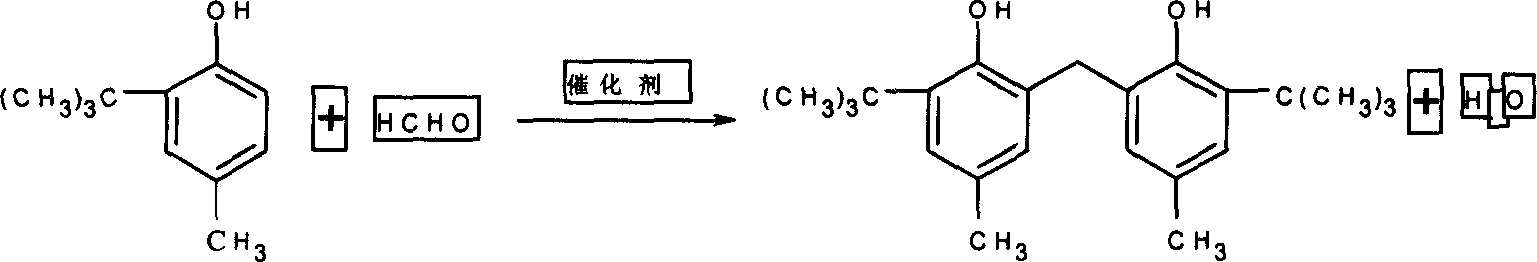

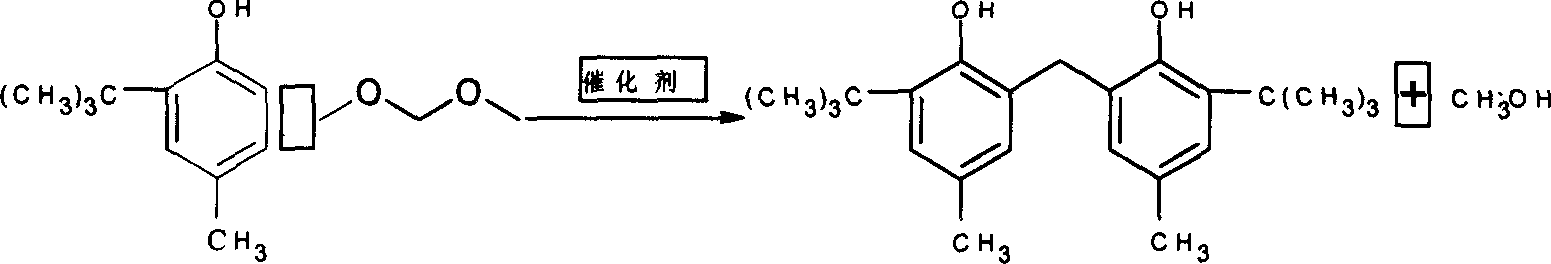

Method for producing 2, 2'-methylene double (4-methyl -6-tertiary butyl phenol)

A technology of tert-butylphenol and methylene bis, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of not involving the stability of the resin catalyst, increase the post-treatment process and the cost of preparation, and affect Problems such as mechanical strength and service life have been achieved to achieve the effect of continuous production, good catalyst stability, and simplified post-reaction treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Resin catalyst A:

[0023] Macroporous strongly acidic (-SOH) based on styrene-divinylbenzene copolymer 3 ) cation exchange resin with an exchange capacity of 4.3 milliequivalents / gram and an average resin pore diameter of 205 angstroms.

[0024] 40 milliliters of catalyst A are loaded respectively in two serial fixed-bed reactors, dry at 90 ℃ for 3 hours; Methylal and 2-tert-butyl-4-cresol mixture (aldehyde / phenol molar ratio=3: 1) Through the metering pump, pass through the first and second reactors at a rate of 80 ml / hour. The reaction temperature of the first reactor is 45 ° C, and the reaction temperature of the second reactor is 80 ° C. The reaction is continuously operated for 200 hours, and the second reaction is collected. The reaction mixture flowing out from the bottom of the reactor is distilled to remove the solvent, and then purified to obtain 2,2'-methylenebis(4-methyl-6-tert-butylphenol) product, and the distilled solvent is recycled and returned to the...

Embodiment 2

[0027] Resin Catalyst B:

[0028]Macroporous strongly acidic (-SOH) based on styrene-divinylbenzene copolymer 3 ) cation exchange resin with an exchange capacity of 4.8 milliequivalents / g and an average resin pore diameter of 350 angstroms. The resin was treated in a vacuum desiccator at a treatment temperature of 105° C. and a treatment time of 2 hours.

[0029] 40 milliliters of catalyst B are loaded respectively in two serial fixed-bed reactors, methylal and 2-tert-butyl-4-cresol mixture (aldehyde / phenol molar ratio=4: 1) are passed metering pump, with 60 The ml / hour rate passes through the first and second reactors successively. The reaction temperature of the first reactor is 40°C, and the reaction temperature of the second reactor is 70°C. The reaction runs continuously for 400 hours, and the reaction mixture flowing out from the bottom of the second reactor is collected and distilled. The solvent is removed, and then purified to obtain 2,2'-methylenebis(4-methyl-6-tert...

Embodiment 3

[0032] AmberlystXN-1005 strongly acidic (-SOH 3 ) macroporous cation exchange resin with a resin exchange capacity of 3.5 milliequivalents / g and an average pore diameter of 80 angstroms. The resin was processed in a vacuum desiccator at a processing temperature of 100° C. for 2 hours.

[0033] Among the two fixed-bed reactors in series, the first reactor is loaded with AmberlystXN-1005 strongly acidic (-SOH 3 ) 40 milliliters of macroporous cation exchange resins, 40 milliliters of catalyst B loaded in the second reactor, with methylal and 2-tert-butyl-4-cresol mixture (aldehyde / phenol molar ratio=3: 1) by metering pump, Pass through the first and second reactors successively at a rate of 50 ml / hour. The reaction temperature of the first reactor is 55 ° C, and the reaction temperature of the second reactor is 80 ° C. The reaction is continuously operated for 200 hours, and the reaction mixture flowing out from the bottom of the second reactor is collected , The solvent is dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com