Composite antioxidant and anti-wear lubricating oil for gasoline engine

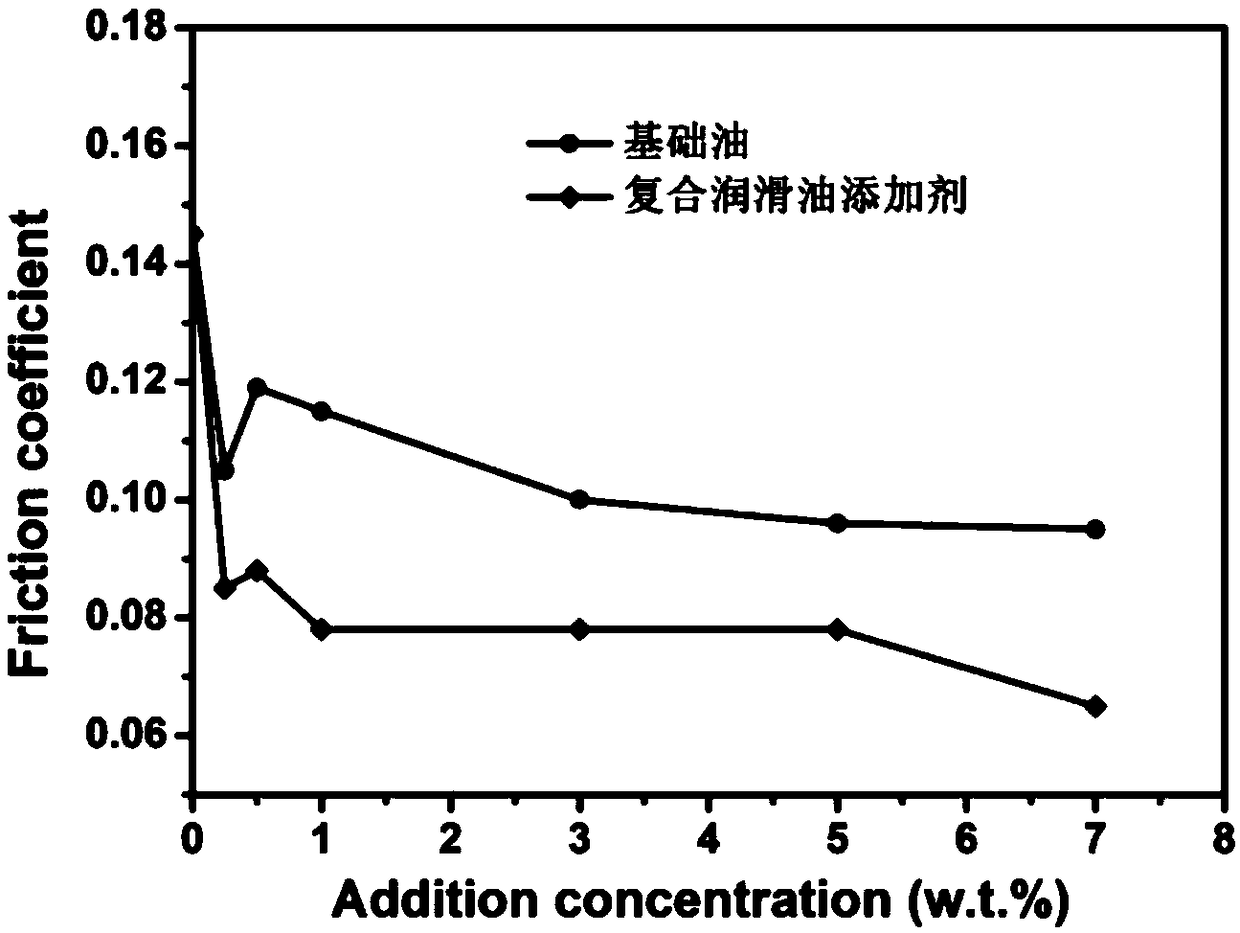

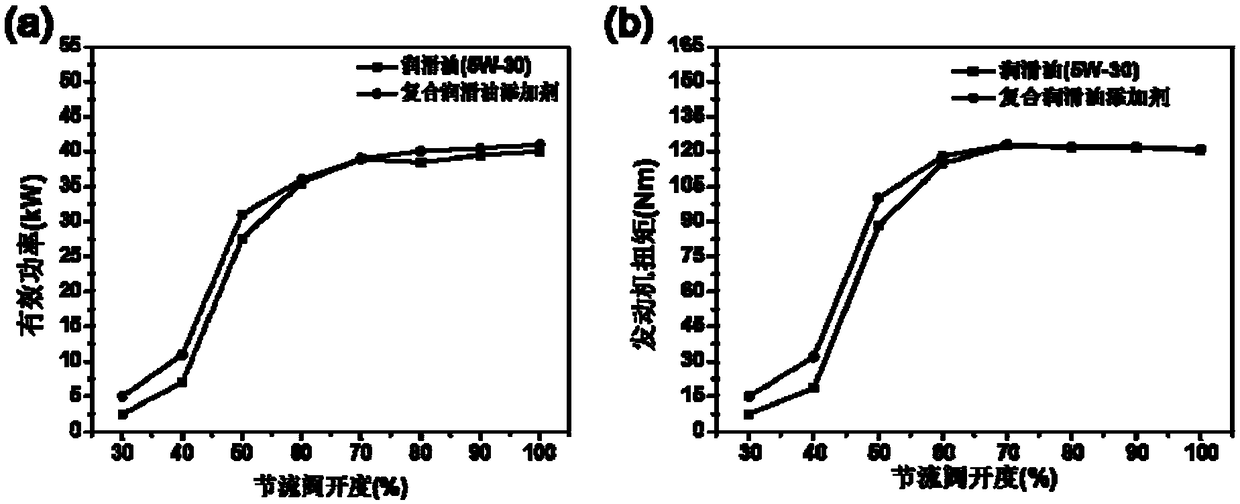

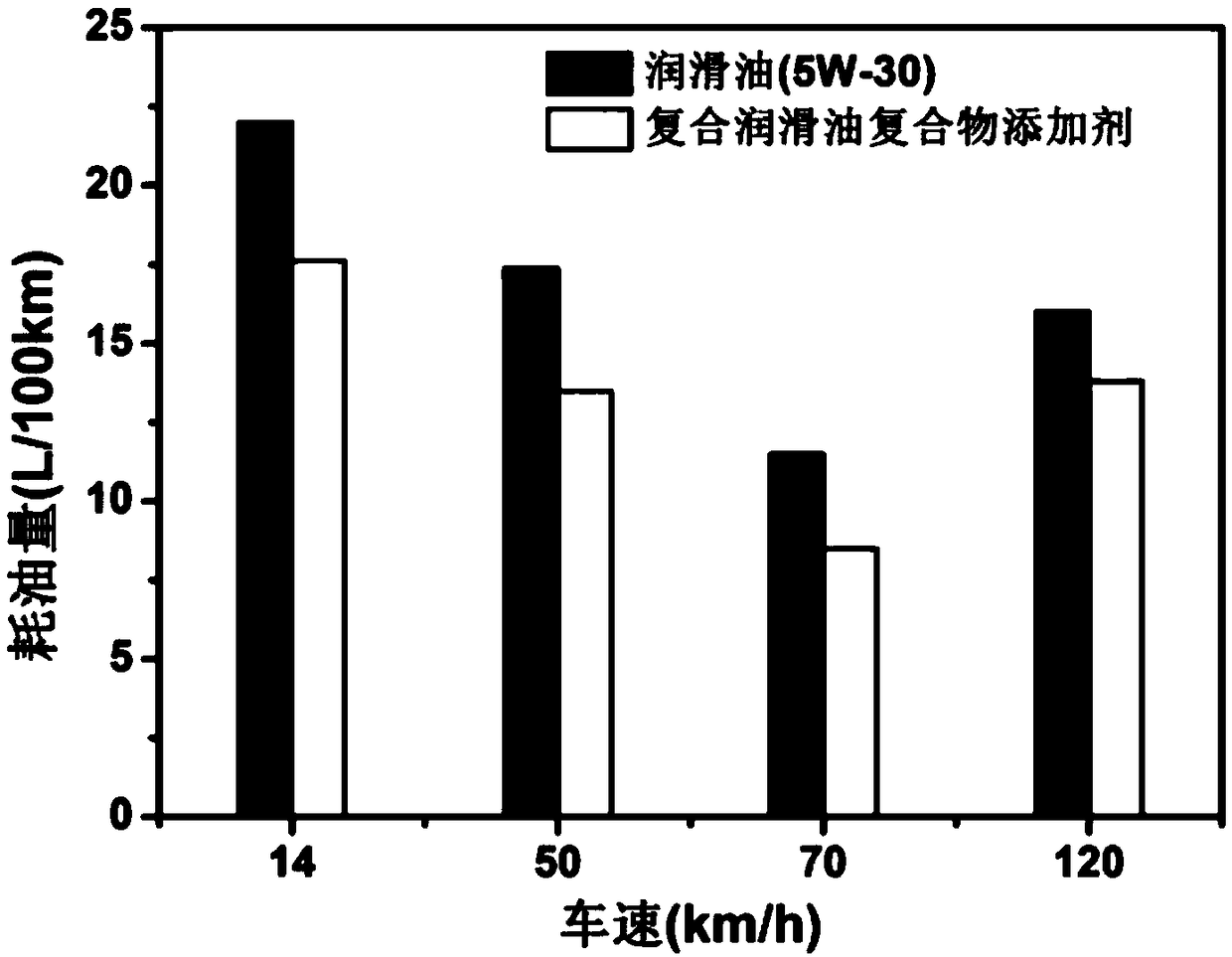

A technology of gasoline engine and lubricating oil additive, applied in lubricating composition, petroleum industry and other directions, can solve problems such as fuel economy reduction, and achieve the effect of reducing friction, good anti-wear performance and reducing wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Antiwear agent: FeS 2 / Preparation of carbon composite materials;

[0030] FeS 2 Preparation of carbon composite materials as lubricating oil additives and anti-wear agents

[0031] The first step: carbon preparation. Dissolve 5g of PEI (polyetherimide) in 15ml of deionized water, stir, transfer to a one-necked bottle after it is completely dissolved, and continue to stir for later use; add 2.4g of bromoacetonitrile into 10ml of ethanol, stir until dissolved; use a dropper to The mixture of bromoacetonitrile and ethanol was slowly added dropwise to the PEI solution, stirred for 36 hours, rotary evaporated at 45°C, washed with ether, and dried in vacuum. Denoted as precursor PEI. Take AgN(CN) with a molar ratio of 1:1 to the precursor PEI material 2 Add it to 5g of precursor material, add water and stir for 12 hours, labeled PEI-DCA, spin evaporate, wash, and vacuum dry. Put PEI-DCA material into tube furnace N 2 Burn to 800°C under atmosphere to obtain the desir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com