Preparation method for 3D printing novel heat preservation frame integrated wall based on numerical simulation

A 3D printing and numerical simulation technology, applied in thermal insulation, walls, ceramic products, etc., can solve the problems of cumbersome construction, and achieve the effect of good mechanical properties and thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

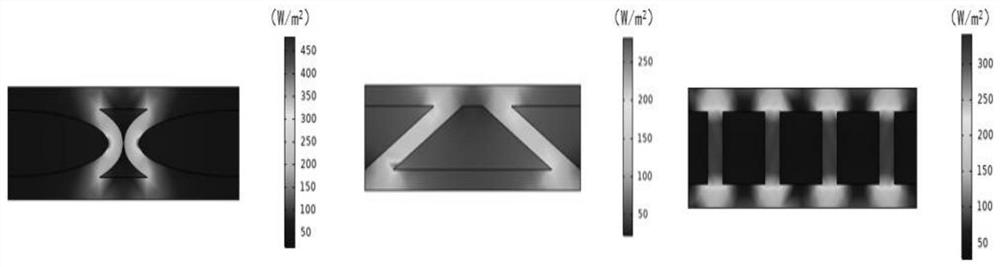

[0029] The invention provides a method for preparing a novel thermal insulation frame integrated wall based on numerical simulation by 3D printing of multi-component solid waste. To calculate the detailed parameters of the thermal insulation integrated wall, the following parameters need to be set during numerical simulation: the thermal conductivity of the material of the special-shaped frame part and the internal filling part, the heat capacity of the material at constant pressure, and the material density.

[0030] First, a model library is established in the numerical simulation software, and the preset structural layout plan, that is, the model in the model library, is imported during the simulation process, and the material parameters are input to obtain the thermal insulation performance effect diagram of the corresponding model.

[0031] The new thermal insulation frame integrated wall includes a special-shaped frame part and an internal filling part filled in the speci...

Embodiment 2

[0037] This example provides a method for preparing a new thermal insulation frame integrated wall based on numerical simulation of multi-component solid waste 3D printing. The ratio of materials used is as follows:

[0038] The ratio of special-shaped frame parts:

[0039] A component: 40 parts of fly ash

[0040] B component: 40 parts of mineral powder

[0041] C component: 100 parts of medium sand

[0042] Component D: 1.3 parts of recycled glass fiber

[0043] E component: sodium silicate powder (granule) 10 parts

[0044] F component: 35 parts of water

[0045] Internal filling ratio:

[0046] G component: 30 parts of fly ash

[0047] H component: 30 parts of mineral powder

[0048] Component I: 10 parts of protein-based foaming agent

[0049] Component J: 1.8 parts of recycled fiberglass fiber

[0050] K component: 30 parts of water

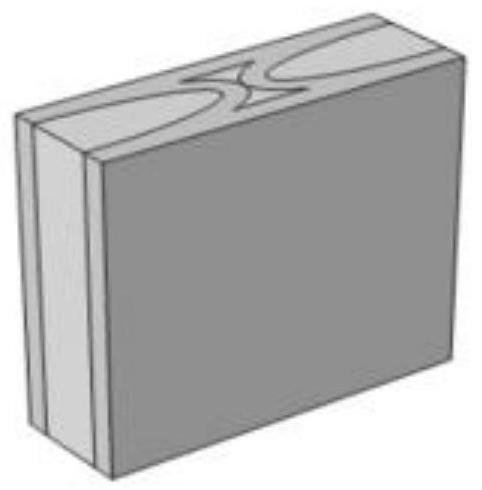

[0051] The shape of the wall is determined by numerical simulation software as figure 2 As shown, the 3D printing path is plan...

Embodiment 3

[0053] In this embodiment, a method for preparing a new thermal insulation frame integrated wall based on numerical simulation of multi-component solid waste 3D printing, the material ratio used is as follows:

[0054] The ratio of special-shaped frame parts:

[0055] A component: 50 parts of fly ash

[0056] B component: 50 parts of mineral powder

[0057] Component C: 3 parts of sodium hydroxide

[0058] D component: 10 parts of sodium silicate

[0059] E component: 38 parts of water

[0060] Internal filling ratio:

[0061] F component: 30 parts of fly ash

[0062] G component: metakaolin 20 parts

[0063] H component: 20 parts of water

[0064] Component I: 5 parts of 70% hydrogen peroxide solution

[0065] J component: 10 parts of sodium silicate

[0066] K component: recycled polypropylene fiber 1 part

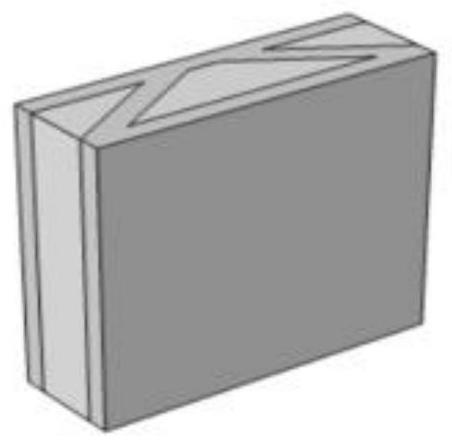

[0067] The shape of the wall is determined by numerical simulation software as image 3 As shown, the 3D printing path is planned. The preparation process is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com