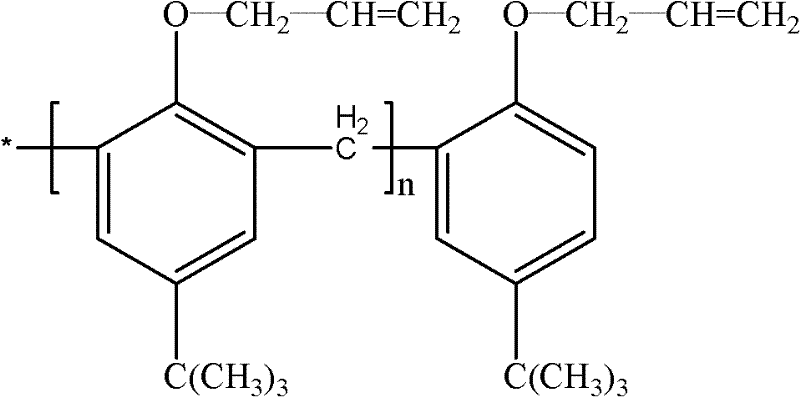

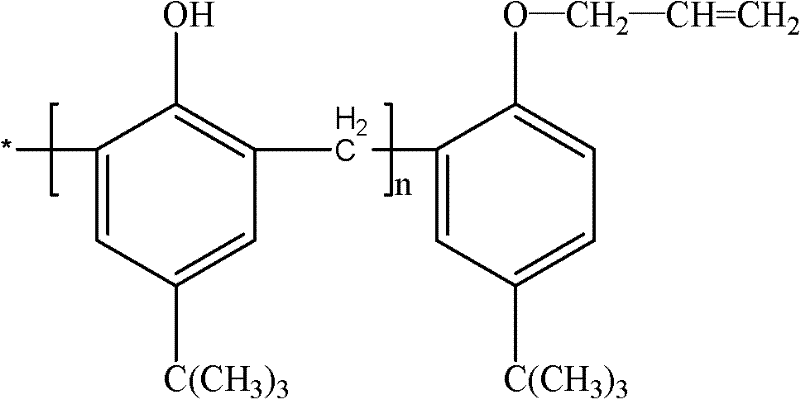

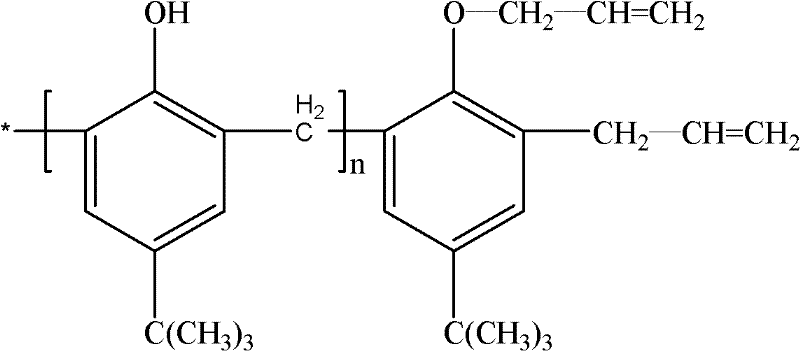

Allyl para-tert-butyl phenyl ether formaldehyde tackifying resin and preparation method thereof

A technology of tert-butyl phenyl ether and tackifying resin, which is applied in the field of chemical engineering, can solve problems such as the decline of adhesion performance, and achieve the effects of high self-adhesive strength, good rubber compatibility, and excellent long-term tackifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix p-tert-butylphenol and formaldehyde at a molar ratio of 1:1, raise the temperature to 90°C to dissolve it completely, add hydrochloric acid until the reaction boils for 3 hours, dissolve it with toluene, wash with hot water until neutral, and press the obtained resin Mix the resin and allyl chloride at a molar ratio of 5:1, dissolve in ethanol, then add 1M potassium hydroxide solution to adjust the pH to 10, heat for 30 minutes, extract with toluene, add 0.5M hydrochloric acid to wash, and let stand to separate. , the supernatant was washed with distilled water to pH 7, and allyl p-tert-butylphenyl ether formaldehyde resin was obtained after vacuum distillation, with a yield of 89% and a purity of 98.2%.

Embodiment 2

[0023] Mix p-tert-butylphenol and formaldehyde at a molar ratio of 1:1, heat up to 100°C to dissolve completely, add hydrochloric acid until the reaction boils for 4 hours, dissolve with toluene, wash with hot water until neutral, and press the obtained resin Mix the resin and allyl chloride at a molar ratio of 4:1, dissolve in ethanol, then add 1M potassium hydroxide solution to adjust the pH to 10, heat for 60 minutes, extract with toluene, add 0.5M hydrochloric acid to wash, and let stand to separate. , the supernatant was washed with distilled water to pH 7, and allyl p-tert-butylphenyl ether formaldehyde resin was obtained after vacuum distillation, with a yield of 91% and a purity of 98.5%.

Embodiment 3

[0025] Mix p-tert-butylphenol and formaldehyde at a molar ratio of 1:1, heat up to 120°C to dissolve it completely, add hydrochloric acid until the reaction boils for 4 hours, dissolve it with toluene, wash with hot water until neutral, and press the obtained resin Mix the resin and allyl chloride at a molar ratio of 2:1, dissolve in ethanol, then add 1M potassium hydroxide solution to adjust the pH to 10, heat for 60 minutes, extract with toluene, add 0.5M hydrochloric acid to wash, and let stand to separate. , the supernatant was washed with distilled water to pH 7, and allyl p-tert-butylphenyl ether formaldehyde resin was obtained after vacuum distillation, with a yield of 89.5% and a purity of 97.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com