Patents

Literature

429 results about "Tert-butylbenzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for making an ink jet ink

A process for making an ink jet ink comprising: a) providing a dispersion containing a pigment, a hydrocarbon carrier, and a polyamine / fatty acid condensation polymer dispersant; b) mixing the pigment dispersion with rigid milling media less than 100 mu m; c) introducing the mixture of step (b) into a mill; d) milling the mixture from step (c) until the pigment particle size is below about 100 nanometers (nm); e) adding to the mixture during or after step d) or f) (below) a stabilizer selected from the group consisting of a polyether polyol; a modified polyester resin; an acrylic polymer; an alkylol ammonium salt of a block copolymer having acidic groups; ethoxylated triethanolamine; a high molecular weight block copolymer having an amine functionality; sorbitan sesquioleate; polyhydroxy stearic acid; butylated polyvinyl pyrrolidone; poly(vinylpyrrolidone / 1-hexadecene); and poly(p-tert-butylstyrene-co-styrene-co-2-sulfoethyl-lithium methacrylate); f) separating the milling media from the mixture milled in step (d); and g) diluting the mixture to obtain an ink jet ink having a pigment concentration suitable for ink jet printers.

Owner:EASTMAN KODAK CO

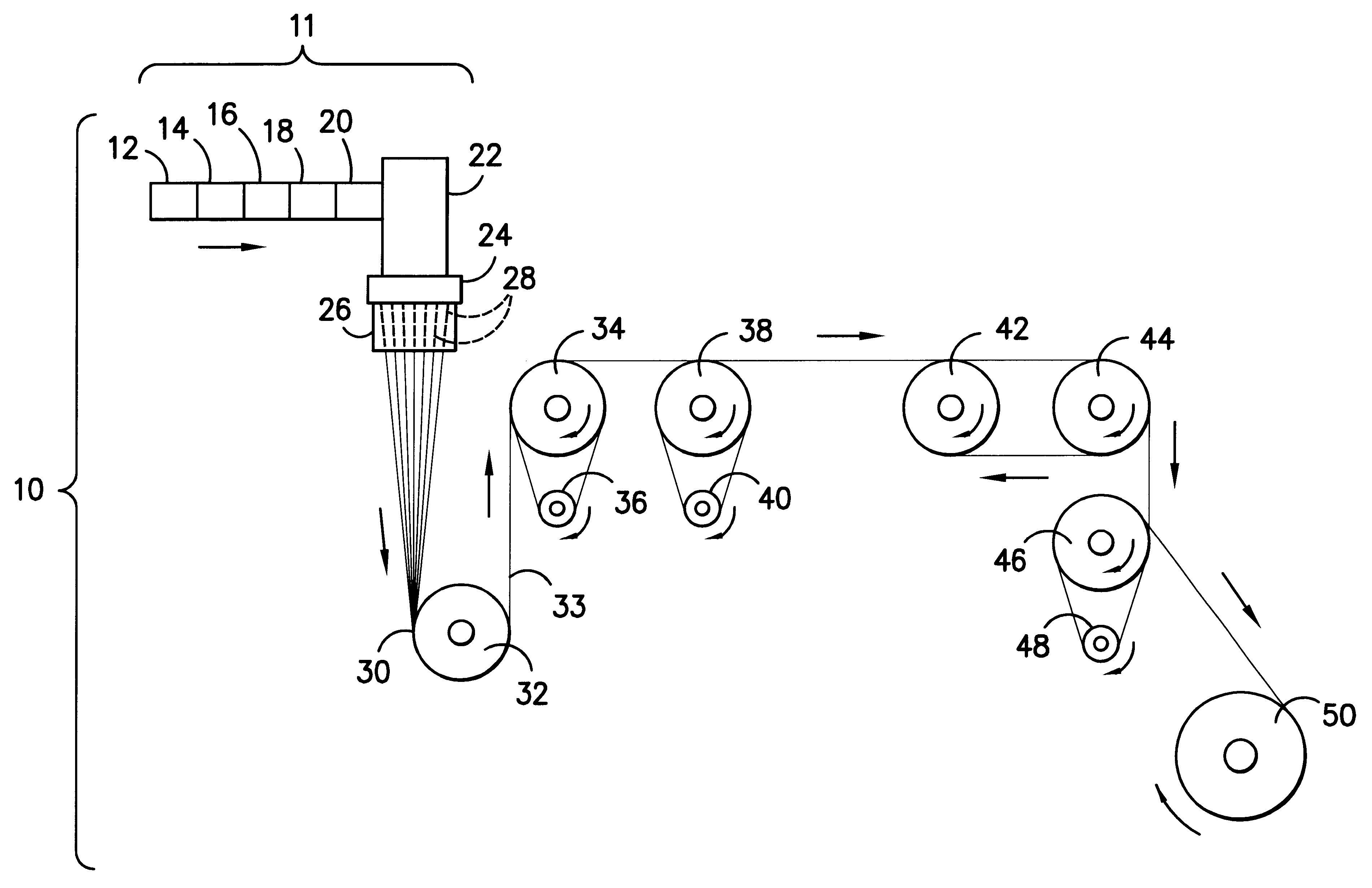

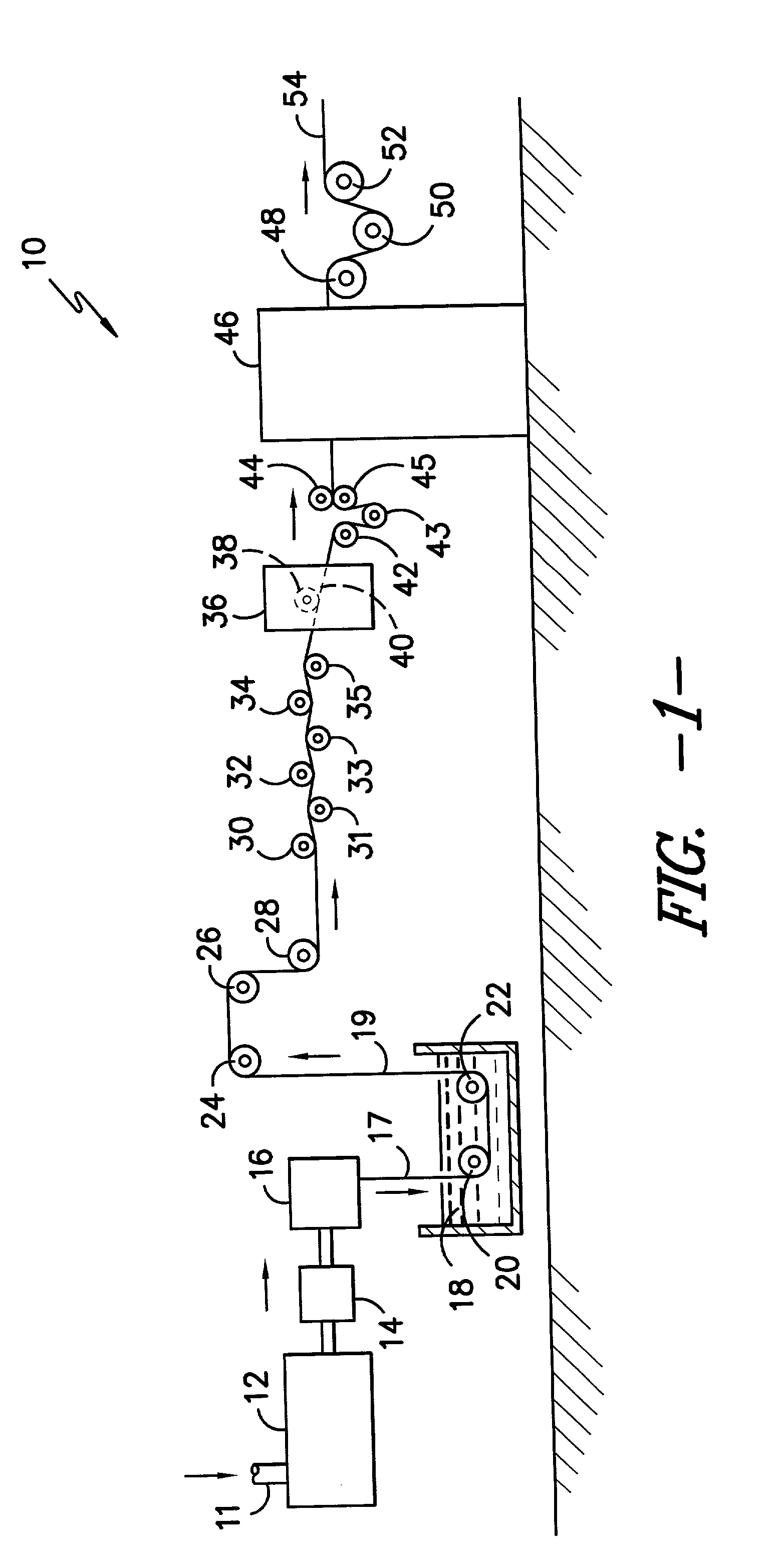

Methods of making low-shrink polypropylene fibers

InactiveUS6656404B2Monocomponent polypropylene artificial filamentWoven fabricsPhosphateLITHIUM PHOSPHATE

Improved polypropylene fibers exhibiting greatly reduced heat- and moisture-shrink problems and including certain compounds that quickly and effectively provide rigidity to the target polypropylene fiber after heat-setting are disclosed herein. In such a manner, the "rigidifying" compounds provide nucleation sites for polypropylene crystal growth. After drawing the nucleated composition into fiber form, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium beuzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11).

Owner:MILLIKEN & CO

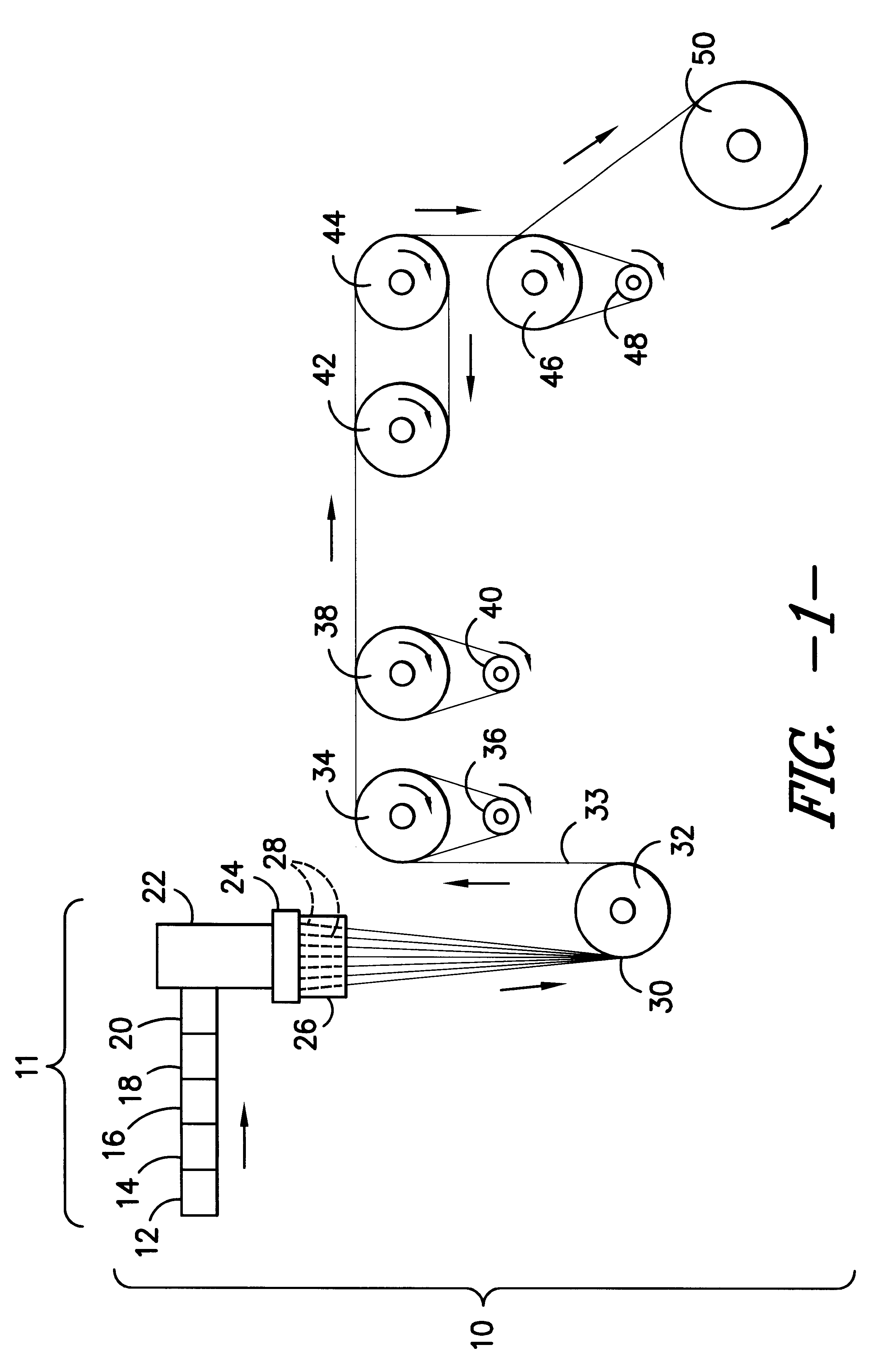

Method of producing low-shrink polypropylene tape fibers

ActiveUS20030127768A1High solubilityLow shrinkage rateLayered productsHollow filament manufactureAspect ratioSodium benzoate

Improvements in preventing heat- and moisture-shrink problems in specific polypropylene tape fibers are provided. Such fibers are basically manufactured through the initial production of polypropylene films or tubes which are then slit into very thin, though flat (and having very high cross sectional aspect ratios) tape fibers thereafter. Such fibers (and thus the initial films and / or tubes) require the presence of certain compounds that quickly and effectively provide rigidity to the target polypropylene tape fiber after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target polypropylene after exposure to sufficient heat to melt the initial pelletized polymer and upon allowing such a melt to cool. The compounds must nucleate polymer crystals at a higher temperature than the target polypropylene without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for polypropylene crystal growth. Upon slitting of the initial film and / or tube, the fiber is then exposed to sufficient heat to grow the crystalline network, thus holding the fiber in a desired position. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as sodium benzoate, certain sodium and lithium phosphate salts (such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11). Specific methods of manufacture of such inventive tape fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

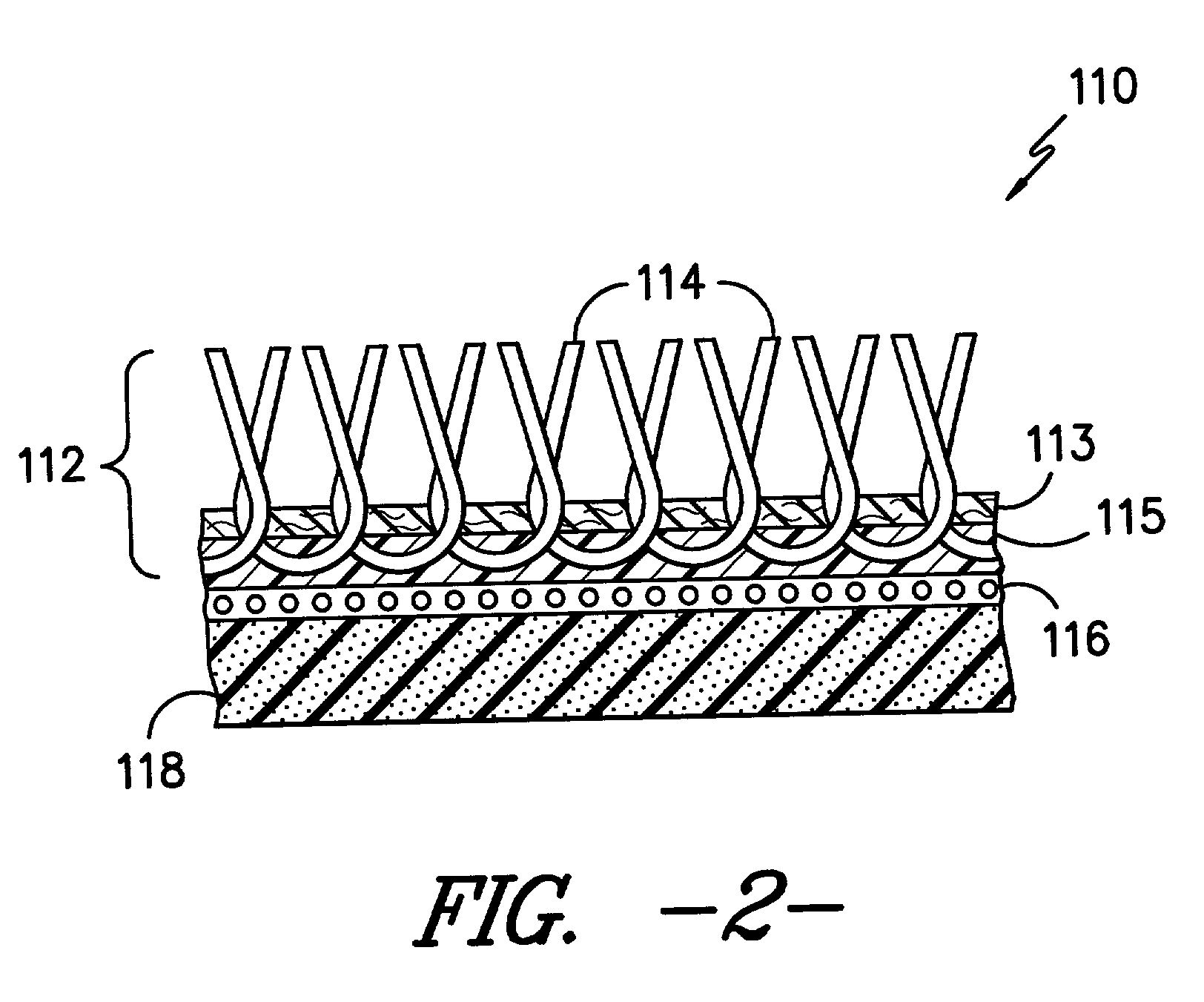

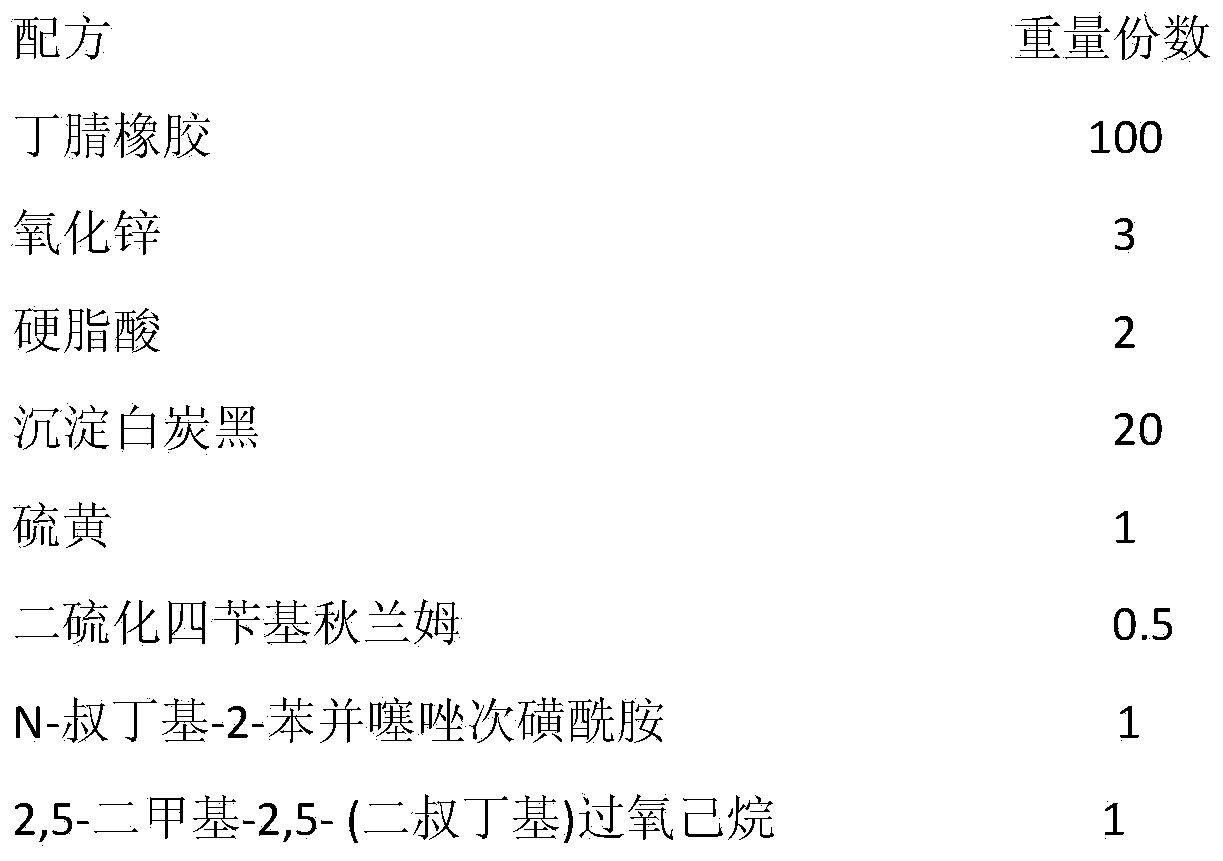

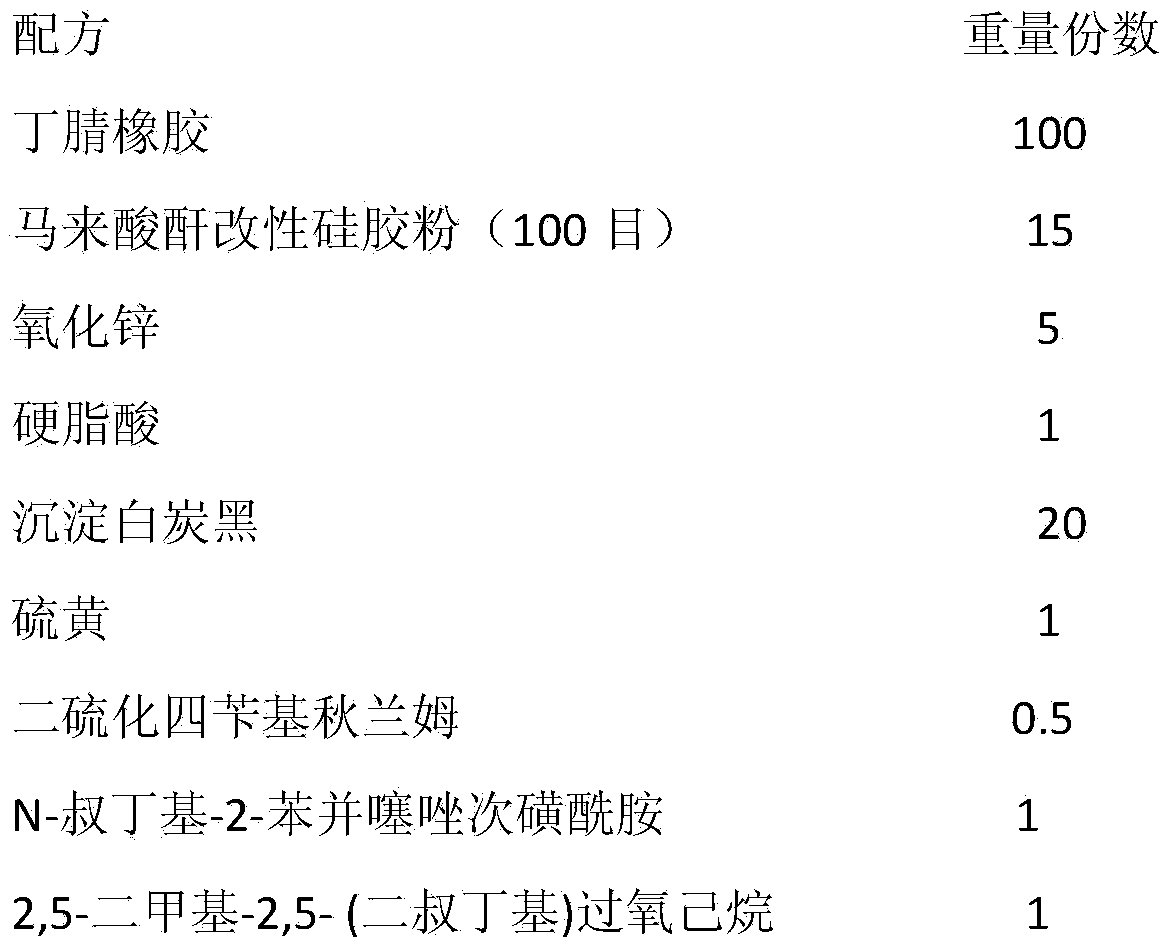

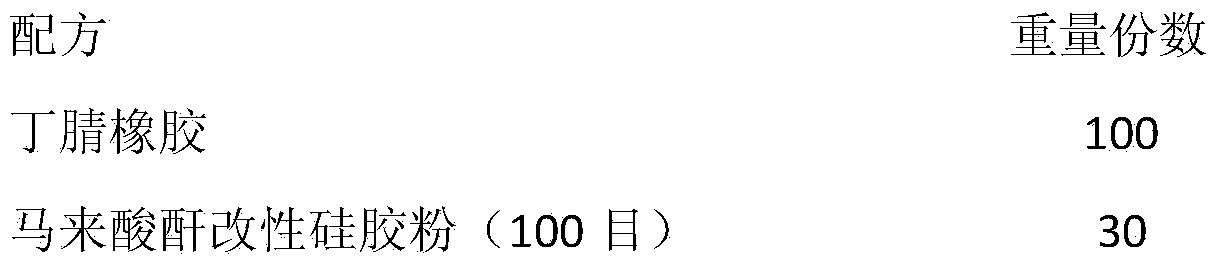

Nitrile rubber/modified silica-gel powder blend and preparation method thereof

The invention provides a nitrile rubber / modified silica-gel powder blend and preparation method thereof. The method comprises the following steps: adding nitrile rubble in an open mill or internal mixer; plasticating for 3-5 minutes; adding zinc oxide, eleaostearic acid, deposited white carbon black, modified silica-gel powder, sulfur, promoter and peroxide; carrying out mixing and milling at 40-60 DEG C, and obtaining the nitrile rubber / modified silica-gel powder blend; the promoter is tetrabenzylthiuramdisulfide and N-t butyl-2-benzothiazolesulfenamide; compression molding of the blend is carried out in a flat vulcanizer, and the vulcanizing temperature is 150-200 DEG C, and the vulcanizing time is 10-30 minutes, and the nitrile rubber / modified silica-gel powder blended vulcanized rubber is prepared. The blended vulcanizied rubber has the advantages of good low temperature resistance, high temperature resistance and higher fracture elongation rate. The invention can improve regeneration utilization rate of wasted silicone rubber, extend application range of silica-gel powder, and the invention has the advantages of simple processing technology, low production cost and good economic benefit.

Owner:SOUTH CHINA UNIV OF TECH +1

Polymer blend compatibilization using isobutylene-based block copolymers

Owner:EXXONMOBIL CHEM PAT INC

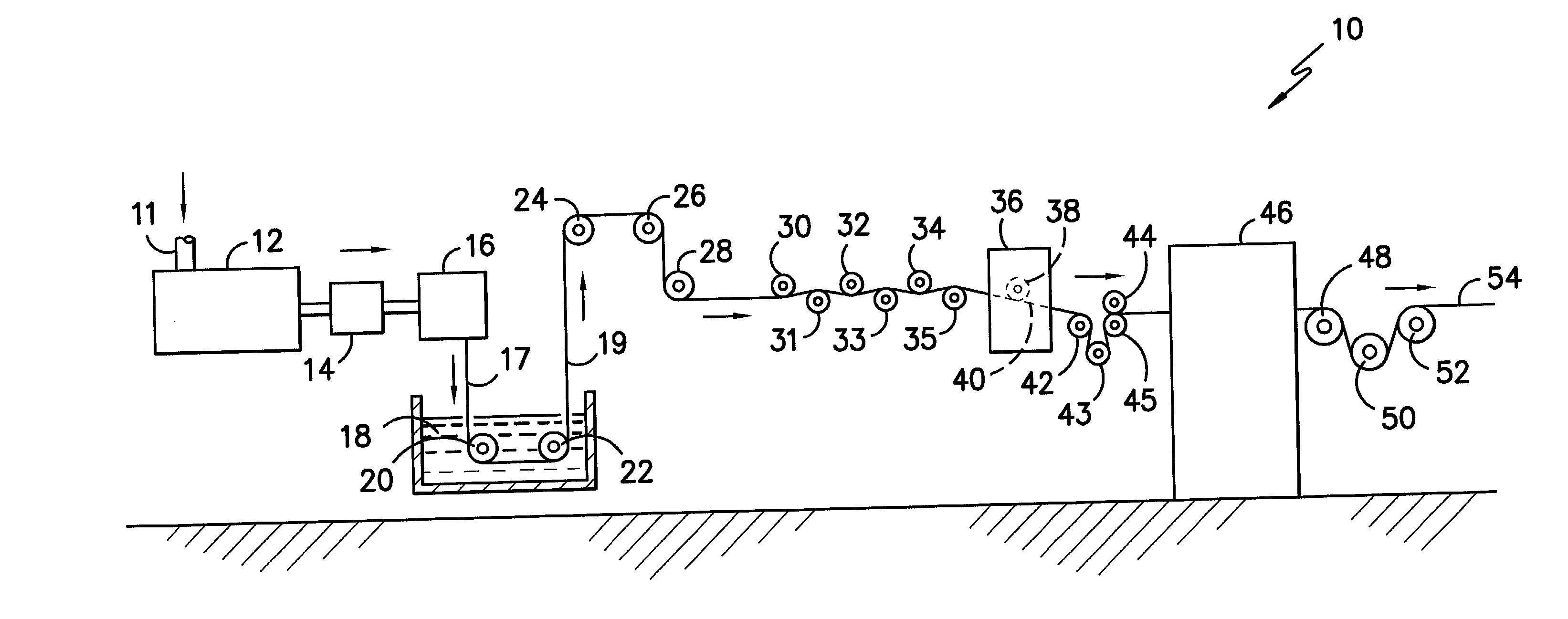

Suspension polymerization process

The present invention is a method of making polymeric particles having a predetermined and controlled size and size distribution. The method includes dissolving a polymer in a solvent to form a solution wherein the solvent is substantially immiscible with water. A suspension of small droplets of the solution is formed in water containing a water soluble promoter and a stabilizer comprising a surfactant free copolymer by high shear agitation. The stabilizer includes (i) about 55 to about 95 percent by weight, based on total monomer weight, of an addition polymerizable p-tert-butyl styrene and / or (ii) about 5 to about 45 percent by weight, based on total monomer weight, of an addition polymerizable ionic monomer. The solvent is removed from the droplets and the solidified polymer particles are separated from the water. The present invention as provides polymer particles having a core of polymer coated with a layer of smaller particles of a copolymer of the stabilizer described in the method.

Owner:EASTMAN KODAK CO

Preparation and application method of polyvinyl chloride (PVC) resin terminator

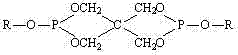

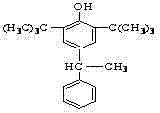

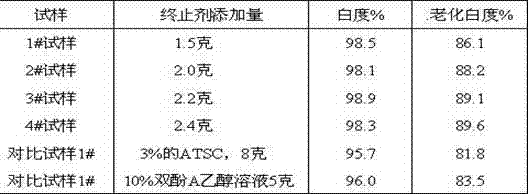

InactiveCN102492064ADifficult to constitute migrationNot easy to cause volatile lossPhosphoric Acid EstersPolymer science

The invention relates to a preparation and application method of a polyvinyl chloride (PVC) resin terminator, belonging to the technical field of chemical products. The invention particularly relates to a liquid antioxidant product, which mainly comprises 2,6-di-bert-butyl-4-(1-phenylethyl)phenol and is obtained by carrying out catalytic alkylation reaction on 2,6-di-bert-butyl phenol and styrene as raw materials. An organic solvent is added into the liquid antioxidant product which mainly comprises the 2,6-di-bert-butyl-4-(1-phenylethyl)phenol, and is sufficiently stirred to obtain the liquid antioxidant product HKY-10. The HKY-10 is compounded with a benzofuran ketone antioxidant and a phosphite ester antioxidant to obtain an oil-soluble compound liquid terminator product as a terminator for a general-purpose PVC resin product preparation process by a suspension method; and the liquid terminator is added in a polymerization reaction process to obtain a PVC resin product with stable properties, thereby enhancing the aging whiteness of the PVC resin product. The PVC resin terminator has the characteristics of no toxicity and environmental protection, and does not generate water pollutants.

Owner:CHANGZHOU UNIV

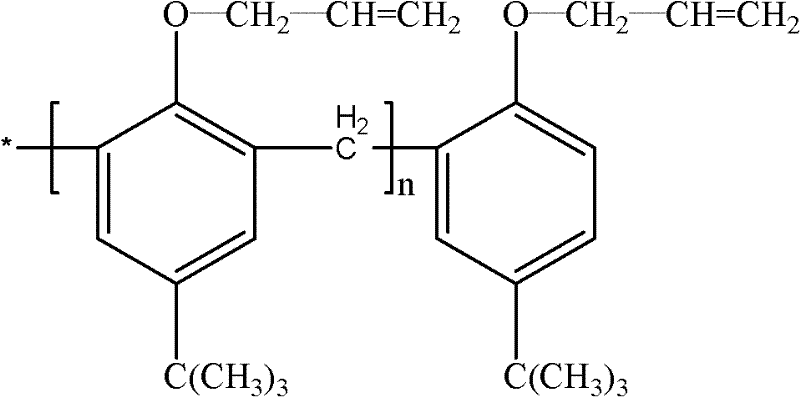

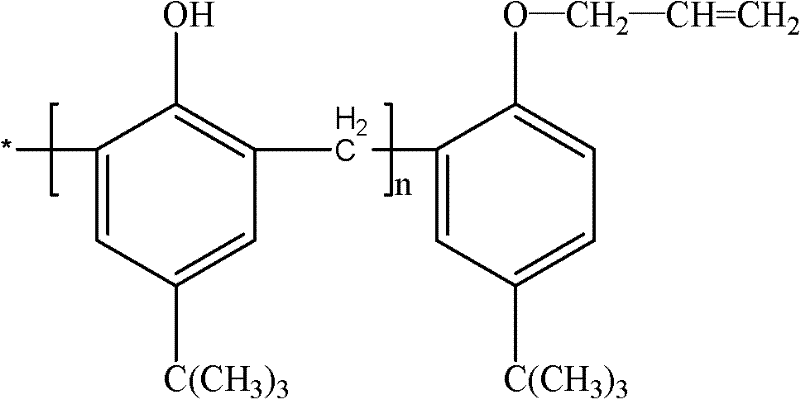

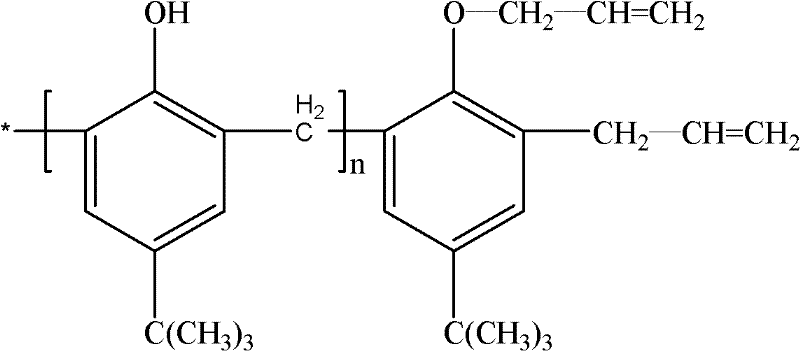

Allyl para-tert-butyl phenyl ether formaldehyde tackifying resin and preparation method thereof

The invention discloses allyl para-tert-butyl phenyl ether formaldehyde tackifying resin and a preparation method thereof. The preparation method comprises the following steps: mixing para-tert-butyl phenol with formaldehyde at the molar ratio of 1:1, increasing the temperature to 80-120 DEG C, adding hydrochloric acid till the boiling of reaction lasts for 3-5 hours, using toluene to dissolve, washing with hot water till neutrality, mixing the obtained resin with allyl chloride at the molar ratio of (3-1):(0.5-2), using ethanol to dissolve, further adding potassium hydroxide to regulate the pH to 8-10, heating for 30-90 minutes, then using the toluene to extract, washing with distilled water till the neutrality, and performing reduced pressure distillation so as to get an allyl para-tert-butyl phenyl ether formaldehyde resin purified product. The product has higher self-adhesion strength and excellent long-acting tackifying capability.

Owner:SOUTH CHINA UNIV OF TECH

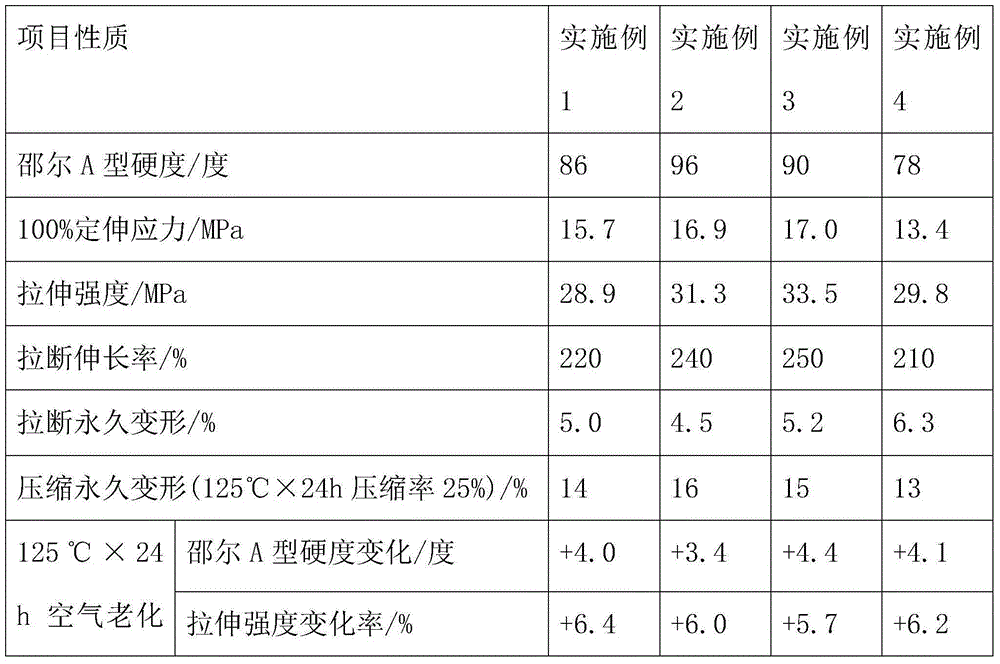

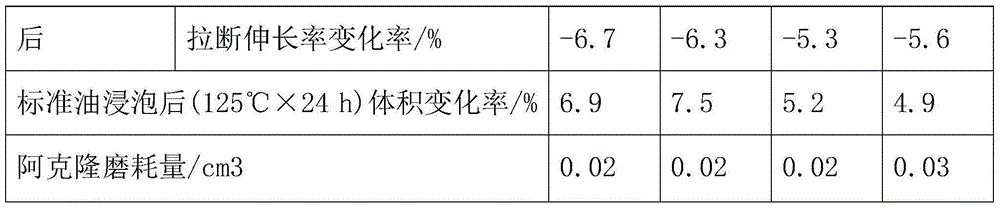

High-performance modified carboxylated nitrile rubber material and preparation method thereof

The invention discloses a high-performance modified carboxylated nitrile rubber material. The material comprises the following raw materials by weight: 90 to 130 parts of modified carboxylated nitrile rubber, 15 to 30 parts of natural rubber, 20 to 40 parts of carbon black N-774, 5 to 10 parts of carbon black N-990, 5 to 10 parts of antimony trioxide, 3 to 5 parts of zinc oxide, 1 to 3 parts of stearic acid, 1 to 3 parts of sulfur, 0.5 to 3 parts of tetrabenzylthiuramdisulfide, 1 to 3 parts of N-tert-butyl-2-benzothiazole sulfonamide, 2 to 6 parts of dioctyl sebacate and 4 to 8 parts of an auxiliary. The modified carboxylated nitrile rubber blending material provided by the invention has higher comprehensive mechanical property, and heat and ageing resistant properties, high-temperature and oil resistant properties and low-compression and permanent-deformation properties.

Owner:合肥市再德高分子材料有限公司

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

InactiveUS20090001313A1Improve thermal stabilityOther chemical processesHeat-exchange elementsBenzoic acidOctanoic Acids

A toxicological friendly antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze composition comprises from 5 to 80 wt. % of an aqueous freezing point depressant selected from alkali metal salts of acetates, formates, proprionates, adipiates, and succinates, and mixtures thereof; 0.1 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.1 to 10 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:CHEVROU USA INC

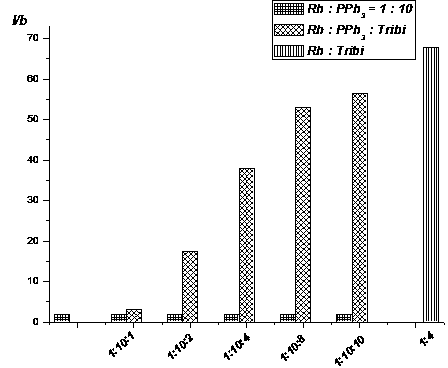

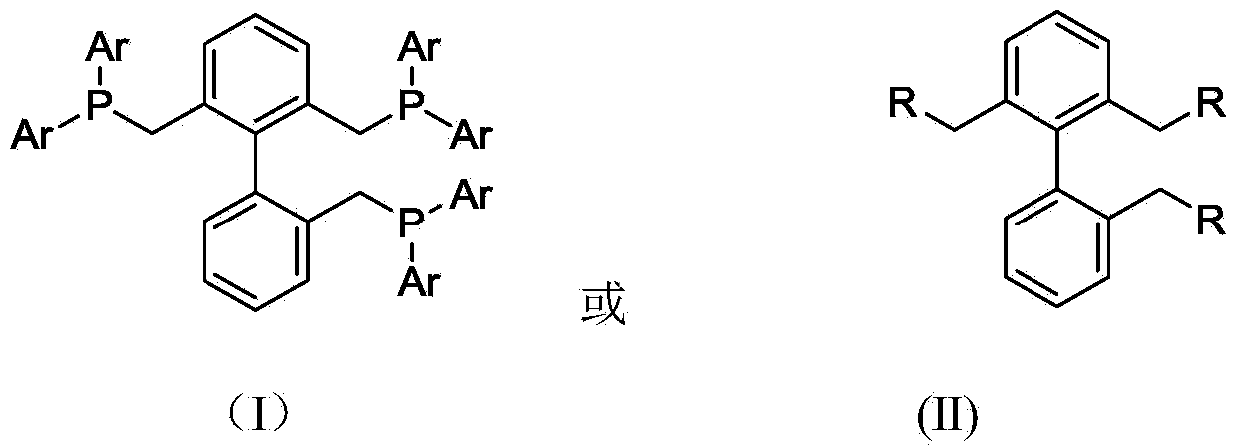

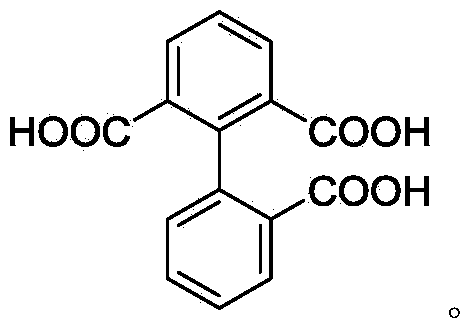

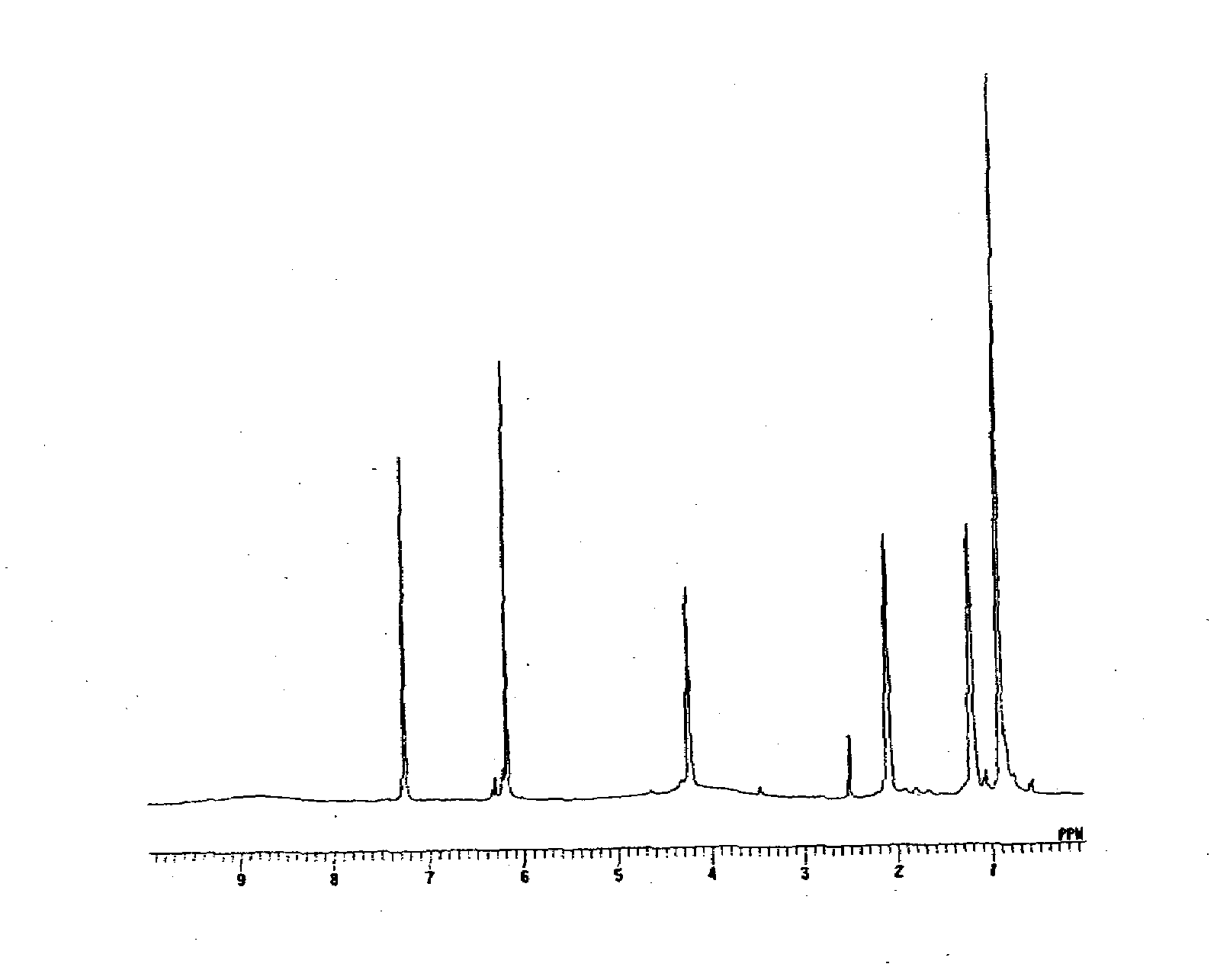

Preparation method of biphenyl triphosphane ligand and application thereof in gradually substituting PPh3 (Triphenylphosphine) in hydroformylation

ActiveCN103804413AHigh yieldEasy to synthesizeOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsReaction rateTrifluoride

The invention discloses a preparation method of a biphenyl triphosphane ligand and an application thereof in hydroformylation reaction. The prepared biphenyl triphosphane ligand has the structure shown as a formula (I) or formula (II) described in the specification. In the formula (I), aryl substituent Ar is benzene, p-methyl benzene, m-benzenyl trifluoride, p-benzenyl trifluoride, 3, 5-dibenzenyl trifluoride, 3, 5-difluorobenzene, 3, 5-dimethyl benzene, 3, 5-di-tert-butyl benzene, 3, 5-di-tert-butyl-4-metoxybenzene, p-metoxybenzene, p-dimethylamino benzene, 2-pyridine, p-fluorobenzene or 2, 3, 4, 5, 6-pentafluoro benzene; in the formula (II), R is in a cyclic phosphonate structure. The biphenyl triphosphane ligand disclosed by the invention can be used as a linear hydroformylation reaction catalyst, so that the selectivity and reaction rate of hydroformylation reaction can be remarkably improved. The biphenyl triphosphane ligand is low in cost and has a huge practical value.

Owner:WUHAN UNIV

Calixresorcinarene compound, photoresist base comprising the same, and composition thereof

InactiveUS20090042123A1Improve sensitivityReduce the amount requiredOrganic chemistryOrganic compound preparationPhenyl groupPhotoresist

A calixresorcinarene compound represented by the following formula (1):wherein eight Rs are n (n is an integer of 1 to 7) substituents that are one or more types of substituents selected from groups represented by the following formula (2), and m (m is an integer shown by 8-n) hydrogen atoms; and R's, which may be the same or different, are each a straight-chain aliphatic hydrocarbon group having 2 to 12 carbon atoms, a branched aliphatic hydrocarbon group having 3 to 12 carbon atoms, a phenyl group, a p-phenylphenyl group, a p-tert-butylphenyl group, and an aromatic group represented by the following formula (3), or a substituent formed by combining two or more of these substituents:wherein R″ is a hydrogen atom or a substituent selected from the substituents represented by the formula (2).

Owner:KINOSHITA HIROO +2

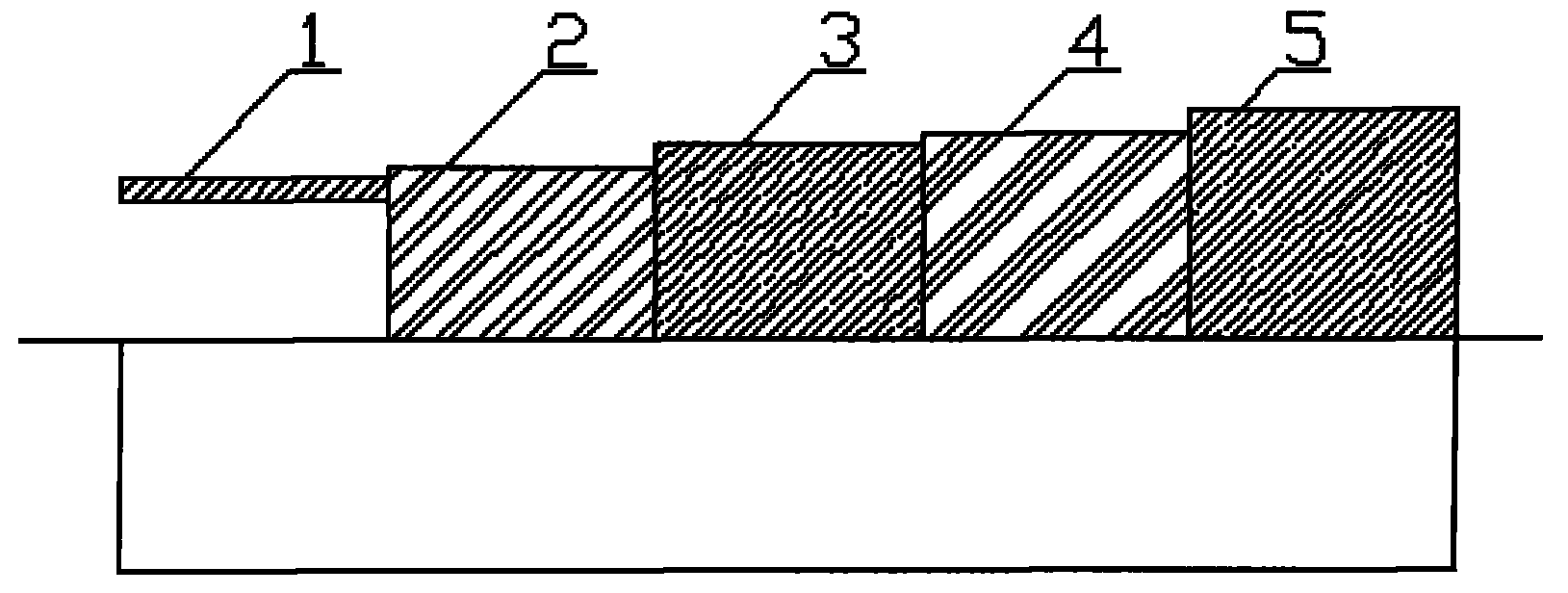

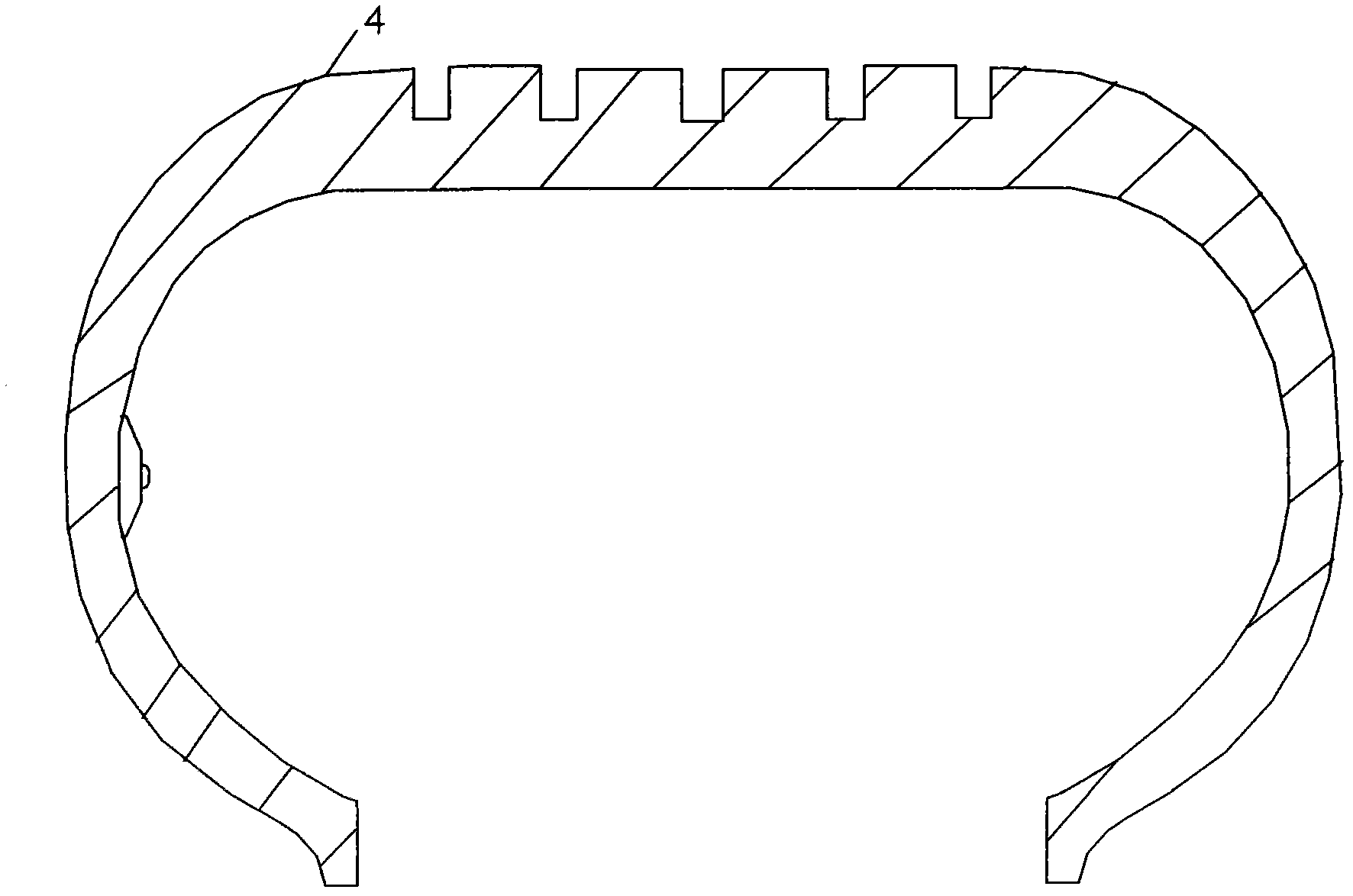

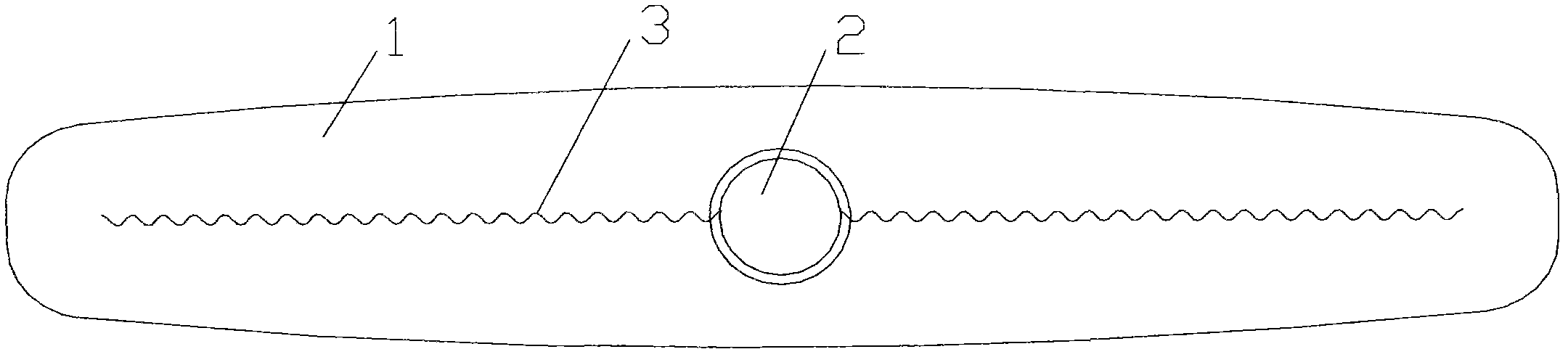

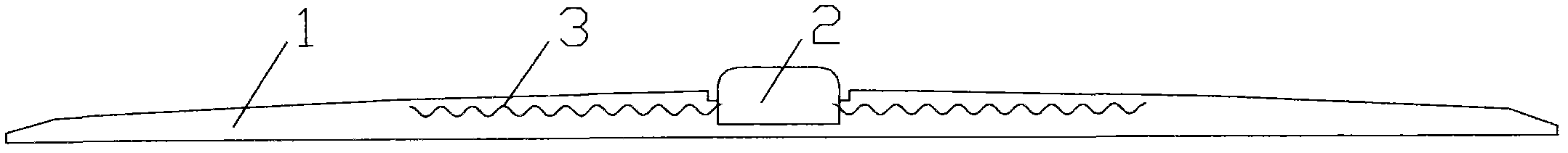

90-degree special temperature selflimiting electric tracing band

InactiveCN101795507AEnhance positive temperature coefficient effectSolve the service lifeHeating element shapesSilicic acidSalicylic acid

The invention discloses a 90-degree special temperature selflimiting electric tracing band, which comprises a conductive core, and a PTC material layer, a polymer insulating inner protective sleeve, an aluminum-magnesium alloy shielding layer and a polymer insulating outer protective sleeve which are covered outside the conductive core in turn, wherein the PTC material is prepared by mixing and melting the following raw material components in part by weight: high-density polyethylene 86-87, carbon black 12-14, tribasic lead sulfate heat stabilizer 0.11-0.13, lead silicate 0.04-0.06, styrenated phenol antioxygen 0.05-0.15, p-tert-butylphenyl salicylate light stabilizer 0.12-0.14 and tribromophenol fire retardant 0.05-0.15. The highest temperature of the band is maintained at 90+ / -5 DEG C, and the band can be used as solar electric tracing band in places with large temperature difference.

Owner:芜湖科阳新材料股份有限公司

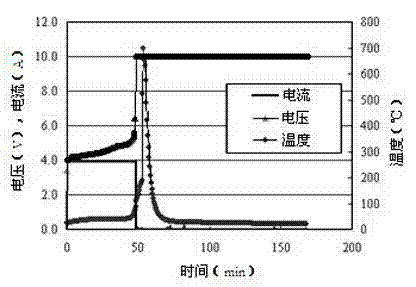

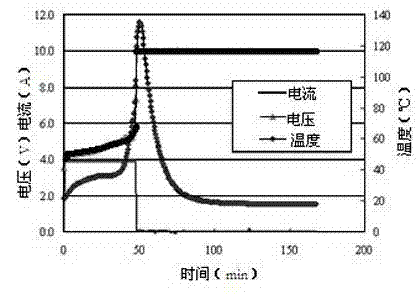

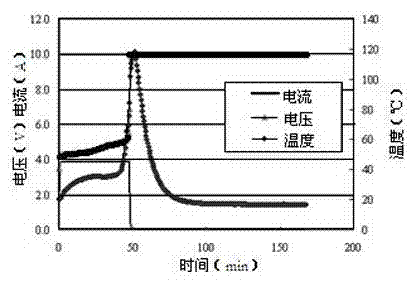

Electrolyte for flexible-package lithium ion secondary batteries and battery with electrolyte

ActiveCN103208648AReduce consumptionPromote circulationSecondary cells servicing/maintenanceHigh temperature storageOrganic solvent

The invention belongs to the technical field of lithium ion secondary batteries, and particularly relates to electrolyte for flexible-package lithium ion secondary batteries. The electrolyte comprises organic solvent, lithium salt and additives. The additives include additive A, additive B and additive C. The additive A is tert-amylbenzene and / or tert-butylbenzene, and the weight percentage of the additives A in the electrolyte is 5-10%. The additive B is at least one of malononitrile, succinonitrile, glutaronitrile, adiponitrile, pimelonitrile, suberonitrile, azelaic dinitrile and sebaconitrile, and the weight percentage of the additive B in the electrolyte is 1-8%. The additive C is fluoroethylene carbonate, and the weight percentage of the additive C in the electrolyte is 2-10%. Compared with the prior art, the electrolyte has the advantages that the additive A, the additive B and the additive C are combined in the high-voltage-design flexible-package lithium ion secondary batteries, good circulating performance and high temperature storage performance of the batteries are guaranteed, and meanwhile, the batteries are enabled to have good anti-overcharge performance.

Owner:DONGGUAN AMPEREX TECH

Dielectric rubber body for packaging sensor and radio-communication system taking dielectric rubber body as carrier

ActiveCN103183876AIncrease elasticityImprove mechanical propertiesOther chemical processesTyre measurementsDielectricPolymer science

The invention relates to a dielectric rubber body for packaging a sensor. The dielectric rubber body is characterized in that the formula thereof comprises 60-70 parts of chlorinated butyl rubber, 10-20 parts of butadiene styrene rubber, 20-30 parts of natural rubber, 20-30 parts of light calcium carbonate, 30-40 parts of carbon black, 5-10 parts of conductive carbon black, 1-3 parts of stearic acid, 2-5 parts of magnesium oxide, 1-5 parts of octyl phenol-phenolic resin, 3-6 parts of zinc oxide, 1-3 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 0.5-2 parts of tetramethyl thiuram disulfide, and 0.5-2 parts of insoluble sulphur. The dielectric rubber body disclosed by the invention is used for a conductive radiofrequency device in tire; the device comprises a radio assembly and an antenna, and can be used for tracking and recording data during manufacturing, sales and use; and the measurement range covers temperature, pressure or other physical parameters in tire. During the loading process of a sensor, the conductive material with a certain dielectric constant and a certain adhesive force disclosed by the invention is chosen, so that the device can be firmly connected with a tire and can be used for transmitting data more stably; simultaneously, via high elasticity and good mechanical property of rubber, the device can withstand the stress brought by cyclic deformation of the tire excellently.

Owner:QINGDAO TONGSHENGTONG RUBBER & PLASTIC

Method for the synthesis of low cost initiators for telechelic polyisobutylenes

Owner:THE UNIVERSITY OF AKRON

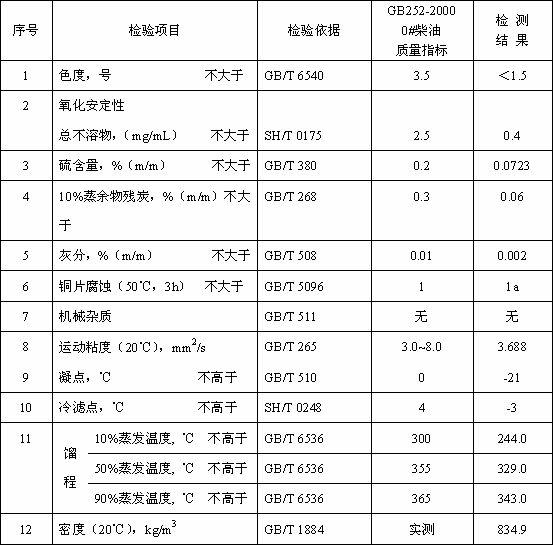

Clean environment-friendly dimethyl carbonate diesel and preparation method thereof

The invention discloses a preparation method of environment-friendly dimethyl carbonate diesel for an automobile. The environment-friendly dimethyl carbonate diesel comprises the following components by weight percent: 50-300ppm of 2,6-tertiary butyl p-cresol, 10-200ppm of tris(2,4-ditert-butyl phenyl) phosphite, 10-200ppm of thiadiazole or benzotriazole, 10-500ppm of isooctyl nitrate or ethyl nitrate, 100-500ppm of lubricity improver, 9.982-29.83% of dimethyl carbonate and 70-90% of diesel. The preparation method comprises the following steps of: adding various additives into dimethyl carbonate and then mixing to obtain a dimethyl carbonate solution I; and then mixing the dimethyl carbonate solution I and dimethyl carbonate with the diesel to obtain the dimethyl carbonate diesel. The dimethyl carbonate diesel disclosed by the invention has the advantages of good stability, corrosion resistance and environmental protection performance, can be intersoluble with the diesel in any proportion, and is simple to prepare, low in cost and strong in competitive power.

Owner:HENAN COAL CHEM IND GROUP INST

Antifreeze Concentrate and Coolant Compositions and Preparation Thereof

ActiveUS20090001312A1Improve thermal stabilityOther chemical processesHeat-exchange elementsChemistryNonanoic acid

An antifreeze composition having improved thermal stability is provided. In one embodiment, the antifreeze concentrate composition comprises from 50 to 99 wt. % of a glycol-based freezing point depressant selected from the group of: alkylene glycols, glycol monoethers, glycerins, and mixtures thereof; 0.01 to 10 wt. % of at least one of a 2-ethylhexanoic acid, isononanoic acid and 3,5,5-trimethylhexanoic acid; and 0.01 to 5 wt. % of at least one of octanoic acid, nonanoic acid, decanoic acid, undecanoic acid, dodecanoic acid, neodecanoic acid, benzoic acid, 2-hydroxybenzoic acid, p-terbutylbenzoic acid, and mixtures thereof. In one embodiment, the composition is employed as a concentrate in admixture with 10 to 90 wt. % water.

Owner:ARTECO NV

Solar photovoltaic backing composite and preparation method thereof

ActiveCN104356613AImprove mechanical propertiesGood weather resistancePhotovoltaic energy generationSemiconductor devicesCarbon nanotubeSolar cell

The invention relates to a solar photovoltaic backing composite and a preparation method thereof and belongs to the technical field of the composites. The solar photovoltaic backing composite is prepared from the following raw materials in parts by mass: 10-25 parts of carbon nanotubes, 10-16 parts of PBT, 2-6 parts of maleic anhydride grafted ethylene propylene diene monomer, 5-10 parts of high-density polyethylene, 2-6 parts of ABS, 2-5 parts of glyceryl tristearate, 1-3 parts of silicone powder, 2-9 parts of citric acid, 2-4 parts of tri[2,4-di-tert-butylphenyl] phosphite, 2-5 parts of silicon carbide fibers and 1-3 parts of gamma-methylacryloxypropyltrimethoxy silane. The solar photovoltaic backing composite has excellent mechanical properties and weather fastness; and the obtained composite also has excellent water vapor barrier property and is capable of effectively protecting a solar cell.

Owner:SUNSHORE SOLAR ENERGY IND

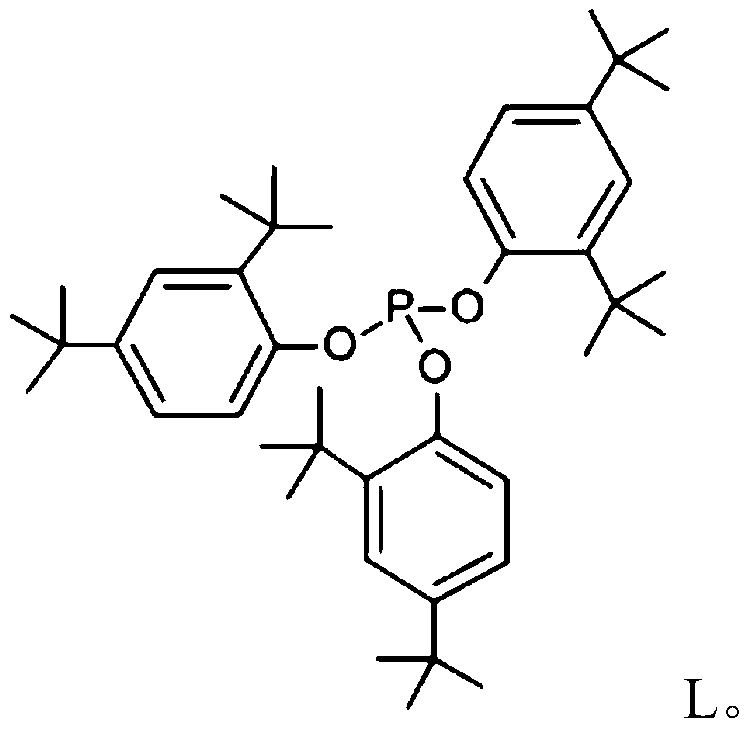

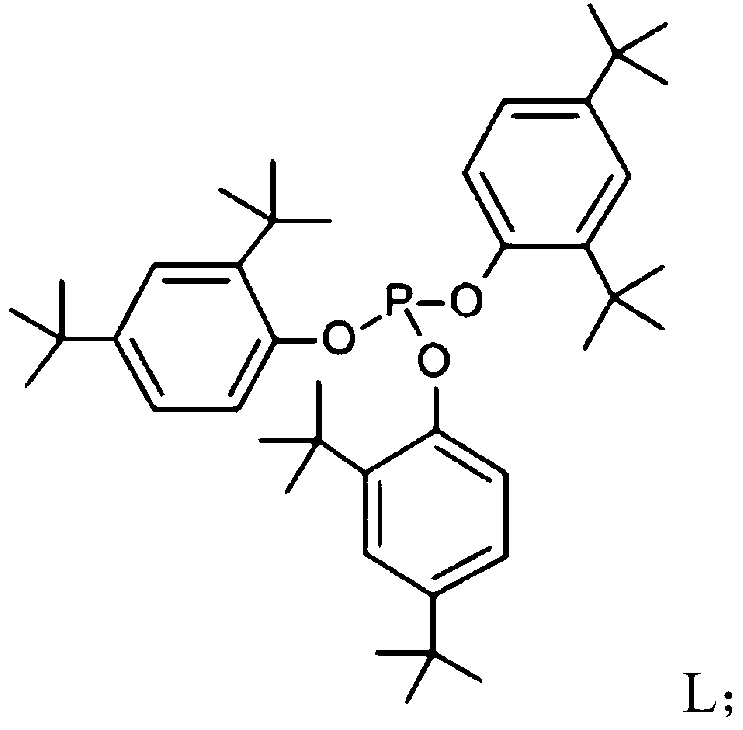

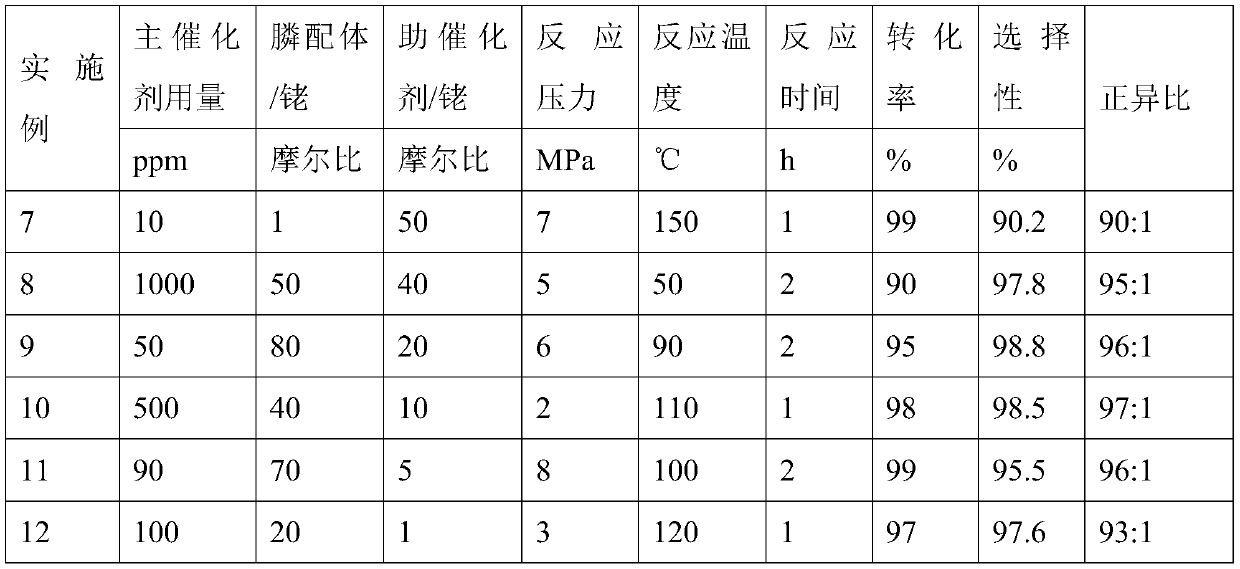

Method for preparing aldehyde by olefin hydroformylation

ActiveCN111348995AHigh activityIncrease positive-to-isotropic ratioPhysical/chemical process catalystsPreparation by carbon monoxide reactionPolymer sciencePtru catalyst

The invention relates to a method for preparing aldehyde through olefin hydroformylation. The method comprises the steps: enabling alpha-olefin and synthesis gas to enter a hydroformylation reactor; carrying out a contact reaction on alpha-olefin and synthesis gas with a catalyst to generate an aldehyde-containing product, wherein the catalyst comprises a main catalyst and a co-catalyst, the maincatalyst is a complex catalyst and comprises a rhodium complex and a phosphine ligand, the phosphine ligand is tris[2,4-di-tert-butylphenyl]phosphite, and the co-catalyst is a nickel-palladium bimetallic phosphinate. The method has the advantages of high normal-to-abnormal ratio in the product, good selectivity and yield, mild reaction conditions and the like.

Owner:WANHUA CHEM GRP CO LTD

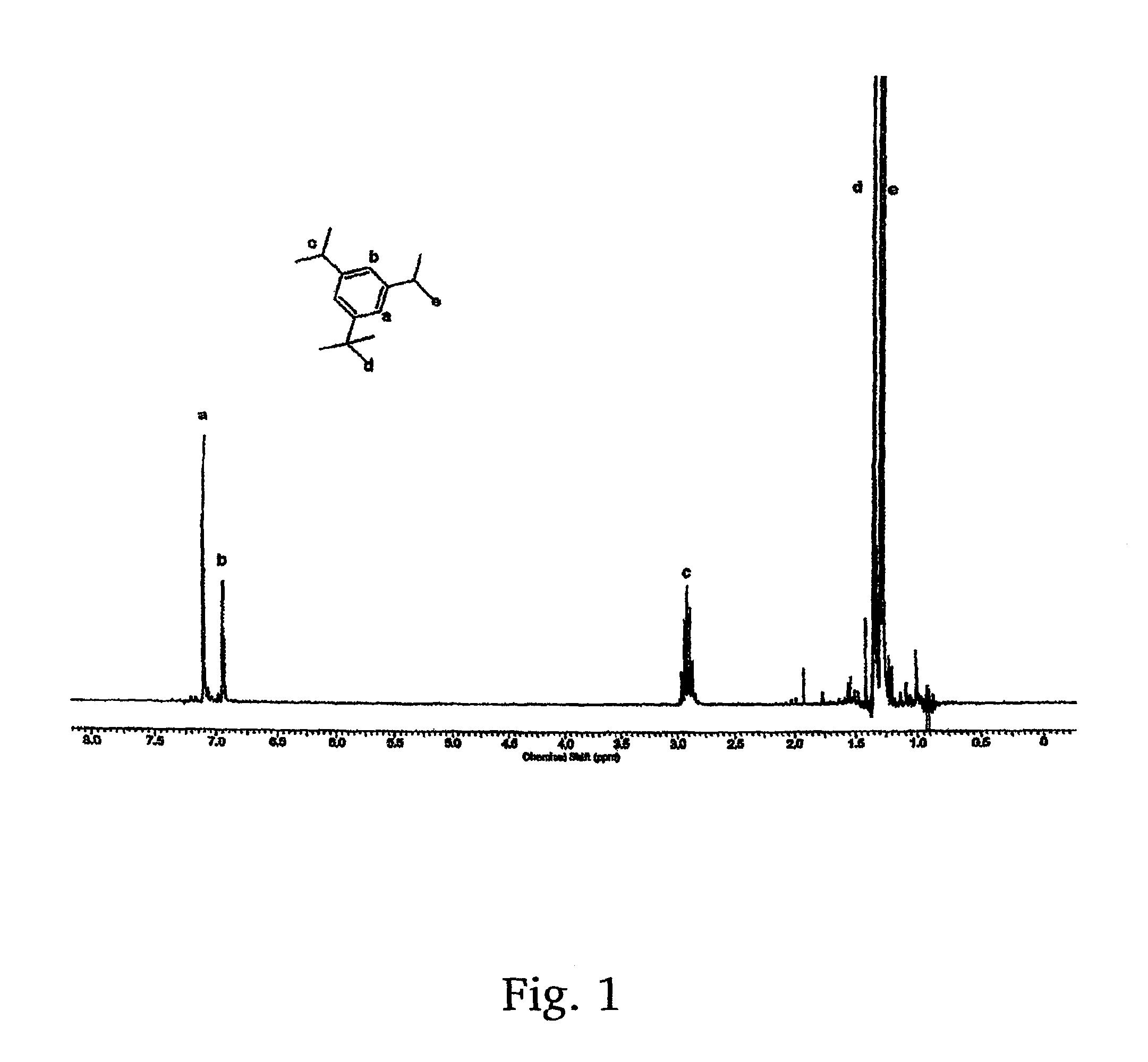

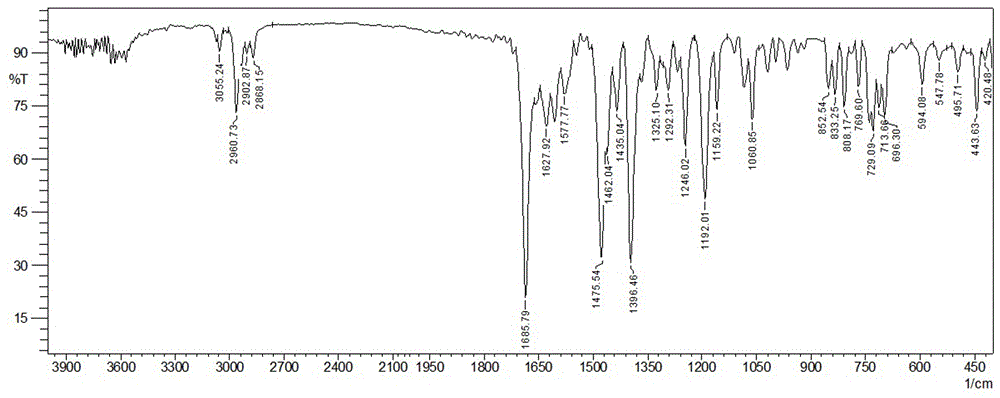

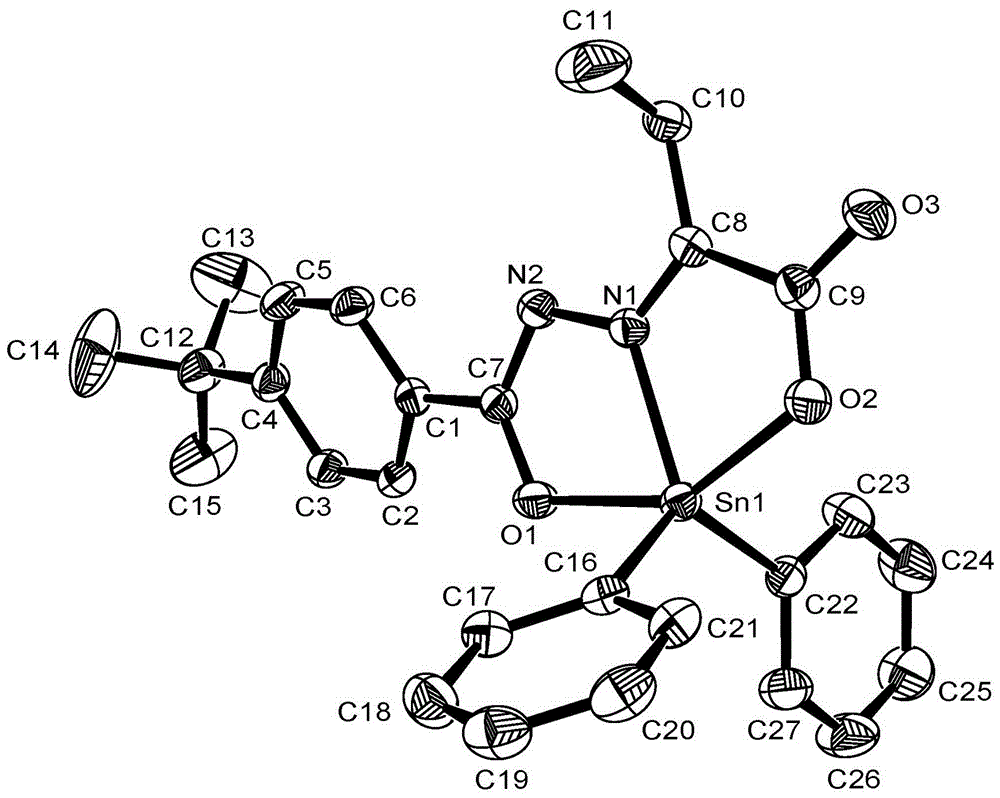

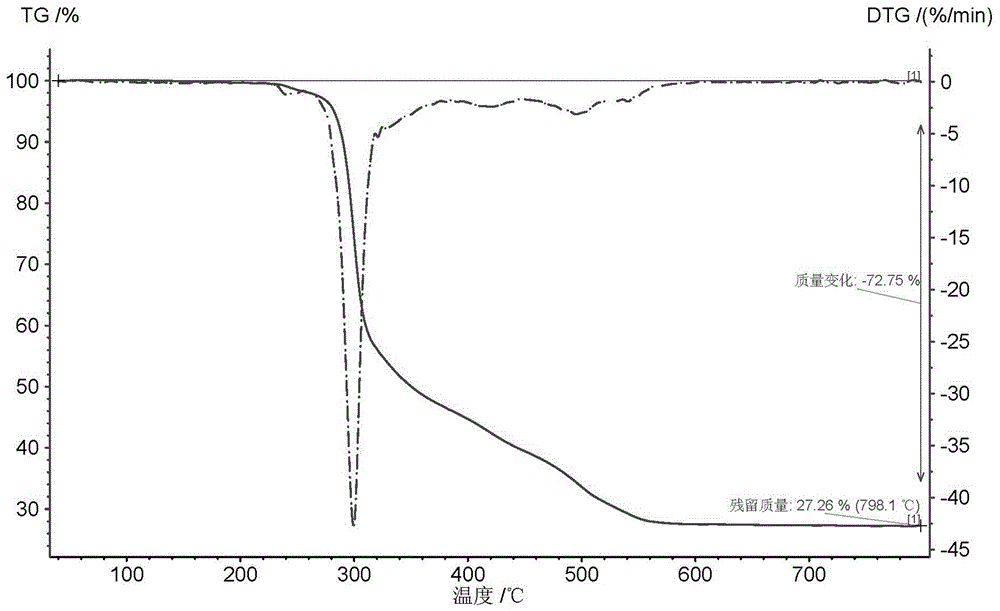

2-oxobutyrate di-tert-butylbenzene carbonylhydrazone diphenyhin complex and preparation method and application thereof

ActiveCN106220675AHas a thermally stable rangeFriendly and beneficialTin organic compoundsOrganic chemistry methodsStructural formulaPhenyl group

The invention discloses a 2-oxobutyrate di-tert-butylbenzene carbonylhydrazone diphenyhin complex shown in the structural formula (I). R is a phenyl group. The invention further discloses a preparation method of the 2-oxobutyrate di-tert-butylbenzene carbonylhydrazone diphenyhin complex and application of the complex to preparing anti-cancer medicine.

Owner:HENGYANG NORMAL UNIV

Gas-phase anti-rust composite packaging film for industry and preparation method thereof

ActiveCN101319067AHigh mechanical strengthIncrease elasticityFlat articlesLow-density polyethyleneBenzoic acid

The invention relates to a rust proofing packaging film, in particular to a gas phase rust proofing industrial composite packaging film and a preparation method thereof. The gas phase rust proofing industrial composite packaging film comprises the compositions by weight proportion: 0 to 0.53 of drewamine, 0.12 to 0.42 of cyclohexane, 0.13 to 0.4 of dicyclohexylamine, 0.09 to 0.28 of phenylformic acid, 0.22 to 0.55 of tert-Butyl benzoic acid, 0 to 0.12 of cinnamylate, 29.5 to 45.1 of low density polyethylente, 29.5 to 45.1 of linear low density polyethylene, 0 to 0.02 of oleamide or erucyl amide and 0 to 0.12 of a diffusing impurity EB-FF. The gas phase rust proofing film has good barrier property and high intensity, saves cost, is nonpoisonous and harmless, prevents the pollution, and can be reused. The preparation method is simple and convenient, the process is easy to control and the production cost is low.

Owner:金荣范

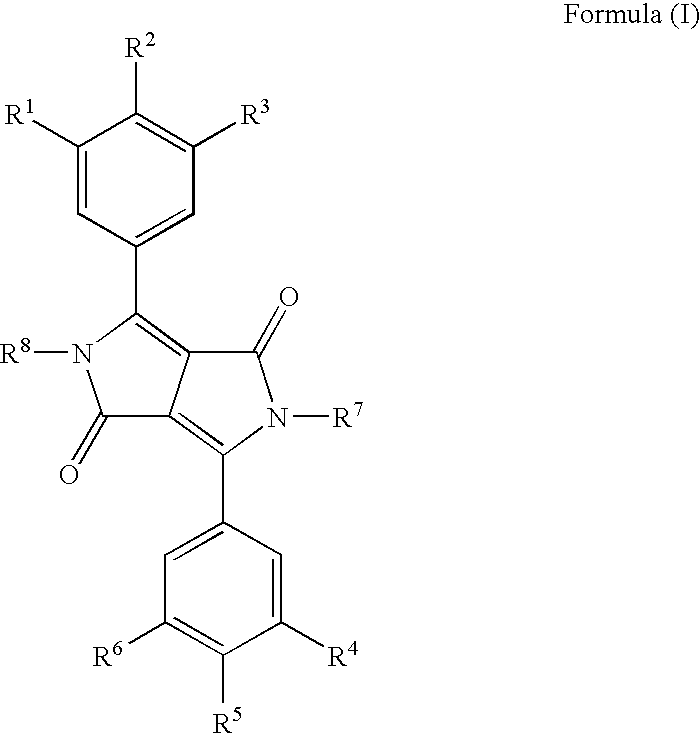

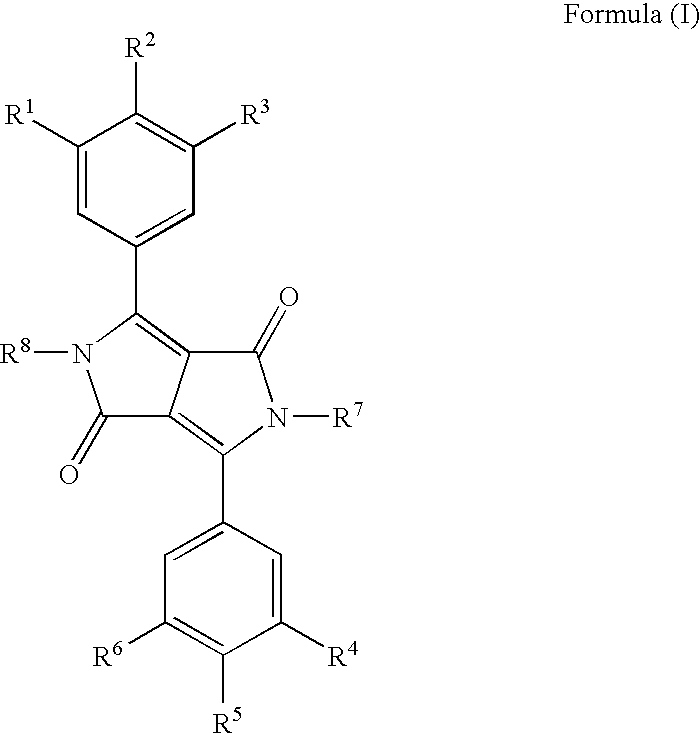

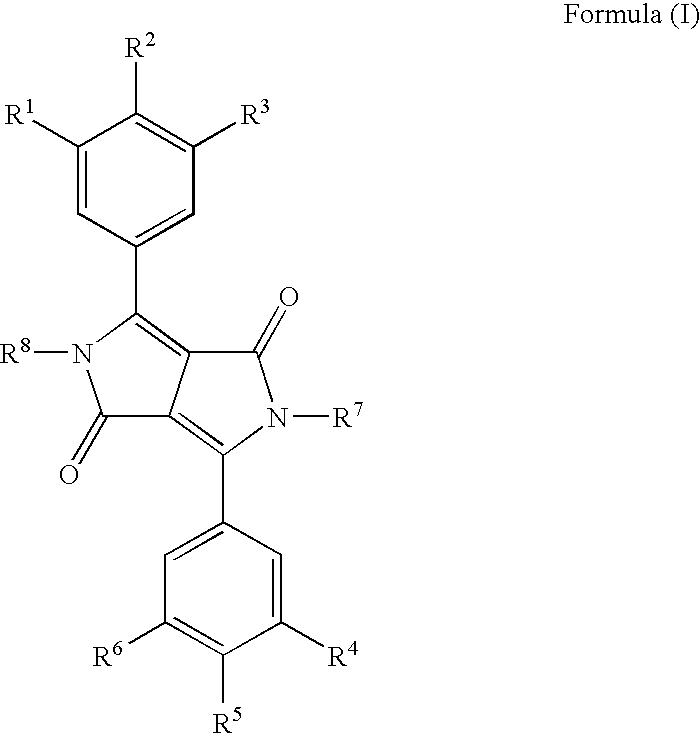

Diketopyrrolo-Pyrrole Compounds

InactiveUS20080308006A1Improve dispersion qualityImprove stabilityOrganic chemistryInksHydrogenEthyl group

A diketopyrrolo-pyrrole compound according to Formula (I):wherein R1, R2, and R3 are independently selected from the group consisting of hydrogen, a halogen atom, a methyl group, an ethyl group, an tert.-butyl group, a phenyl group, a cyano group, and an acid group; R4—, R5, and R6 are independently selected from the group consisting of hydrogen, a halogen atom, a methyl group, an ethyl group, an tert.-butyl group, a phenyl group, and a cyano group; and wherein one of R7 and R8 is a group including two acid functions while the other one of R7 and R8 represents hydrogen. Pigment dispersions, methods for forming pigment dispersions, and use of the diketopyrrolo-pyrrole compound may include Formula (I).

Owner:AGFA NV

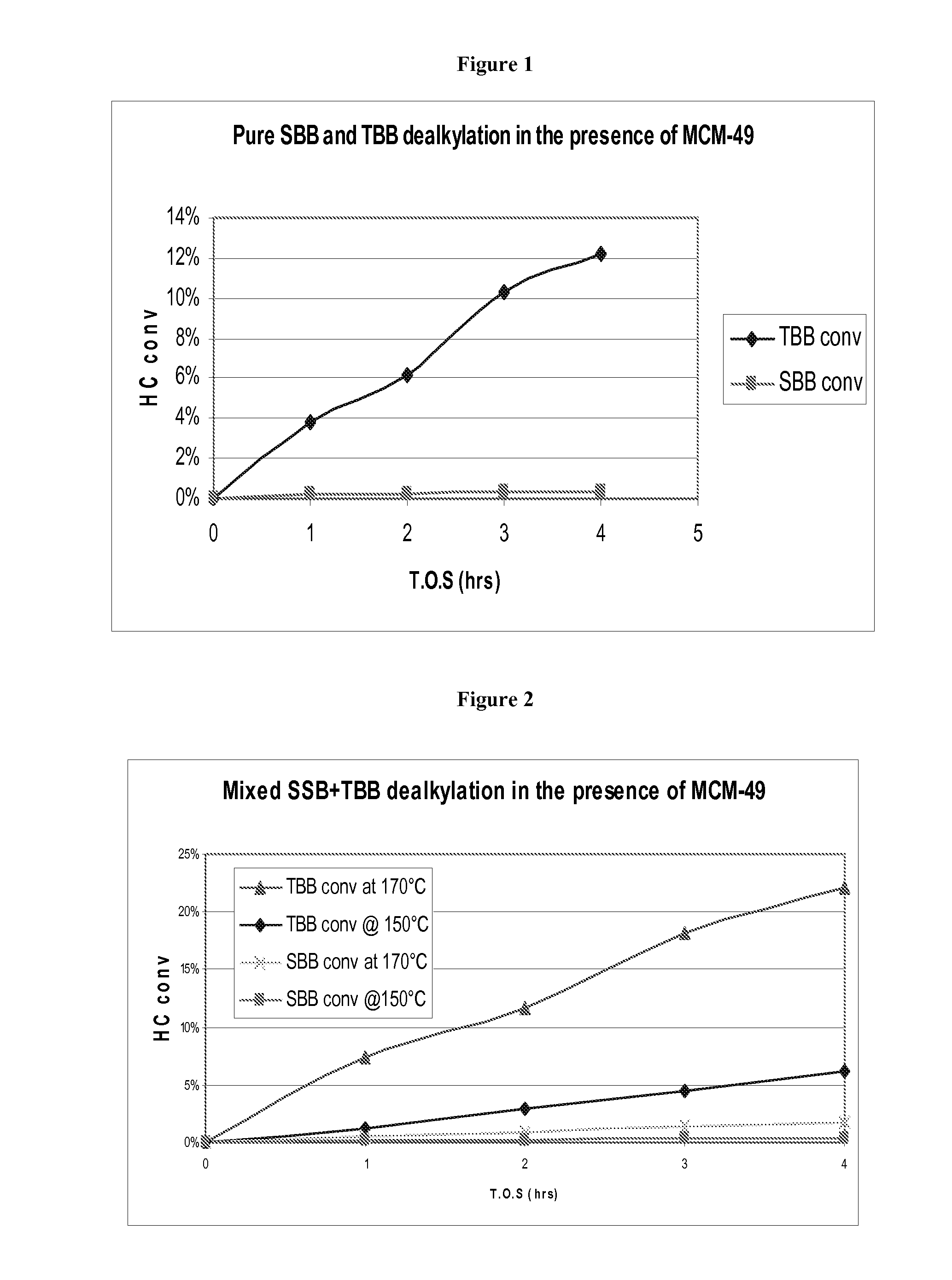

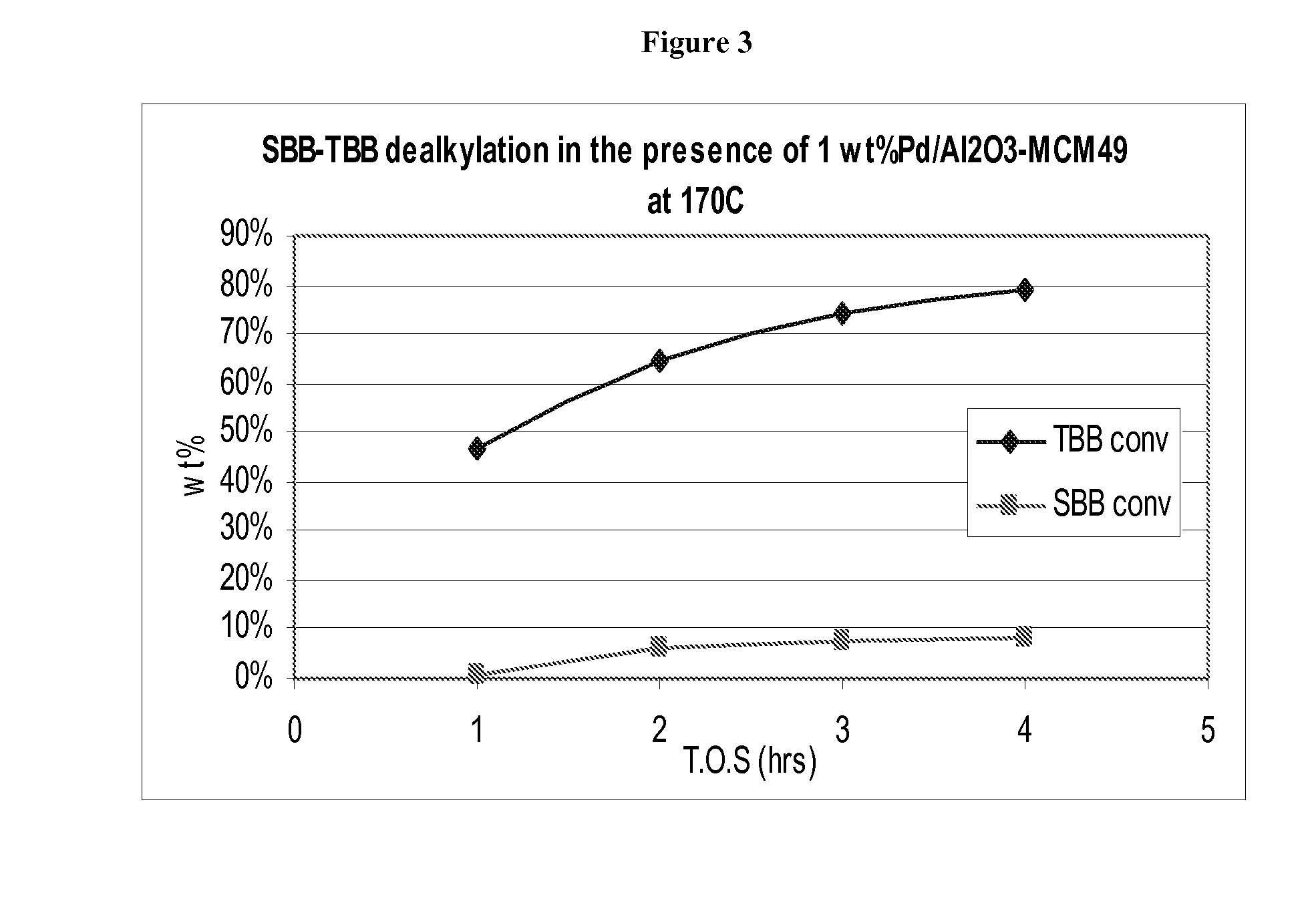

Process for Producing Phenol and Methyl Ethyl Ketone

InactiveUS20110160489A1Lower Level RequirementsOrganic compound preparationMolecular sieve catalystKetonePhenol

In a process for reducing the level of tert-butylbenzene in a mixed butylbenzene feed comprising tert-butylbenzene and sec-butylbenzene, the feed is contacted under dealkylation conditions with a catalyst system comprising a dealkylation catalyst whereby the tert-butylbenzene is selectively dealkylated to produce an effluent stream which comprises benzene and which has a lower concentration of tert-butylbenzene than said feed.

Owner:EXXONMOBIL CHEM PAT INC

Antibacterial anti-mite polyester fiber and preparation method thereof

InactiveCN104264269AEasy to useImprove anti-mite and antibacterial effectMelt spinning methodsMonocomponent polyesters artificial filamentPropionatePolymer science

The invention provides an antibacterial anti-mite polyester fiber and a preparation method thereof. The antibacterial anti-mite polyester fiber comprises the following raw materials in parts by weight: 75-90 parts of polyester chips and 10-25 parts of antibacterial anti-mite master batches, wherein the antibacterial anti-mite master batches comprise the following raw materials in parts by weight: 80-95 parts of polyester chips, 5-15 parts of nano far infrared powder, 0.5-2 parts of aluminic acid ester coupling agents, 0.5-2 parts of stearic acid, 0.05-1 part of tris-(2,4-di-tert-butyl-pheny)-phosphite and 0.05-1 part of pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate). The antibacterial anti-mite polyester fiber disclosed by the invention adopting a silver ion antibacterial anti-mite material has high-efficiency antibacterial and anti-mite effects. Moreover, due to the surface treatment, the antibacterial and anti-mite material has excellent effect of dispersing in a polyester matrix, so that the production operation is simple and convenient, and industrial production is promoted.

Owner:GUANGZHOU ZHONGCHENG NEW MATERIALS TECH

A method of preparing a high-performance wood plastic composite by utilization of waste polystyrene

A method of preparing a high-performance wood plastic composite by utilization of waste polystyrene is disclosed. The method includes a step of drying corn straw, smashing, sieving, dipping with an acid, and adding a silane coupling agent KH-550 and N,N-bis(2-hydroxyethyl) alkyl amine to obtain modified corn straw; a step of smashing waste polystyrene foam to obtain pretreated polystyrene; a step of fully mixing the modified corn straw, nanometer titanium dioxide, molybdenum disulfide, nanometer aluminium hydroxide, nanometer zinc stannate, a silane coupling agent KH-560, a silane coupling agent KH-570, a foaming agent, polytetrafluoroethylene, dicumyl peroxide and the pretreated polystyrene, maintaining the temperature at 140-155 DEG C for 2.5-5 min, and allowing the mixture to stand to obtain a preheated material; and a step of fully mixing the preheated material, nylon, polycarbonate, sulfonated polystyrene, benzotriazole, tris(2,4-ditert-butylphenyl) phosphite, pentaerythritol dioleate and butadiene styrene rubber, and performing hot press processing.

Owner:ANHUI GUANGYUAN TECH DEV

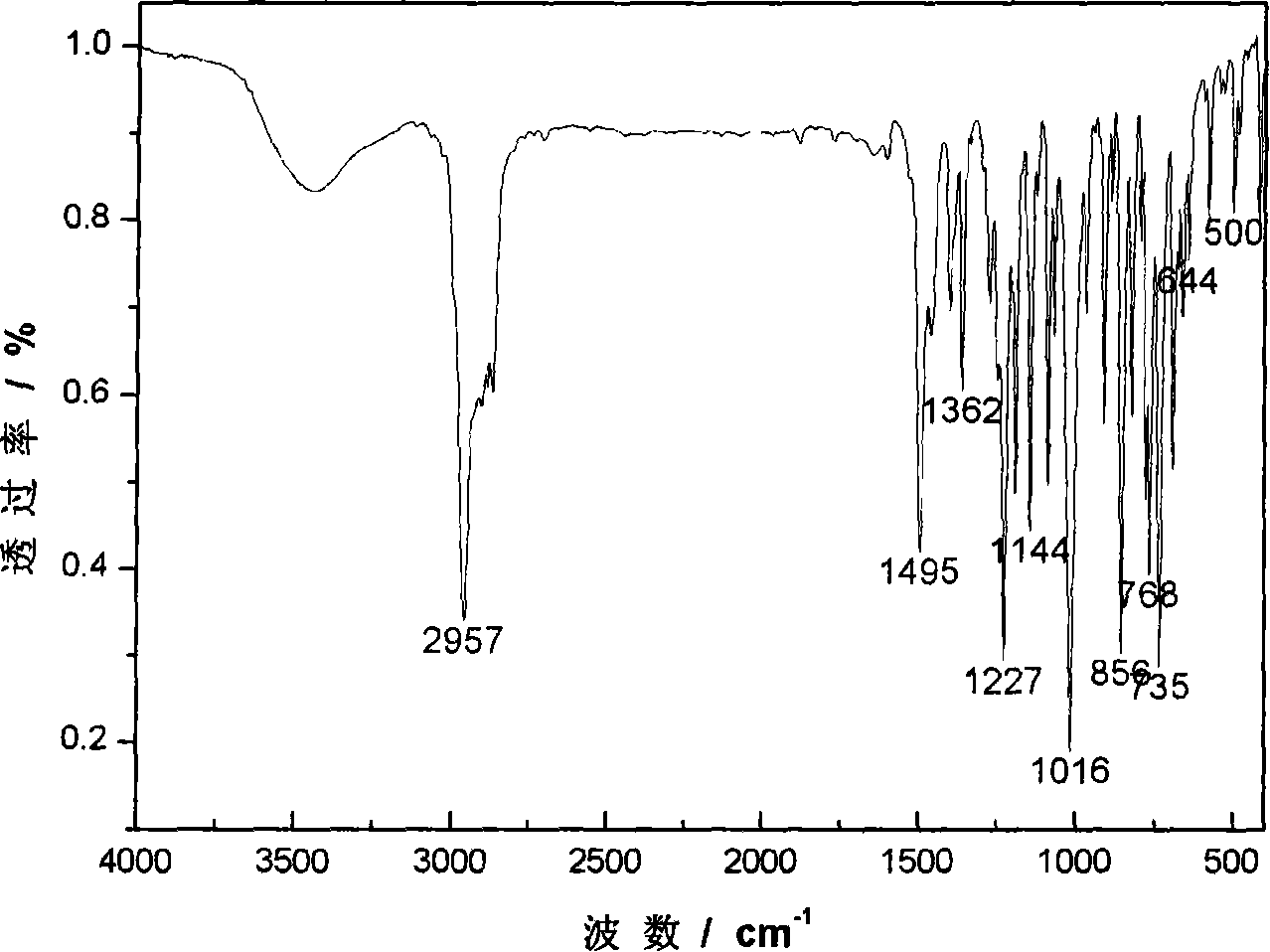

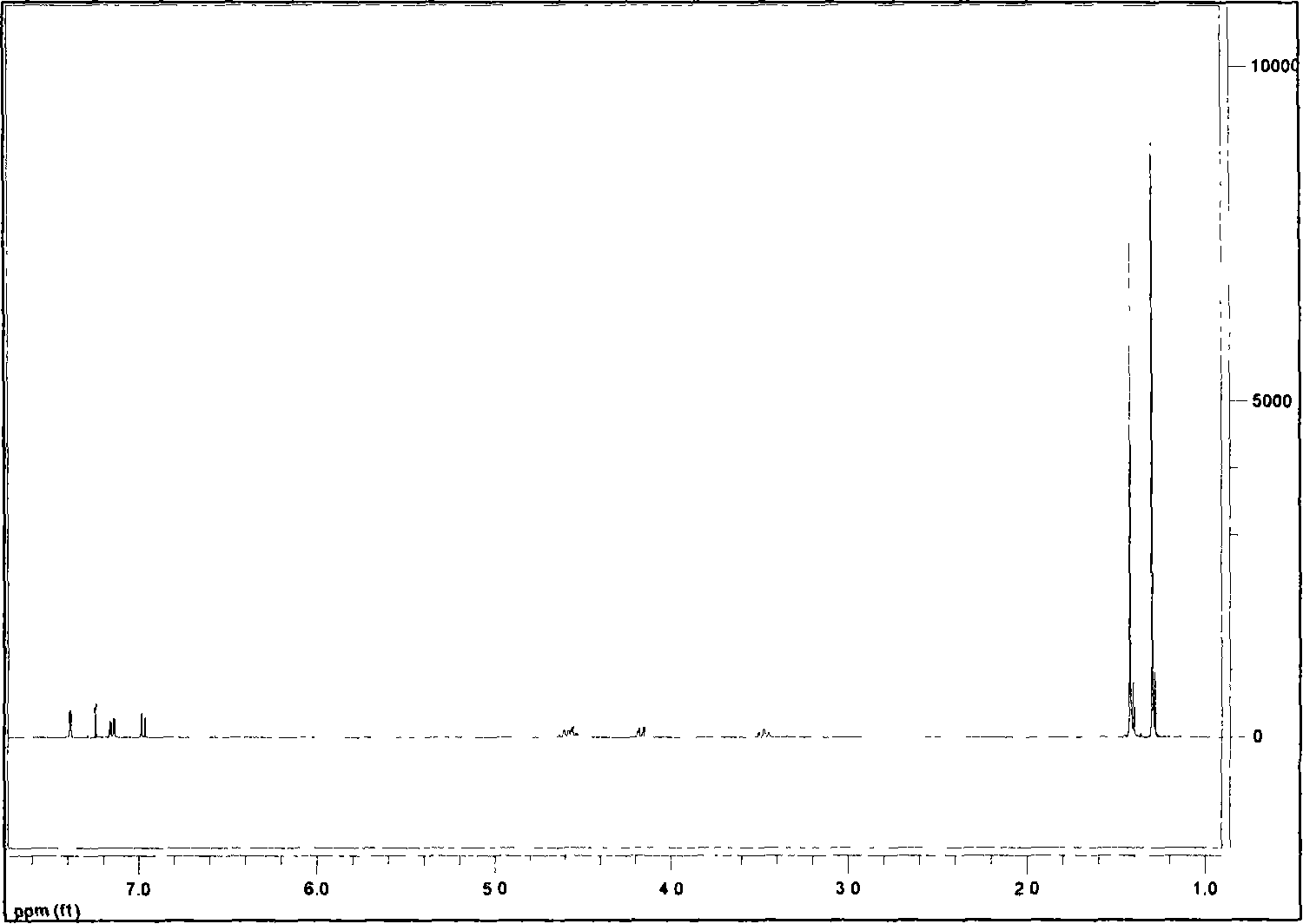

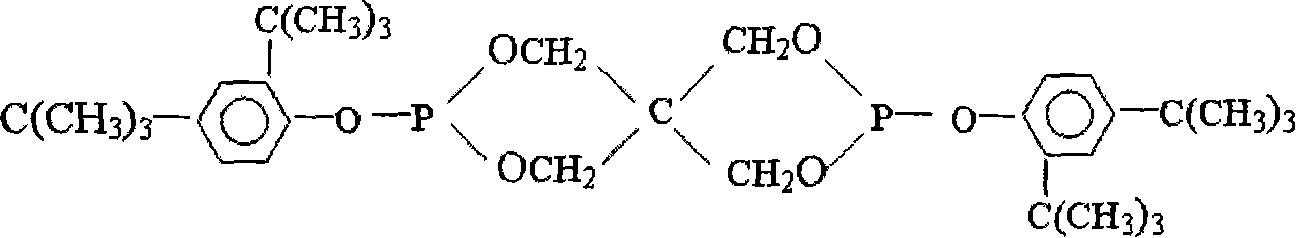

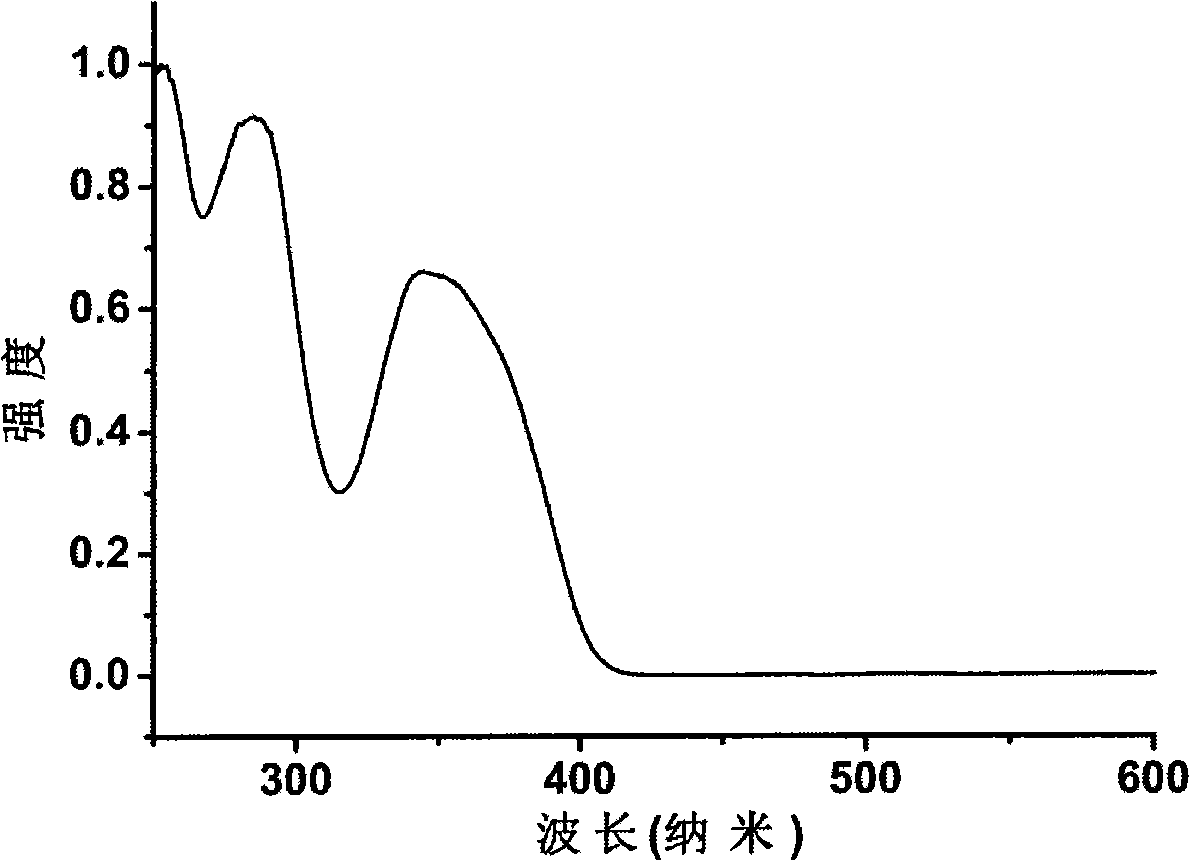

Method for synthesizing bis-(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite

InactiveCN101250200ALow priceImprove responseGroup 5/15 element organic compoundsPentaerythritolSynthesis methods

The invention discloses a synthesis method of bis (2, 4-dibutylbenzene) pentaerythritol diphosphite, which comprises 1, synthesizing dichloropentaerythritol diphosphite: using xylene as solvent, adding pentaerythritol and catalyst, feeding nitrogen gas, adding phosphorous trichloride and absorbing generated hydrogen chloride gas via sodium hydroxide solution, and purifying reaction product to obtain the dichloropentaerythritol diphosphite, 2, synthesizing bis (2, 4-dibutylbenzene) pentaerythritol diphosphite: adding 2, 4-bis-tert-butylphenol into the reaction product of step 1, feeding nitrogen gas and mixing, absorbing generated hydrogen chloride gas via sodium hydroxide solution, and purifying the reaction product to obtain final product. The invention uses 2, 4-bis-tert-butylphenol, pentaerythritol and phosphorous trichloride as main materials, with low cost, easily processed reaction and high reaction yield.

Owner:SOUTH CHINA UNIV OF TECH

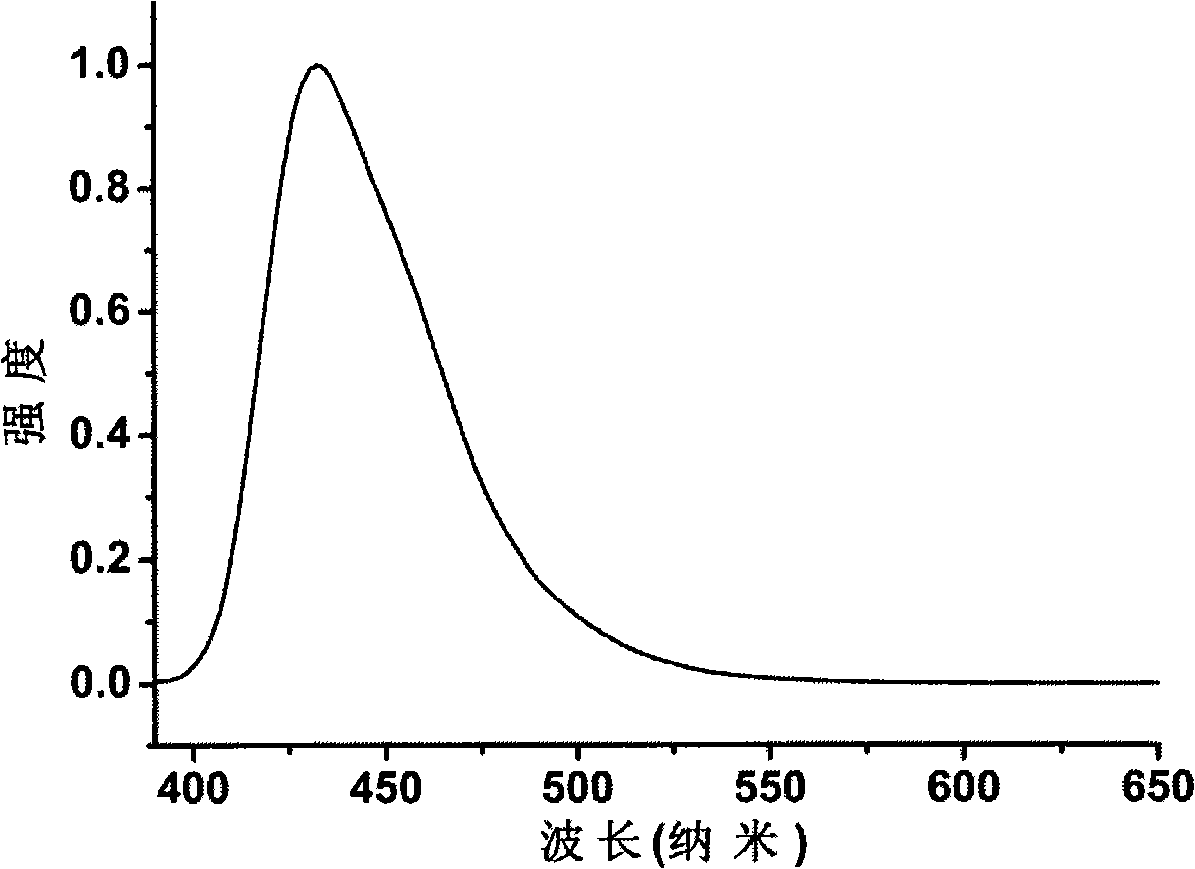

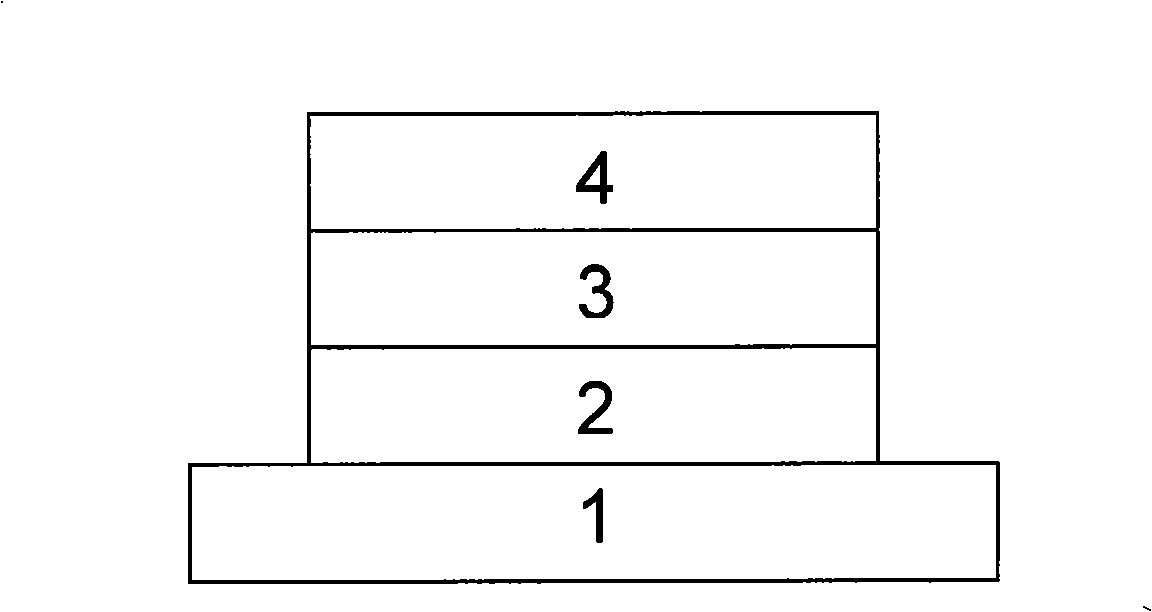

Full-bridge linked triphenylamine compound and application thereof in electroluminescent device

ActiveCN101525335AMolecular rigidityImprove rigidityOrganic chemistrySolid-state devicesHydrogenTransport layer

The invention discloses triphenylamine compound with a full-bridge rigid structure and the application of the triphenylamine compound serving as hole transport layer material in electroluminescent device. The general structure of the compound is right formula; wherein, R is hydrogen atoms, phenyl, 4-triphenylamine or 3-(N-p-tert-butyl phenyl) which are same with each other. The triphenylamine compound has high thermal stability, and a synthetic method thereof is simple to be carried out. The compound can be used for preparing the electroluminescent device by a spin coating process, has low cost and extensive use. The electroluminescent device manufactured by triphenylamine compound serving as cavity transport layer material has electroluminescent performances of high efficiency and high brightness and can be widely applied to the organic electroluminescent field.

Owner:常熟紫金知识产权服务有限公司

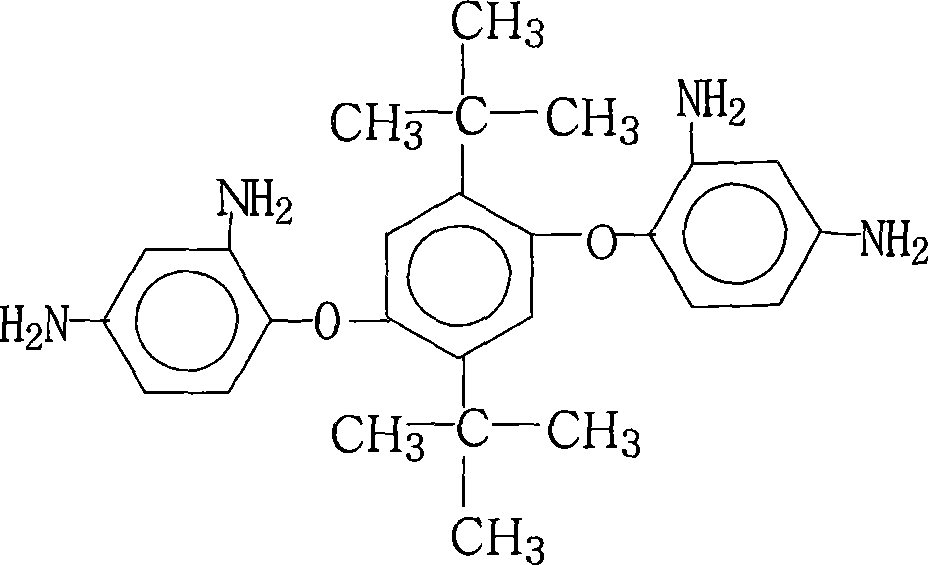

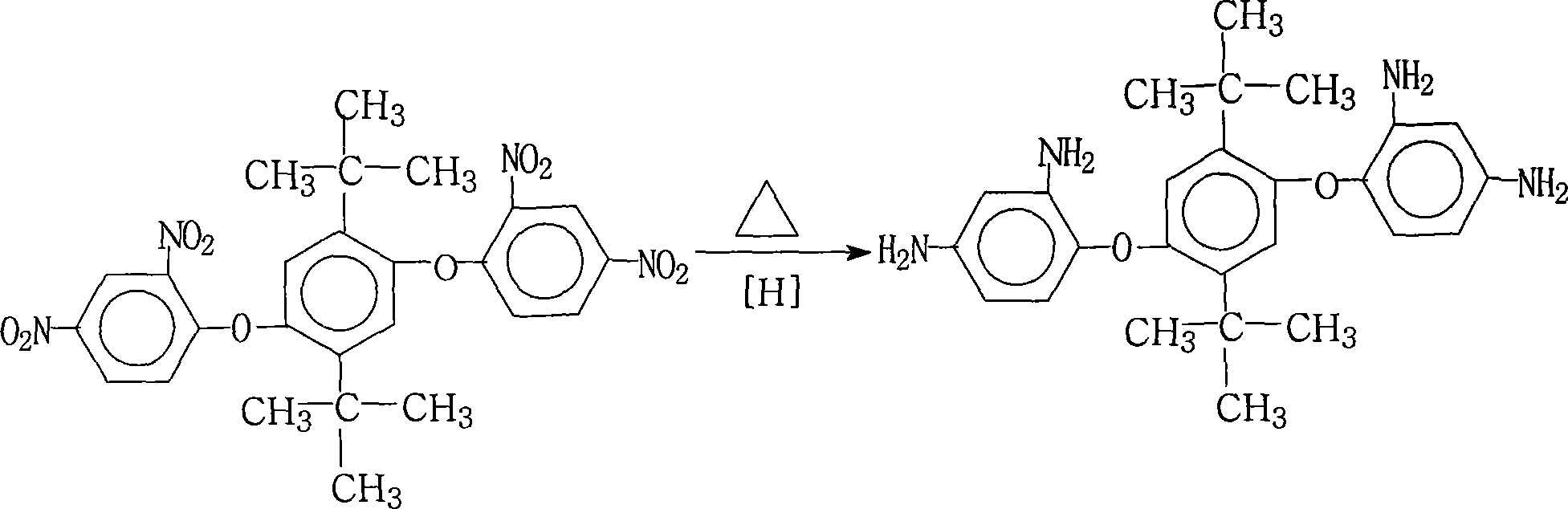

Process for producing 1,4-(2,4-diaminophenyloxy)-2,5-di-t-butyl benzene

InactiveCN101245026AShort timeSignificant energy saving and consumption reductionOrganic compound preparationAmino-hyroxy compound preparationBenzeneHydrazine compound

The invention relates to a preparation method of 1,4-double(2,4-diamino phenoxy)-2,5-d-tert-butylbenzene, comprising the steps as following, after being put into the solvent system of the solution of palladium or carbon hydrazine hydrate and saturated fatty alcohol for reaction for 1 to 5 hours with the temperature of 70 to 85 DEG C, the 1,4-double(2,4-dinitro phenoxy)-2,5-d-tert-butylbenzene is filtered when being hot, mother liquor is cooled off, pure water is dripped in, crystal products are precipitated, filtered, and dried in vacuum, and crystals of the 1,4-double(2,4-diamino phenoxy)-2,5-d-tert-butylbenzene are gained. The method has the simple operation, needs no subsequent refining and purifying technique, takes little time, has the products with the high yield and the purity of more than 99 percent, and is suitable for industrial production.

Owner:DONGHUA UNIV

Improve method for preparing N-tert-butylbenzothiazolesulfenamide

The invention belongs to the field of fine chemical engineering, and relates to an improved method for preparing N-tert-butylbenzothiazolesulfenamide. 2-benzothiazolethiol and tertbutylamine are taken as raw materials, and undergo oxidation reaction by using sodium hypochlorite as an oxidant in the presence of an ionic or nonionic surfactant, and after the reaction is finished, a proper amount of reducing agent is added to remove unreacted sodium hypochlorite so as to improve the stability in the process of drying the product. In the method, sulfuric acid and sodium hydroxide are not needed, so that wastewater amount is small, the product yield is over 95 percent, the smelting point is 105DEG C, and the insoluble matter content in methanol is stabilized in a range of 0.28 to 0.68 percent and reaches the national standard. The consumption of main raw materials is low, and the method is suitable for industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com