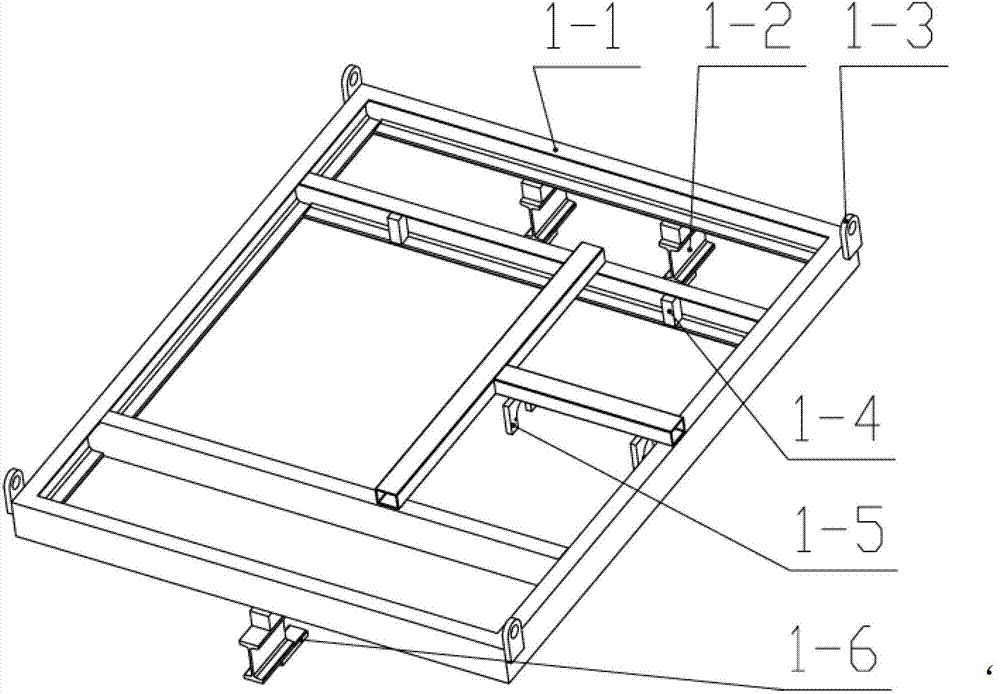

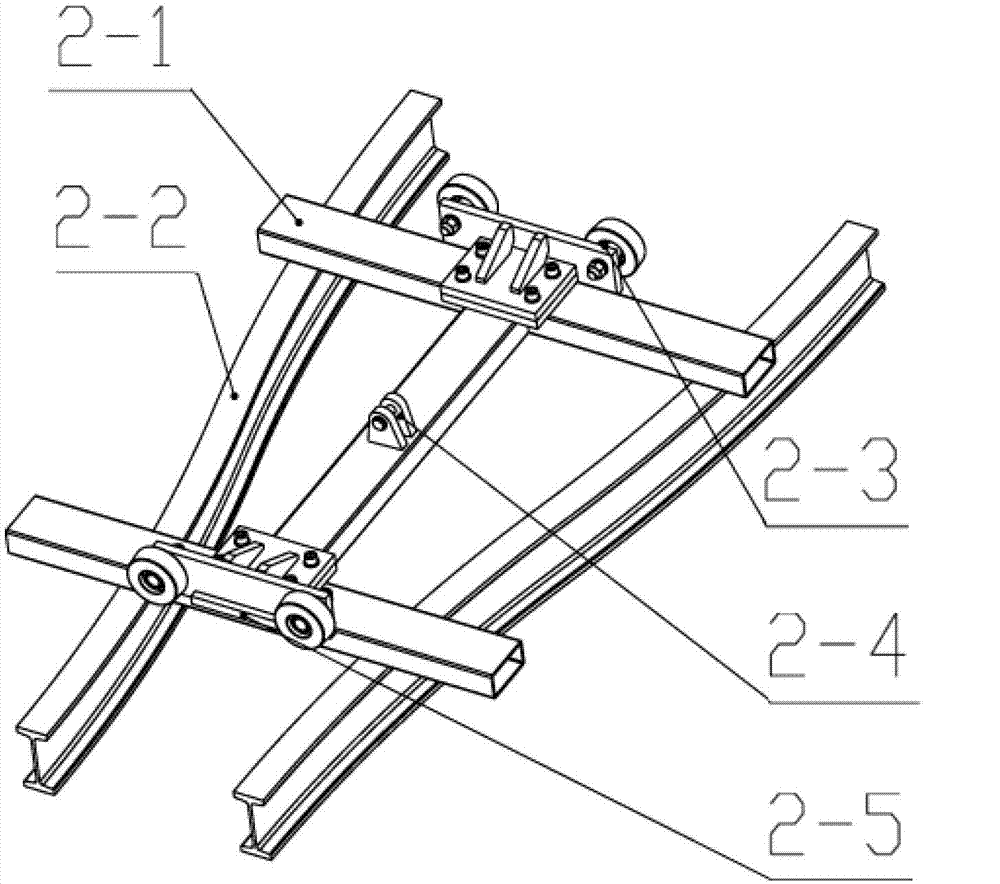

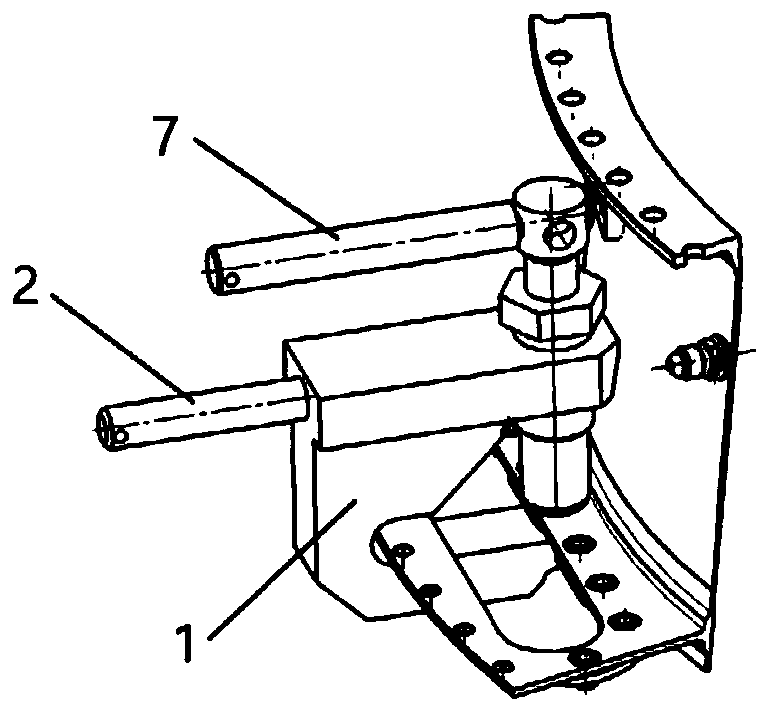

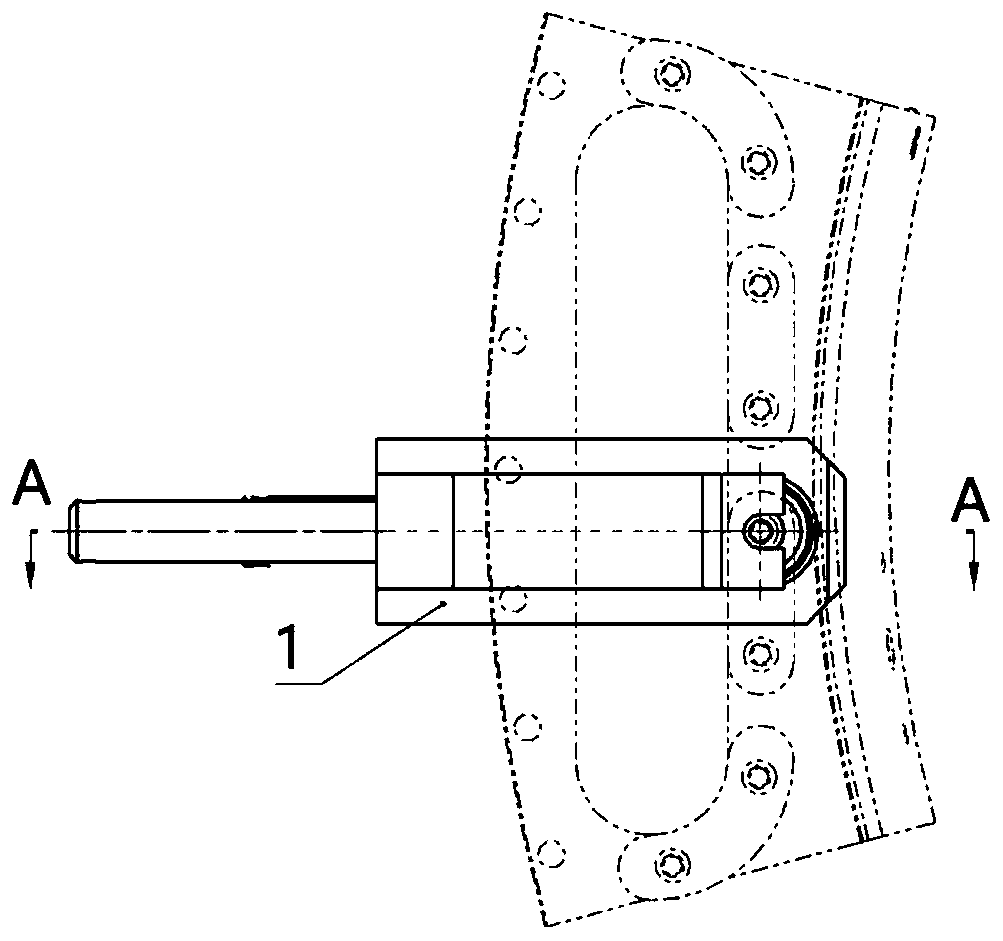

Sliding type monorail crane turnout system for mines

The invention discloses a sliding type monorail crane turnout system for mines, belonging to the technical field of mine equipment. The sliding type monorail crane turnout system comprises a frame assembly, a slide track assembly and a hydraulic cylinder, wherein the slide track assembly is connected with the frame assembly through a wheel set; the wheel set can slide inside the frame assembly freely; a hydraulic cylinder flange is fixedly connected with a hydraulic cylinder connecting flange in the frame assembly; and a piston rod is connected with the slide track assembly through a hinge pin. The sliding type monorail crane turnout system is stable in structure and convenient to operate, potential safety hazards of a monorail crane locomotive are avoided, and the abrasion to wheels is reduced; and meanwhile the remote control is realized, and requirements of mines are met.

Owner:徐州苏煤矿山设备制造有限公司

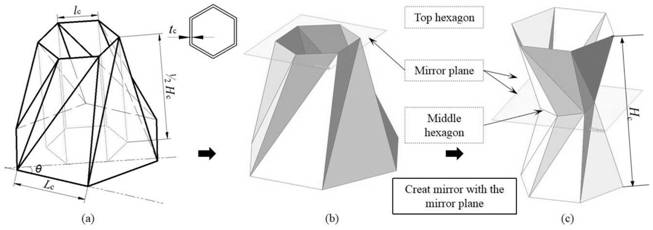

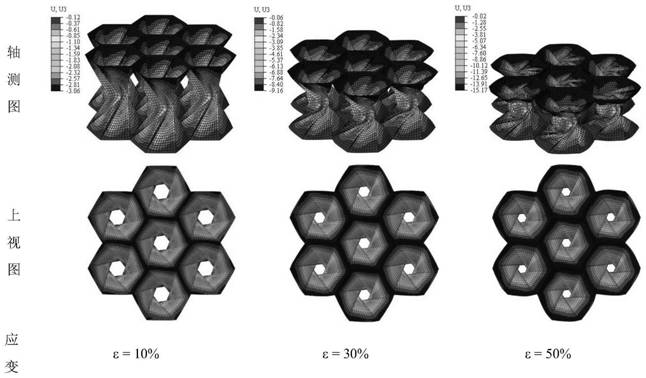

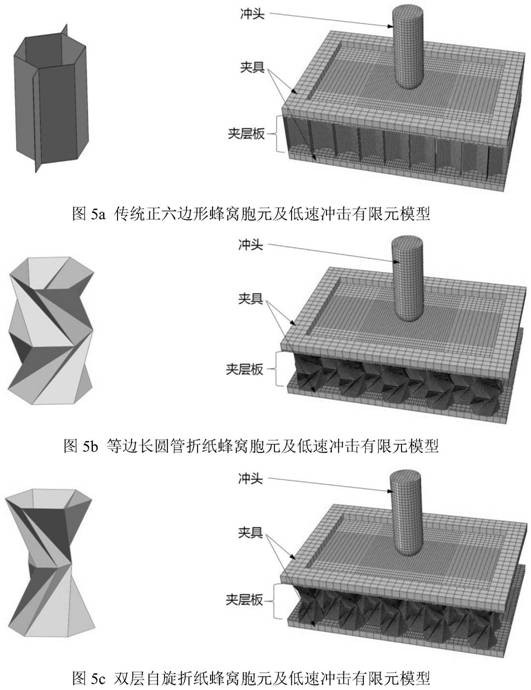

Double-layer spinning origami honeycomb interlayer energy-absorbing material and preparation method thereof

ActiveCN112743933ALower incentive thresholdGuaranteed non-interferenceLaminationLamination apparatusHoneycombEngineering

The invention provides a double-layer spinning origami honeycomb interlayer energy-absorbing material which comprises a core layer and metal skins covering the upper end face and the lower end face of the core layer; the core layer is formed by origami honeycomb cell elements in an array mode, and each origami honeycomb cell element is composed of origami honeycomb unit cells which are symmetrically arranged up and down. The contact ends of the origami honeycomb unit cells and the metal skin are large-diameter ends, and the other ends are small-diameter ends; the large-diameter ends and the small-diameter ends are both in a regular hexagon shape, the side length of the large-diameter ends is twice that of the small-diameter ends, and the included angle between the normal projection of the small-diameter ends and the corresponding sides of the large-diameter ends is 0-30 degrees; and the large-diameter ends and the small-diameter ends of the origami honeycomb unit cells are open. The core layer deforms due to compression of external force, and kinetic energy of an external load is absorbed and converted into strain energy of the double-layer spinning origami honeycomb sandwich structure, so that the loaded process of a protected body is smoother, and the effects of energy absorption and vibration reduction are achieved.

Owner:ZHENGZHOU UNIV

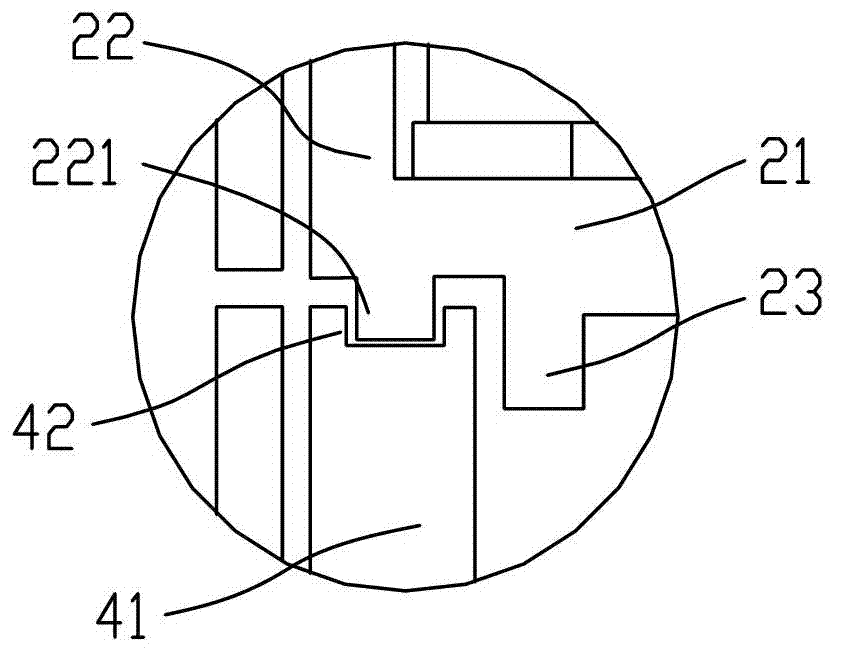

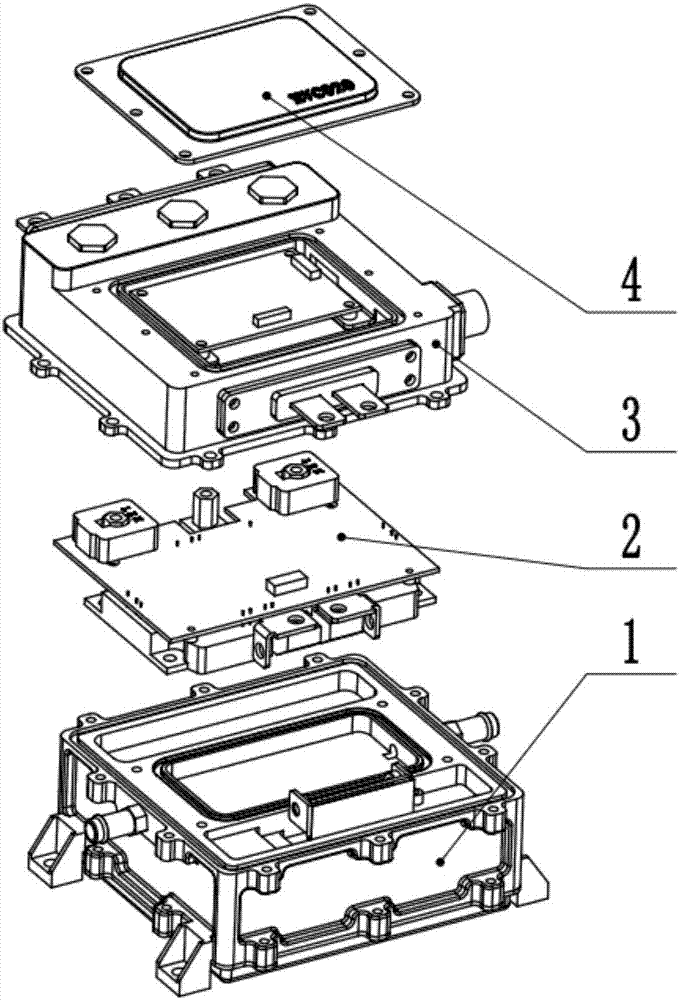

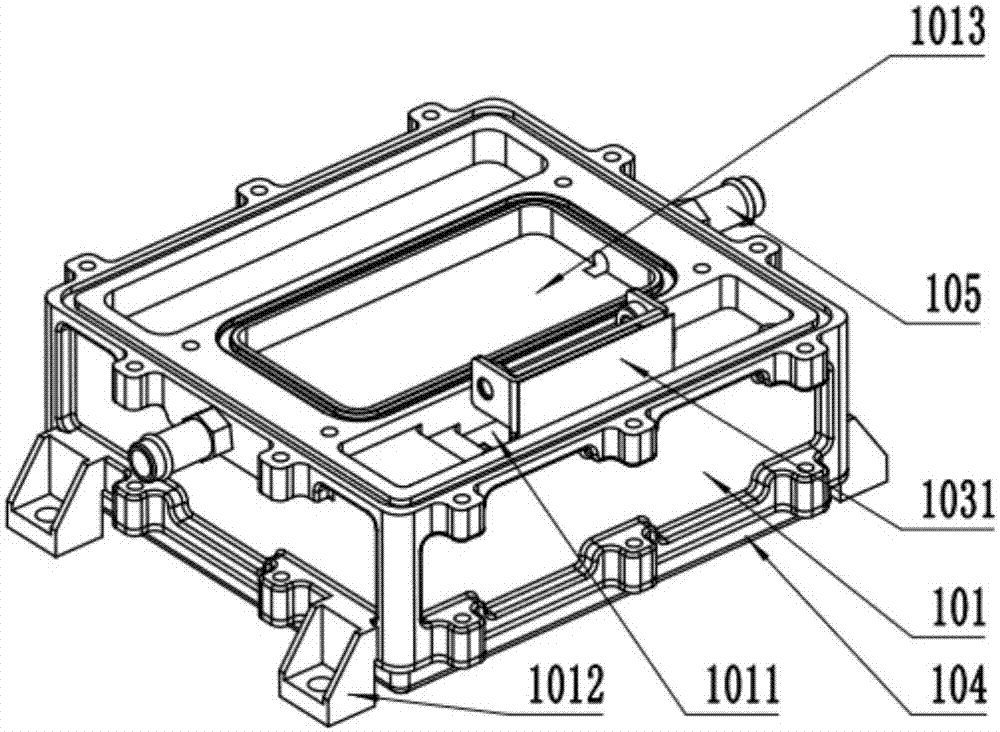

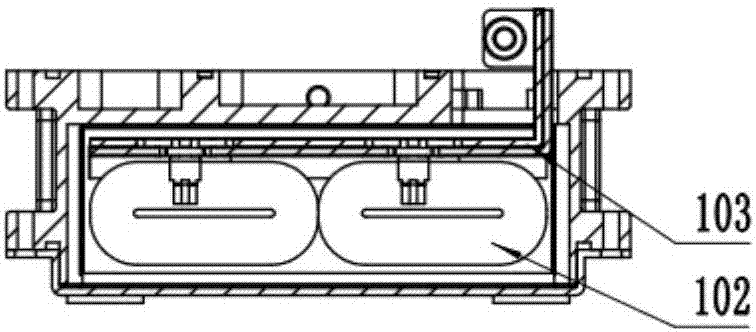

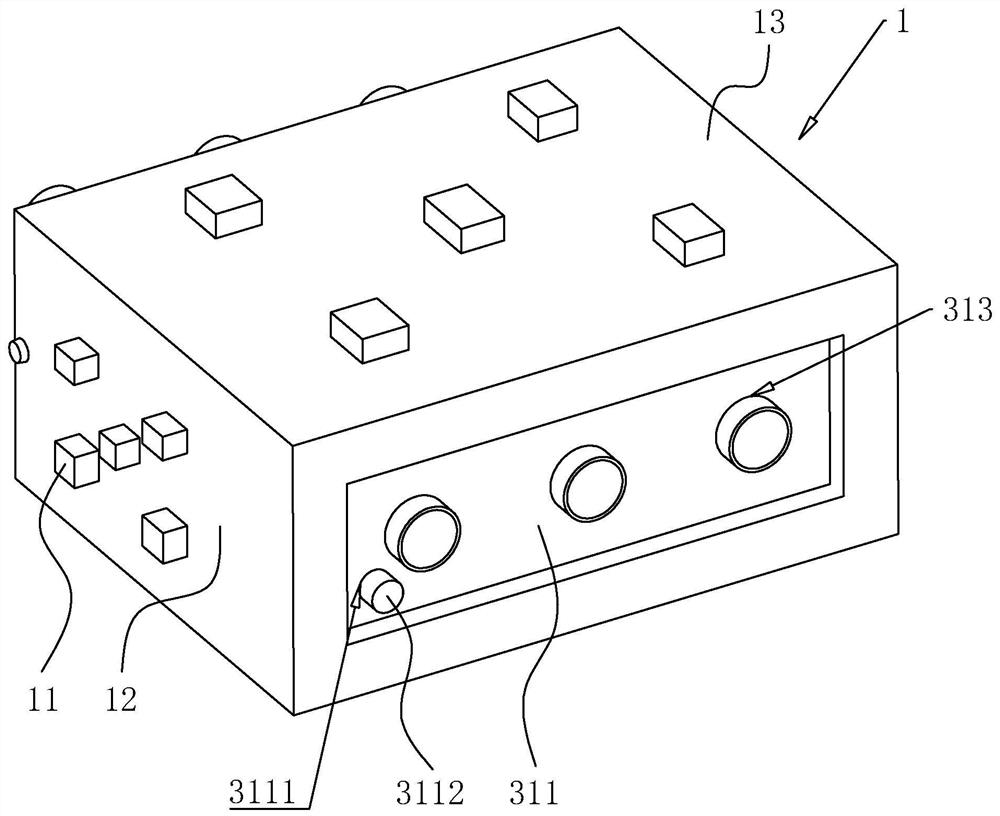

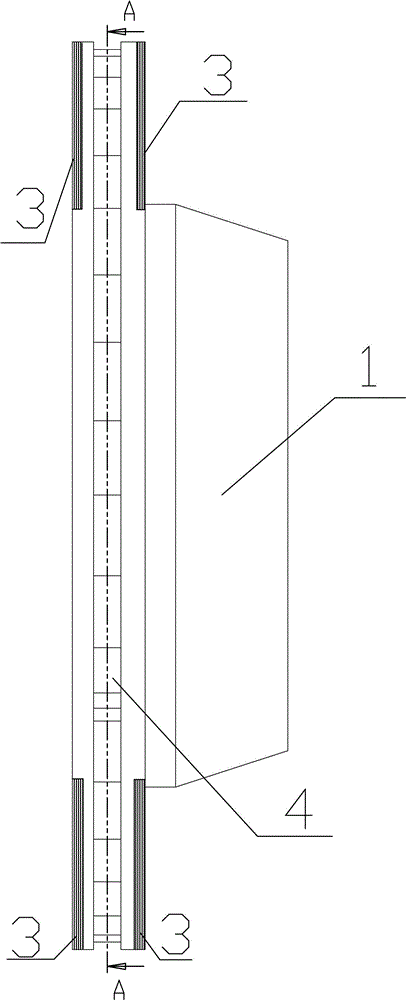

Electric vehicle motor controller structure

ActiveCN107294312AFirmly connectedImprove seismic performanceAssociation with control/drive circuitsFixed capacitor housing/encapsulationElectric machineComputer module

The invention relates to an electric vehicle motor controller structure. The electric vehicle motor controller structure includes a capacitor component (1), a power module assembly (2), a module cover plate assembly (3) and a wire outgoing cover plate (4); the capacitor component (1) is adopted as a supporting component for the motor controller and is located at the bottommost portion of the motor controller; the power module assembly (2) is located directly above the capacitor component (1) and is fixed onto the capacitor component (1); the module cover plate assembly (3) is of a hollow structure and is connected with the capacitor component (1) through mounting holes at the periphery of the module cover plate assembly (3); the wire outgoing cover plate (4) is arranged above the module cover plate assembly (3); the capacitor component (1), the module cover plate assembly (3) and the wire outgoing cover plate (4) form a controller housing; and the outer surface of the capacitor housing (101) of the capacitor component (1) is provided with mounting legs for fixing the motor controller.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

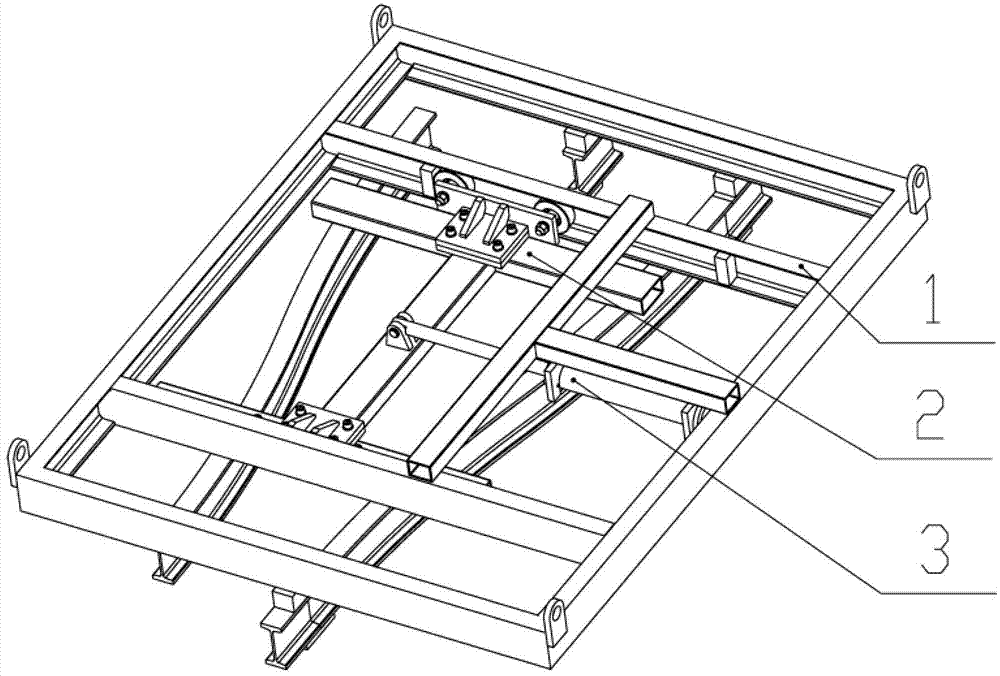

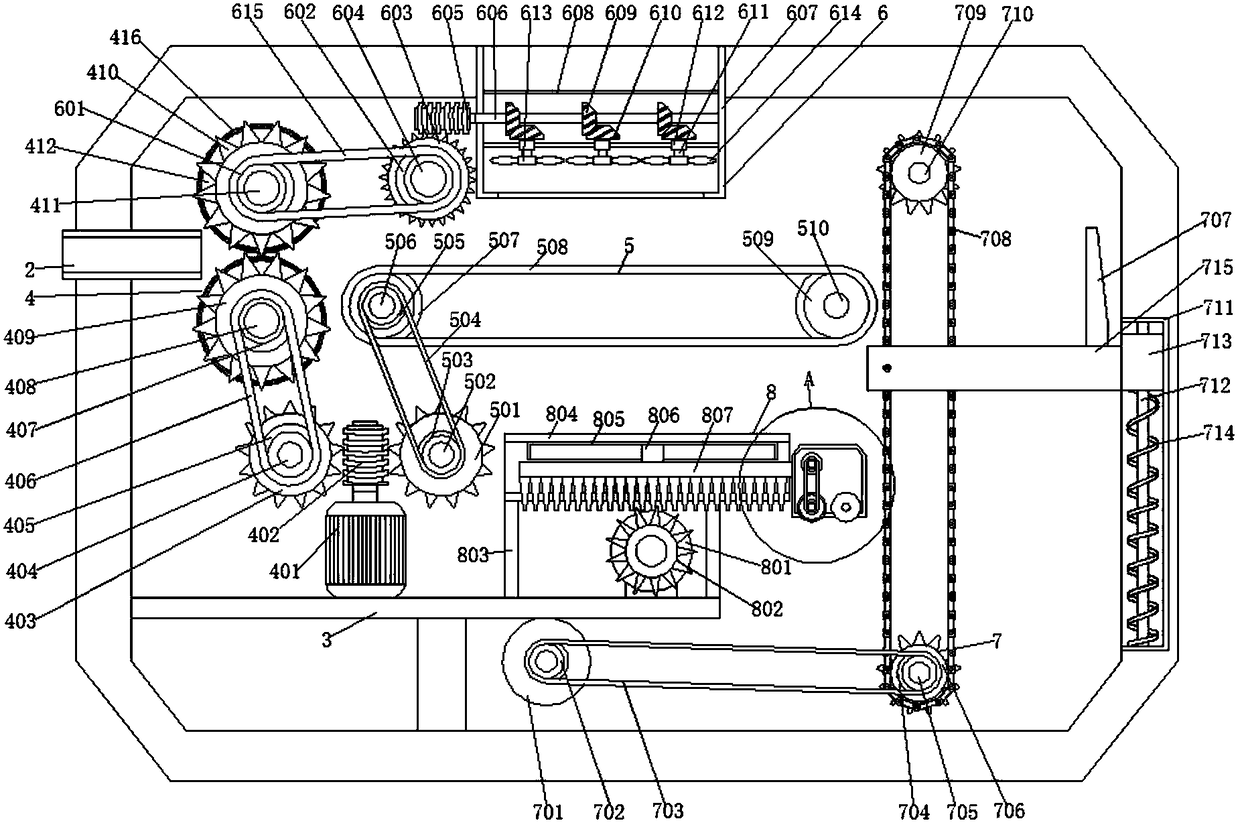

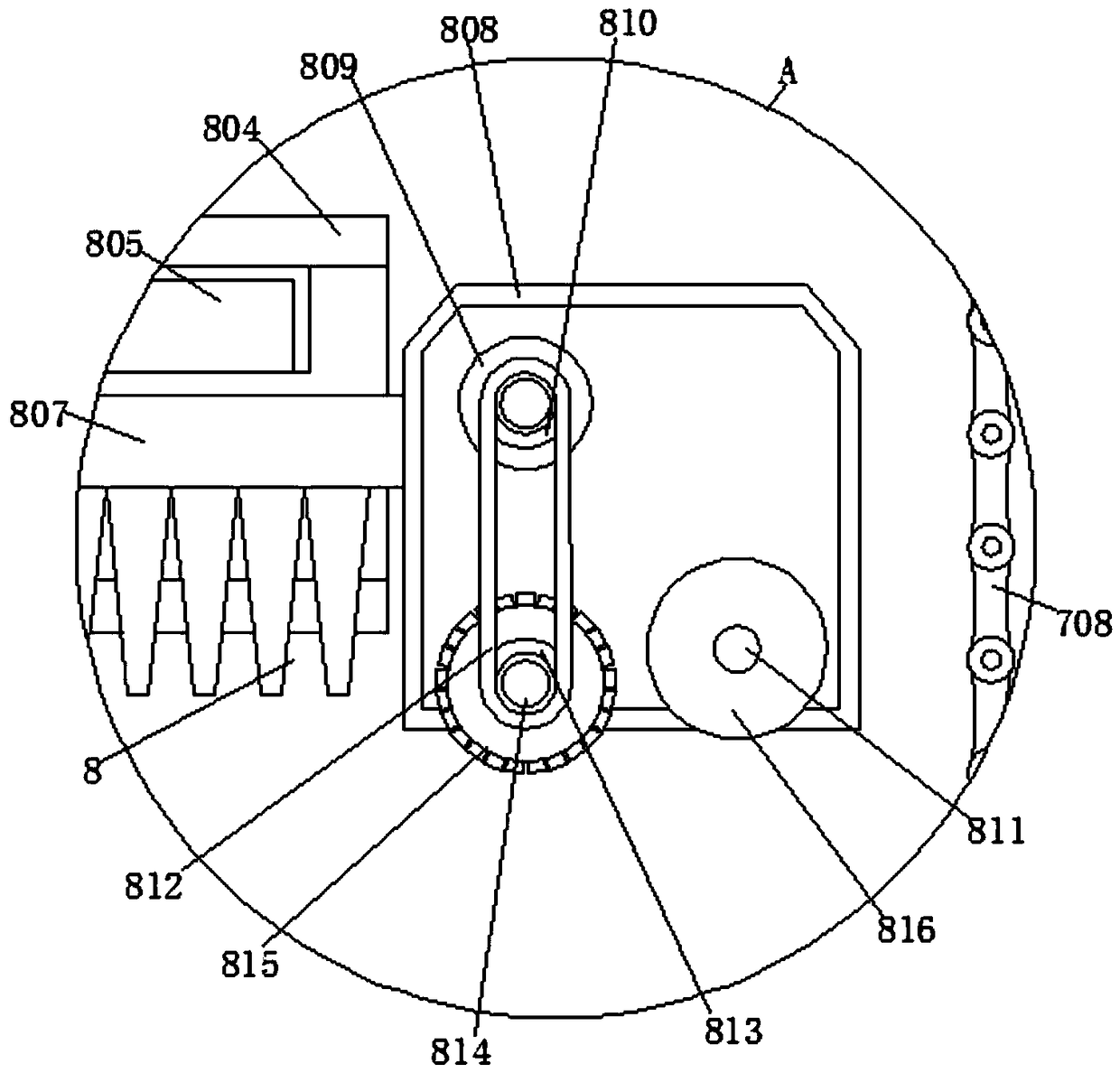

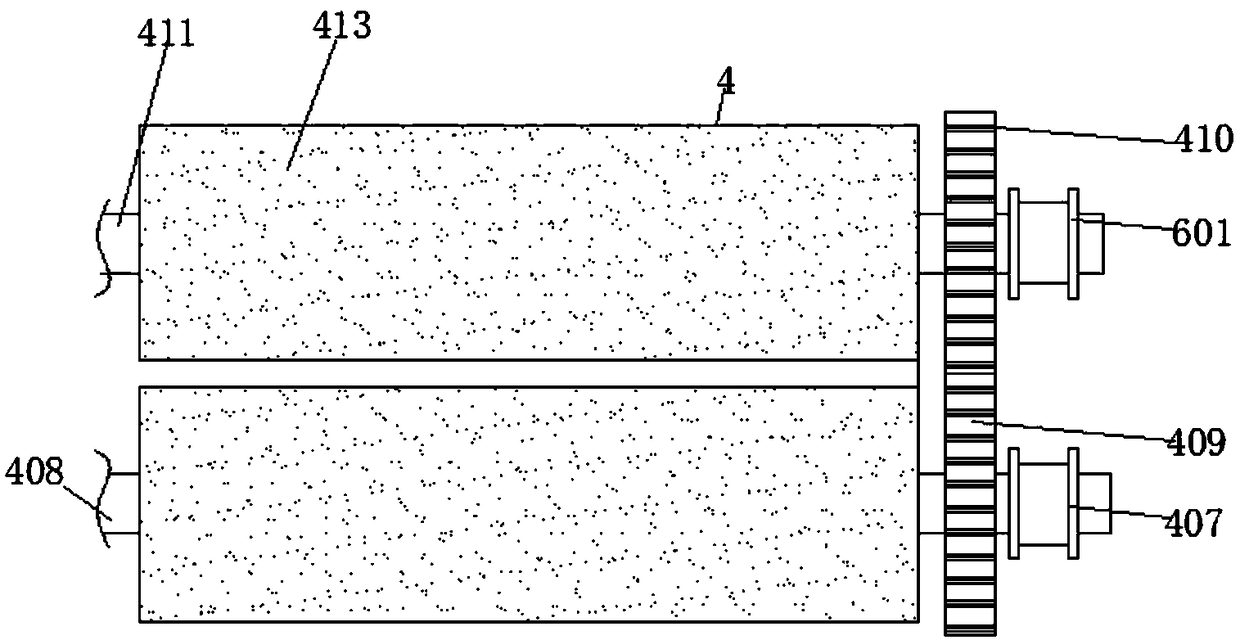

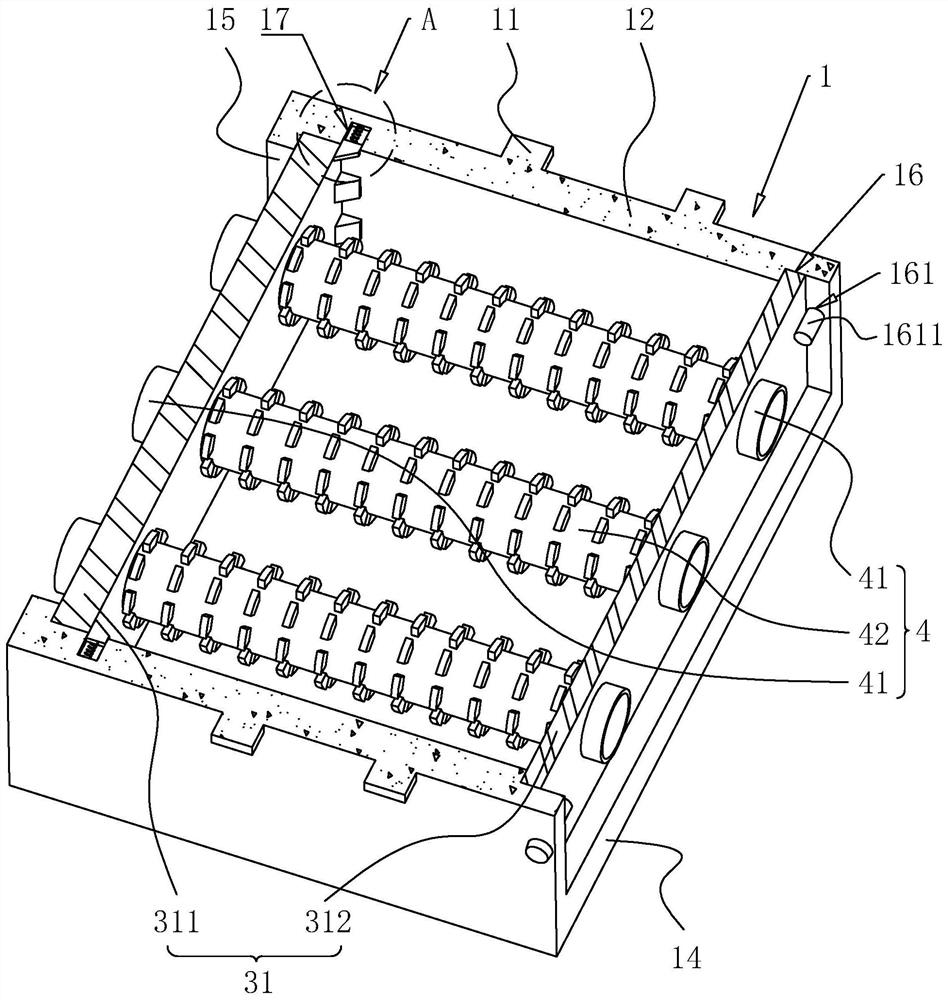

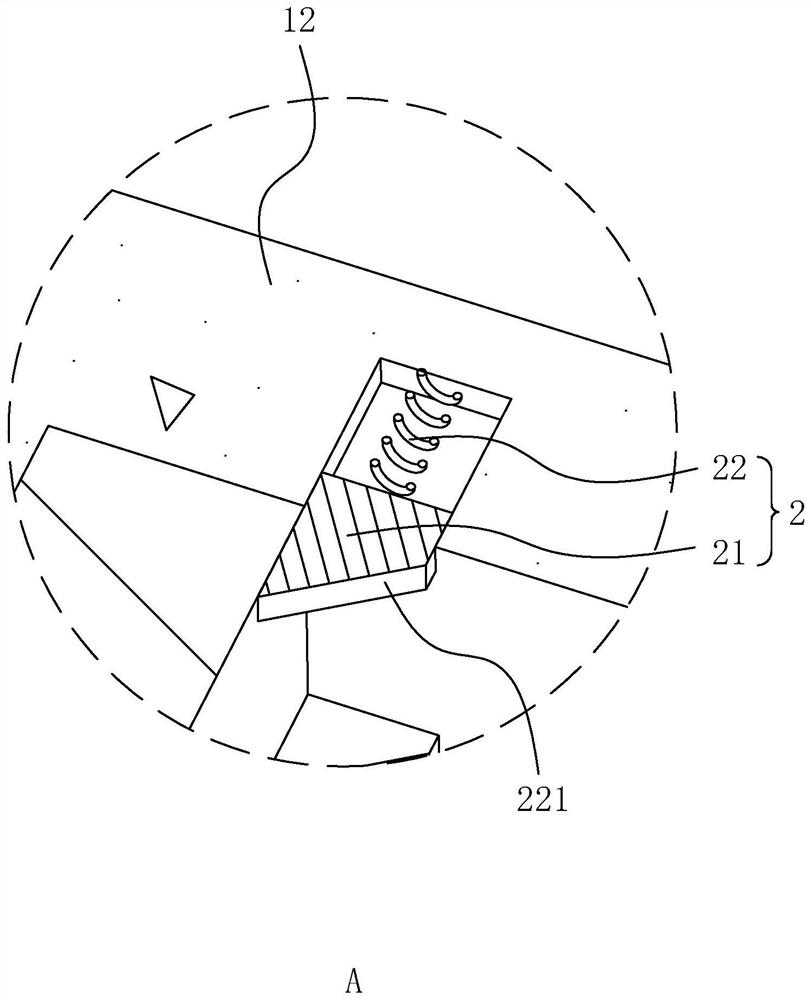

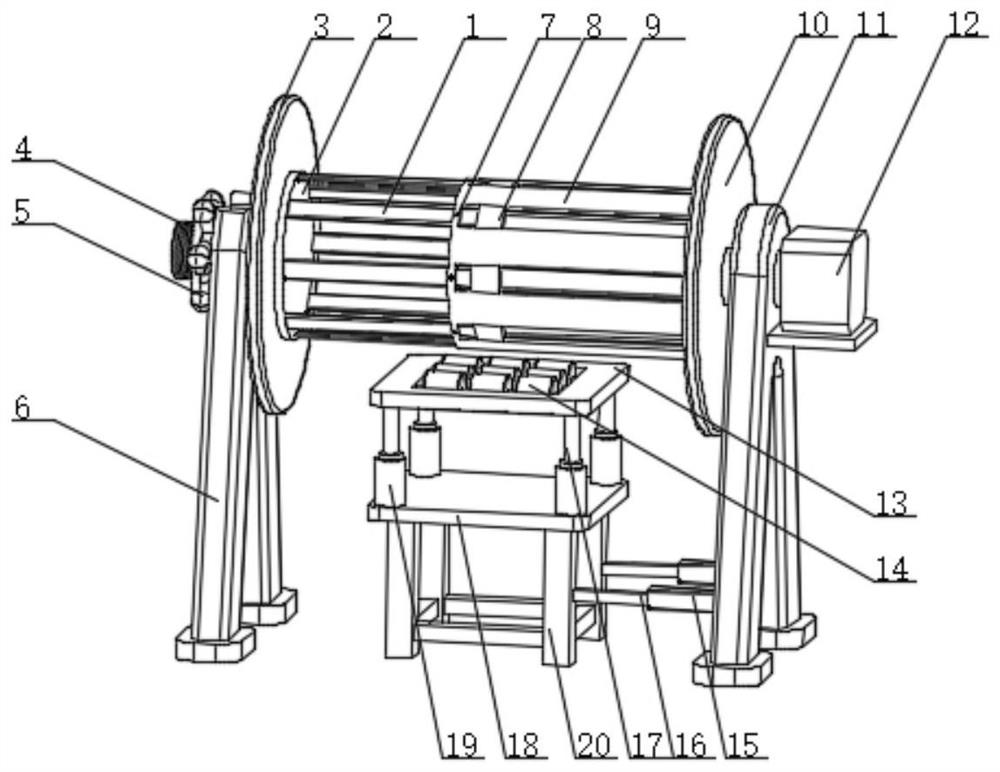

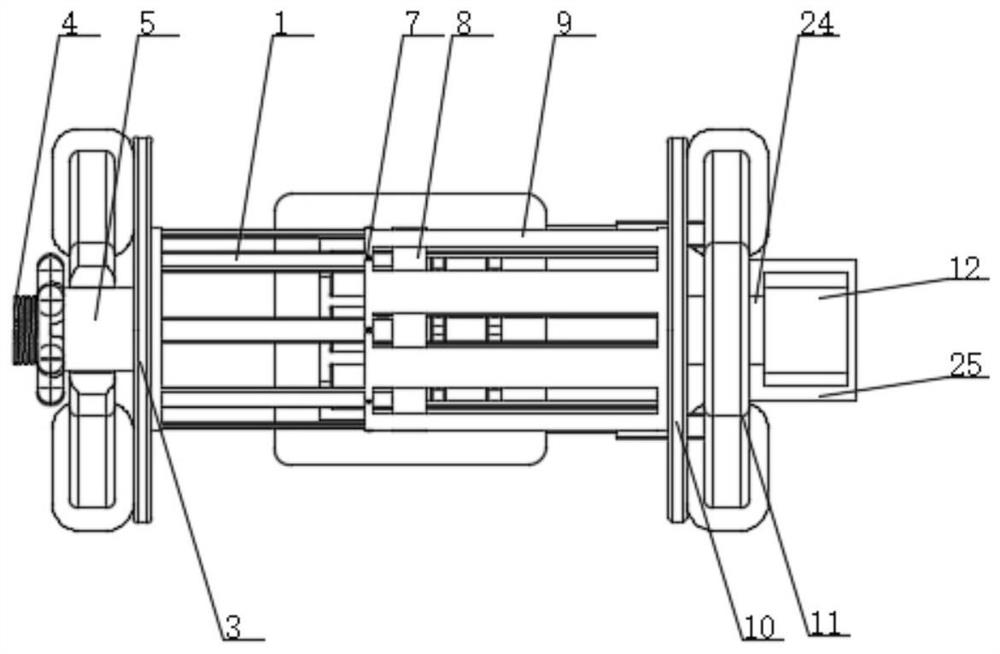

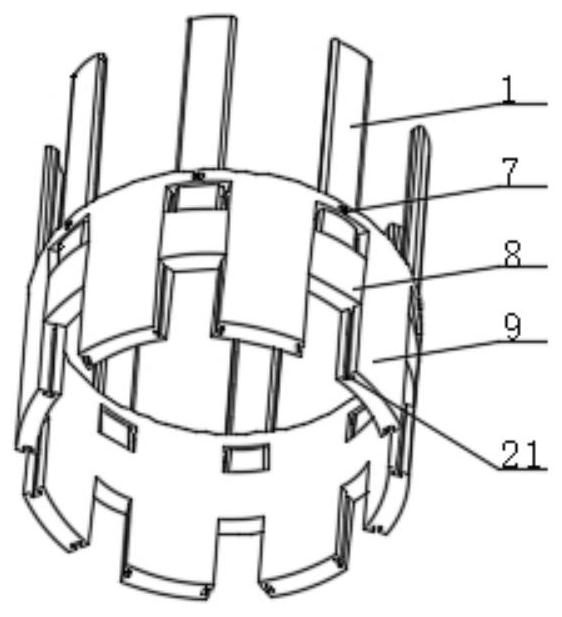

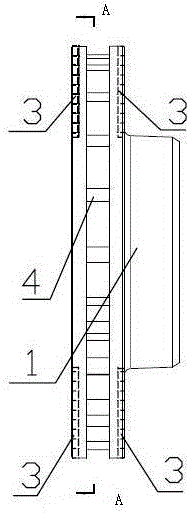

Leveling and strip cutting mechanism for metal hose weaving strip

ActiveCN108500636AFlat surfacePlay a bearing roleMetal sawing devicesOther manufacturing equipments/toolsLeveling mechanismEngineering

The invention relates to the technical field of metal hose machining, in particular to a leveling and strip cutting mechanism for a metal hose weaving strip. The mechanism aims to solve the technicalproblems that leveling and stable cutting are not convenient when strip cutting of a metal hose is carried out. The leveling and strip cutting mechanism for the metal hose weaving strip comprises a machine box, a placing sleeve is inserted into one side of the machine box, and a bearing plate is fixedly connected to the bottom of the inner wall of the machine box through a supporting plate; a leveling mechanism is arranged at the position, corresponding to the placing sleeve, in the machine box; and the bottom of the leveling mechanism is fixedly connected with the upper surface of the bearingplate, and a conveying device is arranged at the position, corresponding to a material discharging opening of the leveling mechanism, in the machine box. According to the mechanism, two leveling sleeves on the leveling mechanism can level the surface of a stainless steel plate in the rotating process, meanwhile, sanding layers are arranged on the surfaces of the two leveling sleeves, in the leveling process, the surface of the stainless steel can be polished, so that the surface of the stainless steel can be smoother.

Owner:MAANSHAN FEIDA BELLOWS MFG CO LTD

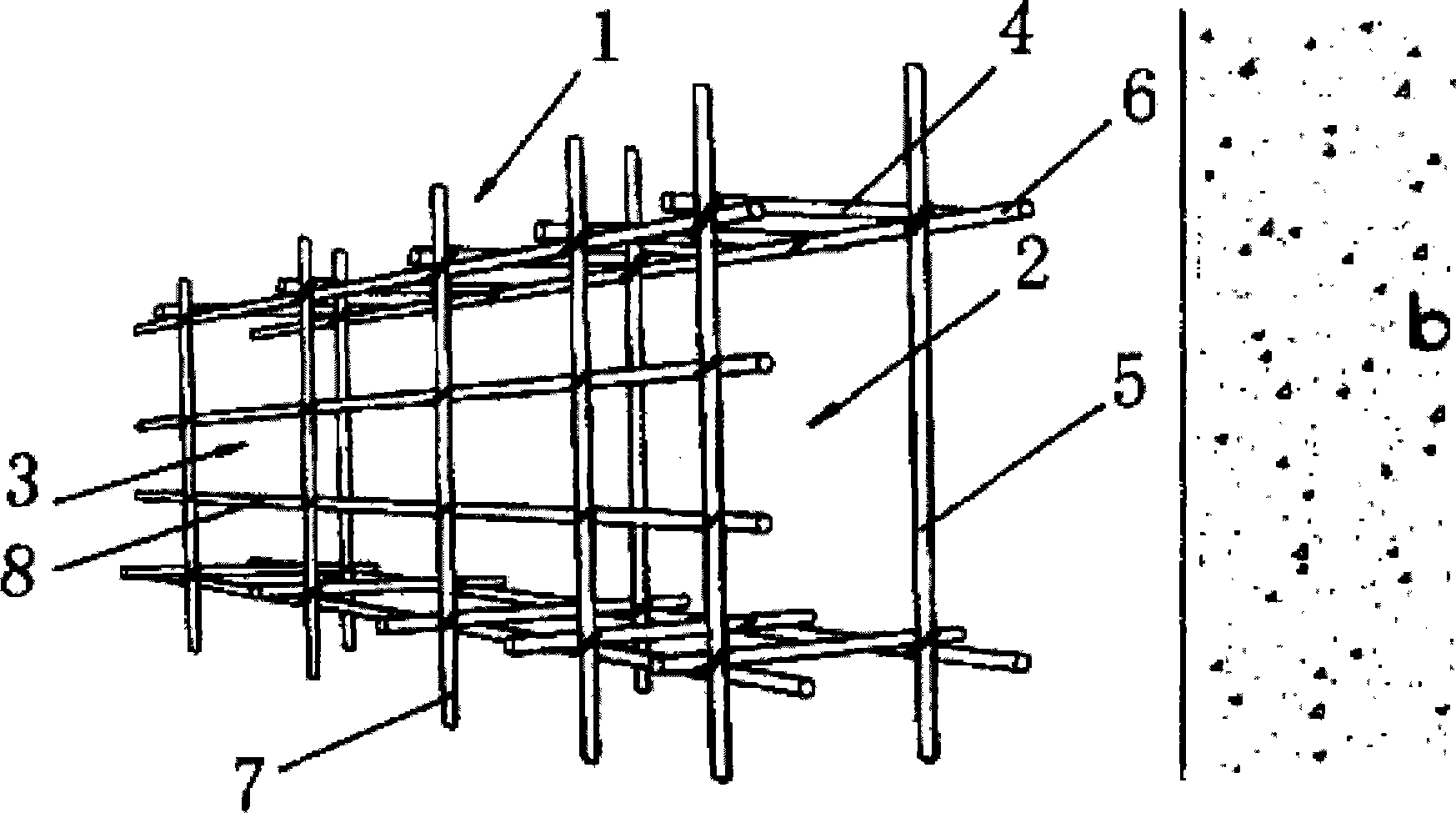

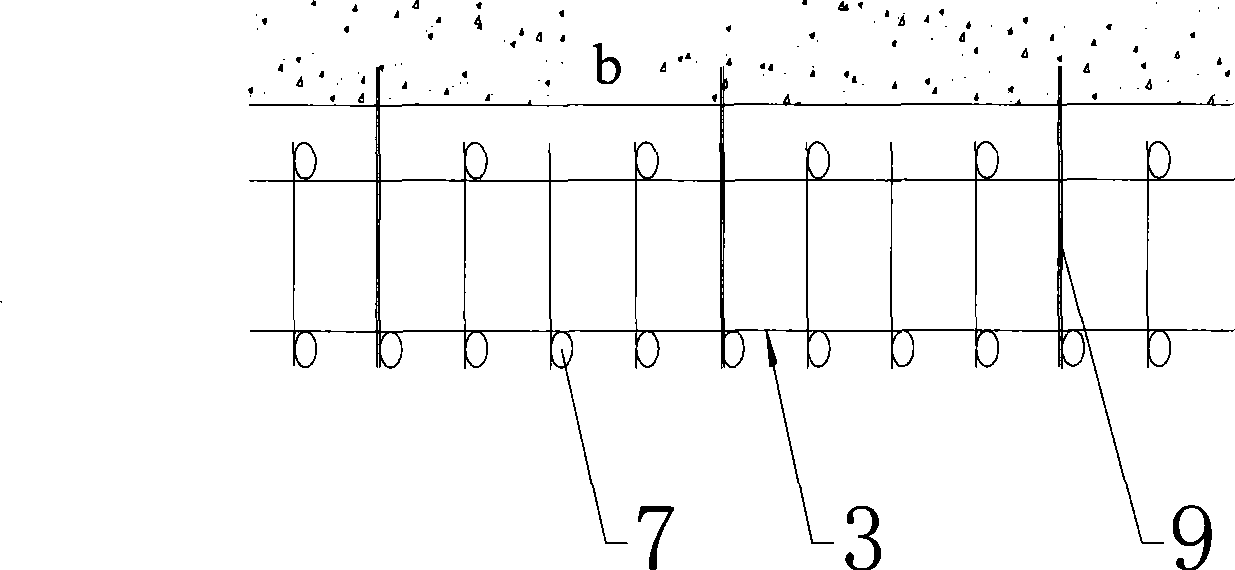

Separated type prefabricated reinforced concrete cow-leg pillar and construction method thereof

The invention discloses a separated type prefabricated reinforced concrete cow-leg pillar and a construction method of the separated type prefabricated reinforced concrete cow-leg pillar. The separated type prefabricated reinforced concrete cow-leg pillar comprises a prefabricated pillar body and a bracket unit which can be arranged on the pillar body in a later period, wherein a bracket reinforced bar is arranged in the bracket unit, one or more bracket connecting areas is arranged on the pillar body, a pillar body preformed hole is formed in the bracket connecting area, a bracket preformed hole corresponding to the pillar body preformed hole is formed in the bracket unit, the pillar body preformed hole is communicated with the bracket preformed hole, and concrete is poured into the pillar body preformed hole and the bracket preformed hole to realize connection of the bracket unit and the pillar body. A prefabricated method is adopted to overcome the defects that the pillar body can be damaged easily when the bracket is additionally arranged by adopting the anchor bar technology, and the working efficiency is low; and the separated type prefabricated construction method is adopted to overcome the defects that the pressing resistance is high and damage can be easily caused when the fabricated pillar together with the bracket is pressed into the ground.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

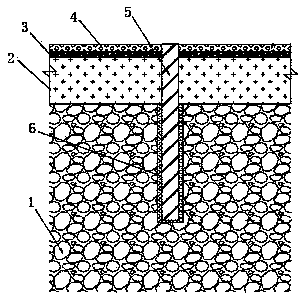

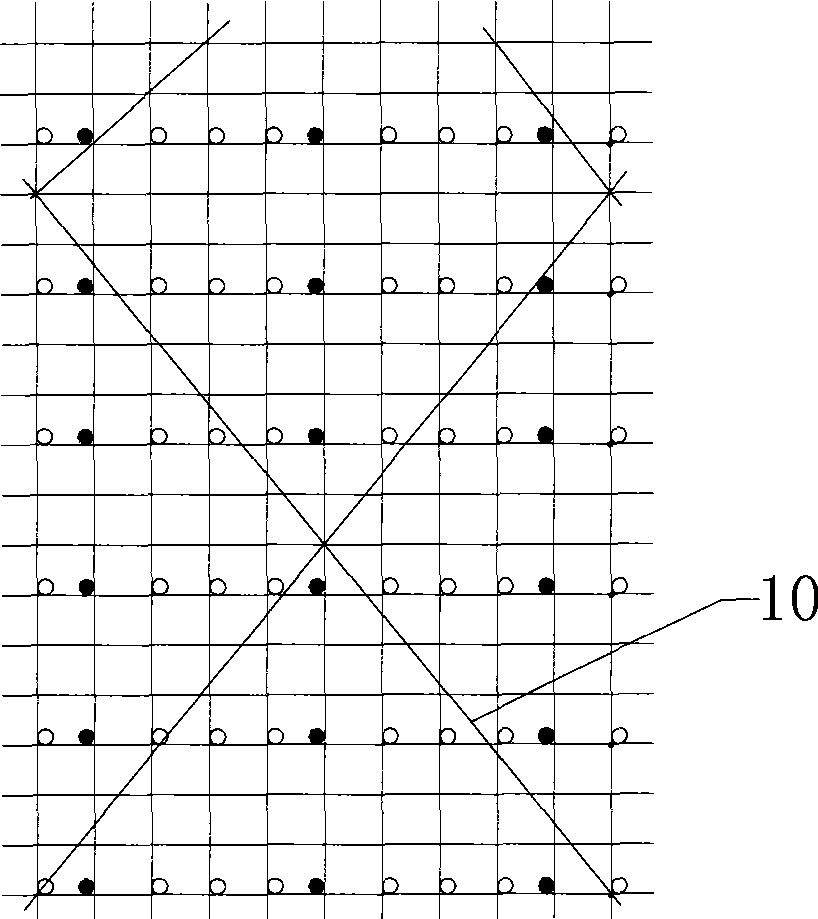

Metal floor and formation method

ActiveCN103628650AImprove the level ofPlay a bearing roleBuilding material handlingFlooringReinforced concreteRebar

The invention discloses a metal floor and a formation method. The metal floor sequentially comprises a steel bar concrete layer (1), a fine stone concrete layer (2), a rubber layer (3) and a steel plate layer (4) from bottom to top, and further comprises a plurality of threaded steel pillars (5). The threaded steel pillars (5) sequentially penetrate through the steel plate layer (4), the rubber layer (3) and the fine stone concrete layer (2), and are inserted into the steel bar concrete layer (1), the upper ends of the threaded steel pillars (5) are flush with the upper surface of the steel plate layer (4), the steel bar concrete layer (1) is made of C55 concrete, and the fine stone concrete layer (2) is made of C25 fine stone concrete. Due to the adoption of the structure, the structure of the metal floor has certain rigidity and strength, noise is reduced or even eliminated, and therefore the whole metal floor can completely meet the requirements.

Owner:中国冶金科工股份有限公司

Device used for mechanical extrusion type flaring

InactiveCN111283612AEven by forceSo as not to damageMetal-working hand toolsPhysicsCombustion chamber

The invention provides a device used for mechanical extrusion type flaring. The device comprises a clamp body, a replaceable anvil, a hexagonal thread sleeve, a transmission screw rod and a moving pin. The clamp body is of an arch structure, a first mounting hole is formed in the upper side wall of the open end of the clamp body, the axis of the first mounting hole is perpendicular to the axis ofthe upper side wall of the clamp body, the transmission screw rod is assembled in the first mounting hole, the moving pin is mounted at one end of the transmission screw rod, the replaceable anvil ismounted at the other end of the transmission screw rod, the free end of the replaceable anvil is a work part, the work part is of a cone structure, the taper of the cone structure is matched with thetaper of a combustion chamber casing conical hole, it is clearly ensured that during flaring of a bypass air guide pipe mounting base, stress is uniform, damage is avoided, and rapid and efficient deforming is achieved. The flaring of a mounting base, a supporting plate self-locking nut, a bush and the like required to be assembled in a multi-model combustion chamber casing assembly can be achieved.

Owner:AECC AVIATION POWER CO LTD

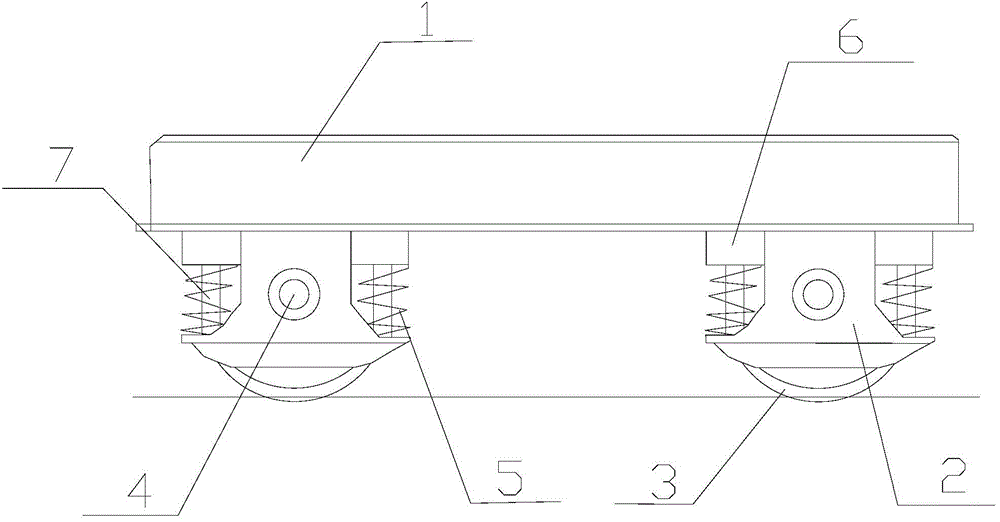

Vibration absorbing for railway vehicle

InactiveCN104648425AAvoid damageSo as not to damageBogiesAxle-boxes mountingEconomic benefitsEngineering

Owner:DALIAN ORIENT METAL

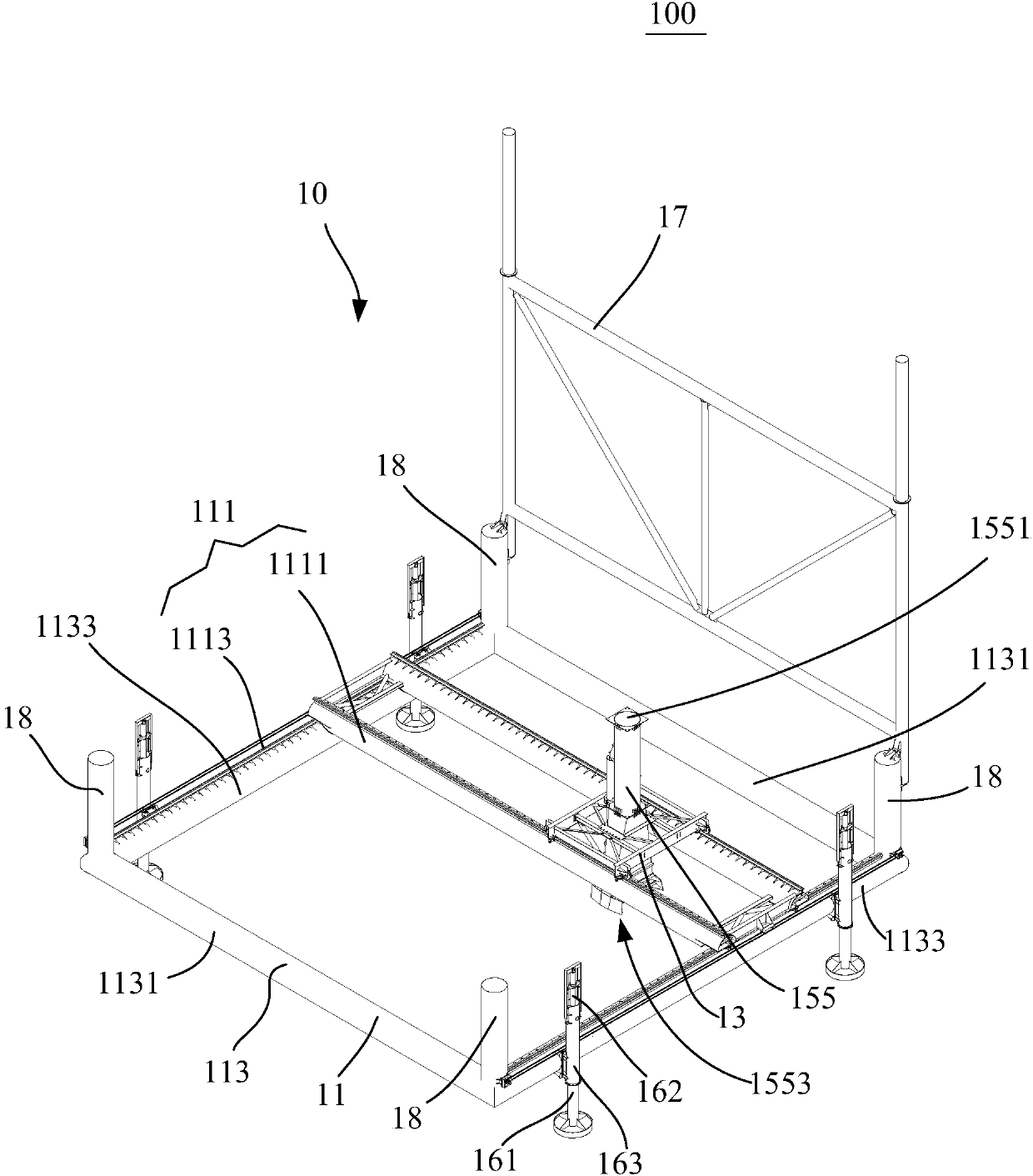

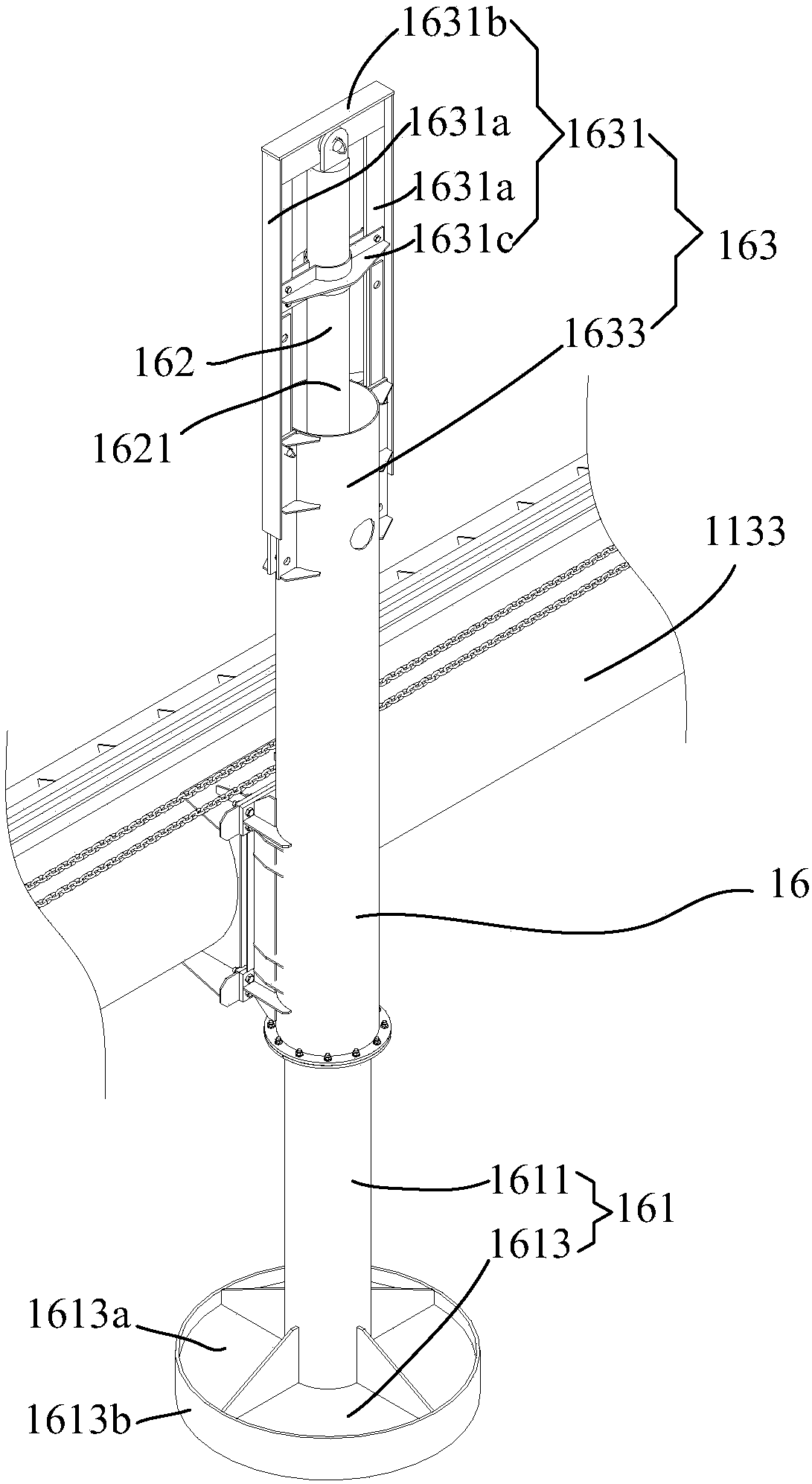

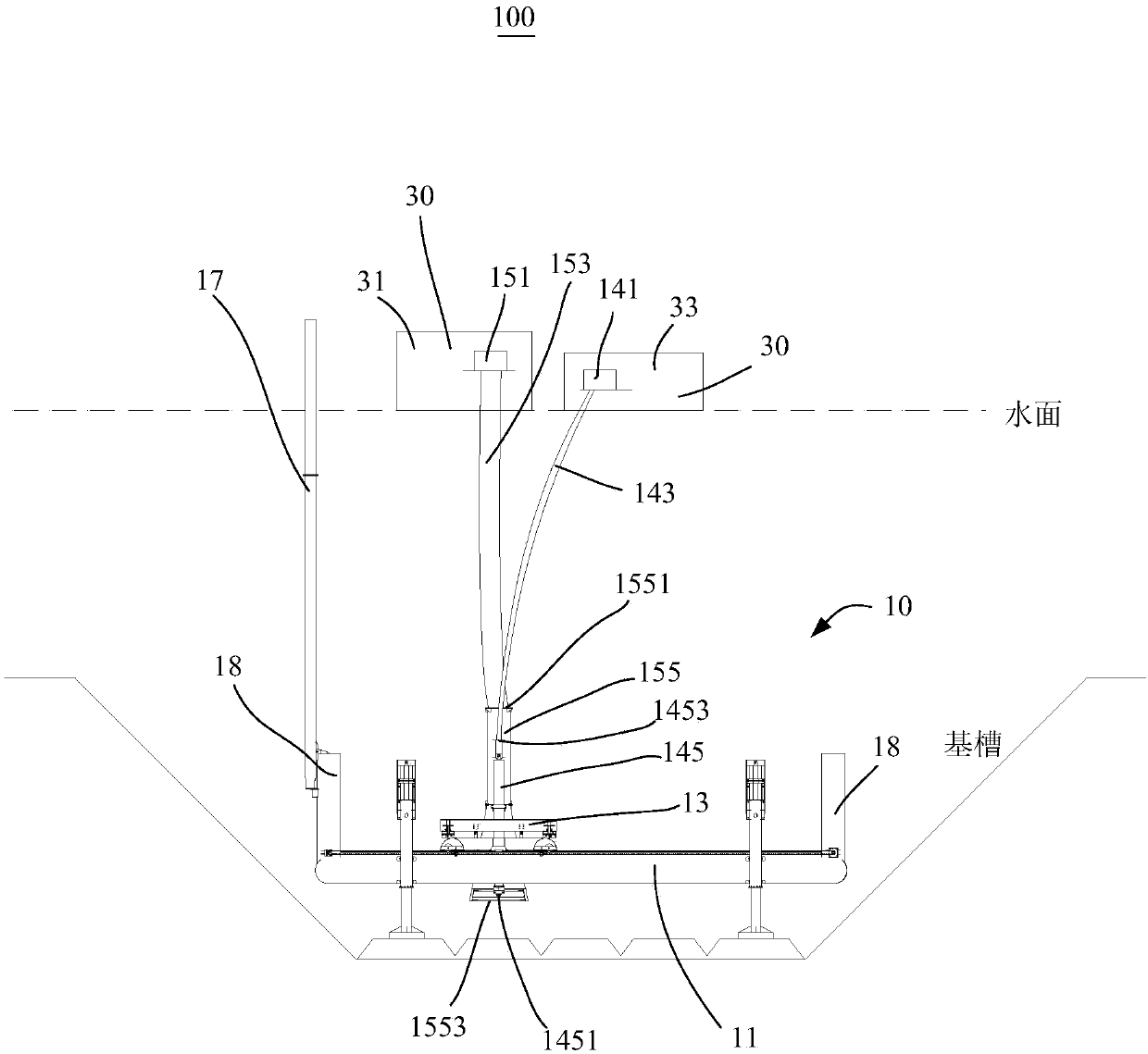

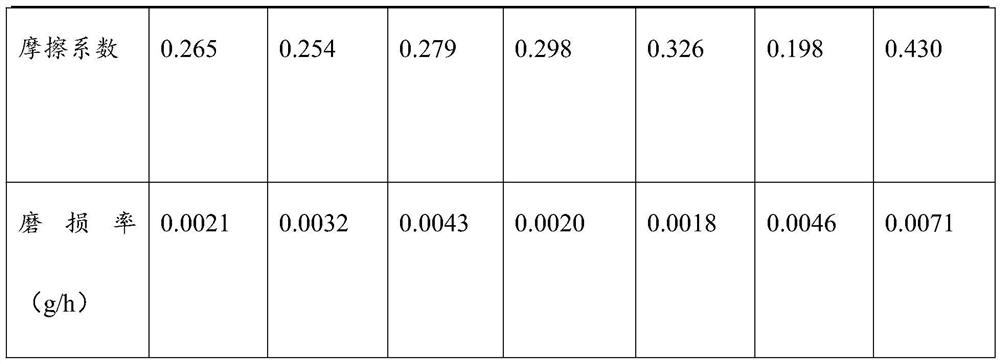

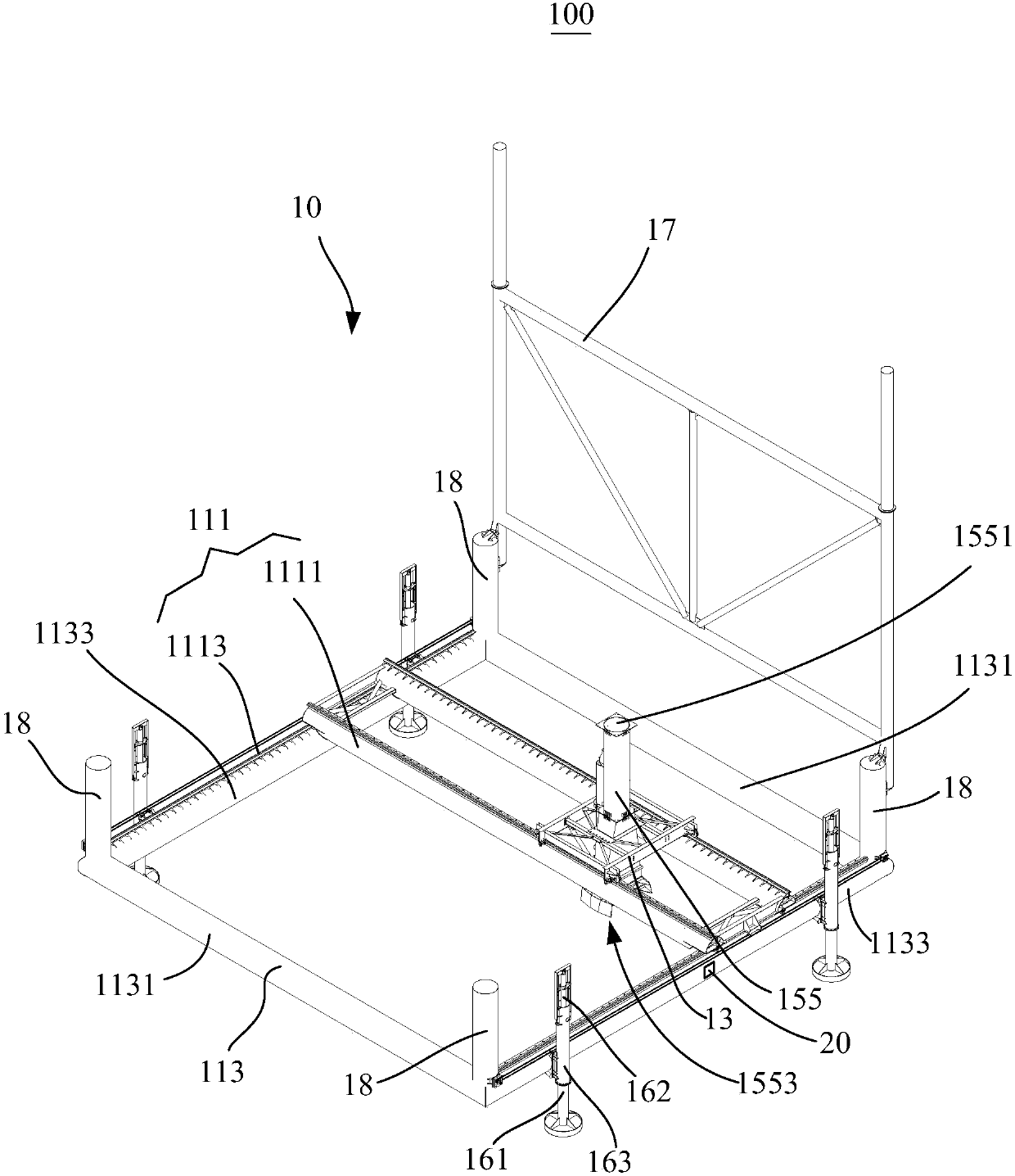

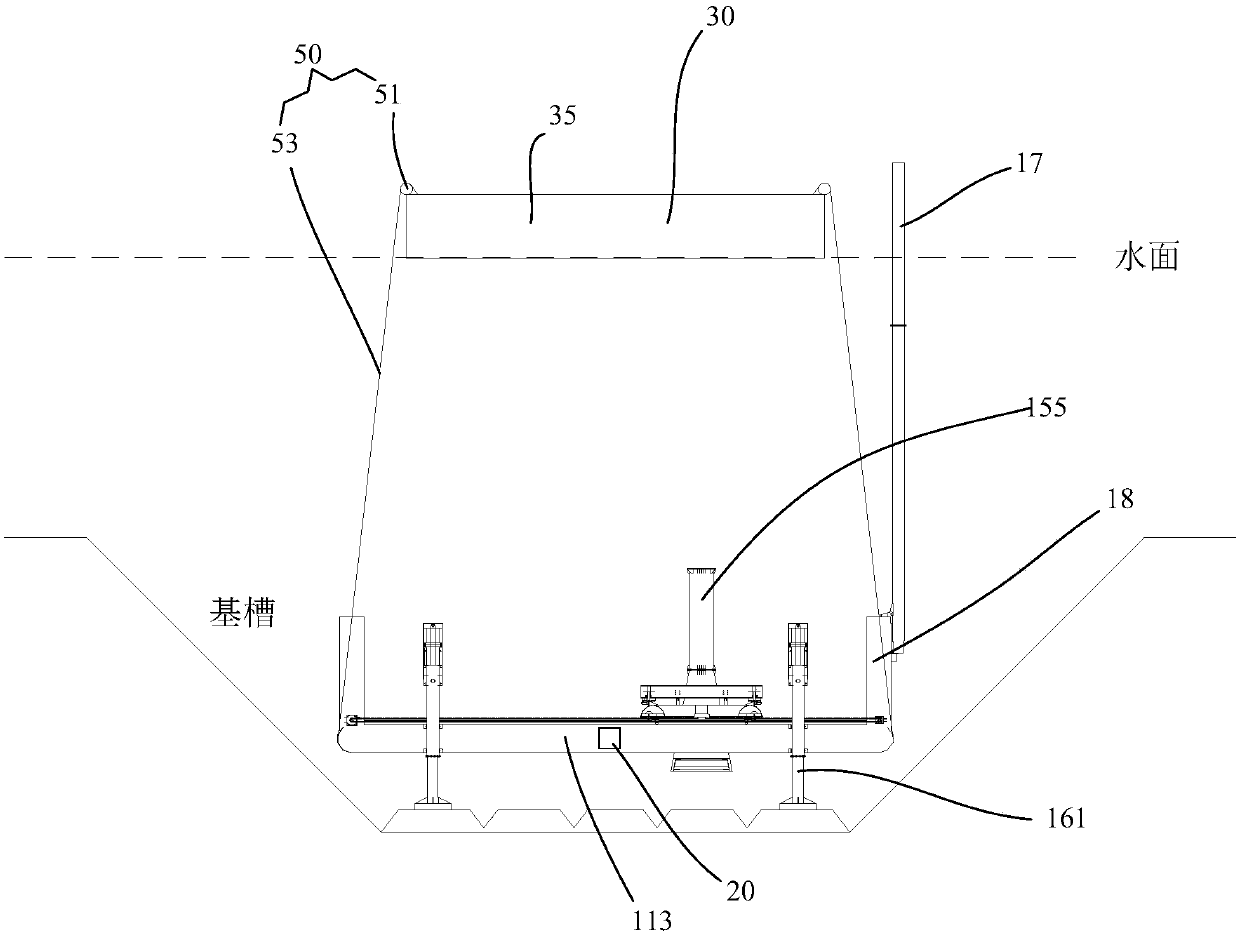

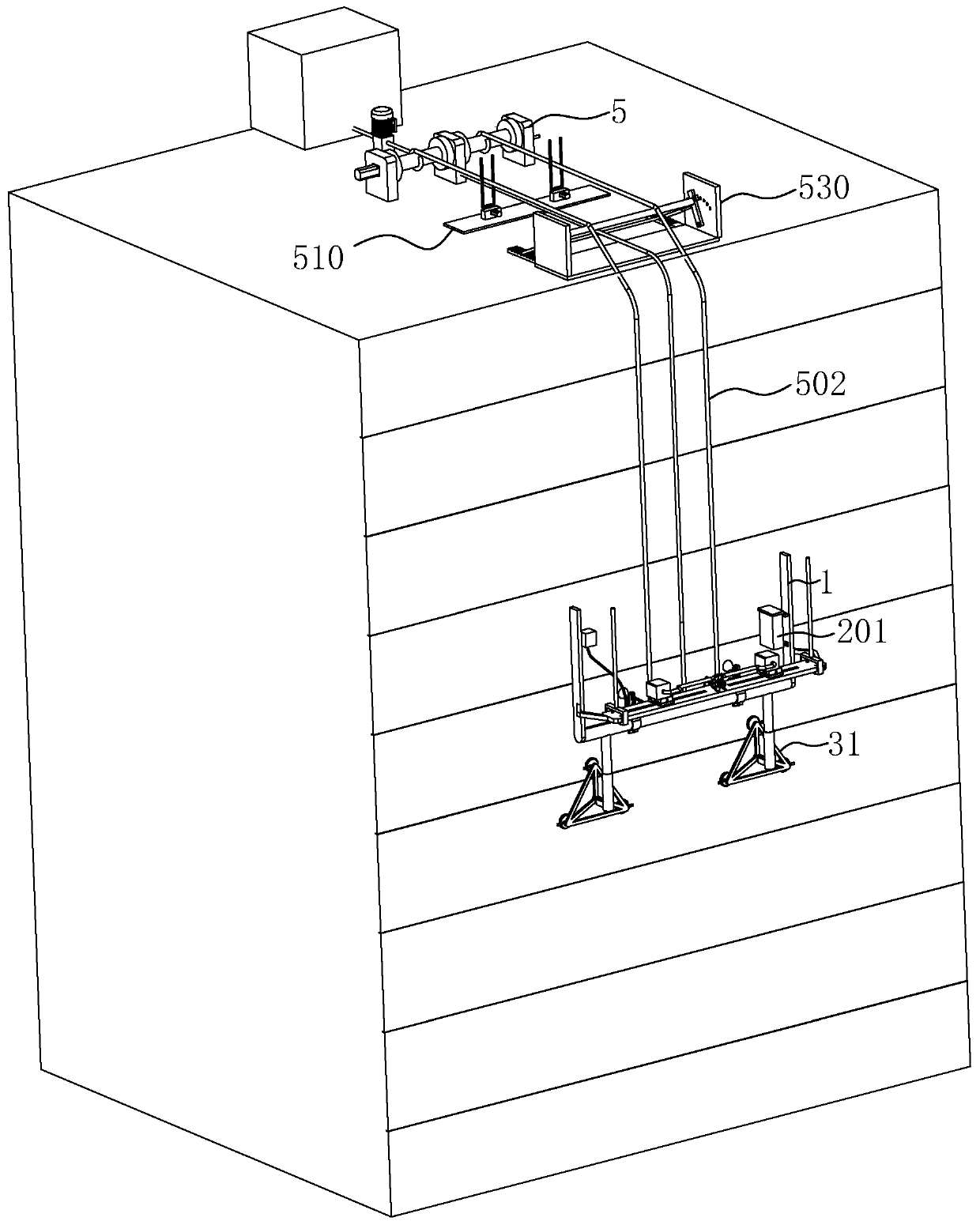

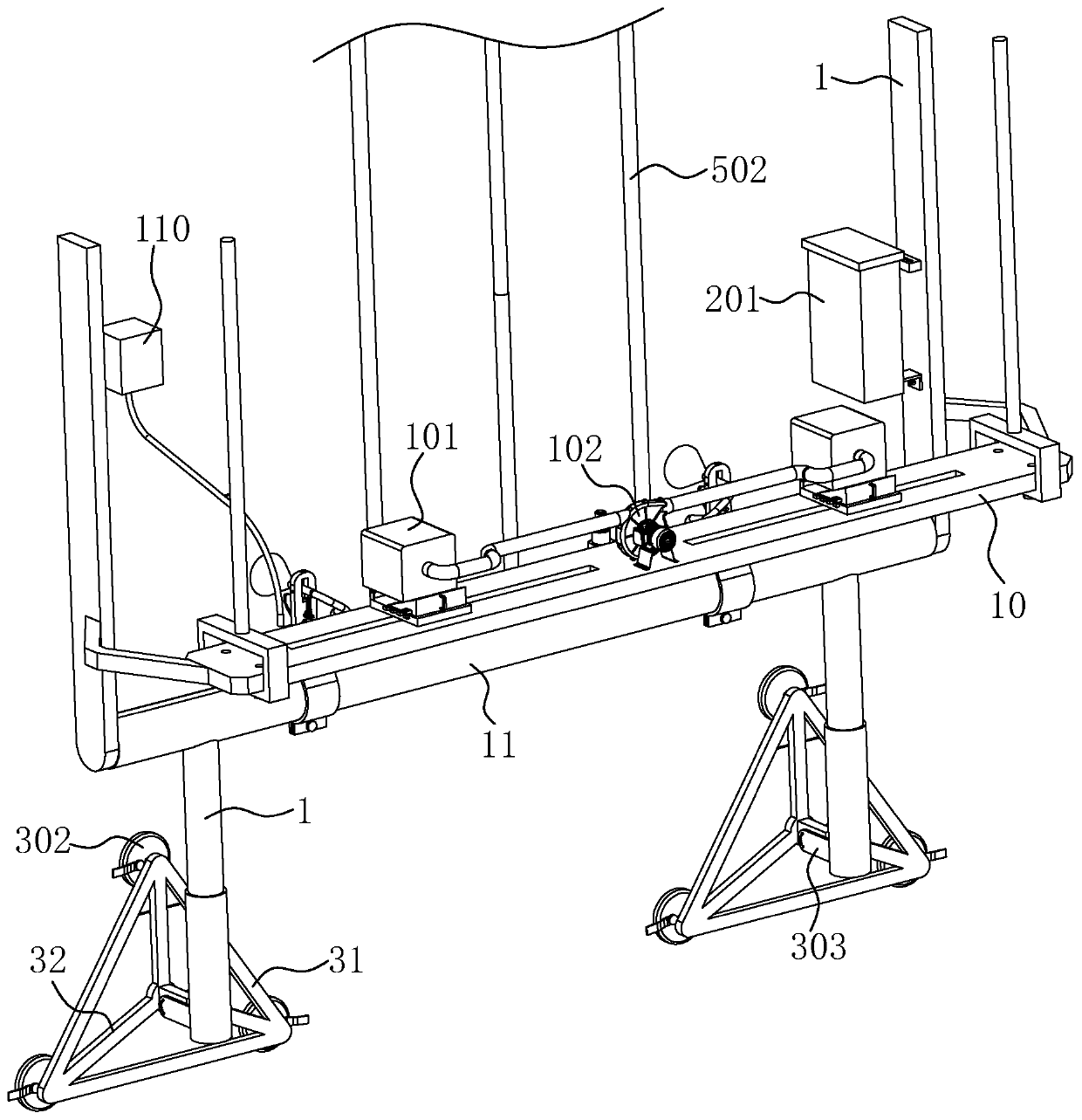

Automatic paver system with adjustable supporting legs and working method of automatic paver system

ActiveCN107724395APlay a bearing rolePositioningArtificial islandsUnderwater structuresDistributed structureWater flow

The invention discloses an automatic paver system with adjustable supporting legs and a working method of the automatic paver system. The automatic paver system with the adjustable supporting legs includes a paving device. The paving device includes a supporting frame, the adjustable supporting legs, a conveying structure and a distributing structure, wherein the adjustable supporting legs includea driving part, a connecting part and supporting leg bodies, the connecting part and the supporting leg bodies are connected with the driving part, the connecting part is connected with the supporting frame, and the supporting leg bodies are supported on a water bottom surface, and driven by the driving part, the connecting part moves up and down relative to the supporting leg bodies to adjust the height of the supporting frame to the water bottom surface; the conveying structure is connected with the supporting frame in a sliding mode; amd the distributing structure is connected with the conveying structure and is provided with a feeding hole and a discharging hole which are used for allowing materials to pass through, the discharging hole extends to the water bottom surface, and the conveying structure drives the distributing structure and the supporting frame to move and drives the discharging hole to conduct material falling. According to the technical scheme of the automatic paver system, the position of material falling is precise; and in the distributing process, the influence of water current and wave is small; working conditions are less limited by a working area; and thecost performance is high.

Owner:CHINA CONSTR ENG HONG KONG

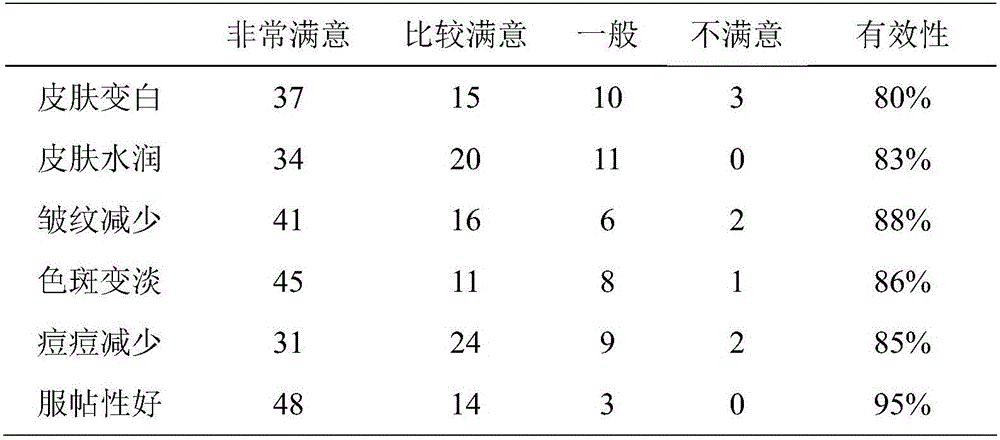

Electro-spinning nanofiber mask with core-shell structure and preparation method thereof

ActiveCN105686957AHigh carrier activityLarge specific surface areaCosmetic preparationsToilet preparationsNanofiberCore shell

The invention relates to an electro-spinning nanofiber mask with a core-shell structure and a preparation method thereof and belongs to the field of natural cosmetics. The electro-spinning nanofiber mask is prepared from, by weight, 5-10 parts of bletilla roots, 5-10 parts of radix paeoniae alba, 5-15 parts of ginseng, 5-10 parts of mulberry fruits, 5-10 parts of malva sylvestris, 5-10 parts of alkanna roots, 1-3 parts of nutrients, 0.5-2 parts of hyaluronic acid and 0.5-3 parts of collagen. The electro-spinning nanofiber mask has the advantages that dirt in skin can be completely removed, the mask can be better attached to the skin, the skin absorbs functional matter more rapidly, whitening, freckle removing, inflammation diminishing, sterilizing and anti-aging repairing are comprehensively combined, and the requirements of people for multiple effects of the mask are met.

Owner:JILIN UNIV

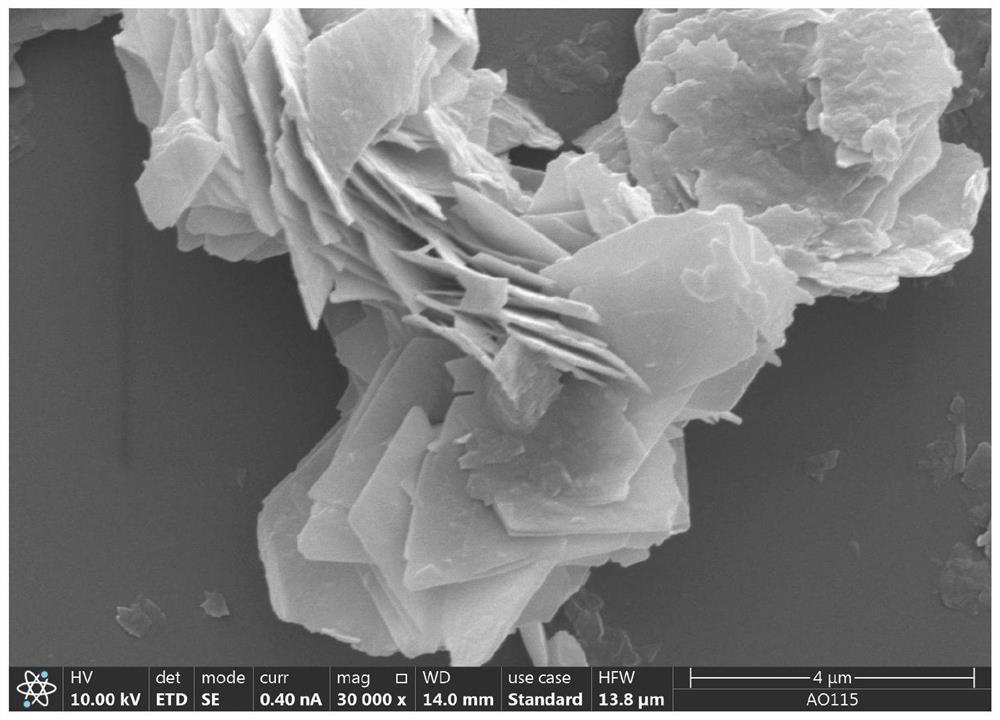

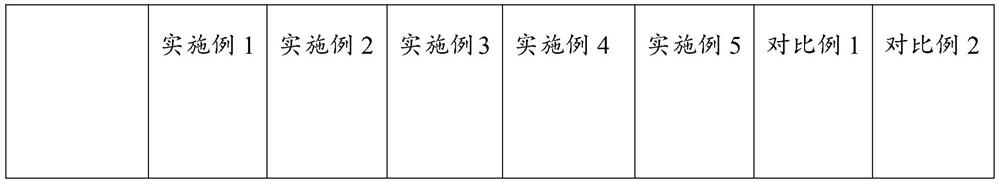

Manganese dioxide modified fiber fabric composite material for ultrasonic motor as well as preparation method and application of manganese dioxide modified fiber fabric composite material

ActiveCN112759890AImprove tribological performanceImprove wear resistanceGlass fiberElectric machinery

The invention provides a manganese dioxide modified fiber fabric composite material for an ultrasonic motor and a preparation method and application thereof, and belongs to the technical field of ultrasonic motors. According to the invention, the aramid fiber and glass fiber mixed fabric is used as an ultrasonic motor friction material for the first time, so that a bearing effect is achieved; the used lamellar nano-manganese dioxide has good bearing capacity, and the bearing capacity of the composite material can be further improved when the lamellar nano-manganese dioxide is loaded on the surface of the fabric; the lamellar nano-manganese dioxide is combined with the aramid fiber and glass fiber mixed fabric, so that the tribological performance of the composite material is improved; according to the invention, the lubricating filler and the lamellar nano manganese dioxide are combined for use, so that the wear resistance of the material can be greatly improved while the friction coefficient is reduced, and the friction coefficient of the obtained composite material is 0.254-0.326; the wear rate is 0.0018-0.0043 g / h, and guidance is provided for the design of an ultrasonic motor friction material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Automatic spreading machine system with detection adjusting structure and working method thereof

ActiveCN107724397APlay a bearing rolePositioningArtificial islandsUnderwater structuresWater flowWorking set

The invention discloses an automatic spreading machine system with a detection adjusting structure and a working method thereof. The automatic spreading machine system with the detection adjusting structure comprises a supporting frame, a plurality of adjusting supporting legs and a distribution structure, wherein the supporting frame is provided with at least one inclinometer, and a master controller is electrically connected with the inclinometer; the master controller is electrically connected with a drive part, and then a connection portion is driven to move up and down relative to the supporting legs so that the height of the supporting frame relative to the horizontal bottom plane can be adjusted; a conveying structure is connected to the supporting frame in a sliding mode; the distribution structure is provided with a feed inlet and a discharge outlet which allow materials to pass through, and the discharge outlet extends towards the horizontal bottom plane; and the conveying structure drives the distribution structure to move relative to the supporting frame, and the discharge outlet is driven to conduct distribution. According to the automatic spreading machine system withthe technical scheme, the discharging position at the bottom face of a foundation trench is accurate, the influence of water flow and waves in the distribution hardly exists, overall size of a spreading device of the automatic spreading machine system is small, the working condition is hardly limited by a working area, and the cost-performance ratio is high.

Owner:CHINA CONSTR ENG HONG KONG

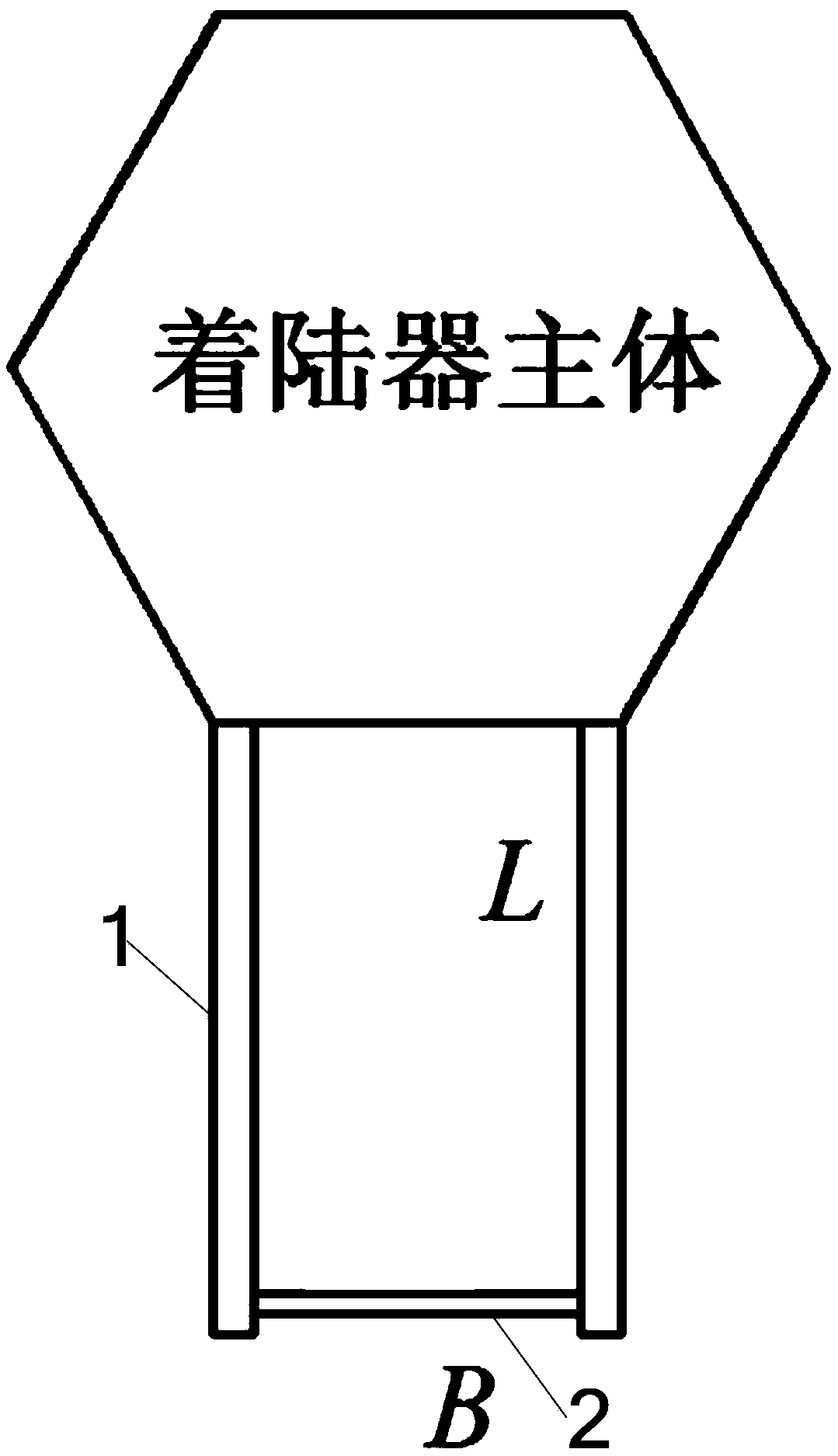

Expandable landing ladder with shape memory effect

ActiveCN108657471AHighly compressibleReduce volumeSystems for re-entry to earthCosmonautic landing devicesMemory effectShape-memory alloy

The invention discloses an expandable landing ladder with a shape memory effect and relates to the field of spaceflight. The expandable landing ladder is used for solving the problem that an existinglanding ladder is complex in structure and large in weight and consequently bears the large weight during launching. Two omega-shaped shape memory composite beams are oppositely closed; a gap betweenthe two omega-shaped shape memory composite beams is filled with shape memory foam; two resistance-type heating sheets are pasted to the inner surfaces of the two omega-shaped shape memory composite beams correspondingly, and the resistance-type heating sheets are used for increasing the temperature of the omega-shaped shape memory composite beams to be larger than the glass-transition temperatureof the omega-shaped shape memory composite beams in the power-on state, so that the omega-shaped shape memory composite beams are expanded; and the shape memory foam has compressibility and is used for providing the extra bearing capacity for expanding of the omega-shaped shape memory composite beams. The expandable landing ladder serves as an important bridge for connecting a lander with the surface of a planet.

Owner:HARBIN INST OF TECH

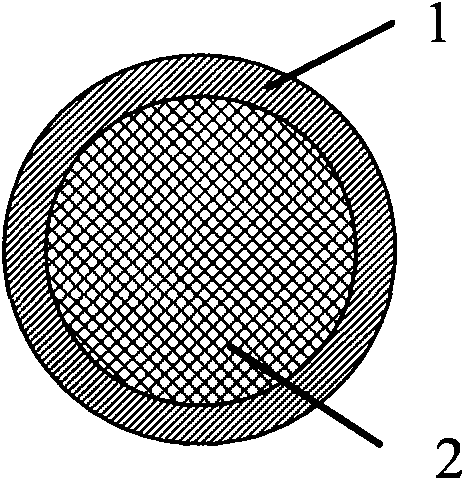

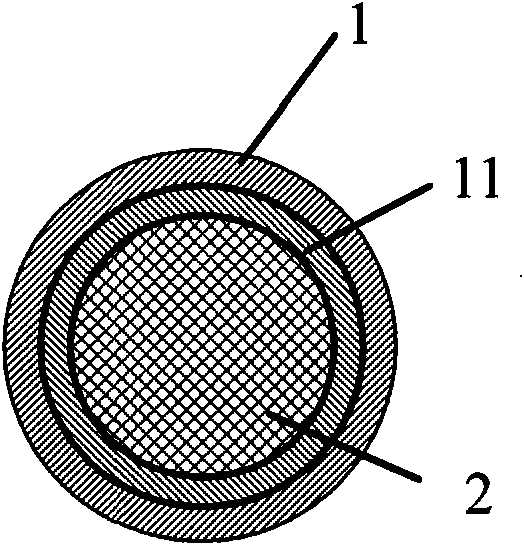

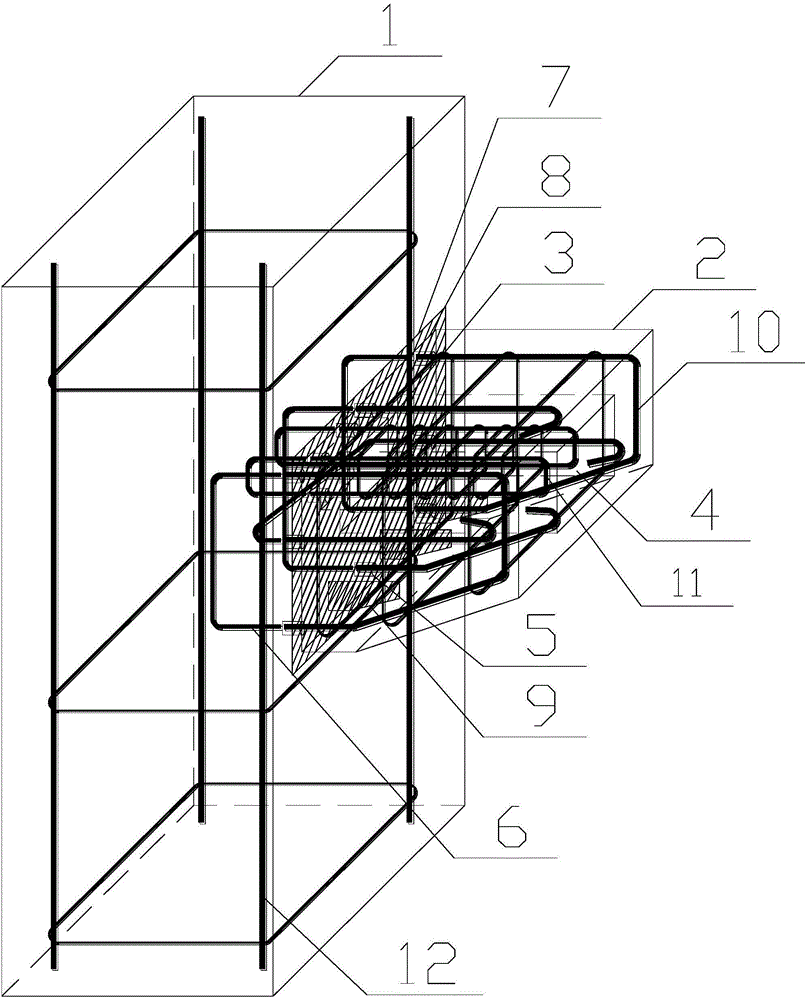

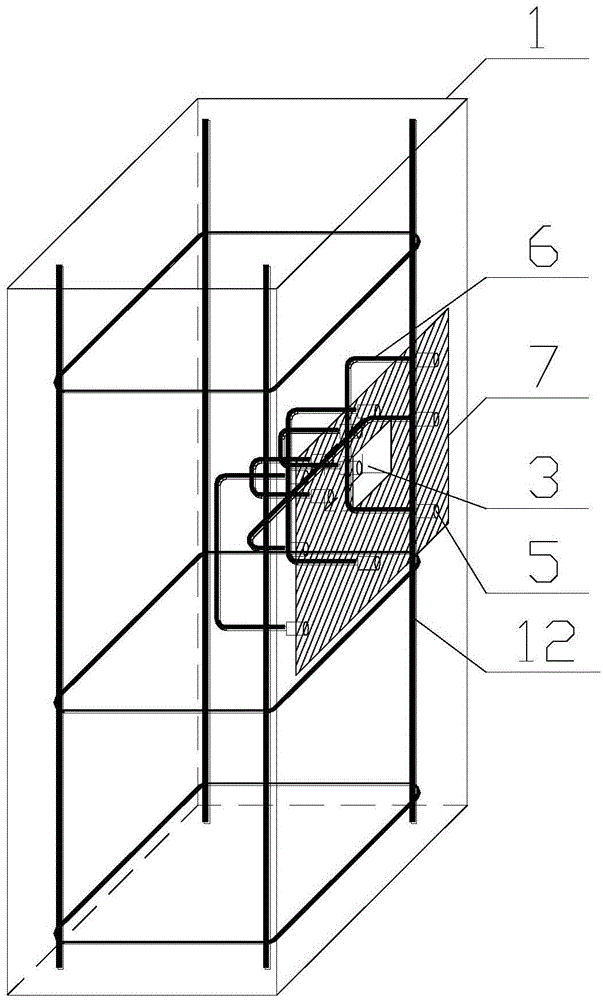

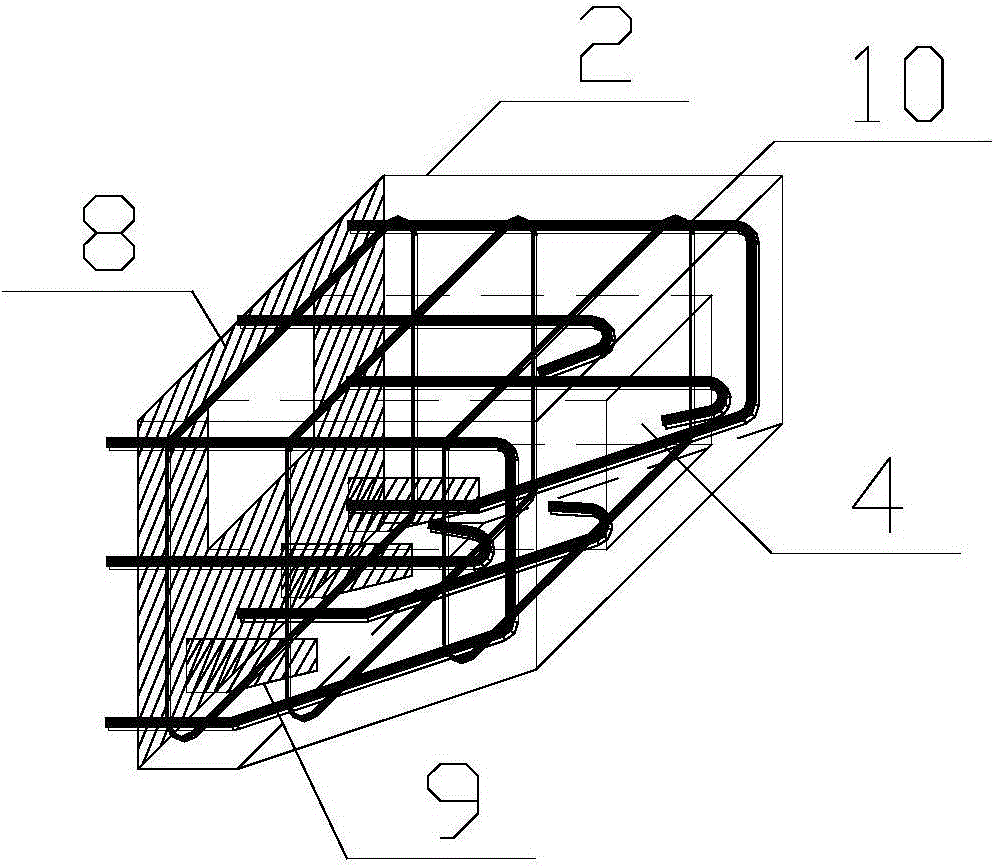

Scaffold

InactiveCN101377093AEasy to truncateEasy to operateBuilding support scaffoldsBiomedical engineeringMain bearing

The present invention discloses a scaffold (1), which comprises an inner scaffold body (2) and an outer scaffold body (3); wherein, the inner scaffold body (2) is arranged close to a building; the outer scaffold body (3) is arranged away from the building; small cross rods (4), which are arranged between the outer scaffold body (3) and the inner scaffold body (2), connect the outer scaffold body (3) and the inner scaffold body (2) together; the material of at least part of the inner scaffold body (2) is different from the material of the outer scaffold body (3); and moreover, the rigidity of the material of the outer scaffold body (3) is not less than the rigidity of the material of the inner scaffold body (2). Given that the outer scaffold body of the scaffold plays a main role in bearing and that the inner scaffold body is not a main bearing part, the outer scaffold body needs to be constructed with highly rigid material, while at least part of the inner scaffold body can adopt material with relatively low rigidity and strength, and thereby, the construction cost of the scaffold can be reduced. In the preferred embodiment of the scaffold, the inner scaffold body is made of material which can be easily cut, so a manual tool can easily cut the inner cross rods and / or inner upright rods of the inner scaffold body, and therefore construction is convenient.

Owner:SINOSCAFF GROUP

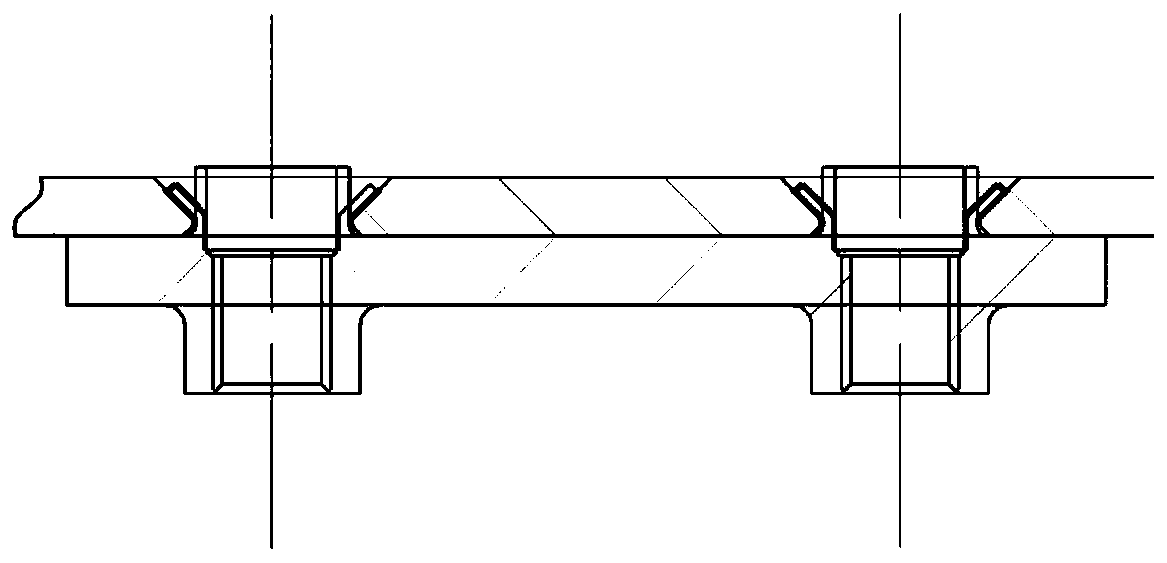

Pipeline through-wall structure and construction process thereof

ActiveCN112727084AImprove stabilityPlay a bearing rolePipesForms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention relates to a pipeline through-wall structure and a construction process thereof, and relates to the field of pipeline through-wall construction. The pipeline through-wall structure comprises a supporting frame, a plugging assembly and a plurality of through-wall pipelines, wherein the plugging assembly comprises two sealing plates, one of the sealing plates is fixedly connected to one opening end of the supporting frame in a one-to-one correspondence mode, a plurality of connecting holes are formed in the sealing plates in a penetrating mode, The through-wall pipeline is arranged in the connecting hole in a penetrating mode, a pouring hole is formed in the bottom of any sealing plate, an exhaust hole is formed in the top of the other sealing plate, The pipeline through-wall construction process comprises the following steps that a hole is reserved when a wall body is poured, the supporting frame is placed in the hole, then concrete pouring is conducted, after the wall body is formed, the through-wall pipeline penetrates through the sealing plates, then the sealing plates are fixed in the supporting frame, and finally concrete is poured into the supporting frame. The pipeline through-wall structure and the construction process thereof have the effect of improving the wall stability during pipeline wall penetrating.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

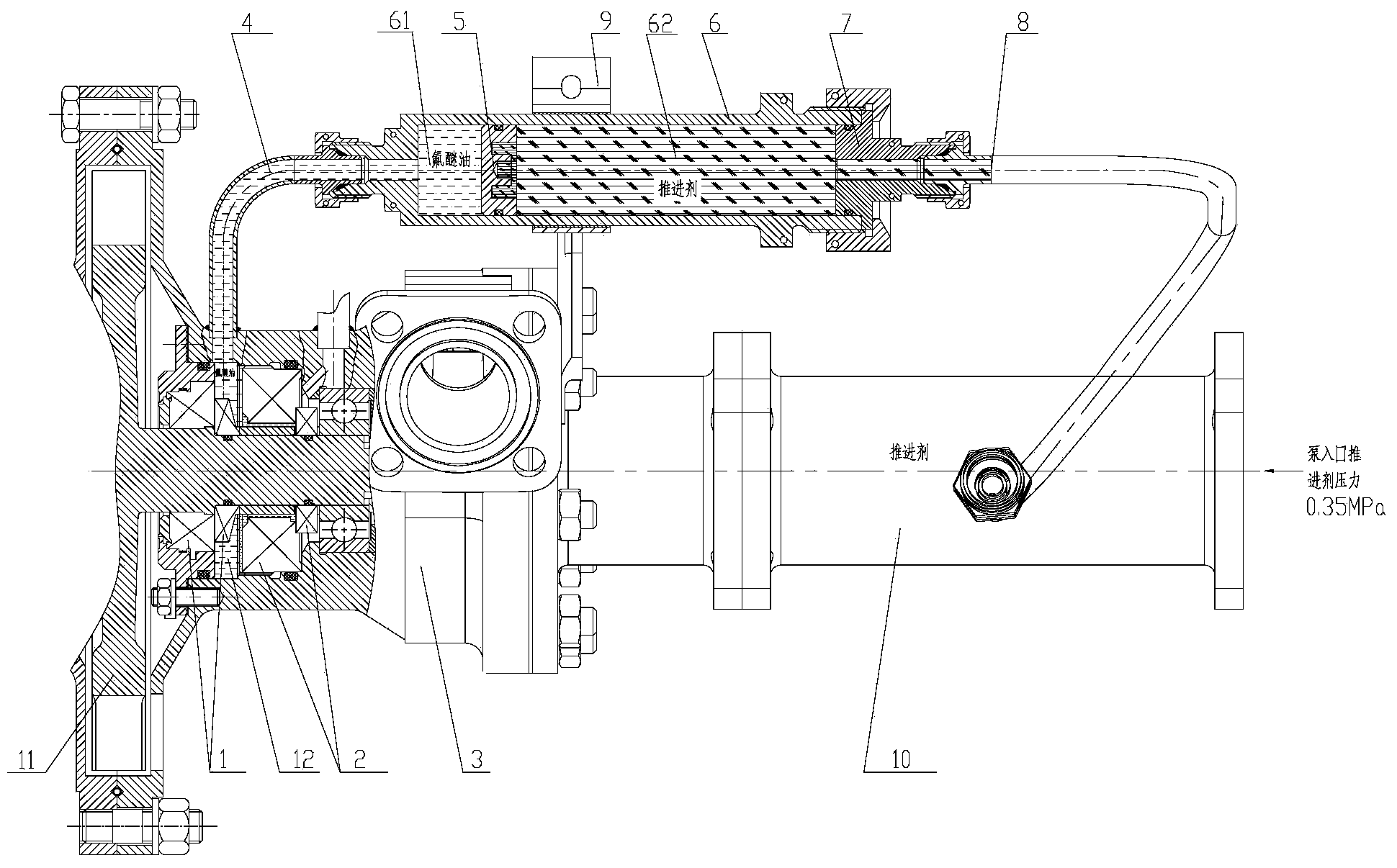

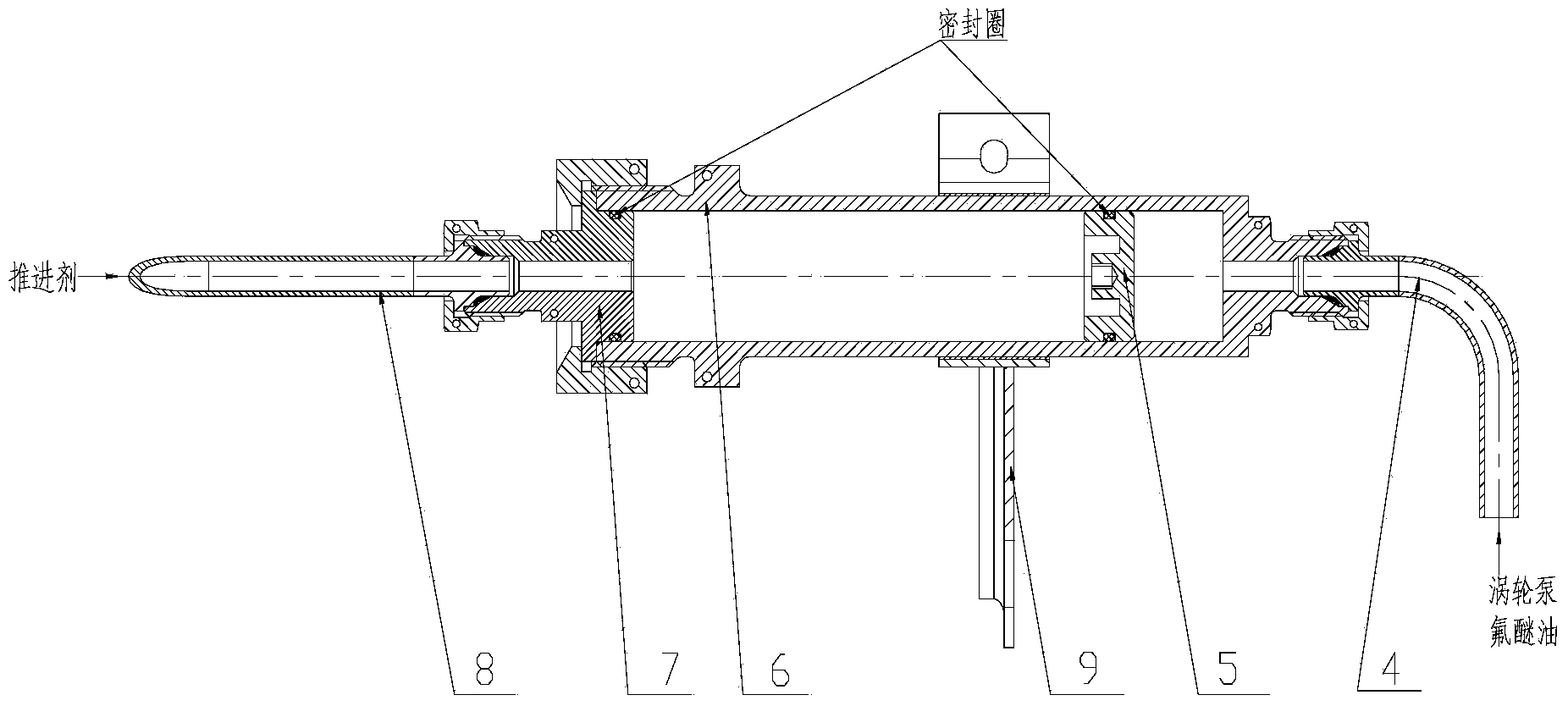

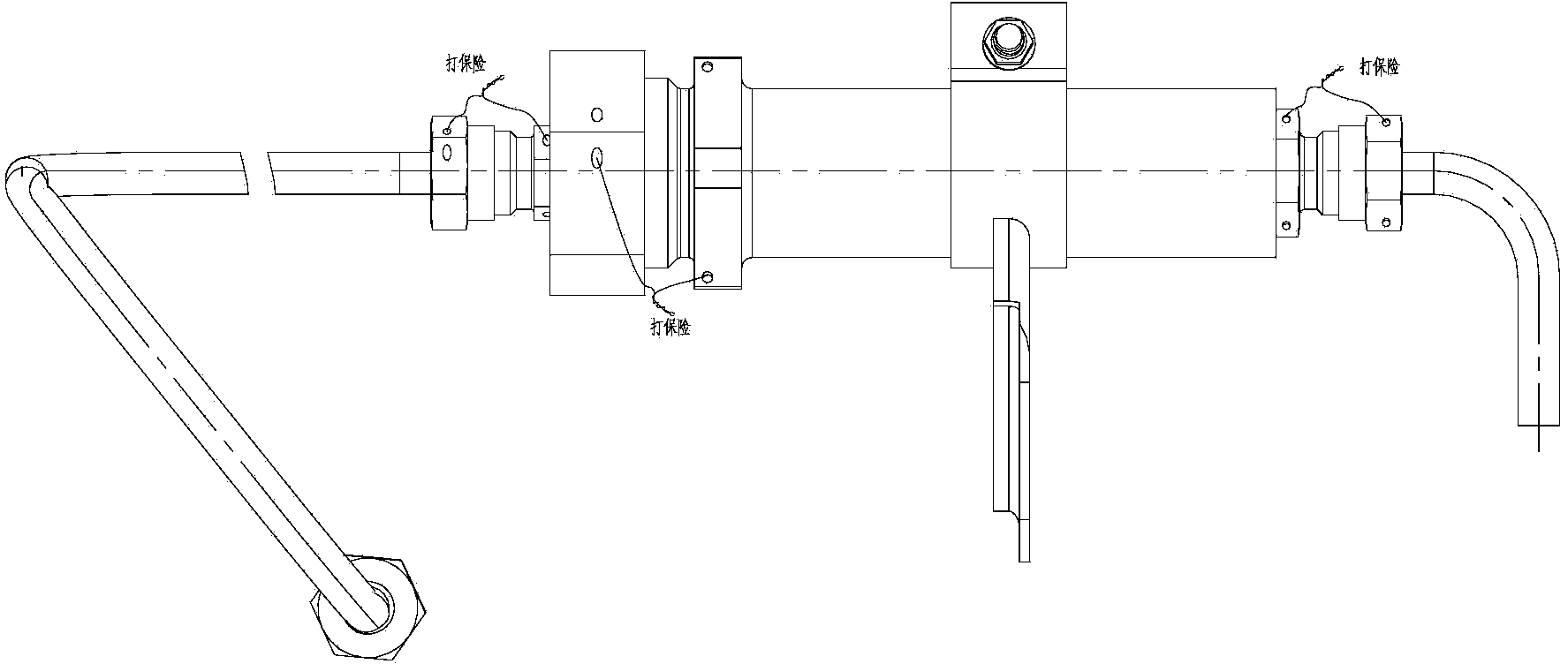

Novel pressure stabilization device for double-end surface sealing of turbine pump

ActiveCN104235052AMeet long-term storage requirementsGuaranteed tightnessPump componentsPumpsPressure stabilizationHigh pressure

The invention relates to a novel pressure stabilization device for double-end surface sealing of a turbine pump. The novel pressure stabilization device comprises an oil cylinder, an oil inlet guiding pipe, a balance piston, a cylinder cover and a balance loop circuit, wherein the oil cylinder is fixedly arranged on a turbine pump body and is divided into an isoflurane oil cavity and a propellant cavity by the balance piston, one end of the oil inlet guiding pipe is fixedly arranged at one end of the oil cylinder and is communicated with the isoflurane oil cavity, the other end of the oil inlet guiding pipe is fixedly arranged on a turbine pump shell and is connected with a closed oil cavity, the cylinder cover is fixedly arranged at the other end of the oil cylinder, one end of the balance loop circuit is fixedly arranged on the cylinder cover and is communicated with the propellant cavity through the cylinder cover, and the other end of the balance loop circuit is fixedly arranged on the turbine pump body and is communicated with an oxidant pump inlet pipeline. The novel pressure stabilization device for the double-end surface sealing of the turbine pump, disclosed by the invention, has the advantages that the phenomenon that the end surface sealing is damaged due to abnormal high pressure of the isoflurane oil cavity during the work of a double-end surface sealing structure of an engine turbine pump is overcome, the volume is small, the weight is light, high temperature resistance and corrosion resistance are realized, the novel pressure stabilization device is beneficial for long-time storage and does not need to be subjected to secondary maintenance, and meanwhile, the high pressure of the isoflurane oil cavity can be eliminated.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

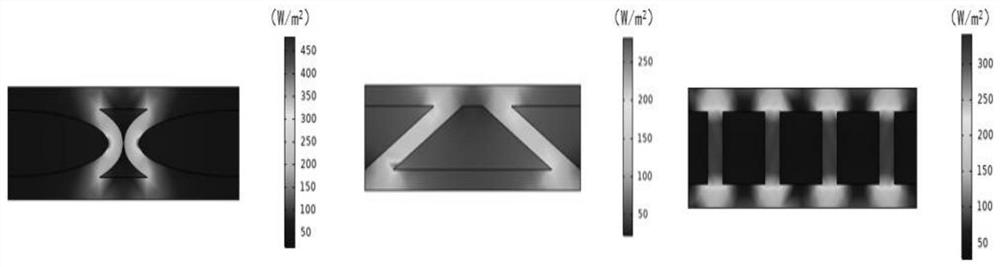

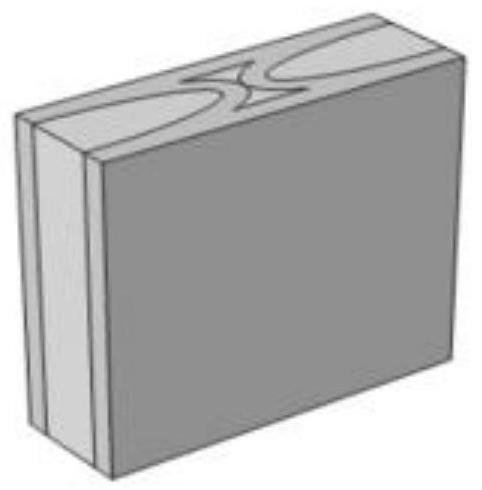

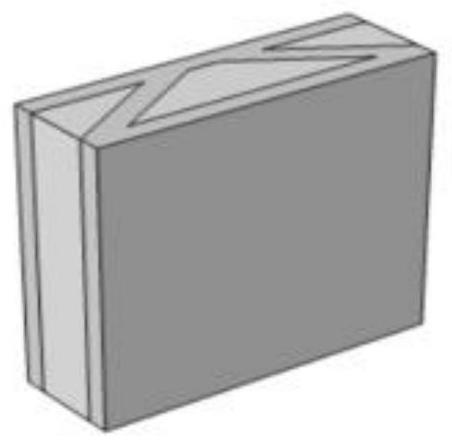

Preparation method for 3D printing novel heat preservation frame integrated wall based on numerical simulation

PendingCN114102796AGuaranteed thermal insulation performanceAchieve deliveryAdditive manufacturing apparatusConstruction material3d printInsulation layer

The invention relates to a numerical simulation-based preparation method of a 3D printing novel thermal insulation frame integrated wall. A special-shaped frame part and an internal filling part filled in the special-shaped frame part are included; wherein the special-shaped frame part is divided into an external enclosure structure and an internal supporting structure, and the special-shaped frame part and the internal filling part are printed through the 3D printing technology at the same time; the special-shaped frame part determines the frame shape meeting the requirement through numerical simulation software before printing. The novel heat preservation frame integrated wall solves the problem that the heat preservation performance and the mechanical performance of a cement-based material cannot be considered at the same time, the mechanical performance and the heat preservation performance can be improved at the same time, and the problem that the heat preservation performance of a wall cannot meet the requirement in construction is solved. In engineering practice, an insulating layer does not need to be externally pasted again, and the problems that a common wall body is composed of building blocks in construction, the integrity is not high enough, and meanwhile stress defects exist are solved. Solid waste is used as a substrate, and low carbon and waste utilization are achieved.

Owner:HEBEI UNIV OF TECH

High temperature nanometer non-burning slide plate and processing technique thereof

ActiveCN106986619AImprove high temperature performanceImprove antioxidant capacitySlide plateEngineering

The invention relates to a high temperature nanometer non-burning slide plate and a processing technique thereof. By applying a method for shaping for many times, namely, a primary shaped slide plate is prepared firstly, and then slide plates in line of dimension requirement are shaped through gradually expanding outwards for several times on this basis; the slide plate is integrated structure. By applying the method of shaping for many times and the progressive way, the slide plate is more compactly pressed, and the primary shaping dimension is big; thus the primary shaped slide plate is not easy to deform and damage even through being pressed during the secondary shaping; meanwhile, the slide plate is provided with a reinforcing pipe to provide stress load during the pressing process, thus the shaping quality of the slide plate is further guaranteed; meanwhile, the reinforcing pipe is further arranged to be a hollow pipe, thus the reinforcing pipe can play a certain bearing effect during the secondary shaping and the third shaping; the reinforcing pipe also can be deformed and compactly inlaid in the groove for being pressed, thus the shaping quality and compact consistence of the slide plate are guaranteed.

Owner:JIANGSU YUEZHAN NEW MATERIALS

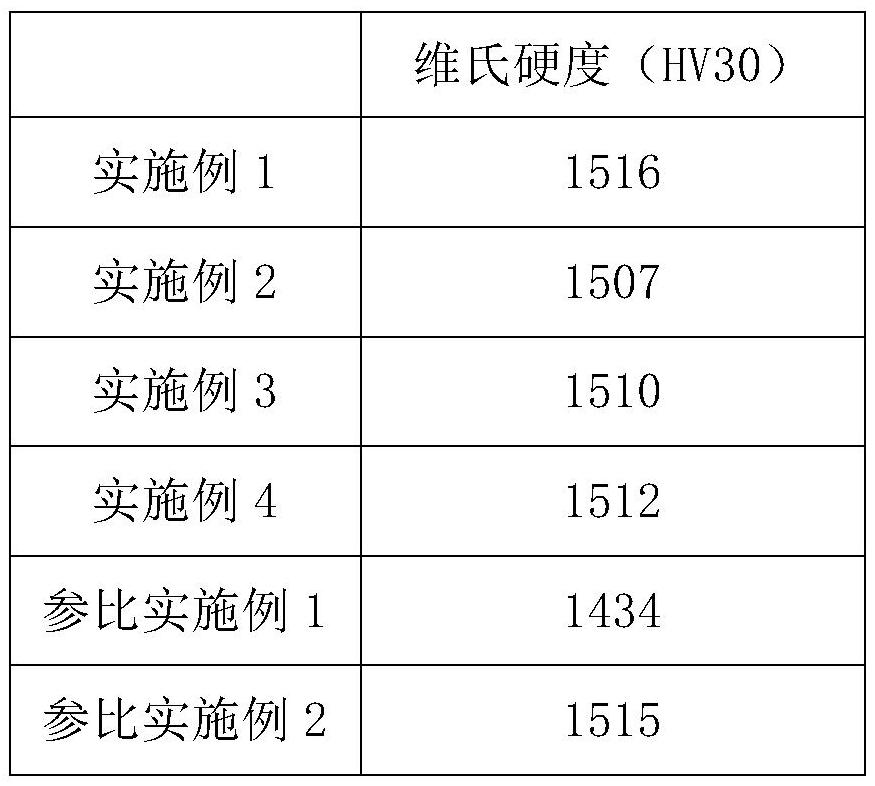

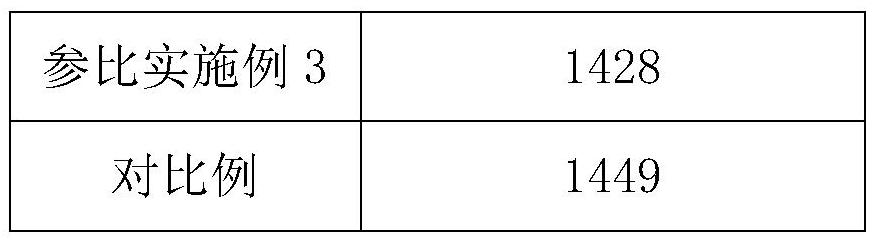

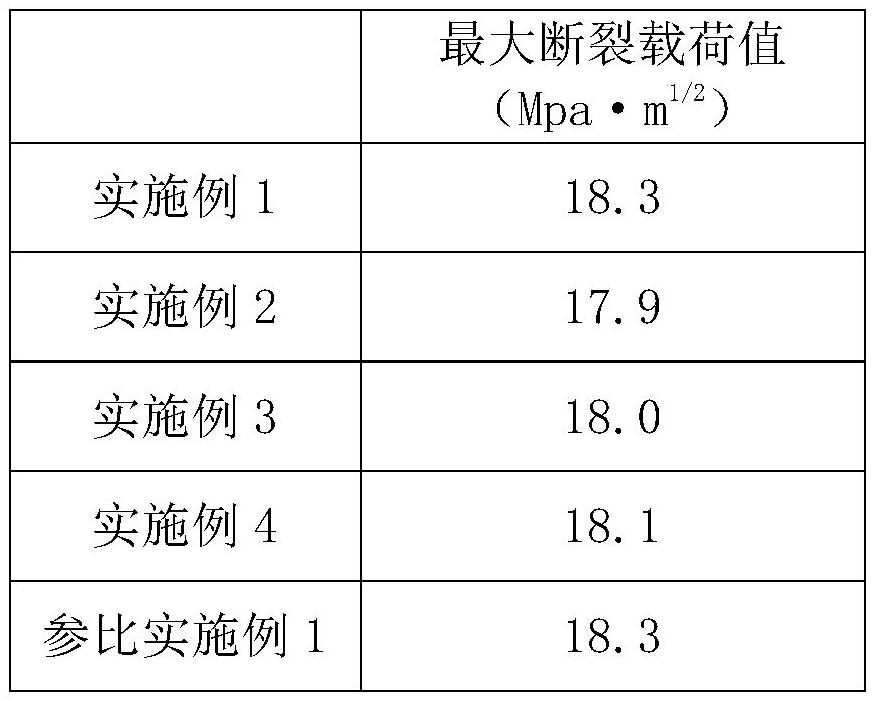

Hard alloy surface boronizing method

ActiveCN111705293AImprove permeabilityHigh hardnessSolid state diffusion coatingCarbide siliconSand blasting

The invention provides a hard alloy surface boronizing method. The method comprises the following steps that (1), sand blasting treatment is performed on a hard alloy, and an oxide layer on the surface of the hard alloy is removed; (2), a boronizing agent is poured into a boronizing container, the hard alloy treated in the step (1) is buried into the boronizing agent, and then the boronizing container is closed and put into a sintering furnace, wherein the boronizing agent is composed of the following components, by weight percentage, 10-15% of a boron supply agent, 25-30% of an activator andthe balance a filler, wherein the boron supply agent is composed of equal weight of boron nitride and boron carbide; the activator is composed of equal weight of potassium fluoborate and tetrafluoroboric acid pyrrolidine salt; the filler is silicon carbide; and (3), the sintering furnace is vacuumized until the vacuum degree is 100 Pa, inert gas is injected into the sintering furnace until the pressure in the sintering furnace reaches 0.07 MPa, heating starts to be performed, heat preservation is performed for 2-6 hours after the temperature is increased to 1,100-1,300 DEG C, heating is stopped, and then the temperature is cooled to the room temperature. By the adoption of the hard alloy surface boronizing method, a boronizing layer formed by the method is large in thickness, and the hardness, the wear resistance, the bending strength and the toughness of the hard alloy can be effectively improved.

Owner:广东正信硬质材料技术研发有限公司

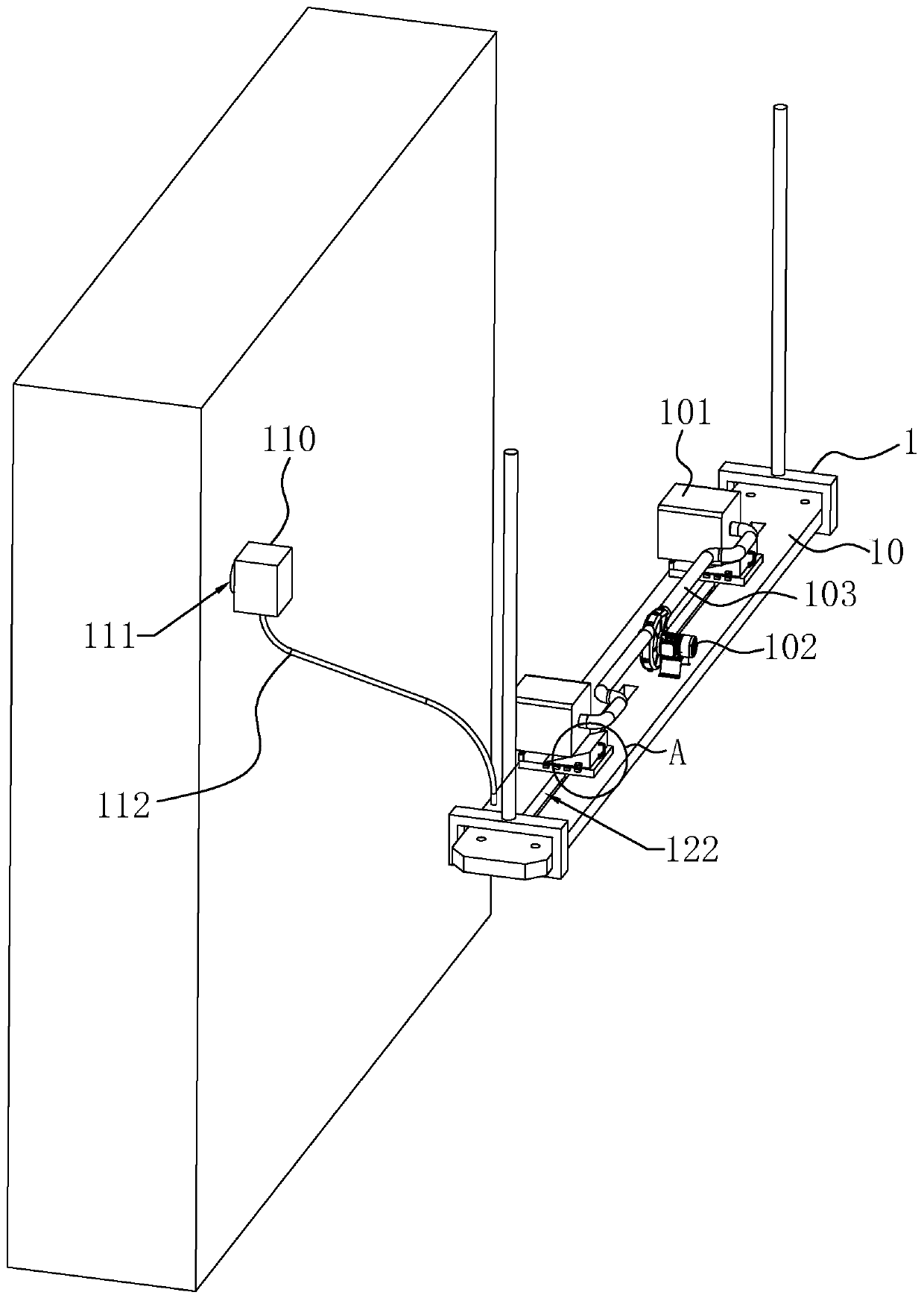

Spray detection equipment for building exterior walls and exterior windows

PendingCN110082276AImprove accuracyEasy to adjustPermeability/surface area analysisAuto regulationEngineering

The invention relates to spray detection equipment for building exterior walls and exterior windows and belongs to the technical field of water permeability test of a building. The technical scheme ischaracterized in that the spray detection equipment comprises a spray assembly mounted on a mounting rack; a water pressure detection assembly mounted on the mounting rack; a blower assembly mountedon a bearing strip plate of the mounting rack; a wind pressure detection assembly mounted on the mounting rack; an adsorption assembly for fixing the mounting rack to a wall; an automatic adjusting device arranged on the mounting rack and used for adjusting the spraying direction of the spray assembly to allow the spray assembly to spray in a predetermined direction; and high-altitude fall prevention device arranged on a roof and used for fixing the spray assembly at a predetermined position in the air. The spray detection equipment can achieve comprehensive spray detection during use, so thatdetection data accuracy of the spray detection equipment can be improved, and overall safety of the equipment can be improved.

Owner:深圳市居安建筑科技有限公司

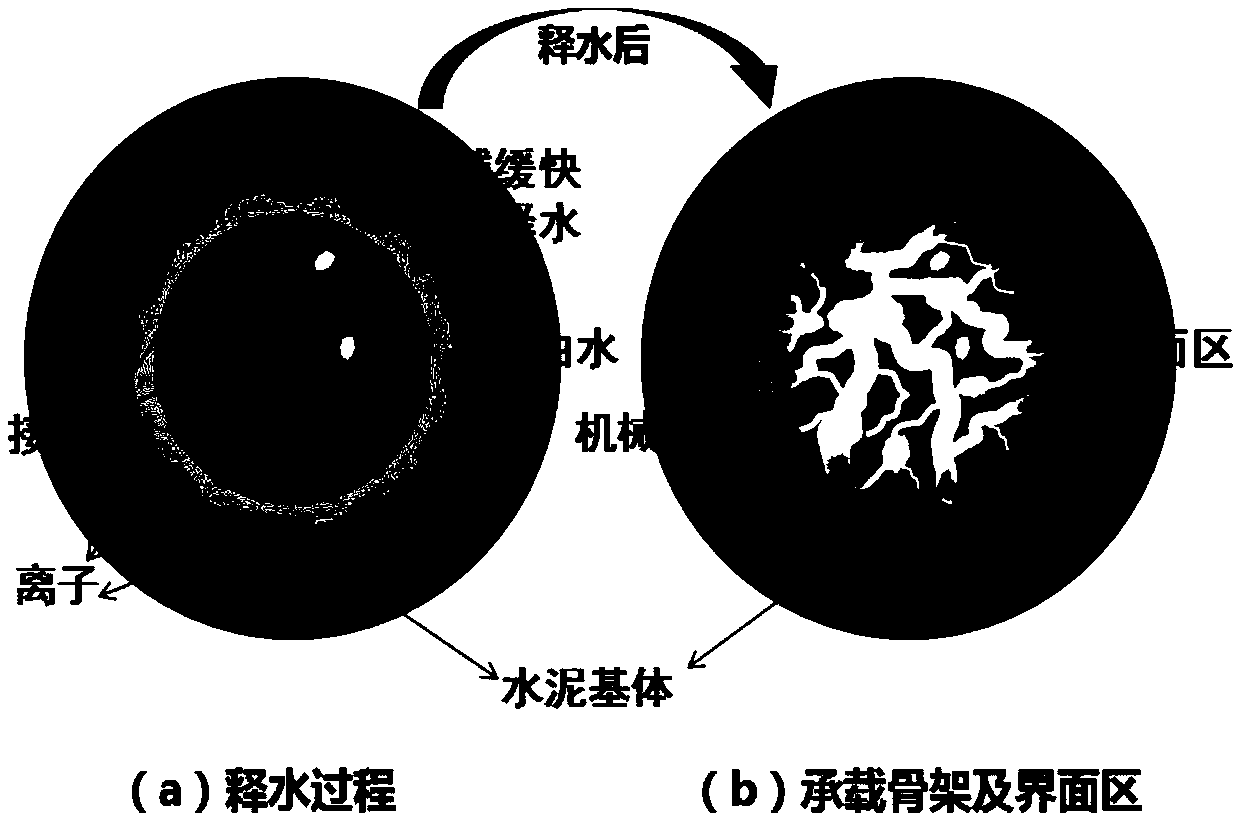

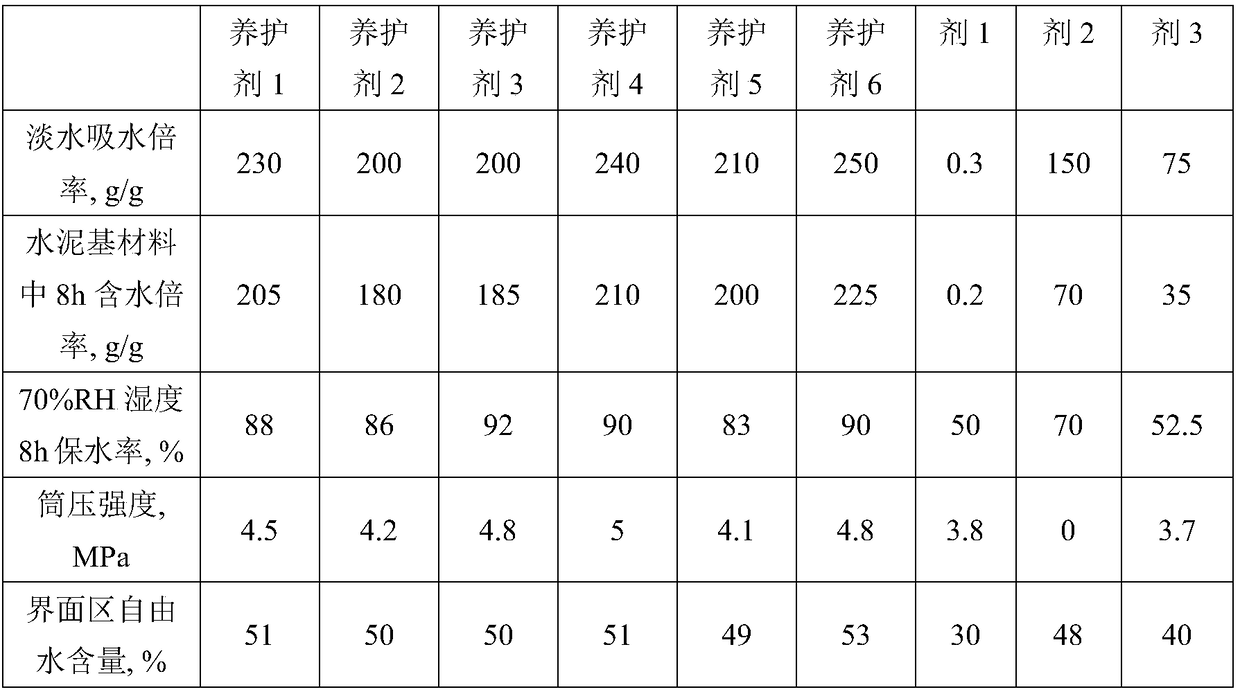

Preparation method of concrete having no strength negative effect and high internal curing efficiency

The invention discloses a preparation method of concrete having no strength negative effect and high internal curing efficiency. The technical scheme is characterized by firstly carrying out advancedwater absorption on a skeleton structure curing agent, then mixing the skeleton structure curing agent with river sand and break stones, and finally adding cement and residual water in sequence and uniformly stirring, thus obtaining the concrete, wherein the adding amount of the skeleton structure curing agent accounts for 0.1 to 0.5 percent of the mass of the concrete, and the preparation methodof the skeleton structure curing agent comprises the following steps: uniformly mixing raw material powder, a porous conditioning agent and water, thus obtaining a raw material lump; then drying, roasting and smashing, thus obtaining a porous rigid PM (Particulate Matter) skeleton; immersing the porous rigid PM skeleton in liquid SAP (Super Absorbent Polymer) gel for loading, and then drying, thusobtaining the skeleton structure curing agent of a rigid skeleton structure. The preparation method disclosed by the invention is simple and reliable in technology, low in production cost and high incuring efficiency, and has no strength negative effect.

Owner:HUBEI UNIV OF TECH

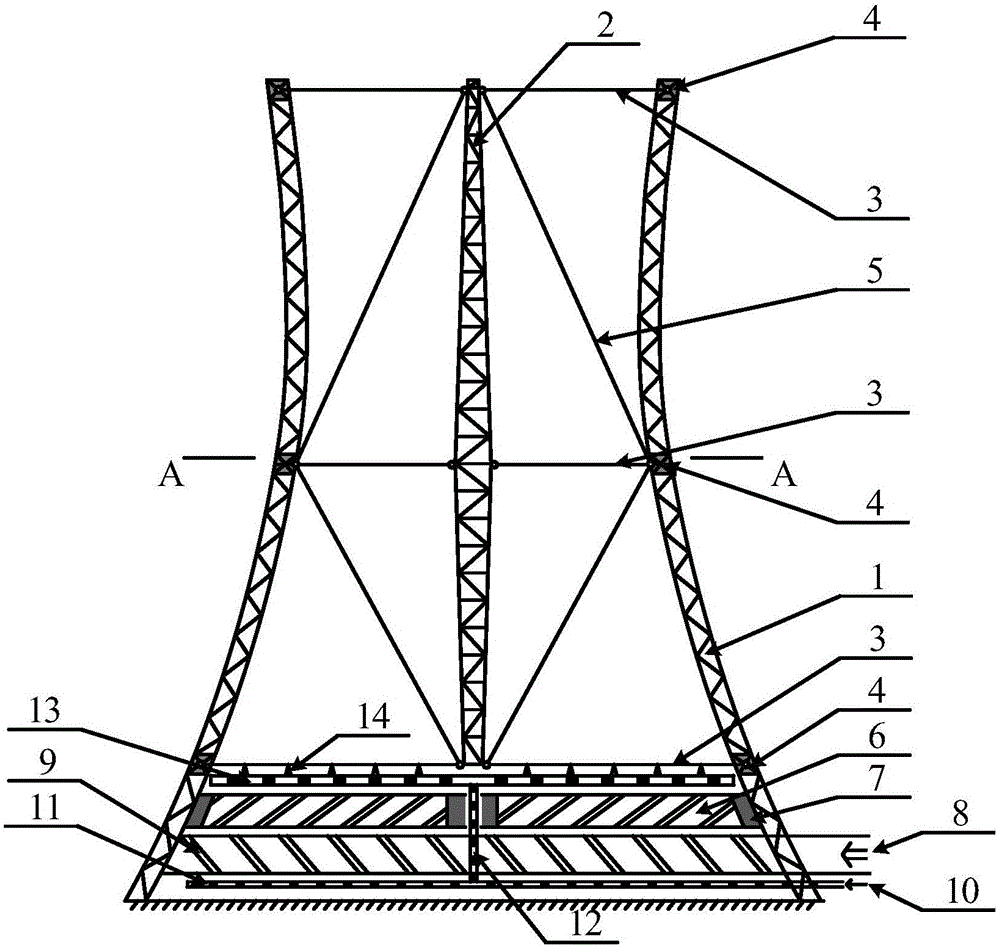

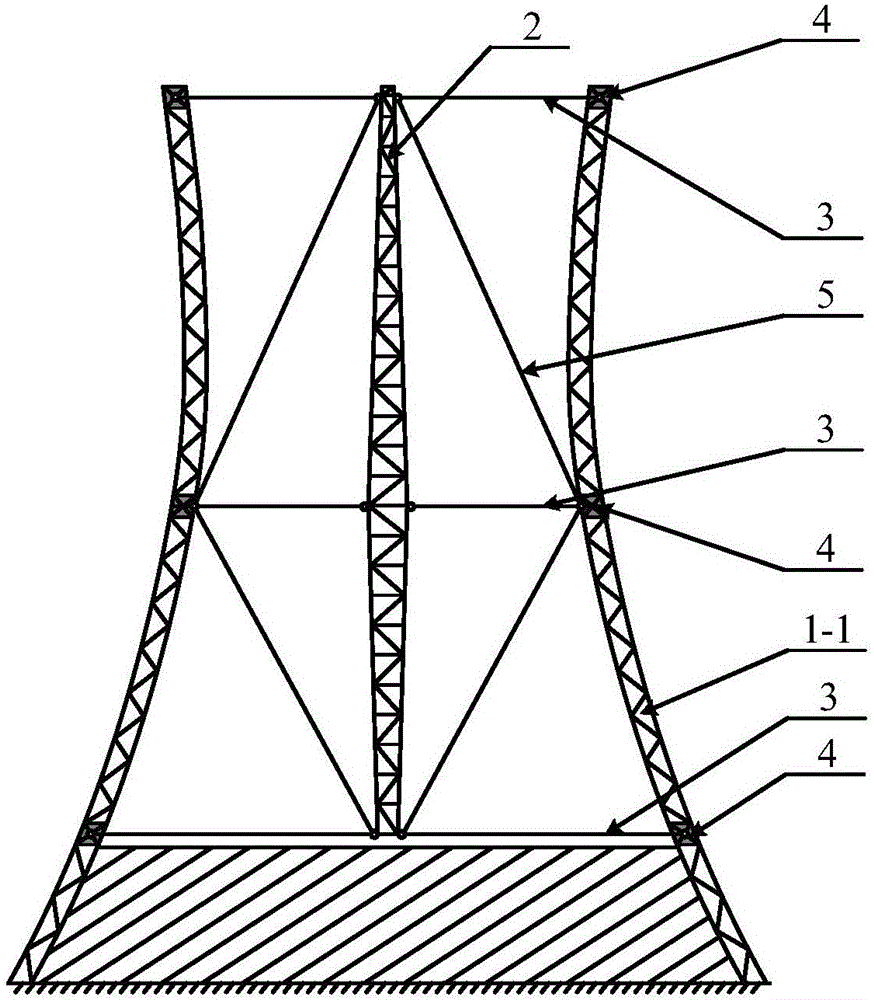

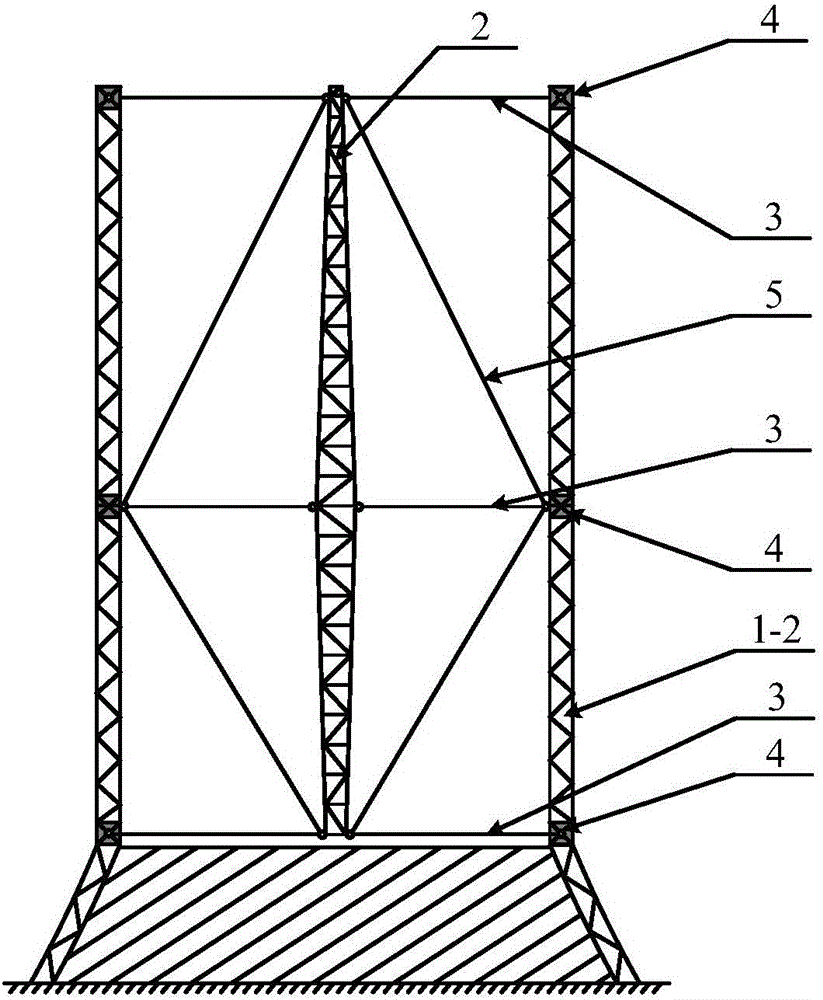

Novel grid cooling tower with crossed steel structure

InactiveCN105756381AReduce out-of-plane local deformationImprove synergistic performanceArched structuresVaulted structuresCooling towerPre stressing

The invention discloses a novel grid cooling tower with a crossed steel structure and relates to the grid cooling tower with the crossed steel structure, which is suitable for indirect type cooling, and belongs to the technical field of structural engineering. On the basis of a pure-steel double-curve-surface grid cooling tower, a central supporting truss flying column is additionally arranged; the central supporting truss flying column is connected with a peripheral grid shell by utilizing a pre-stress cable disc and a space inclined radiation pre-stress inhaul cable, so that a more stable space cable truss (composed of the cable disc, the fly column and the space inclined radiation pre-stress inhaul cable) and a steel grid shell crossed structure are formed. By adopting a multiple-side-force-resisting system, the side resisting rigidity and the bearing capability of the structure are remarkably improved and the utilization rate of materials is improved, so that structural design requirements of an ultra-large-size cooling tower can be met. The novel grid cooling tower adopts a steel cable and full-steel structure, and has the advantages of high production efficiency, high construction precision, short construction period, small influences caused by weather temperatures, low construction cost and the like.

Owner:TSINGHUA UNIV +1

Winding device for warp knitting fabric production

The invention discloses a winding device for warp knitting fabric production. The device comprises a telescopic rod, a fixing plate is arranged at the side end of the telescopic rod, a first limiting plate is arranged at the side end of the fixing plate, a threaded rod is arranged at the side end of the first limiting plate, a fixing handle is arranged on the outer surface of the threaded rod, a first supporting frame is arranged at the lower end of the fixing handle, a limiting block is arranged at the side end of the telescopic rod, a limiting sleeve is arranged at the side end of the limiting block, and a jackscrew is embedded in the inner side of the limiting sleeve. According to the winding device for warp knitting fabric production, through cooperation of the telescopic rod, the limiting sleeve, the limiting block and the jackscrew, the width of a winding structure can be adjusted, the limitation of overall use of the device is reduced, and through cooperation of a bearing wheel, a supporting plate, a limiting shaft and a spring, when a user disassembles wound fabric, the fabric is supported, and a device main body is prevented from rolling over.

Owner:海宁凯兴新材料股份有限公司

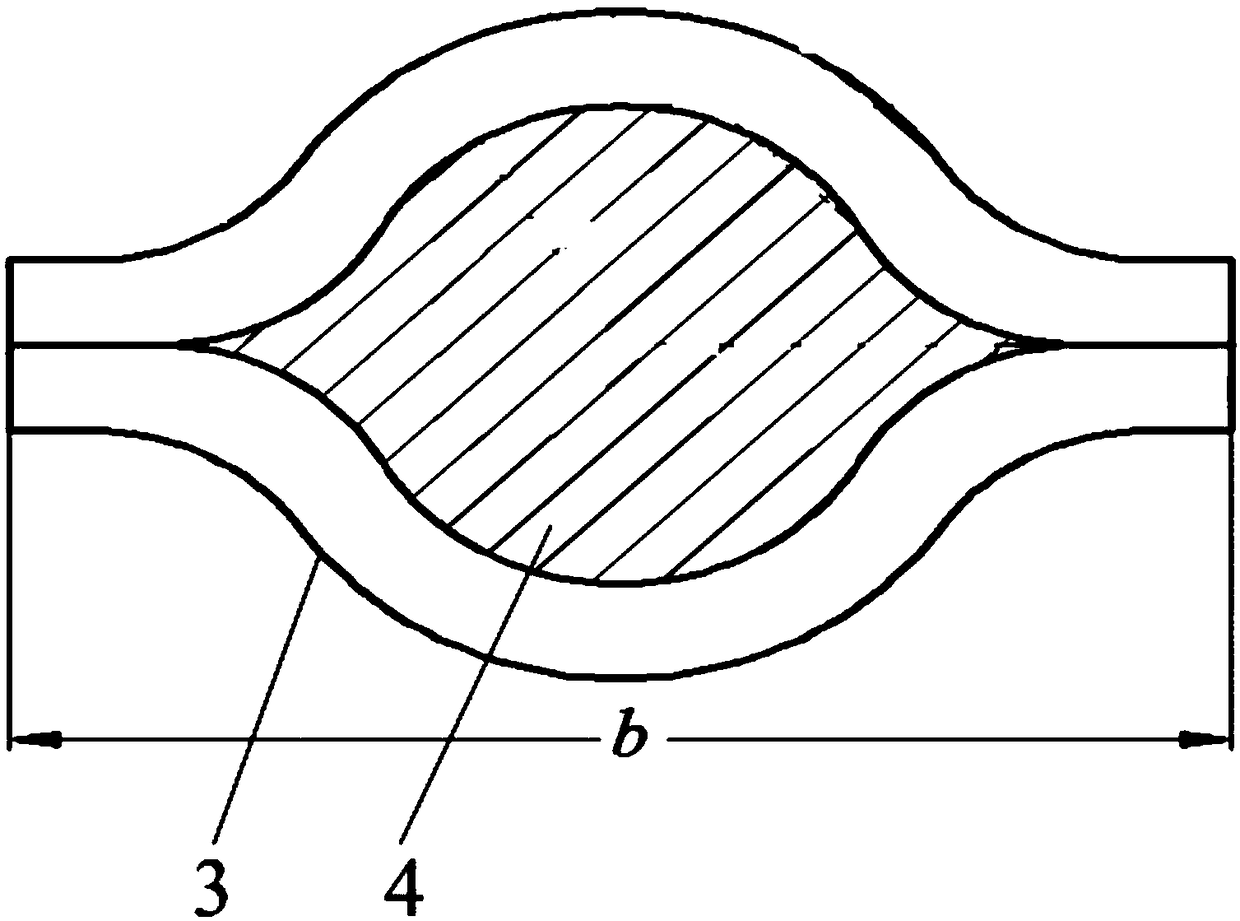

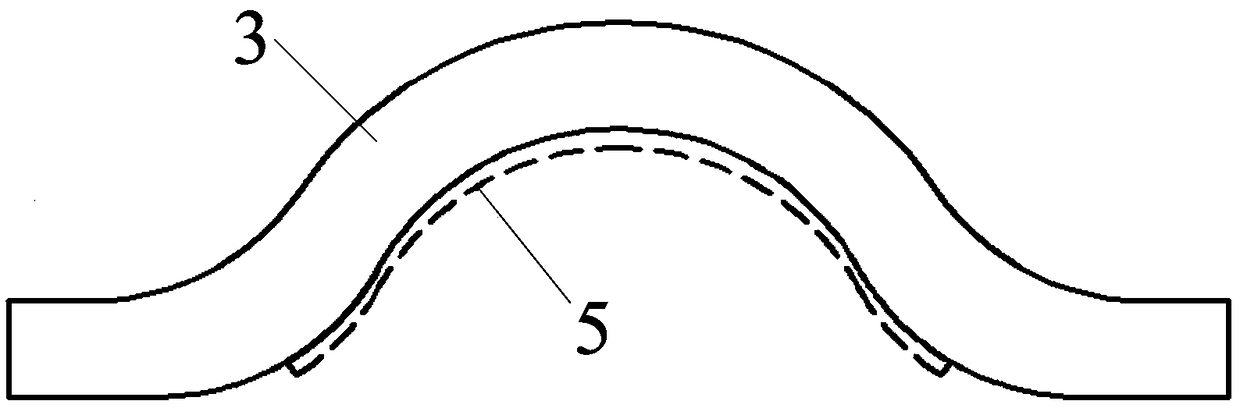

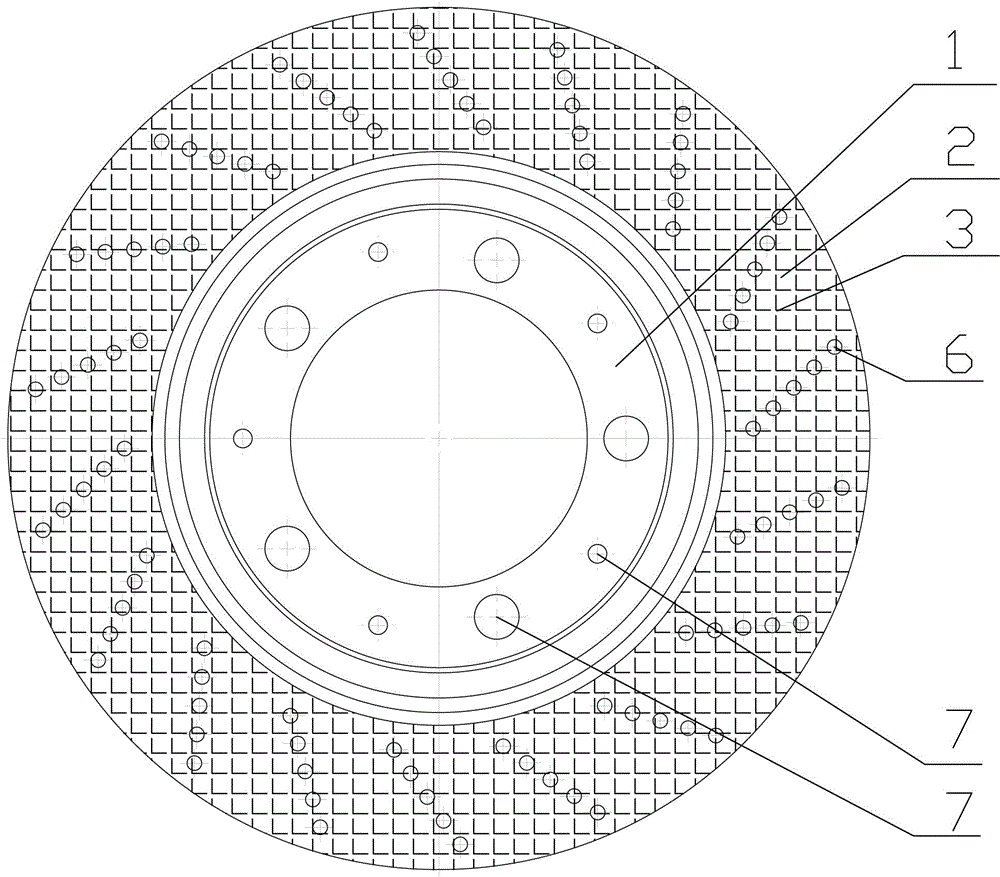

Silicon carbide foam ceramic/aluminum alloy composite material brake disc and preparation method thereof

ActiveCN104235237BReduce weightImprove feeding capacityBraking membersFriction liningCeramic compositeAlloy composite

A friction disc of metal / continuous-structure phase ceramic composite material and a method for manufacturing same are provided. The friction disc comprises a metal disc body (1) and a friction layer of metal / continuous-structure phase ceramic composite material arranged on one side or symmetrically arranged on both sides of the disc body. The metal disc body (1) is a metal backboard mechanically connected with the friction layer (3); or the metal disc body can be made of the same material as the composite material in the friction layer (3), and integrally cast with the friction layer; or the metal disc body can be made of the same material as the metal material in the friction layer (3) and integrally cast with the friction layer; or the metal disc body can be made of the same material as the metal material in the friction layer (3) and integrally cast with the friction layer, the disc body having reinforcing ribs. The friction disc of composite material can significantly reduce the weight of clutch plates and friction braking plates, and also has excellent friction and wear performance. It can not only carry out safe and effective friction clutch and brake operation for various kinds of rotating machinery, but also achieve the purpose of reducing cost, light weight and energy saving.

Owner:SHIJIAZHUANG DONGDA HUITONG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com