Fuel online dehydration and deoxygenation equipment

A fuel and equipment technology, applied in the field of comprehensive security, can solve the problem that the anti-icing agent cannot be dehydrated and deoxidized online, and achieve the effect of realizing long-term storage requirements, saving storage and transportation costs, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

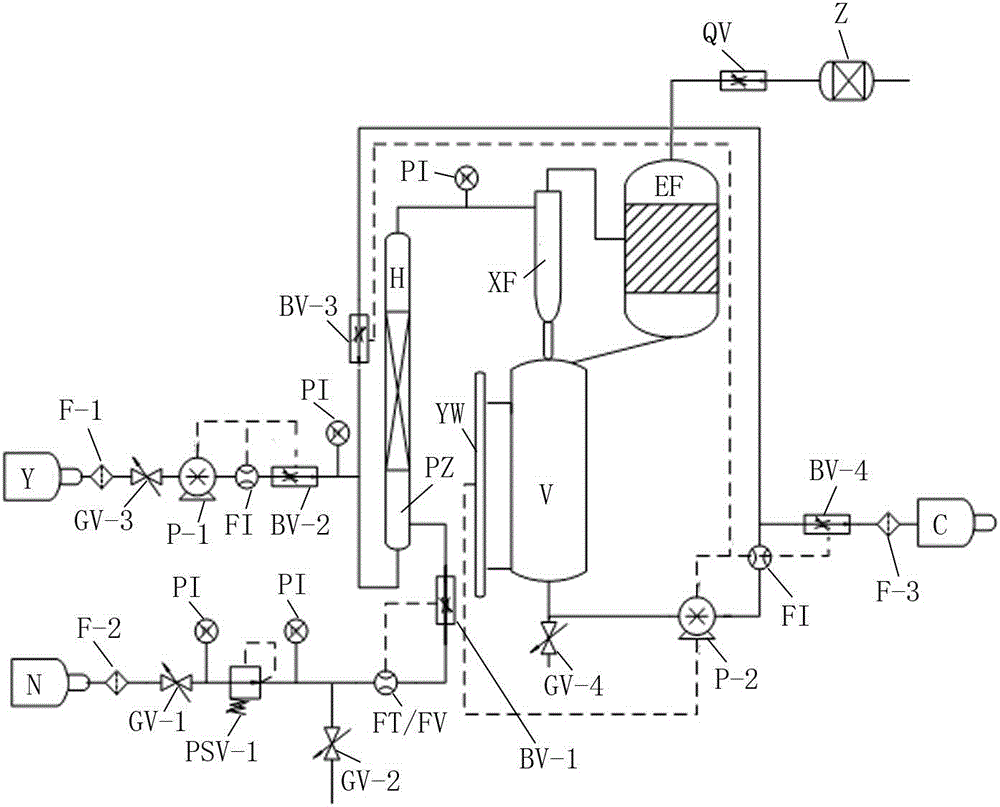

[0030] Such as figure 1 As shown, the cabinet is equipped with a gas inlet and a liquid inlet. After the nitrogen cylinder N is connected to the gas inlet, it passes through the gas filter F-2, the ball valve GV-1, the inlet pressure reducing valve PSV-1, and the gas mass flowmeter FT / FV is connected to the PZ inlet of the Venturi mixer; after the oil tank Y is connected to the liquid inlet, it passes through the oil filter F-1, the ball valve GV-3, the oil inlet pump P-1, and the liquid mass flowmeter FI is connected to the PZ inlet of the Venturi mixer. The venturi mixer outlet is connected to the H inlet of the static pipeline mixer, the H outlet of the static pipeline mixer is connected to the cyclone separator XF inlet, and the cyclone separator XF outlet is respectively connected to the secondary separation tank EF inlet and the buffer oil tank V inlet, two The fuel outlet of the secondary separation tank is connected to the buffer oil tank V, and the exhaust port of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com