Sewing machine oil composition

A technology of sewing machine oil and composition, which is applied in the direction of lubricating composition, petroleum industry, additives, etc., can solve the problems of few sewing machine oil patents and reports, no application involved, no consideration of antioxidant toxicity, etc., and achieve good light stability , good anti-oxidation performance, excellent anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

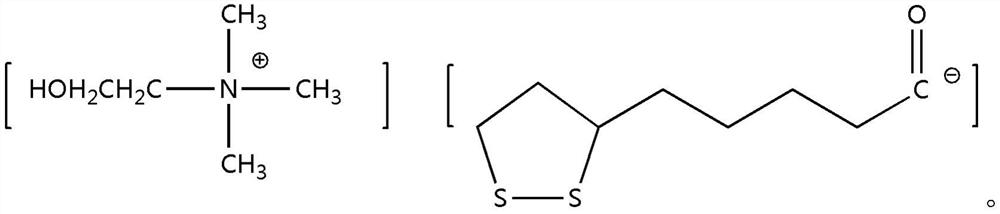

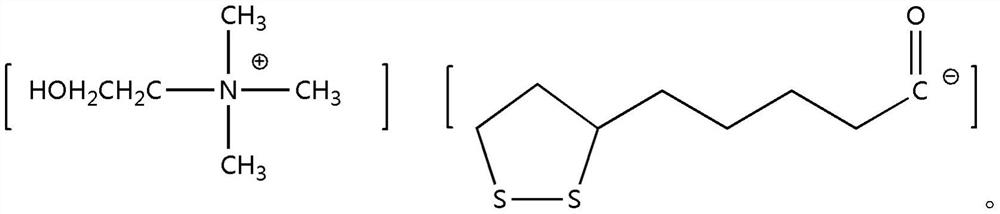

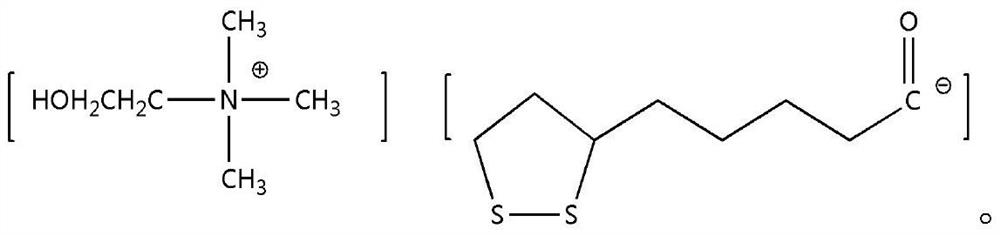

Image

Examples

Embodiment 1

[0042] The components and content of the sewing machine oil composition of the present embodiment are shown in the table below:

[0043] name Dosage (wt%) Alkylated phenyl phosphorothioate 0.30 Dialkyldithiocarbamate 0.10 ionic liquid 0.15 tert-Butylhydroquinone TBHQ 0.20 TH-944 0.10 Basic Barium Dinonylnaphthalene Sulfonate 0.02 T902 0.02 Polyether polymer compound 0.01 HVI P2 99.10

Embodiment 2

[0045] The components and content of the sewing machine oil composition of the present embodiment are shown in the table below:

[0046]

[0047]

Embodiment 3

[0049] The components and content of the sewing machine oil composition of the present embodiment are shown in the table below:

[0050] name Dosage (wt%) Alkylated phenyl phosphorothioate 0.24 Dialkyldithiocarbamate 0.08 ionic liquid 0.10 tert-Butylhydroquinone TBHQ 0.30 TH-944 0.10 Neutral Barium Dinonylnaphthalene Sulfonate 0.02 Basic Barium Dinonylnaphthalene Sulfonate 0.01 T902 0.02 Polyether polymer compound 0.01 HVI P2 99.12

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com