Heat preservation and insulation wallboard

A thermal insulation and wall panel technology, applied in building components, buildings, building structures, etc., can solve problems such as insufficient strength, breakage, deformation, etc., and achieve the effects of not easily deformed or damaged, ensuring thermal insulation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

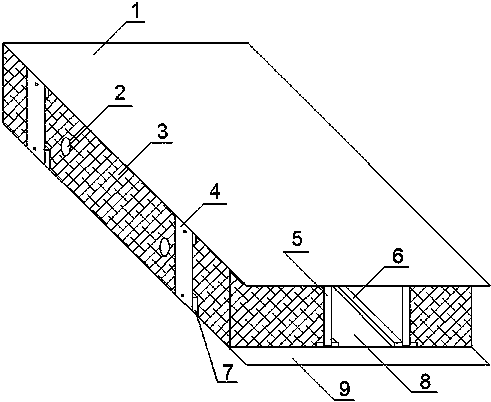

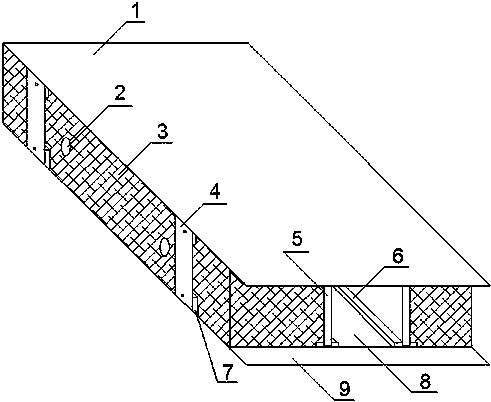

[0015] like figure 1 A thermal insulation wallboard shown includes two panels 1, a number of connecting partitions 5 connecting the two panels 1 and located in the two panels, the connecting partitions 5 divide the space inside the two panels 1 into several areas, Several heat insulation layers 3 installed in the two panels 1 are provided with beam layers 9 at one or both ends of the two panels 1 , and threading holes 2 are left in the inner spaces of the two panels 1 .

[0016] The panels 1 are square, and a number of fixing pieces 4 are arranged on the edges of the two panels 1 to connect the two panels.

[0017] In this embodiment, the panel 1 is made of cement board, and the thermal insulation layer is made of lightweight thermal insulation material.

[0018] Positioning and connecting blocks 7 are arranged on the inner surface edge of the panel 1 , and the fixing piece 4 is installed on the corresponding positioning and connecting blocks 7 on the two panels 1 .

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com