Method for inhibiting oxidation of MXene nano material and application of MXene nano material in anticorrosive paint

A nanomaterial and nanosheet technology, applied in anti-corrosion coatings and other directions, can solve problems such as weakening and affecting material properties, and achieve the effect of preventing oxidation and degradation and improving oxidation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

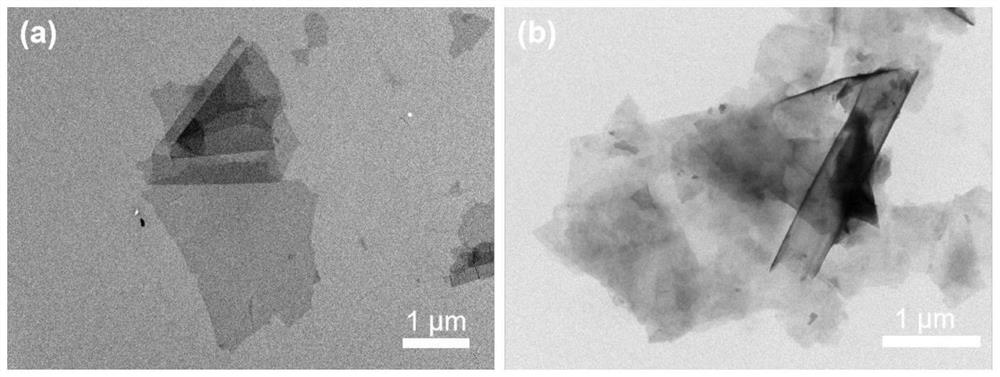

[0043] Fresh MXene nanosheets (transmission electron microscopy images such as figure 1 As shown in (a), by dispersing 0.5g MXene in 95mL:5mL toluene:3-aminopropyltriethoxysilane solution and stirring continuously at 80°C for 12h under reflux system, silane-functionalized MXene nanoparticles were obtained Materials (F-MXene) such as figure 1 (b).

[0044] Take 0.1 g of the silane-functionalized MXene nanosheets obtained above and add it to 40 g of epoxy resin (MU-618) by solution mixing, stir vigorously for 30 min at room temperature and fully disperse, and then mix with 20 g of curing agent (CU-600). , to obtain a uniformly dispersed nanocomposite coating (Epoxy / F-MXene).

[0045] The above epoxy resin is epoxy resin (MU-618) and curing agent (CU-600), which were purchased from Shanghai Runtan New Material Technology Co., Ltd.

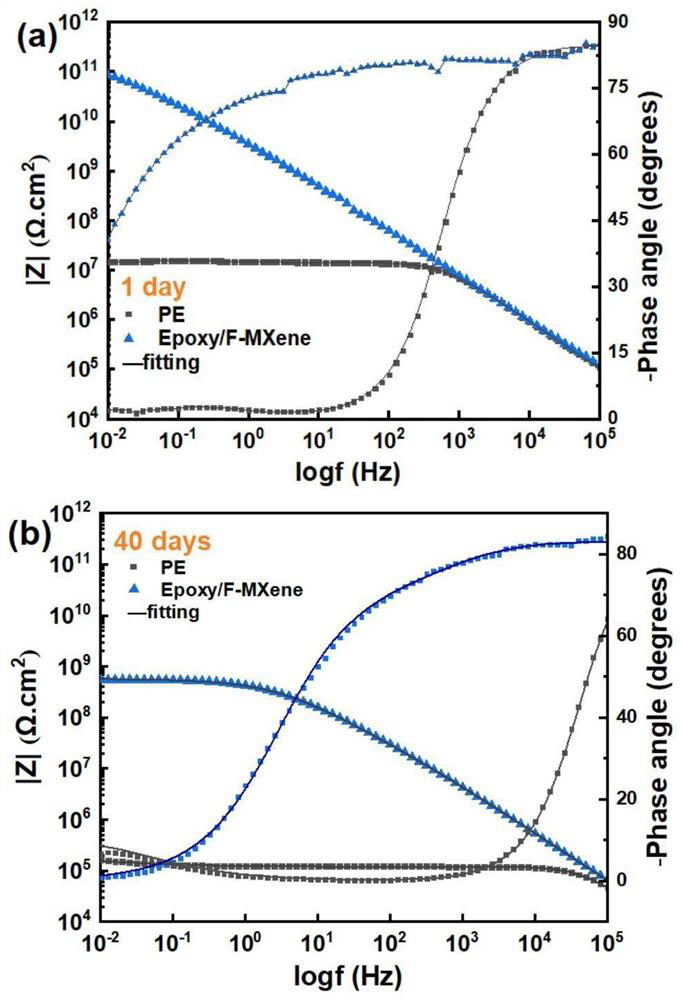

[0046] The nanocomposite coating obtained above was coated with a paint brush on a Q235 steel substrate, cured at room temperature for 72 hours, t...

Embodiment 2

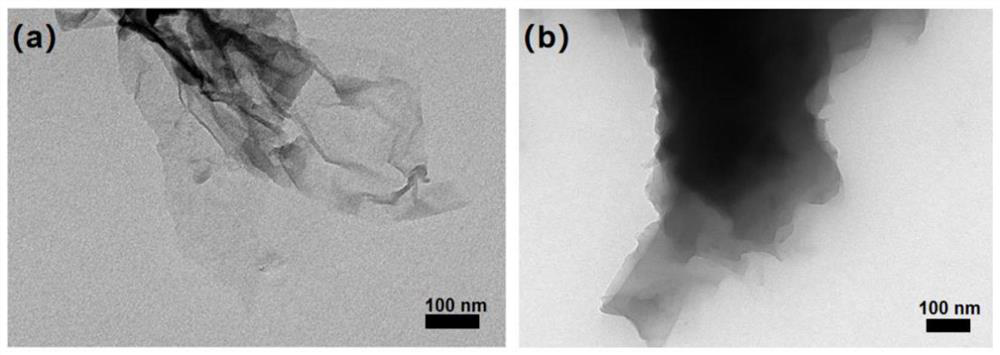

[0050] 50 mL of graphene oxide (GO) (10 mg / mL) was mixed with 20 mL of ethanol, mixed and sonicated in a water bath for 60 min. Then, 50 mL of fresh MXene aqueous solution (10 mg / mL) was added to the mixture, and the mixture was magnetically stirred at room temperature for 1 h. The resulting mixture was transferred to a 200 mL Teflon-lined autoclave and heated at 120 °C for 4 hours. Finally, the resulting solution was centrifuged and washed several times with water and ethanol, and freeze-dried to obtain the nanohybrid (GO@MXene), as shown in image 3 (a).

[0051] Silane functionalization was performed by refluxing 0.5 g of the nanohybrid in a mixture of 3-aminopropyltriethoxysilane (5 mL) and deionized water (95 mL) at 80 °C for 12 h. The refluxed product was washed several times with absolute ethanol and deionized water, and finally freeze-dried to obtain the modified nanohybrid (F-GO@MXene), such as image 3 shown.

[0052] Depend on image 3 (a) As shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com