Lithium battery pole piece, preparation method thereof and lithium battery

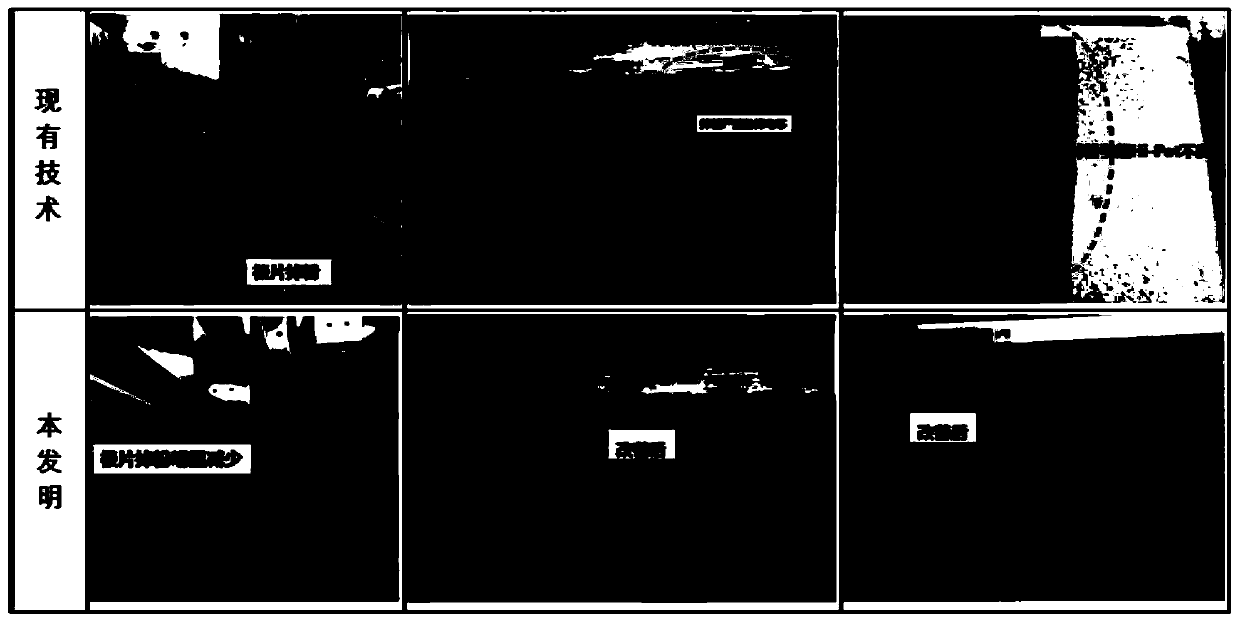

A lithium battery and pole piece technology is applied to the lithium battery pole piece and its preparation, and the field of lithium batteries, which can solve the problem that the preparation method needs to be improved, and achieve the effects of improving the reliability of the pole piece, improving the oxidizing property, and increasing the surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

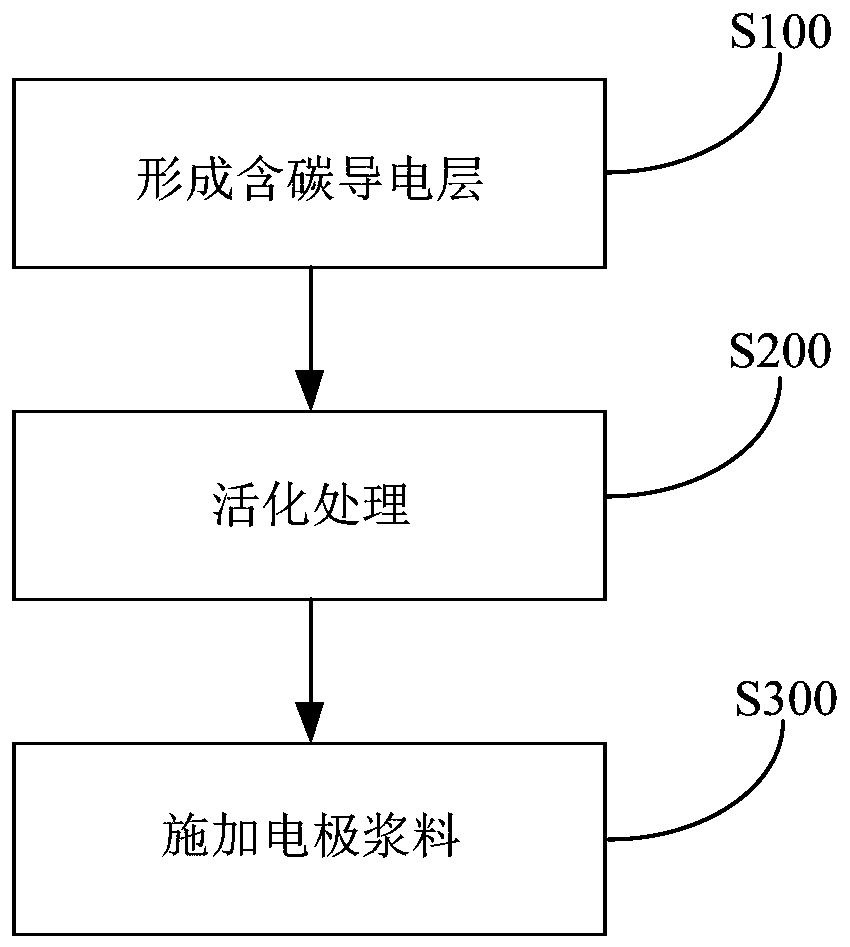

[0064] Prepare lithium battery negative electrode sheet according to the following steps:

[0065] (1) Coating a carbon-containing conductive layer on the copper foil surface, wherein the carbon-containing conductive layer is coated with a slurry comprising 60 parts of carbon black, 35 parts of styrene-butadiene rubber emulsion, 5 parts of polyvinyl chloride and 400 parts of deionized water formed on at least a part of the surface of the copper foil and cured.

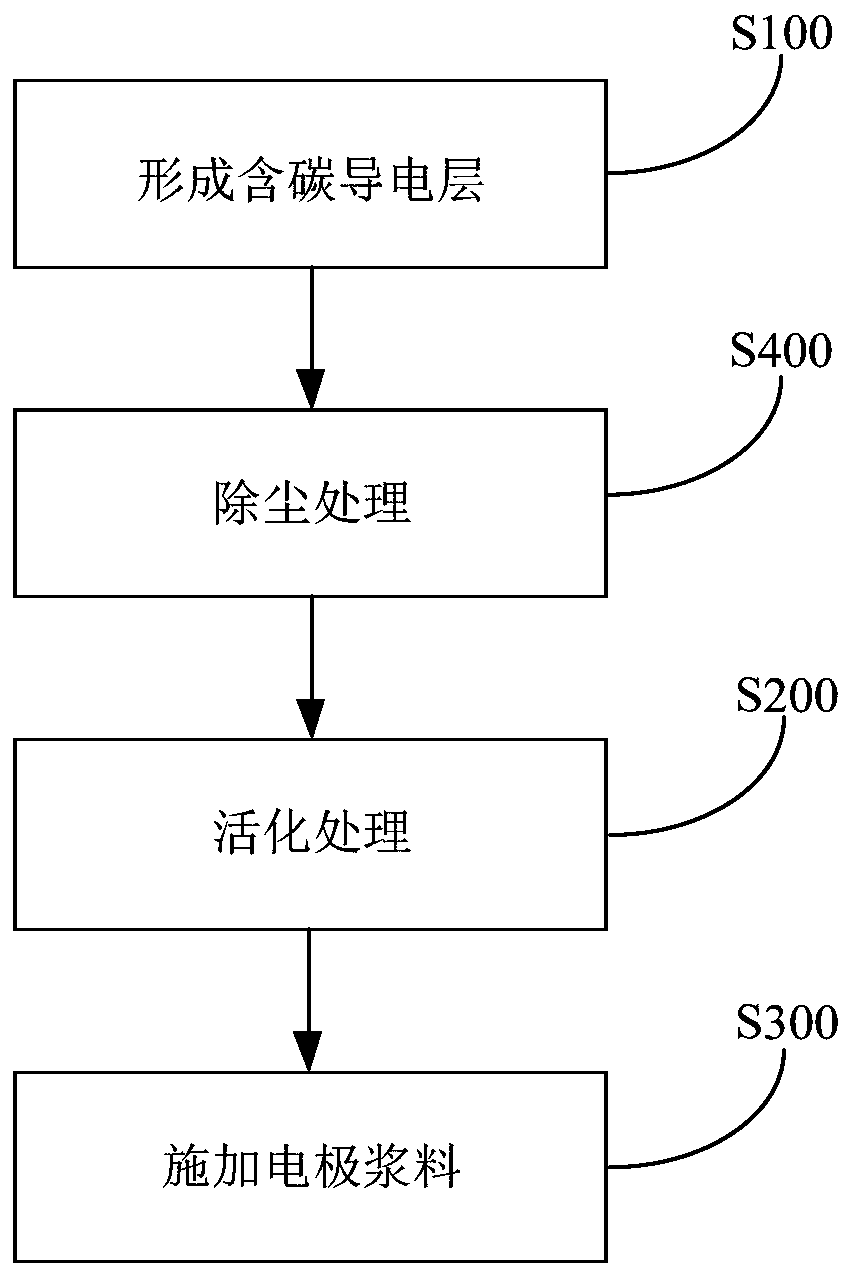

[0066] (2) Perform microwave ultrasonic treatment or negative pressure vacuum treatment on the carbon-containing conductive layer and the foil materials on both sides.

[0067] (3) Corona treatment was performed on the carbon-containing conductive layer according to the following conditions: the power of the corona processor was 10 kW, the distance between the corona treatment and the carbon-containing conductive layer was 1 mm, and the corona treatment time was 0.5 s.

[0068] (4) Coating the negative electrode slurr...

Embodiment 2

[0070] The lithium battery negative electrode sheet was prepared in the same manner as in Example 1, except that in step (3), the power of the corona processor was 5kW.

Embodiment 3

[0072] The lithium battery negative electrode sheet was prepared in the same manner as in Example 1, except that in step (3), the power of the corona processor was 20 kW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com