Steel fiber concrete high overall container used for disposal of radioactive substance and its preparation method

A technology of steel fiber concrete and radioactive substances, which is applied in the field of steel fiber concrete high-integral containers for radioactive substance disposal and its preparation, which can solve the problems of unreachable, short service life, and inability to carry out safety monitoring, and achieve the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

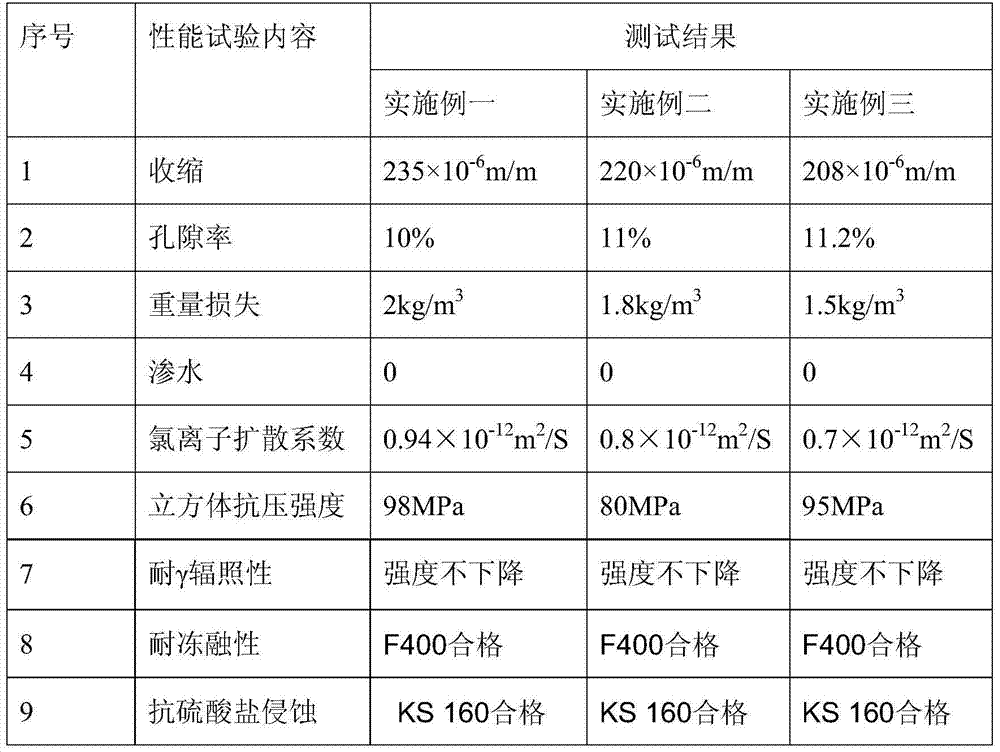

Examples

Embodiment 1

[0030] The steel fiber concrete high-integral container for radioactive material disposal is made of concrete poured from the following materials, including 360kg of cement, 25kg of silica fume, 190kg of slag, 45kg of fly ash, 150kg of water, 574kg of sand, 1067kg of gravel, and copper-plated steel Fiber 101kg, water reducer 13.8kg. The corresponding mass of the steel fiber can be converted according to the determined incorporation volume and the known density.

[0031] Put the raw materials of any one of the above-mentioned steel fiber concrete high-integral containers for radioactive material disposal in the molding room at 20°C one day in advance; Dry mix in the mixer for 1-2 minutes, add water and wet mix for 3 minutes, the total mixing time is controlled within 6 minutes, and then cast and form; Curing is carried out under the conditions of temperature 20°C±2°C and relative humidity above 95%RH.

[0032] The particle size distribution of the stones is 5mm-10mm and 10mm-2...

Embodiment 2

[0042] The difference between this embodiment and the first embodiment lies in the change of raw materials. Among them, 360kg of cement, 45kg of silica fume, 165kg of slag, 30kg of fly ash, 138kg of water, 574kg of sand, 1067kg of stone, 117kg of hook steel fiber, and 12kg of water reducing agent.

Embodiment 3

[0044] The difference between this embodiment and the first embodiment lies in the change of raw materials. Among them, 360kg of cement, 30kg of silica fume, 190kg of slag, 20kg of fly ash, 168kg of water, 574kg of sand, 1067kg of gravel, 93.6kg of steel fiber, double-mixed with copper-plated steel fiber and hook steel fiber, and 15kg of water reducing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com