Metal floor and formation method

A metal floor and floor technology, which is applied in construction, construction material processing, building construction, etc., can solve the problem of easy to emit loud noise, and achieve the effect of eliminating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

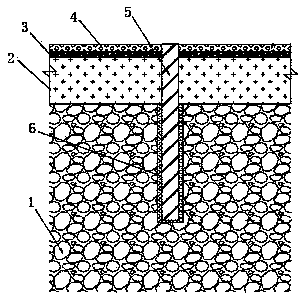

[0028] Such as figure 1 As shown, a metal floor described in this embodiment includes a reinforced concrete layer 1, a fine stone concrete layer 2, a rubber layer 3, a steel plate layer 4, and several threaded steel columns 5 from bottom to top. 5 runs through the steel plate layer 4, rubber layer 3, and fine stone concrete layer 2 in sequence, and is inserted into the reinforced concrete layer 1. The upper end of the threaded steel column 5 is flush with the upper surface of the steel plate layer 4, and the fine stone concrete layer 2, rubber layer 3 1. The steel plate layer 4 is stably connected with the reinforced concrete layer 1 under the action of the threaded steel column 5 as a whole.

[0029] In order to ensure that the bottom layer has a higher strength, the reinforced concrete layer 1 of this embodiment is C55 concrete, and in order to realize leveling more conveniently and quickly, the fine stone concrete layer 2 adopts C25 fine stone concrete.

[0030] As prefer...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is that high-strength building rebar glue 6 is filled between the threaded steel column 5 and the reinforced concrete layer 1 in this embodiment, which is used to improve the pull-out resistance of the threaded steel column 5 force.

[0034] A forming method for realizing the above-mentioned metal floor, comprising the following process steps:

[0035] Step (1), after the reinforced concrete layer is formed and solidified, remove the debris and floating soil on the upper surface of the reinforced concrete layer, pour fine stone concrete, level it, and the height of the leveling layer is 4~5cm, that is, the thickness of the fine stone concrete is kept at 4~ 5cm, the upper surface of the fine stone concrete is as flat as possible and located on the same level;

[0036] Step (2), after pouring the fine stone concrete, water and cure for 6-8 days, so that the solidification strength of the fine stone con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com