Preparation method of self-support solid-state multi-component mask

A multi-component, self-supporting technology, applied in the direction of medical preparations containing active ingredients, skin care preparations, pharmaceutical formulations, etc., can solve the complex operation of the preparation method of the sizing method, which is not suitable for batch production in factories, and cannot be completely Bonding and other issues, to achieve the effect of easy components and fiber structure, good biocompatibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

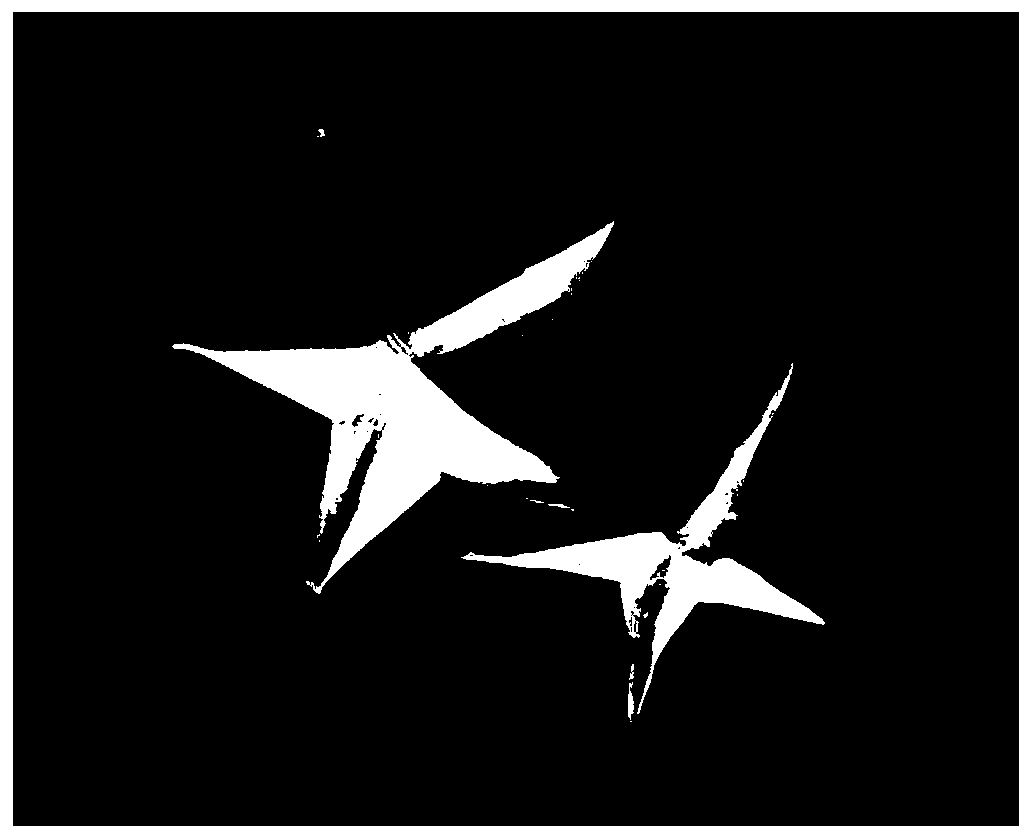

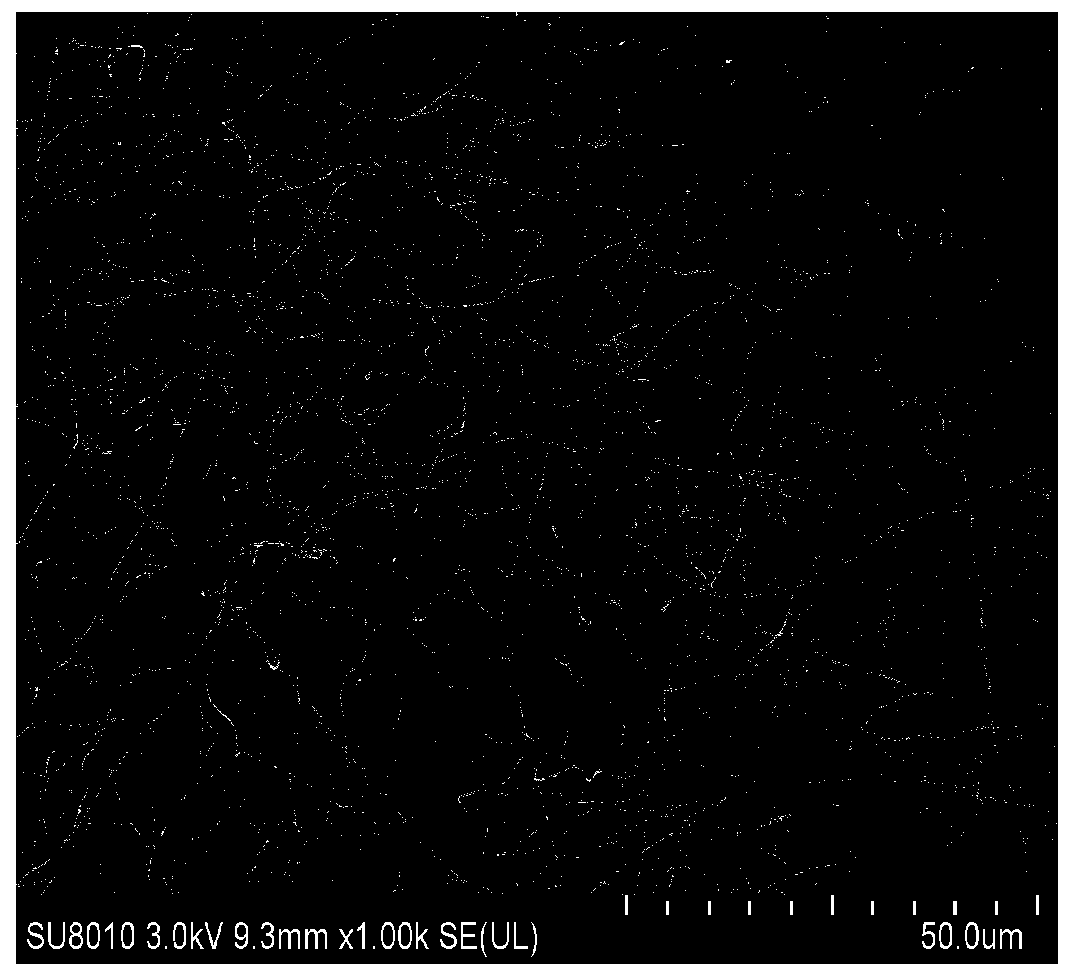

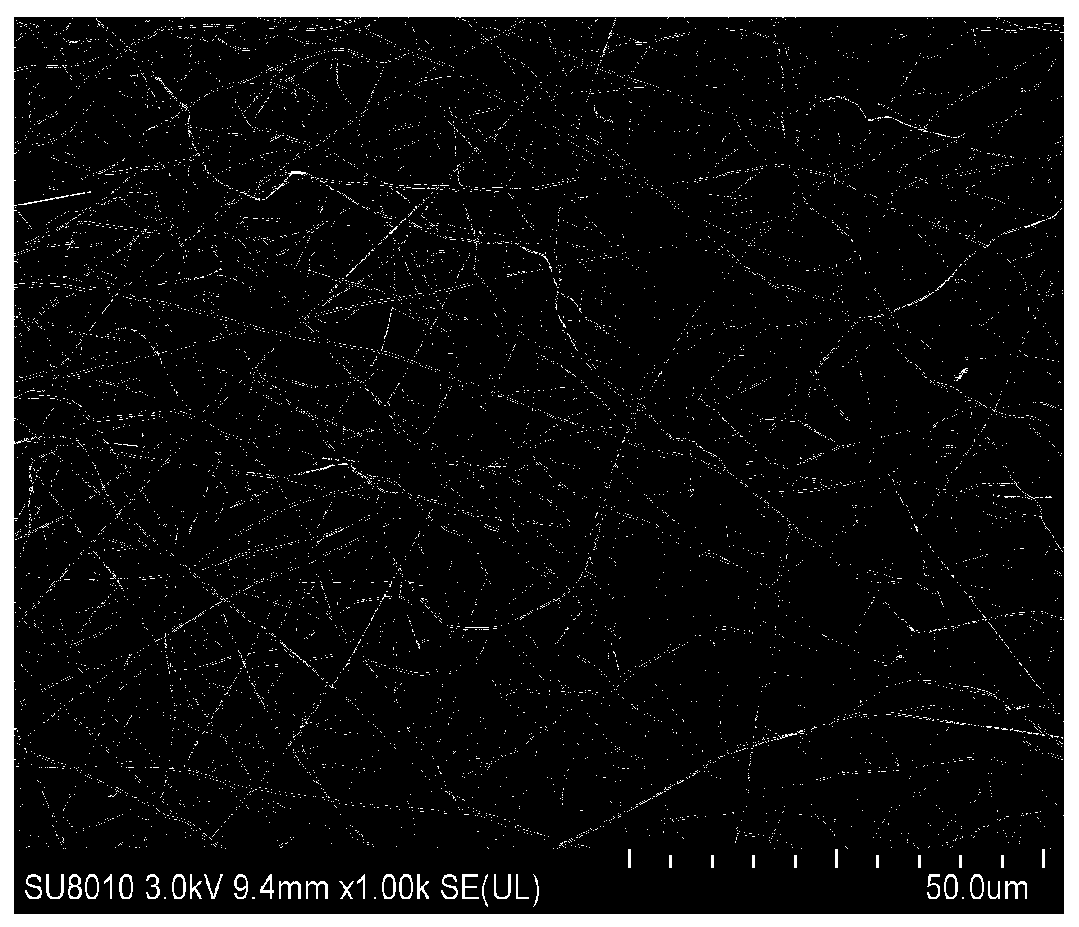

Image

Examples

Embodiment 1

[0041] A preparation method of a self-supporting solid multi-component facial mask, the steps are as follows:

[0042] (1) Add polyvinylpyrrolidone (PVP) (weight-average molecular weight is 780000) in absolute ethanol, stir at room temperature, after PVP dissolves completely, make concentration be 0.09g / mL (quality of polyvinylpyrrolidone / absolute ethanol volume) of the PVP solution; then in the PVP solution, add resveratrol (the addition of resveratrol is 2% of the PVP quality), continue to stir until dissolved, as the nuclear layer spinning solution;

[0043] (2) Add polyvinyl alcohol (PVA) (number average molecular weight: 63800) into deionized water, then raise the temperature to 70°C, condense and reflux under stirring, after the PVA is completely dissolved, cool to room temperature, and make the concentration 0.08g / mL (the quality of polyvinyl alcohol / the volume of deionized water) PVA solution; then add nicotinamide (the addition of nicotinamide is 2% of the PVA quality...

Embodiment 2

[0048] A preparation method of a self-supporting solid multi-component facial mask, the steps are as follows:

[0049] (1) Add polyvinylpyrrolidone (PVP) (weight average molecular weight is 900000) in dehydrated alcohol, stir at room temperature, after PVP dissolves completely, make concentration be 0.07g / mL (quality of polyvinylpyrrolidone / dehydrated alcohol volume) of the PVP solution; then in the PVP solution, add vitamin E (the addition of vitamin E is 3% of the PVP quality), continue to stir until after dissolving, as the nuclear layer spinning solution;

[0050] (2) Add polyvinyl alcohol (PVA) (number-average molecular weight: 75,000) into deionized water, then raise the temperature to 70°C, condense and reflux under stirring, after the PVA is completely dissolved, cool to room temperature, and make the concentration 0.1g / mL (the volume of the quality / deionized water of polyvinyl alcohol) PVA solution; Then in PVA solution, add water-soluble β-glucan (the addition of wat...

Embodiment 3

[0055] A preparation method of a self-supporting solid multi-component facial mask, the steps are as follows:

[0056] (1) Add polyvinylpyrrolidone (PVP) (weight average molecular weight is 1000000) in absolute ethanol, stir at room temperature, after PVP dissolves completely, make concentration be 0.1g / mL (quality of polyvinylpyrrolidone / absolute ethanol volume) of the PVP solution; then in the PVP solution, add arbutin (the addition of arbutin is 6% of the PVP quality), continue to stir until after dissolving, as the nuclear layer spinning solution;

[0057] (3) Add polyvinyl alcohol (PVA) (number average molecular weight: 77,000) into deionized water, then raise the temperature to 70°C, condense and reflux under stirring, after the PVA is completely dissolved, cool to room temperature, and make the concentration 0.1g / mL The PVA solution of (the quality of polyvinyl alcohol / the volume of deionized water); then add malic acid (the addition of malic acid is 2% of PVA quality) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com