Leadless low melting point phosphate glass

A technology of phosphate glass and low-melting glass, which is applied in the field of low-melting glass of ZnO-Sb2O3-P2O5 system, can solve the problem that the corrosion resistance of phosphate glass cannot meet the sealing requirements, and achieve the effect of improving chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

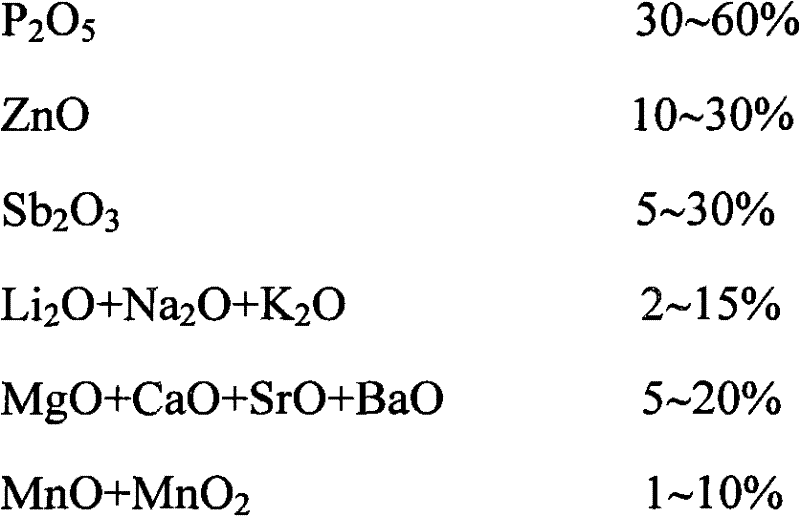

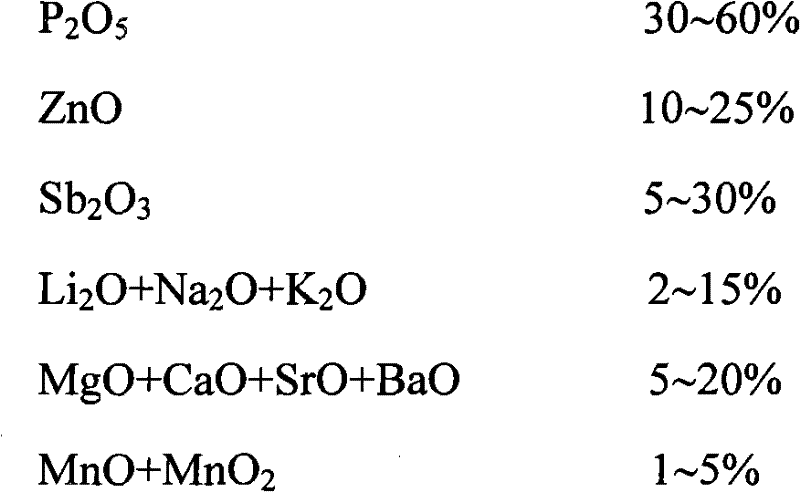

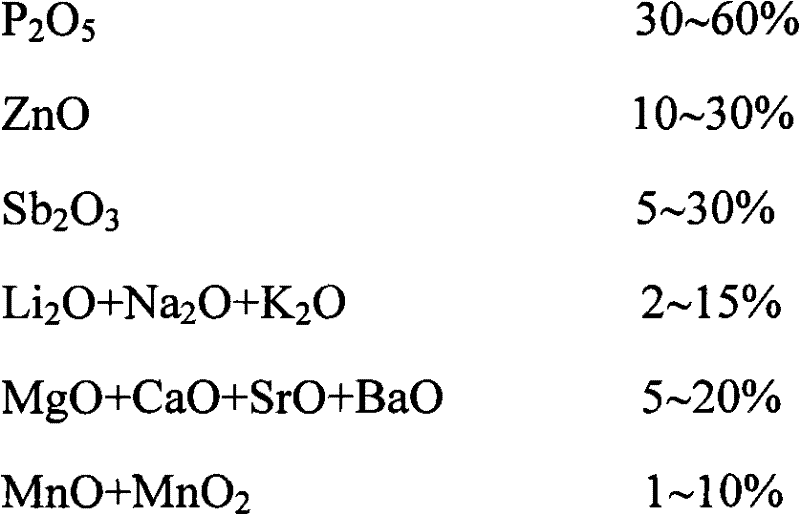

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is specifically described below through examples, and the content of the present invention is not subject to any restriction by the following examples.

[0029] The present invention melts glass samples by means of a high-temperature electric furnace in a laboratory, and the raw materials used are analytically pure chemical reagents, such as introducing P 2 o 5 Ammonium dihydrogen phosphate or phosphorus pentoxide or phosphoric acid, zinc oxide introduced into ZnO, introduced into Sb 2 o 3 antimony trioxide, carbonates of alkali metal oxides and alkaline earth metal oxides, manganese monoxide of MnO, MnO 2 manganese dioxide, introducing SiO 2 of silica, the introduction of Al 2 o 3 of aluminum hydroxide, introducing B 2 o 3 of boric acid etc. The batch materials of each component were put into a platinum crucible and melted in a high-temperature electric furnace to form a glass sample. Pour the melted uniform glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com