Hydrogenation synthesis heat transfer liquid and preparation method thereof

A technology of heat transfer liquid and deep hydrogenation, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as short service life and environmental pollution, and achieve excellent product quality, good heat transfer performance, and pure molecular components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

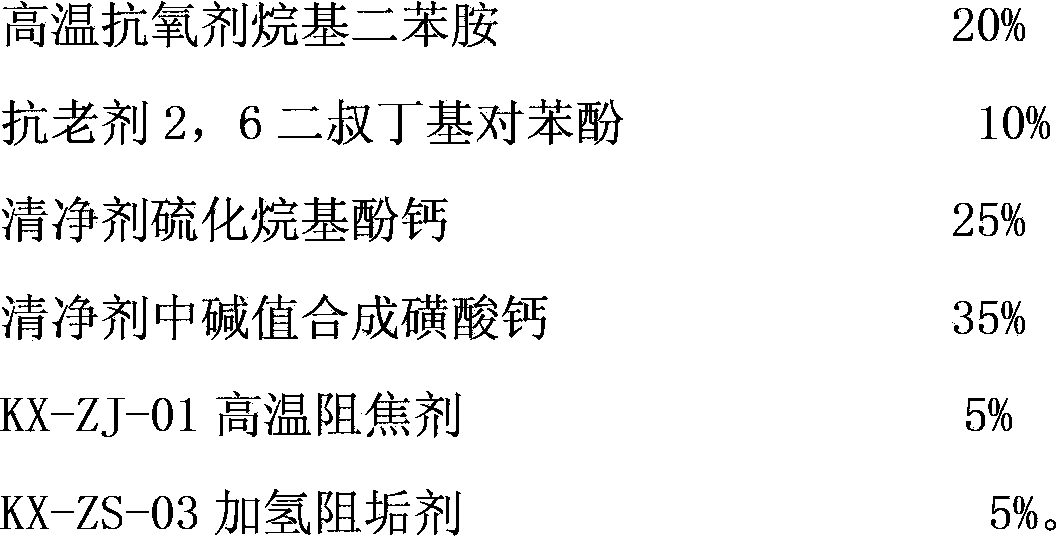

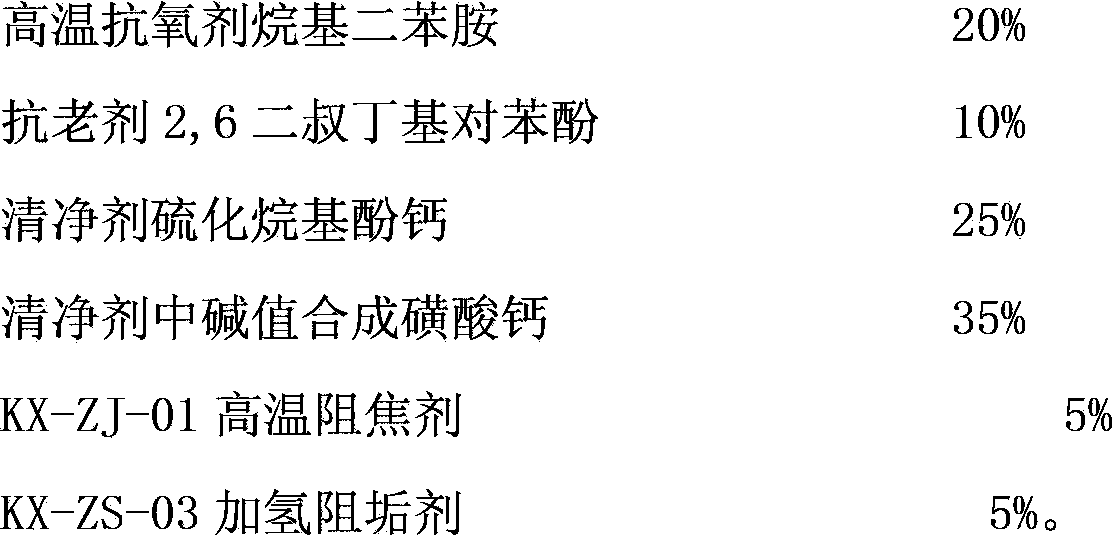

[0014] Hydrogenated synthetic heat transfer fluid is prepared by adding functional additives to deeply hydrogenated base oil, wherein the functional additives are prepared from the following mass fractions of raw materials:

[0015]

[0016] The addition amount of the functional additive is 1.5% of the mass of the deeply hydrogenated base oil.

[0017] KX-ZJ-01 high temperature coking inhibitor is produced by Shandong Kexin Petrochemical Co., Ltd.

[0018] KX-ZS-03 hydrogenation scale inhibitor is produced by Shandong Kexin Petrochemical Co., Ltd.

[0019] The preparation method of the hydrogenated synthetic heat transfer fluid is as follows: adding functional additives into deeply hydrogenated base oil according to the proportion, and fully merging through ultrasonic wave or mechanical stirring to obtain a finished product.

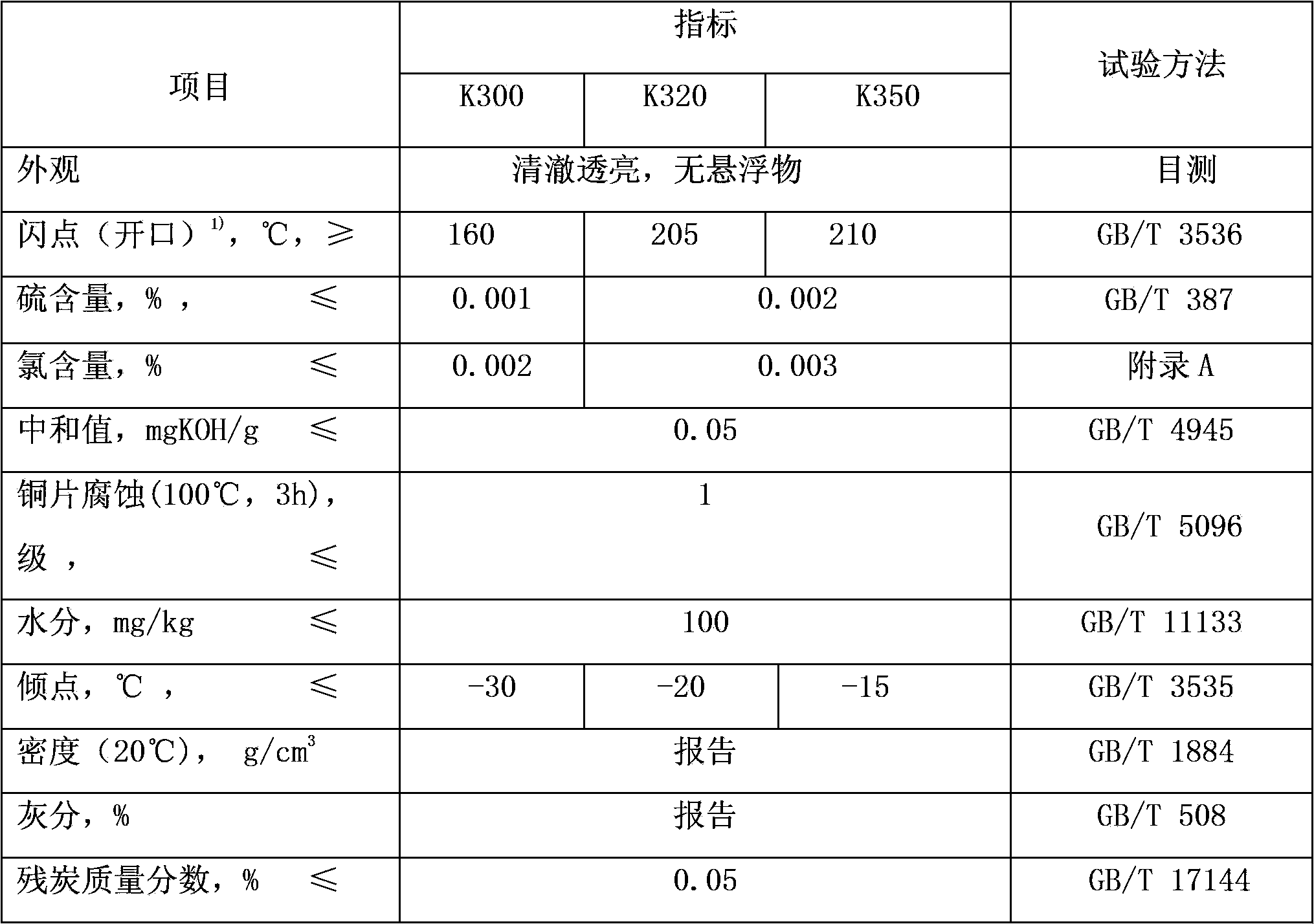

[0020] The performance index of the product is shown in the table below.

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com