Patents

Literature

192results about How to "Guaranteed chemical stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Leadless platinum electrode slurry and manufacturing method thereof

InactiveCN101168472AImprove liquidityPromote wettingMaterial analysis by electric/magnetic meansElectrically-conductive paintsPlatinumAdhesive

The invention relates to a leadless platinum electrode slurry and process for preparation, wherein the platinum electrode slurry is prepared from 2-10mass% leadless glass adhesive, 2-10mass% metal oxide, 10-20mass% organic adhesive, and ultra-fine platinum powder at left amount. The production comprises leadless glass adhesive preparation, organic adhesive preparation, leadless platinum electrode slurry formulation, and slurry treatment. The invention can produce leadless platinum electrode slurry which lead content is lower than 100ppm, while the slurry applied in the electrode of zirconium oxide oxygen sensor can sinter at 1200DEG C, and via the formula adjustment of the leadless glass adhesive, the invention can produce platinum electrode slurry which can sinter at 800-1500DEG C. The electrode has the advantages of strong zirconium oxide substrate adhesive force, high conductivity, and stable electrical property.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

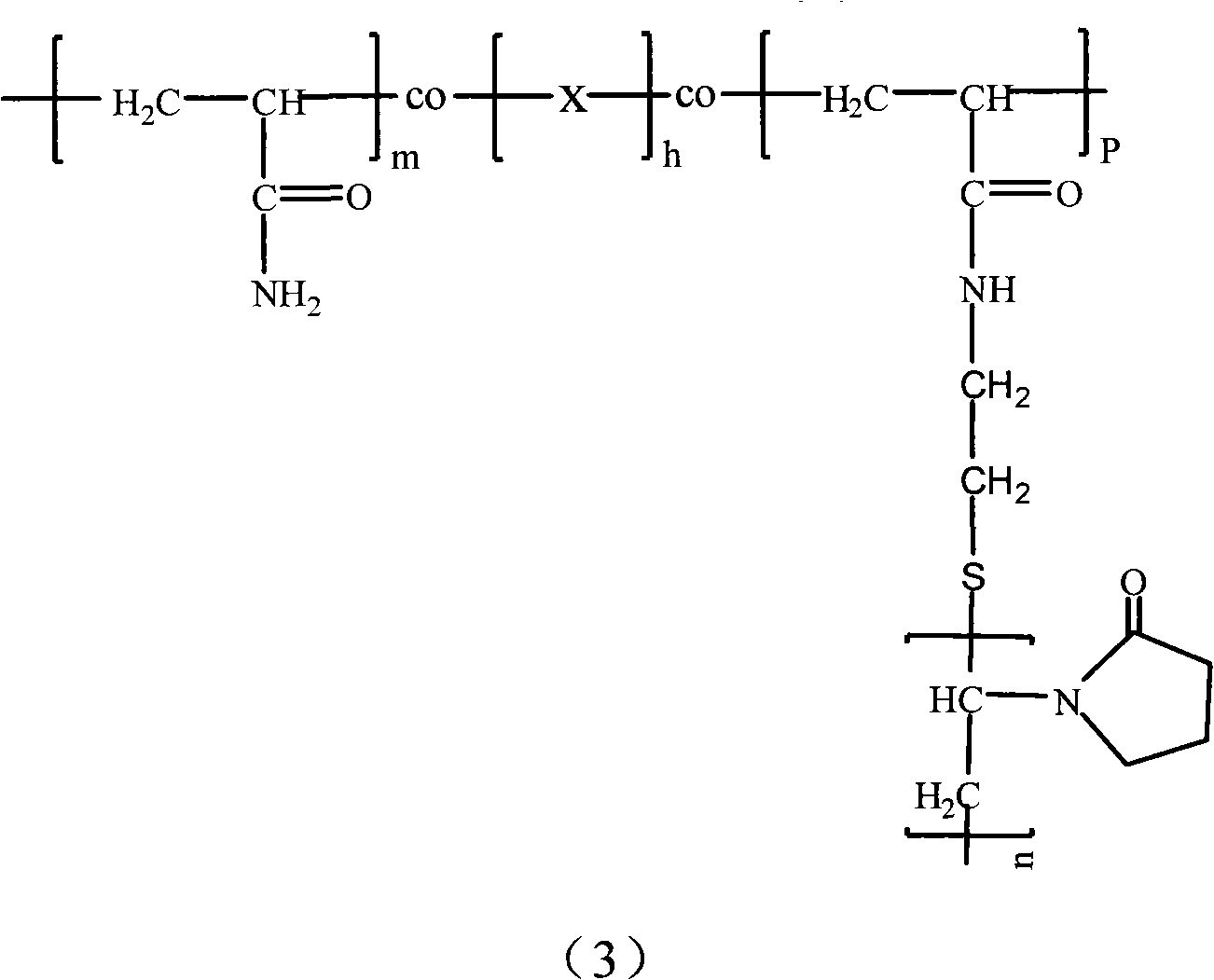

Heat-resistant salt-tolerate graft polyacrylamide and preparation method thereof

ActiveCN102050926AGood chemical stabilityReduce interfacial tensionDrilling compositionMethacrylamideSide chain

The invention belongs to the field of water-soluble flooding polymer study, particularly relates to a high-molecular-weight heat-resistant salt-tolerate graft polyacrylamide synthesized with macromolecule monomer route. The preparation method of the heat-resistant salt-tolerate graft polyacrylamide comprises obtaining poly(N-vinyl pyrrolidone)acrylamide macromolecule monomer through chain transfer free radical polymerization and terminal group replacement; and copolymerizing the macromolecule monomer with acrylamide, N-vinyl pyrrolidone, N,N-dimethylacrylamide, 2-acrylamido-2-methylpropanesulfonic acid or other heat-resistant salt-tolerate monomer in the present of an oxidation-reduction composite initiation system to obtain target product. The invention ensures the heat-resistant salt-tolerate performance of the copolymer from molecular design, and the functional long graft side chain can increase the viscoelasticity of polymer modules and reduce solution surface tension. The inventive product is used for type III oil reservoir, and provides a possible solution for increasing recovery efficiency of chemical flooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

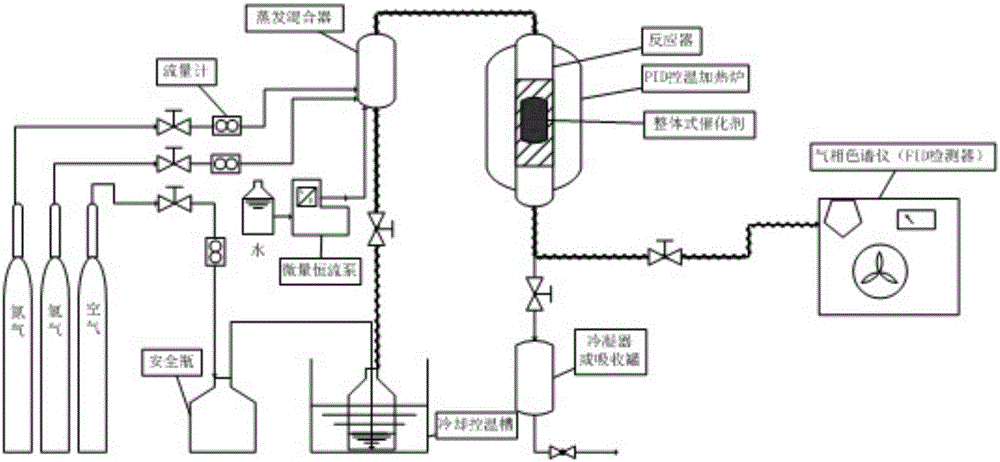

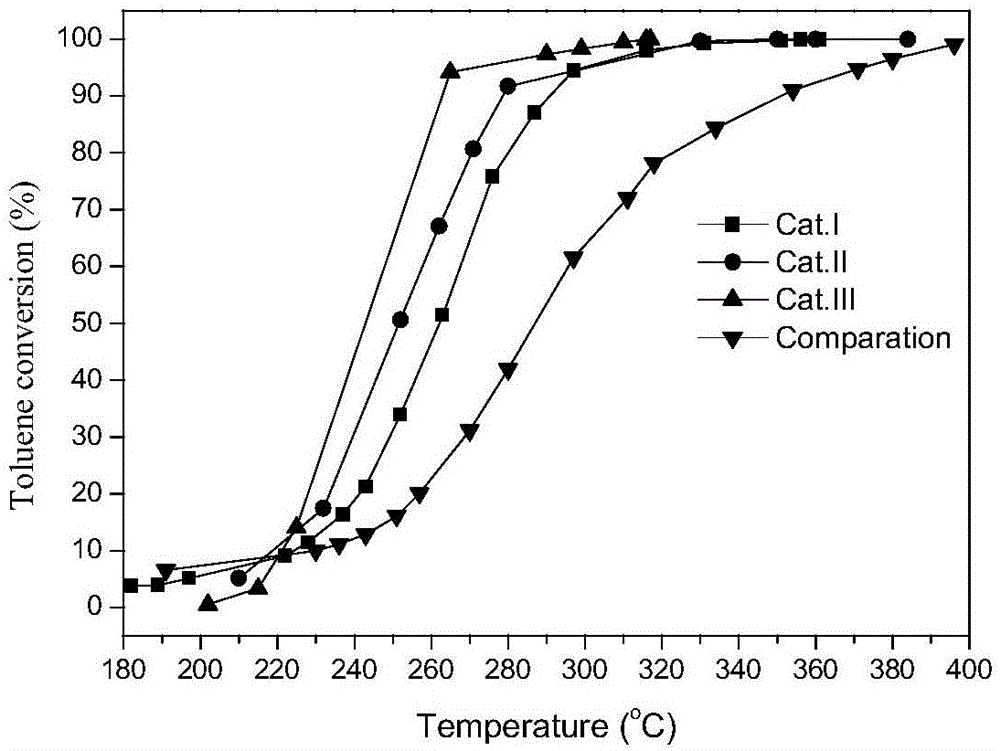

VOCs (volatile organic chemcials) catalytic combustion integral catalyst and preparation method thereof

ActiveCN106732585ATightly boundImprove anti-sintering performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationAir volumeAdhesive

The invention provides a VOCs (volatile organic chemcials) catalytic combustion integral catalyst, and belongs to the technical field of catalysts. The VOCs catalytic combustion integral catalyst is prepared from the following raw materials in parts by mass: 82 to 87 parts of cordierite honeycomb ceramic carrier, 10 to 14 parts of gamma-Al2O3, 0.8 to 1.5 parts of oxide additive, and 0.01 to 0.05 part of active component Pd, wherein the gamma-Al2O3, the oxide additive and the active component Pd are used as coating layers. The invention also relates to a preparation method of the catalyst. The preparation method comprises the following steps of firstly, dispersing the Pd onto the special gamma-Al2O3 carrier, drying, and calcining, so as to obtain powder; adding an adhesive, a lubricant and water for preparing slurry, coating the cordierite honeycomb ceramic carrier with the slurry, drying and calcining, so as to obtain the catalyst. The catalyst has the characteristics that by using low-content noble metal Pd as the active component, the cost is low, the low-temperature ignition is quick, the anti-vulcanizing and anti-aging properties are realized, the catalyst is suitable for large air volume and high air speed, the dispersion property is good, the easiness in sintering is avoided, and the like; the catalyst is especially suitable for the catalyst combustion of sulfur-containing VOCs.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

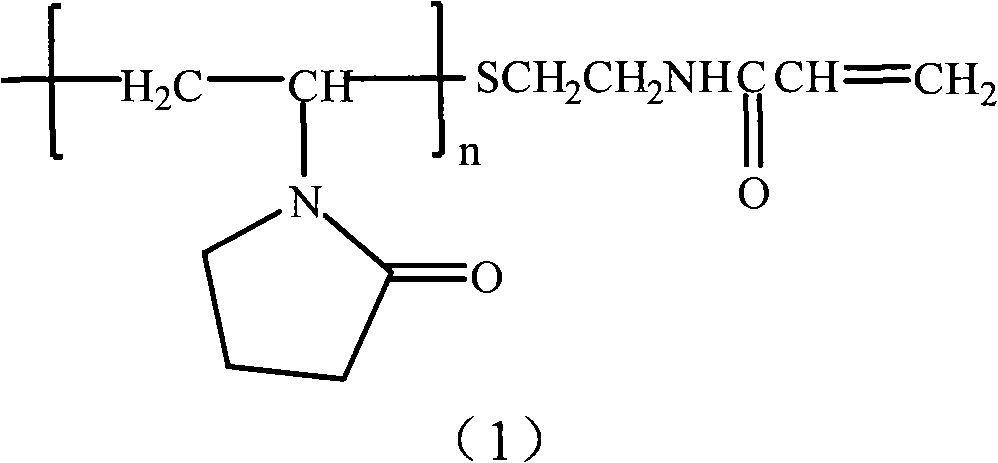

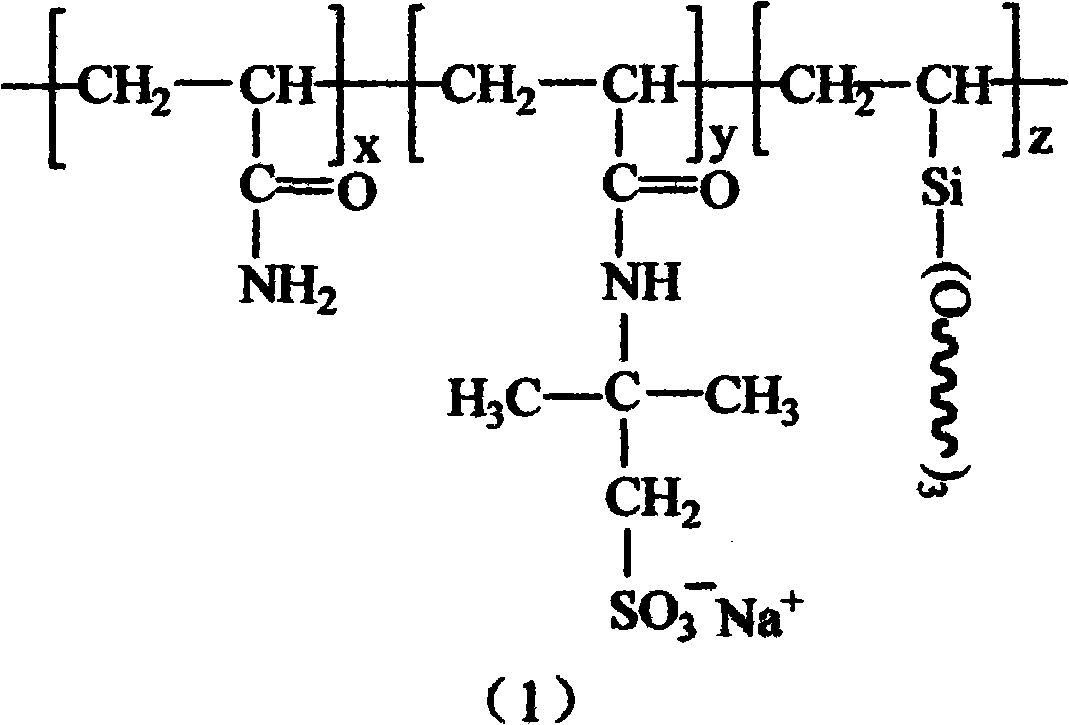

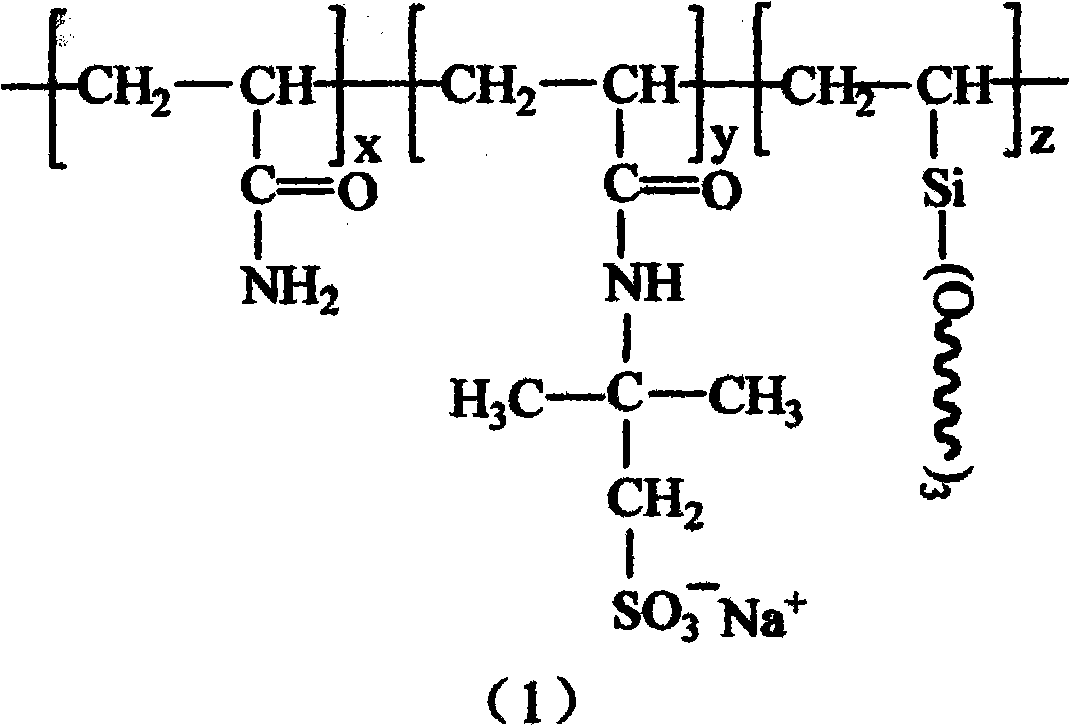

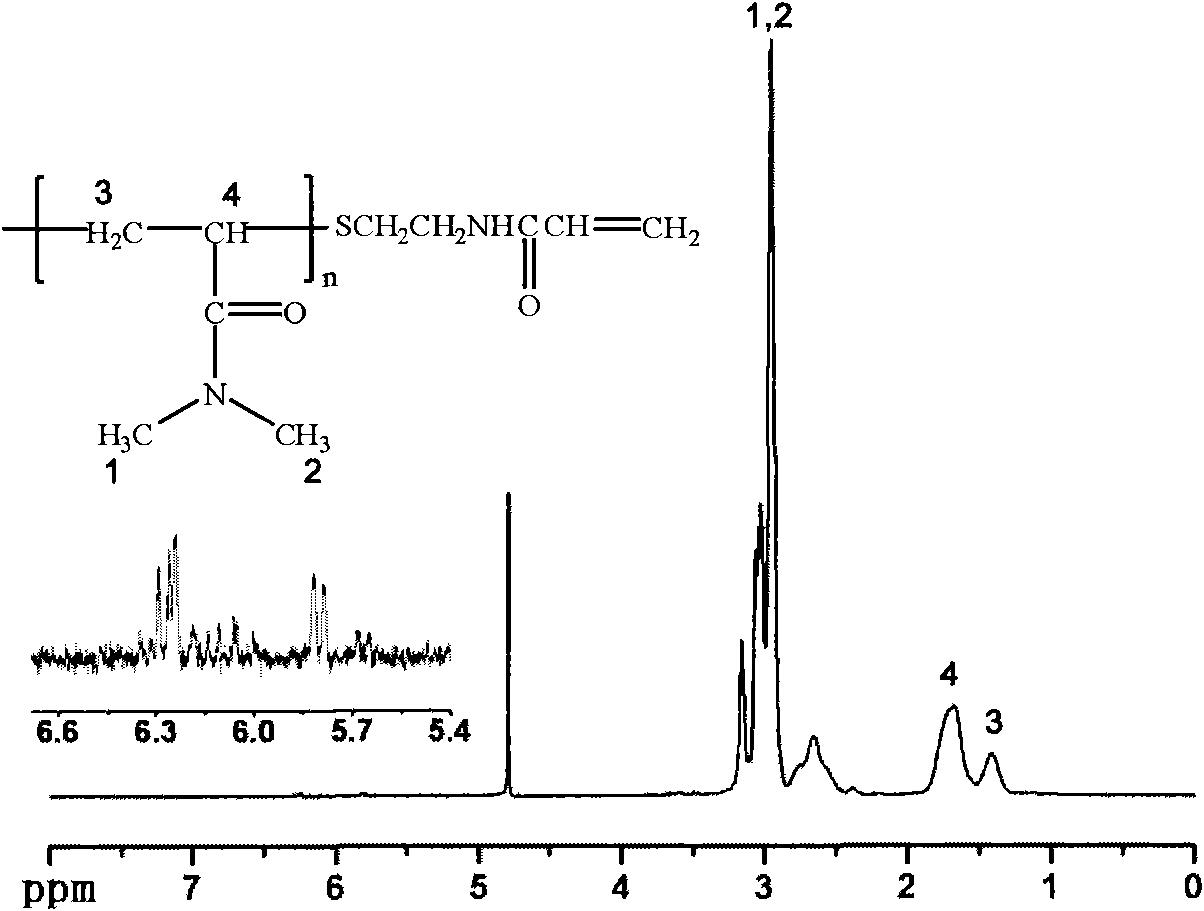

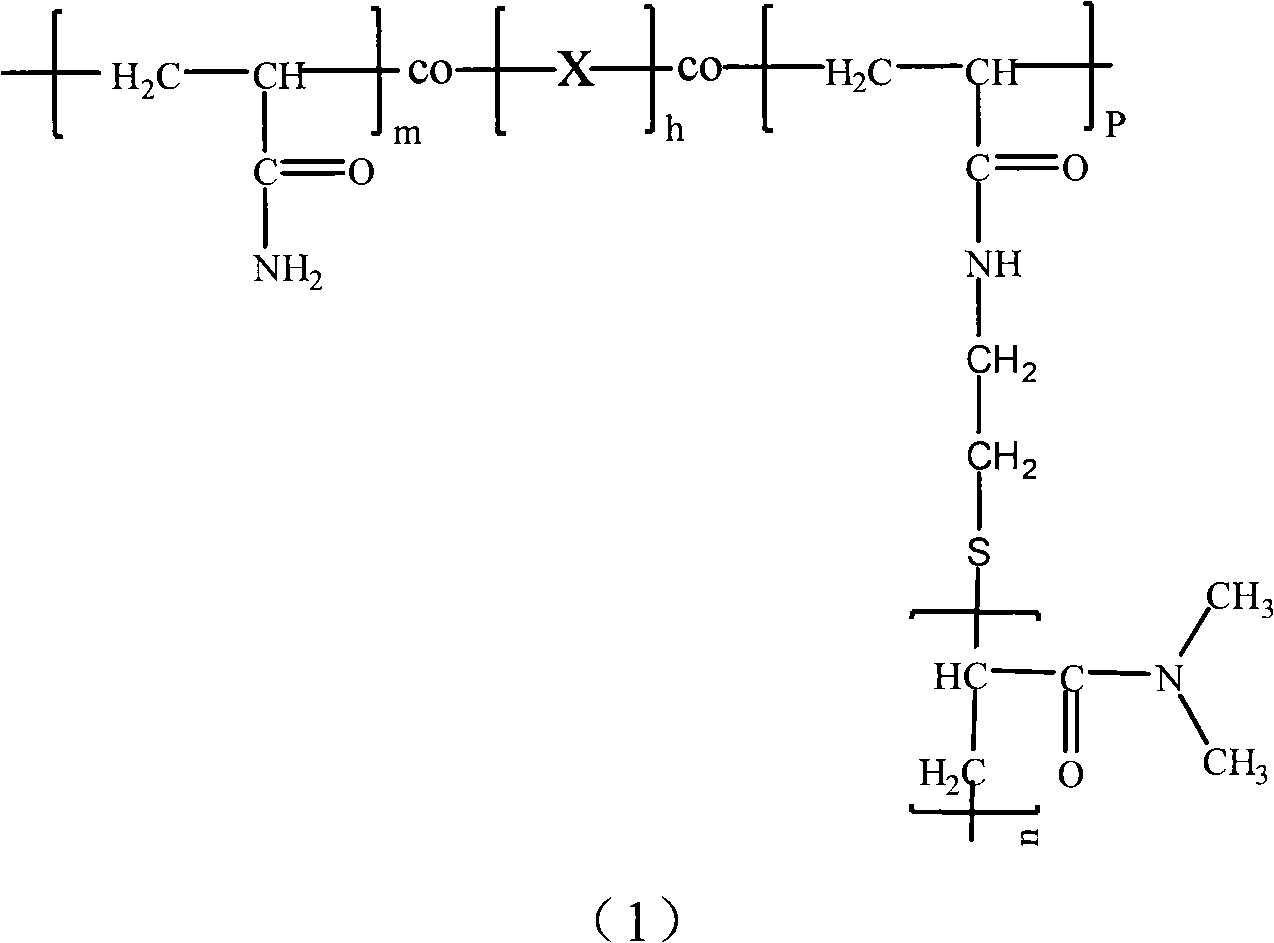

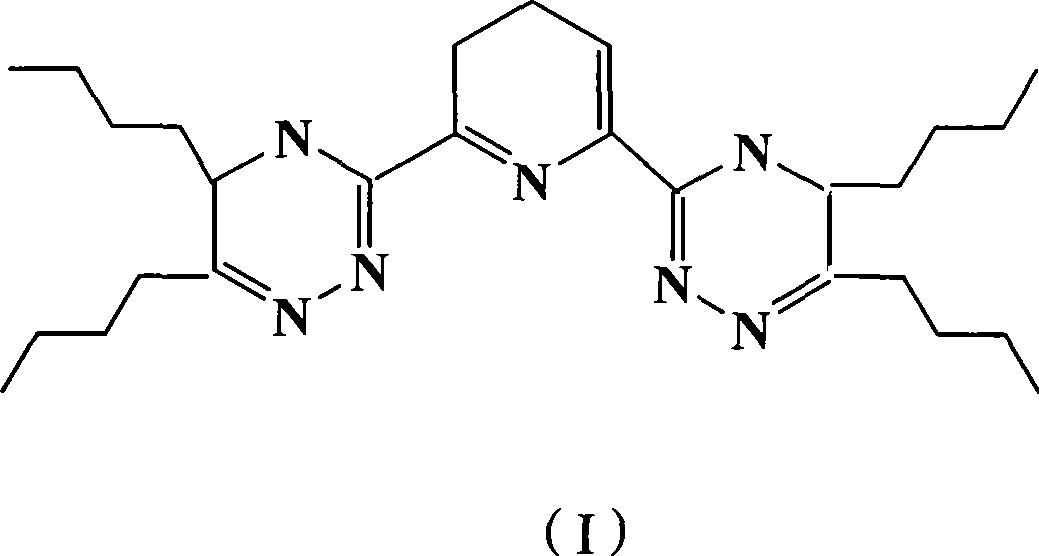

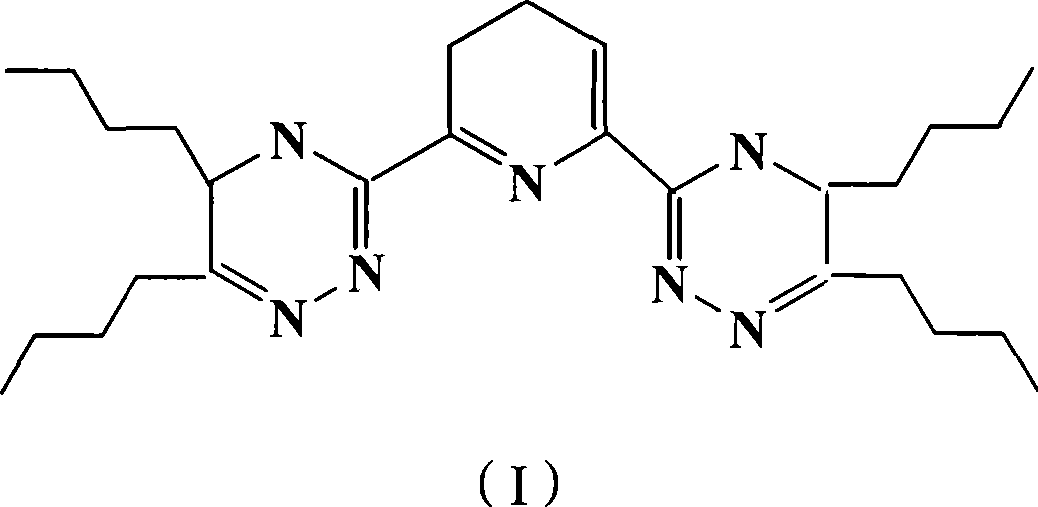

Long-branched chain polyacrylamide copolymer and preparation method thereof

ActiveCN102382241AGood temperature and salt resistanceHigh viscoelasticityDrilling compositionSalt resistancePolymer science

The invention discloses a long-branched chain polyacrylamide copolymer. The structural formula of the long-branched chain polyacrylamide copolymer is shown as formula (1). An organic silicon monomer with temperature resistance and salt resistance is introduced into an acrylamide copolymer so as to improve the temperature resistance and salt resistance of polyacrylamide; the introduction of a long-branched chain organic silicon flexible chain greatly improves the entwisting capability of a polymer molecular chain so as to improve the viscoelasticity of the polymer for reducing the interface tension of a grafting copolymer solution and improve the affinity of displacing fluid and displaced fluid in practical use; and a copolymer main chain is formed by copolymerizing the organic silicon monomer, acrylamide and monomers with temperature resistance and salt resistance, such as 2-acrylamino-2-methy propanesulfonic acid, N-vinyl pyrrolidone, N,N-dimethyl acrylyl and the like, thereby ensuring the chemical stability of the main chain.

Owner:CHINA PETROLEUM & CHEM CORP +1

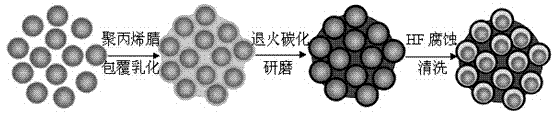

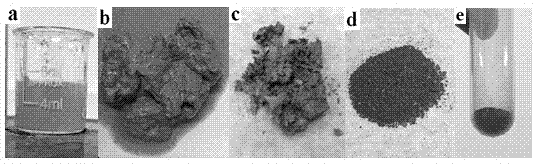

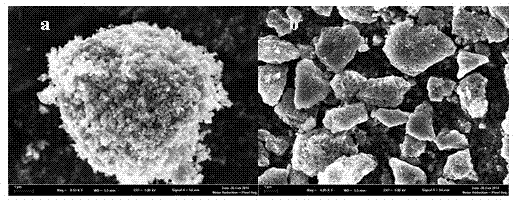

Pomegranate-like structured composite material preparation method

InactiveCN104300125AEasy to prepareThe preparation method is safeMaterial nanotechnologyCell electrodesMaterials preparationSilica particle

The invention discloses a pomegranate-like structured composite material preparation method which comprises the following steps: S1, taking a polyacrylonitrile solution, adding silica nanoparticles, and fully dispersing; S2, adding deionized water after stirring for emulsification to obtain a mud like precursor; S3, heating the mud like precursor obtained in the S2, and annealing to obtain a solid composite; and S4, grinding the solid composite obtained in the S3 into micron particles, adding a hydrogen fluoride solution for corrosion for a certain period of time, washing hydrogen fluoride, and drying to obtain a pomegranate-like structured composite material. According to the method, polyacrylonitrile is used for coating the silica particle surface, the polyacrylonitrile is emulsified when meeting water, so that the coated silicon particles are agglomerated, the coated silicon particles are carbonized and ground for formation of the pomegranate shaped structured silicon carbon composite material, HF is used for direct corrosion of the silicon nanoparticles in the material for preparation of the hollow pomegranate-like structured composite material, and detailed structure characterization and electrochemical performance testing of the material show that the material is good in performances.

Owner:SUN YAT SEN UNIV

Preparation of high-temperature floamed ceramic

InactiveCN101323538AWide operating temperature rangeGuaranteed chemical stabilityCeramicwarePorosityContinuous use

The invention provides a preparation method of a high temperature foam ceramics, which is characterized in that: zirconium diboride-aluminum oxide composite ceramic powder is prepared into ceramic slurry, polyurethane foaming plastic with certain bore diameter and porosity is soaked into the ceramic slurry so that the ceramic slurry evenly adheres to the surface of the pores of the polyurethane foaming plastic to form a ceramic slurry layer, which are then prepared into a polyurethane foaming plastic ceramic blank, and then are subjected to drying, degreasing and sintering, and the high temperature foam ceramics is prepared. The invention adjusts the high temperature resisting performance of the high temperature foam ceramics prepared by adjusting the ratio of zirconium diboride and aluminum oxide, therefore, the high temperature foam ceramics can resist high temperature and greatly expand working temperature scope; the high temperature foam ceramics prepared by the method can resist high temperature and keep chemical stability under high temperature condition; therefore, in high temperature working environment, the high temperature foam ceramics can be used repeatedly or continuously for the performances of thermal-shock resistance, oxidation resistance, molten steel erosion resistance, and the like, when being used in the filtration of molten steel, showing good performance.

Owner:SHANDONG UNIV OF TECH

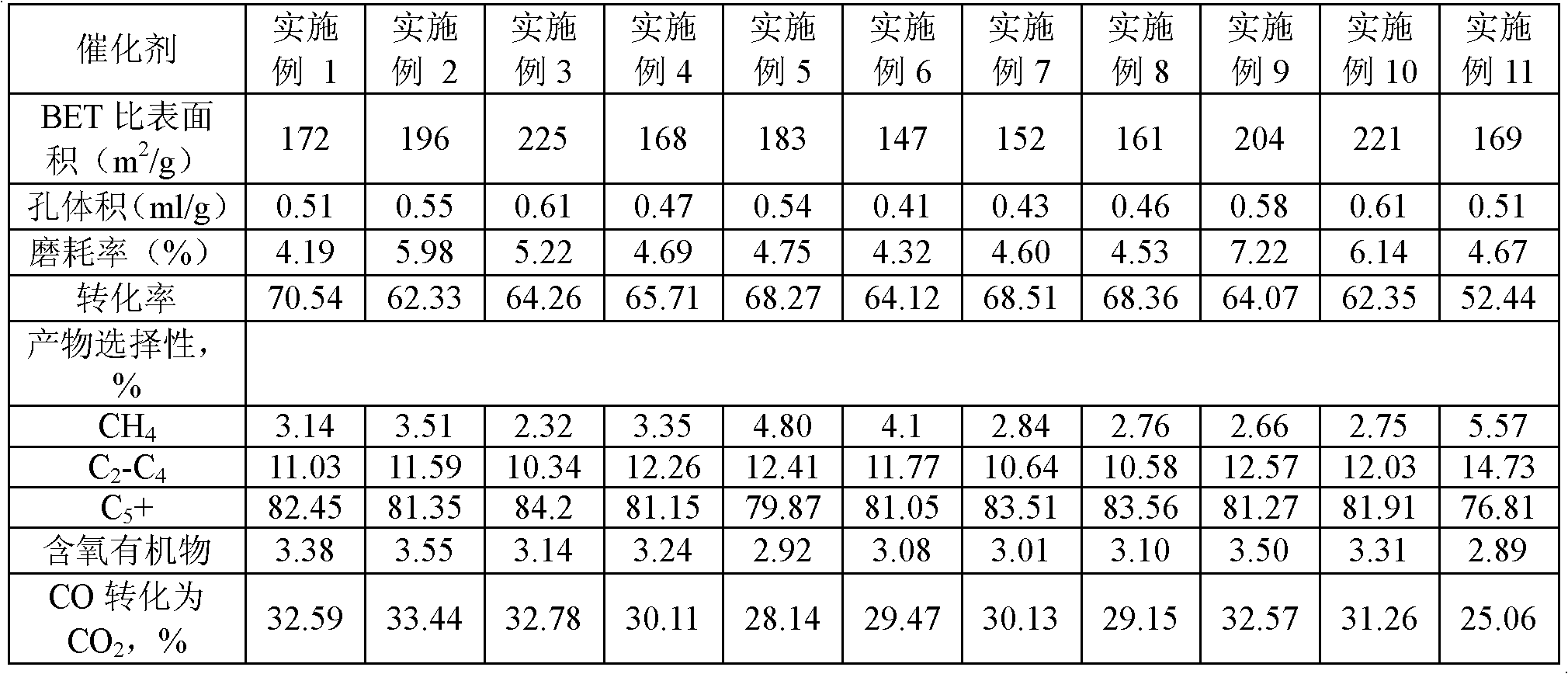

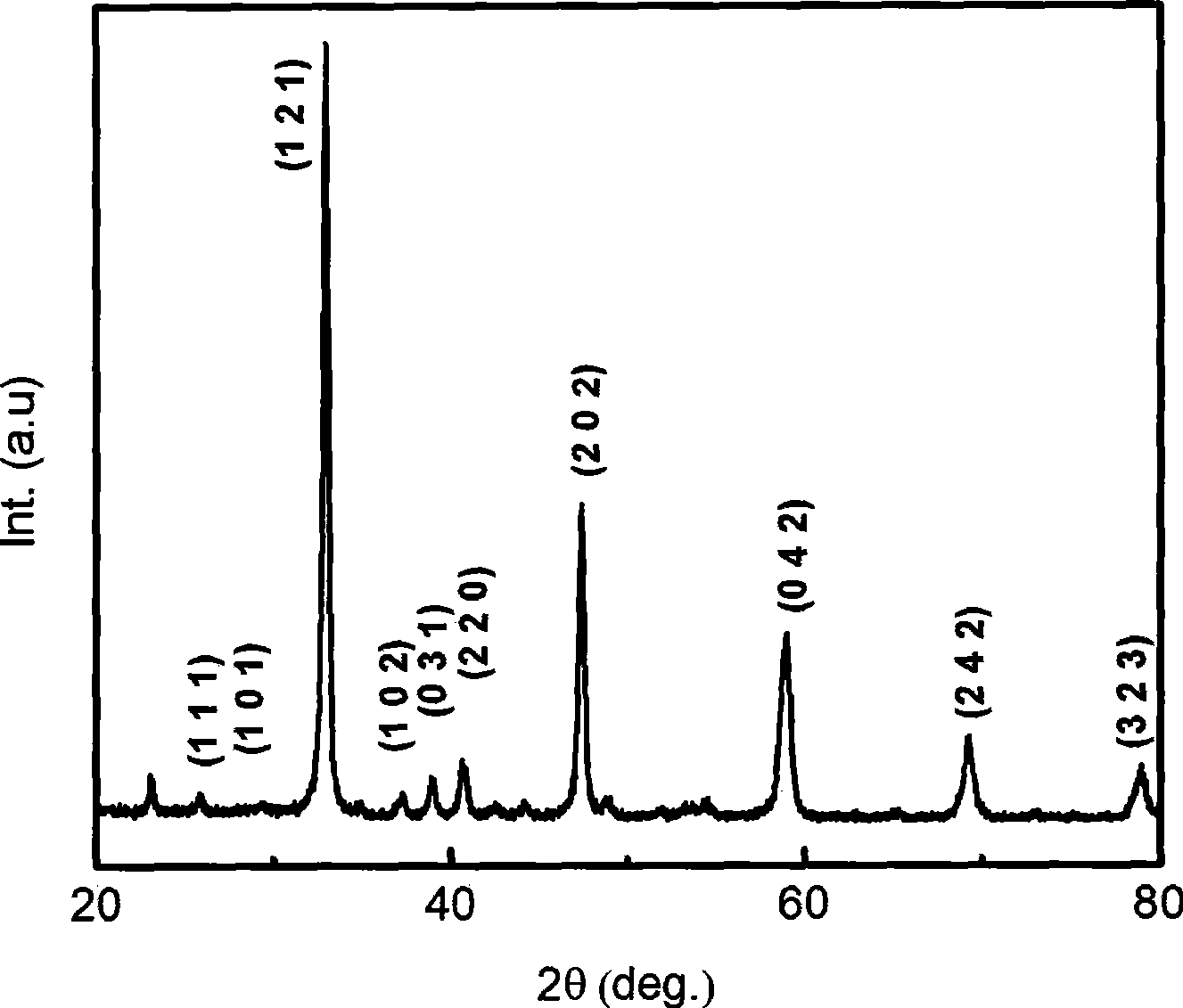

Preparation method of Fischer-Tropsch synthesis precipitated iron catalyst

ActiveCN102658143AFlexible control of specific surface areaFlexible control of pore volumeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSlurryCoprecipitation

The invention discloses a preparation method of a Fischer-Tropsch synthesis precipitated iron catalyst. The method comprises the following steps: preparing a precipitation slurry through a coprecipitation reaction; 2, filtering, washing and slurrying the precipitation slurry to obtain a catalyst precursor slurry; 3, carrying out a concurrent flow reaction on a silicon compound solution and a nitric acid solution to preparing a silicon sol; 4, mixing the catalyst precursor slurry with the silicon sol, and filtering to prepare a filter cake; 5, slurrying the filter cake to obtain a catalyst slurry; and 6, carrying out spray drying shaping and roasting on the catalyst slurry to obtain the Fischer-Tropsch synthesis precipitated iron catalyst. The preparation method of the Fischer-Tropsch synthesis precipitated iron catalyst of the invention has the advantages of flexible control of the specific surface area and the pore volume of the catalyst in a wide range according to experiment requirements, good control of the physical abrasion of the catalyst in a low level according to different preparation conditions, and simultaneous guarantee of the chemical stability of the catalyst.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

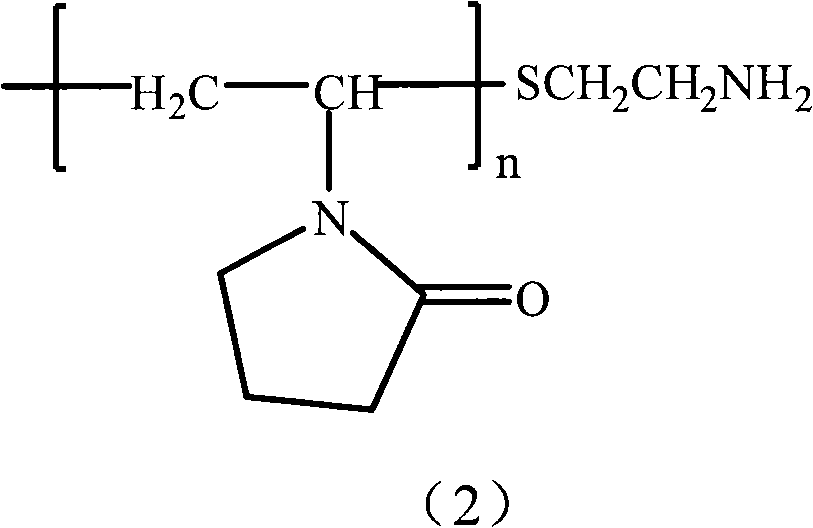

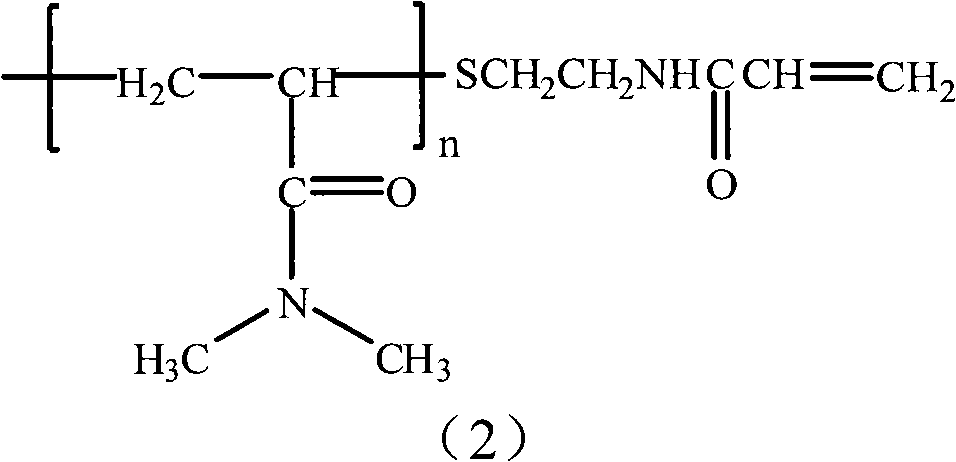

Temperature and salt resistant grafted polyacrylamide and preparation method thereof

ActiveCN102050913AHigh monomer conversion rateGood temperature resistanceDrilling compositionMethacrylamideWater soluble polymers

The invention relates to a temperature and salt resistant grafted polyacrylamide synthesized by a macromonomer route, belonging to the research field of water-soluble polymer used for displacement of reservoir oil. A method of chain transfer free radical polymerization and terminal group replacement is adopted to obtain a polyacrylamide (N,N-dimethylacrylamide) type macromonomer. Under an oxidation-reduction complex initiation system, temperature and salt resistant monomers, such as the macromonomer, acrylamide, N-polyvinyl pyrrolidone, N,N-dimethylacrylamide, 2-Acryloylamino-2-methyl propanesulfonic acid and the like, are copolymerized to obtain a target product. From molecular design, a functional long-grafted side chain can increase the viscoelasticity of the polymer molecule and lower solution surface tension. The product provided by the invention can be used for three-class oil deposit and provides a possible solution for improving the recovery ratio for chemical displacement of reservoir oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

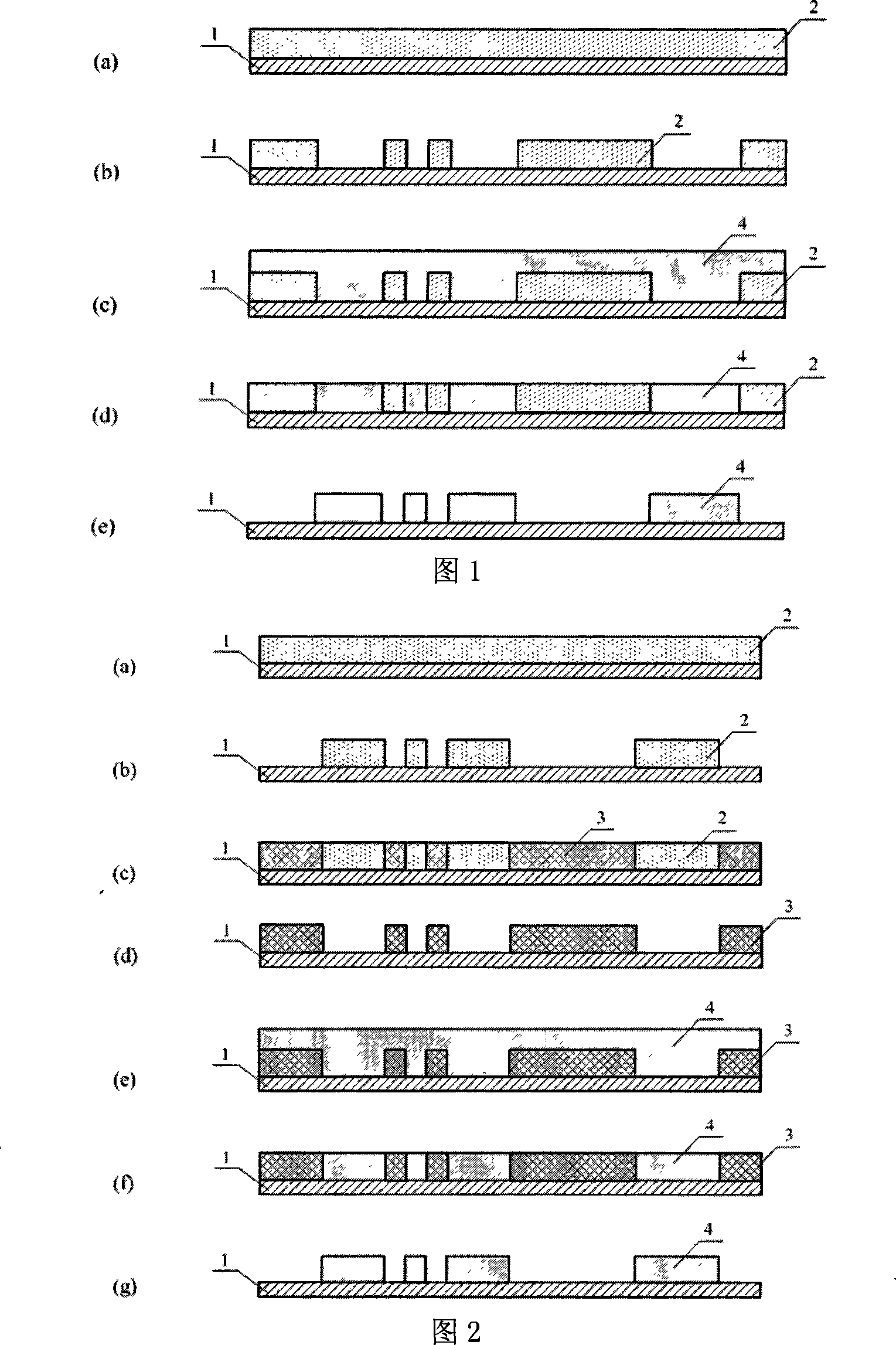

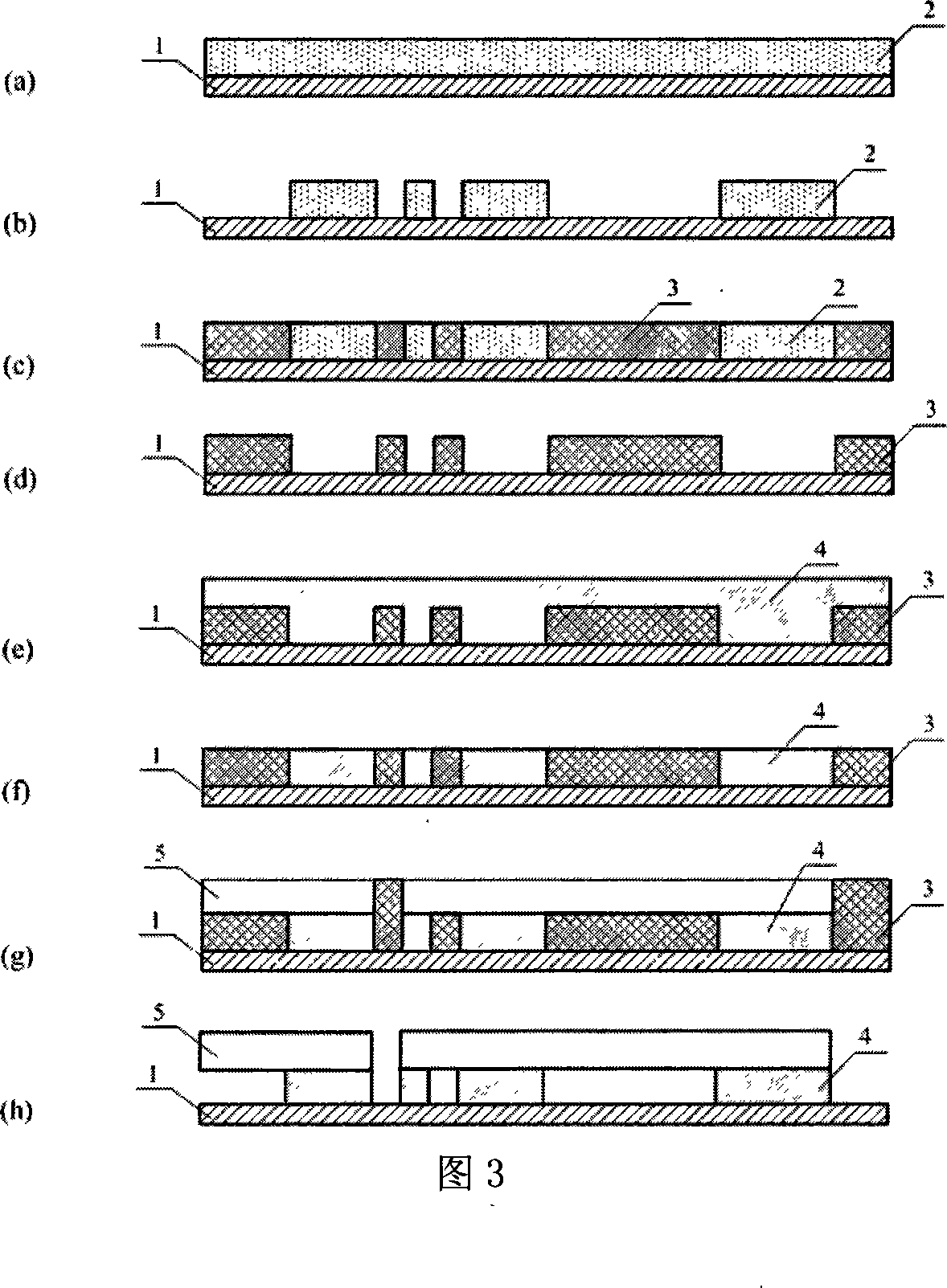

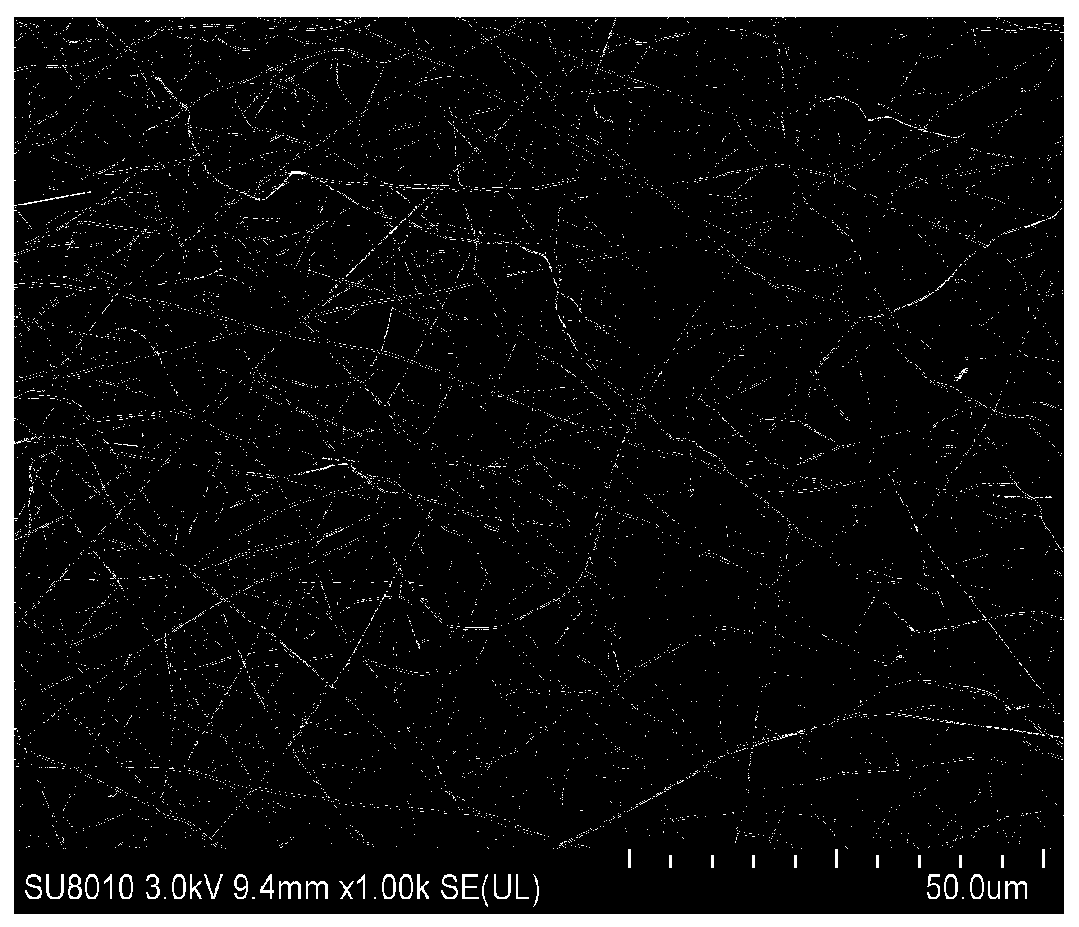

Universal film material graphics method

InactiveCN101143699AVersatilityImprove graphics qualityDecorative surface effectsChemical vapor deposition coatingGraphicsMicro structure

The invention discloses a graphic method for a universal film material in the technical field of micro machine processing. The invention prepares a disposable plane micro mould on a basal by photolithograph or mask plating; the film material is deposited on the whole basal, to fill the gap of the micro mould; the redundant part of the film which is higher than the micro mould is removed by grinding, and the film is reduced to be as thick as required; the disposable plane micro mould is removed selectively, to obtain the required micro structure. The invention can manufacture not only manufacture single structures but also laminated structures; can integrate with the sacrificial layer process to manufacture a suspend structure; is not restrained by the material, thickness and deposition method of the film and the substrate material, and is universal; solves the problem that conventional methods of some film materials cannot manufacture quite thick and neat boundary micro structures; has simple process and quite high graphic quality; is compatible with conventional micro processing technologies; does not need special processes and equipments; and is easy to be promoted.

Owner:SHANGHAI JIAO TONG UNIV

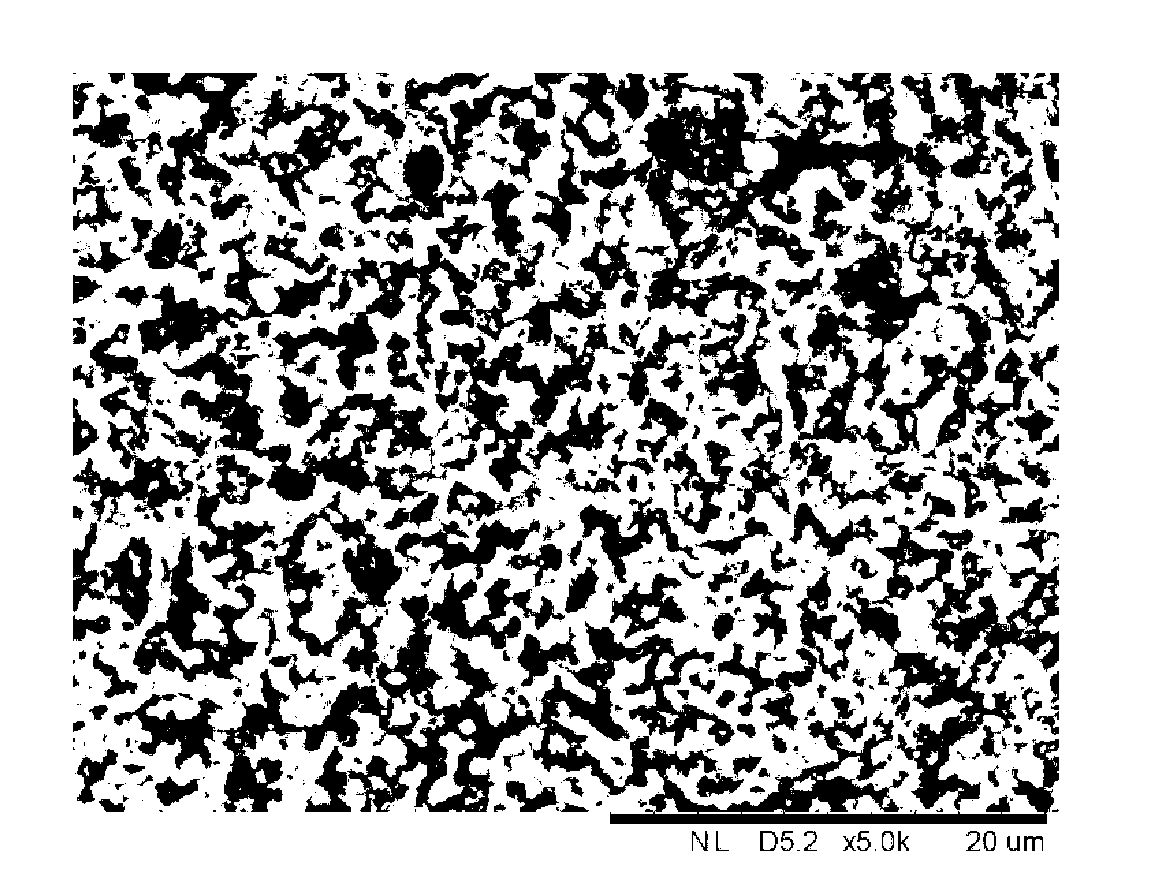

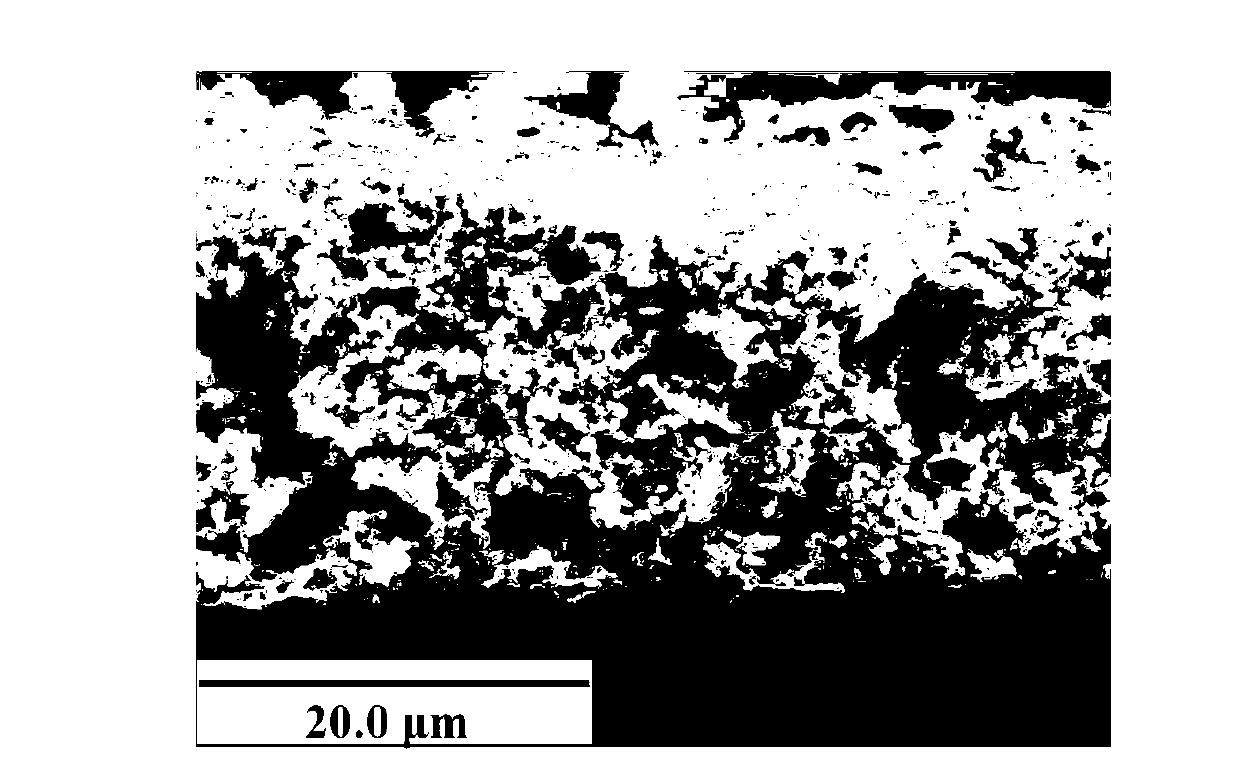

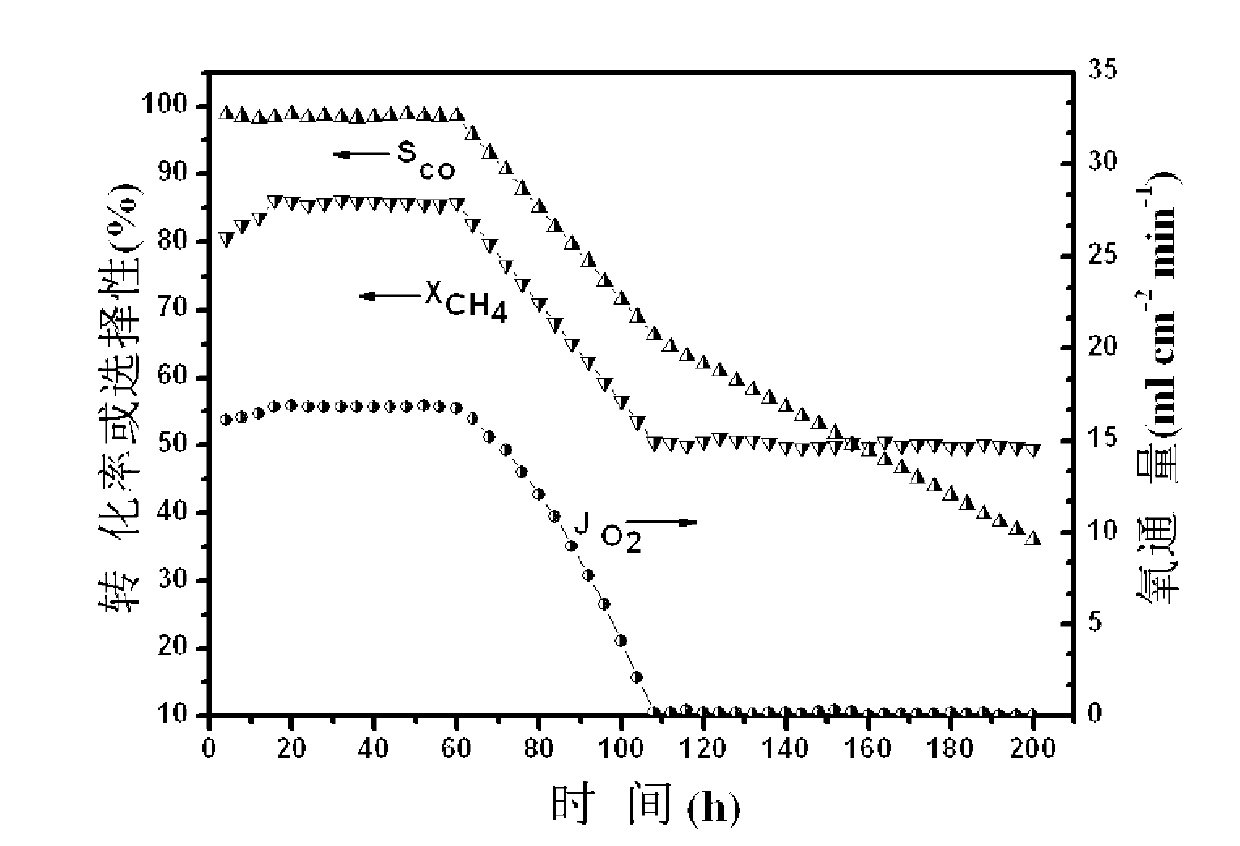

Multi-layer composite ceramic oxygen permeation film as well as preparation and application thereof

ActiveCN103272488AReasonable designHigh Oxygen Osmotic FluxSemi-permeable membranesDispersed particle separationComposite filmComposite ceramic

The invention relates to a multi-layer composite ceramic oxygen permeation film as well as preparation and an application thereof. The composite film is composed of a porous layer which is resistant to a reaction atmosphere and has a protective function, and a compact layer which has high oxygen permeation performance. Methods such as a spraying method are adopted for combining the porous layer with the compact layer, and the multi-layer composite ceramic oxygen permeation film is prepared through certain degree of thermal treatment. According to the invention, the design is reasonable, the structure is compact, the traditional design concept is broken through, and the practicability of an oxygen permeation film reactor can be effectively enhanced. The invention is applicable to a film reaction process, particularly the multiple-reaction coupling, and solves the problem that a traditional single-layer reactor is hardly balanced between the high oxygen permeation performance and excellent chemical stability.

Owner:NANJING TECH UNIV

Method for adding polyunsaturated fatty acid in animal milk

A method for directly adding unsaturated fatty acids to animal's milk includes such step as heating the animal's milk to 35-90 deg.C, directly adding unsaturated fatty acids by 0.01-10 vol%, stirring, and homogenizing by high pressure or high-speed shearing or ultrasonic waves to make the fat particle be wrapped by protein and phosphatide, generating a new stable system.

Owner:广州风行乳业股份有限公司 +2

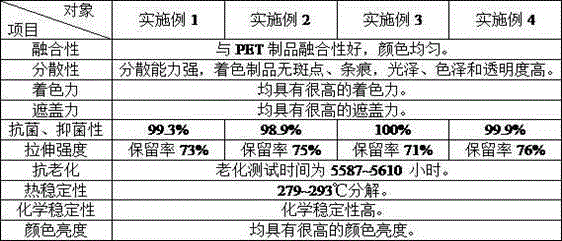

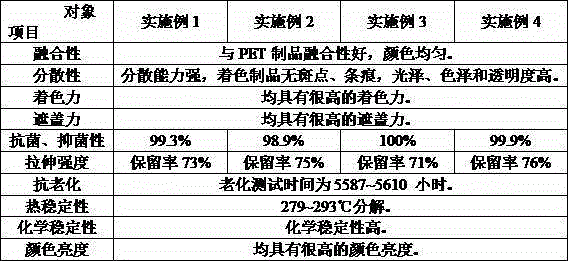

Preparing technology for color master batches

The invention relates to the technical fields of color master batches and preparing technologies thereof, in particular to a preparing technology for color master batches, and particularly discloses a preparing technology for color master batches for high-speed spinning fibers. The preparing technology includes the steps of carrier grinding, coloring material grinding, matched material grinding, assistant grinding, mixed grinding, high-speed grinding, extrusion prilling and drying. The color master batches prepared with the technology can be easily mixed with PET product plastic, and the even coloring effect can be achieved. Dispersibility, coloring strength and covering power are improved, weather resistance, acid resistance, heat resistance and cold resistance are achieved, the chemical stability of pigment is kept, and the color master batches are more environmentally friendly and healthier in the use process.

Owner:JIEDONG PARIS WANZHU SHAHUA TEXTILES CO LTD

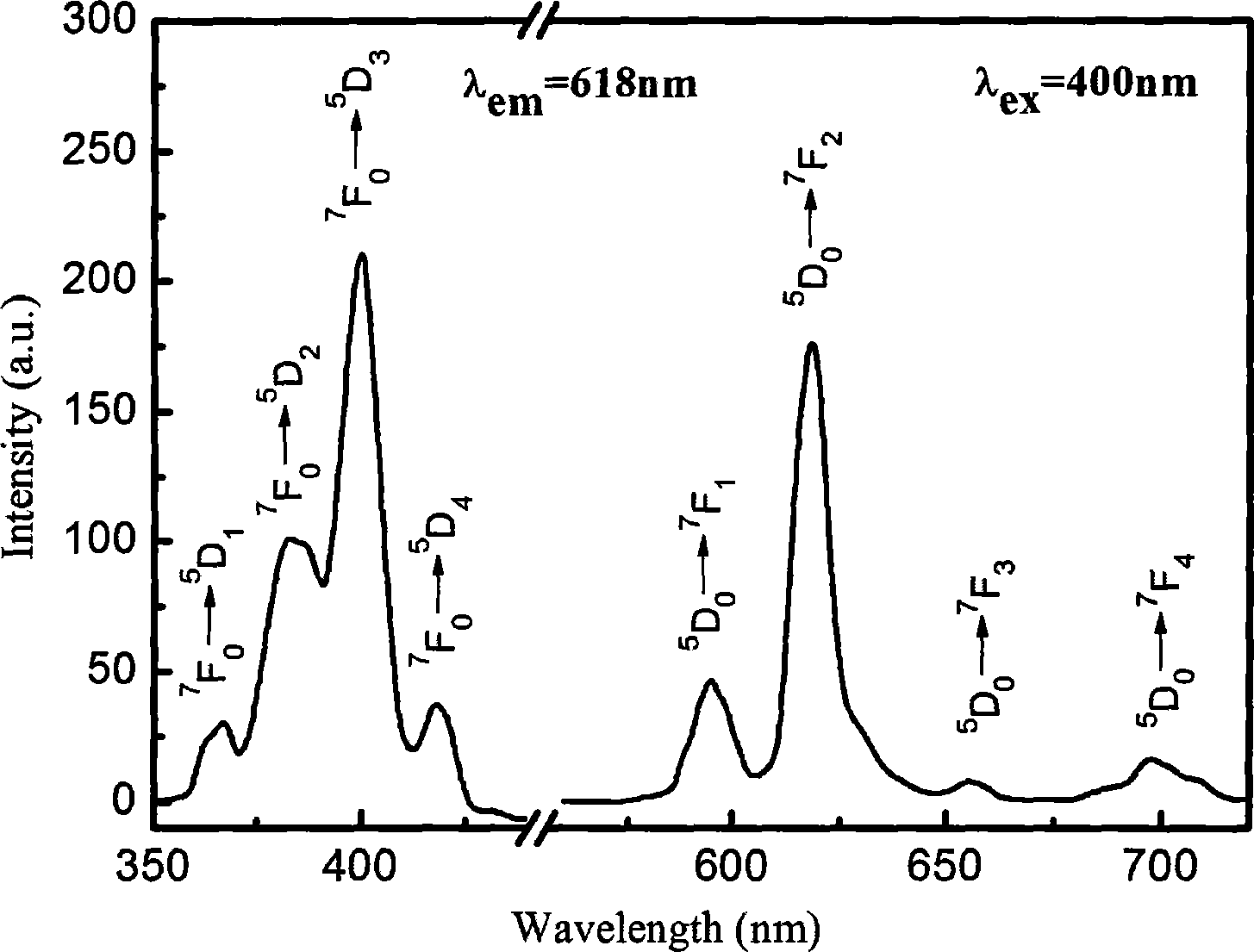

Preparation of doped calcium titanate (CaTiO3: Eu3+) fluorescent powder

InactiveCN101376523AGood chemical stabilitySmall grain sizeTitanium compoundsLuminescent compositionsAlcoholDissolution

The invention relates to a preparation method of Eu-doping calcium titanate CaTiO3:Eu<3+> fluorescent powders, which comprises the steps as follows: a soluble europium salt, a calcium salt and Ti(OC4H9)4 are weighed according to the mole ratio that is 1:49:50 to 1:4:5 among Eu<3plus>, Ca<2plus> and Ti<4plus>, and are respectively dissolved in absolute ethyl alcohol, and the confected solution is stirred for ample dissolution; (2) a mixed ethanol solution of the europium salt and the calcium salt is added in an ethanol solution of Ti(OC4H9)4, and a sol is obtained through stirring; (3) the sol is placed at the temperature ranging from 0 to 50 DEG C to obtain a wet gel which is put in a baking box for drying; (4) the dried gel is milled into powders, the obtained powders are calcined for 2 to 8 hours to obtain the CaTiO3:Eu<3plus> fluorescent powders. In the preparation method, the prepared CaTiO3:Eu<3plus> fluorescent powders have high chemical durability, small grain size, pure crystalling phase and low calcination temperature; the preparation method has simple technology, and is easy for industrialized production.

Owner:DONGHUA UNIV

Color masterbatch formula

The invention relates to the technical field of plastic coloration, and in particular to the technical field of high-speed textile fiber coloration, and discloses a color masterbatch formula, which is prepared from the following components in parts by weight: 20 to 50 parts of polyethylene terephthalate, 5 to 30 parts of toner, 5 to 25 parts of dispersing agent, 1 to 8 parts of heat stabilizer, 1 to 8 parts of antibacterial agent, 1 to 8 parts of antioxidant and 1 to 5 parts of additive. Compared with an existing color masterbatch, the color masterbatch disclosed by the invention can be easily mixed with a PET (polyethylene terephthalate) plastic product, so as to achieve an effect of even coloration. Not only the dispersity, the tinting strength, the covering power are improved, but also the properties of weather resistance, acid resistance, heat resistance and cold resistance are attained, and the chemical stability of a pigment is maintained.

Owner:JIEDONG PARIS WANZHU SHAHUA TEXTILES CO LTD

Lead-free silver electrode size and preparation method thereof

InactiveCN101609724AUniform adhesionImprove conductivityConductive materialCable/conductor manufactureSilver electrodeMaterials science

The invention relates to a lead-free silver electrode size and a preparation method thereof. The invention is characterized in that the size comprises the following compositions in portion by weight: 60 to 75 weight portions of ultrafine silver powder, 2 to 10 weight portions of lead-free glass binder, 2 to 5 weight portions of oxide and 10 to 30 weight portions of organic binder. The lead-free silver electrode size can completely replace a conventional leaded glass size; and the lead-free silver electrode size can be fused through sintering at a temperature of 600 DEG C and has good fluidity, can be wetted with a ceramic substrate and shows stable performance and good electric performance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

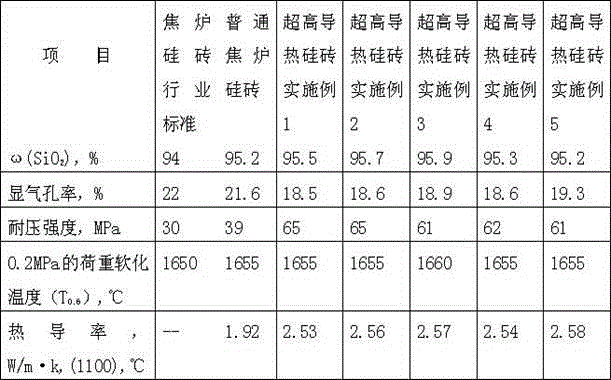

Superhigh-thermal conductivity silica brick for coke oven charing chamber furnace wall and preparation method thereof

The invention discloses a superhigh-thermal conductivity silica brick for a coke oven charing chamber furnace wall and a preparation method thereof. The superhigh-thermal conductivity silica brick comprises, by weight, 60-70% of crystalline silica, 10-20% of fused silica, 3-20% of waste silica bricks, 1-15% of Si3N4, 1-4% of an additive, 6.9-9.5% of a binder and 0.1-0.3% of a water reducer. The preparation method comprises the following steps of carrying out wet-grinding blending on the raw materials with the above ratio, carrying out mechanical pressing molding and carrying out drying roasting to obtain the superhigh-thermal conductivity silica brick. The superhigh-thermal conductivity silica brick has thermal conductivity of 2.50-2.60w / m.k improved by more than 25% than the traditional silica brick thermal conductivity and has obvious energy saving and emission reduction effects.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP +1

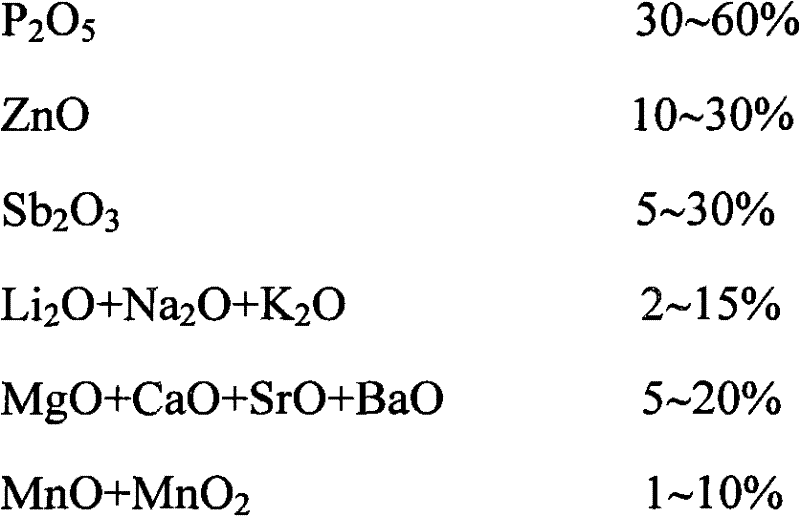

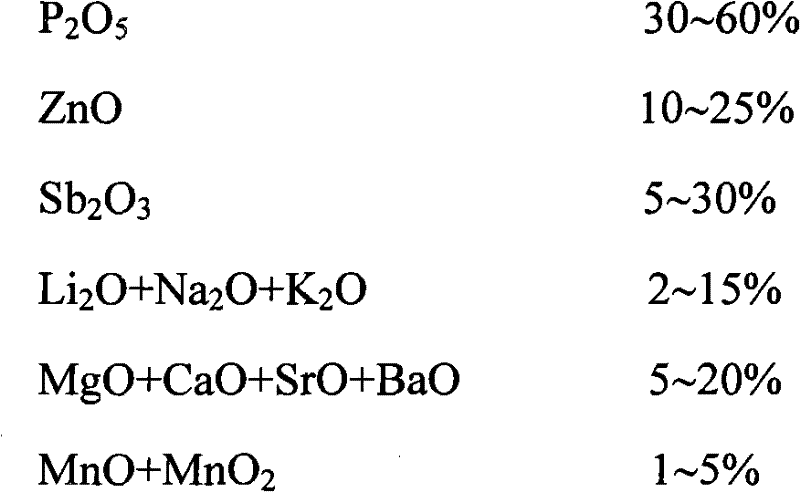

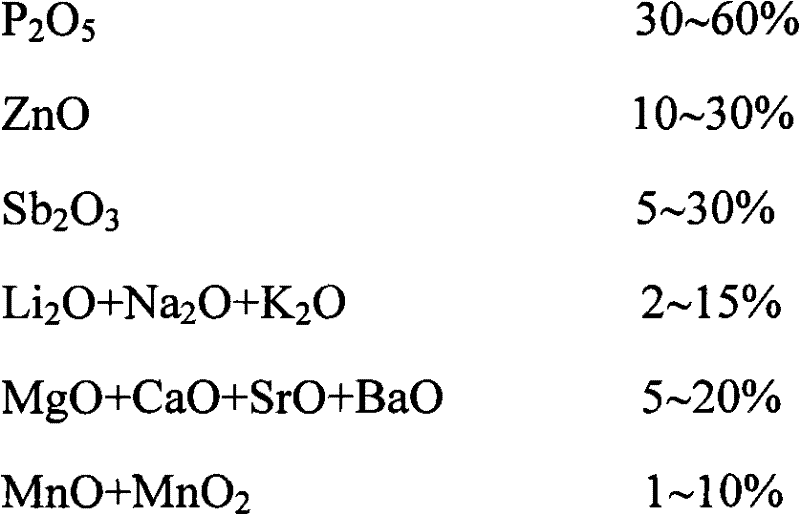

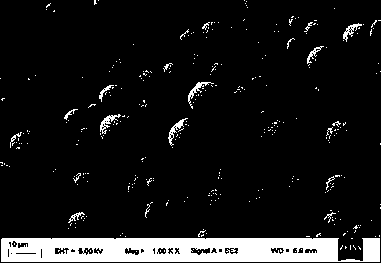

Leadless low melting point phosphate glass

InactiveCN102211870AGood chemical stabilityGuaranteed crystallization performanceMetallurgyWorking temperature

The invention discloses leadless ZnO-Sb2O3-P2O5 system low melting point glass, which mainly comprises the following components in percentage by mass: 30 to 60 percent of P2O5, 10 to 30 percent of ZnO, 5 to 30 percent of Sb2O3, 2 to 15 percent of Li2O, Na2O and K2O, 5 to 20 percent of MgO, CaO, SrO and BaO, and 1 to 10 percent of MnO and MnO2. The glass also comprises the following components in percentage by mass: 0 to 5 percent of SiO2, 0 to 10 percent of B2O3, and 0 to 15 percent of Al2O3. The working temperature of the phosphate glass is not more than 500 DEG C, the chemical stability is high, and the swelling coefficient is moderate, so the phosphate glass can be widely applied in the fields of middle and low temperature sealing of electronic products, manufacturing of high-temperature resistant paints, inflaming retarding when filled with a polymer material, and the like.

Owner:金招娣

High-nickel ternary positive electrode material containing active oxygen removing agent and preparation method thereof

PendingCN110071278AInhibit oxidation and decomposition gas productionAvoid impedanceCell electrodesSecondary cells servicing/maintenanceFiltrationDecomposition

The invention discloses a high-nickel ternary positive electrode material containing an active oxygen removing agent. The high-nickel ternary positive electrode material containing the active oxygen removing agent comprises the active oxygen removing agent and a high-nickel ternary material. The invention also provides a preparation method of the high-nickel ternary positive electrode material coated with the active oxygen removing agent; and according to the preparation method, the high nickel ternary positive electrode material and the active oxygen removing agent are dissolved in absolute ethanol according to a certain mass ratio for ultrasonic dispersion, and the high-nickel ternary positive electrode material coated with the active oxygen removing agent is obtained by performing vacuum drying on the sample at 100 degrees centigrade for 12 to 24 hours after filtration. The preparation method of the high-nickel ternary positive electrode material coated with the active oxygen removing agent can not only eliminate the active oxygen formed during circulation or storage of the high-nickel ternary positive electrode material, and inhibit the oxidative decomposition and gas production of the electrolyte, but also eliminate the residual lithium on the surface of the high-nickel ternary positive electrode material, reduce the surface residual alkali, and maintain chemical stabilityof the carbonate solvent in the electrolyte; therefore, the cycle performance and stability are improved, and the cycle storage gas production and impedance increase of the battery are effectively inhibited; and the coating process is simple and easy to operate.

Owner:SUNWODA ELECTRIC VEHICLE BATTERY CO LTD

Preparation method of pre-melting electroslag

The preparation method for premelting electroslag comprises: loading the material with 0.20-0.65 fluorite, 0.15-0.32 raw bauxite, 0-0.10 high raw magnesiteú¼0.05-0.32 high calcium material and 0-0.6 recovered slag in the arc furnace with material height as 0.5-1m; spreading carbon powder and iron filling on material top to arc and burn for melting after electrifying; cooling, and breaking with size as 1-40mm. this invention avoids slag segregation to ensure its chemical stability, has no dust pollution, and conserves energy.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

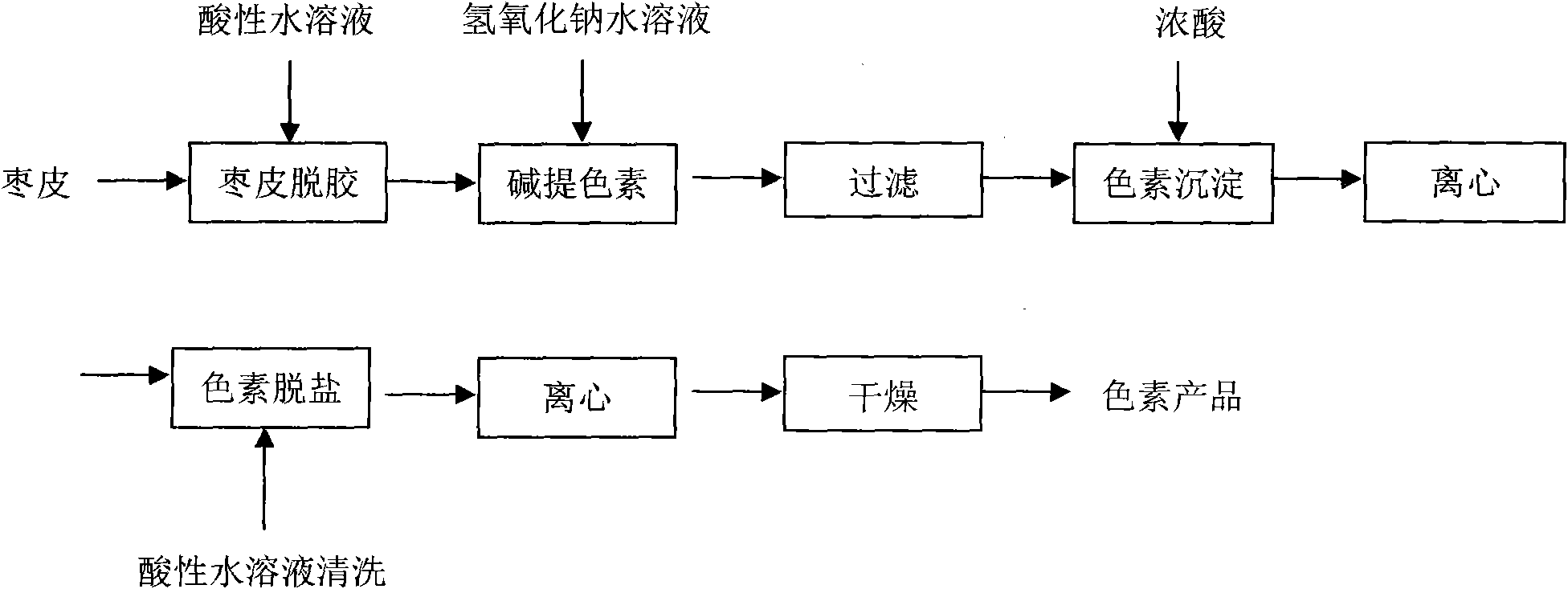

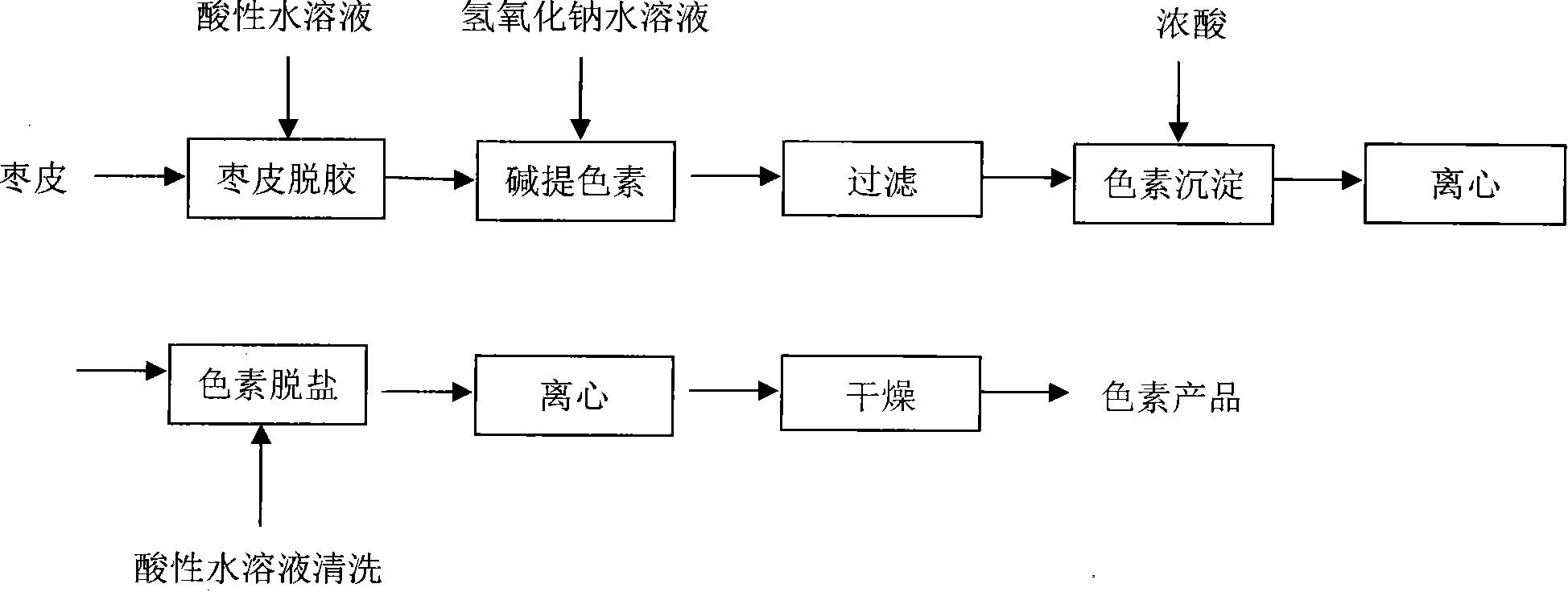

Preparation technique of natural pigment from red jujube peel

The invention relates to a preparation technique of natural pigment from red jujube peel. Firstly, viscous pectin in a jujube peel is removed to ensure the powder state of a finished pigment product; extraction is carried out at room temperature to ensure the chemical stability and the natural state of the pigment product; and alkali dissolution and acid deposition are carried out with simple process and low cost. The preparation technique is characterized by comprising the following steps of: firstly, extracting and removing the pectin in the jujube peel by using an acid extraction method; then, extracting the jujube peel pigment with a water solution of sodium hydroxide at room temperature, and carrying out fine filtration to remove tiny peel dregs and other impurities from the pigment extracting solution; and finally, adding concentrated acid to deposit the pigment, centrifuging, cleaning the deposits with acidulous water to remove salts in the pigment, centrifuging and drying to obtain a pigment product.

Owner:YANTAI UNIV

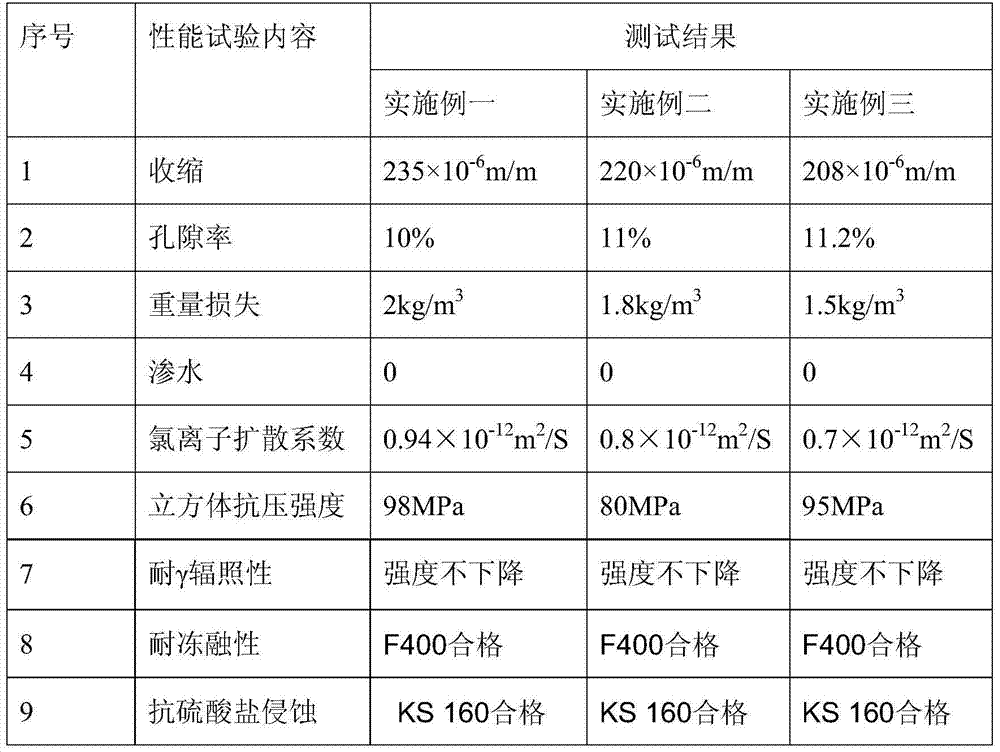

Steel fiber concrete high overall container used for disposal of radioactive substance and its preparation method

The invention discloses a steel fiber concrete high overall container used for disposal of radioactive substance and its preparation method. The steel fiber concrete high overall container comprises a main body and a cover poured by concrete doping with a water reducer and steel fiber, the concrete is composed of a gel material, aggregate and water, by metering the concentration of concrete according to 2400kg / m<3>, a gelling material in each cubic meter of concrete is 550-600kg; the gelling material comprises the following raw materials by mass percentage: 46-76% of cement, 2.7-7.7% of silicon ash, 22-39% of slag and 2.7-7.7% of fly ash; the mass ratio of water to the gelling material is 0.23-0.28: 1; the aggregate is composed of sand and cobblestone, the sand rate is 33-38%; the doping amount of the water reducer accounts for 1.5-2.5% of total mass of the gelling material; and the doping amount of steel fiber accounts for 0.5-1.6% of total volume of the concrete. The steel fiber concrete high overall container used for disposal of radioactive substance and its preparation method can realize the surface treatment of nuclear waste and can reduce the treatment cost.

Owner:CHINA BUILDING MATERIALS ACAD +1

Method for synthesizing iron-containing brucite at high temperature and high pressure

InactiveCN108793259AGuaranteed chemical stabilityOxygen fugacity controlUltra-high pressure processesIron compoundsPlatinumIron powder

The invention discloses a method for synthesizing iron-containing brucite at high temperature and high pressure. The method comprises the following steps of using analytically pure magnesium hydroxide, analytically pure iron powder (Fe) and analytically pure iron hydroxide, and uniformly grinding and mixing according to a molar ratio of 27:1:2, so as to obtain a starting raw material; enabling a tabletting machine to tablet the starting raw material into a cylindrical sample; selecting the analytically pure iron powder, and pressing into two iron sheets; then, putting the cylindrical sample and the iron sheets into a platinum snap fastener in a sandwich structure of iron sheet-cylindrical sample-iron sheet, and sealing; finally, loading the platinum snap fastener into an iron snap fastenerand sealing, placing the iron snap fastener into an h-BN (hexagonal boron nitride) tube, and using h-BN as a pressure transfer medium; assembling the h-BN tube into a high-pressure synthesis assemblyblock, placing into a cubic large press, and reacting for 8h at high temperature of 600 to700 DEG C and high pressure of 3 GPa, so as to obtain an iron-containing brucite sample, wherein the iron-containing brucite sample is a single material phase without impurity phase. The method solves the difficult problem of failure to artificially synthesize the existing iron-containing brucite sample.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Special modified high and low temperature resistant sealing part material produced by polytetrafluoroethylene regeneration method, sealing part and preparation method thereof

ActiveCN101608043AEfficient removalDecomposition and purification treatment effect is goodAlkali freeMaterials processing

The invention provides a special modified high and low temperature resistant sealing part material produced by a polytetrafluoroethylene regeneration method, which consists of regenerative polytetrafluoroethylene powder processed by special step, high-temperature magnesium oxide and alkali-free glass fiber powder. A sealing part formed by processing the material has good high and low temperature resistant performance and can keep good using performance within the range of -220 DEG C-+350 DEG C, thereby not only keeping the unique chemical stability of the polytetrafluoroethylene, but also keeping the toughness and the broad operatability of a high temperature resistant and micro-fibrous internal unchanged structure of the material; furthermore, the sealing part also has the advantage of super-strong sealing property, wear resistance and lubricity, so that the range of applications is wider. The material can not only be used in the sealing field, but also be used in matching energy conservation and emission reduction of solar energy manufacturing industry, as well as equipment of military industry.

Owner:义乌市秉杞氟塑科技有限公司

Rustproof rubber and manufacturing method thereof

The invention relates to a rubber material, and in particular to a rustproof rubber and a manufacturing method thereof. The rustproof rubber comprises by weight 45%-55% of a raw rubber, 3.0%-3.8% of an anti-rust agent, 0.7%-0.9% of an accelerant, 5.0%-7.0% of zinc oxide, 0.8%-1.2% of stearic acid, 5.0%-7.0% of DCP (dicumyl peroxide), 8.6%-9.6% of carbon black, 0.8%-1.2% of an antioxidant D and the balance of light calcium carbonate. When contacting with metal, the rubber provided by the invention can provide excellent rustproof protection to inhibit corrosion of metal and meanwhile avoid possible corrosion of the rubber during contact with the metal.

Owner:沈阳防锈包装材料有限责任公司

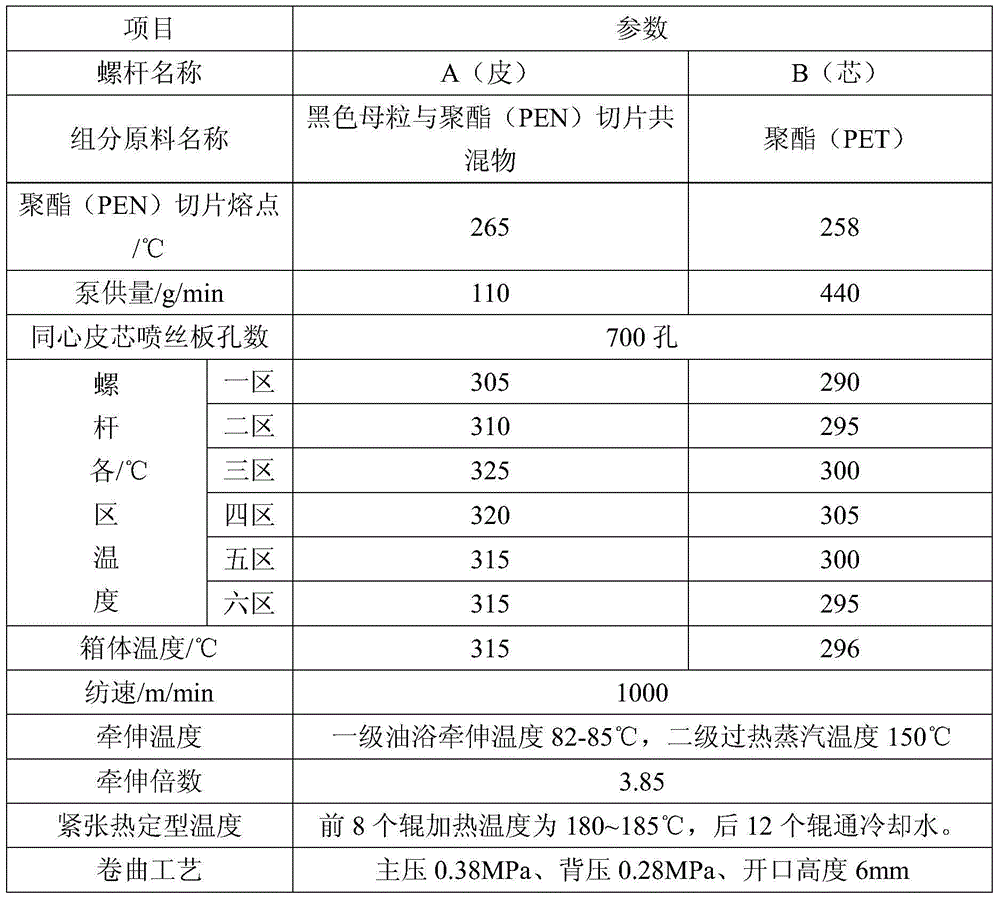

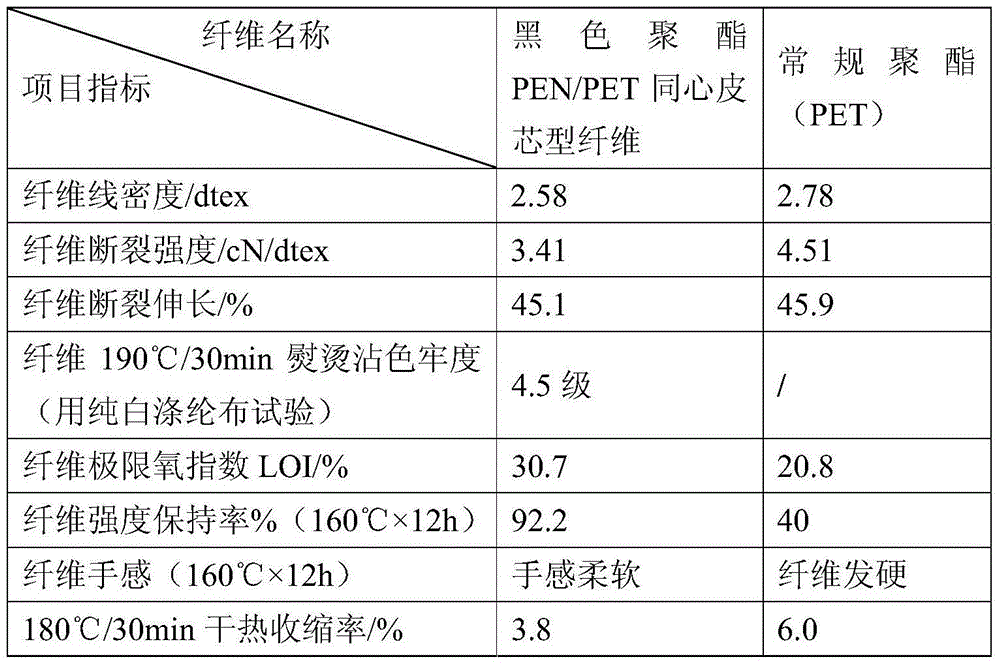

Colored polyester concentric sheath-core composite fiber and manufacturing method thereof

ActiveCN104532399AGuaranteed chemical stabilityMaintain gas barrier propertiesMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterFiber

The invention provides a colored PEN / PET concentric sheath-core composite fiber. The sheath layer comprises a colored master batch and PEN, wherein the weight ratio of the colored master batch to the PEN is 5-15:95-85, and the colored master batch comprises colored powder and PEN, and the weight ratio of the colored powder to the PEN is 25-35:75-65. The core layer comprises PET. The weight ratio of the sheath layer components to the core layer component is 15-25:85-75. The defect that PEN fiber forming and dyeing are difficult is overcome, and the fiber keeps the unique chemical stability, gas barrier property, flame retardance, heat resistance and the like of the PEN fiber. The PET economical efficiency and favorable PEN fiber properties are organically combined, the PEN using cost is greatly reduced, the application range of the PEN in the fiber field is enlarged, and meanwhile the application range of the PET fiber in the industrial field can be broadened further.

Owner:SHANGHAI DEFULUN CHEM FIBER

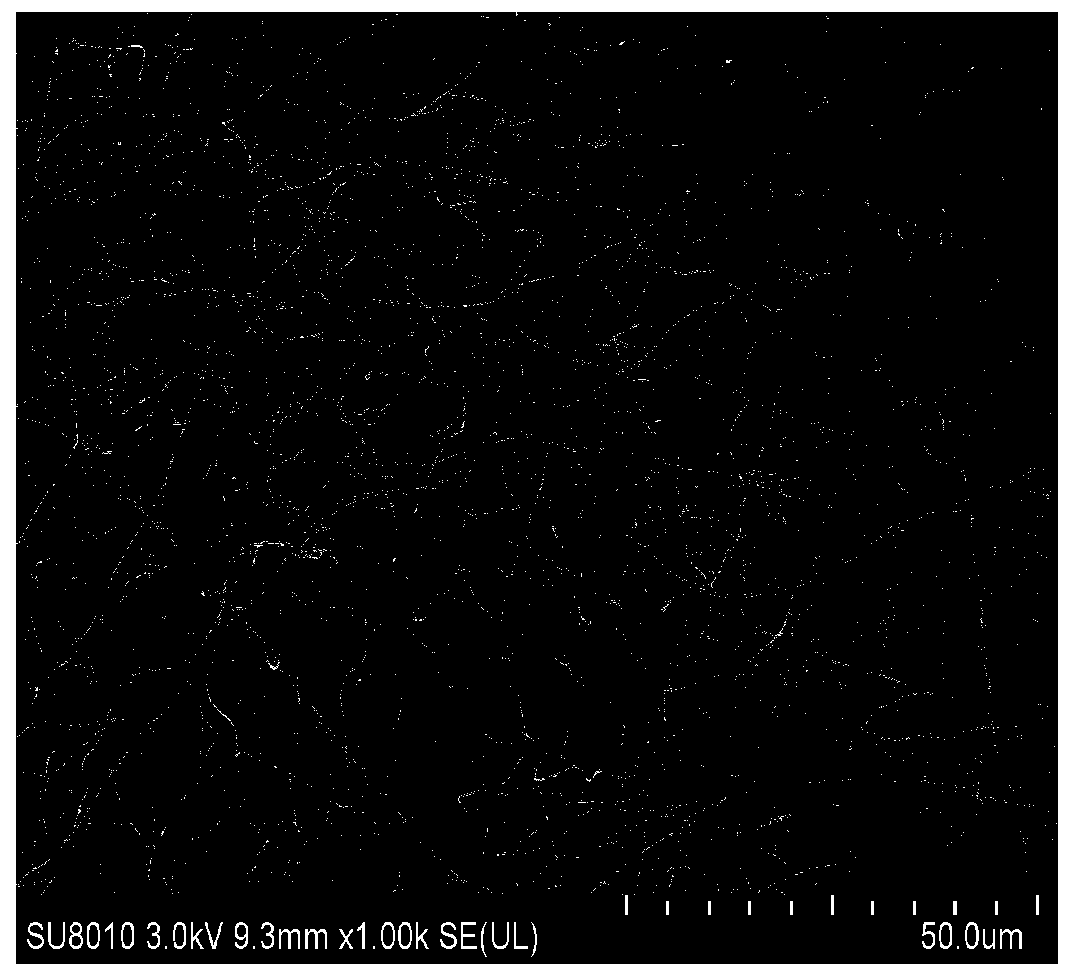

Composite skeleton reinforced ceramic based filter material preparation method

InactiveCN109824377ARealize chemical bond connectionImprove pore structureSustainable biological treatmentFiltration separationFiltrationMechanical property

The invention belongs to the technical field of environment-friendly materials and discloses a composite skeleton reinforced ceramic based filter material preparation method. The method includes: uniformly stirring and dispersing modified graphene oxide, macromolecular organic matter dispersion liquid and an antifoaming agent to obtain graphene oxide dispersion liquid; mixing diatomite with strongacid solution, performing hydrothermal reaction, filtering, washing, drying and calcining to obtain pretreated diatomite; subjecting the pretreated diatomite, the graphene oxide dispersion liquid, calcium carbonate, magnesium carbonate, sodium fluoride and nano iron powder to ball milling and mixing, and then standing for aging to obtain an aged material; rubbing the aged material to make balls,naturally drying, performing heat-preservation sintering at different temperatures under the protection of nitrogen while the temperature rise rate is controlled, cooling, and discharging to obtain acomposite skeleton reinforced ceramic based filter material. The ceramic based filter material prepared according to the technical scheme has excellent filtration performances as well as mechanical properties and has a promising prospect in development of the technical industry of environment-friendly materials.

Owner:吕莉

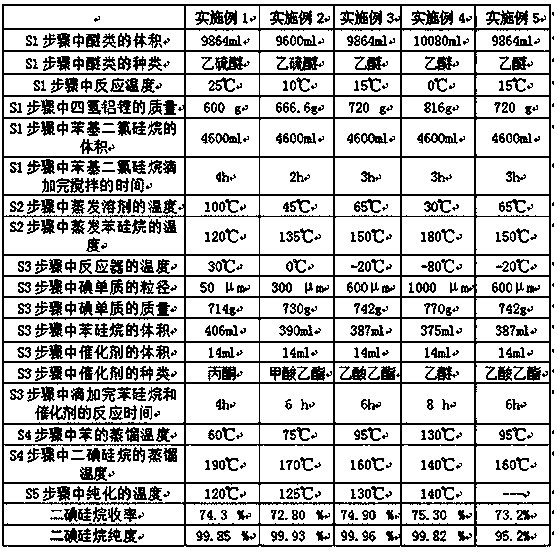

Preparation method of high-purity diiodosilane

ActiveCN110606491AImprove reaction kineticsImprove conversion rateHalogenated silanesInorganic compoundReaction temperature

The invention provides a preparation method of high-purity diiodosilane, and relates to the field of preparation of inorganic compounds. The preparation method of the high-purity diiodosilane comprises the following steps: under the protection of inert gas, with ethers as a solvent, performing a reaction on lithium aluminum hydride with phenyl dichlorosilane to prepare a phenylsilane mixture; heating the phenylsilane mixture for evaporating out phenylsilane, and collecting the phenylsilane; by controlling the reaction temperature to be -80 DEG C to 30 DEG C, dropwise adding the collected phenylsilane into the powdery iodine elementary substance under the stirring condition, meanwhile, adding an oxygen-containing organic compound as a catalyst, and performing a reaction to obtain a diiodosilane mixture; raising the temperature of the diiodosilane mixture to distill the crude diiodosilane. According to the preparation method of the high-purity diiodosilane provided by the invention, theinitial raw material is the non-toxic material phenyl dichlorosilane, and compared with the traditional highly toxic chemical phenyl trichlorosilane as the initial raw material, the safety of the process is greatly improved.

Owner:天津绿菱气体有限公司

Preparation method of self-support solid-state multi-component mask

ActiveCN110438665AReduced likelihood of inactivationImprove securityCosmetic preparationsToilet preparationsSolubilityElectrospinning

The invention provides a preparation method of a self-support solid-state multi-component mask. The preparation method is characterized in that oil-soluble skincare effective substances are dissolvedin polyvinyl pyrrolidone to serve as the core-layer spinning solution, water-soluble skincare effective substances are dissolved in polyvinyl alcohol to serve as the shell-layer spinning solution, a coaxial electrostatic spinning method is used to load the water-soluble skincare effective substances to the fiber shell layer and load the oil-soluble skincare effective substances to the fiber core layer, and accordingly two or more skincare effective substances different in solubility are loaded into a fiber membrane at the same time, and the mask can have better or various effects. The preparation method is simple in preparation process and easy in component and fiber structure control, and the self-support mask prepared by the method is good in mechanical performance and breathability.

Owner:INST OF PHARMACY SHANDONG PROV ACAD OF MEDICAL SCI

Preparation method of stabilized lithium metal powder

InactiveCN106299240AGuaranteed chemical stabilityAvoid contactSecondary cellsNon-aqueous electrolyte accumulator electrodesState of artLithium metal

The invention belongs to the technical field of lithium ion batteries and relates to a preparation method of stabilized lithium metal powder. The preparation method comprises adding low temperature solid asphalt into a reactor with a jacket, heating to melt the low temperature solid asphalt, cutting battery level purity lithium metal into small pieces in an inert atmosphere, adding a lithium ion good conductor and the lithium metal into the asphalt melt, carrying out stirring to obtain a precursor, adding the precursor into a graphitization furnace in an inert atmosphere and carrying out heating to realize asphalt graphitization. Compared with the prior art, the preparation method comprises melting low temperature solid asphalt, then adding the lithium ion good conductor and the small lithium metal pieces into the asphalt melt so that the lithium ion good conductor and the small lithium metal pieces are coated with the asphalt and carrying out asphalt graphitization so that the stabilized lithium metal powder with the graphite and lithium ion good conductor coating lithium metal surface is obtained. The preparation method is simple and easy and realizes a high yield and a low cost.

Owner:东莞市亿顺新材料有限公司

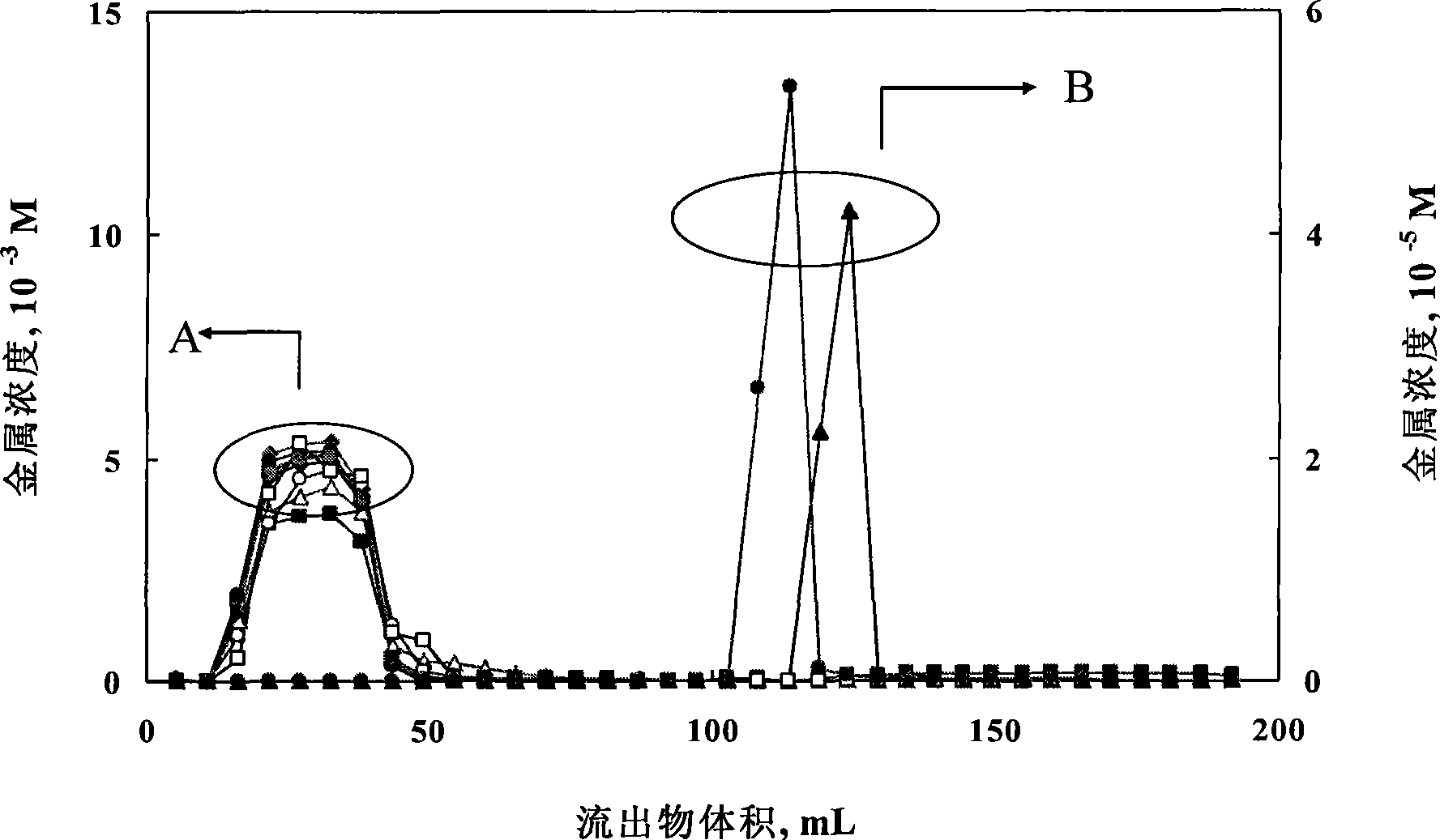

Sorbent for mutual separation of MA/RE in high-level waste and preparation thereof

InactiveCN101502790AEasy to identifyImprove adsorption capacityOther chemical processesSilicon compoundsMass ratioSorbent

The invention discloses a sorbent for MA / RE mutual separation in high-level waste and a preparation method thereof. The sorbent is prepared from 2, 6-di-(5, 6-di-n-butyl-1, 2, 4-triazine-3-radical)-pyridine loaded on macropore SiO2 of a coated polymer, and the mass ratio of the macropore SiO2 to R-BTP is (1-20):1. The sorbent has good identification capability on MA, high adsorption capacity and high recovering rate; when the sorbent is used in an adsorptive separation process, the sorbent does not need to be diluted or dissolved by with diluent of special performance, and can avoid introducing large amount of toxic solvent substances or generating secondary radioactive waste; and the ion diffusion, adsorption and desorption rate of the sorbent are remarkably improved, and the sorbent can run safely under the condition of high flow rate and is a safe and economic sorbent for efficiently mutually separating MA / RE in the high-level waste.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com