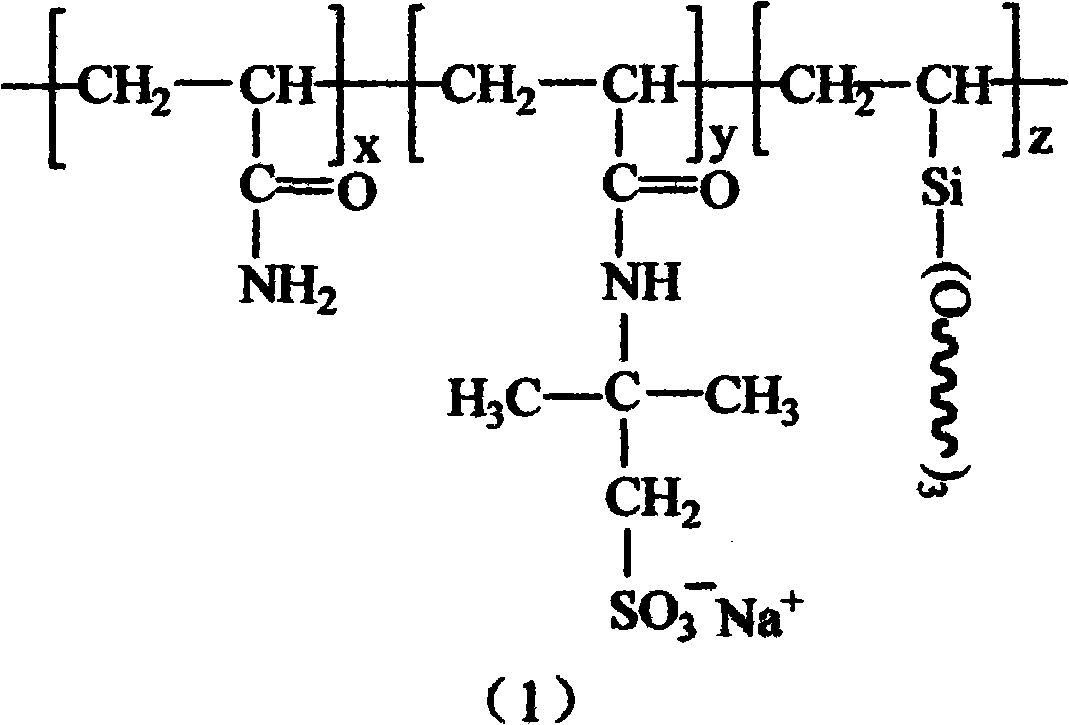

Long-branched chain polyacrylamide copolymer and preparation method thereof

A polyacrylamide and acrylamide technology, which is applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of lack of mature polyacrylamide products for oil displacement, and achieve chemical stability and improve viscoelasticity. , the effect of reducing the interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 6g of acrylamide, 3.5g of 2-acrylamido-2-methylpropanesulfonic acid and 0.5g of triethoxyvinylsilane into the polymerization reaction bottle, and then add 1% sodium lauryl sulfate aqueous solution in sequence 1.0g, 0.5g of 1% urea aqueous solution, dissolved in 23.0g of deionized water, then added sodium hydroxide to adjust the pH to 7.0, put the polymerization reaction bottle in a constant temperature water bath, emulsified nitrogen gas to drive oxygen for 30 minutes, then added 0.1% 1.0 g of potassium persulfate aqueous solution and 1.0 g of 0.1% potassium bisulfite aqueous solution were used to initiate the reaction at 10° C. and stop after continuing to pass nitrogen gas for five minutes. After 2 hours of polymerization reaction, the temperature was raised to 50° C. to continue the reaction for 3 hours to obtain milky white of latex particles. The latex particles are taken out, dried after demulsification, crushed, and sieved to obtain a white long-chain branche...

Embodiment 2

[0032] Add 5g of acrylamide, 4.9g of 2-acrylamido-2-methylpropanesulfonic acid and 0.1g of acryloxypropyltriethoxysilane into the polymerization reaction bottle, and then add 1% of dodecyl Dissolve 5.0 g of sodium sulfate aqueous solution, 1.0 g of 1% urea aqueous solution, and 23.0 g of deionized water, then add sodium hydroxide to adjust the pH to 8.0, put the polymerization reaction bottle in a constant temperature water bath, emulsify and pass nitrogen gas to drive oxygen for 30 minutes, Add 2.0 g of 0.1% ammonium persulfate aqueous solution and 2.0 g of 0.1% potassium bisulfite aqueous solution, initiate the reaction at 15°C, continue to pass nitrogen for five minutes and then stop, after 2 hours of polymerization reaction, raise the temperature to 50°C and continue the reaction for 4 hours , to obtain milky white latex particles. The latex particles are taken out, dried after demulsification, crushed, and sieved to obtain a white long-chain branched acrylamide copolymer....

Embodiment 3

[0034] Add 6g of acrylamide, 3.7g of 2-acrylamido-2-methylpropanesulfonic acid and 0.3g of triacetoxyvinylsilane into the polymerization reaction bottle, and then add 1% of dodecylbenzenesulfonic acid in sequence Dissolve 2.0 g of sodium aqueous solution, 0.5 g of 1% urea aqueous solution, and 23.0 g of deionized water, then add sodium hydroxide to adjust the pH to 9.0, put the polymerization reaction bottle in a constant temperature water bath, emulsify and pass nitrogen gas to drive oxygen for 30 minutes, then add 0.1% ammonium persulfate aqueous solution 5.0g and 0.1% sodium bisulfite aqueous solution 5.0g, initiate reaction at 20 DEG C, stop after continuing to feed nitrogen for five minutes, polymerize after 6 hours, be warming up to 50 DEG C and continue reaction for 3 hours, Milky white latex particles were obtained. The latex particles are taken out, dried after demulsification, crushed, and sieved to obtain a white long-chain branched acrylamide copolymer. The tested...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com