Quick drying and easily stripped adhesive capable of resisting rust of thread parts and preparation method of adhesive

An easy-to-peel, thread technology, applied in anti-corrosion coatings, coatings, wax coatings, etc., can solve the problem of low tensile strength and elongation of the anti-rust film of the thread, unable to achieve easy peeling, high-performance anti-rust, and protruding parts of the thread. Easy to lack of glue and other problems, to achieve the effect of large-scale industrial production, outstanding rust resistance and low flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

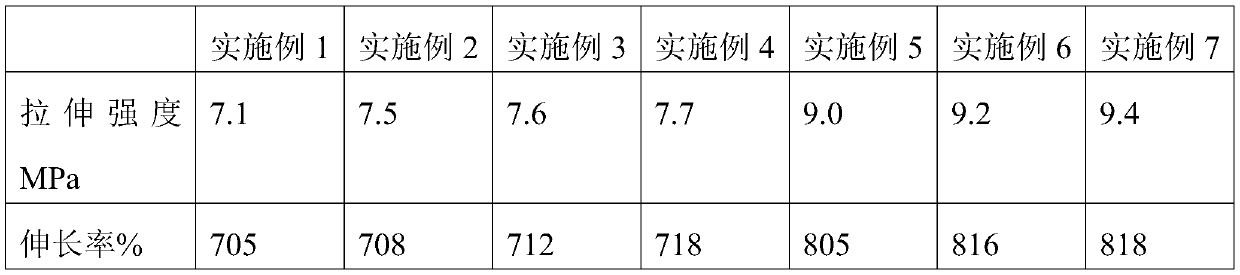

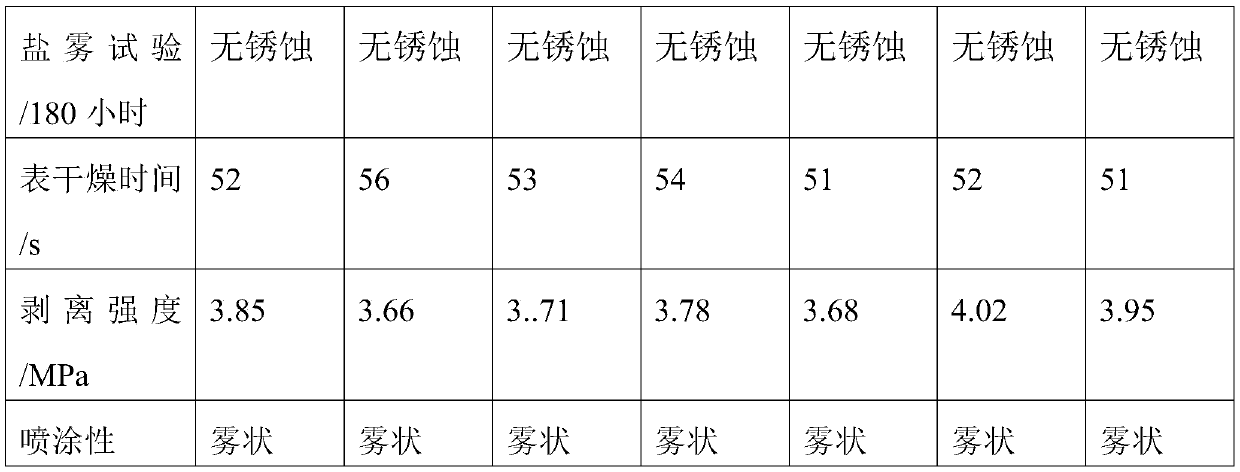

Examples

Embodiment 1

[0030] A quick-drying, easy-to-peel antirust glue for threads, consisting of the following raw materials: 20kg of hydrogenated thermoplastic styrene-butadiene rubber, 5kg of wax material, 4kg of antirust material, 40kg of solvent, 0.5kg of thickener and 0.1kg of silicone oil;

[0031] The waxy material is obtained by mixing ozokerite and vaseline according to a mass ratio of 1:1;

[0032] The anti-rust material is calcium petroleum sulfonate;

[0033] Described solvent is ethyl acetate;

Embodiment 2

[0036] A quick-drying, easy-to-peel antirust glue for threads, consisting of the following raw materials: 35kg of hydrogenated thermoplastic styrene-butadiene rubber, 10kg of wax material, 10kg of antirust material, 60kg of solvent, 1.0kg of thickener and 0.5kg of silicone oil;

[0037] The waxy material is obtained by mixing vaseline and liquid paraffin according to a mass ratio of 1:4;

[0038] The antirust material is barium petroleum sulfonate;

[0039] Described solvent is 120# gasoline;

Embodiment 3

[0042] A quick-drying, easy-to-peel antirust glue for threads, consisting of the following raw materials: hydrogenated thermoplastic styrene-butadiene rubber 25kg, wax material 6kg, antirust material 8kg, solvent 45kg, thickener 0.6kg and silicone oil 0.2kg;

[0043] The waxy material is obtained by mixing ozokerite or liquid paraffin according to a mass ratio of 1:2;

[0044] The antirust material is obtained by mixing calcium petroleum sulfonate and barium petroleum sulfonate according to a mass ratio of 1:1;

[0045] The solvent is obtained by mixing ethyl acetate and 120# gasoline according to a mass ratio of 4:5;

[0046] Described thickener is lithium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com