Novel pressure stabilization device for double-end surface sealing of turbine pump

A technology of a voltage stabilization device and a turbo pump, which is applied to the components, pumps, and pump components of a pumping device for elastic fluids, can solve the problems of end face seal damage, unfavorable long-term storage, and limited voltage stabilization capability, and eliminates the need for Exceptionally high pressure, good maintenance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

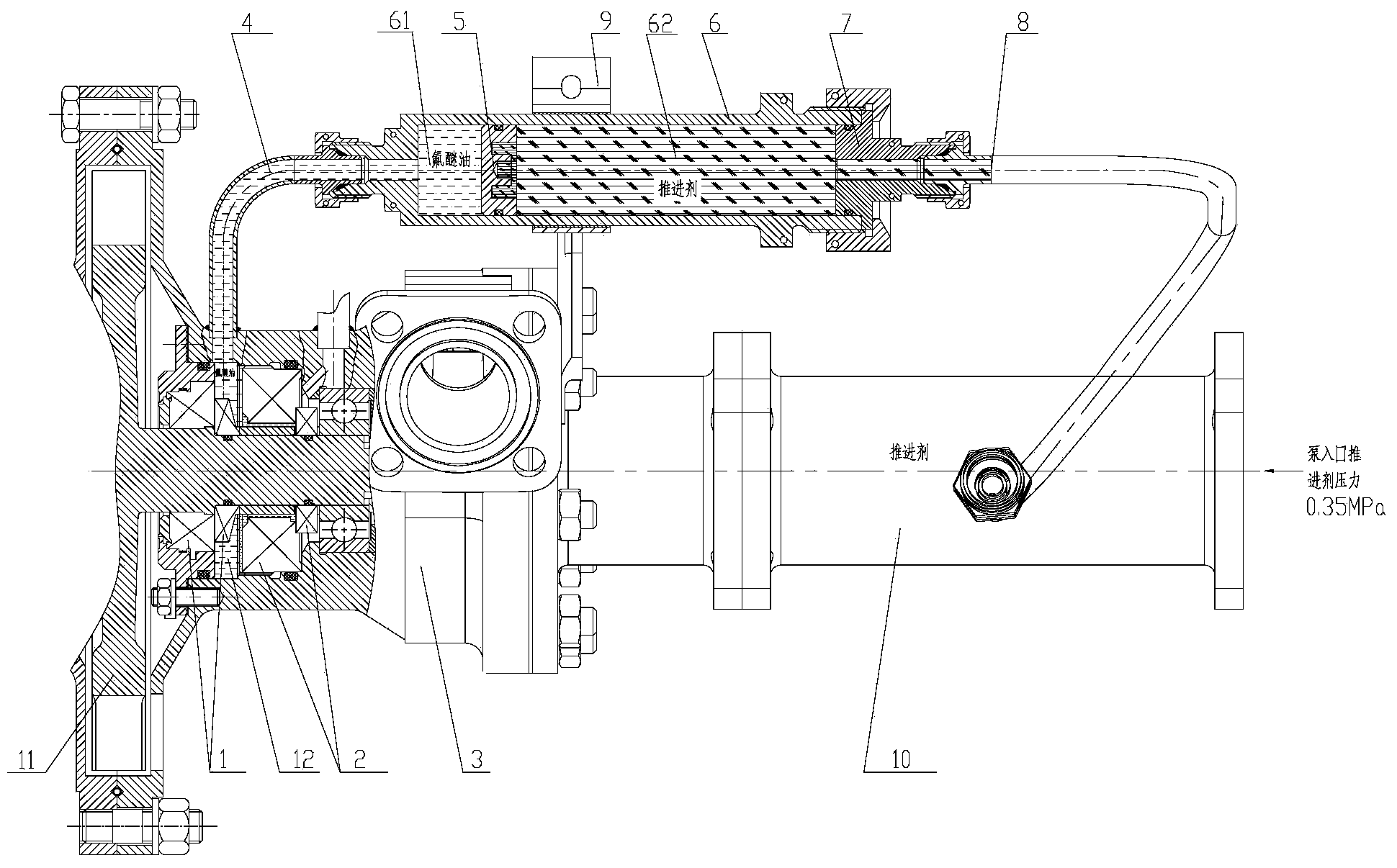

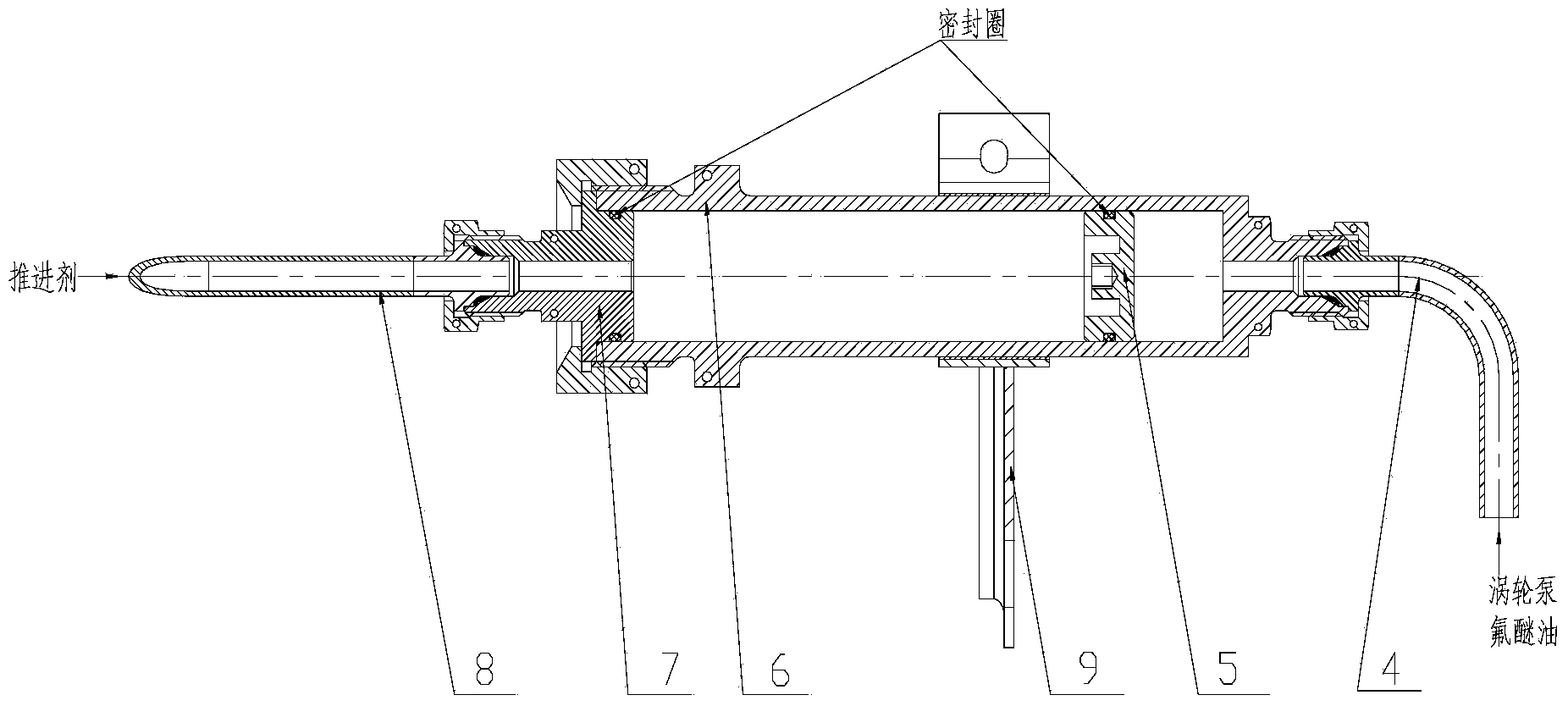

[0026] When a normal turbo pump is assembled, the double-end seal oil chamber 12 is filled with about 28mL of fluoroether oil. In the case of a turbo pump without a pressure stabilizing device, the amount of liquid oxidant leaked by the spring-type end face seal is theoretically calculated to be 1mL. The leaked oxidant medium absorbs heat and vaporizes in the remaining cavity of the sealed oil chamber (the largest cavity is 8mL based on experience), expands rapidly and suppresses pressure, and the pressure in the oil chamber can rise to 7.6MPa instantly. In order to keep the oxidant spring-type end face seal from being damaged under this leakage amount (oil chamber pressure ≤ 1.8MPa), it can be known from the above gas isothermal calculation that an effective volume of at least 33.78mL is required to reduce the oil chamber pressure from 7.6MPa to 1.8MPa to achieve the unloading capacity. pressure effect. The total volume of the designed oil cylinder of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com