Patents

Literature

46results about How to "Improve dispersion quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

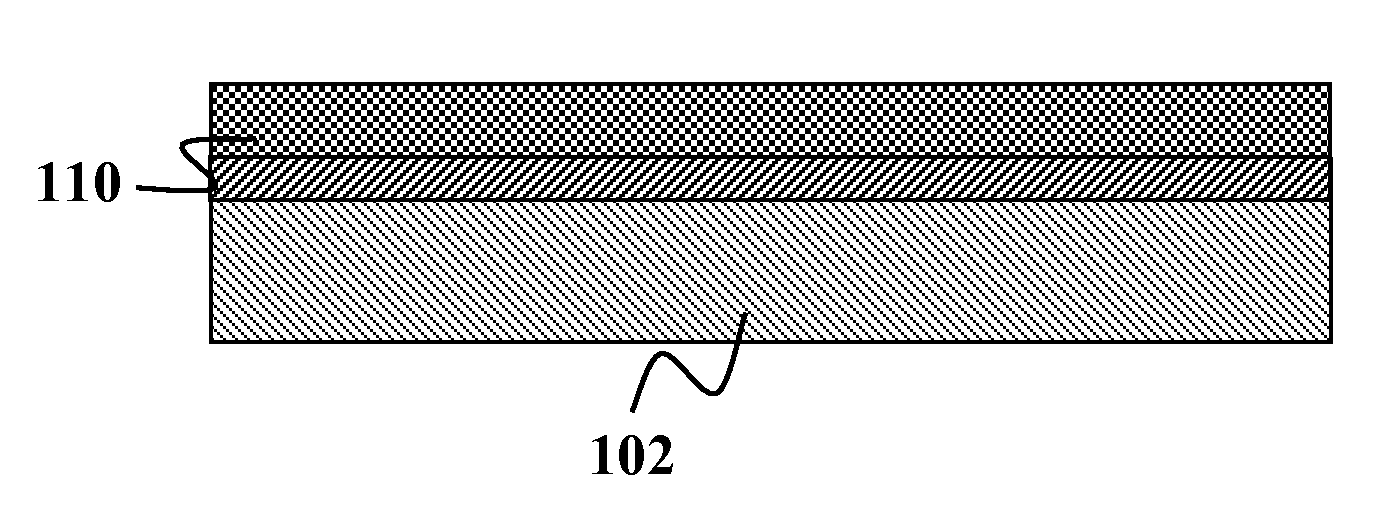

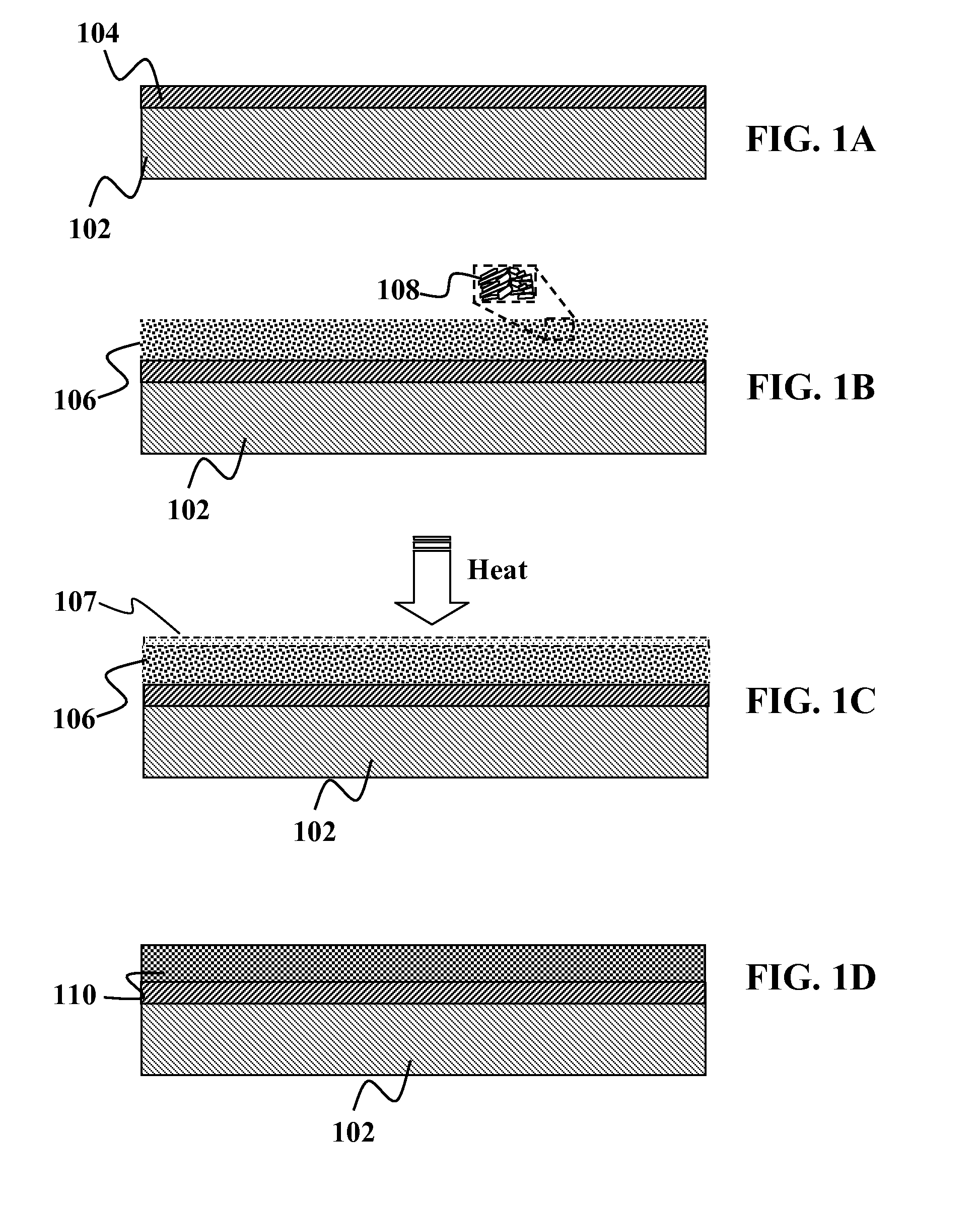

High-throughput printing of semiconductor precursor layer from chalcogenide microflake particles

InactiveUS20080121277A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingNanoparticleParticle method

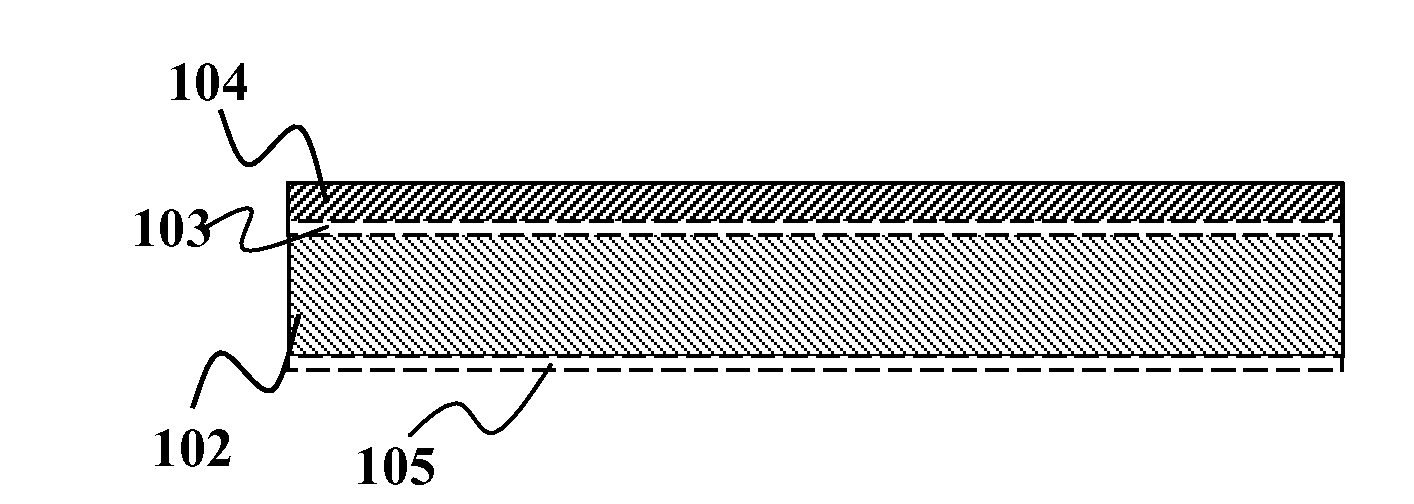

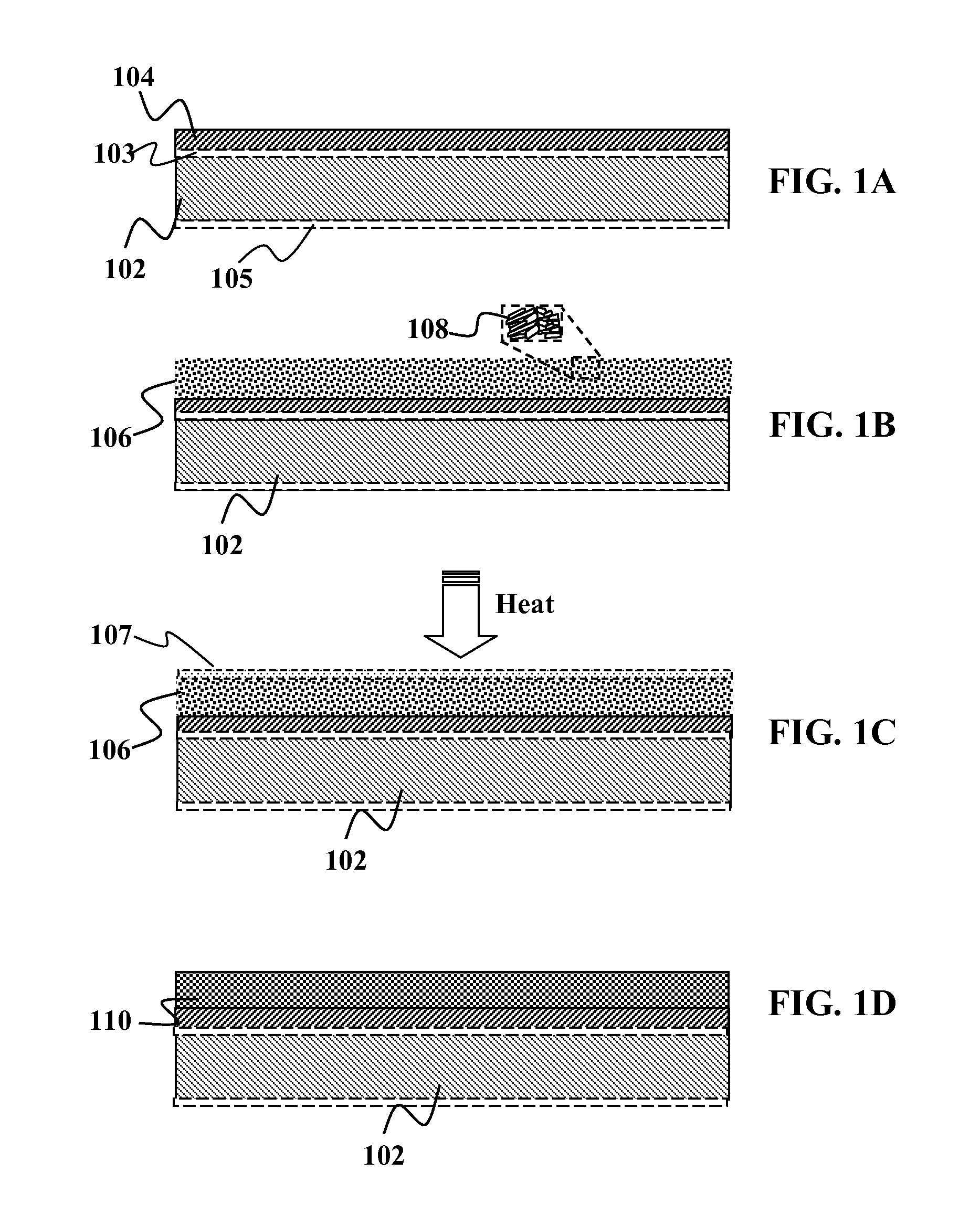

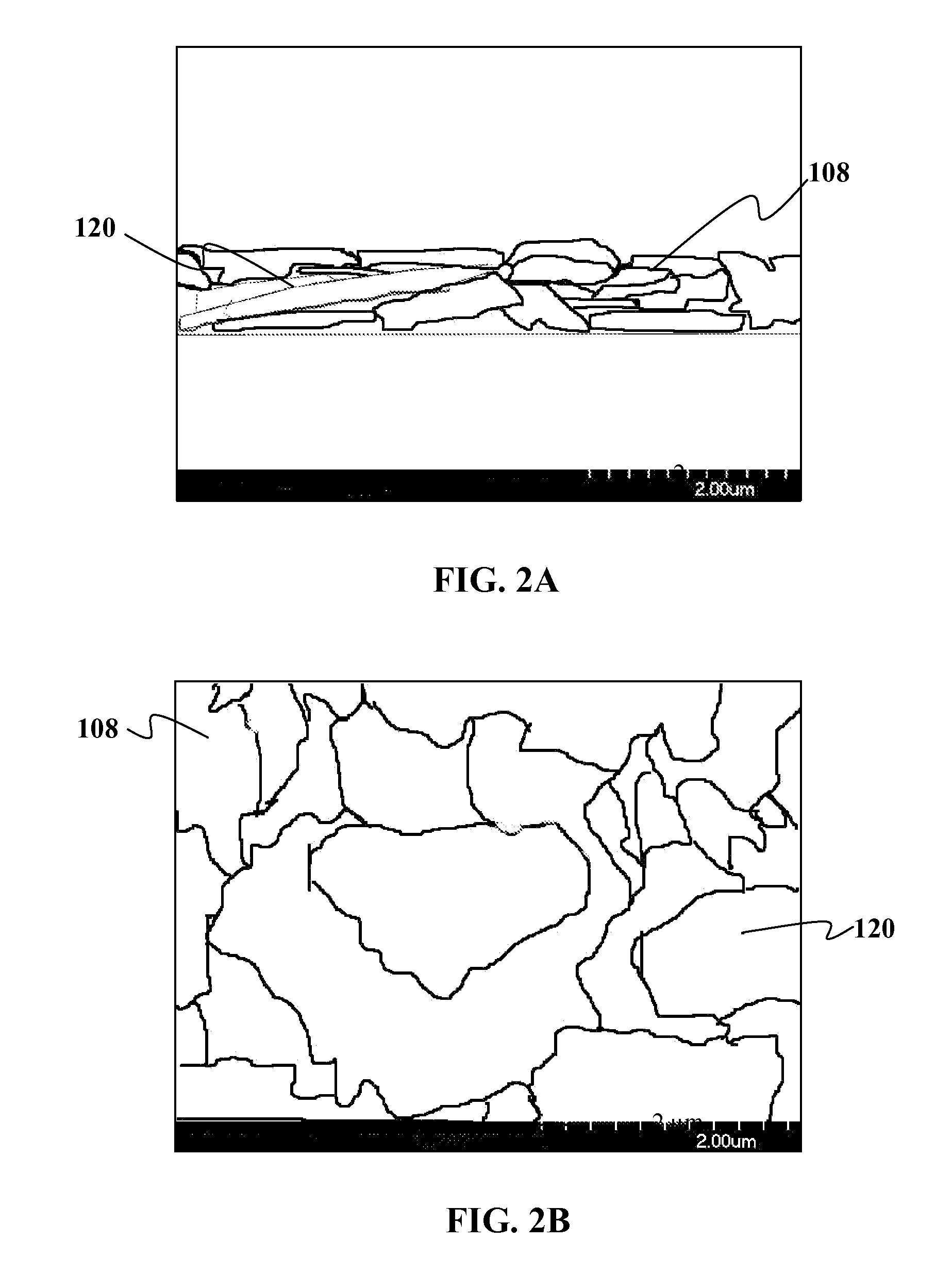

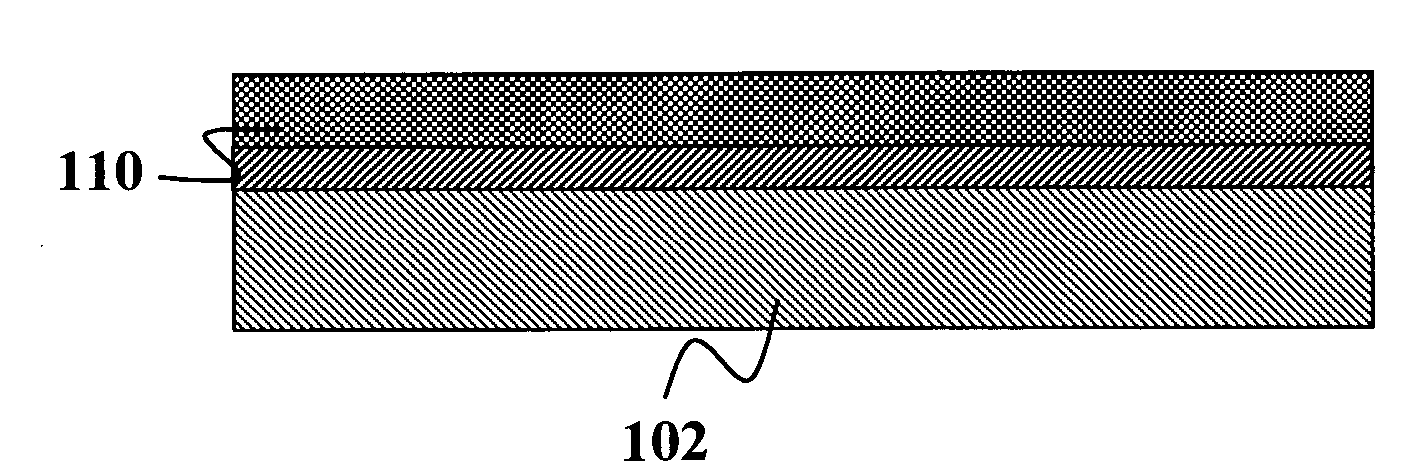

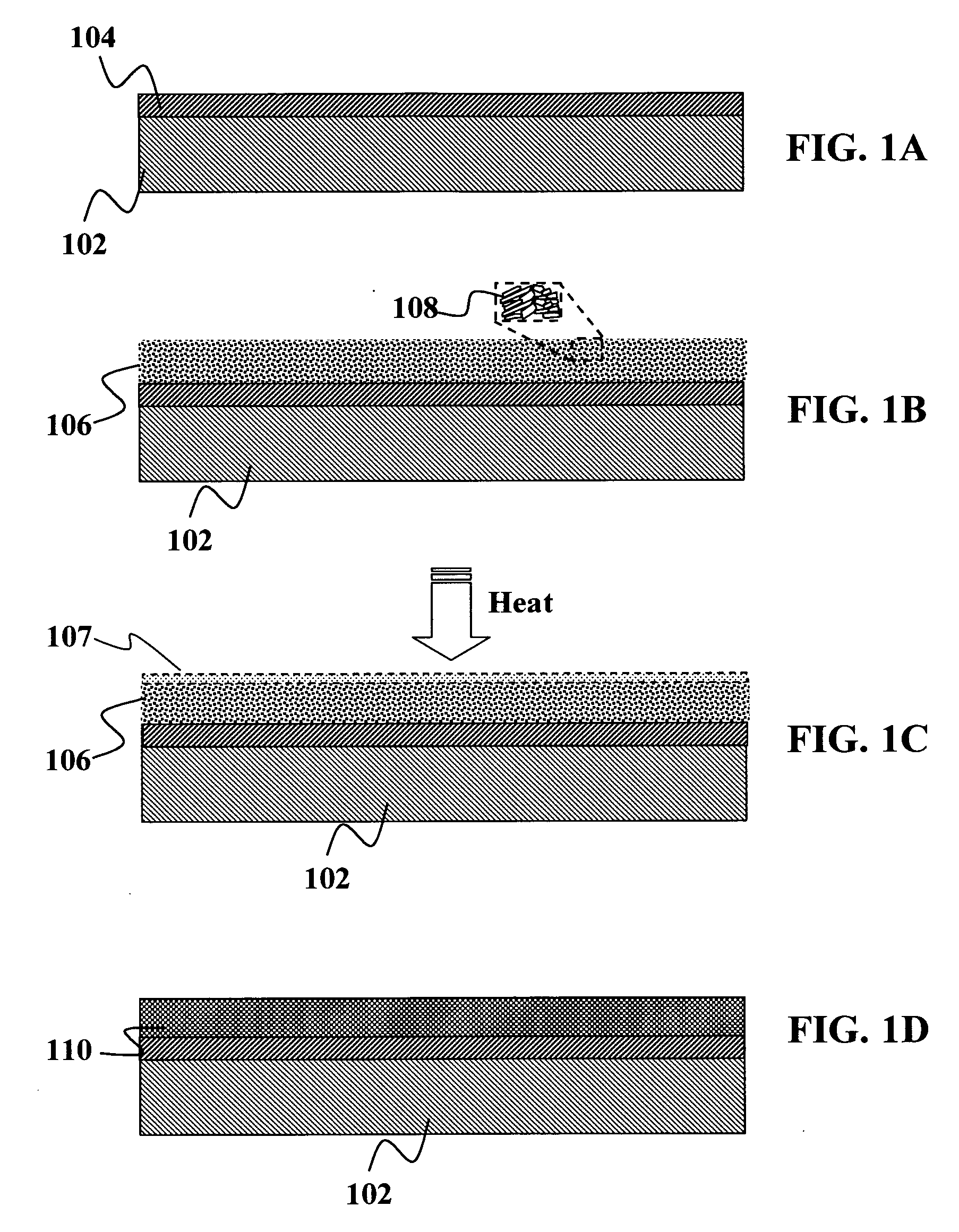

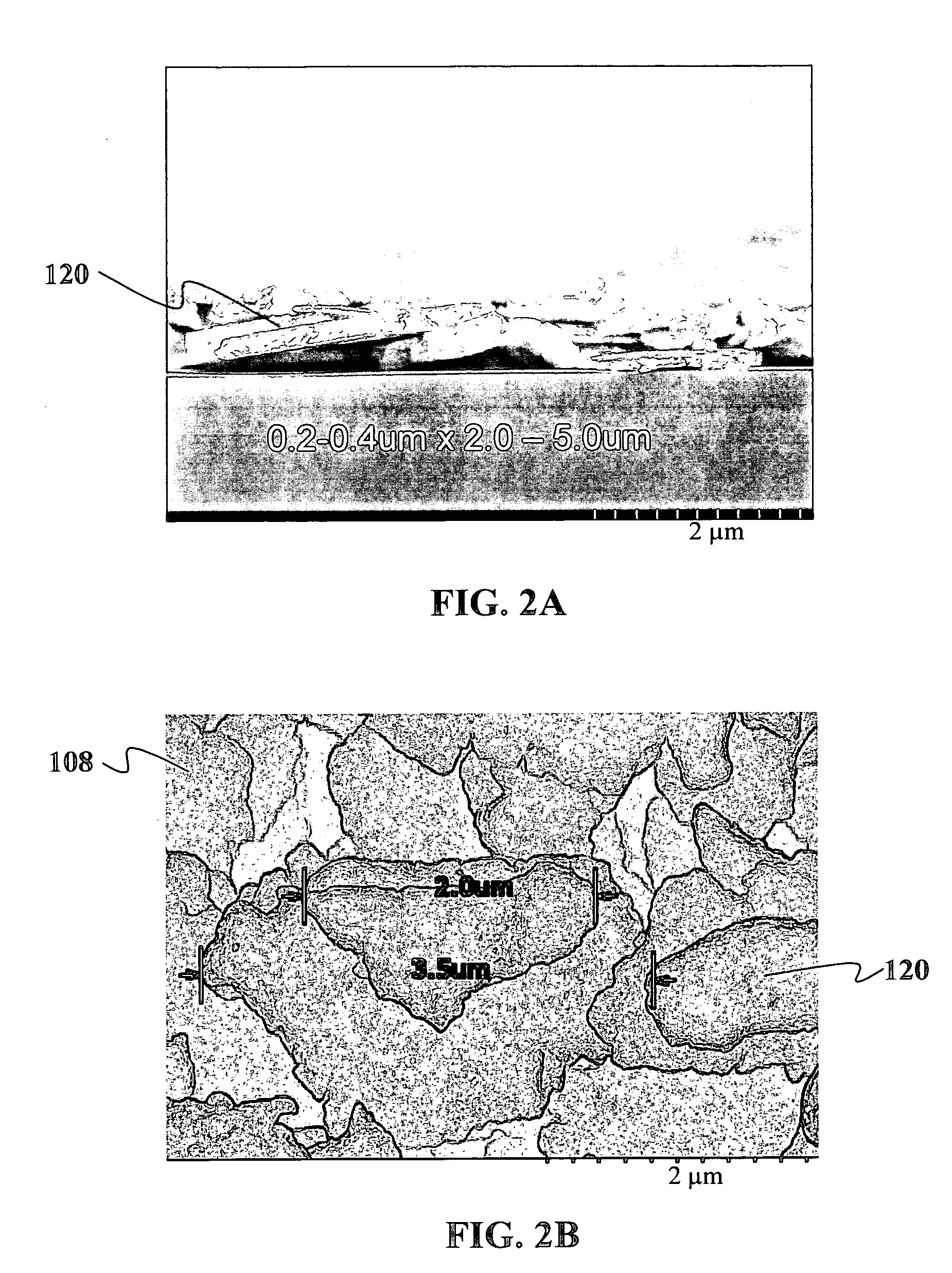

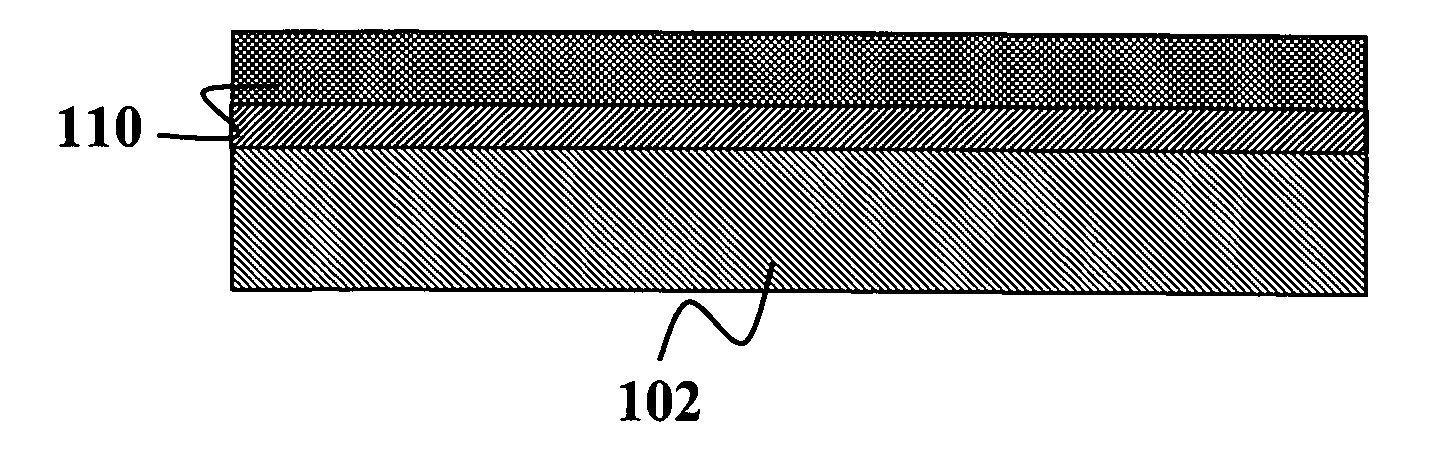

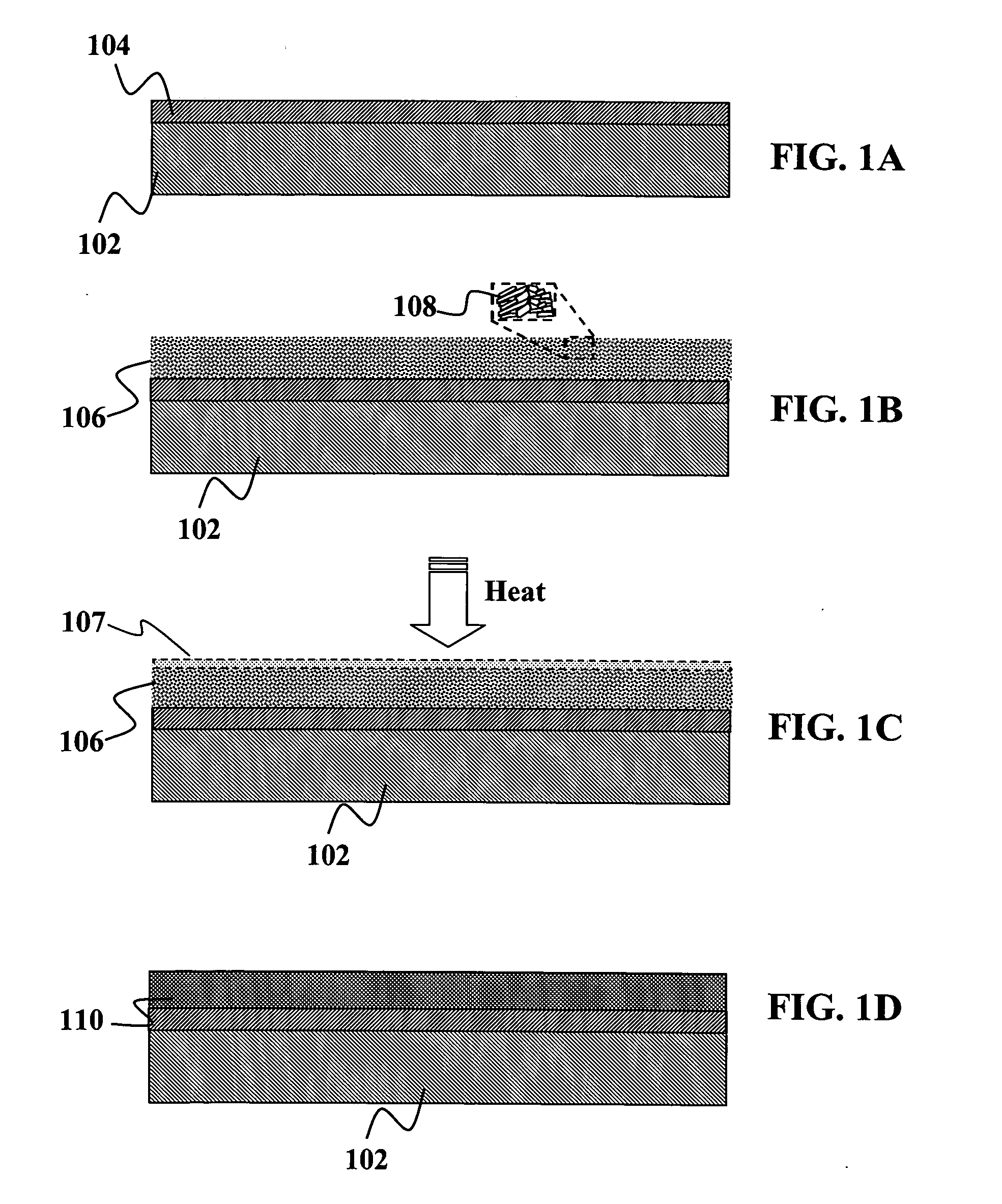

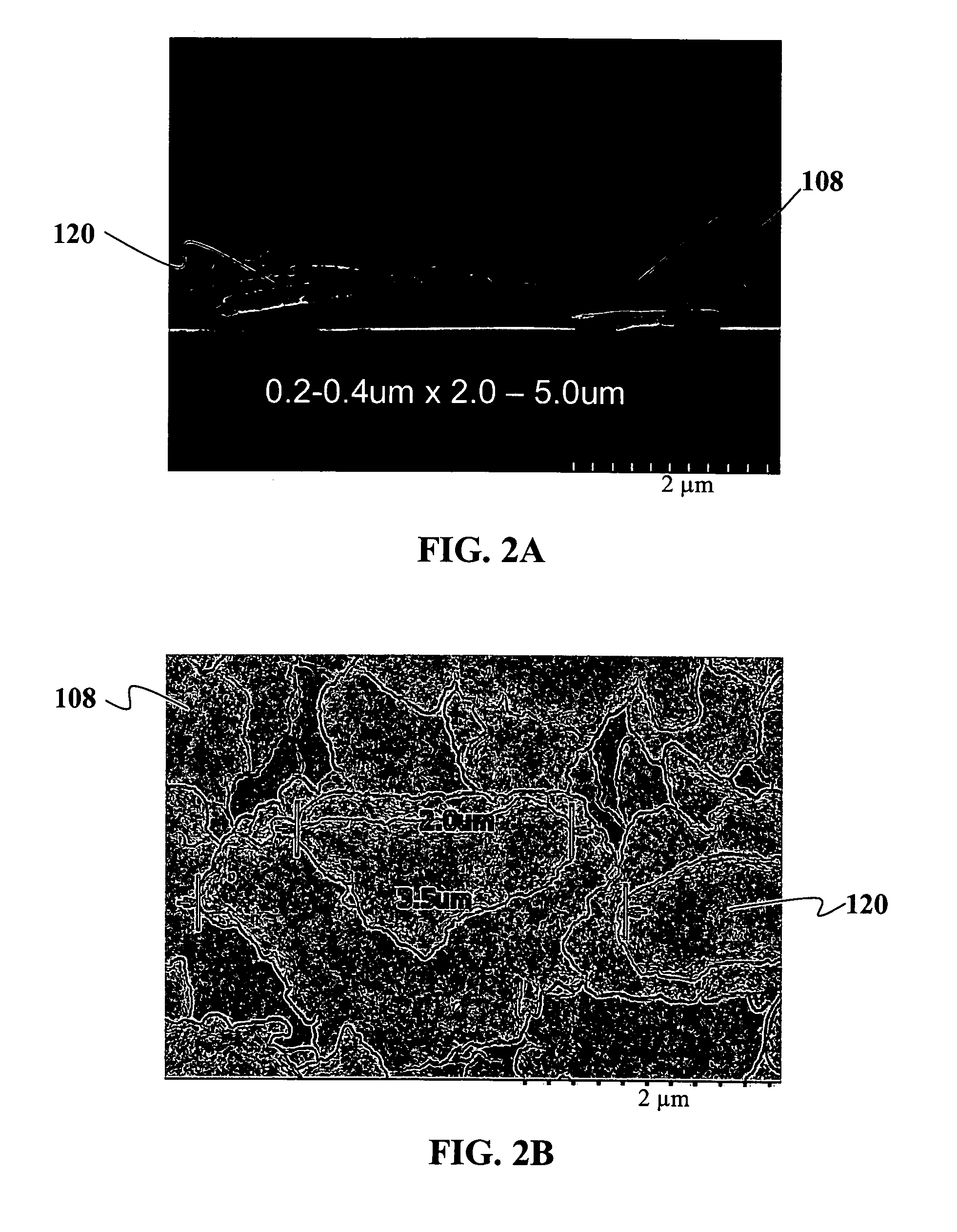

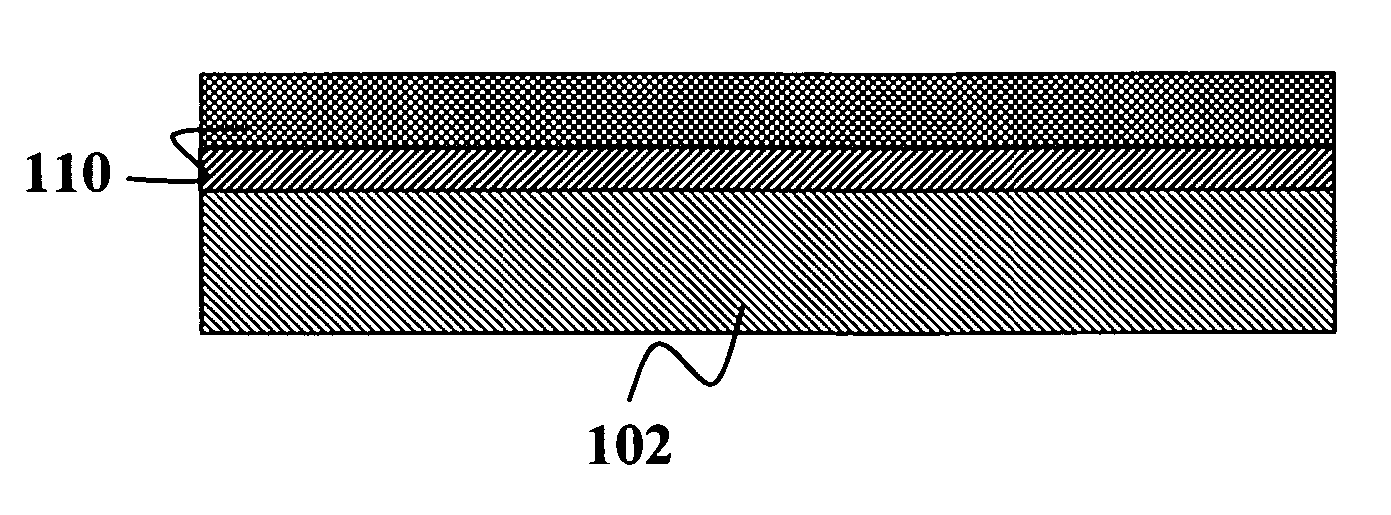

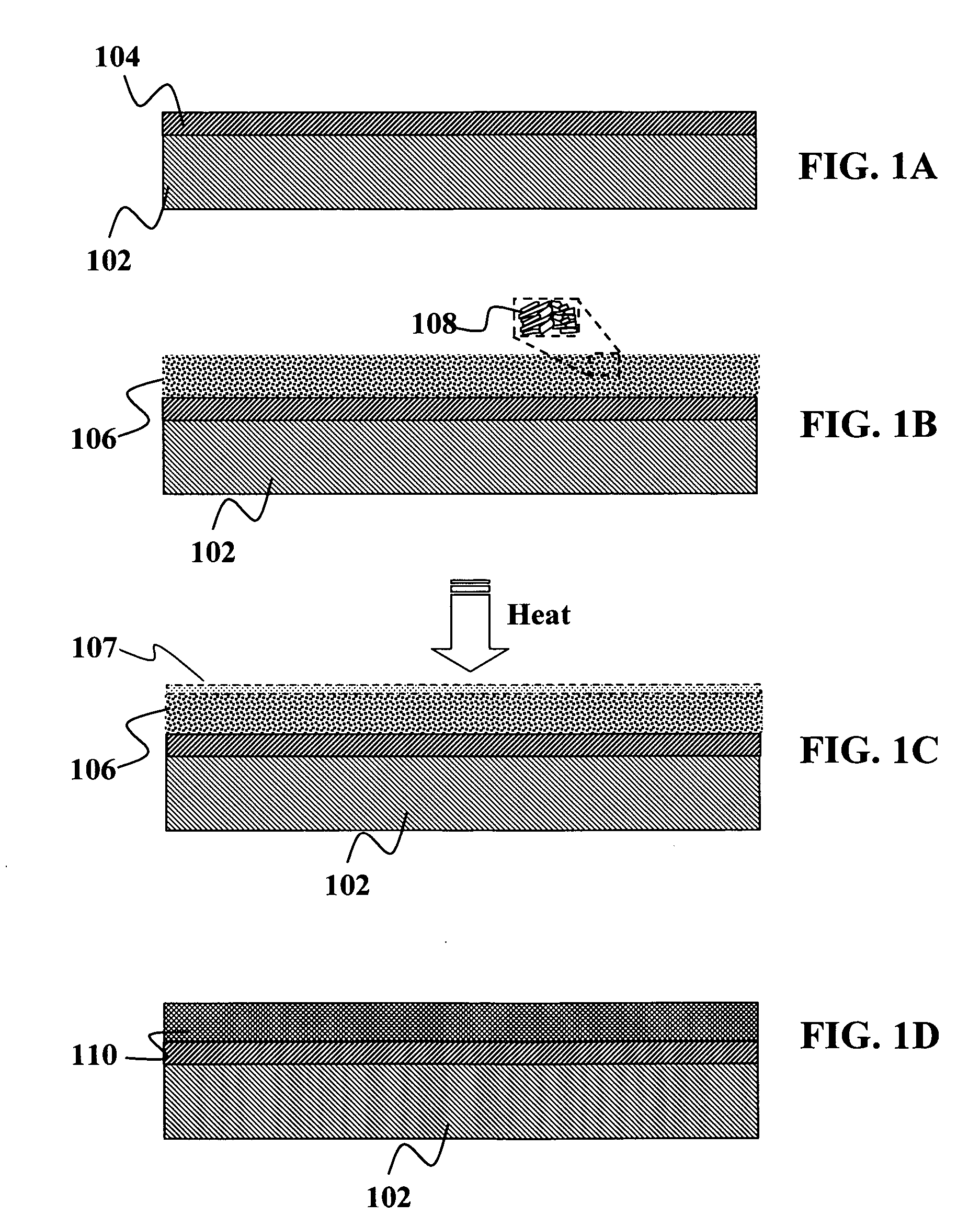

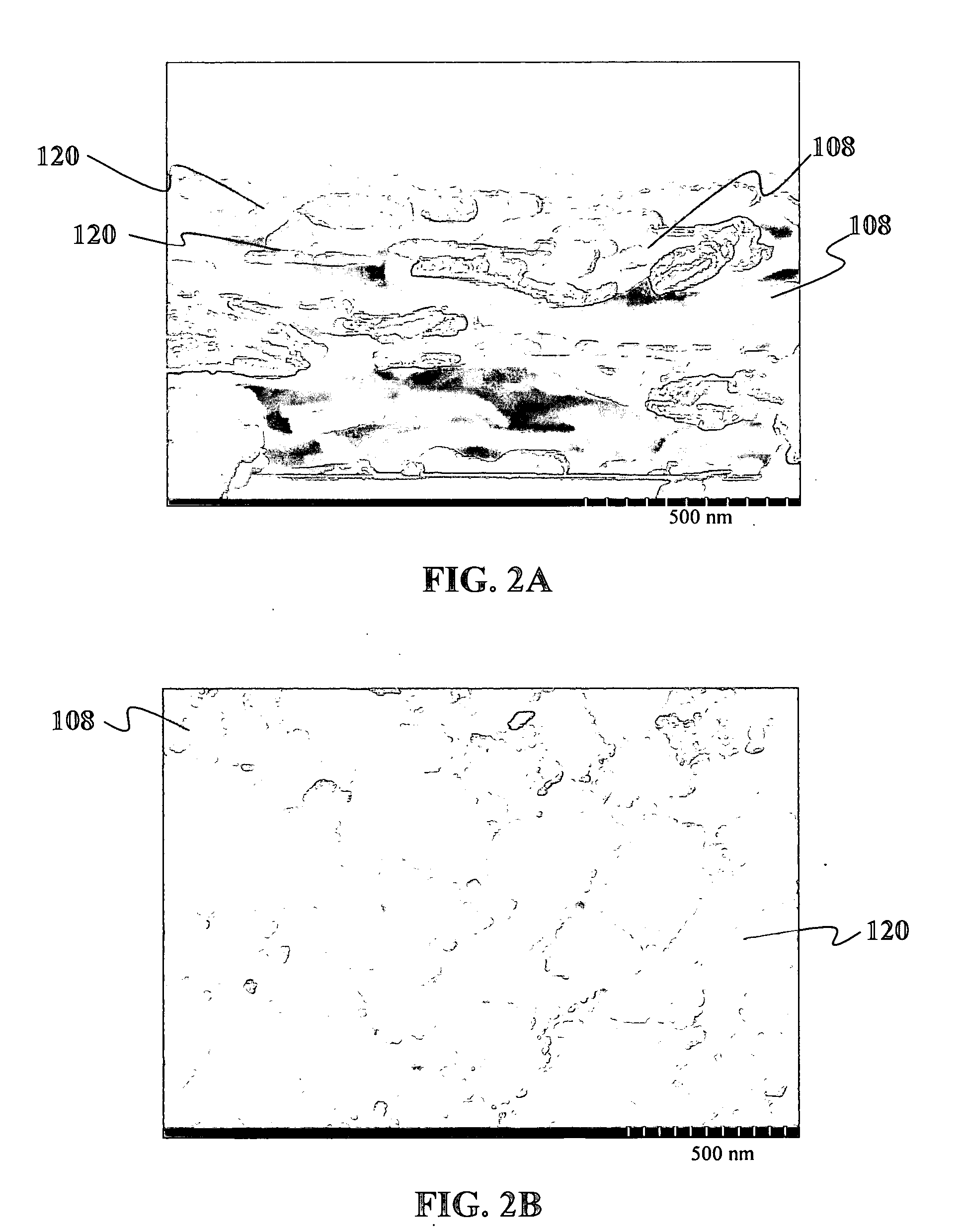

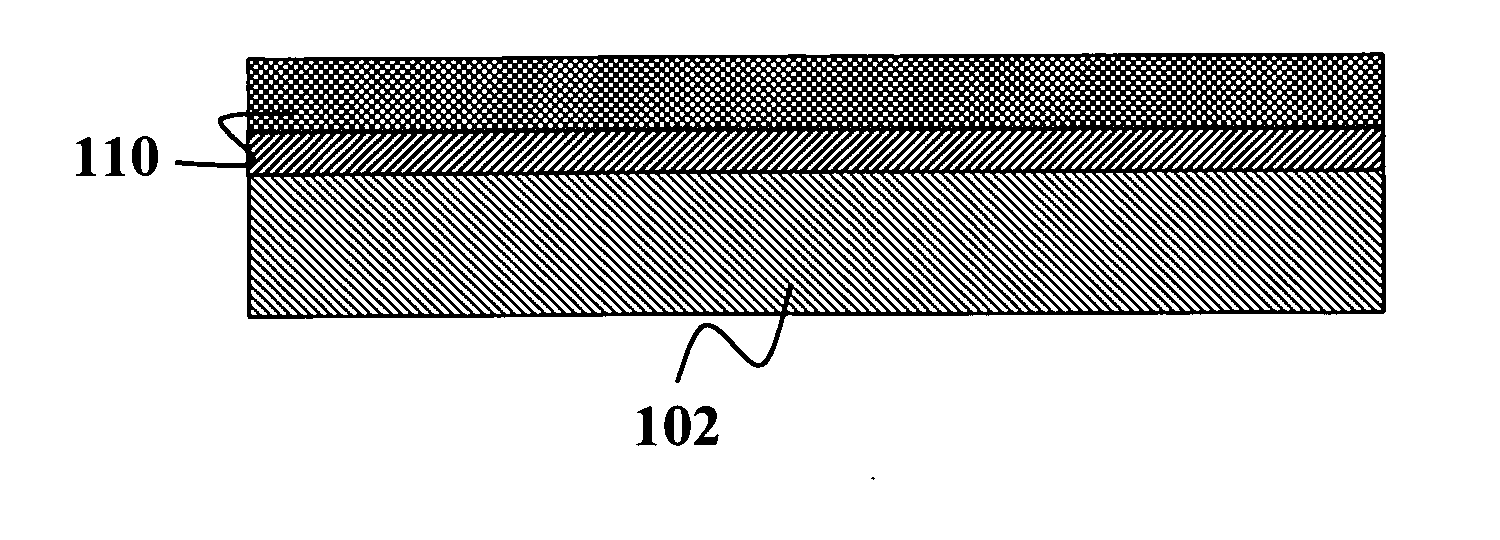

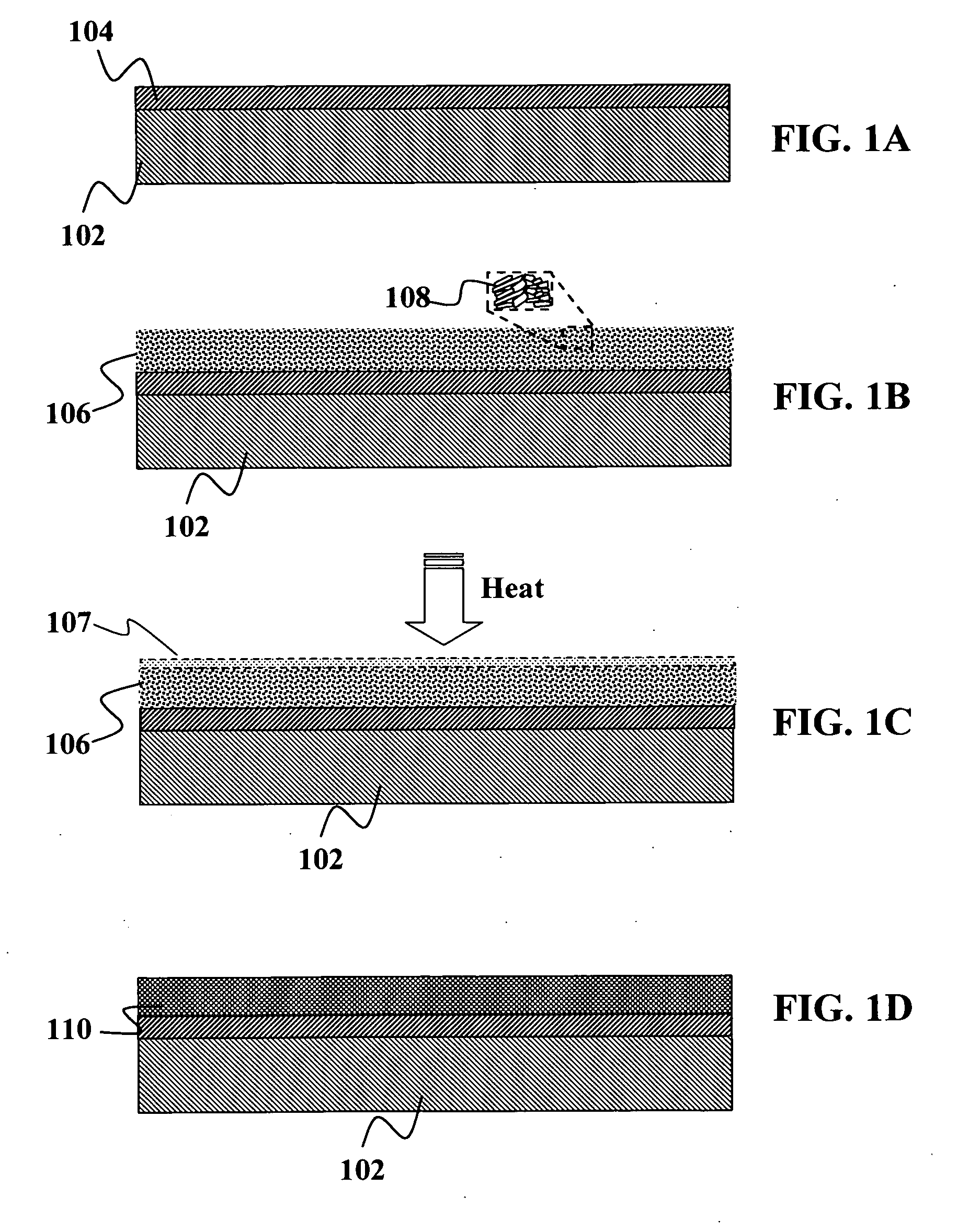

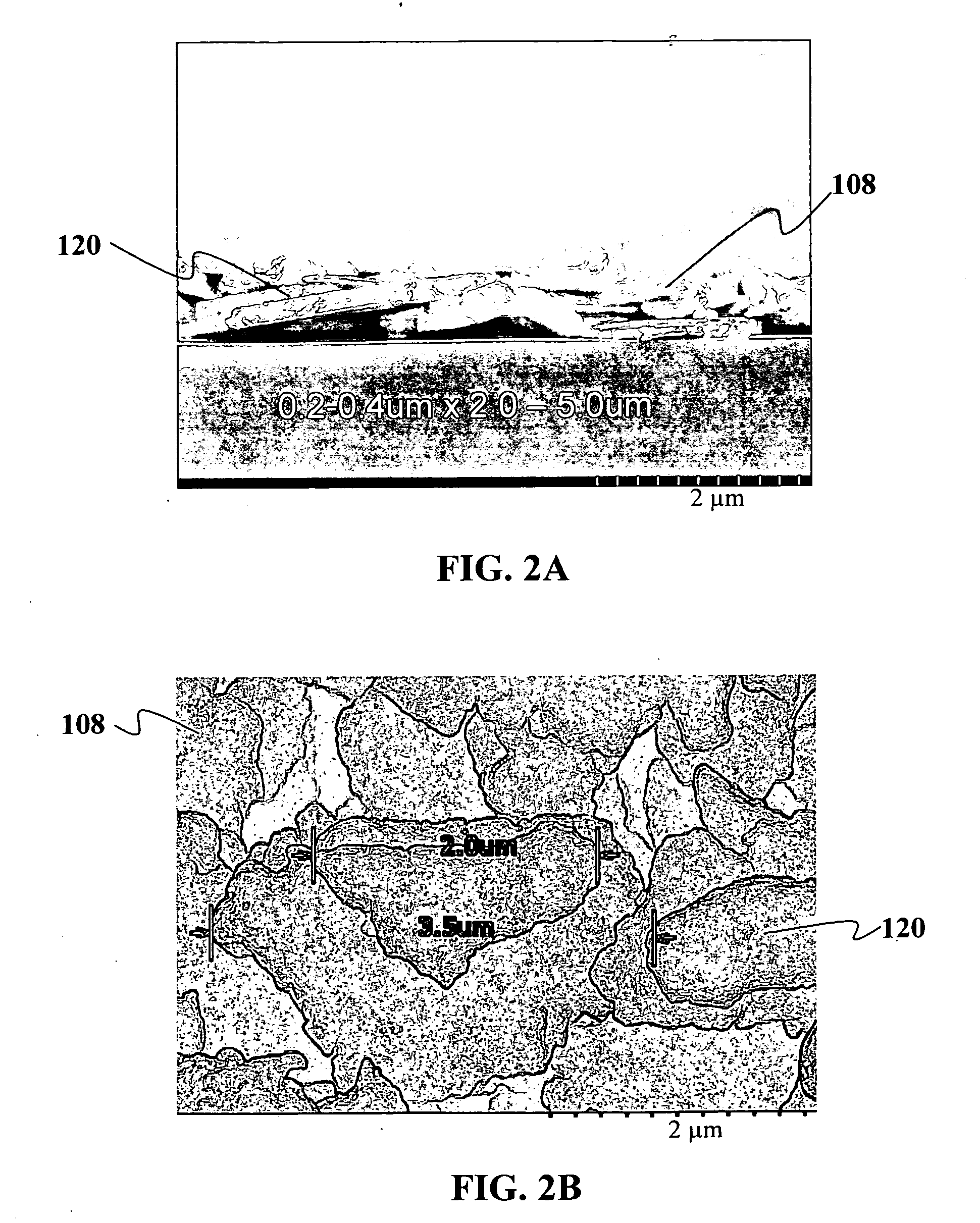

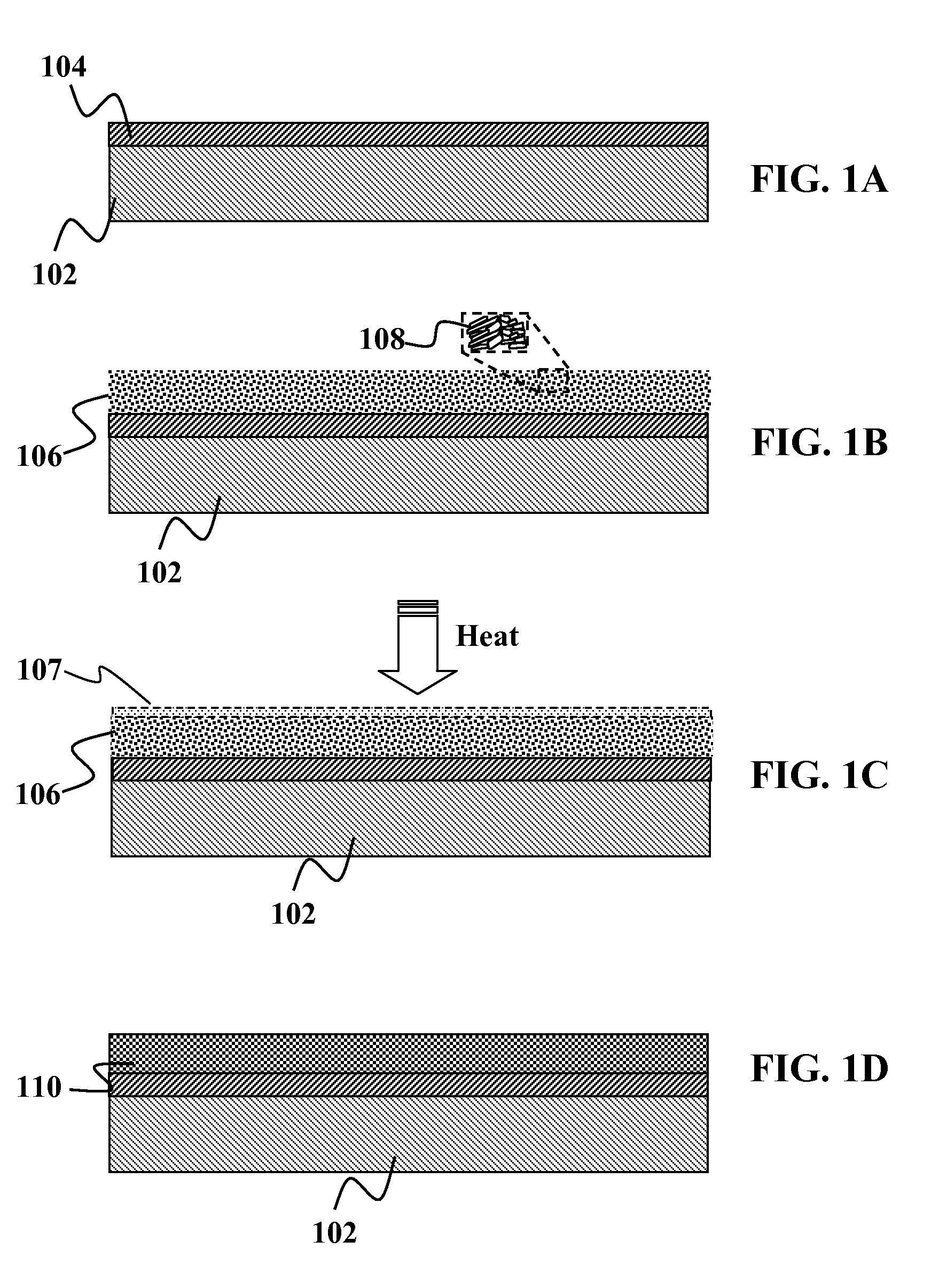

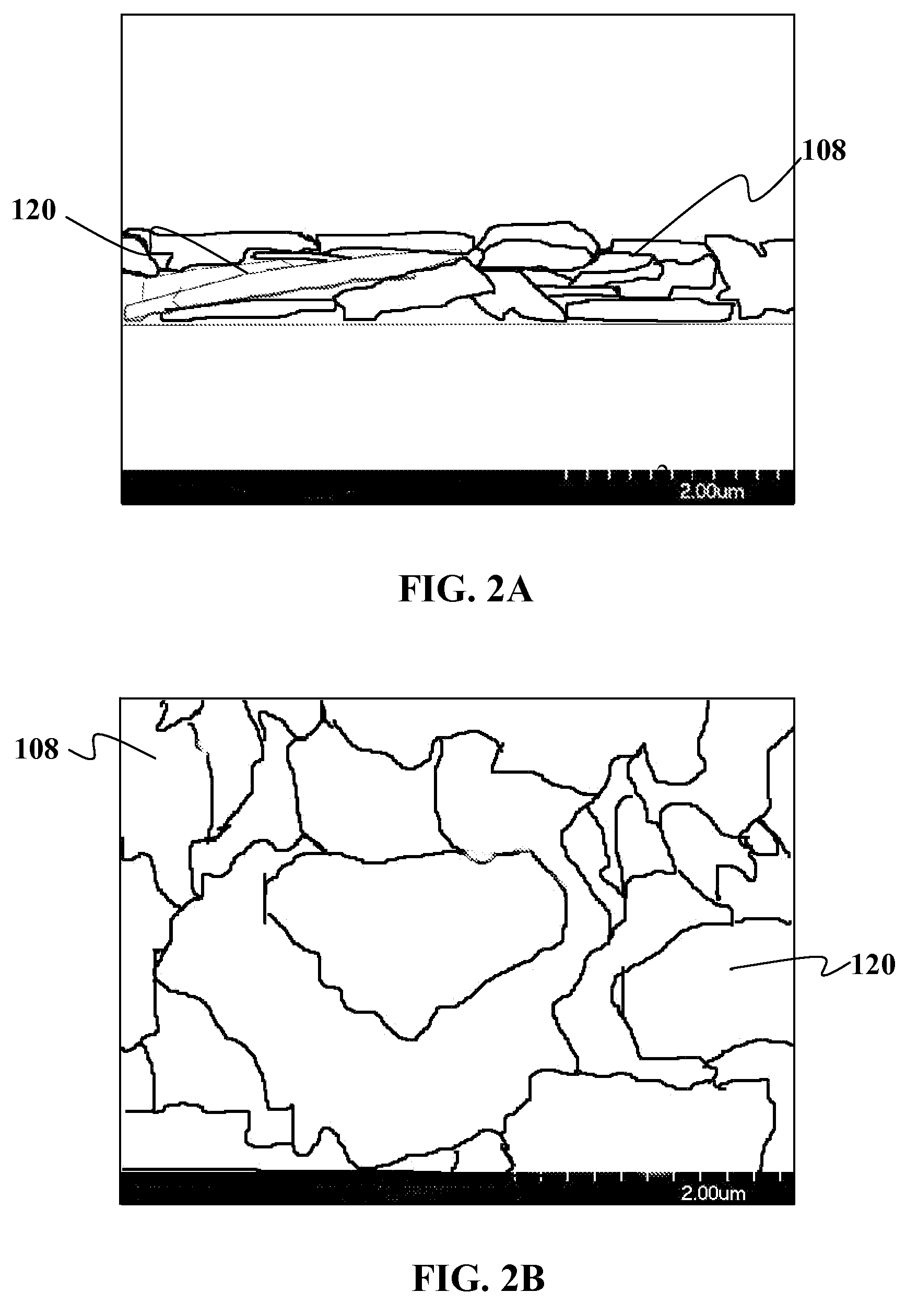

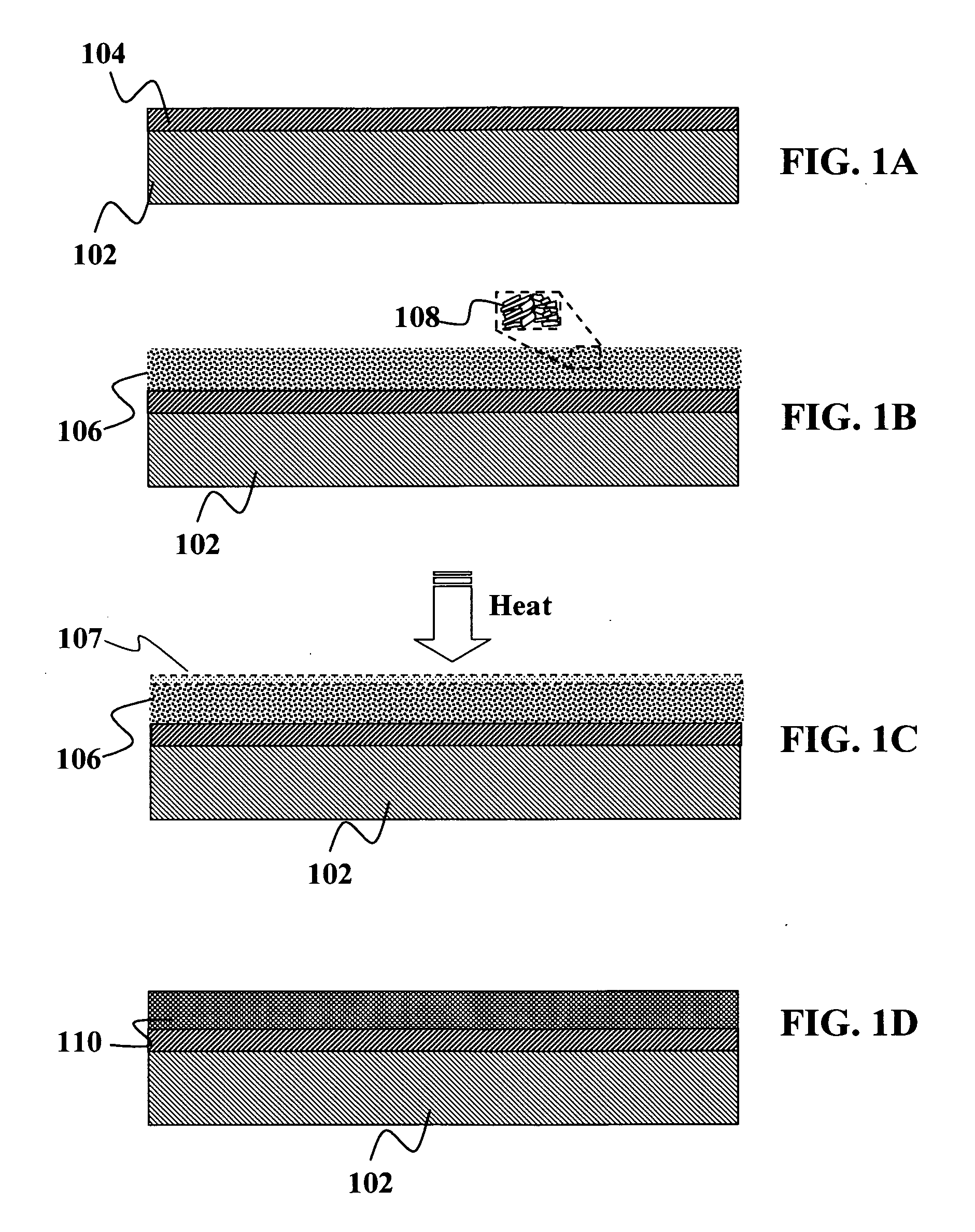

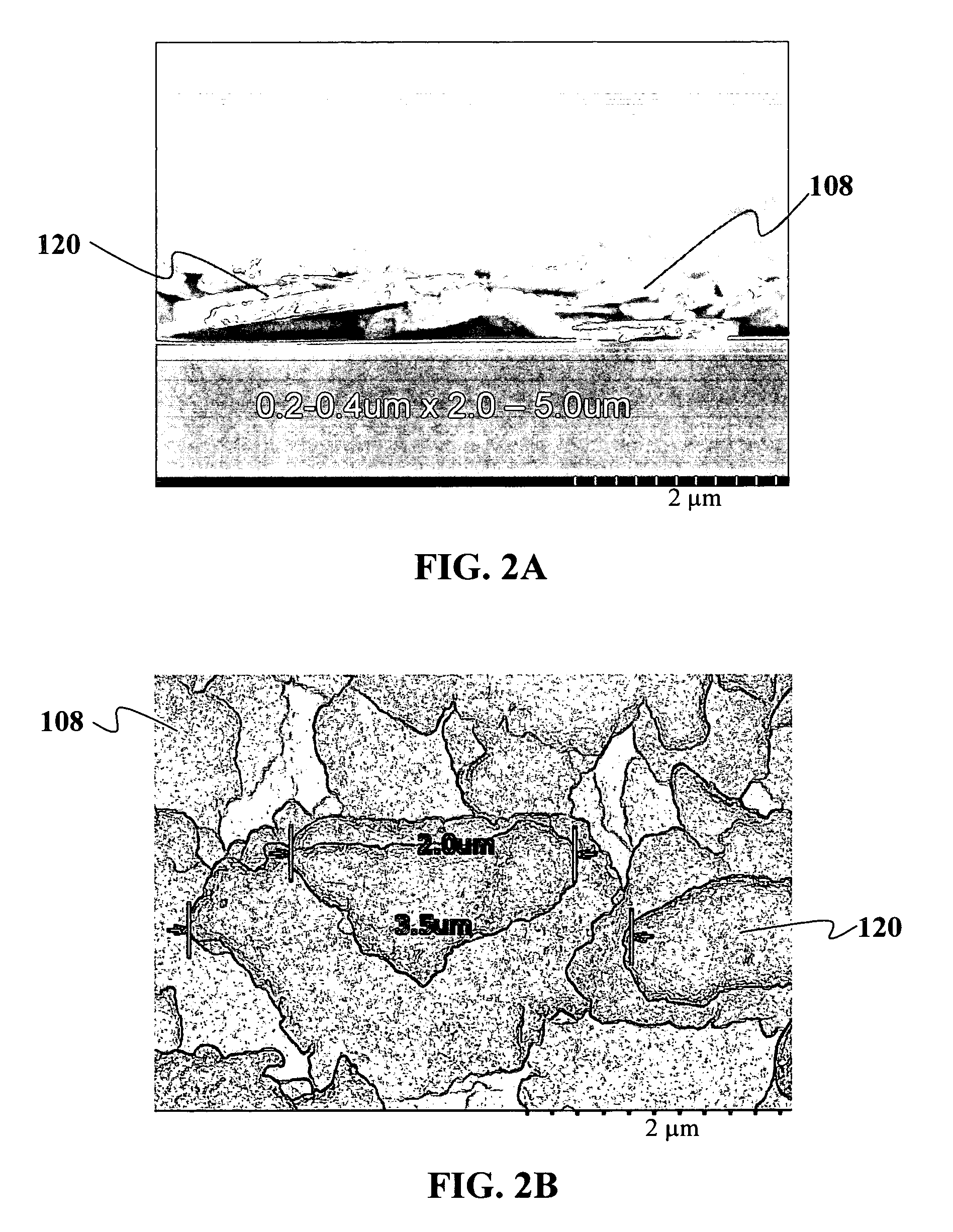

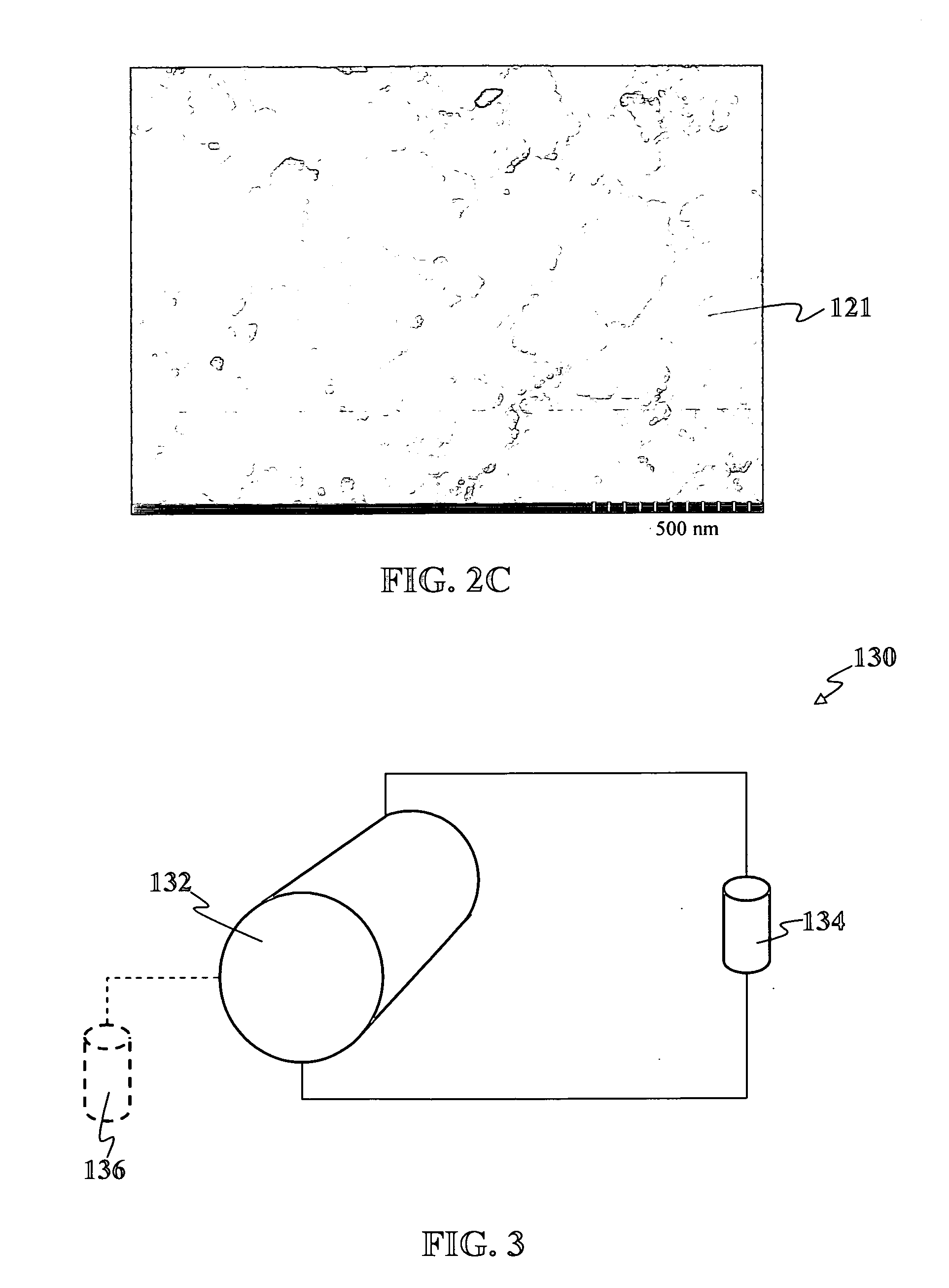

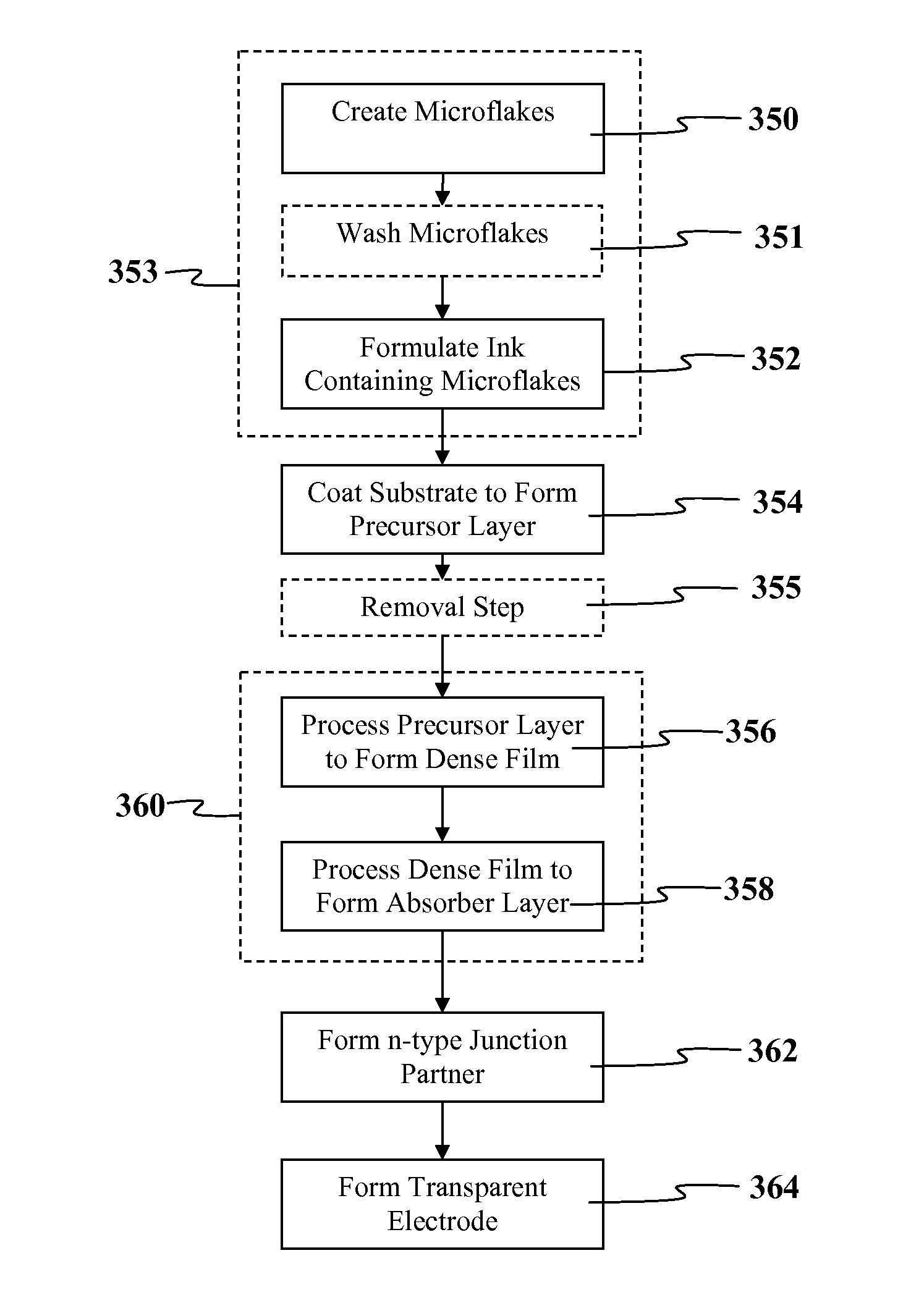

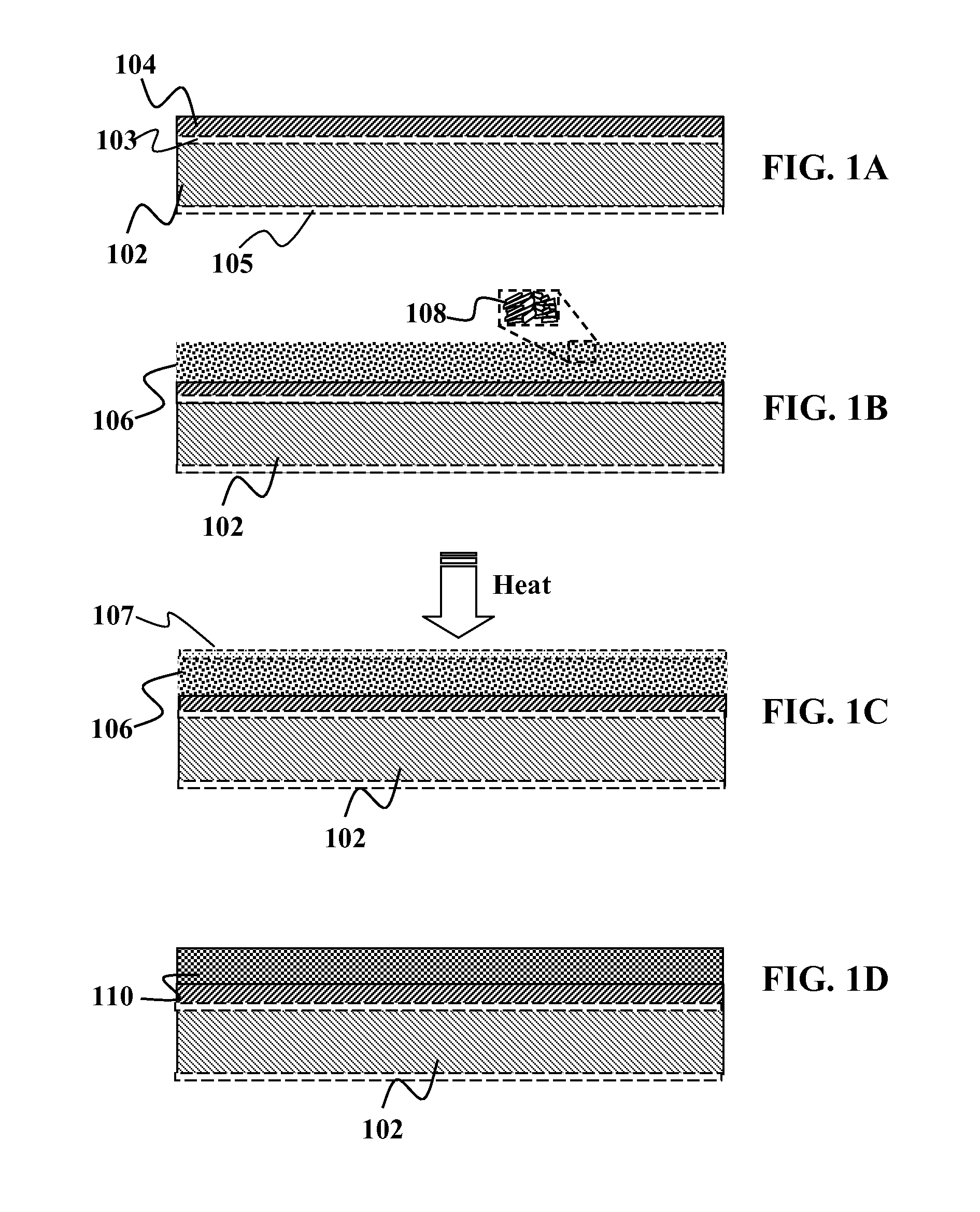

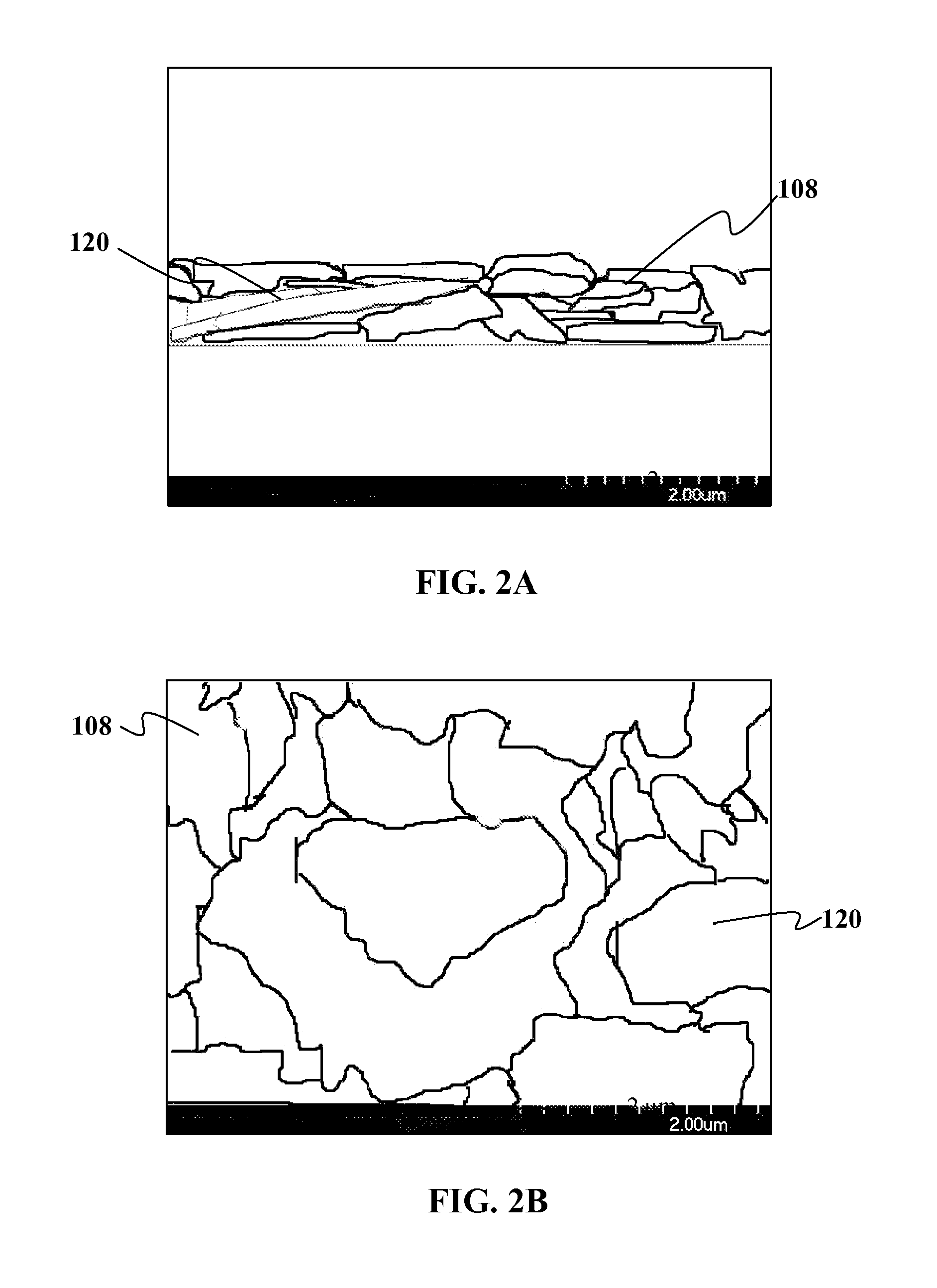

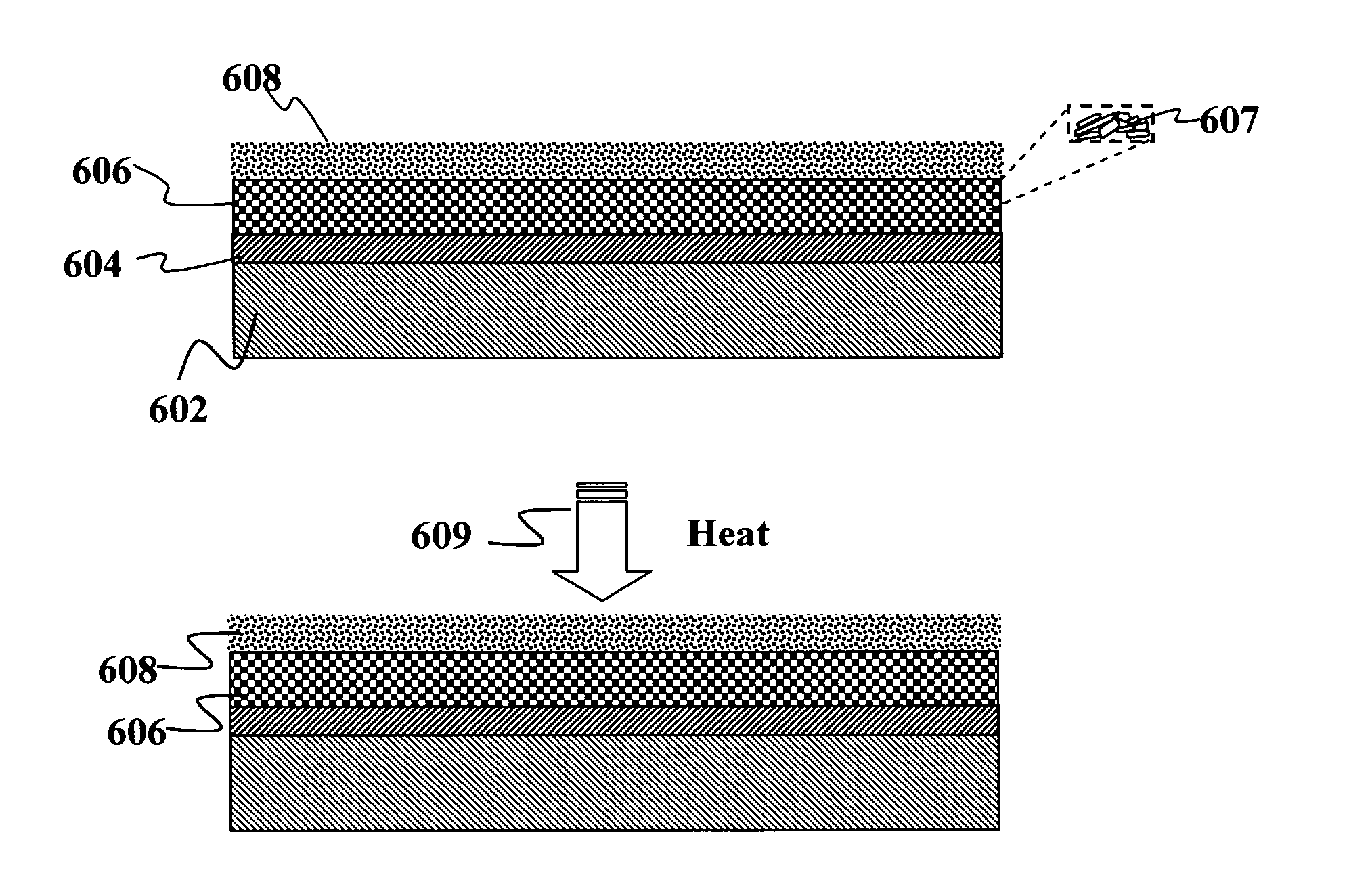

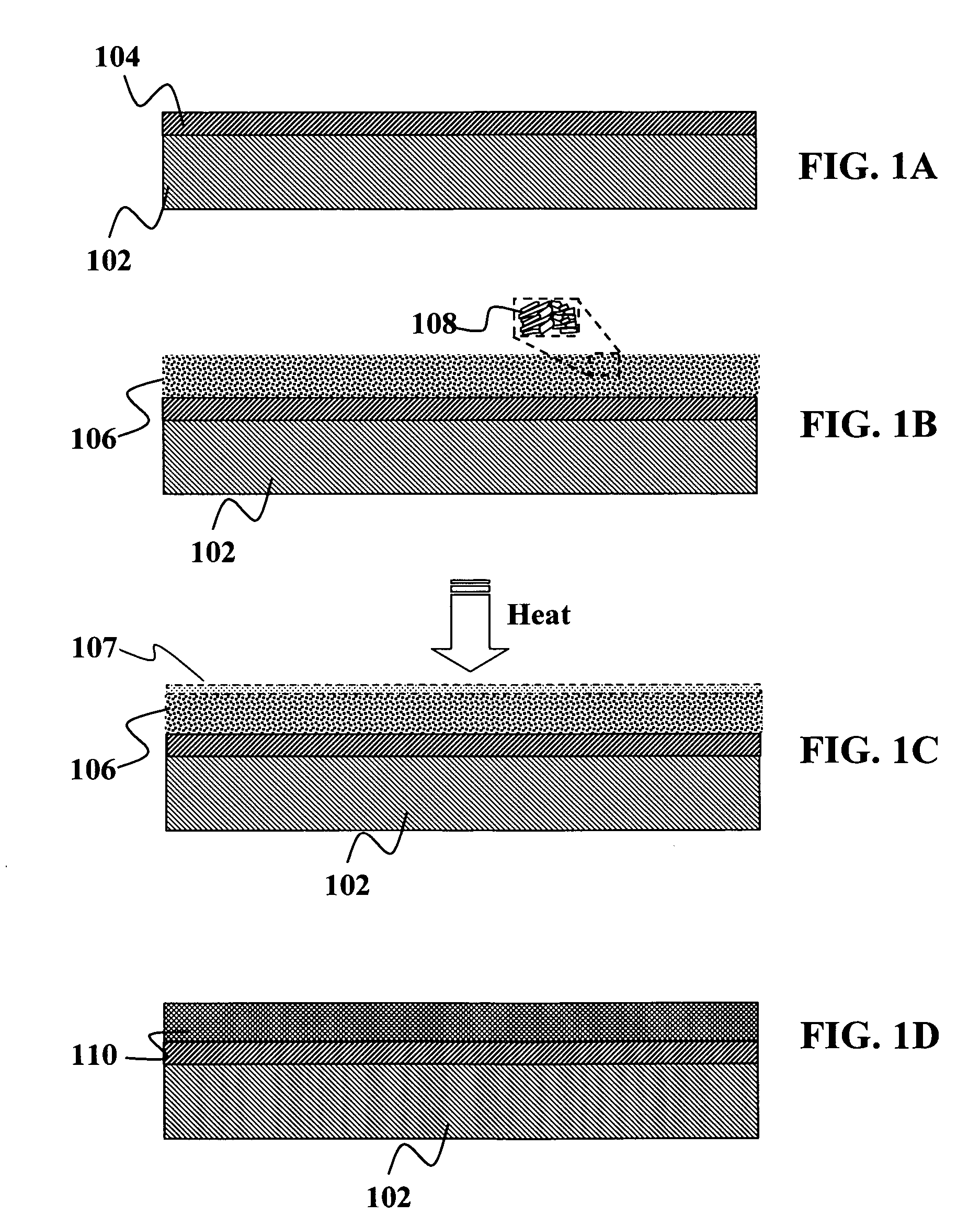

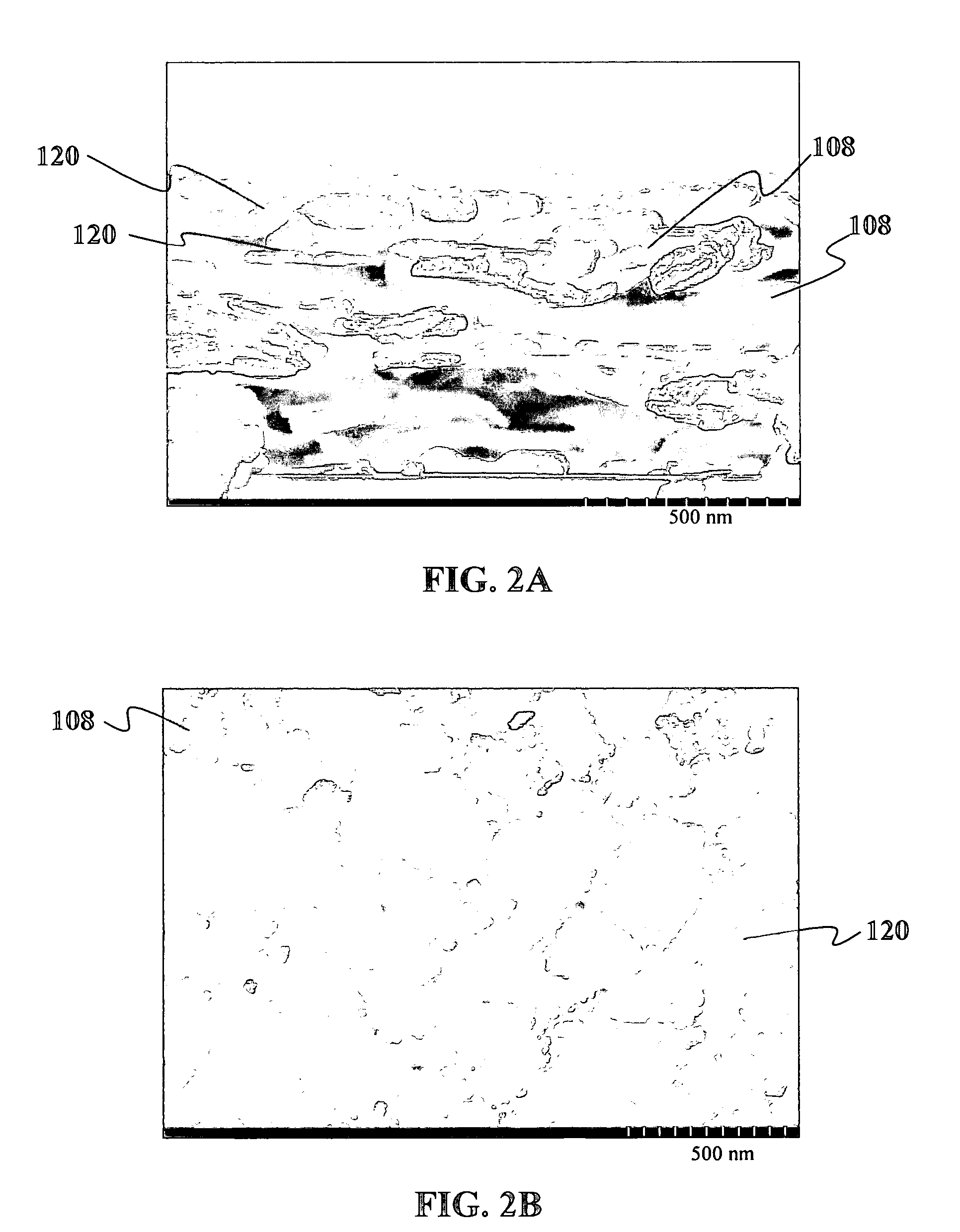

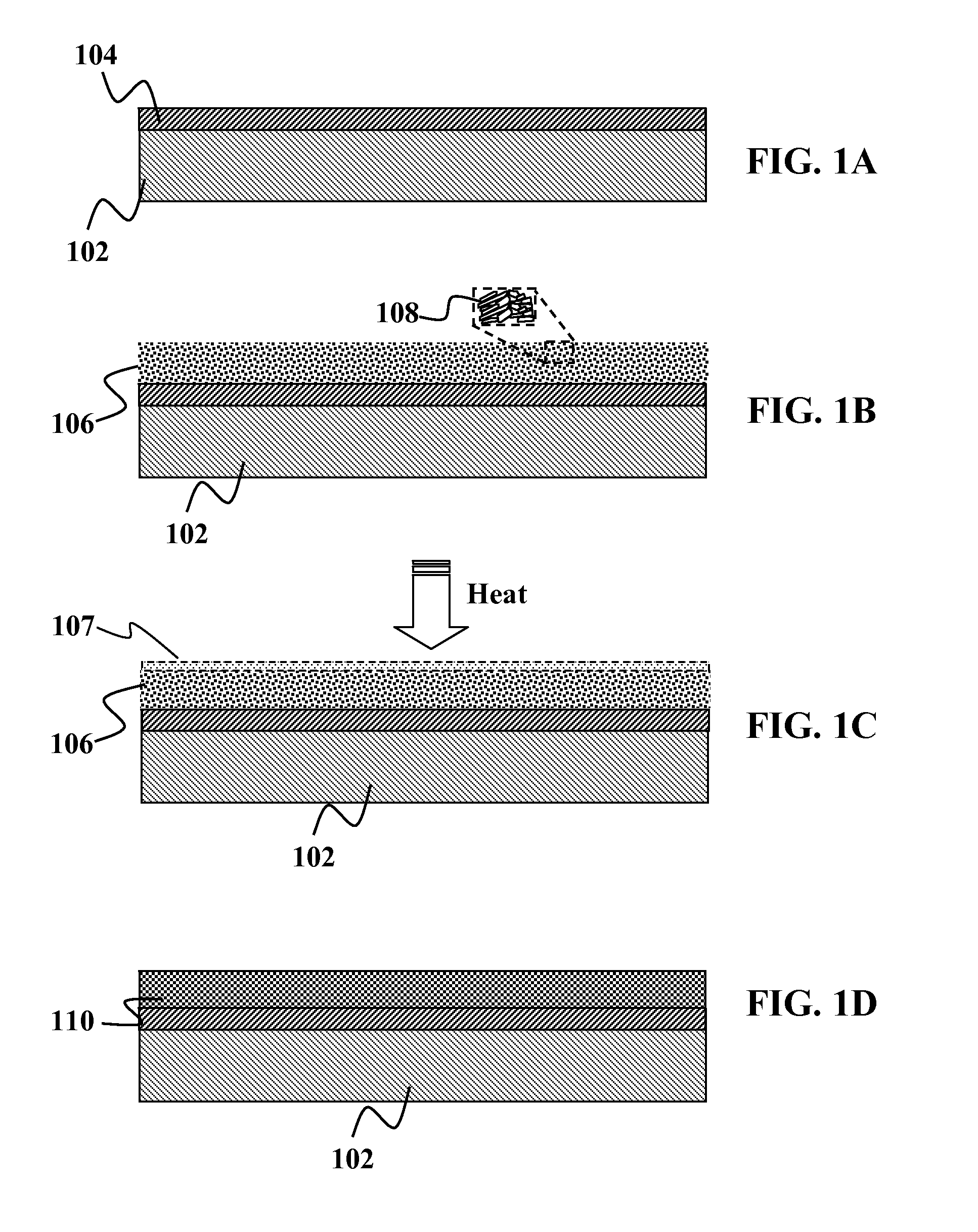

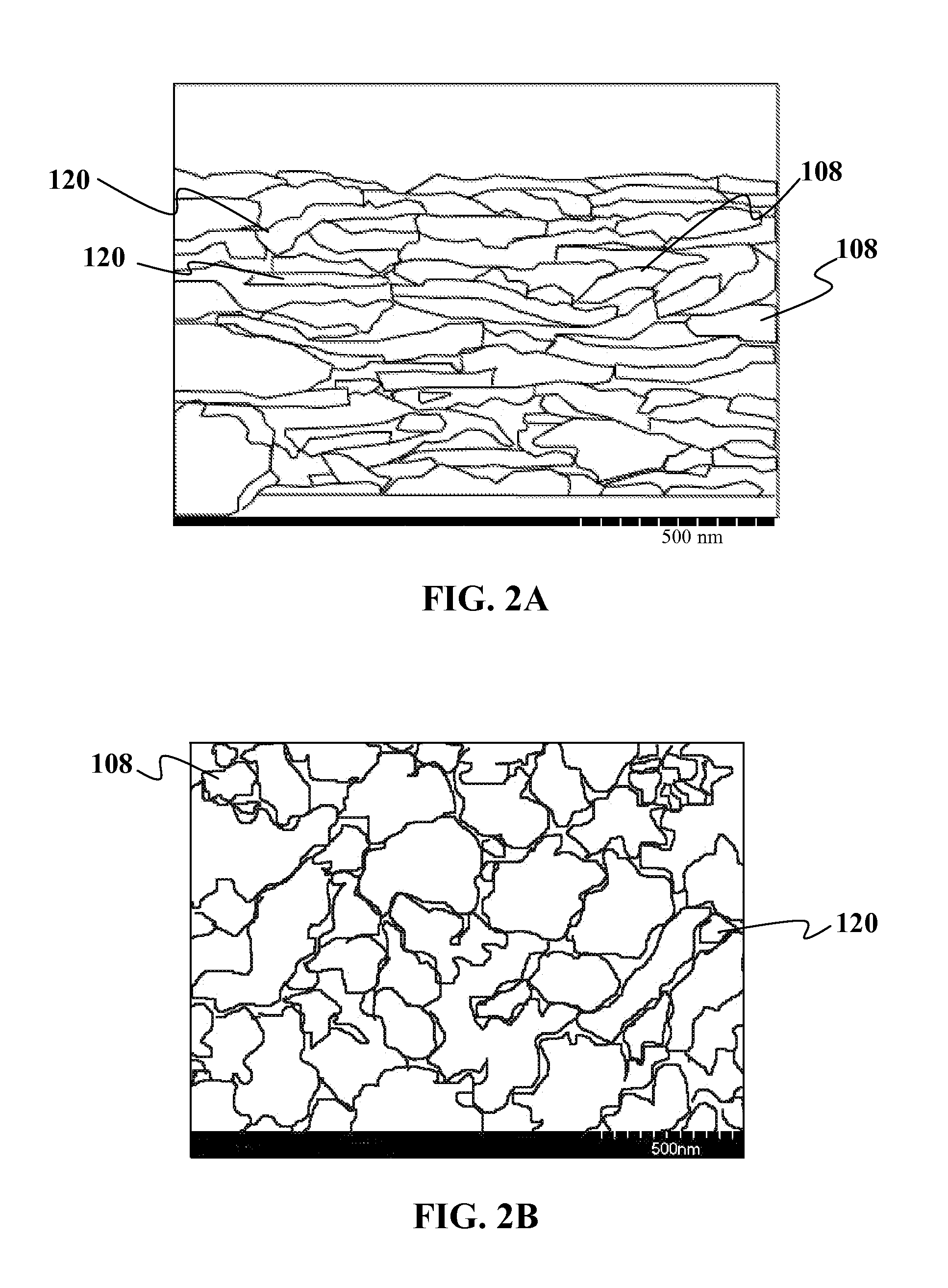

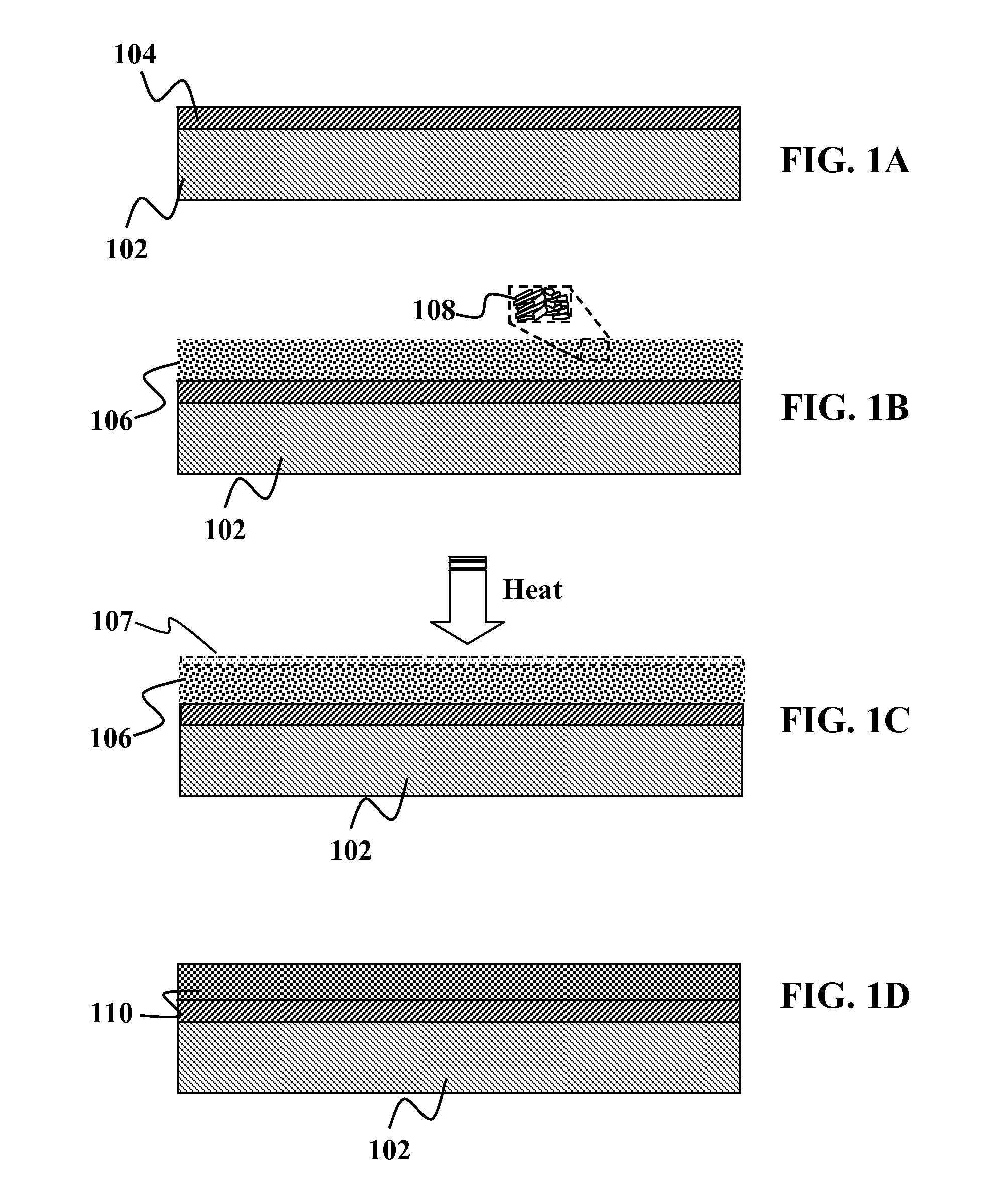

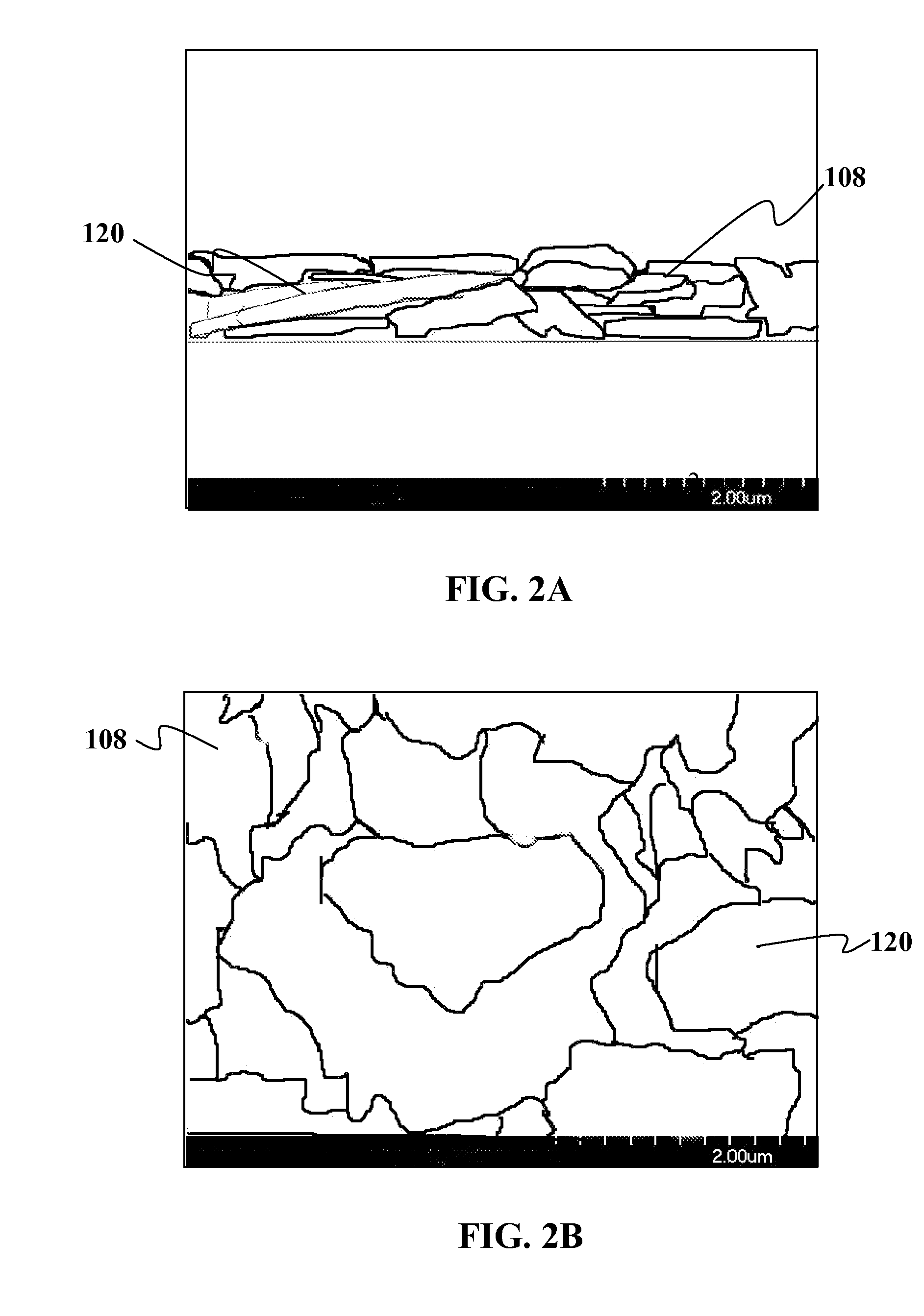

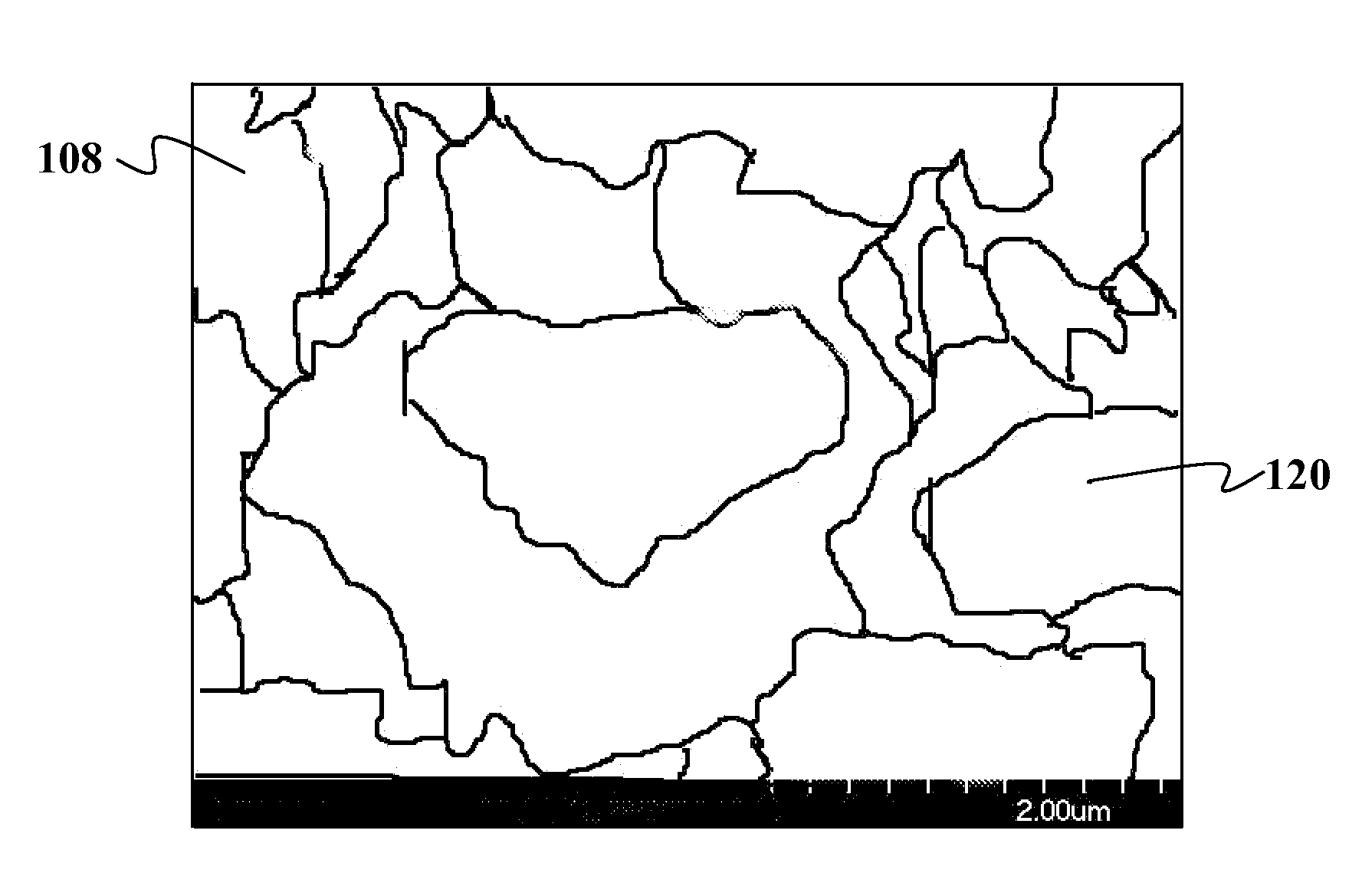

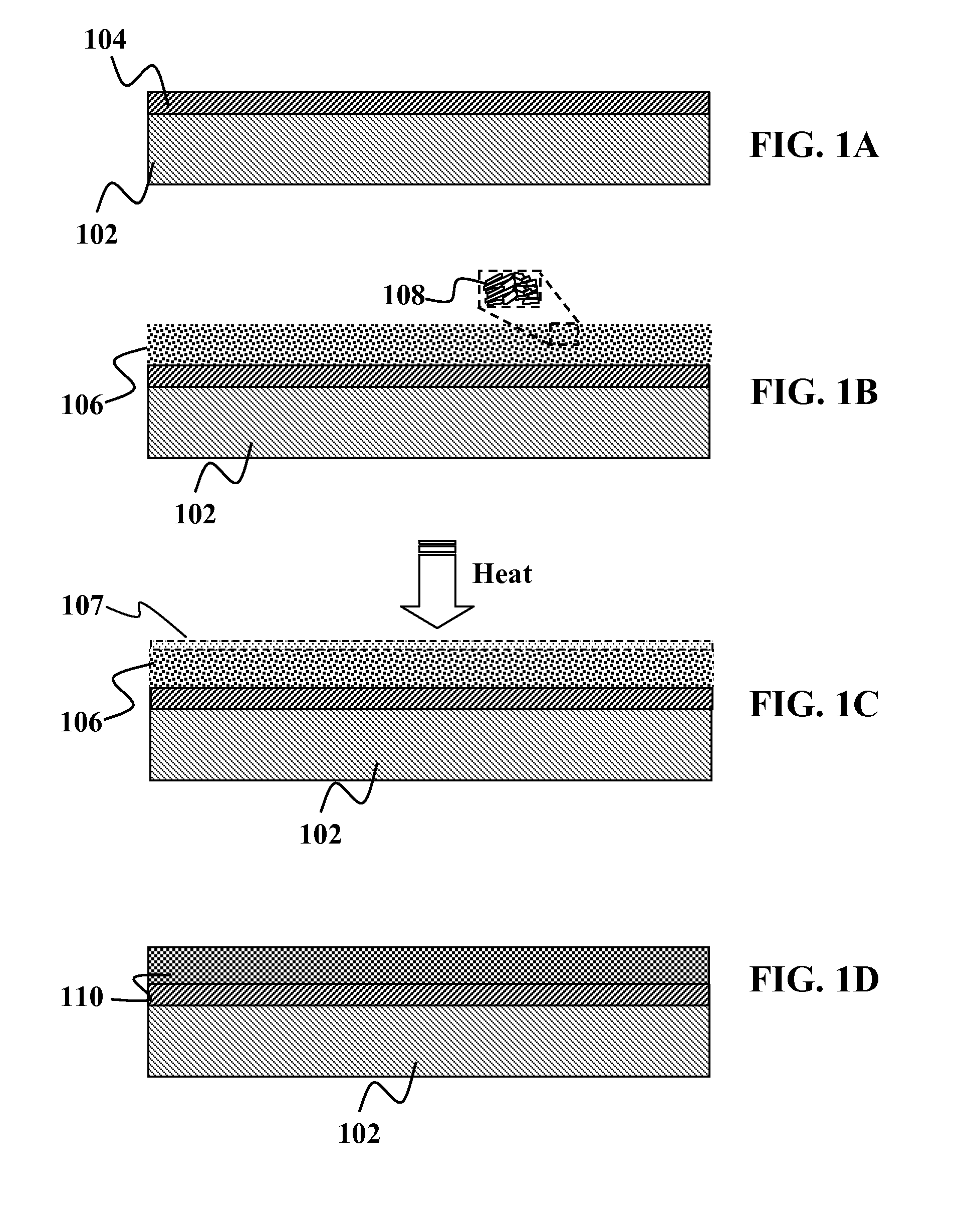

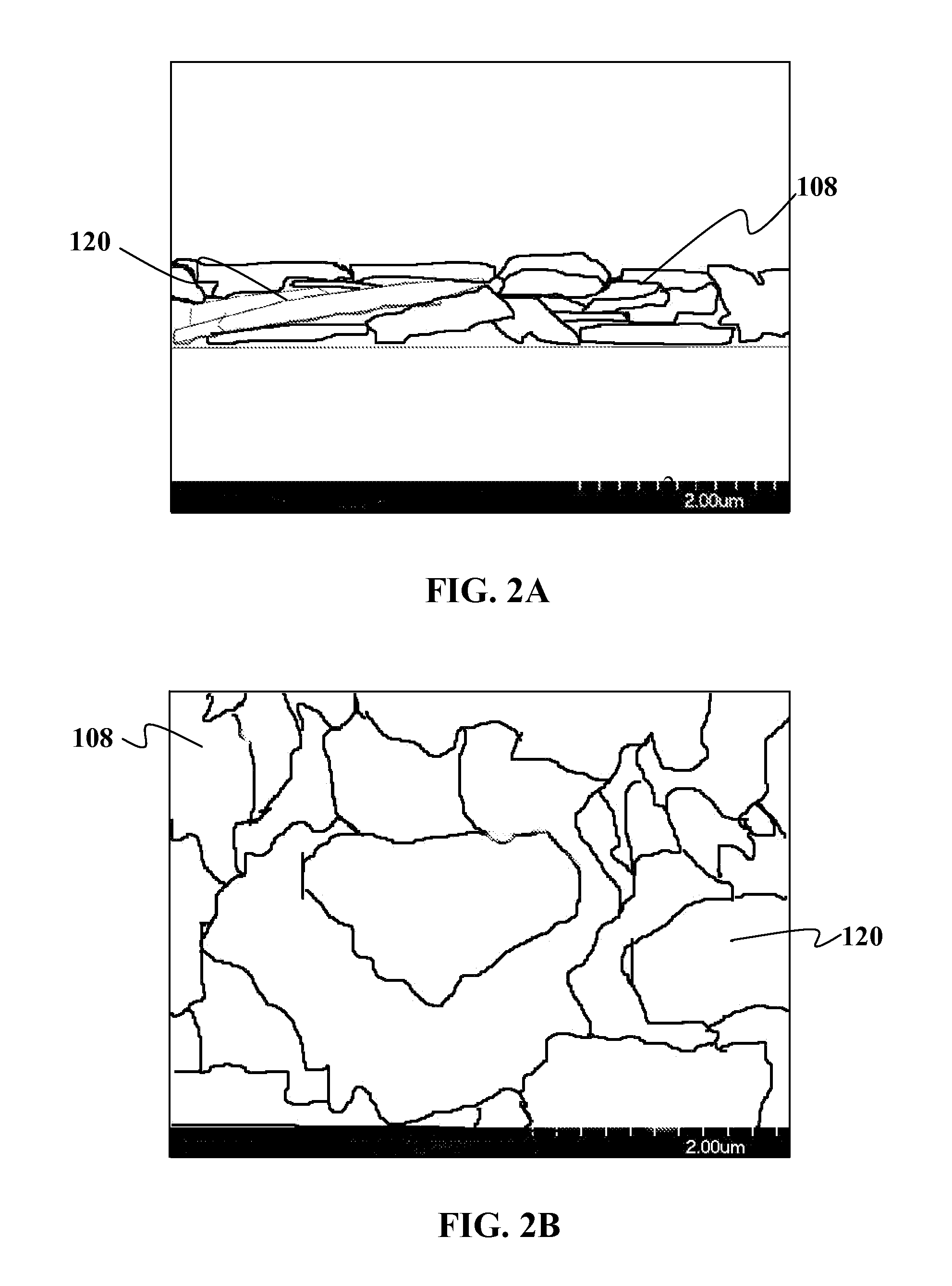

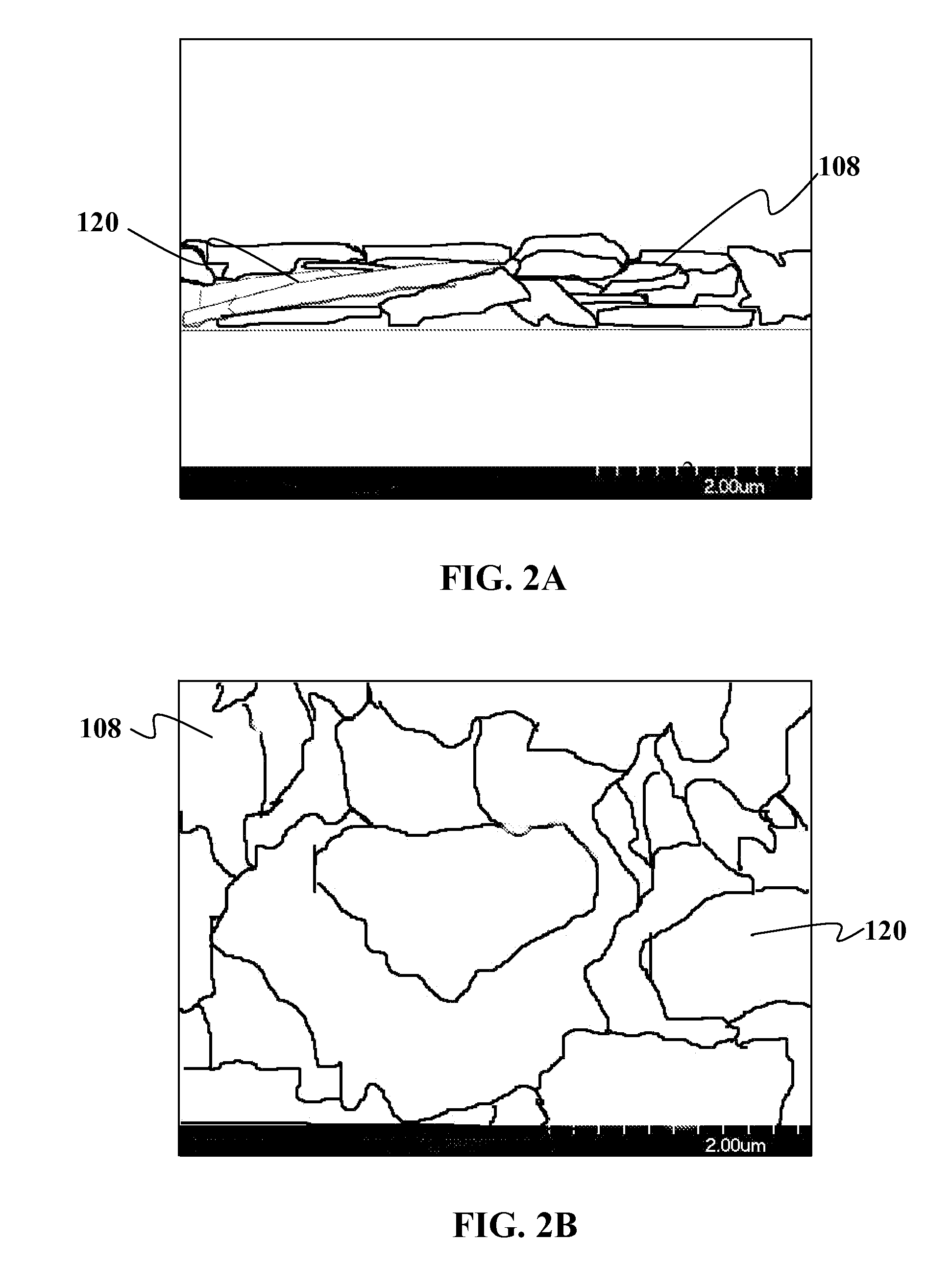

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes is particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

Photovoltaic devices printed from nanostructured particles

InactiveUS20070163638A1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingParticle methodSolar cell

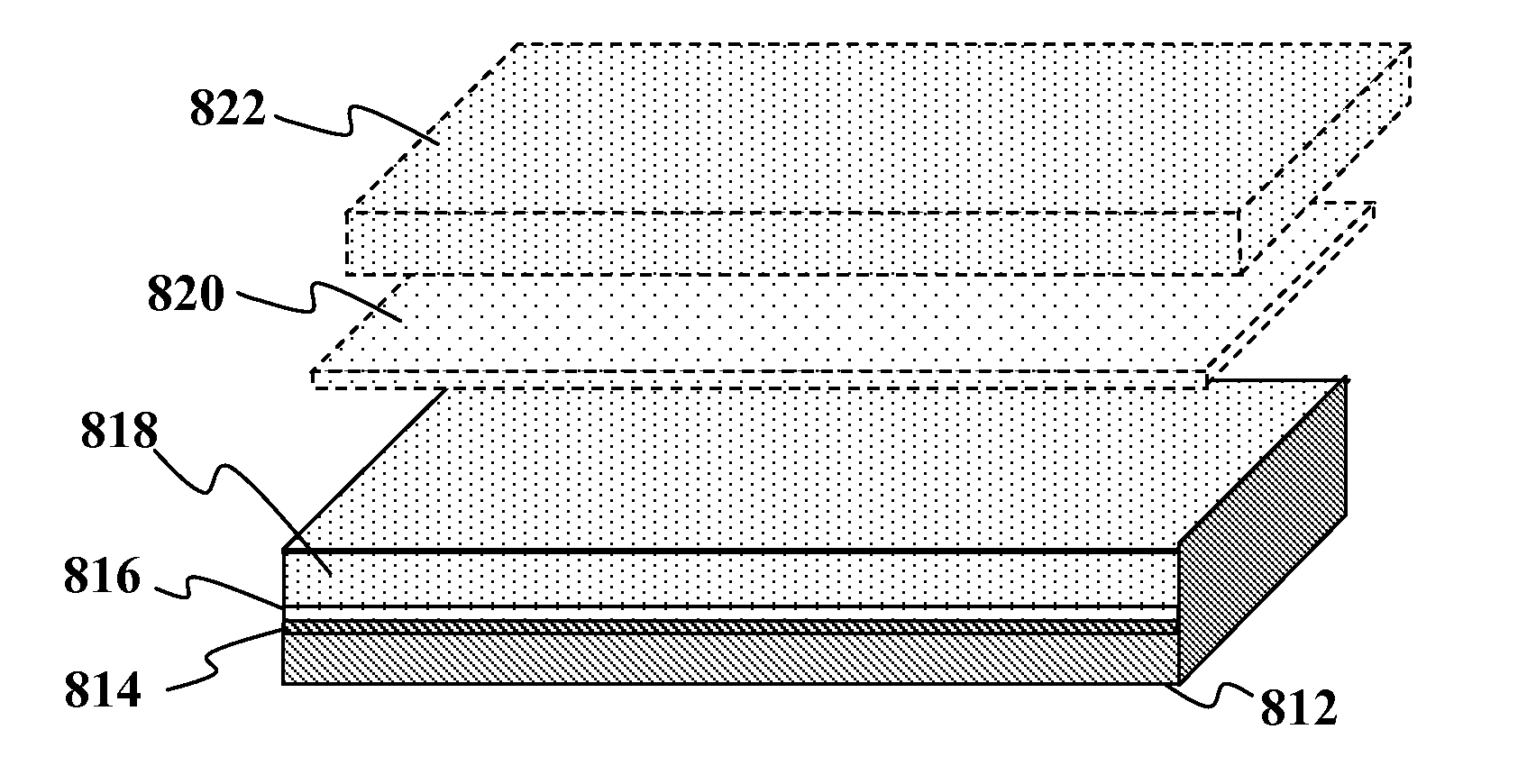

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, a solar cell is provided that comprises of a substrate, a back electrode formed over the substrate, a p-type semiconductor thin film formed over the back electrode, an n-type semiconductor thin film formed so as to constitute a pn junction with the p-type semiconductor thin film, and a transparent electrode formed over the n-type semiconductor thin film. The p-type semiconductor thin film results by processing a dense film formed from a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA, wherein the dense film has a void volume of about 26% or less. The dense film may be a substantially void free film.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of semiconductor precursor layer from inter-metallic microflake articles

InactiveUS20070163642A1Efficient and simplified creationIncrease contactFinal product manufactureLiquid/solution decomposition chemical coatingNanometreAspect ratio

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of semiconductor precursor layer from nanoflake particles

InactiveUS20070163637A1Efficient and simplified creationIncrease contactFinal product manufactureTransportation and packagingNanoparticleParticle method

Methods and devices are provided for transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after selective forces settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be nanoflakes that have a high aspect ratio. The resulting dense films formed from nanoflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of semiconductor precursor layer from microflake particles

InactiveUS20070163639A1Efficient and simplified creationIncrease contactMolten spray coatingFinal product manufactureNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of semiconductor precursor layer from chalcogenide particles

InactiveUS20080124831A1Efficient and simplified creationIncrease contactSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of nanostructured semiconductor precursor layer

InactiveUS20070163383A1Increase contactReduce the temperatureMolten spray coatingFinal product manufactureHigh fluxNanostructure

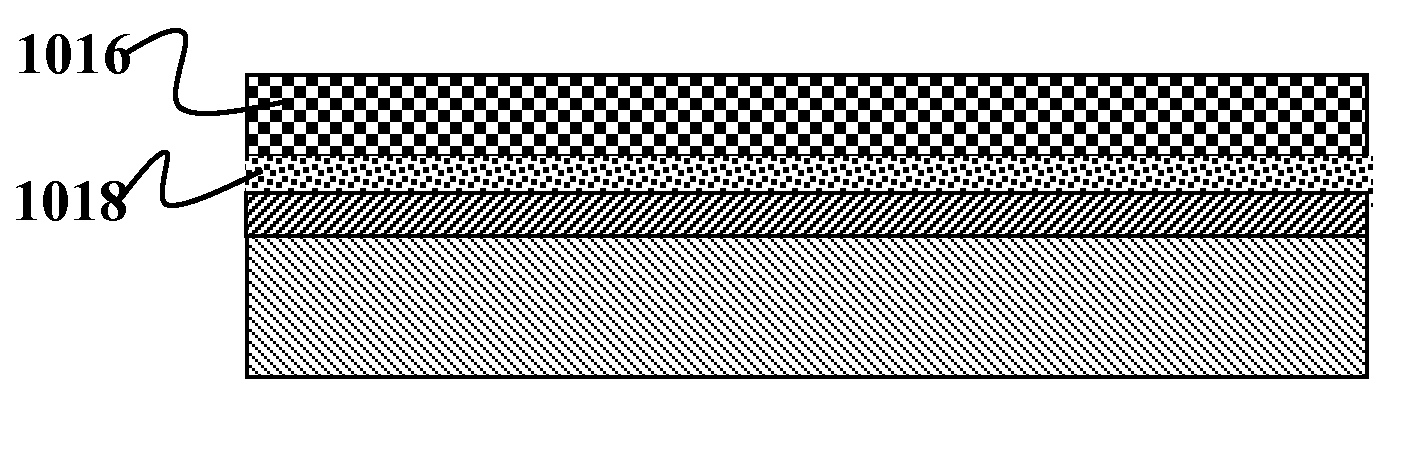

Materials and devices are provided for high-throughput printing of nanostructured semiconductor precursor layer. In one embodiment, a material is provided that comprises of a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA. The microflakes may be created by milling precursor particles characterized by a precursor composition that provides sufficient malleability to form a planar shape from a non-planar starting shape when milled, and wherein overall amounts of elements from Groups IB, IIIA and / or VIA contained in the precursor particles combined are at a desired stoichiometric ratio of the elements. It should also be understood that other flakes such as but not limited to nanoflakes may also be used to form the precursor material.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of semiconductor precursor layer from inter-metallic microflake particles

InactiveUS8329501B1Efficient and simplified creationIncrease contactMolten spray coatingTransportation and packagingNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes is particularly useful in forming photovoltaic devices. In one embodiment, at least one set of the particles in the ink may be inter-metallic flake particles (microflake or nanoflake) containing at least one group IB-IIIA inter-metallic alloy phase.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of semiconductor precursor layer from nanoflake particles

InactiveUS7700464B2Increase contactReduce the temperatureTransportation and packagingMetal-working apparatusNanoparticleHigh flux

Owner:AERIS CAPITAL SUSTAINABLE IP

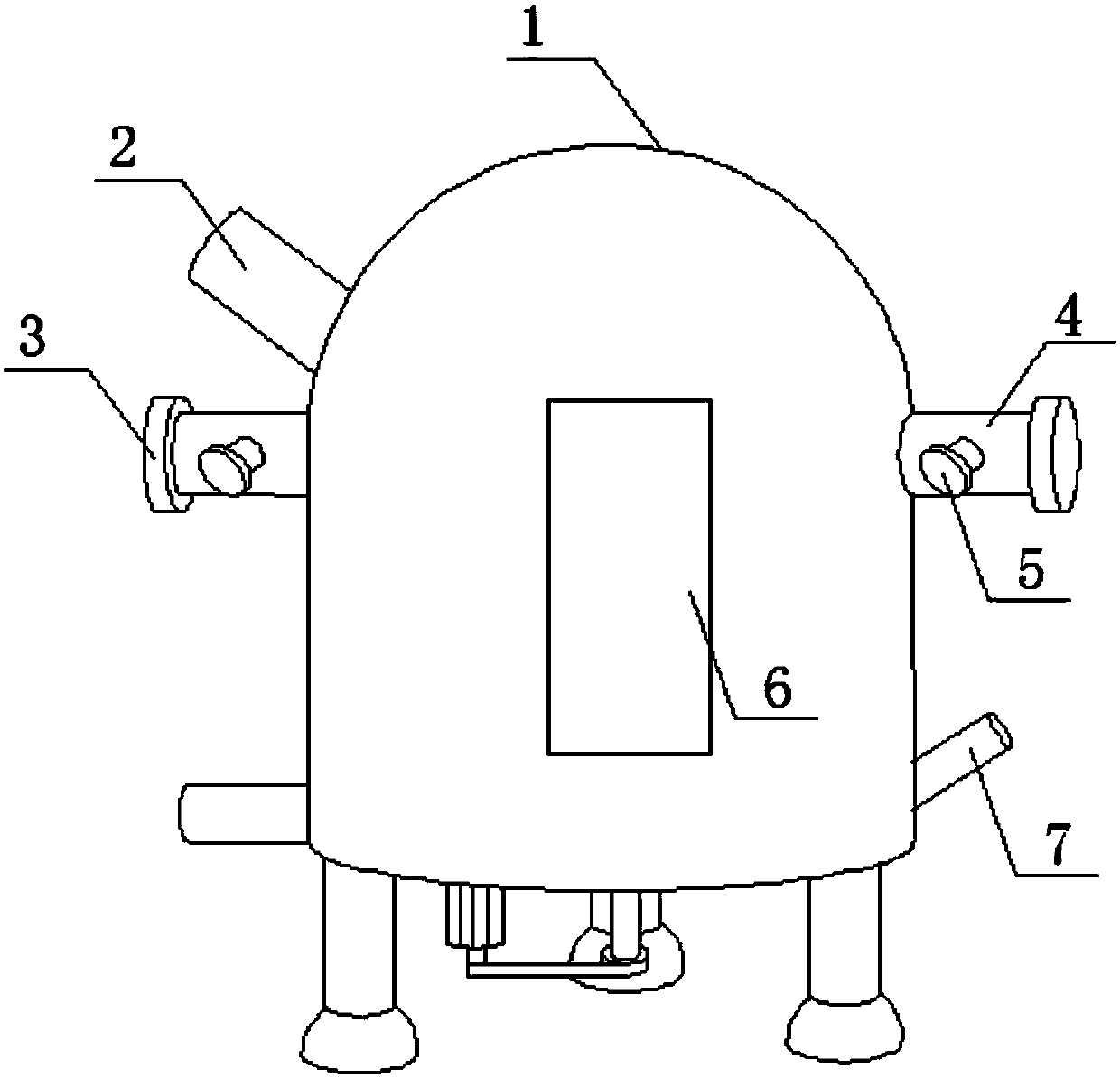

Desulfurization and denitrification method for tail gas, used equipment and product application thereof

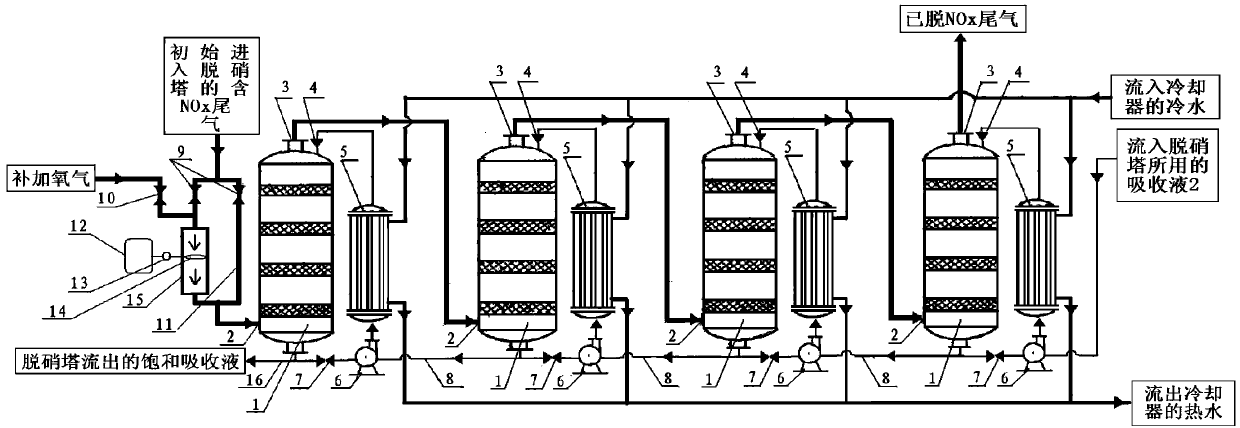

InactiveCN105080307AReduce material costsLow costOther chemical processesDispersed particle separationCorrosion preventionChemistry

The present invention discloses a desulfurization and denitrification method for tail gas, used equipment and product application thereof. According to the method provided by the present invention, an oxidative catalyst is not used in a desulfurization column or a denitration column, or a small amount of the oxidative catalyst with a simplified formula added is used outside the desulfurization column and the denitration column, so that the cost is reduced significantly. The oxidative catalyst is not used in the desulfurization column or the denitration column to avoid the severe corrosion of the desulfurization column and denitration column texture by the material, so that the texture cost of the desulfurization column and the denitration column is reduced significantly; The volume of the processed material is small: only 30%-10% of the material in volume in the desulfurization column and the denitration column, and the cost for equipment corrosion prevention is lowered, so that a small amount of the oxidative catalyst used and a simplified formula can be facilitated.

Owner:陈汇宏 +2

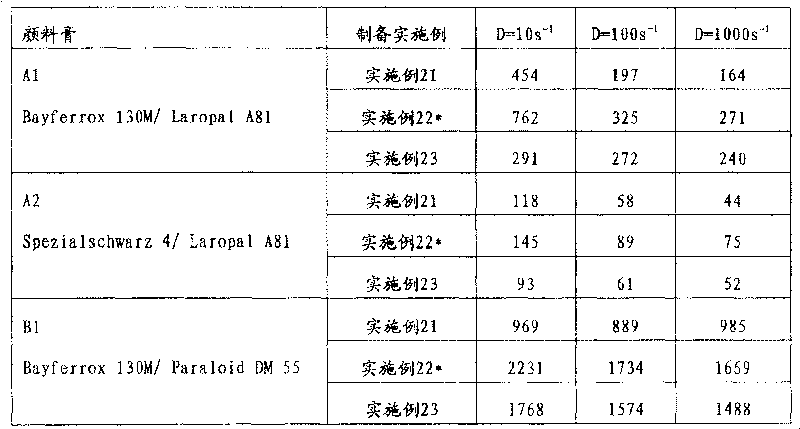

Addition compositions suitable as dispersants and dispersion stabilizers

ActiveCN1692975AIncreased process reliabilitySmall shrinkageTransportation and packagingOrganic dyesOrganic chemistryAmino radical

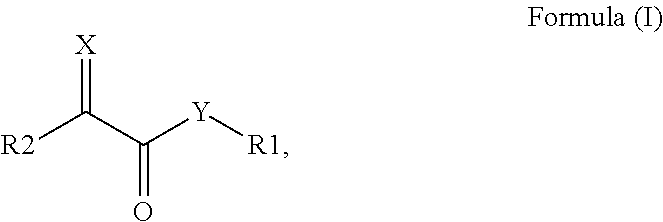

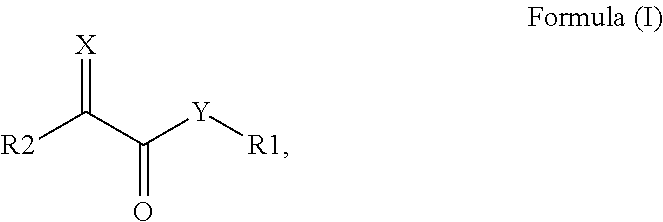

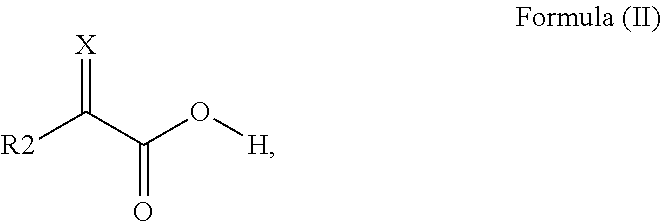

The invention relates to addition compounds which are obtainable by reacting a) one or more polyisocyanates containing uretdione groups with b) one or more compounds of the formula (I) where XH and Y is are defined in the specification, with the proviso that substantially all free isocyanate groups of component a) are reacted with the compounds of the formula (I) to give an intermediate which contains uretdione groups, and subsequently the uretdione groups are reacted with c) one or more compounds of the general formula (II) in which R and Z are given the meanings in the specification, if desired, after this reaction, reacting any reactive amino groups still present in the reaction - 56 - product with compounds that are reactive towards amino groups; and also salts or quaternization products of the addition compounds. The invention further relates to a process for preparing the addition compounds and to their use, particularly as dispersion stabilizers and dispersants.

Owner:BYK CHEM GMBH

High-Throughput Printing of Semiconductor Precursor Layer from Nanoflake Particles

InactiveUS20100267222A1Efficient and simplified creationIncrease contactTransportation and packagingFinal product manufactureNanoparticleParticle method

Methods and devices are provided for transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after selective forces settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be nanoflakes that have a high aspect ratio. The resulting dense films formed from nanoflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

High-throughput printing of nanostructured semiconductor precursor layer

InactiveUS20110092010A1Increase contactReduce the temperatureLiquid surface applicatorsMolten spray coatingNanostructureSemiconductor

Materials and devices are provided for high-throughput printing of nanostructured semiconductor precursor layer. In one embodiment, a material is provided that comprises of a plurality of microflakes having a material composition containing at least one element from Groups IB, IIIA, and / or VIA. The microflakes may be created by milling precursor particles characterized by a precursor composition that provides sufficient malleability to form a planar shape from a non-planar starting shape when milled, and wherein overall amounts of elements from Groups IB, IIIA and / or VIA contained in the precursor particles combined are at a desired stoichiometric ratio of the elements. It should also be understood that other flakes such as but not limited to nanoflakes may also be used to form the precursor material.

Owner:VAN DUREN JEROEN K J +2

Insoluble sulfur pre-dispersed rubber masterbatch and preparation method thereof

The invention discloses an insoluble sulfur pre-dispersed rubber masterbatch and a preparation method thereof. The preparation method comprises the following steps of: adding EVA (Ethylene-Vinyl Acetate) and a dispersing agent to a insoluble sulfur masterbatch composite formed by taking an ethylene-propylene diene copolymer and styrene butadiene rubber as colloids, and plasticating at 95-105 DEG C for 15-16 minutes; when the mooney viscosity reaches 23-26 and the surface temperature of plasticated rubber is 18-20 DEG C, adding insoluble sulfur IS7020 and naphthenic oil, and controlling the temperature at 59-63 DEG C; respectively knifing left and right for 4-6 times and 3-4 minutes every time, rolling for 4-6 times and the total time of 1-2 minutes, and tabletting and granulating to prepare the insoluble sulfur IS60-75 rubber masterbatch. Compared with the traditional product technology, the insoluble sulfur pre-dispersed rubber masterbatch disclosed by the invention has the advantage that raw materials of 38 micrometers are all sieved, is not adhered at room temperature without dust flying, can ensure the activity of IS by being pre-dispersed by using a rubber carrier, has very good compatibility with different rubbers, still has lower viscosity and low shearing rate at lower mixing temperature and is easy to disperse and automatically metered. According to the invention, the mixing speed is accelerated, and good dispersion and distribution can be realized within a short time.

Owner:朝阳明宇化工有限公司

High-throughput printing of semiconductor precursor layer from microflake particles

InactiveUS8846141B1Increase contactReduce the temperatureFinal product manufacturePretreated surfacesNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:AERIS CAPITAL SUSTAINABLE IP

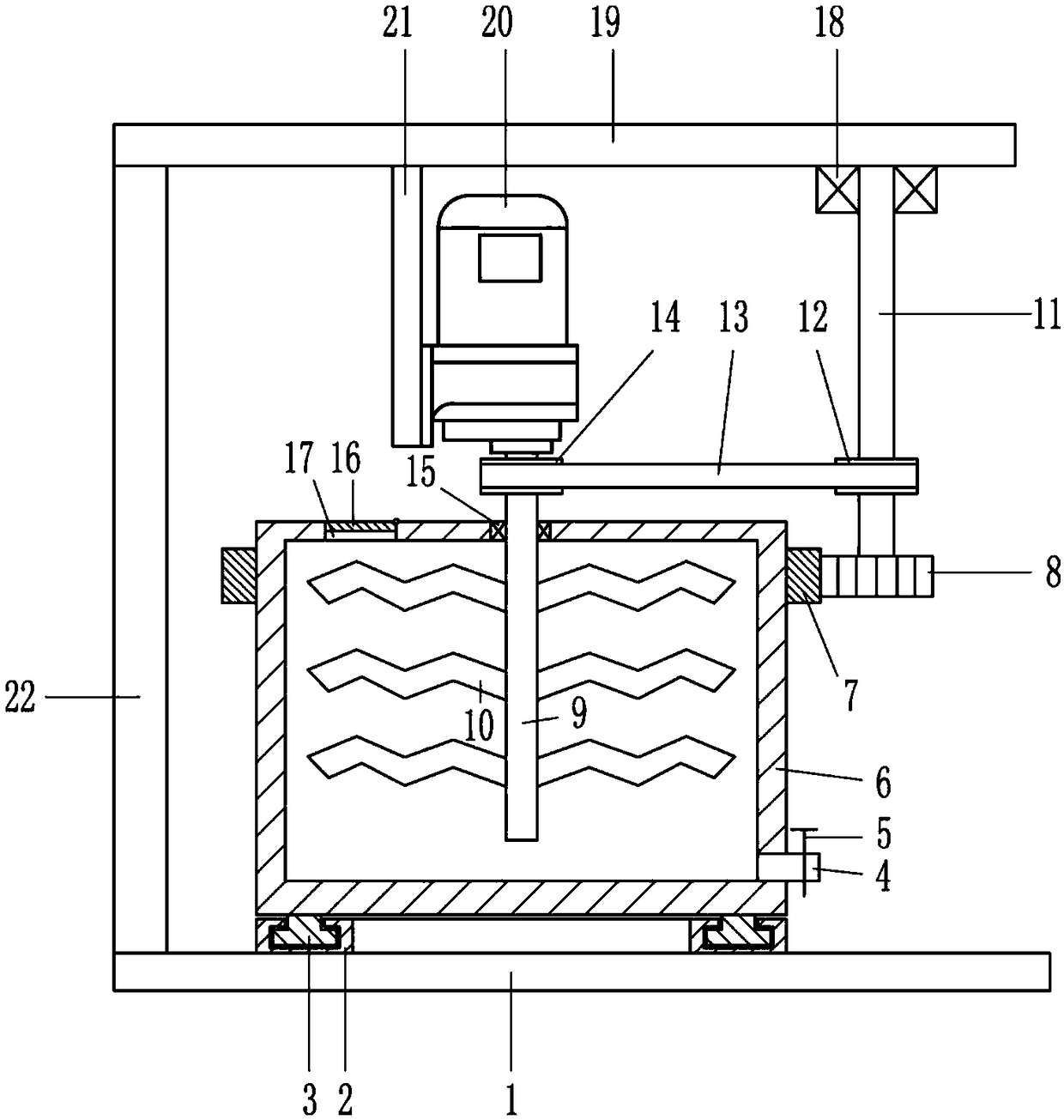

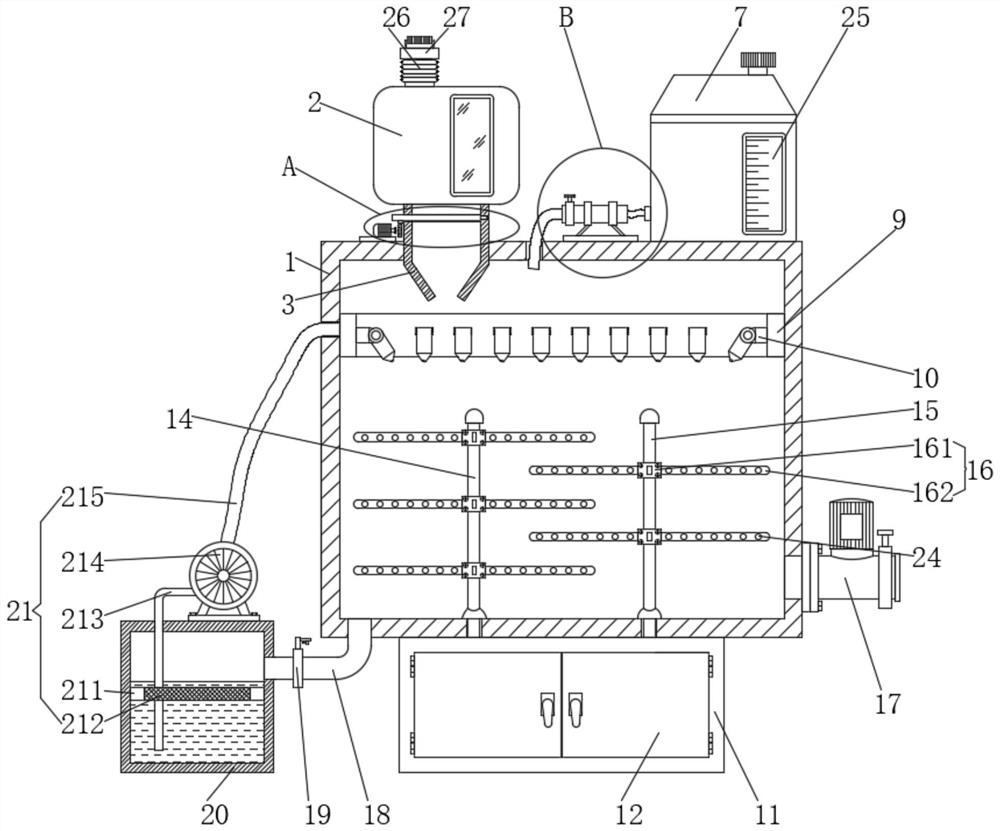

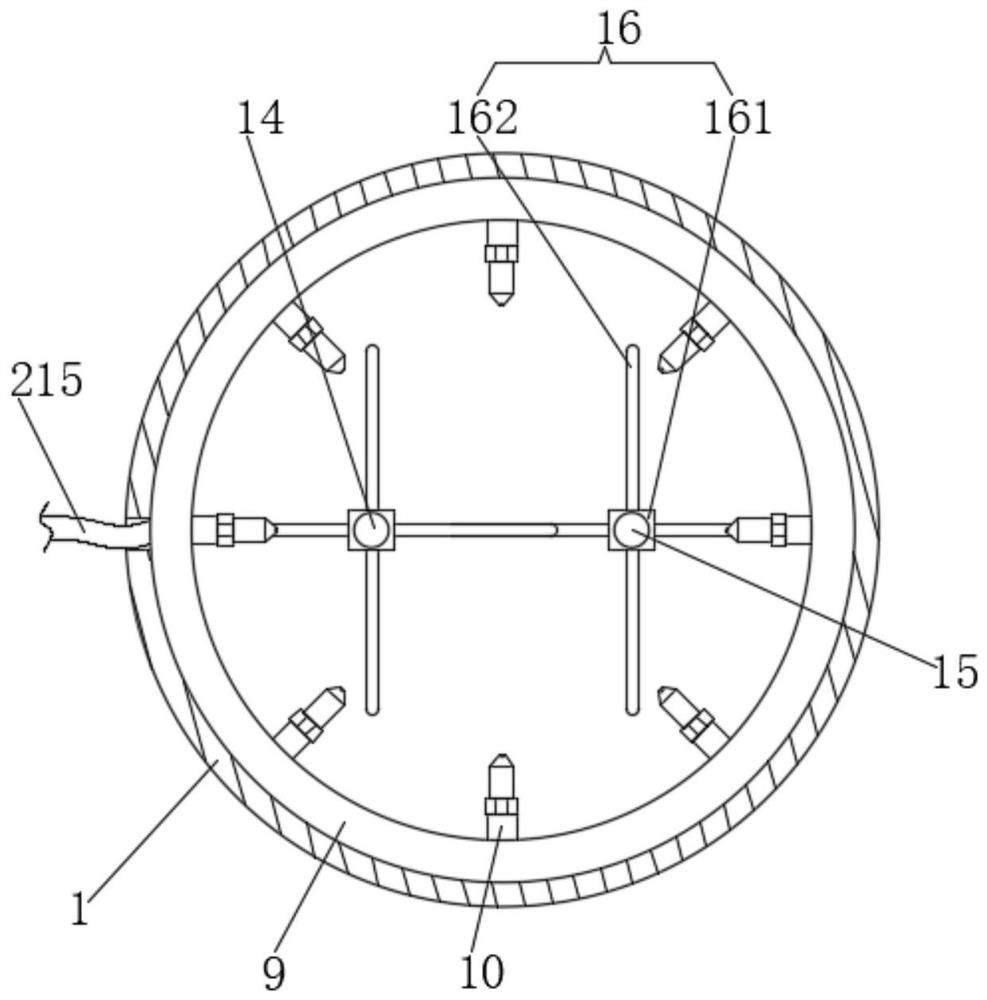

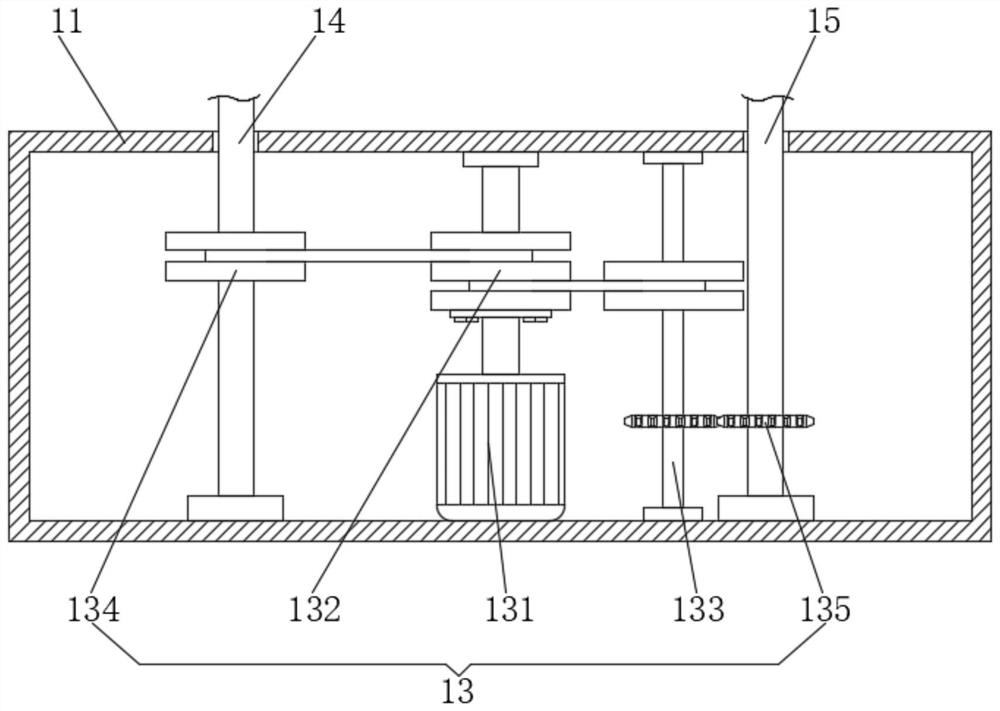

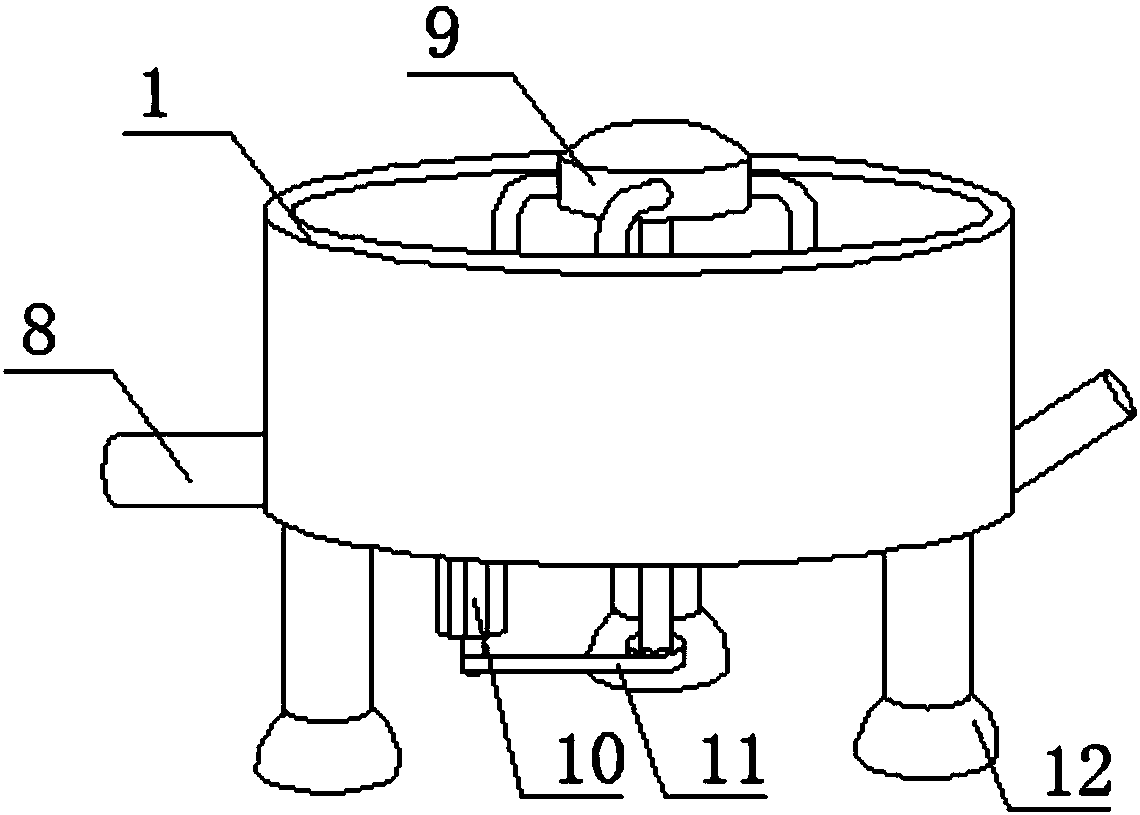

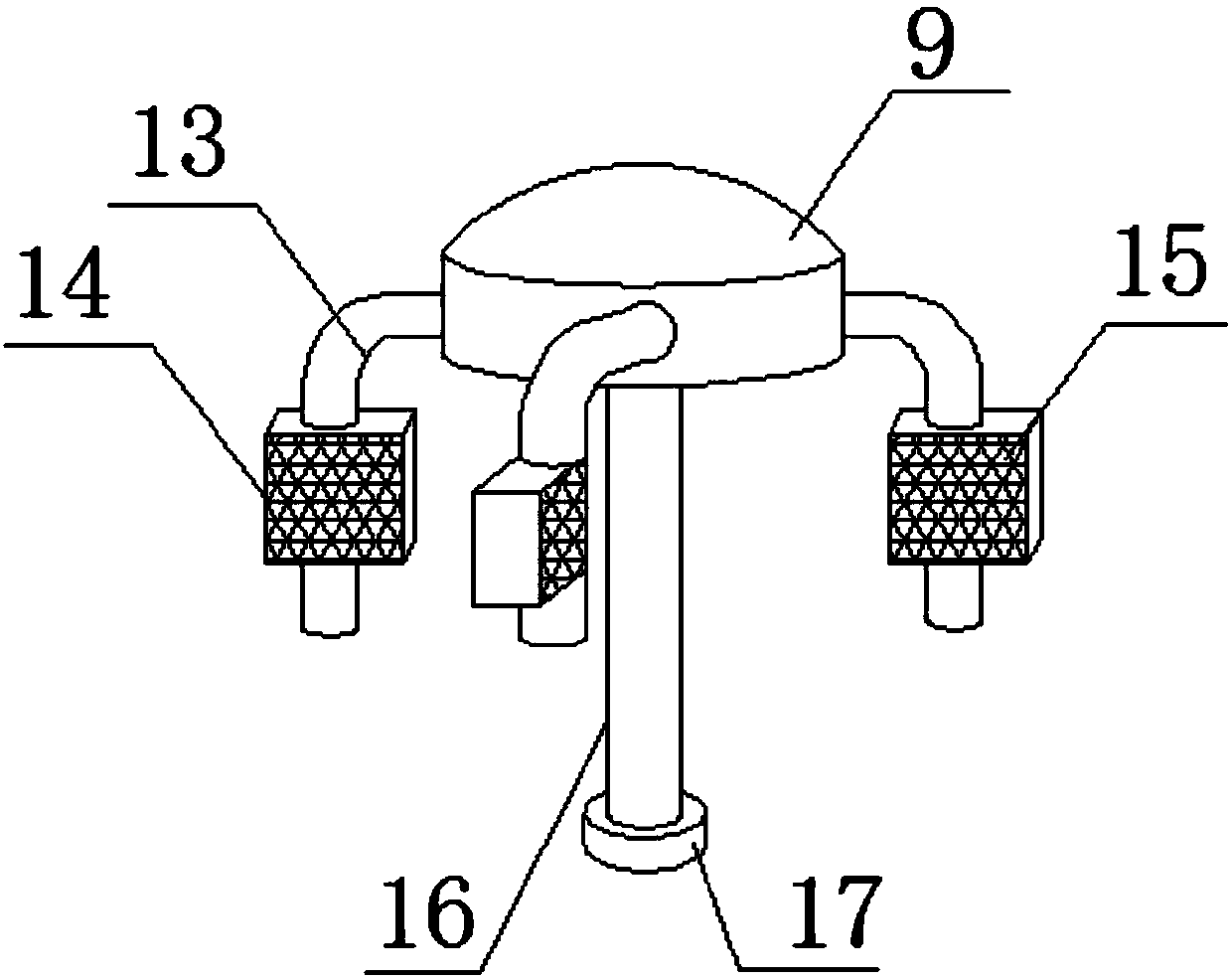

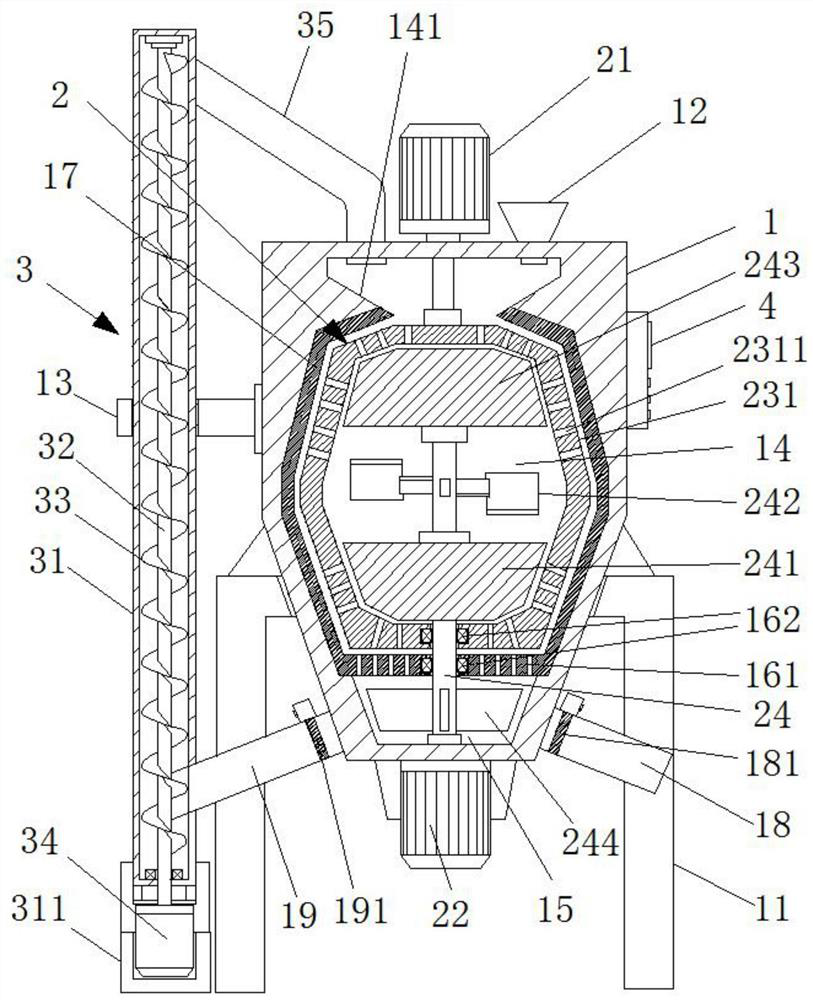

Dispersing and stirring apparatus for producing oil paint

PendingCN108854760AStir quicklyStir wellRotating receptacle mixersTransportation and packagingRapid mixingOil paint

The invention belongs to the field of production of oil paint, and particularly relates to a dispersing and stirring apparatus for producing oil paint. The invention aims at providing a dispersing andstirring apparatus, which can rapidly mix and stir the oil paint and can ensure the dispersing quality of the oil paint, for producing the oil paint. The dispersing and stirring apparatus for producing the oil paint comprises a first installation plate, annular slide rails, slide blocks, a stirring frame, an outer gear ring, a first gear, a stirring rod, first stirring blades, a third installation plate and a side plate; and the side plate is fixedly connected to one side part of the first installation plate, the annular slide rails are fixedly connected to the top of the first installation plate, the stirring frame is connected with the annular slide rails in a sliding manner by virtue of the slide blocks, and a discharging pipe is fixedly connected to one side part of the stirring frame. The dispersing and stirring apparatus for producing the oil paint has the beneficial effects that the oil paint production raw materials can be rapidly and uniformly stirred, the oil paint is not adhered to the inner wall of the stirring frame when being poured out, and the excessive surplus oil paint can be avoided.

Owner:毛学兰

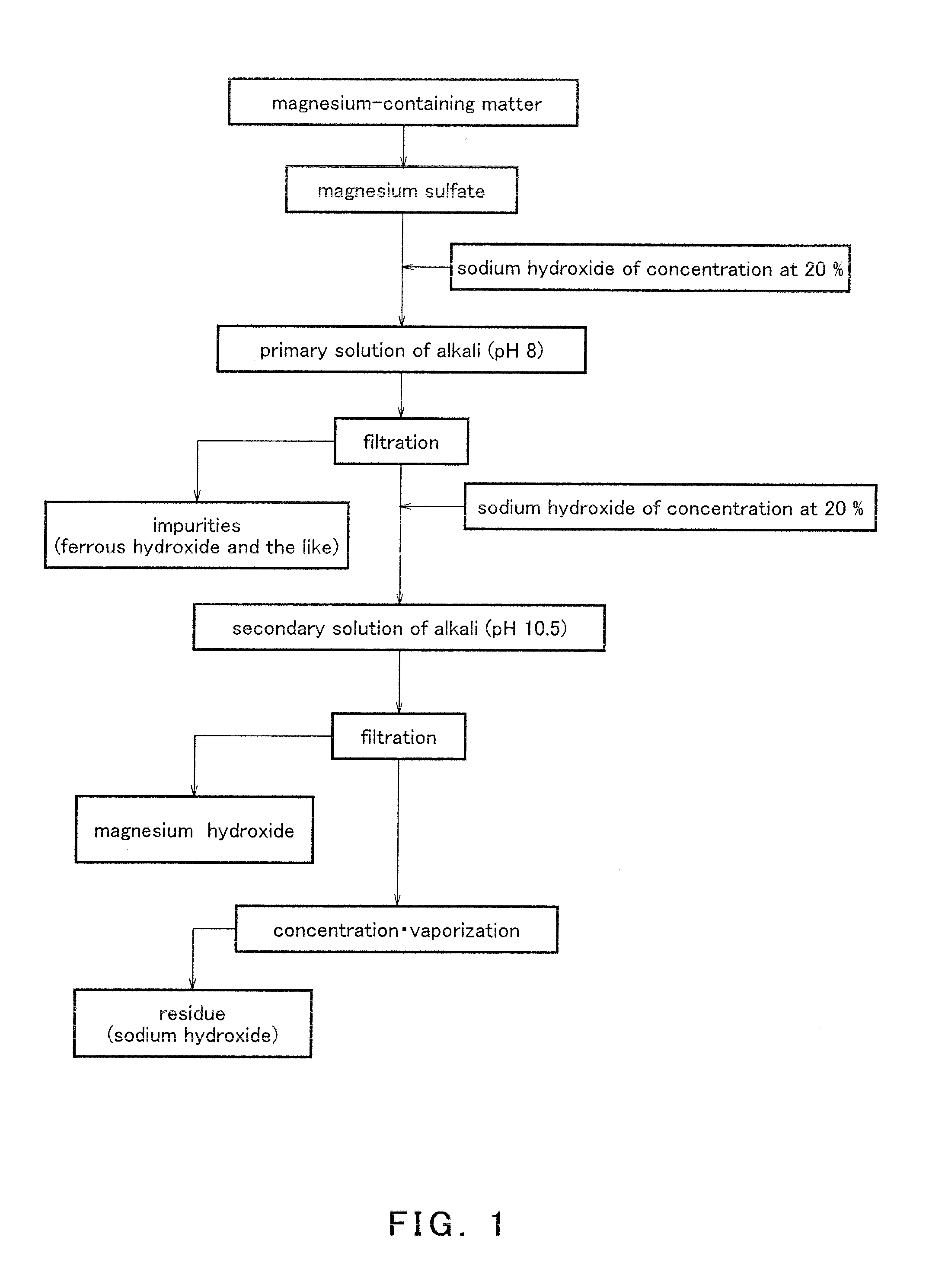

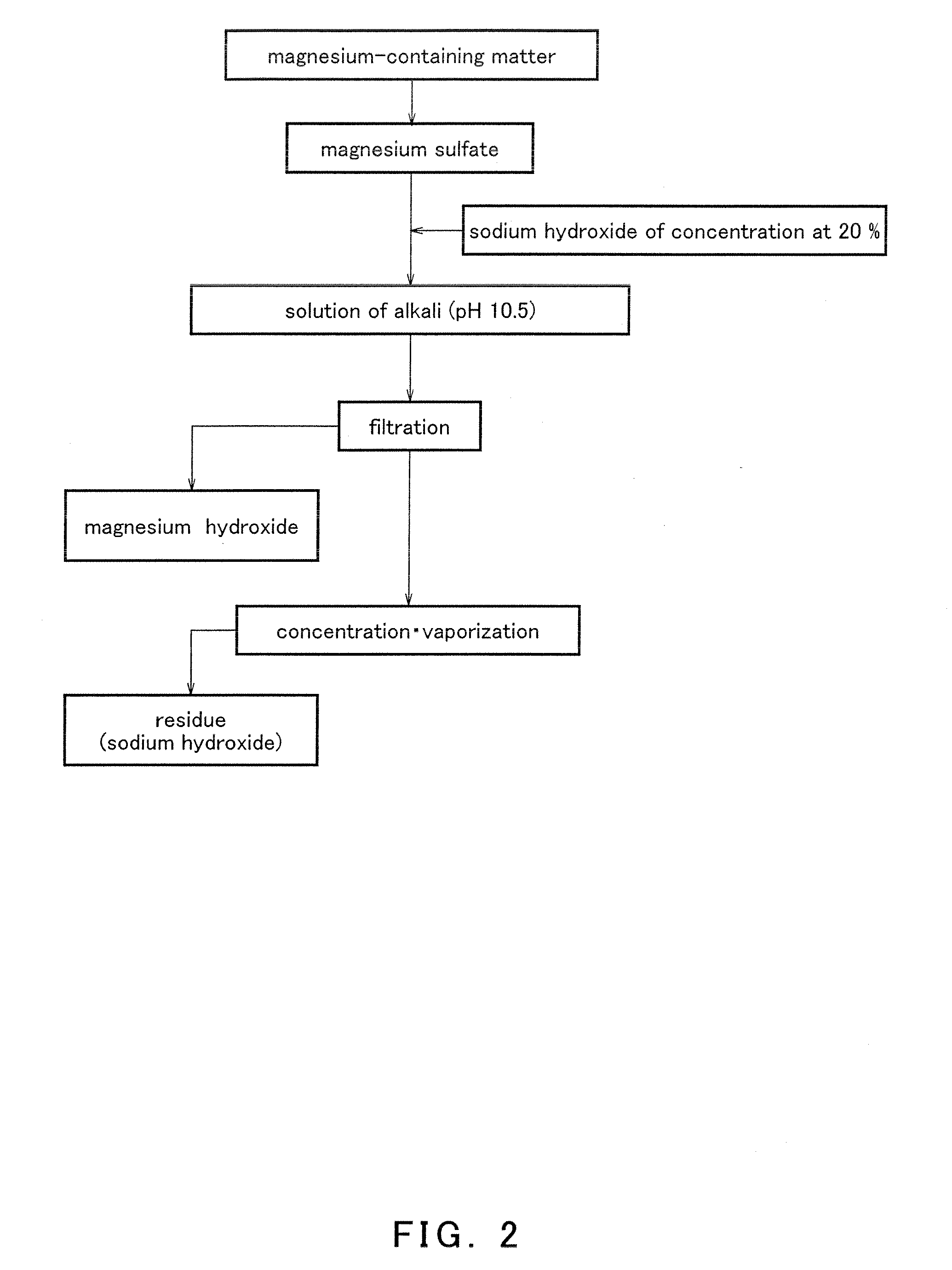

Magnesium hydroxide, method for producing magnesium hydroxide and a fire retardant comprising the magnesium hydroxide, and a fire-retarded resin composition containing the magnesium hydroxide

InactiveUS20100069555A1Large specific surface areaImprove dispersion qualityOxide/hydroxide preparationSynthetic resin layered productsAlkalinityHydroxide magnesium

Magnesium hydroxide having a large specific surface area is provided. A magnesium-containing matter is chemically decomposed by a solution of acid, and a primary solution of alkali with weak alkalinity is obtained by adding a solution of alkali to the solution of acid, and impurities contained in the primary solution of alkali are eliminated, and a secondary solution of alkali with strong alkalinity is obtained by adding a solution of alkali to the primary solution of alkali, and successively a magnesium hydroxide is deposited in secondary solution of alkali.

Owner:NOZAWA CORP

High-Throughput Printing of Semiconductor Precursor Layer From Microflake Particles

InactiveUS20090246906A1Increase contactReduce the temperatureMolten spray coatingFinal product manufactureNanoparticleParticle method

Methods and devices are provided for high-throughput printing of semiconductor precursor layer from microflake particles. In one embodiment, the method comprises of transforming non-planar or planar precursor materials in an appropriate vehicle under the appropriate conditions to create dispersions of planar particles with stoichiometric ratios of elements equal to that of the feedstock or precursor materials, even after settling. In particular, planar particles disperse more easily, form much denser coatings (or form coatings with more interparticle contact area), and anneal into fused, dense films at a lower temperature and / or time than their counterparts made from spherical nanoparticles. These planar particles may be microflakes that have a high aspect ratio. The resulting dense film formed from microflakes are particularly useful in forming photovoltaic devices.

Owner:ROBINSON MATTHEW R +2

Surface modified pigments and non-aqueous inks therewith

A method for preparing a surface modified organic pigment includes the steps of a) reacting the organic pigment in an aromatic hydrocarbon solvent with a surface modifying reagent to form a surface modified organic pigment; and b) washing and drying the surface modified organic pigment; wherein the surface modifying reagent is represented by Formula (I):wherein,X is selected from the group consisting of O, S and N—R3; Y is selected from the group consisting of —O and NR4; R1 to R4 are each independently selected from the group consisting of hydrogen, an alkyl group, an alkenyl group, an alkynyl group, a -aralkyl group, an alkaryl group, and an aryl group and s heteroaryl group; with the proviso that when Y—R1 is different from OH that at least one of R2 to R4 is substituted by at least one functional group having a pKa between 2.5 and 9.

Owner:AGFA NV

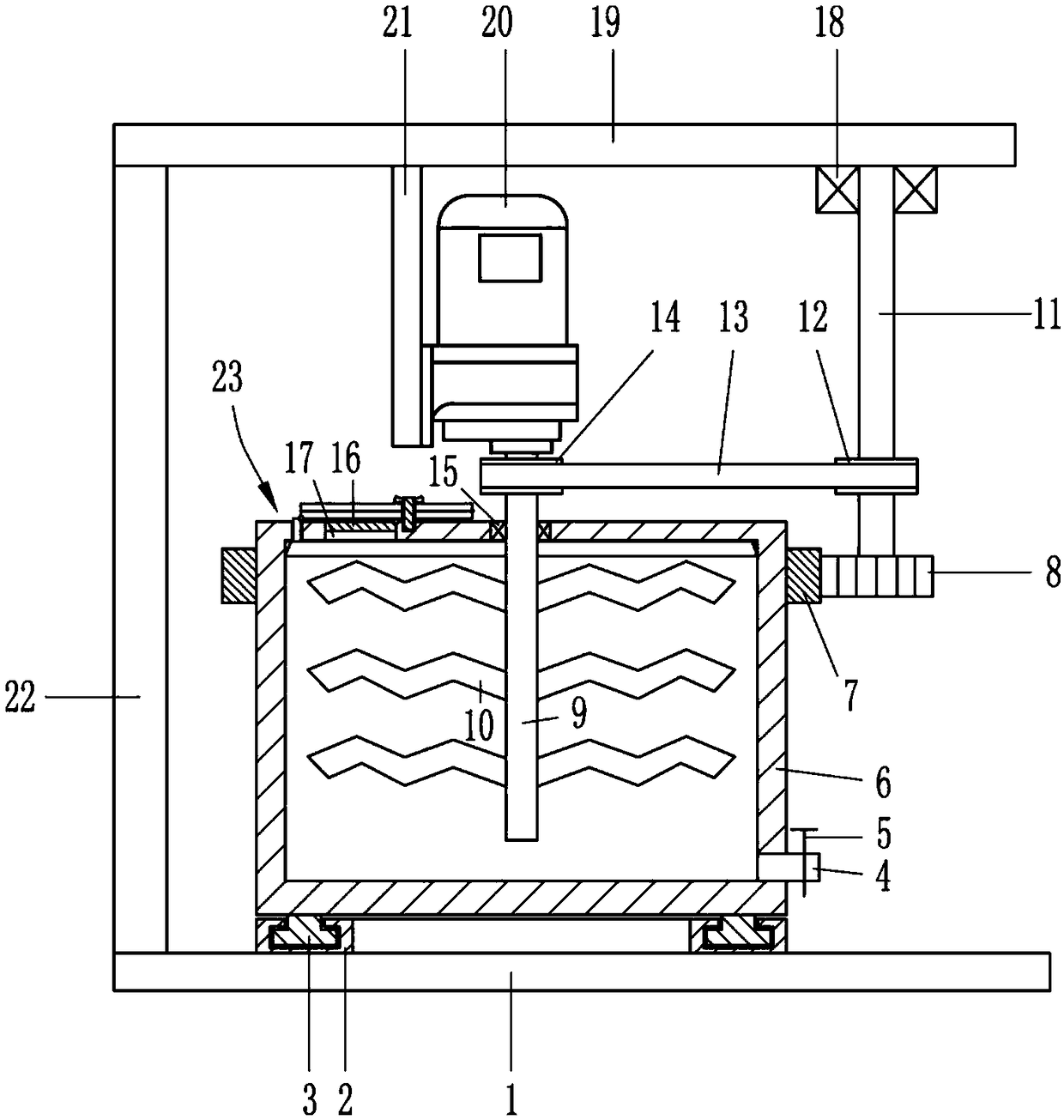

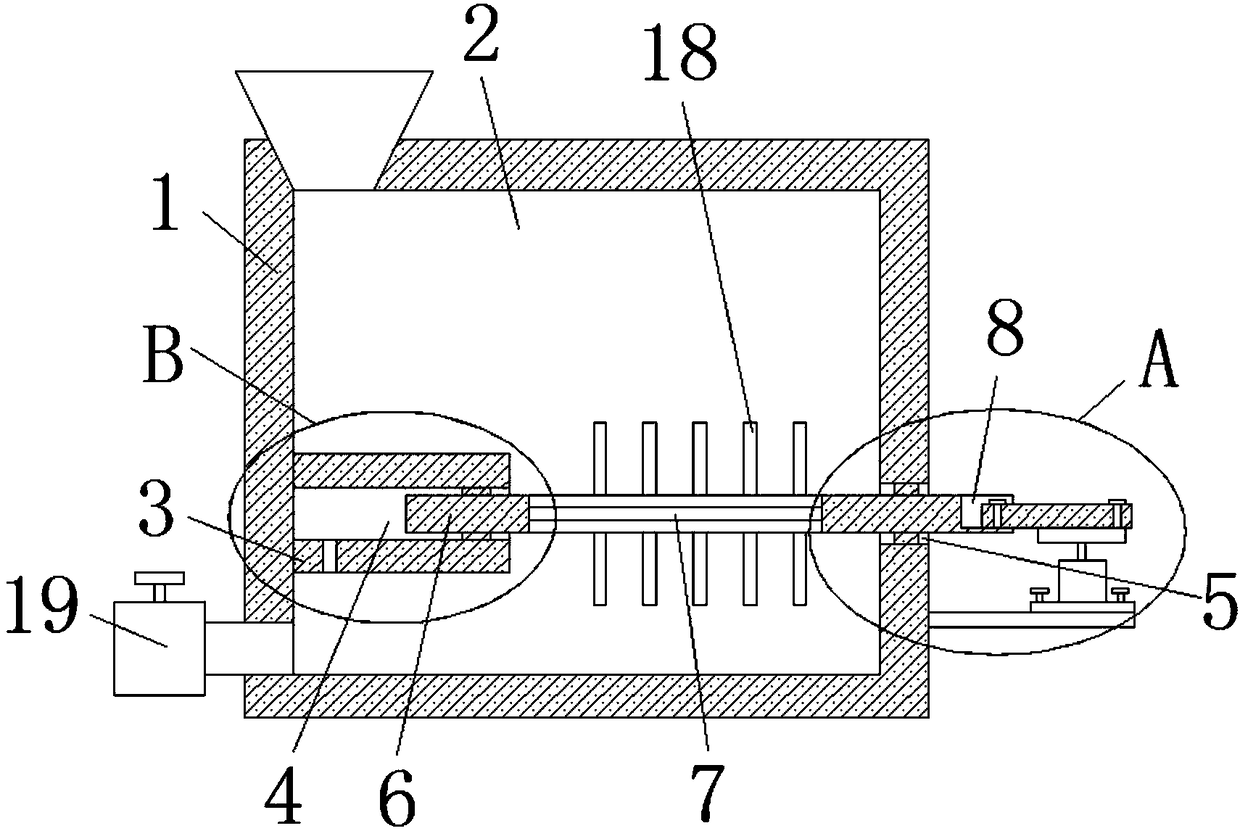

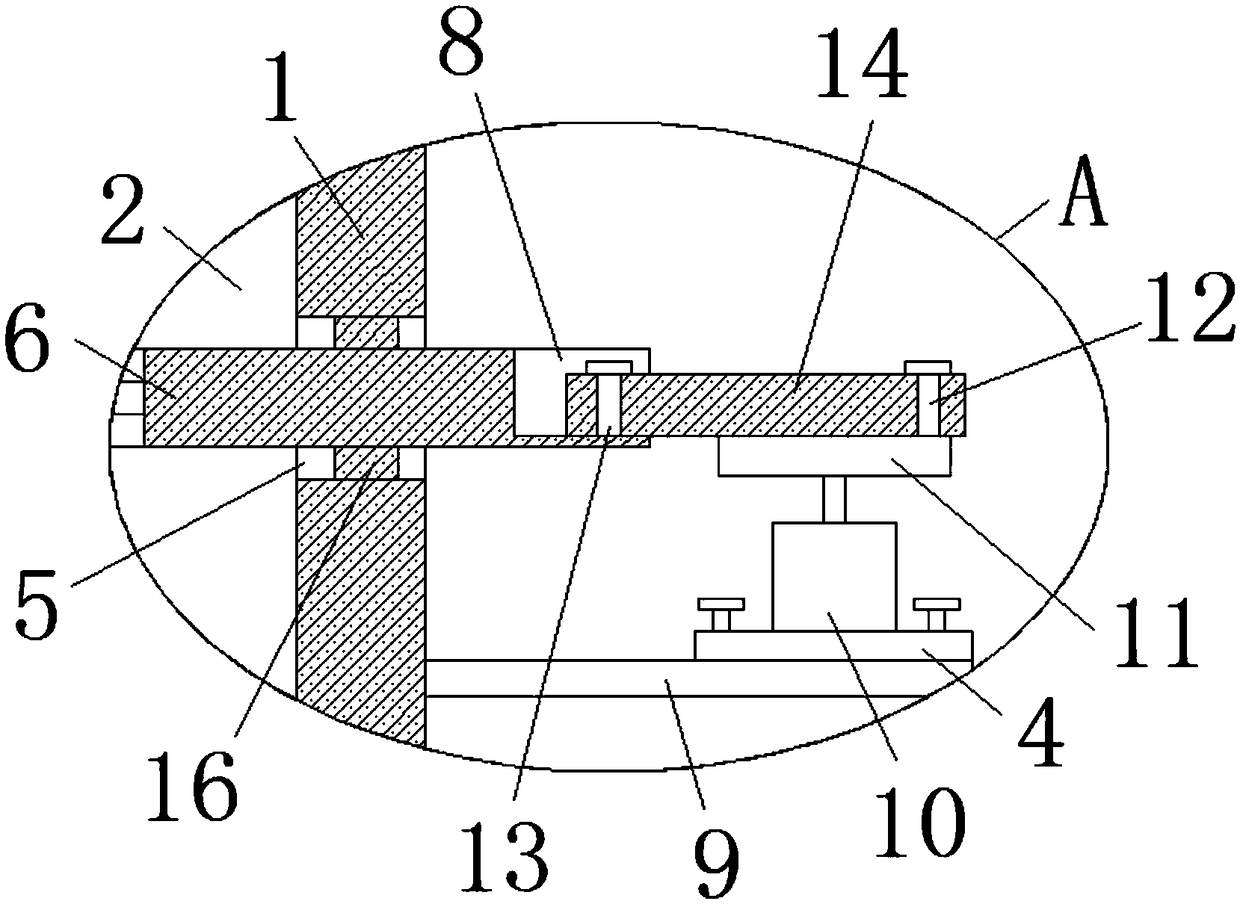

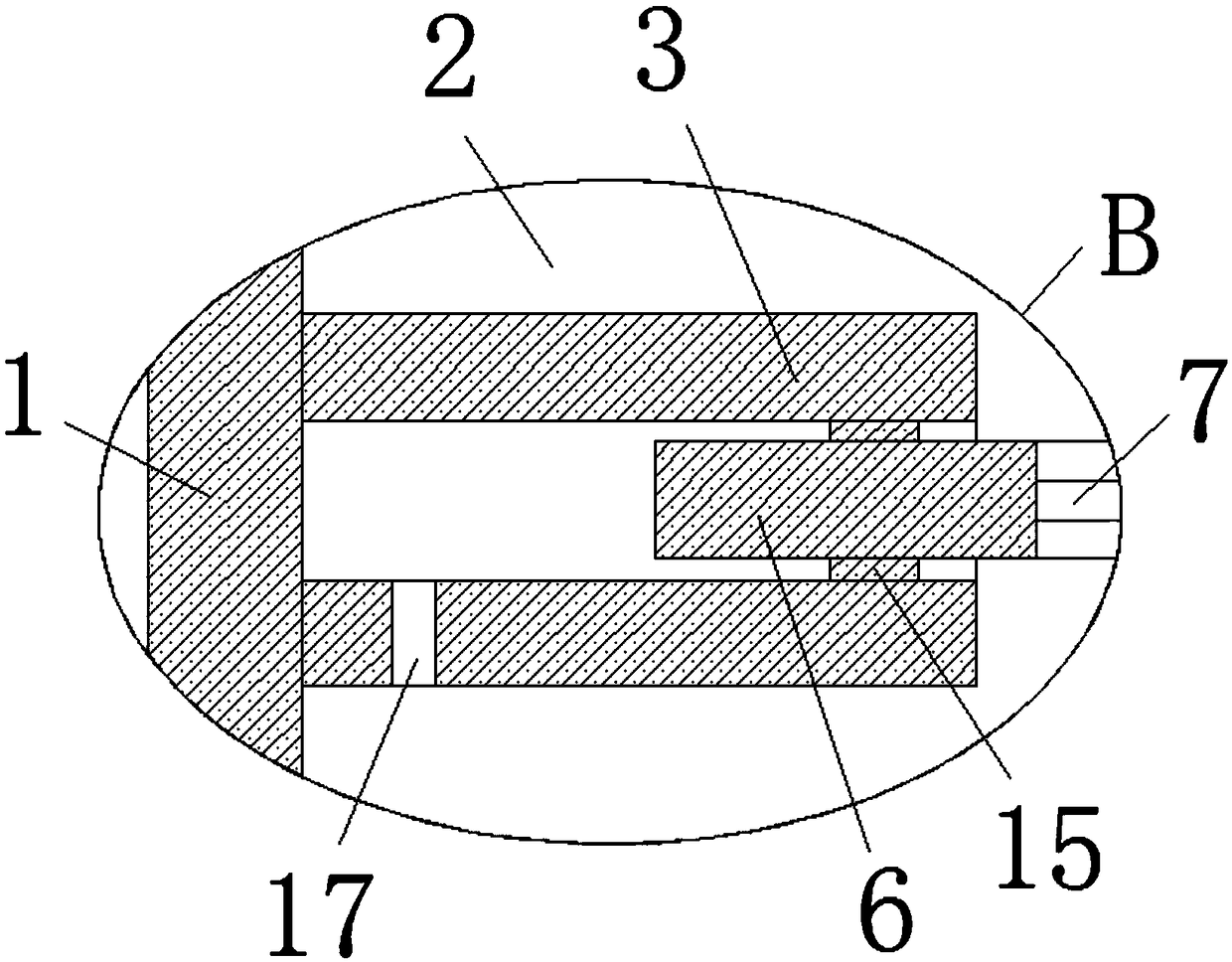

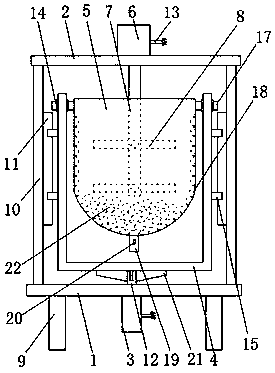

Efficient-dispersion coating dispersing device for coating production

InactiveCN112546900AImprove dispersion qualityControl ratioRotary stirring mixersTransportation and packagingManufacturing engineeringCoating

The invention relates to the technical field of coating production, in particular to an efficient-dispersion coating dispersing device for coating production. The device comprises a box body, a storage barrel is arranged on the left side of the upper part of the box body, the bottom of the storage barrel is communicated with a feeding pipe, the bottom of the feeding pipe penetrates through the boxbody and extends into the box body, the feeding pipe is in bolted connection with the inner wall of the box body, and a sliding groove is formed in the inner wall of the feeding pipe. Through the arrangement of a baffle, a transmission structure, a control structure, a power box, a linkage structure and a stirring structure, the device has the advantages that the ratio of filler to paint can be conveniently controlled, convenience is brought to an operator, dispersing operation in different directions can be conducted, and the dispersing quality is improved, and the problem that existing dispersing devices cannot conveniently adjust and control the ratio of filler to paint, most of existing dispersing devices conduct unidirectional dispersion mixing operation, so that the dispersing effect of the produced paint is poor is solved.

Owner:MAANSHAN JINHAN PAINT MFG

Mixing device of dyestuffs for clothing fabrics

InactiveCN107596953AWell mixedGood dispersionTransportation and packagingRotary stirring mixersTransmission beltEngineering

The invention discloses a mixing device of dyestuffs for clothing fabrics. The mixing device comprises a loading tank, a charging pipe, draught fans, air inlet pipes, adjusting bolts, an observation window, a water feeding pipe, a liquid discharging pipe, a connector, a first motor, a transmission belt, supporting legs, mounting rods, baffle plates, mesh holes, a rotary rod, a belt wheel, filtering screens, a second motor, a receiving hopper, wind direction plates and rotary shafts. The mixing device disclosed by the invention has the beneficial effects that the two filtering screens and the two air inlet pipes are mounted in the loading tank so that when the dyestuffs fall off from the upper part in a working process, the two filtering screens can be used for dispersing and stirring the dyestuffs. The wind direction plates and the rotary shafts in the air inlet pipes can be used for adjusting the direction of wind entering the filling tank according to actual requirements in the working process and various wind directions can be selected according to different amounts of the dyestuffs, so that the dispersion and mixing effect of the dyestuffs is better. The device disclosed by theinvention is convenient to use and the speed of dispersing and mixing the dyestuffs can be increased; the quality of dispersing the dyestuffs can be improved and the fabrics are more uniformly rendered.

Owner:响水岛寅服饰有限公司

Pre-dispersing masterbatch for rubber accelerator ETU (N,N-ethylene thiourea) and preparation method of pre-dispersing masterbatch

The invention discloses pre-dispersing masterbatch for an rubber accelerator ETU (N,N-ethylene thiourea) and a preparation method of the pre-dispersing masterbatch. The pre-dispersing masterbatch comprises components in parts by weight as follows: 72-82 parts of ETU, 8-16 parts of rubber carriers, 2-4 parts of EVA (ethylene vinyl acetate copolymer) resin, 1-3 parts of epoxidized methyl acetorieinoleate, 2-4 parts of saturated fatty acid zinc, 1-8 parts of naphthenic oil and 1-3 parts of color masterbatch. The pre-dispersing masterbatch for the rubber accelerator ETU is convenient to store, transport and weigh, the preparation method of the pre-dispersing masterbatch is simple and high in operability, original activity of ETU can be guaranteed, the problems that ETU is prone to agglomeration and is non-uniform in dispersion when directly put into rubber for mixing are solved, the problem of ETU dust pollution can be solved, and the health problem of an operator caused by inhalation of ETU dust is solved; besides, the masterbatch is colored, so that material identification and management are facilitated, mistaken charging caused by the operator during feeding for follow-up rubber product mixing is avoided, and the application of the color masterbatch has no influence on colors of follow-up prepared rubber products.

Owner:NINGBO ACTMIX POLYMER

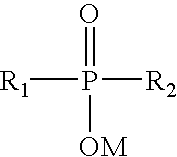

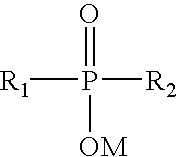

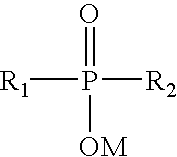

Particulate inorganic solids treated with organophosphinic compounds

ActiveUS7091262B2Good dispersionExcellent lacingPigmenting treatmentGroup 5/15 element organic compoundsCompound aParticulates

A treatment for particulate inorganic solids is provided. This treatment, which uses certain organophosphinic compounds, imparts improved physical and chemical qualities including lacing resistance, improved dispersion and decreased chemical reactivity when these treated particulate inorganic solids are incorporated into polymeric matrices. The addition of the organophosphinic compounds of the present invention may flexibly be incorporated into known processes at varying points, and are preferably added downstream of any filtering steps or to a dry particulate inorganic solid.

Owner:TRONOX LLC

Dye mixing device for garment processing

InactiveCN108514844AWell mixedImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingSlide plateEngineering

The invention discloses a dye mixing device for garment processing. The dye mixing device comprises a mixing tank, a cavity is formed in the mixing tank, two baffles are fixedly mounted on one inner wall of the cavity, a sliding plate is slidably mounted on one sides, close to each other, of the two baffles, a mounting hole is formed in the top of the sliding plate, a filter screen is fixedly mounted on the side wall of the mounting hole, a sliding hole is formed in the other inner wall of the cavity, one side of the sliding plate penetrates through the sliding hole and extends to one side ofthe mixing tank, the filter screen is located between the sliding hole and the baffles, a supporting plate is fixedly mounted at one side of the mixing tank, the supporting plate is located below thesliding hole, and a motor is mounted on the top of the supporting plate. The dye mixing device is reasonable in design, simple in structure and convenient to operate, the filter screen and stirring rods can be continuously vibrated, the filter screen can filter impurities in dye, the stirring rods make the dye mixing more uniform, and the mixing effect of the dye is improved.

Owner:湖州吴兴华溢服装厂

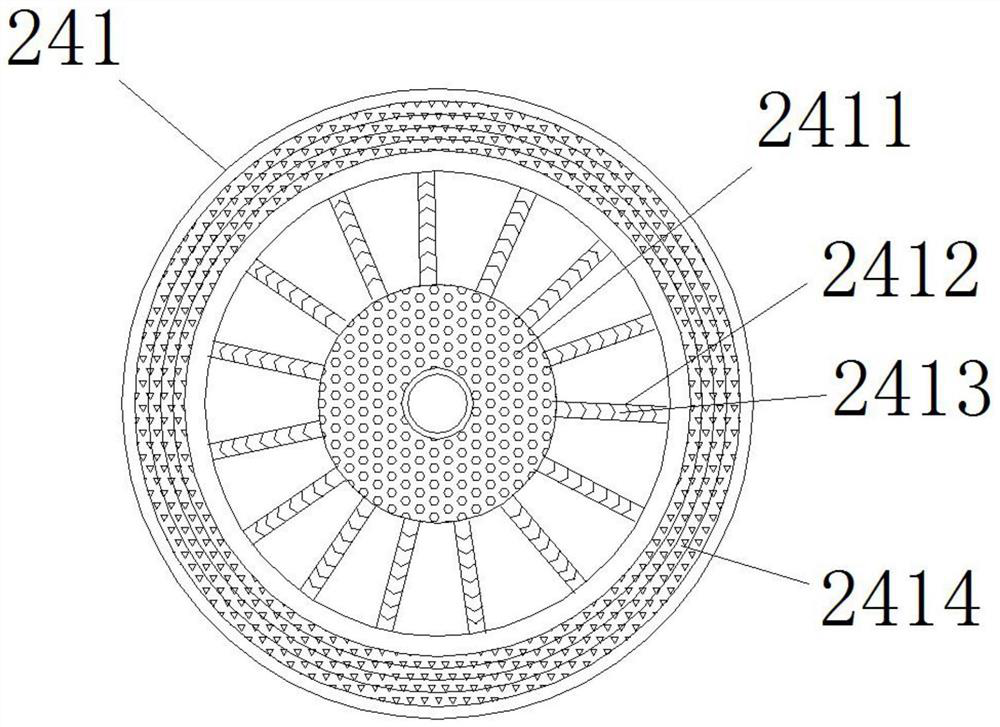

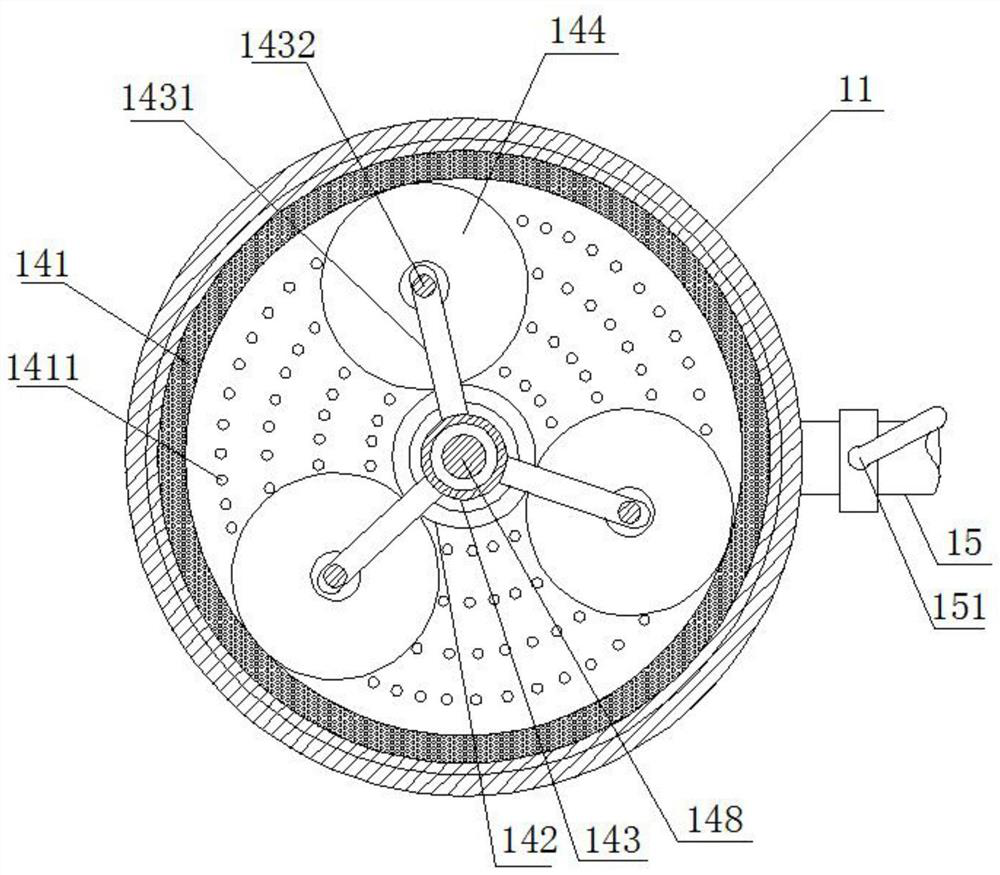

Efficient grinding disc type dispersion structure and method for carbon nanotube slurry production

ActiveCN112517141AFull dispersionEffective dispersionCocoaGrain treatmentsElectric machineryEngineering

The invention discloses an efficient grinding disc type dispersion structure for carbon nanotube slurry production. The efficient grinding disc type dispersion structure comprises a shell, a dispersion device and a lifting device, wherein the dispersion device comprises a first motor, a second motor, an upper rotating shaft and a lower rotating shaft; the first motor and the second motor are arranged at the top and the bottom of the shell respectively; an output shaft of the first motor is connected with the upper rotating shaft; the upper rotating shaft is connected with a grinding basket; through holes are formed in the top, the bottom and the side wall of the grinding basket; an output shaft of the second motor is connected with the lower rotating shaft; the lower rotating shaft perpendicularly penetrates through a grinding partition plate and the bottom of the grinding basket; pushing paddles, a lower grinding disc, shearing paddles and an upper grinding disc are sequentially arranged on the lower rotating shaft; the pushing paddles are positioned in a conveying cavity; the tail ends of the pushing paddles are attached to the side wall of the conveying cavity; the lower grinding disc, the shearing paddles and the upper grinding disc are all located in an inner cavity of the grinding basket; and the shearing paddles are located between the upper grinding disc and the lower grinding disc. According to the efficient grinding disc type dispersion structure, slurry can be fully dispersed, and agglomerated macromolecular particles can be effectively dispersed, so that the dispersion quality is improved.

Owner:HUBEI YUHAO HIGH-TECH NEW MATERIAL CO LTD

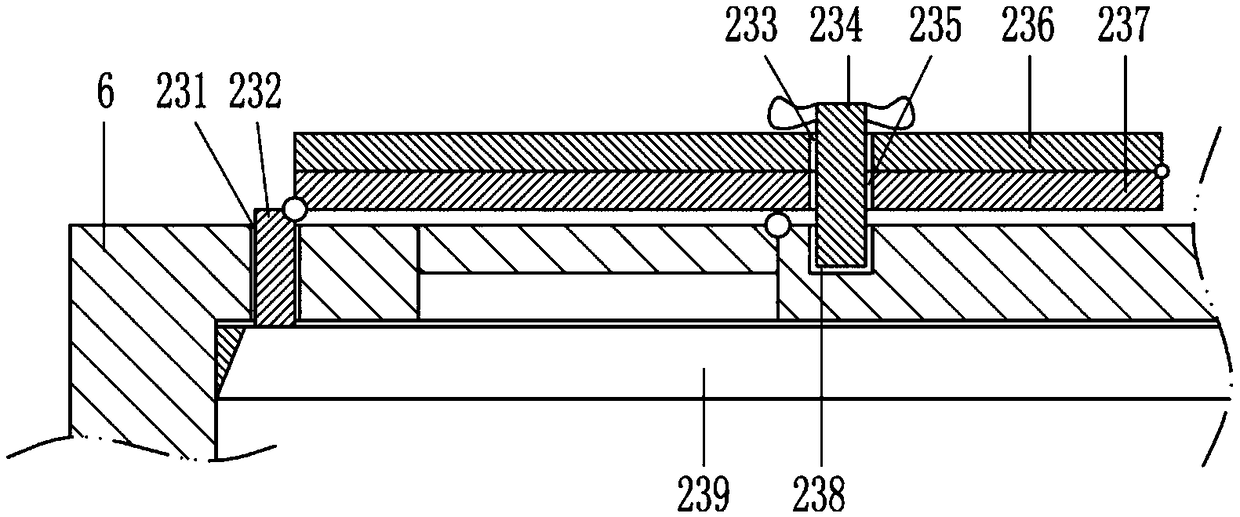

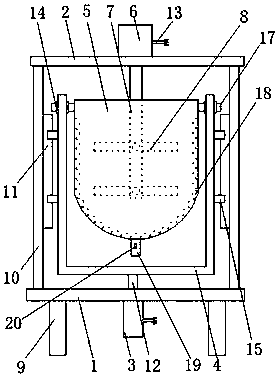

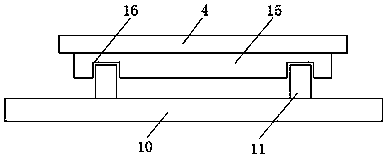

Dispersion equipment for coating production

InactiveCN108940055AImprove dispersion qualityQuality improvementShaking/oscillating/vibrating mixersTransportation and packagingBiochemical engineeringDrive shaft

The invention discloses dispersion equipment for coating production. The dispersion equipment comprises a bottom plate, a top plate, a cylinder, a bearing rack, a dispersion drum, a motor, a transmission shaft and a stirring rod. The dispersion equipment is characterized in that the bottom plate is arranged on a bracket; the top plate is arranged on a vertical plate; the cylinder is arranged on the bottom plate; the bearing rack is arranged on the piston rod; connecting rods are arranged on two sides of the dispersion drum, and are arranged in a bearing; the motor is arranged on the top plate,and is provided with a power cord; one end of the transmission shaft is connected with the motor, and the other end of the transmission shaft is arranged in the dispersion drum; and the stirring rodis arranged on the transmission shaft in the dispersion drum. According to the dispersion equipment, the dispersion drum has a structure of rotating on the bearing rack due to the arrangement of the connecting rods, so that coating in different positions in the dispersion drum can contact the stirring rod, and can be stirred and dispersed, and the dispersion efficiency of the coating is further improved.

Owner:周兆平

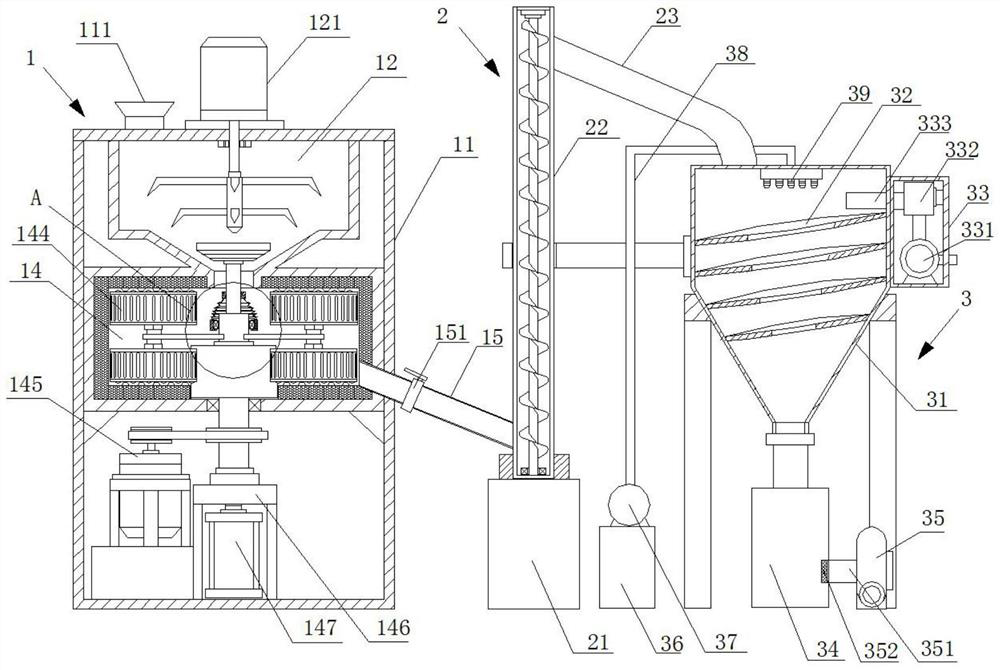

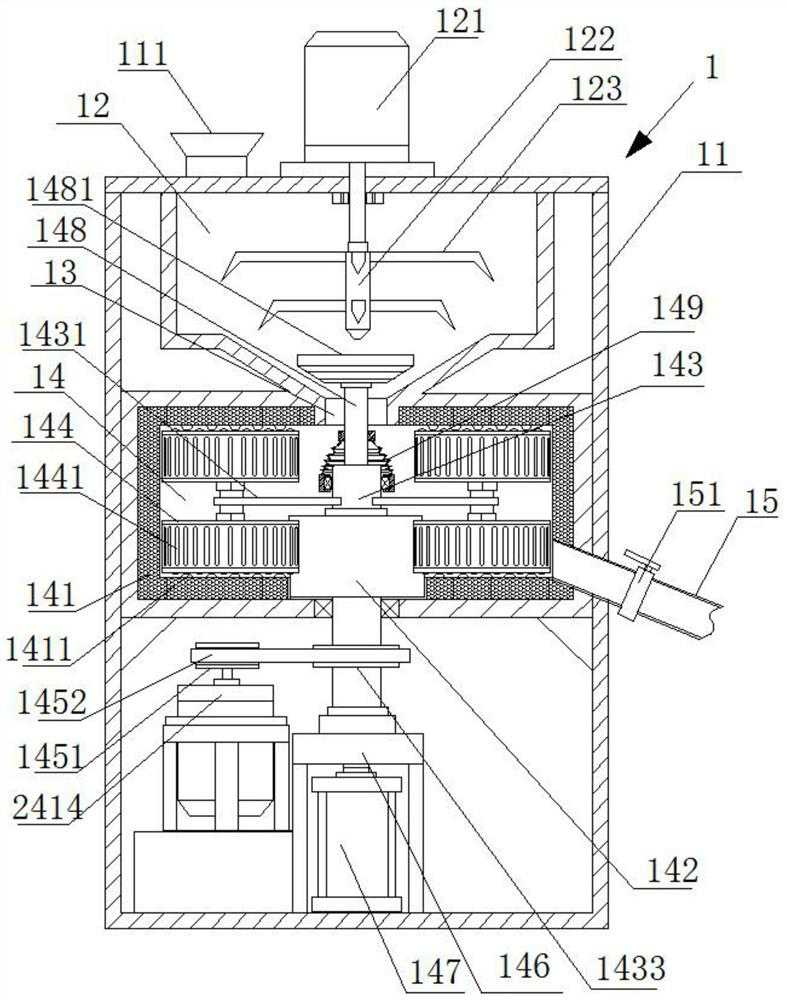

Graphene powder preparation system for carbon nanotube slurry preparation

ActiveCN112517188ADispersion will workImprove dispersion qualityTransportation and packagingRotary stirring mixersSlurryGraphene

The invention relates to a graphene powder preparation system for carbon nanotube slurry preparation. The graphene powder preparation system comprises a grinding device, a conveying device and a drying device, wherein the drying device comprises a drying cylinder and a water tank; the top of the drying cylinder is connected with a conveying pipe; the upper end of the inner wall of the drying cylinder is provided with guide plates; the guide plates are arranged in a spiral rising manner; a heating box is arranged on the side wall of the drying cylinder; an induced draft fan and an electric heater are arranged in the heating box; an air outlet pipe is arranged on an air outlet of the induced draft fan; the electric heater is arranged on the air outlet pipe; the other end of the air outlet pipe penetrates through the heating box and the drying cylinder and is located above the guide plates; the water tank is arranged on one side of the drying cylinder and provided with a water pump; the water pump is connected to the interior of the water tank through a pipeline; the output end of the water pump is connected with a water conveying pipe; one end of the water conveying pipe is connectedwith the top of the drying cylinder; and an atomization nozzle is connected to the top of the inner wall of the drying cylinder. Under the action of the guide plates, graphene powder rolls down alongthe guide plates, so that the drying time of the graphene powder is prolonged.

Owner:HUBEI YUHAO HIGH-TECH NEW MATERIAL CO LTD

Insoluble sulfur predispersed rubber masterbatch and preparation method thereof

The invention discloses an insoluble sulfur pre-dispersed rubber masterbatch and a preparation method thereof. The preparation method comprises the following steps of: adding EVA (Ethylene-Vinyl Acetate) and a dispersing agent to a insoluble sulfur masterbatch composite formed by taking an ethylene-propylene diene copolymer and styrene butadiene rubber as colloids, and plasticating at 95-105 DEG C for 15-16 minutes; when the mooney viscosity reaches 23-26 and the surface temperature of plasticated rubber is 18-20 DEG C, adding insoluble sulfur IS7020 and naphthenic oil, and controlling the temperature at 59-63 DEG C; respectively knifing left and right for 4-6 times and 3-4 minutes every time, rolling for 4-6 times and the total time of 1-2 minutes, and tabletting and granulating to prepare the insoluble sulfur IS60-75 rubber masterbatch. Compared with the traditional product technology, the insoluble sulfur pre-dispersed rubber masterbatch disclosed by the invention has the advantage that raw materials of 38 micrometers are all sieved, is not adhered at room temperature without dust flying, can ensure the activity of IS by being pre-dispersed by using a rubber carrier, has very good compatibility with different rubbers, still has lower viscosity and low shearing rate at lower mixing temperature and is easy to disperse and automatically metered. According to the invention, the mixing speed is accelerated, and good dispersion and distribution can be realized within a short time.

Owner:朝阳明宇化工有限公司

Addition compositions suitable as dispersants and dispersion stabilizers

ActiveCN1692980BIncreased process reliabilitySmall shrinkageTransportation and packagingOrganic dyesPolymer scienceComposite material

The invention relates to addition compounds which are obtainable by reacting a) one or more polyisocyanates containing uretdione groups with b) one or more compounds of the formula (I) where XH and Yis are defined in the specification, with the proviso that substantially all free isocyanate groups of component a) are reacted with the compounds of the formula (I) to give an intermediate which contains uretdione groups, and subsequently the uretdione groups are reacted with c) one or more compounds of the general formula (II) in which R and Z are given the meanings in the specification, if desired, after this reaction, reacting any reactive amino groups still present in the reaction - 56 - product with compounds that are reactive towards amino groups; and also salts or quaternization products of the addition compounds. The invention further relates to a process for preparing the addition compounds and to their use, particularly as dispersion stabilizers and dispersants.

Owner:BYK CHEM GMBH

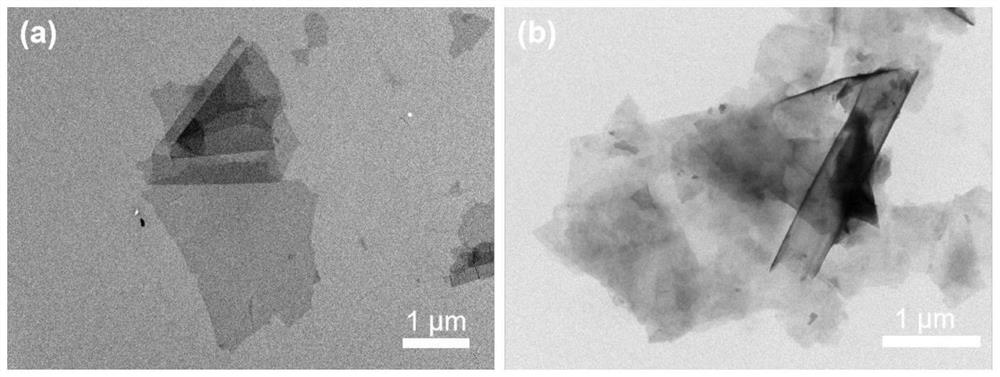

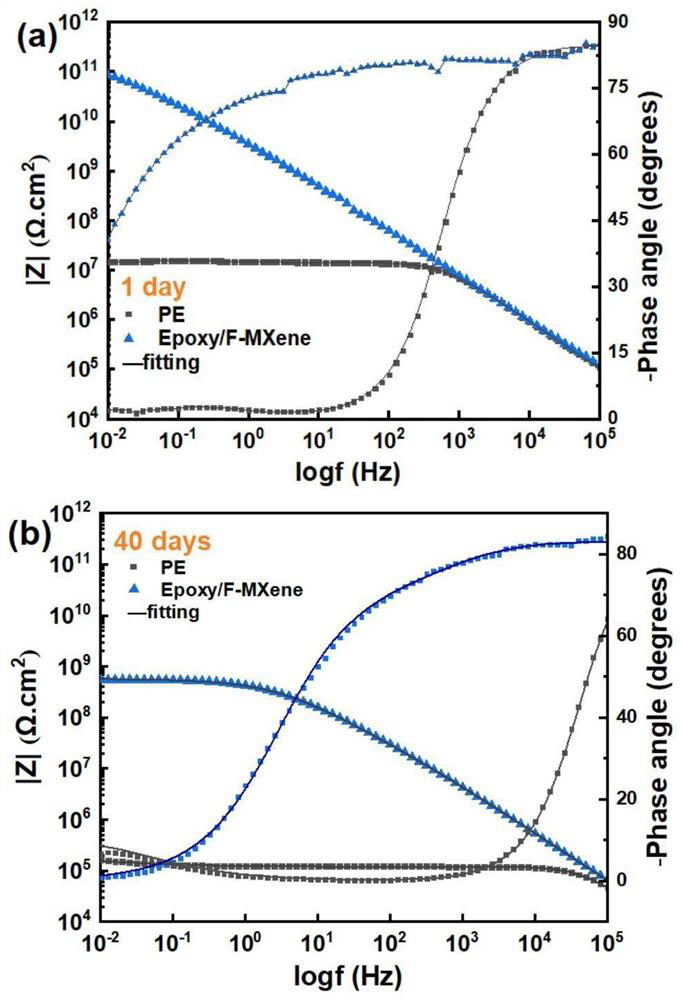

Method for inhibiting oxidation of MXene nano material and application of MXene nano material in anticorrosive paint

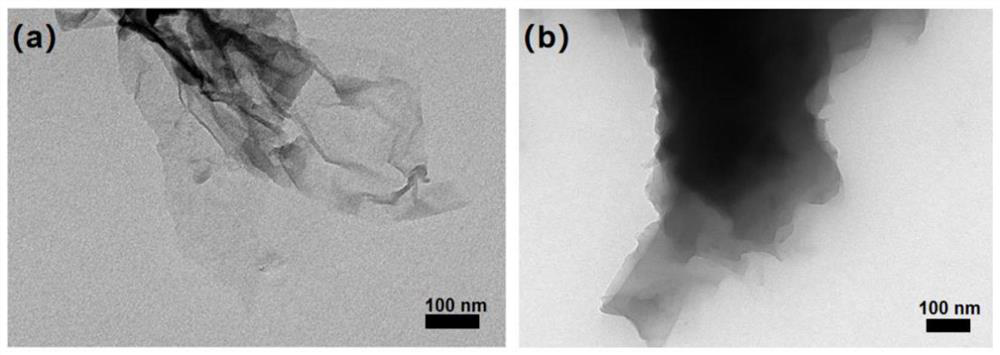

ActiveCN114854237AImprove oxidationGuaranteed chemical stabilityAnti-corrosive paintsPolymer coatingsGraphite

The invention relates to an anti-corrosion nano-filler, in particular to a method for inhibiting oxidation of an MXene nano-material and application of an obtained stable material serving as the anti-corrosion nano-filler in a polymer coating. A protective layer is formed on the surface of the MXene nanosheet, so that the complete two-dimensional sheet structure of the MXene nanomaterial is maintained, and oxidation is inhibited. The obtained non-oxidation MXene nanosheet with a defect-free and sheet-shaped structure is used as an anti-corrosion nano filler in a polymer coating so as to develop a long-term anti-corrosion coating on a metal structure. Therefore, oxidation of the MXene nanosheets is inhibited through covalent functionalization with alkoxy silane or hybridization with the graphene-based nanomaterial, and meanwhile, the dispersion quality of the MXene nanosheets in a polymer matrix is improved. The modified MXene-based nanosheet is used as a nanofiller in a polymer coating, and can exert long-acting corrosion resistance in a polymer matrix.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com