Long-acting anti-wear and friction-reducing agent composition, lubricating grease and processing oil

A technology of anti-friction agent and composition, which is applied in the field of long-acting anti-wear anti-friction agent composition and lubricating grease and processing oil. Improve the lubricating ability of oil products, reduce the wear scar diameter data, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0044] The long-acting anti-wear and friction reducer composition prepared in this embodiment includes in parts by mass: 50 parts of molybdenum sulfide di-n-butyldithiocarbamate, 15 parts of dibutyldithiocarbamate, 5 parts Parts of 2,5-bis(tert-dodecyldithio)-1,3,4-thiadiazole, 3 parts of 2,2'-octyl-mercaptobenzothiazole, 10 parts of tris(nonylphosphite) phenyl ester), 5 parts of bis-(2,4-di-tert-butylphenyl) pentaerythritol diphosphite, 6 parts of sulfurized olefin cottonseed oil, and 6 parts of sulfurized glyceride.

[0045] The formulation of the long-acting antiwear and friction reducer composition of this embodiment is shown in Table 1.

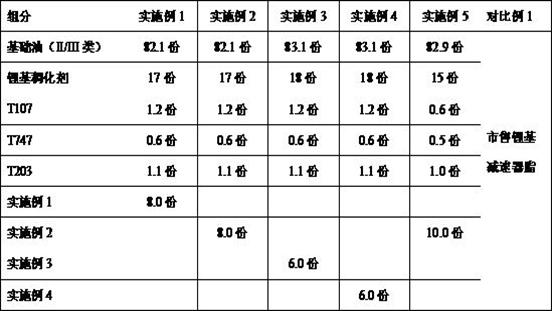

[0046] In this embodiment, the above-mentioned long-acting anti-wear and friction-reducing agent composition is used to prepare lubricating grease, which includes: 8.0 parts of long-lasting anti-wear and friction-reducing agent composition, 82.1 parts of API II / API III base oil, 17 parts lithium-based thickener, 1.2 parts calcium overba...

Embodiment 2)

[0050] The long-acting anti-wear and friction reducer composition prepared in this embodiment includes in parts by mass: 55 parts of molybdenum sulfide di-n-butyldithiocarbamate, 15 parts of dibutyldithiocarbamate, 3 parts Parts of 2,5-bis(tert-dodecyldithio)-1,3,4-thiadiazole, 2 parts of 2,2'-octyl-mercaptobenzothiazole, 8 parts of phosphorous tris(nonyl phenyl ester), 2 parts bis-(2,4-di-tert-butylphenyl) pentaerythritol diphosphite, 6 parts sulfurized olefin cottonseed oil, 9 parts sulfurized glycerides.

[0051] In this embodiment, the above-mentioned long-acting anti-wear and friction-reducing agent composition is used to prepare lubricating grease, which includes: 8.0 parts of long-lasting anti-wear and friction-reducing agent composition, 82.1 parts of API II / API III base oil, 17 parts lithium-based thickener, 1.2 parts calcium overbase sulfonate T107, 0.6 parts dodecenyl succinate half ester T747 and 1.1 parts zinc diisooctyl dithiophosphate T203. The preparation temp...

Embodiment 3)

[0056] The long-acting anti-wear and friction reducer composition prepared in this embodiment includes in parts by mass: 58 parts of molybdenum di-n-butyl dithiocarbamate, 12 parts of dibutyl dithiocarbamate, 5 parts Parts of 2,5-bis(tert-dodecyldithio)-1,3,4-thiadiazole, 2 parts of 2,2'-octyl-mercaptobenzothiazole, 10 parts of tris(nonylphosphite) phenyl esters), 7 parts sulfurized olefin cottonseed oil, 6 parts sulfurized glycerides.

[0057] In this embodiment, the above-mentioned long-acting anti-wear and friction-reducing agent composition is used to prepare lubricating grease, which includes: 6.0 parts of long-lasting anti-wear and friction-reducing agent composition, 83.1 parts of API II / API III base oil, 18 parts of lithium-based thickener, 1.2 parts of calcium overbase sulfonate T107, 0.6 parts of dodecenyl succinate half ester T747 and 1.1 parts of zinc diisooctyl dithiophosphate T203. The preparation temperature is 200-260°C.

[0058] The formulation of the long-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com