Full-bridge linked triphenylamine compound and application thereof in electroluminescent device

An electroluminescent device, a technology of triphenylamine, applied in the field of organic electroluminescent materials, can solve the problems of high molecular reformation energy and reduced molecular conjugation, and achieve high thermal stability, enhanced conjugation ability, thermal Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

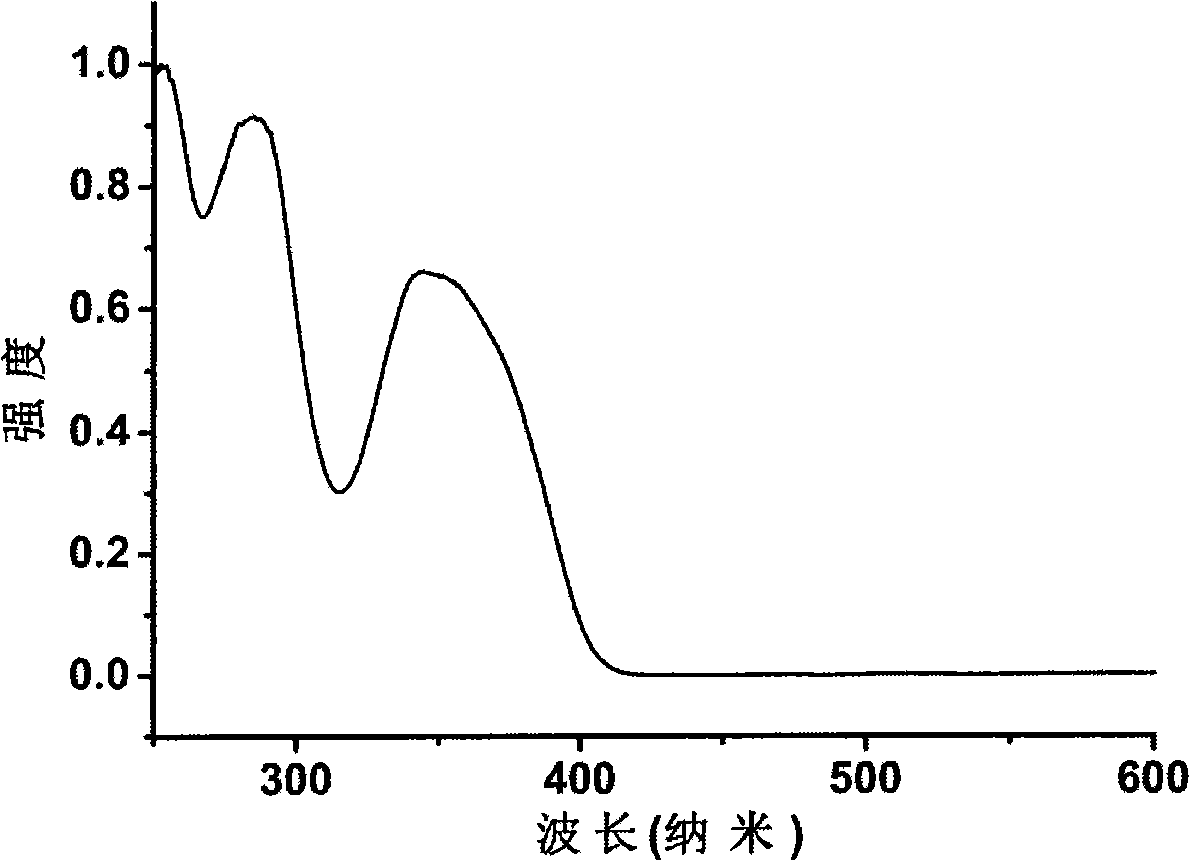

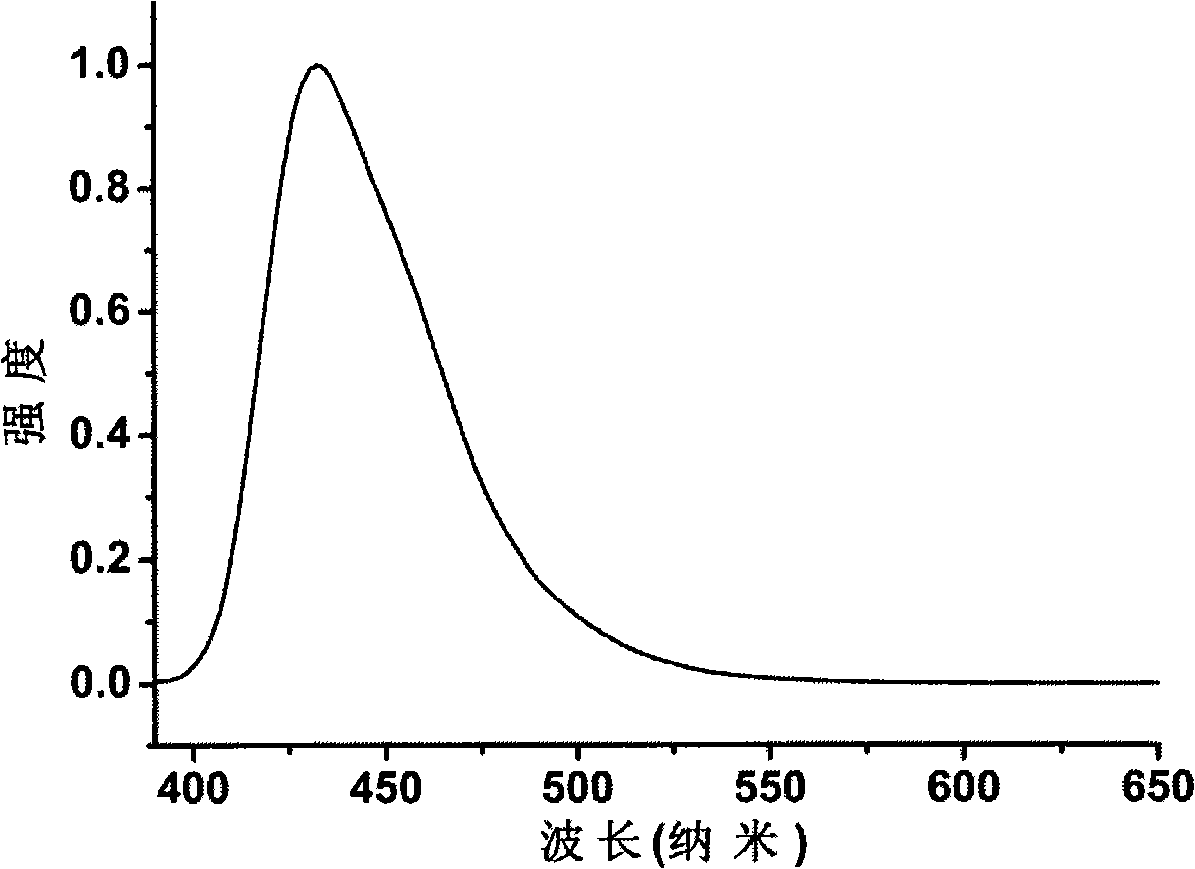

[0019] Preparation of 4,8,12-tris(xylylmethylene) bridged triphenylamine (abbreviated as HTM1)

[0020]

[0021] 3.87g p-bromotoluene (22.6mmol) was dissolved in 30ml absolute ether in a Schlenk tube. 9.3ml of n-BuLi (2.45M, 22.8mmol) was dropped into the Schlenk tube at -10°C, and reacted at low temperature for 1 hour after the drop was completed. 0.90g of 2,2',2"-triphenylamine tricarboxylate (2.15mmol) was dissolved in 20ml of absolute anhydrous THF and dropped into a Schlenk tube, and reacted for 3h. After the reaction was completed, dilute NH 4 Cl solution for quenching. Ether extraction. The organic phase was separated, washed three times with water, anhydrous Na 2 SO 4 dry. The organic solvent was spin-dried, and the obtained crude product was dissolved in 30 ml of glacial acetic acid, and heated to reflux. Carefully add 3ml of concentrated HCl dropwise and react for 3h. After the reaction, the solution was poured into 200 ml of ice water. 20ml of chloroform ...

Embodiment 2

[0023] Preparation of 2,6,10-triphenyl-4,8,12-tris(xylylmethylene) bridged triphenylamine (abbreviated as HTM2)

[0024]

[0025] 1.00 g (1.22 mmol) of 4,8,12-tris(xylylmethylene) bridged triphenylamine was dissolved in 20 ml of chloroform in a 50 ml round bottom flask. 0.68 g NBS (3.82 mmol) was added. The reaction was stirred at room temperature for 12h. After the reaction, the organic phase was washed with water three times. Anhydrous Na 2 SO 4 dry. Use petroleum ether: dichloromethane = 3: 1 (volume ratio) for column separation. 1.22 g of white solid 2,6,10-tribromo-4,8,12-tris(xylylmethylene) bridged triphenylamine was obtained with a yield of 95%. 1 H NMR (300MHz, CDCl 3 , δ): 6.91(s, 6H), 6.86(d, J=8.1Hz, 12H), 6.55(d, J=8.1Hz, 12H), 2.30(s, 18H); 13 C NMR (75MHz, CDCl 3 , δ): 141.809, 136.132, 134.261, 130.772, 130.701, 130.001, 128.697, 116.098, 55.293, 21.124.Ahal.Calcd.for C 63 h 48 Br 3 N (%): C, 71.47; H, 4.57; N, 1.32.Found: C, 71.23; H, 4.40; N, 1...

Embodiment 3

[0028] Preparation of 2,6,10-tris(4-triphenylamino)-4,8,12-tris(xylylmethylene) bridged triphenylamine (abbreviated as HTM3)

[0029]

[0030] HTM3 can be prepared in a similar manner to Example 2. 1 H NMR (300MHz, CDCl 3 , δ): 7.18-7.15(m, 18H), 7.05-6.91(m, 30H), 6.78(d, J=7.2Hz, 12H), 6.65(d, J=7.2Hz, 12H), 2.21(s, 18H).Anal.Calcd.for C 117 h 90 N 4 (%): C, 90.54; H, 5.85; N, 3.61.Found: C, 91.01; H, 6.16; N, 3.36; MALDI-TOF-MS: m / z 1551.5 (M + ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com