Superhigh-thermal conductivity silica brick for coke oven charing chamber furnace wall and preparation method thereof

A heat-conducting silicon and carbonization chamber technology, applied in the field of ultra-high heat-conducting silicon bricks, can solve the problem of not taking into account the comprehensive use performance, and achieve the effects of tight bonding, guaranteeing life, and reducing the porosity of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

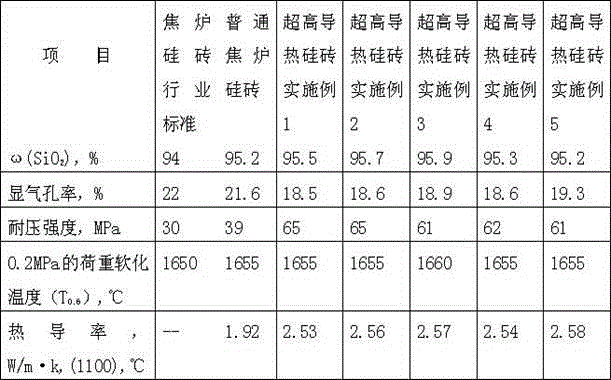

Embodiment 1

[0020] The starting materials crystalline silica, fused silica, waste silica bricks, and silicon nitride are mixed according to 60%, 19%, 20%, and 1% by weight, and the additives are as follows: potassium feldspar + 1%, clay + 0.3%, fluorite + 1%, sodium tripolyphosphate + 0.1%, pulp waste liquid + 1% (all are percentages of the total weight of the starting material). After weighing the above-mentioned raw materials, put them into a wet mill and knead for 25 minutes, put the mixed mud into the mold cavity and press it into a mold, and put the machine-pressed green body into a dryer at a temperature of 100 ℃, keep warm for 24 hours, put the dried green body into the tunnel kiln for firing, the firing temperature is 1400 ℃, keep warm for 72 hours, and the finished product will be finished after cooling out of the kiln.

Embodiment 2

[0022] The starting materials crystalline silica, fused silica, waste silica bricks, and silicon nitride are proportioned according to 65%, 12%, 10%, and 13% by weight, and the additives are as follows: potassium feldspar + 1%, clay + 0.3%, fluorite + 1%, sodium tripolyphosphate + 0.1%, pulp waste liquid + 1% (all are percentages of the total weight of the starting material). After weighing the above-mentioned raw materials, put them into a wet mill for 25 minutes of kneading, put the mixed mud into the mold cavity and press it into a mold, and put the machine-pressed green body into a dryer at a temperature of 80 ℃, keep warm for 24 hours, put the dried green body into the tunnel kiln for firing, the firing temperature is 1430 ℃, keep warm for 72 hours, and the finished product will be finished after cooling out of the kiln.

Embodiment 3

[0024] The starting materials crystalline silica, fused silica, waste silica bricks, and silicon nitride are proportioned according to 67%, 13%, 10%, and 10% by weight, and the additives are as follows: potassium feldspar + 1%, clay + 0.3%, fluorite + 1%, sodium tripolyphosphate + 0.1%, pulp waste liquid + 1% (all are percentages of the total weight of the starting material). After weighing the above-mentioned raw materials, put them into a wet mill and knead for 25 minutes, put the mixed mud into the mold cavity and press it into a mold, and put the machine-pressed green body into a dryer at a temperature of Between 70°C and heat preservation for 24 hours, put the dried body into a tunnel kiln for firing at a firing temperature of 1450°C, heat preservation for 72 hours, and the finished product after cooling out of the kiln.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com