Patents

Literature

58results about How to "Good rust resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel environment friendly high-efficiency rust-preventive pigment and method for producing the same

InactiveCN101508851AGood chemical stabilityGood rust resistanceAnti-corrosive paintsPigment pastesSlagChromium

Owner:广州化工研究设计院有限公司 +1

Corrosion-inhibition type water-based metal cleaner

The invention discloses a corrosion-inhibition type water-based metal cleaner. The corrosion-inhibition type water-based metal cleaner comprises the following raw materials in parts by weight: 15-30 parts of coconut diethanolamide, 5-12 parts of octyl phenol polyoxyethylene ether, 3-10 parts of alkyl benzene sodium sulfonate, 7-15 parts of sodium xylene sulfonate, 5-10 parts of citric acid, 4-12 parts of sodium citrate, 1-4 parts of polyvinyl chloride latex, 0.5-3 parts of non-ionic polyacrylamide, 4-10 parts of sodium carbonate, 15-30 parts of hydrophilic alcohol, 3-6 parts of instant modified sodium disilicate, 15-30 parts of dodecanedioic triethanolamine, 2-5 parts of N-lauroyl sarcosine triethanolamine, 3-8 parts of mercaptobenzothiazole sodium, 1-5 parts of a defoaming agent, 1-5 parts of a fungicide, 30-40 parts of soft water and 100-150 parts of water. The corrosion-inhibition type water-based metal cleaner disclosed by the invention is strong in detergency, good in anti-rusting property, less in environment-friendly pollution, high in cleaning speed, less in residues after cleaning, good in stability and capable of being used in hard water.

Owner:CHAOHU GUANGFENG METAL PROD

Compsn. of rust inhibiting lubricant special for chain

InactiveCN1415713AGood rust resistanceExcellent extreme pressure and wear resistanceAdditivesEnvironmental chemistryP-Cresol

A composite antirust hebricant for chain contains sulfonate as antirust agent, olefine butanedioic acid type antirust agent, dialkyldithiophosphate-formaldehyde-lipoamin condensate, plant oil, phenyltriazole lipoamine salt, polyisobutylene, vaseline, 2,6-ditert-butyl p-cresol, and basic oil. Its advantages are excellent resistance to rust, salt fog and abrasion, high adhesive, and good water displacing nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

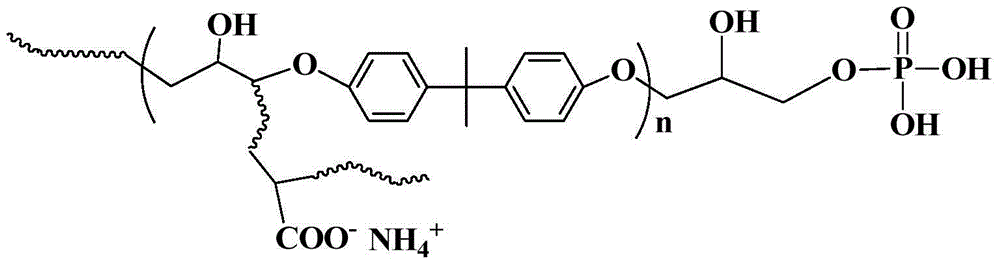

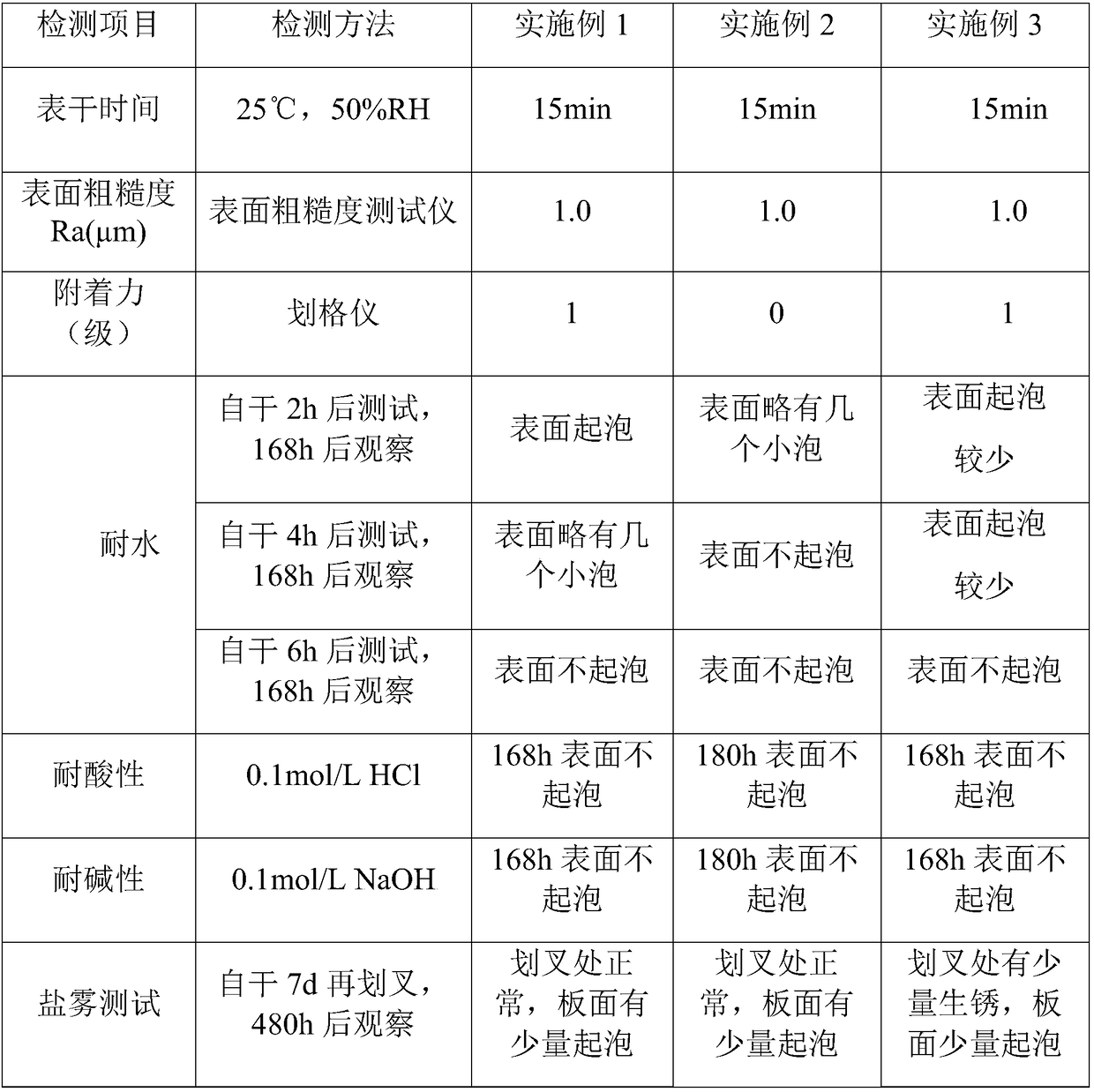

Acrylic acid modified epoxy phosphate ester resin and preparation method of aqueous dispersion thereof

The invention belongs to the field of coating and provides acrylic acid modified epoxy phosphate ester resin and a preparation method of aqueous dispersion thereof. The formula comprises 40-45 parts of epoxy resin, 20-30 parts of a solvent, 0.4-0.5 part of phosphoric acid and 8-12 parts of acrylic acid (acrylate) monomer, wherein the acrylic acid monomer accounts for 1.4-2 parts, an initiator accounts for 0.5-0.8 part, a neutralizer accounts for 3.2-5.2 parts and water accounts for 80-100 parts. The preparation method comprises the following steps: modifying the epoxy resin by using the phosphoric acid, reacting the epoxy resin with the acrylic acid and the ester monomer thereof, adding the neutralizer and deionized water, stirring and emulsifying to obtain the aqueous dispersion of the acrylic acid modified epoxy phosphate ester resin, wherein the acid value of the emulsion is 10-12 mg KOH / g, and the solid content is 28-38%. The main body of the obtained resin dispersion is epoxy resin, has a phosphate structure and has a good adhesive force on a metal base material, so that the corrosion resistance is excellent, carboxyls are introduced by the modification of the acrylic resin and provides water dispersibility after being neutralized by the neutralizer, the resin can be made into a water-based paint, the VOC content is greatly reduced, and a plurality of carboxyls are carried on the epoxy main chain to be crosslinked with such resin as amino, urea formaldehyde and phenolic aldehyde to be made into stoving varnish.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

High magnetic permeability soft magnetic powder for inductors and production method thereof

InactiveCN109411175AGood rust resistanceAvoid large lossesTransportation and packagingMetal-working apparatusMagnetic powderAdhesive

The invention discloses a production method of high magnetic permeability soft magnetic powder for inductors. The method comprises the following steps of: (1) uniformly mixing soft magnetic metal powder with blueing water in a heating state and obtaining blueing film-coated passivation powder after the water is evaporated to dryness, wherein the soft magnetic metal powder is carbonyl iron powder and / or iron silicon chromium alloy and the blueing liquid is obtained by mixing sodium hydroxide solution, sodium nitrite solution and sodium nitrate solution; (2) weighing a glue material according tothe ratio and dissolving the glue material in acetone to obtain an adhesive; (3) mixing the passivation powder with the adhesive, pumping air while stirring until the liquid is completely evaporatedand carrying out extrusion granulation; and (4) baking and drying the obtained granules in an oven and screening. The invention also discloses the high magnetic permeability soft magnetic powder for the inductors, which is prepared by adopting the method. The method disclosed by the invention has the advantages that under the circumstance of guaranteeing that the powder material has good rust resistance and insulativity, the magnetic permeability is avoided being lost by a large margin and the quality of the powder material is improved.

Owner:HEFEI ECRIEE TAMURA ELECTRIC

Titanium nanometer polymer alloy coating material and application method thereof

ActiveCN103881563AStorage stableGood rust resistanceConjugated diene hydrocarbon coatingsPretreated surfacesCarbon blackOxide

The invention relates to a titanium nanometer polymer alloy coating material and an application method thereof. The titanium nanometer polymer alloy coating material comprises a primer which is composed of nanometer organic titanium imide copolymer resin, epoxy resin, methylated amino resin, bismaleimide resin powder, liquid acrylonitrile butadiene rubber, active zinc oxide, a coating auxiliary, N-methylpyrrolidinone, dimethylformamide, methyl isobutyl ketone and superfine zinc powder, and a finish which is composed of nanometer organic titanium imide copolymer resin, epoxy resin, methylated amino resin, bismaleimide resin powder, liquid acrylonitrile butadiene rubber, alpha-phase nanometer aluminum oxide, pigment carbon black, coating auxiliary, N-methylpyrrolidinone, dimethylformamide and methyl isobutyl ketone. The titanium nanometer polymer alloy coating material is more excellent in properties than imported products used at present, the protective service life of the material is prolonged by 2-3 times, and therefore, the maintenance cost of equipment and the cost of oil and gas exploitation are greatly reduced, and the titanium nanometer polymer alloy coating material satisfies customers.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

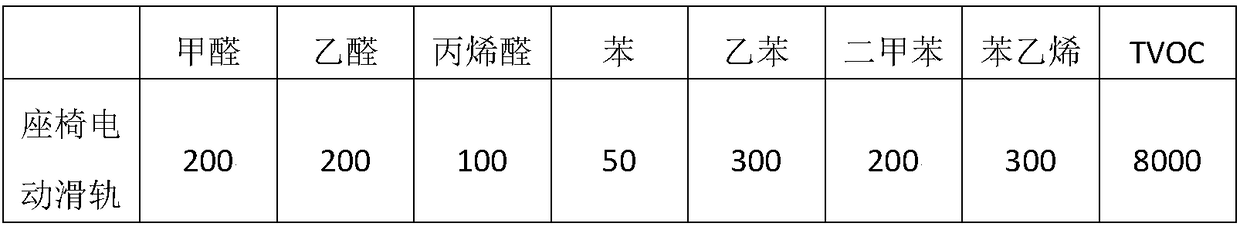

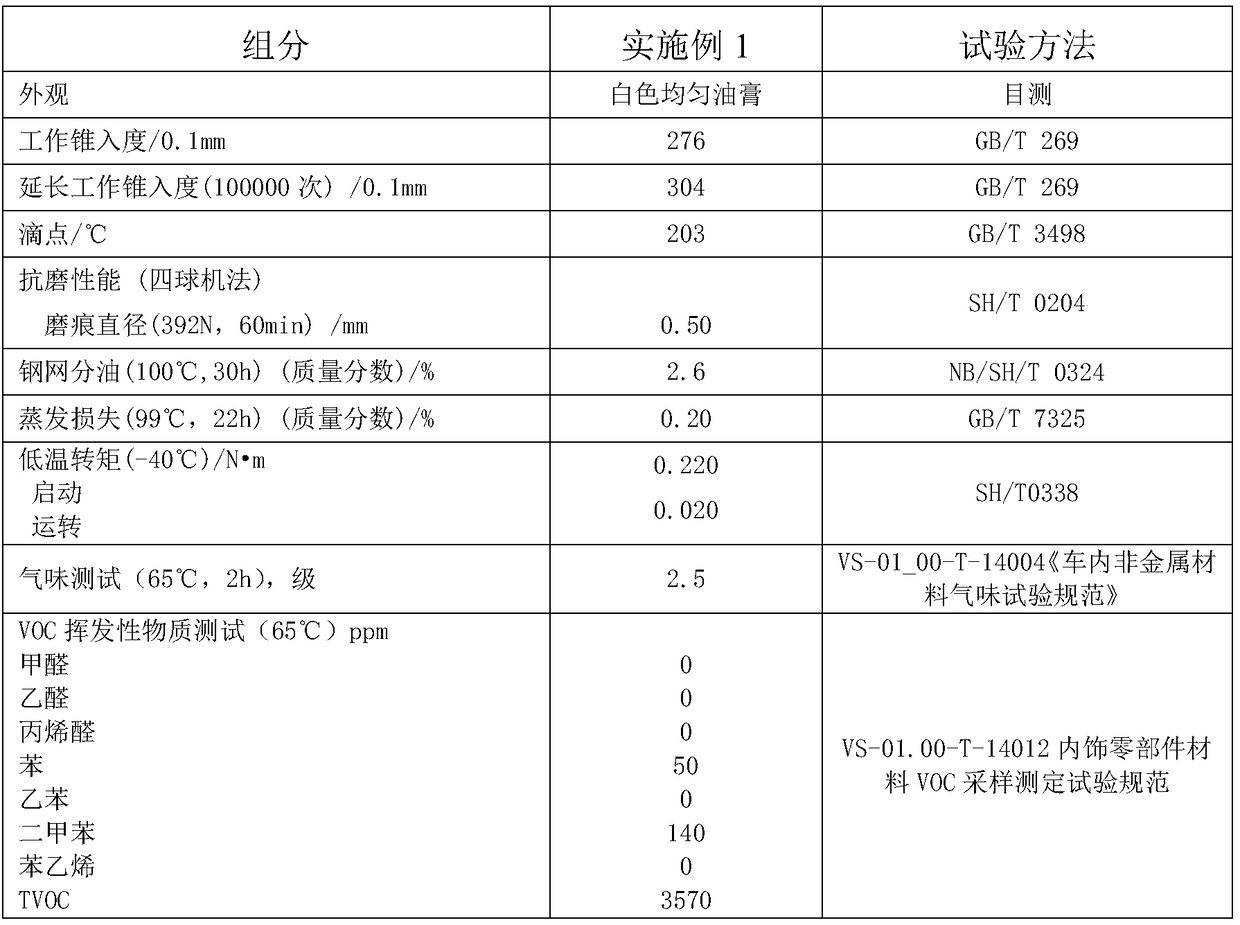

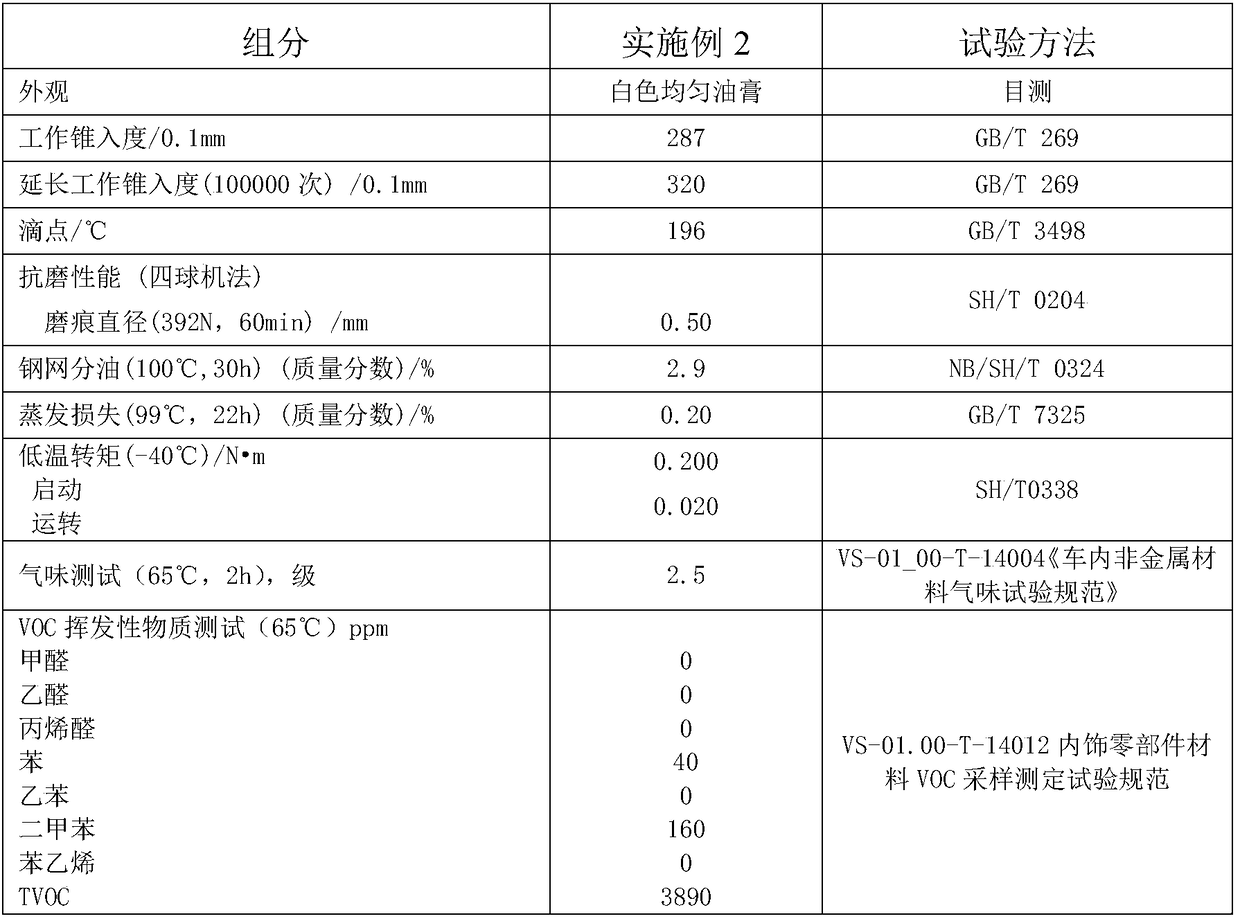

Low-smell composition of automobile seat electric slide rail lubricating grease and preparation method thereof

InactiveCN109054934AGood high and low temperature resistanceGood rust resistanceLubricant compositionCar seatRust converter

The invention relates to a low-smell composition of automobile seat electric sliderail lubricating grease and a preparation method thereof. The composition comprises the raw materials in percentage byweight: 60-65% of basic oil, 35-40% of a densifier, 0.5% of a structure modifier, 0.5% of an antioxidant and 0.5% of an antirust agent. The prepared environment-friendly automobile seat electric seatsliderail lubricating grease can effectively solve the problems that the noise generated by the slide rail in the operation process is high, the slide rail operates slowly at the low temperature, theoriginal equipment manufacturer smell and toxic and harmful substances exceed the standard by strictly controlling the variety selection of raw materials in the original formula of the product, the investigation of the adding amount and the technology in the preparation process. The lubricating grease has the excellent high and low temperature resistance, mechanical stability, colloid stability,the good antirust performance and long service life, meanwhile meets the environment-friendly and non-toxic requirements, and belongs to the low-smell lubricating material.

Owner:CHINA PETROLEUM & CHEM CORP

Water-borne rusty anticorrosive primer and preparation method thereof

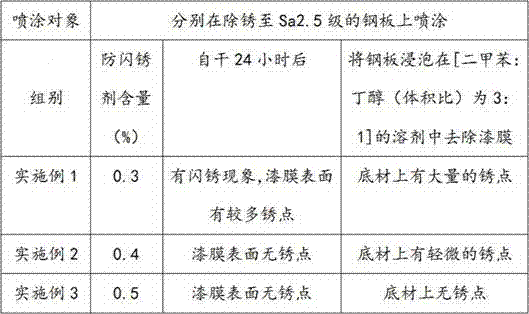

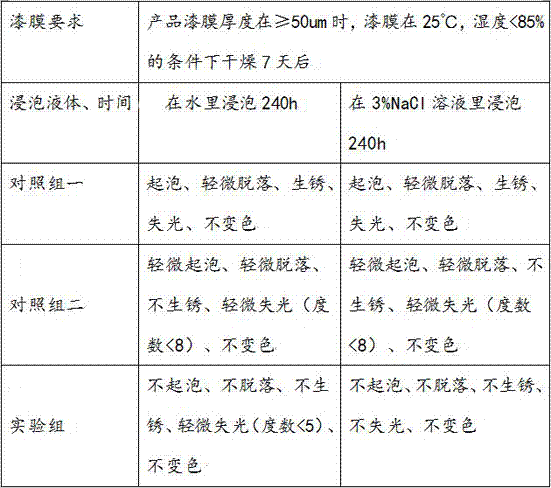

PendingCN109207034AGood rust resistanceImprove initial water resistanceAnti-corrosive paintsPolyester coatingsDefoamerSolvent

The invention discloses a water-borne rusty anticorrosive primer and a preparation method thereof. The water-borne rusty anticorrosive primer comprises the following raw material components in parts by weight: 20-30 parts of water-borne modified alkyd resin, 0.2-1 part of a defoamer, 0.1-1 part of a dispersant, 0.1-1 part of an anti-flash rust agent, 0.5-2 parts of a thickener, 0.1-0.5 part of a pH regulator, 0.1-0.5 part of a leveling agent, 0.1-1 part of a drier, 0.1-1 part of a wetting agent, 0.5-2 parts of a rust converter, 0.1-0.5 part of an anti-mildew thixotropic agent, 30-40 parts of pigments and fillers, 0.5-3 parts of a cosolvent and 30-40 parts of deionized water. The water-borne rusty anticorrosive primer provided by the invention has excellent water resistance, acid and alkaliresistance and salt spray resistance, can be directly applied to a corroded metal surface without strict rust removal and surface treatment, and is quite suitable for large steel components which aredifficult to be thoroughly surface-treated, and has broad application prospects and development potential.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Cleaning liquid capable of preventing steel from being corroded

The invention discloses cleaning liquid capable of preventing steel from being corroded, which is prepared from the following raw materials in parts by weight: 2.7 to 5.3 parts of hydroxyethylidene diphosphonic acid, 4.2 to 5.6 parts of active alumina powder, 5.2 to 7.6 parts of ethylene diamine disuccinic acid, 5.4 to 7.6 parts of 2-acrylamide, 3.5 to 5.6 parts of phosphate ester salts, 3.2 to 5.6 parts of glycerol monooleate hexamer and 5.6 to 7.3 parts of a corrosion inhibitor. The cleaning liquid not only has the cleaning ability, but also is corrosion inhibitors capable of preventing the corrosion of steel. An experiment shows that the cleaning agent has good anti-corrosion performance for steel, copper, aluminum, tin and alloys thereof; the cleaning ability is improved since activated alumina powder and ethylenediamine disuccinic acid are added. The cleaning liquid has good scavenging effect on difficultly washed oil dirt and polymers dirt particularly; the cleaning agent can be prepared at room temperature so that the energy is saved and the operation is easy.

Owner:QINGDAO HUIERTONG TRADING

Metal rustproof wax using emulsifying wax as main body and preparation method thereof

ActiveCN103173124AGood rust resistanceEasy to useWax coatingsAnti-corrosive paintsEmulsionAlkylphenol

The invention discloses a metal rustproof wax using emulsifying wax as a main body and a preparation method thereof. The metal rustproof wax consists of the following raw materials in parts by weight: 50-60 parts of emulsifying wax, 37-43 parts of 70# microcrystalline wax, 0.8-1.2 parts of ferrocene, 4-6 parts of film-forming resin, 3-5 parts of modified kieselguhr, 15-18 parts of vanay, 0.6-0.8 part of glycol monobutyl ether, 1-3 parts of modified pure acrylic emulsion, 0.4-0.6 part of aluminum hydroxide, 0.5-0.7 part of dimercaptoacetic acid isooctyl diisooctyl tin, 1.2-1.5 parts of octadecylamine, 0.7-0.9 part of propylene glycol, 5-7 parts of zirconia, 2-4 parts of alkylphenol polyoxyethylene ether, 0.9-1.1 parts of antioxygen 168 and 1-3 parts of sodium tripolyphosphate. By using the emulsifying wax as a main raw material, the metal rustproof wax disclosed by the invention has good rustproof performance and is convenient to use, and moreover modified kieselguhr and modified pure acrylic emulsion are added in the raw materials, so the rustproof wax disclosed by the invention has temperature resistance and surface smoothness which are better than those of the similar products, and has good flowability, salt fog resistance and humidity resistance.

Owner:FULAIYIN AUTOMOBILE PARTS

Metal processing cleaning saponification solution

The invention discloses a metal processing cleaning saponification solution, and belongs to the technical field of chemical engineering. The metal processing cleaning saponification solution comprises the following ingredients in parts by weight: 80 parts of base oil, 28 parts of petroleum sodium sulfonate, 14 parts of phosphoric acid, 0.3 parts of critic acid, 3 parts of zinc oxide, 8 parts of benzotriazole, 0.5 parts of fatty acid ethanol ester, 1.5 parts of antioxidant, and 12 parts of alcohol. The metal processing cleaning saponification solution is applicable to metal processing, the use concentration of the metal processing cleaning saponification solution is 2%, so that the usage amount is less, the metal processing cleaning saponification solution has good antirust property on nickel plating pieces, steel, copper and cast irons, and is better in cleaning and lubrication properties.

Owner:安徽顺驰电缆股份有限公司

Lubrication cutting fluid and its preparation method

InactiveCN103396874AImprove lubrication statusGood rust resistanceLubricant compositionLubricationButanedioic acid

The invention relates to a lubrication cutting fluid and its preparation method. The lubrication cutting fluid is characterized by being made of the following raw materials by weight part: 3-4 of ammonium molybdate, 2-3 of benzoic acid, 4-5 of polyethylene glycol, 1-2 of castor amide, 2-3 of alkenyl succinic acid, 3-4 of zinc dialkyl dithiophosphate, 4-5 of dimethyl silicon oil, 1-2 of triphenyl phosphite, 1-2 of petroleum sodium sulfonate, 5-6 of a film assistant, and 250 of water. According to the invention, the lubrication state can be improved, so that the product can have good and stable lubricity under high and low temperature conditions.

Owner:岳西县新峰机械制造有限公司

Rust removing and preventing liquid for steel and preparation method thereof

ActiveCN103614714ALow manufacturing process costGood rust resistanceMetallic material coating processesRosinChemistry

The invention discloses a rust removing and preventing liquid for steel. The rust removing and preventing liquid is prepared from the following raw materials in parts by weight: 1-2 parts of diallylamine, 2-3 parts of rosin-polythylene oxide ester, 1-2 parts of phosphoric acid, 1-2 parts of magnesium chloride, 2-3 parts of thiourea, 1-2 parts of sodium dodecyl sulfate, 6-9 parts of diethylene glycol dibenzoate, 1.5-2.5 parts of peregal, 1-2 parts of EDTA (ethylene diamine tetraacetic acid) disodium, 4-5 parts of additives, and 300 parts of water. The rust removing and preventing liquid for steel disclosed by the invention is rapid in rust removal; due to an adopted high-molecular polymer and a chelating agent, a layer of thin film is formed on the metal surface so as to achieve air-isolating and anti-oxidation effects, and the thin film is easily removed just by virtue of water washing. The rust removing and preventing liquid for steel disclosed by the invention is low in manufacturing process cost, and suitable for being used under the low temperature condition of 12-35 DEG C, and the film can be rapidly formed in 0.5-3 minutes, so that the rust prevention performance of the rust removing and preventing liquid for steel is good, and superior to GB6807 standards; the rust removing and preventing liquid for steel disclosed by the invention is small in environmental pollution, and beneficial to popularization and utilization.

Owner:FUYANG ANGU BOILER PRESSURE VESSEL MFG

Primer-topcoat paint used for steel structures and allowing painting on rusty surfaces

InactiveCN107163745AExcellent anti-rust and corrosion effectGood condensation abilityAnti-corrosive paintsLacquerDefoaming Agents

The invention discloses primer-topcoat paint used for steel structures and allowing painting on rusty surfaces. The primer-topcoat paint used for steel structures and allowing painting on rusty surfaces is prepared from raw materials in percentage by weight as follows: 55%-65% of an acrylic polymer emulsion, 0.1%-0.2% of a defoaming agent, 0.15%-0.25% of a base material wetting agent, 0.1%-0.3% of a wetting dispersant, 2%-20% of titanium dioxide, 5%-9% of zinc phosphate, 0.3%-0.5% of a flash-rust inhibitor, 3%-4% of dipropylene glycol mono butyl ether, 0.1%-0.2% of ammonium hydroxide, 0.4%-0.6% of a thickening agent, 0.05%-0.1% of a corrosion remover and 10%-20% of deionized water. The primer-topcoat paint used for steel structures and allowing painting on rusty surfaces adopts a reasonable formula and can be directly used on rusty steel, the same paint is required to be applied twice or above, flash rust and early rust cannot occur, and the paint is safe, environment-friendly and excellent in performance.

Owner:中山市粤马科技有限公司

Modified nanoscale titanium dioxide-containing metal rust prevention wax and preparation method thereof

The invention discloses a modified nanoscale titanium dioxide-containing metal rust prevention wax and a preparation method thereof. The modified nanoscale titanium dioxide-containing metal rust prevention wax comprises raw materials in parts by weight: 70-80 of PE (polyethylene) wax, 30-40 of styrene, 1-2 of dicyclopentadienyl iron, 4-5 of film-forming resin, 1-2 of modified diatomaceous earth, 10-15 of dibutyl phthalate, 0.9-1.1 of fatty alcohol polyoxyethylene ether sulfate, 2-3 of dibutyltin dilaurate, 2-4 of tribasic lead sulphate, 3-5 of N-phenyl-2-naphthylamine, 1-3 of dodecencylsuccinic acid, 5-7 of modified nanoscale titanium dioxide, 1-3 of Tween 80, and 0.8-1.2 of catechol. The rust prevention wax not only has good rust prevention property and is convenient to use, but also adds the modified nanoscale titanium dioxide into raw materials; and compared with the similar products, the rust prevention wax has better temperature resistance performance and better surface flatness, as well as good flowability, salt fog resistance, and heat and humidity resistance.

Owner:HEFEI CITY TENVER PRECISION CASTING

Novel multifunctional cutting fluid with good performance and preparation method of novel multifunctional cutting fluid

ActiveCN104120012AGood rust resistanceImprove wear resistanceLubricant compositionMaleic anhydrideChemistry

The invention discloses a novel multifunctional cutting fluid with a good performance. The novel multifunctional cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 1-2 parts of potassium carbonate, 2-3 parts of potassium carbonate, 1-2 parts of vinyl trimethoxyl silane, 4-6 parts of titanium diboride, 2-3 parts of titanium diboride, 3-5 parts of sodium laurylsulfate, 2-3 parts of triethanolamine borate, 2-4 parts of diethanol amine borate maleic anhydride compound ester, 5-7 parts of an auxiliary and 200 parts of deionized water. The novel multifunctional cutting fluid disclosed by the invention has good anti-rust performance to nonferrous metals such as black metal and copper and is a high performance cutting fluid for materials such as cast iron, stainless steel, high-carbon steel and copper. The auxiliary is added to further enhance the wear resistance, dispersibility, lubricity and film-forming property. A surfactant is added, so that the cutting fluid has good permeability and cleaning performance. The cutting fluid disclosed by the invention is reasonable in formula and simple in process.

Owner:菏泽市汇信知识产权运营有限公司

Anti-wear and anti-rust cutting fluid

InactiveCN108384612AGood rust resistancePrevents moisture from attacking the surfaceLubricant compositionChemistryLanthanum

The invention discloses anti-wear and anti-rust cutting fluid, which is prepared from the following raw materials: mineral oil, phthalimide valerate alcohol amine rare earth salt, sorbitan citrate, tetrabutyl quaternary pentyl acetate, lanthanum phytate, zinc molybdate, tungsten carbide, copper borate, an emulsifier, polyoxyethylene polyoxypropylene pentaerythritol ether, a surfactant and water. The zinc molybdate, tungsten carbide and copper borate in the anti-wear and anti-rust cutting fluid are good in corrosion inhibition effect, and also have excellent wear resistance and wear reduction performance; the cutting fluid provided by the invention is good in wear resistance, high in corrosion protection efficiency, safe and environmentally-\ friendly.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Anti-corrosion concrete preparation method

The invention provides an anti-corrosion concrete preparation method and relates to the field of concrete. The method utilizes 260 to 300 parts by weight of cement, 500 to 600 parts by weight of broken stones, 700 to 800 parts by weight of sand, 70 to 100 parts by weight of mineral powder, 50 to 70 parts by weight of fly ash, 80 to 100 parts by weight of a water reducing agent, 20 to 30 parts by weight of an epoxy resin coating, 20 to 30 parts by weight of inorganic zinc-rich paint, 150 to 200 parts by weight of water, 40 to 60 parts by weight of a gelling agent, 30 to 50 parts by weight of acrylamide gel, 20 to 40 parts by weight of high-density polyethylene, 30 to 50 parts by weight of an acrylic adhesive, 10 to 30 parts by weight of an antioxidant DLTP, 10 to 30 parts by weight of an antioxidant TPP and 20 to 30 parts by weight of carbon fibers. The epoxy resin coating and inorganic zinc-rich paint are sprayed to the surface of a reinforcing steel bar and form a protective film forprotecting the steel bar so that the steel bar surface has a strong anti-corrosion function. Under combination of acrylamide base and high-density polyethylene, the concrete has high waterproof performances and prevents water from penetrating into the concrete.

Owner:连云港市建筑设计研究院有限责任公司

Cleaning agent for rust-proof cold-rolled steel sheets before annealing

The invention discloses a cleaning agent for rust-proof cold-rolled steel sheets before annealing. The cleaning agent comprises the following components by weight percent: 30-40% of sodium hydroxide, 20-30% of sodium carbonate, 10-20% of trisodium phosphate, 10-20% of sodium benzoate, 2-7% of ethylene diamine tetraacetic acid and 3-8% of n-tetradecyl polyoxyethylene ether. When the cleaning agent is used, the cleaning agent is added to water according to a weight percent of 3-5% to prepare cleaning solution and the cold-rolled steel sheets before annealing are cleaned in the cleaning solution at 70-85 DEG C. The cleaning agent has the beneficial effects that the cleaning agent does not have strong pungent smell, can be directly added to cleaning section water before recrystallization annealing of the cold-rolled steel sheets, is convenient and easy to use, has good cleaning effects, has high cleaning efficiency being above 99%, has excellent rust-proof property, is suitable for cleaning the cold-rolled steel sheets, alloying galvanized sheets, hot galvanized sheets and the like and enables the rust-proof period of the steel sheets in the middle process to be over 15 days.

Owner:武汉钢铁有限公司

Long acting work shop bicomponent element precoating priming paint

A high-durability precoated dual-component priming paint for workshop is composed of the component A prepared proportionally from ethyl n-silicate, alcohol solvent, and acidified water and the component B prepared proportionally from polyvinylic acid resin, alcohol solvent, assistant, powder and active magnetic iron powder. Its advantages are high antirust powder, high weldability, and high resistance to flush and rubb.

Owner:WUHAN FUMAISHI NEW MATERIAL CHEM

Pseudoplastic water-based dye type printing ink for ball-point pen

The invention discloses a pseudoplasticity water base dye type ink used for ball pens. Polyvinyl alcohol is used as the fixing agent of dye to last the color retention of writing for long; tannin is used as an important color matching component to deepen the color without causing fading; sulphuric acid is added as PH value regulator to lead the ink to be more stable and resistant to aging; organic phosphates are used as anti-rust lubricant to lead the ink not to corrode metal materials caused by reacting in various materials; and dextrine or maltodextrin used is non-toxic and safe glucide and has the property of high solubility and extremely excellent water retention when being put in water. The dye type ink can lead to the lasting retention of writing, has good anticorrosion and antirust performances as well as extremely good ageing stability and writing quality and is convenient and practical in writing, and the writing is easy to be eliminated.

Owner:刘丙阳

Quick drying and easily stripped adhesive capable of resisting rust of thread parts and preparation method of adhesive

InactiveCN110437701AGood rust resistanceHigh bonding strengthWax coatingsAnti-corrosive paintsSolventParaffin wax

The present invention discloses a quick drying and easily stripped adhesive capable of resisting rust of thread parts and a preparation method of the adhesive. The adhesive consists of the following components in parts by weight: 20-35 parts of hydrogenated thermoplastic styrene-butadiene rubber, 5-10 parts of wax material, 4-10 parts of antirust material, 40-60 parts of solvent,0.5-1.0 part of lithium stearate, and 0.1-0.5 part of silicone oil, wherein the wax material is a mixture of two or three kinds of ozocerite, vaseline and liquid paraffin, and the anti-rust material is one or two of petroleum calcium sulfonate or barium petroleum sulfonate. The quick drying and easily stripped adhesive capable of resisting rust of thread parts in the invention has good coating performance and smallfluidity when coating, and can ensure that thread protruding parts are not lack of the adhesive, therefore, and the adhesive has good anti-rust effect. The adhesive has the characteristics of quick drying, no need for air drying, and capability of facilitating next step after coating; and no adhesive residue exits when peeling, good anti-rust performance is achieved, and no rust happens when thesalt spray resistance is greater than 180 hours, and the adhesive can be used for temporary storage and anti-rust protection of spare parts of aerospace and national defense equipment manufacturing.

Owner:SHANDONG NORTH MODERN CHEM IND

Multi-functional cutting fluid and preparation method thereof

The invention discloses a multi-functional cutting fluid and a preparation method thereof. The multi-functional cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 3-4 parts of fatty acid diethanolamine borate ester, 2-3 parts of sebacic acid, 1-2 parts of petroleum sodium sulfonate, 4-5 parts of acetyl triethyl citrate, 3-4 parts of tributyl citrate, 1-2 parts of vinyl succinic acid, 1-2 parts of urea, 1-2 parts of acrylonitrile, 2-3 parts of zinc dialkyl dithiophosphate, 5-6 parts of coalescing agent and 240 parts of water. The novel multi-functional cutting fluid disclosed by the invention has a good rust prevention performance on nonferrous metals such as black metals and copper, so the multi-functional cutting fluid is an efficient cutting fluid for materials such as cast iron, stainless steel, high-carbon steel and copper, and is a multi-functional cutting fluid with excellent performance.

Owner:林志虎

Metal rustproof paraffin using chlorinated paraffin as main body and preparation method thereof

The invention discloses metal rustproof paraffin using chlorinated paraffin as a main body and a preparation method thereof. The metal rustproof paraffin consists of the following raw materials in parts by weight: 70-75 parts of chlorinated paraffin, 20-25 parts of mineral oil, 1-3 parts of ferrocene, 5-6 parts of film-forming resin, 3-6 parts of modified kieselguhr, 10-12 parts of dibutyl phthalate, 0.8-1.2 parts of butyl naphthalene sulfonate, 1-2 parts of modified benzoic acid monoethanolamine, 0.5-0.7 part of triethylene diamine, 0.9-1.1 parts of urotropin, 1.3-1.5 parts of benzotriazole fatty amine, 2-4 parts of zirconium fluoride, 0.7-0.9 part of alkylphenol polyoxyethylene ether, 1-3 parts of antioxygen 1010 and 2-4 parts of dialkyl phosphorodithioic zinc. By using the chlorinated paraffin as the main raw material, the metal rustproof paraffin disclosed by the invention has good rustproof performance and is convenient to use, and moreover modified kieselguhr and modified benzoic acid monoethanolamine are added in the raw materials; and the chlorinated paraffin has temperature resistance and surface smoothness which are better than those of the similar products, and has good flowability, salt fog resistance and humidity resistance.

Owner:FULAIYIN AUTOMOBILE PARTS

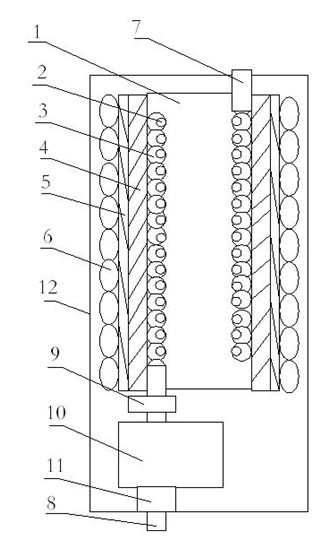

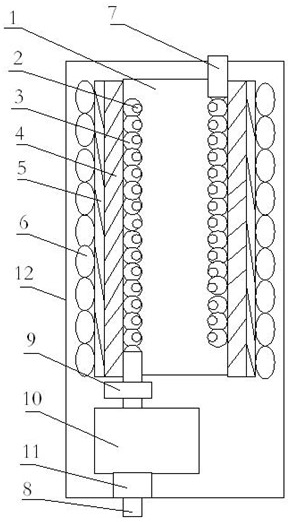

Energy-saving instantaneous variable-frequency electromagnetic water heater

InactiveCN102322689AHigh heat conversion efficiencyFast heatingFluid heatersInduction heating apparatusProcess engineeringHeat sink

The invention relates to an energy-saving instantaneous variable-frequency electromagnetic water heater, which comprises a shell, a heating cylinder and a power supply control device. A water outlet and a water inlet communicated with a heat dissipation sheet are respectively arranged at the upper end and the lower end of the heating cylinder. A high-temperature resistance waterproof insulation coil electrically connected with the power supply control device is wound outside the heating cylinder. A spiral magnetic steel pipe is wound in the heating cylinder. A magnetic steel bar is arranged in the magnetic steel pipe. The energy-saving instantaneous variable-frequency electromagnetic water heater disclosed by the invention has the benefits that: the water heater has the advantages of high heat conversion efficiency, rapid heating speed, water and electricity separation, safety, reliability, low noise, no pollution, beautiful appearance, practicability, simple installation, convenience maintenance, steady working, long service life, low fault rate, maintenance-free, energy saving, emission reduction and low cost; the water heater can automatically work by setting temperatures according to user requirements; after being magnetized, water in the pipeline has the functions of removing and preventing scale, simultaneously, the water also has the good integrated functions of sterilizing, removing seaweeds, resisting corrosion, retarding corrosion and the like.

Owner:聂福宇

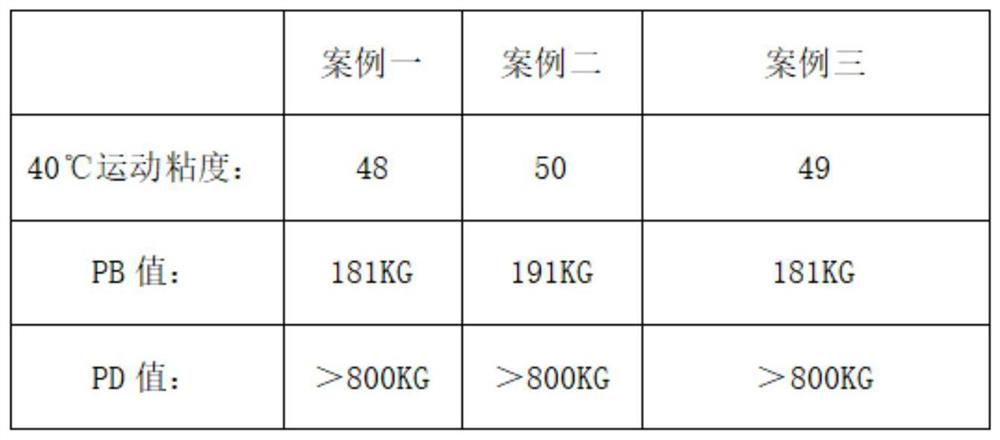

Trace lubricating oil and preparation method thereof

PendingCN114214110AGood rust resistanceImprove cleanliness and dispersibilityAdditivesSulfidationCorrosion inhibitor

The invention provides trace lubricating oil and a preparation method thereof, and relates to the technical field of lubricants, and the trace lubricating oil comprises the following components in parts by weight: 5-10 parts of an extreme pressure agent, 3-5 parts of vulcanized lard, 7-10 parts of super-alkali calcium sulfonate, 3-5 parts of an anti-wear agent, 0.3-0.6 part of an antioxidant additive, 0.5-0.6 part of a clearing agent, 0.02-0.1 part of a corrosion inhibitor, and the balance of non-drying oil. According to the trace lubricating oil, the extreme pressure agent is adopted as the additive, the additive contains high-activity sulfur and can provide good extreme pressure property, the super-base-number calcium sulfonate can provide the extreme pressure property and also has excellent anti-rust property, so that the trace lubricating oil has excellent anti-rust property, and finally through the added clearing agent, the trace lubricating oil has excellent anti-rust property. According to the present invention, the added corrosion inhibitor can effectively improve the detergency and the dispersibility, can strongly neutralize the corrosion of corrosive acid, can further improve the anti-rust performance, and in conclusion, has characteristics of high practicality and prominent creativity.

Owner:AMER TECH CO LTD

Cutting fluid

InactiveCN111154533AGood rust resistanceGood antibacterial propertiesLubricant compositionTert-butylbenzeneEnvironmental geology

The invention discloses a cutting fluid. The cutting fluid is prepared from, by weight, 35-45% of mineral oil, 5-12% of sodium petroleum sulfonate, 3-6% of a lubricant, 2-5% of alkoxy polyether, 1-4%of diethanol amine, 1-3% of a metal corrosion inhibitor, 0.5-2% of a defoaming agent, 0.1-1% of tert-butylbenzoic acid, and the balance of water, and the pH value after combination is 8.5-9.5. The cutting fluid has excellent antirust performance, and is free of harmful ingredients such as chlorine and sodium nitrite, environmentally friendly and reliable to use, good in antibacterial property, capable of effectively preventing the cutting fluid from deteriorating and stinking, low in foam, beneficial to greatly widening the application range, good in lubricating property, capable of greatly reducing the cost, beneficial to the machining precision of the surface of a product, high in applicability and good in practicability.

Owner:仪征市伟尔机械服务部

Galvanized steel plate nick protection rust inhibitor

The present invention discloses a galvanized steel plate nick protection rust inhibitor. Raw materials of the rust inhibitor comprise a deep refined environmental protection base oil, a rust inhibitor, nanometer quartz powder and an aromatic amine antioxidant. The galvanized steel plate nick protection rust inhibitor of the present invention has the following advantages that: the rust inhibitor has excellent anti-rust performance and strong adhesion; the galvanized steel plate nick can be effectively protected; the rust inhibitor contains a special anti-rust component providing an extremely effective effect for the galvanized steel plate; with the thin oil film, nick rust can be effectively prevented, and stain can not be formed on the front surface and the back surface of the steel plate; the rust inhibitor does not contain formaldehyde, benzene, heavy metals and other hazardous substances so as to provide good effects for environmental protection and physical and mental health of operators; the closed film has characteristics of excellent smoothness, discoloration resistance, corrosion resistance, high adhesion and the like; the rust inhibitor has good penetration, wherein the rust inhibitor can penetrate the pore, and general anti-rust oils are difficult to reach the pore; and the galvanized steel plate nick protection rust inhibitor of the present invention is applicable for surface anti-rust treatments between processes or indoor and outdoor steel, aluminum and alloy product instruments.

Owner:AMER TECH CO LTD

Environment-friendly high-temperature-resistant cutting fluid

The invention discloses an environment-friendly high-temperature-resistant cutting fluid. The cutting fluid is prepared from, by mass, 30-45 parts of hydrotreated base oil, 9-16 parts of anti-wear reagent at extreme pressure, 15-20 parts of diethanol amine, 0.5-1 part of anti-rusting agent, 10-12 parts of boric acid, 18-22 parts of oleamide, 12-19 parts of lauryl sodium sulfate, 3-8 parts of ethylene glycol, 20-28 parts of polyoxyethylene octylphenol ether, 1-3 parts of emulsification adjustment agent, 1-4 parts of dicarboximide, 2-5 parts of polydimethylsiloxane and 95-130 parts of water. The invention further discloses a preparation method of the environment-friendly high-temperature-resistant cutting fluid. The cutting fluid has no bad influence on a lathe, and all indexes of the cutting fluid are superior to those of saponified oil; meanwhile, the cutting fluid has good cooling, cleaning and anti-rusting properties, is nonpoisonous, odorless and nonerosive to human bodies, does not corrode equipment and does not pollute the environmen.

Owner:全椒县兴盛化工厂

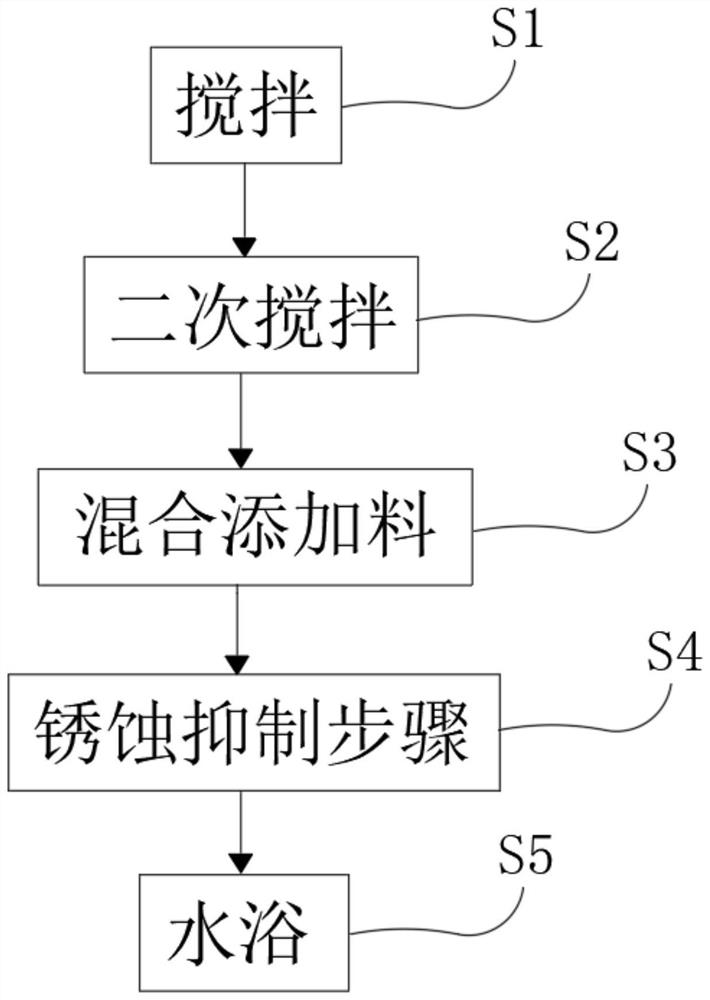

Oilless and antirust production method of stainless steel band subjected to stress relief annealing

The invention relates to an oilless and antirust production method of a stainless steel band subjected to stress relief annealing. The production method comprises the steps: firstly, upwards rolling a steel band, applying a tension, spraying and re-rolling while the steel band is applied with the tension, downwards rolling, and cleaning so that the antirust processing of the stainless steel band is completed. The stainless steel band which is treated by adopting the production method and subjected to the stress relief annealing is better in antirust capacity of the whole surface, has an antirust function after being cleaned, and is capable of reducing the use cost of a customer; the probability of rusting a product produced by adopting the stainless steel band is lower.

Owner:无锡华生精密材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com