Preparation of multi-arm carbon nano-tube lubricant additive

A multi-arm carbon nanotube and lubricating oil additive technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problem of less CNTs, and achieve the effects of not easy to decompose, improve dispersibility, and easy to operate in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

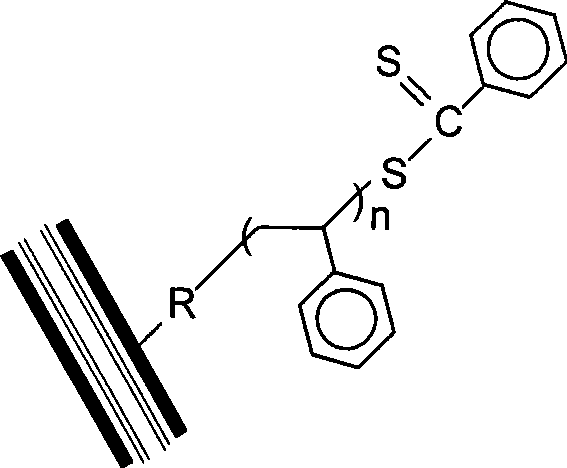

[0026] Polystyrene-modified carbon nanotube lubricant additives:

[0027] 1. Disperse 2 grams of MWCNT into 30 ml of concentrated nitric acid, acidify by reflux for 20 hours, wash until neutral, and dry to obtain 1.3 grams of MWCNT-COOH. Add 1 g of MWCNT-COOH to 25 ml of SOCl 2 React at 70°C for 24 hours, distill off residual SOCl 2 , the residue was immediately reacted with 40 ml of purified ethylene glycol at 120° C. for 48 hours. After centrifugation and drying, 0.9 g of MWCNT-OH was obtained. 0.6 gram of MWCNT-OH and 2.8 g of chain transfer agent CPAD were dissolved in 25 ml of anhydrous methylene chloride, 2.3 g of DCC was added, and the mixture was reacted in the dark at room temperature for 24 hours and then centrifuged, washed and dried to obtain 0.6 gram of MWCNT-SC (S ) Ph.

[0028] 2. Add 0.08g of MWCNT-SC(S)Ph, 1g of styrene and AIBN (0.1mL of 0.5M DMF solution) into 4ml of DMF, and the mixture is vacuumed and nitrogen-filled, then stirred and reacted at 100°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com