Color masterbatch formula

A color masterbatch and formulation technology, which is applied in the field of plastic coloring and high-speed textile fiber coloring, can solve problems such as lack of reach, uneven color, product mixing, etc., and achieve enhanced anti-aging performance, improved dispersibility, and improved antibacterial performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

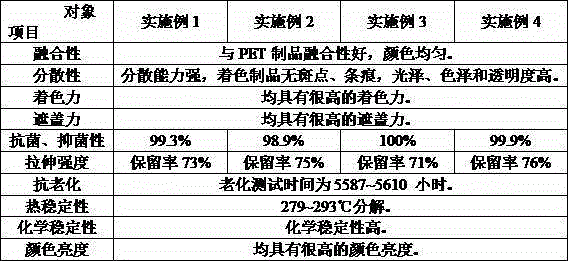

Embodiment 1

[0026] A color masterbatch formula, the color masterbatch formula is composed of the following components, the content of each component is calculated in parts by weight: 20 parts of carrier, 5 parts of toner, 5 parts of dispersant, 1 part of epoxy glyceride, shell 1 part of polysaccharide, 1 part of tea polyphenol, 1 part of benzotriazole ultraviolet absorber and 1 part of brightening agent.

[0027] Wherein, the carrier is a mixture carrier, and the mixture carrier is prepared from the following raw materials in parts by weight: 10 parts of polyolefin, 8 parts of polyethylene terephthalate, and 5 parts of polyamide resin. The polyethylene terephthalate is polyethylene terephthalate, polybutylene terephthalate or polyethylene terephthalate.

[0028] The toner is one of phthalocyanine red, phthalocyanine blue, phthalocyanine green, sunfast scarlet, macromolecule red, macromolecule yellow, permanent yellow, permanent violet and azo red.

[0029] The dispersant is any two of po...

Embodiment 2

[0031] A color masterbatch formula, the color masterbatch formula is composed of the following components, the content of each component is calculated in parts by weight: 40 parts of carrier, 10 parts of toner, 10 parts of dispersant, 3 parts of epoxy fatty ester, carboxyl 3 parts of methyl chitosan, 3 parts of phytic acid, 2 parts of benzotriazole UV absorber and 2 parts of brightening agent.

[0032] Wherein, the carrier is a mixture carrier, and the mixture carrier is prepared from the following raw materials in parts by weight: 13 parts of polyolefin, 10 parts of polyethylene terephthalate, and 8 parts of polyamide resin. The polyethylene terephthalate is polyethylene terephthalate, polybutylene terephthalate or polyethylene terephthalate.

[0033] The toner is one of phthalocyanine red, phthalocyanine blue, phthalocyanine green, sunfast scarlet, macromolecule red, macromolecule yellow, permanent yellow, permanent violet and azo red.

[0034] The dispersant is any two of ...

Embodiment 3

[0036] A color masterbatch formula, the color masterbatch formula is composed of the following components, the content of each component is calculated in parts by weight: 60 parts of carrier, 20 parts of toner, 20 parts of dispersant, 6 parts of calcium stearate, nano 6 parts of silver, 6 parts of tocopherol, 4 parts of benzotriazole UV absorber and 4 parts of brightening agent.

[0037] Wherein, the carrier is a mixture carrier, and the mixture carrier is prepared from the following raw materials in parts by weight: 16 parts of polyolefin, 13 parts of polyethylene terephthalate, and 12 parts of polyamide resin. The polyethylene terephthalate is polyethylene terephthalate, polybutylene terephthalate or polyethylene terephthalate.

[0038] The toner is one of phthalocyanine red, phthalocyanine blue, phthalocyanine green, sunfast scarlet, macromolecule red, macromolecule yellow, permanent yellow, permanent violet and azo red.

[0039] The dispersant is any two of polyethylene w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com