Patents

Literature

139 results about "Phthalocyanine green" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phthalocyanine green G, which has many commercial names, is a synthetic green pigment from the group of phthalocyanine dyes, a complex of copper(II) with chlorinated phthalocyanine. It is a soft green powder, which is insoluble in water.

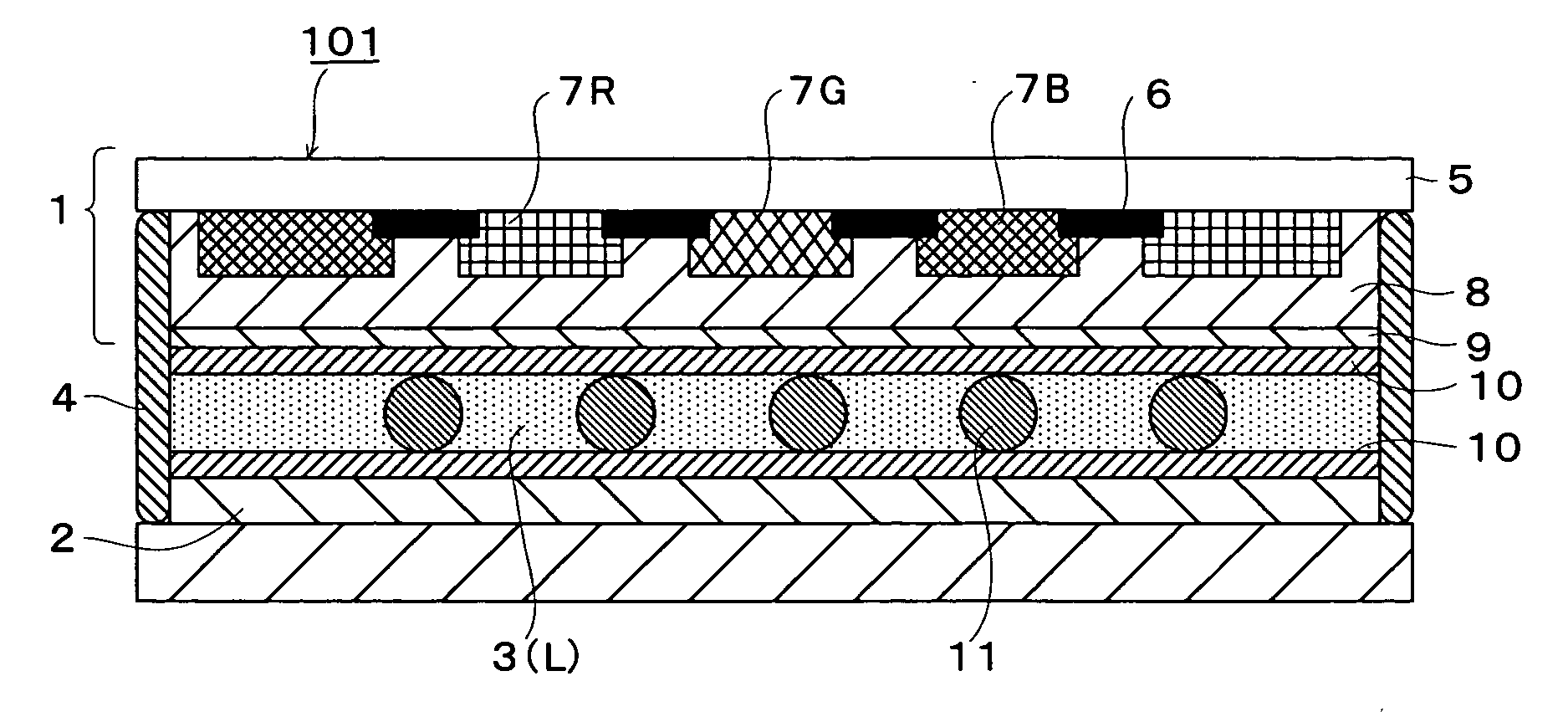

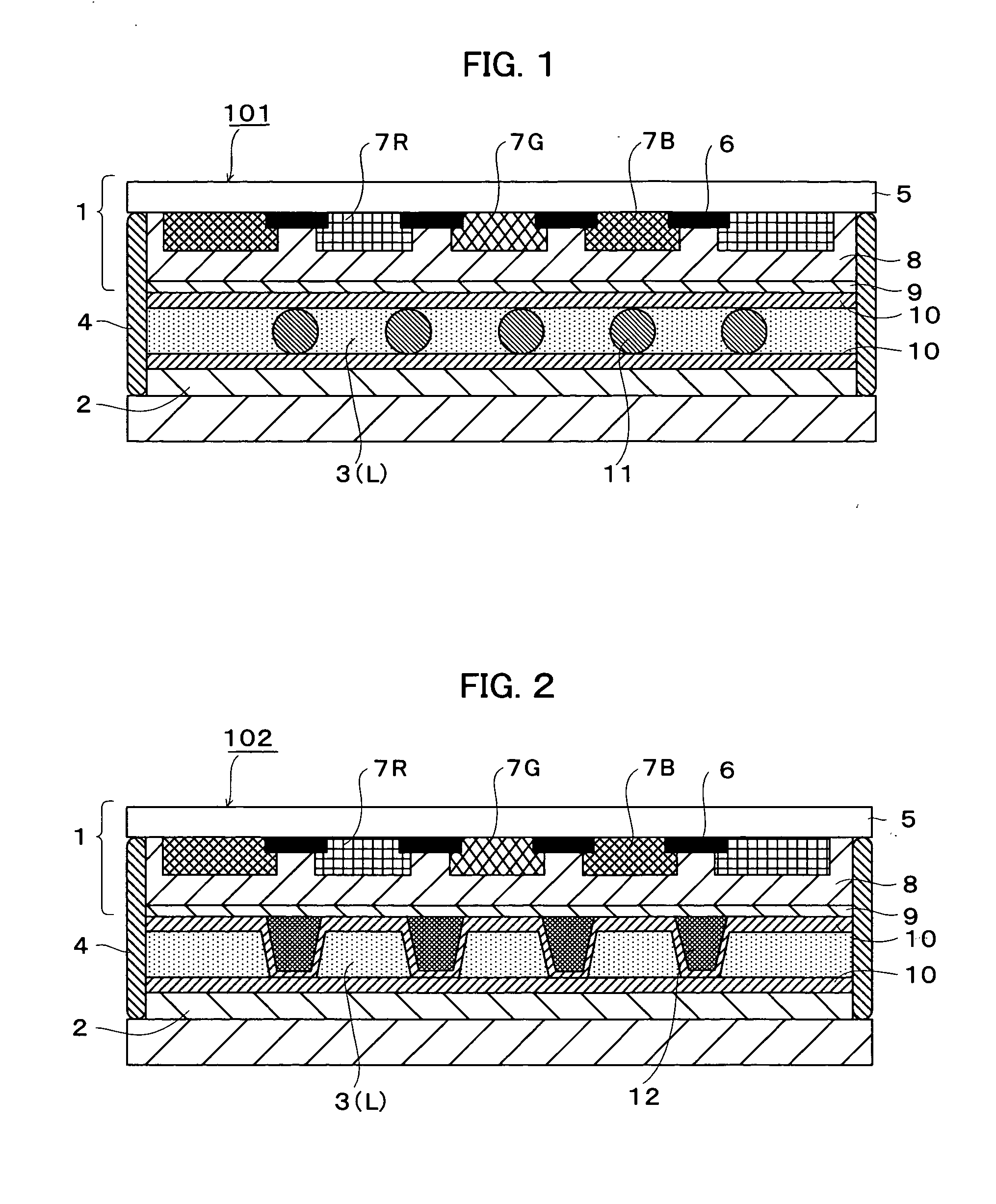

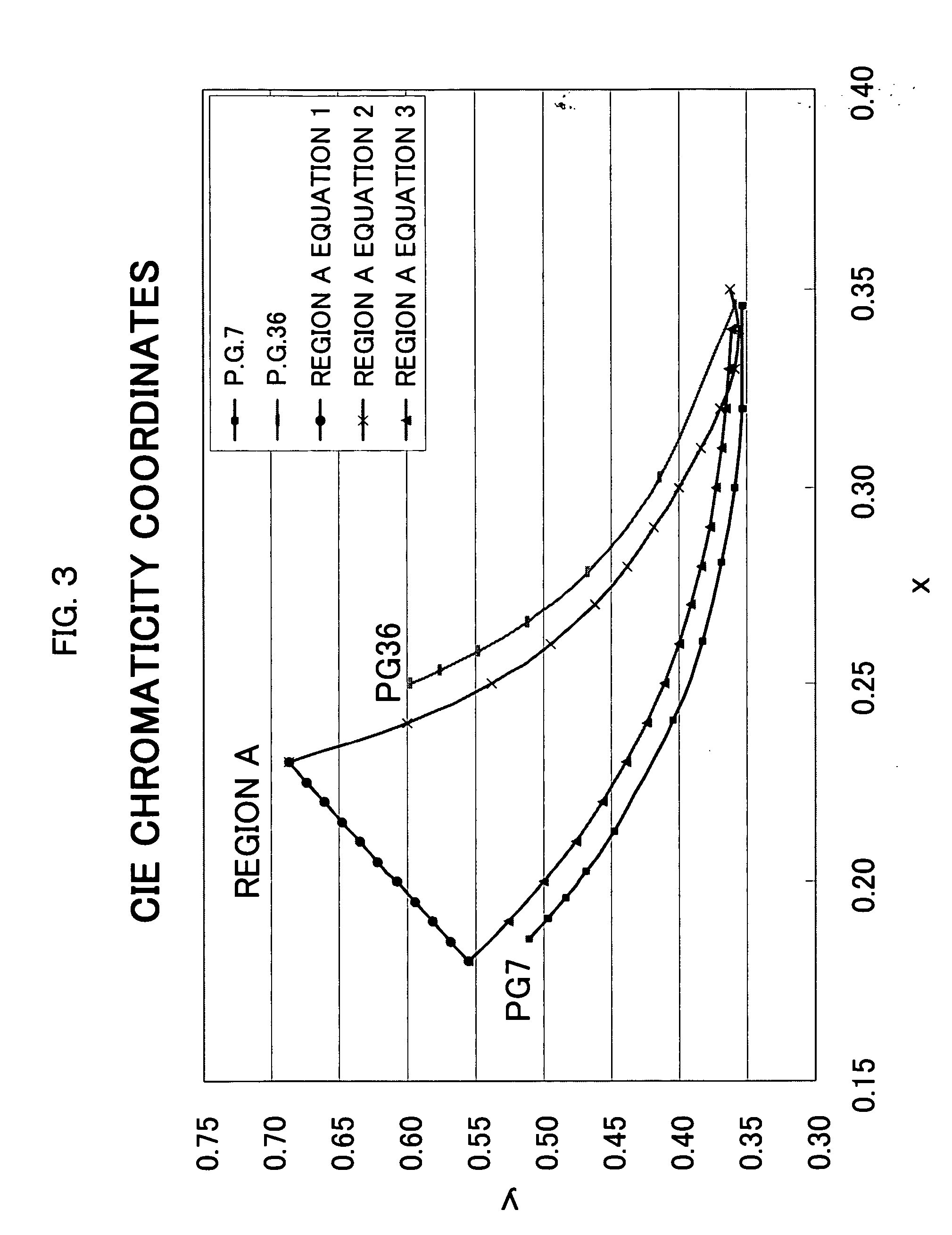

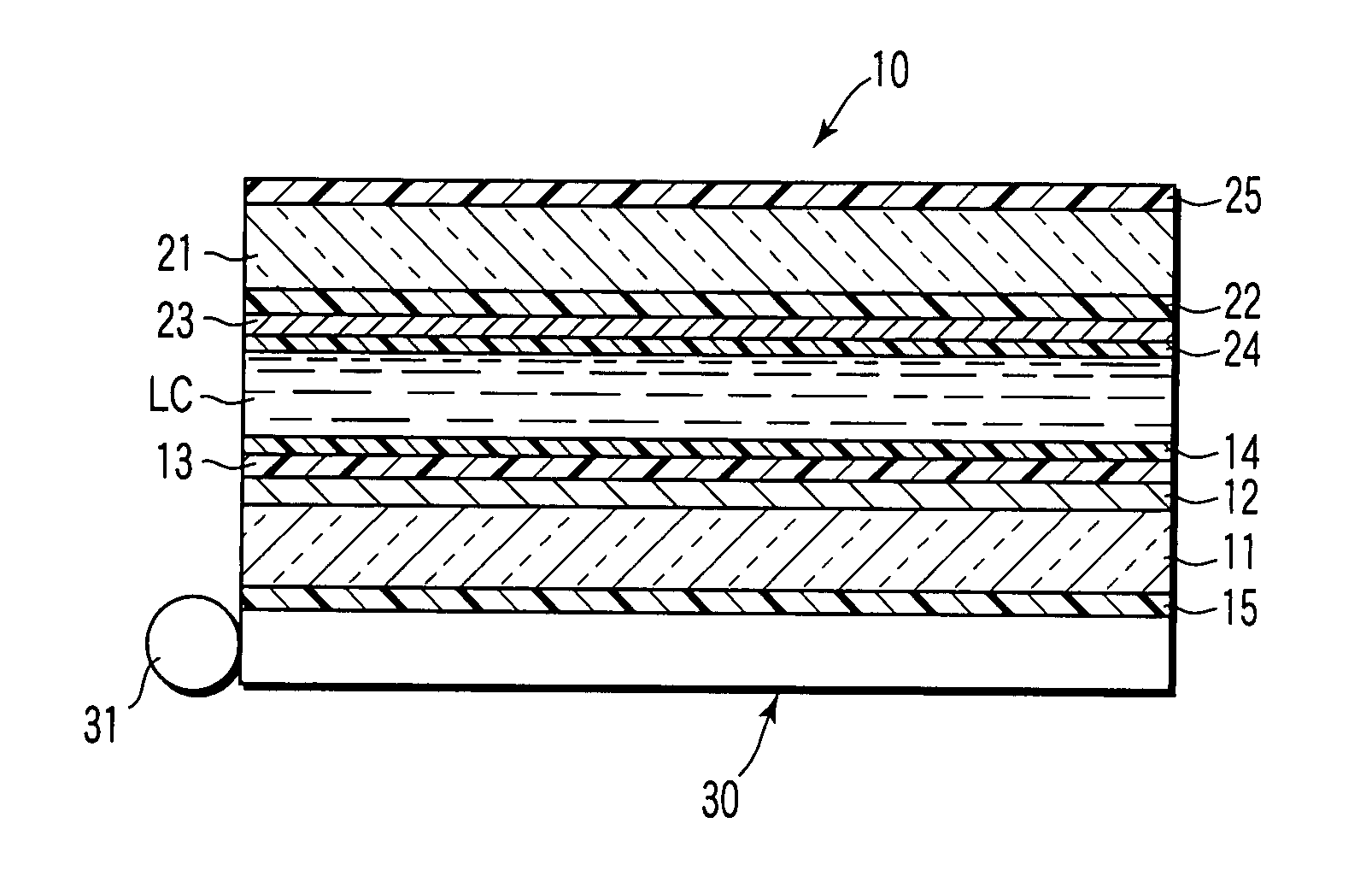

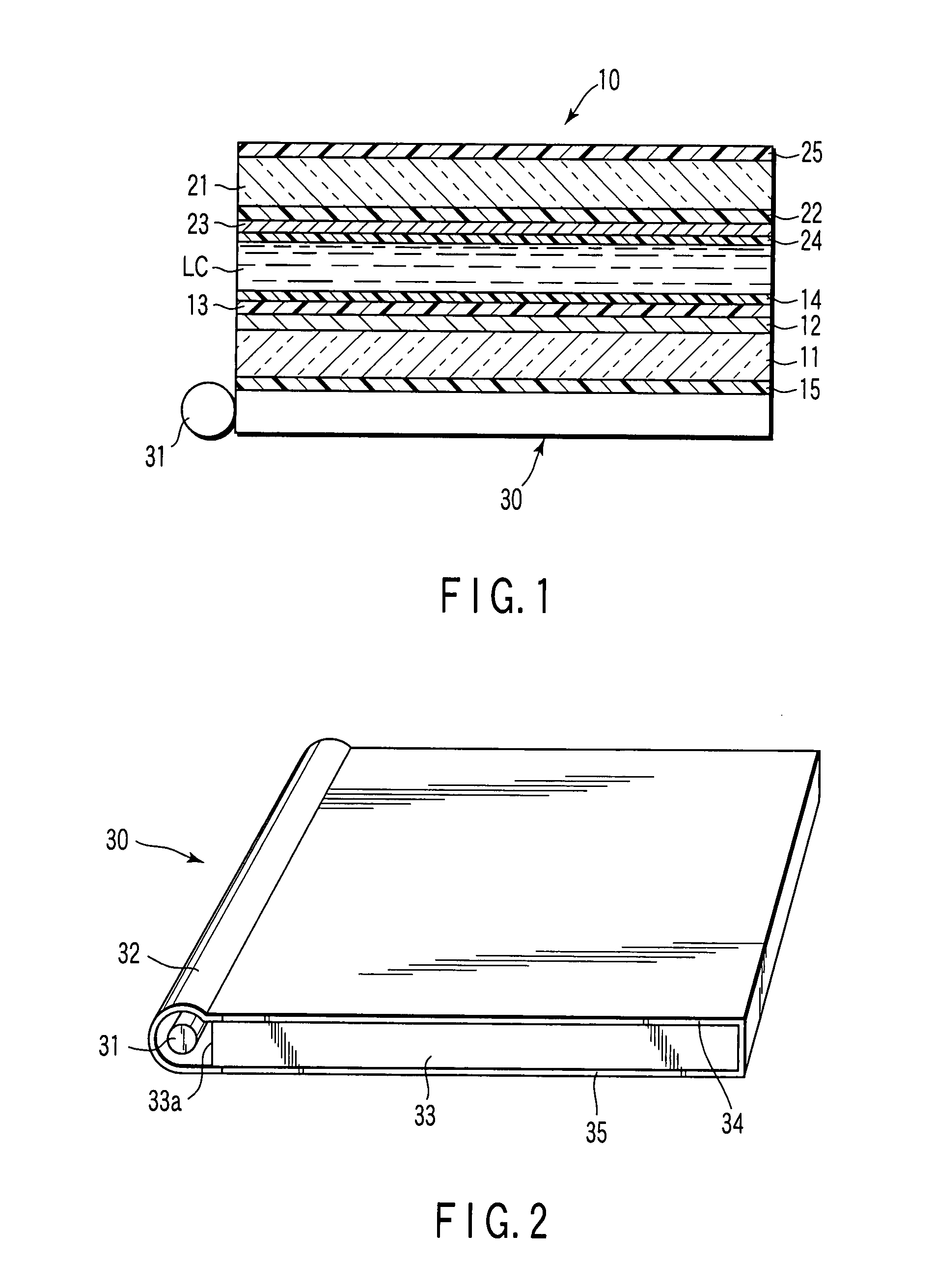

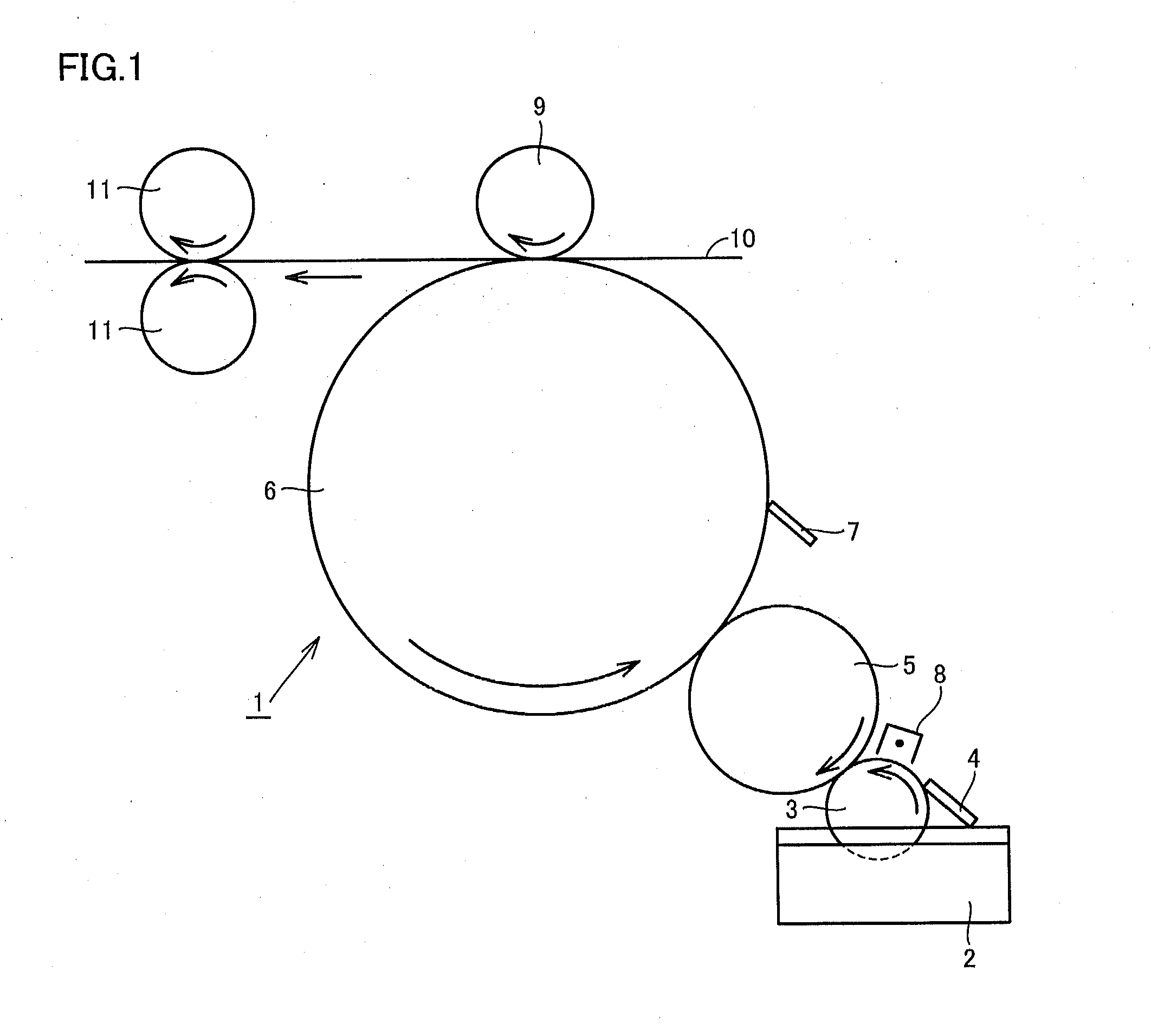

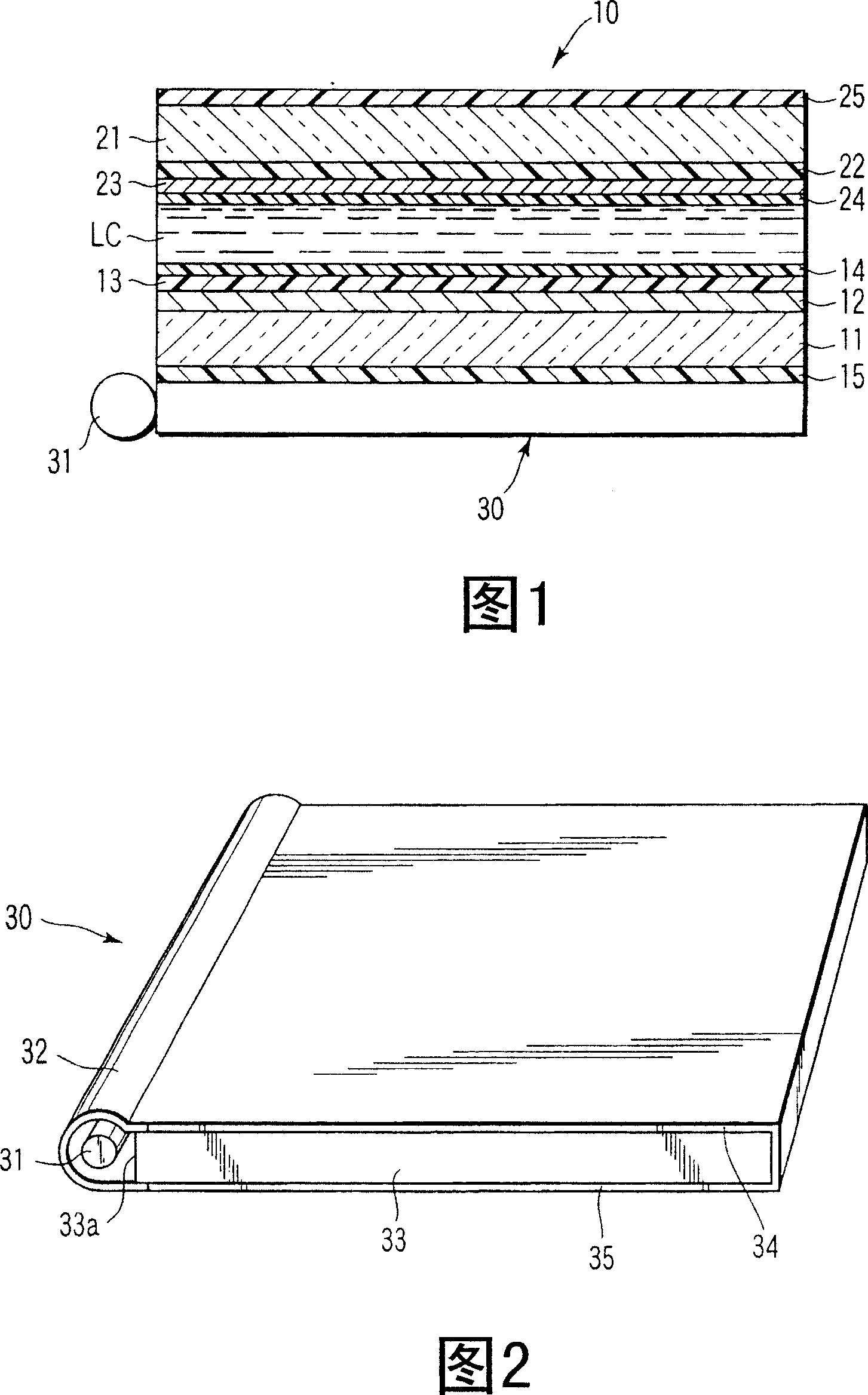

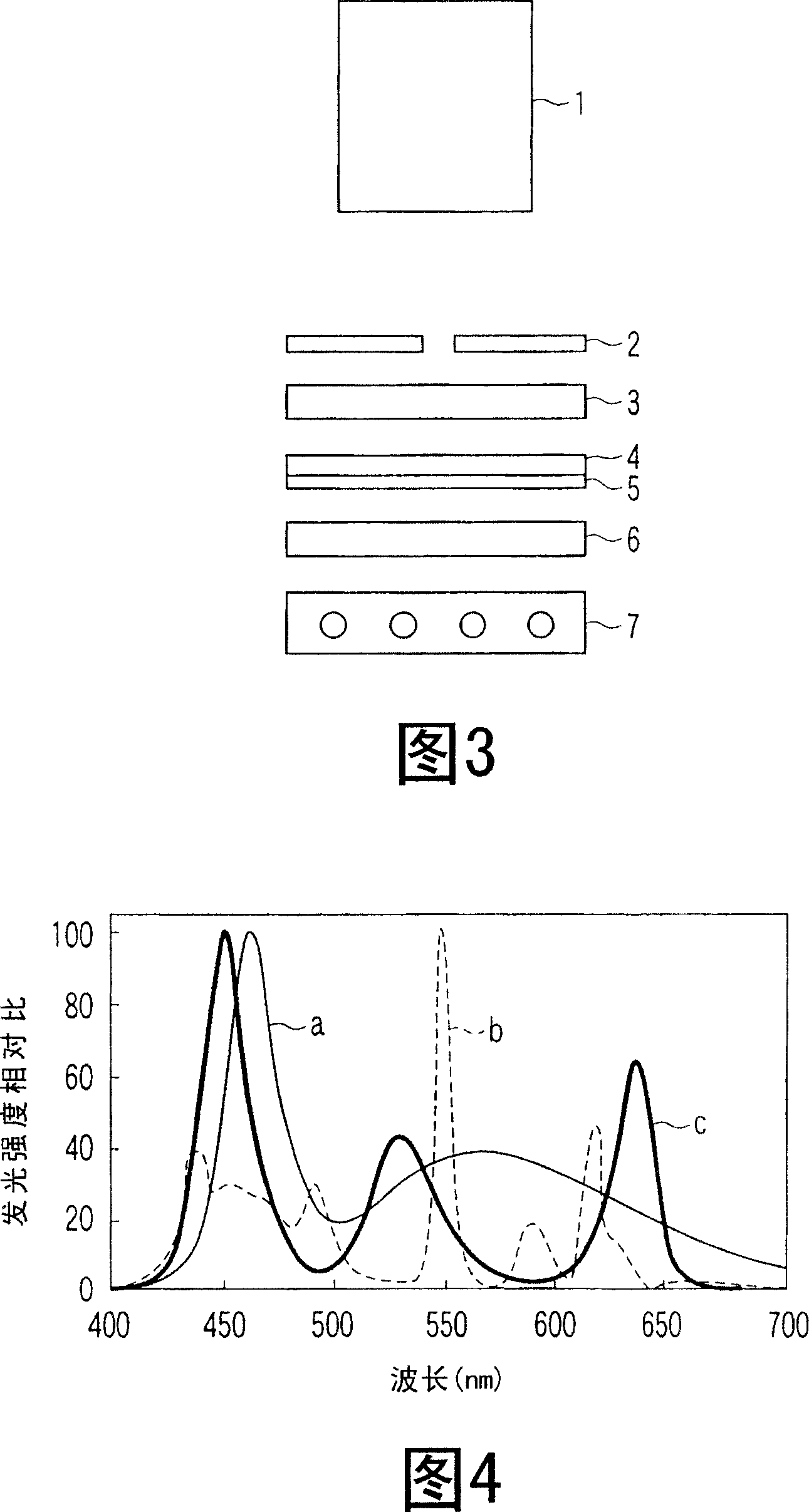

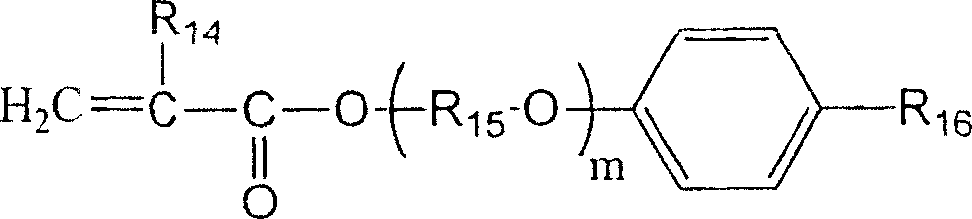

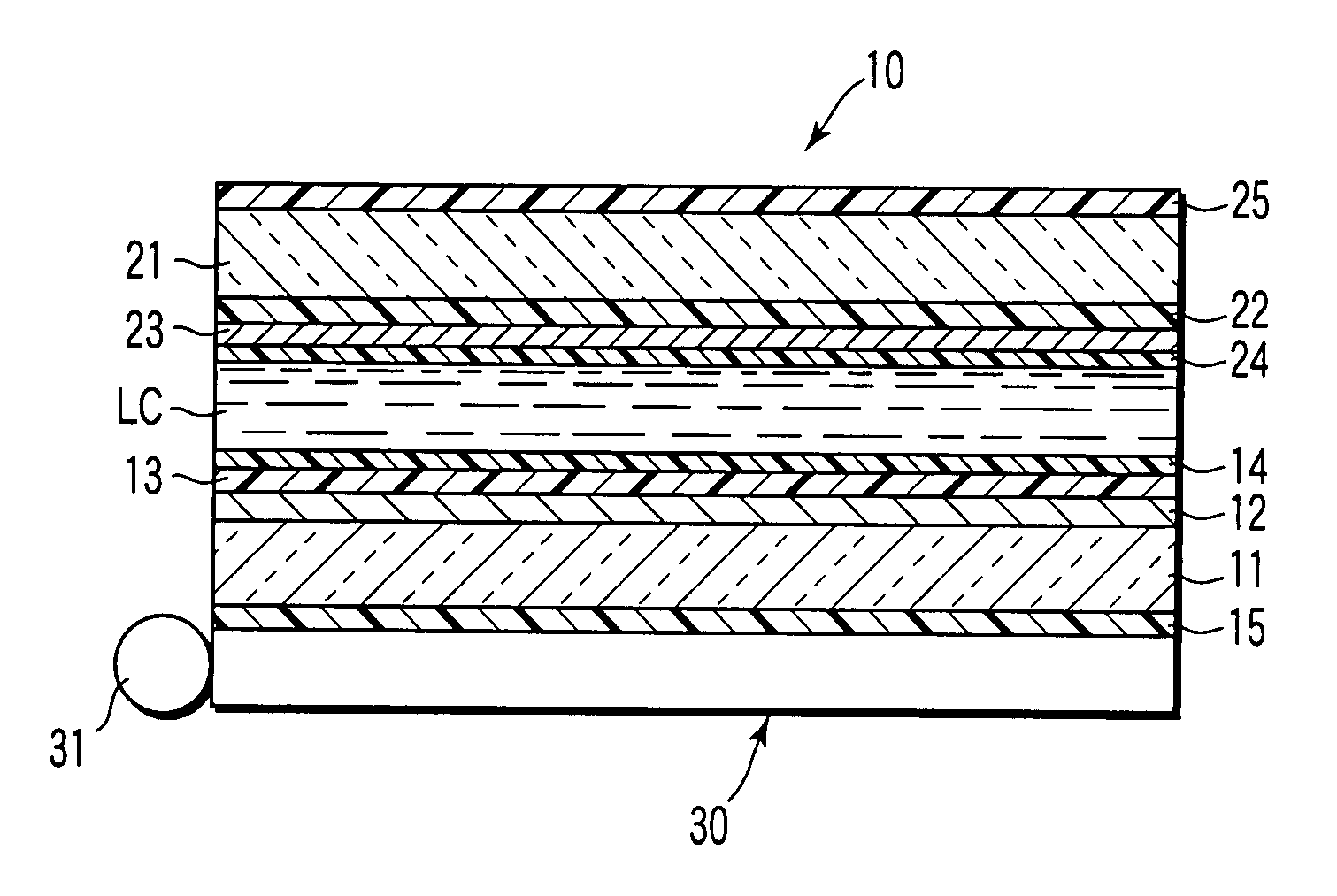

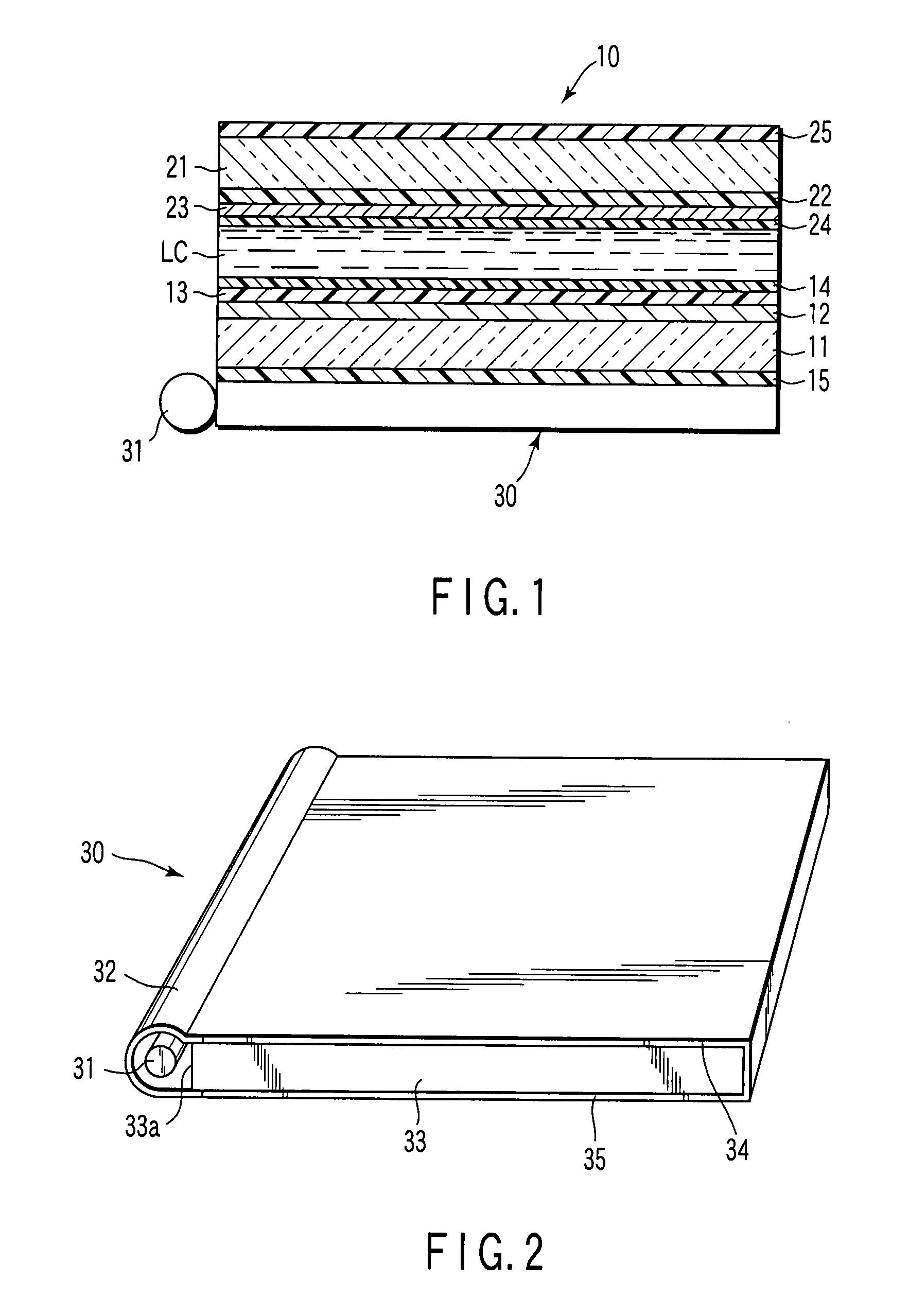

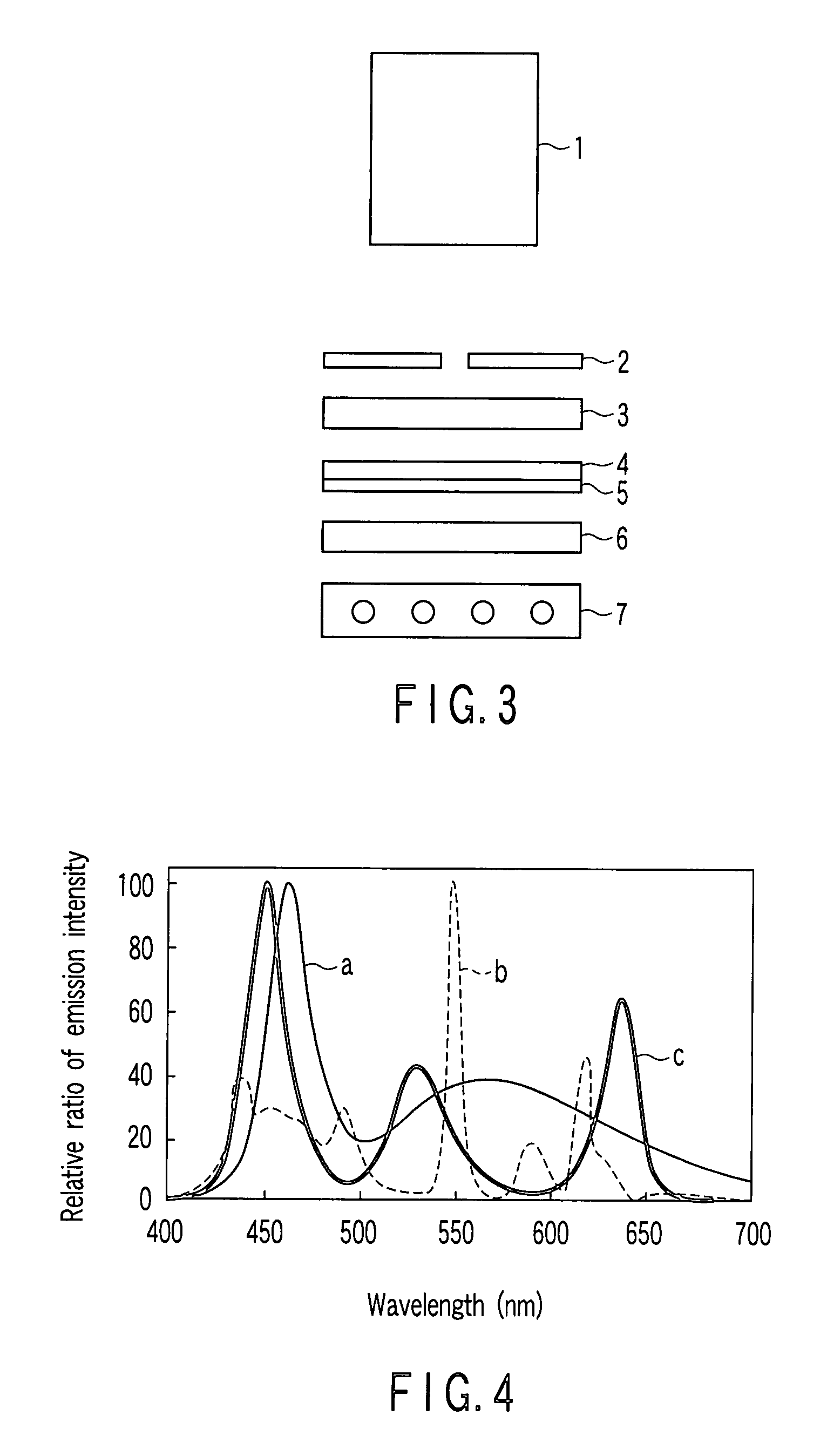

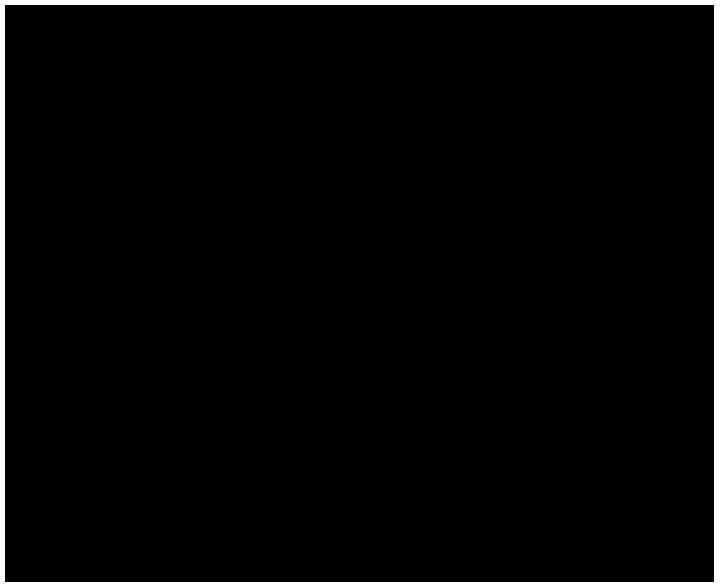

Green pigment for color filter, green pigment dispersion, photosensitive color composition, color filter, and liquid crystal panel

ActiveUS20060098316A1High strengthPromote formationPhotosensitive materialsPhotomechanical apparatusPhotopigmentPigment dispersion

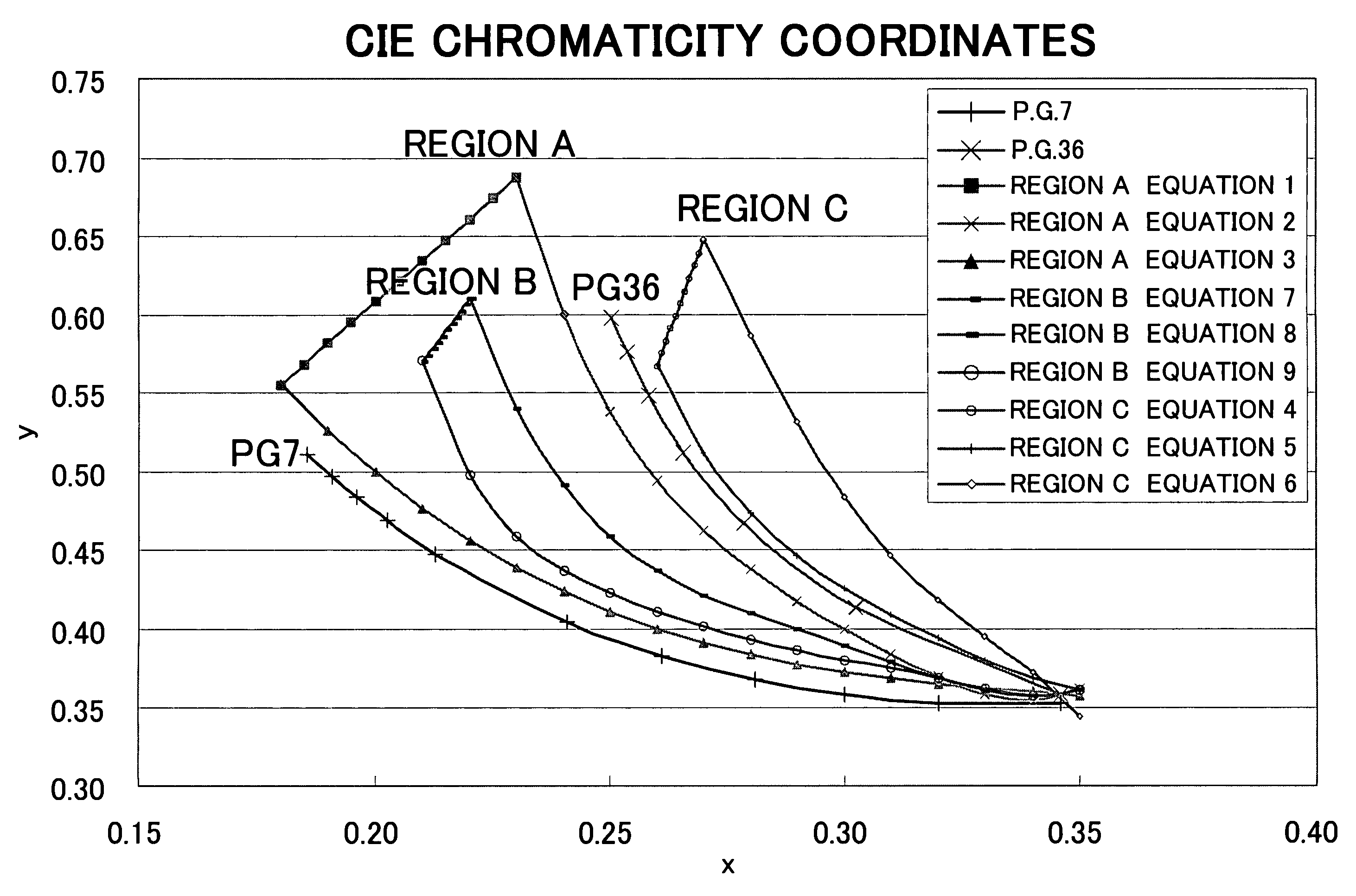

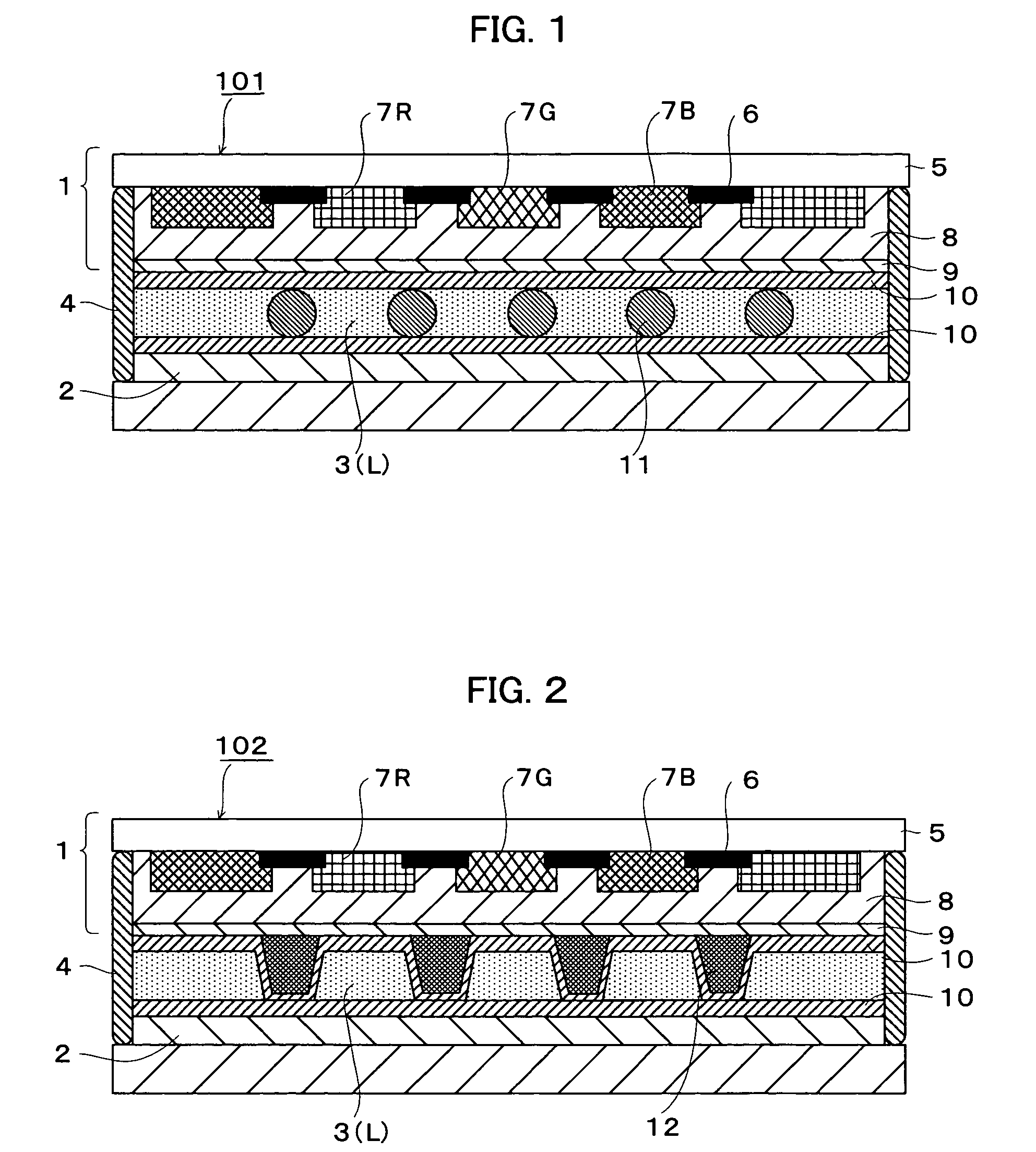

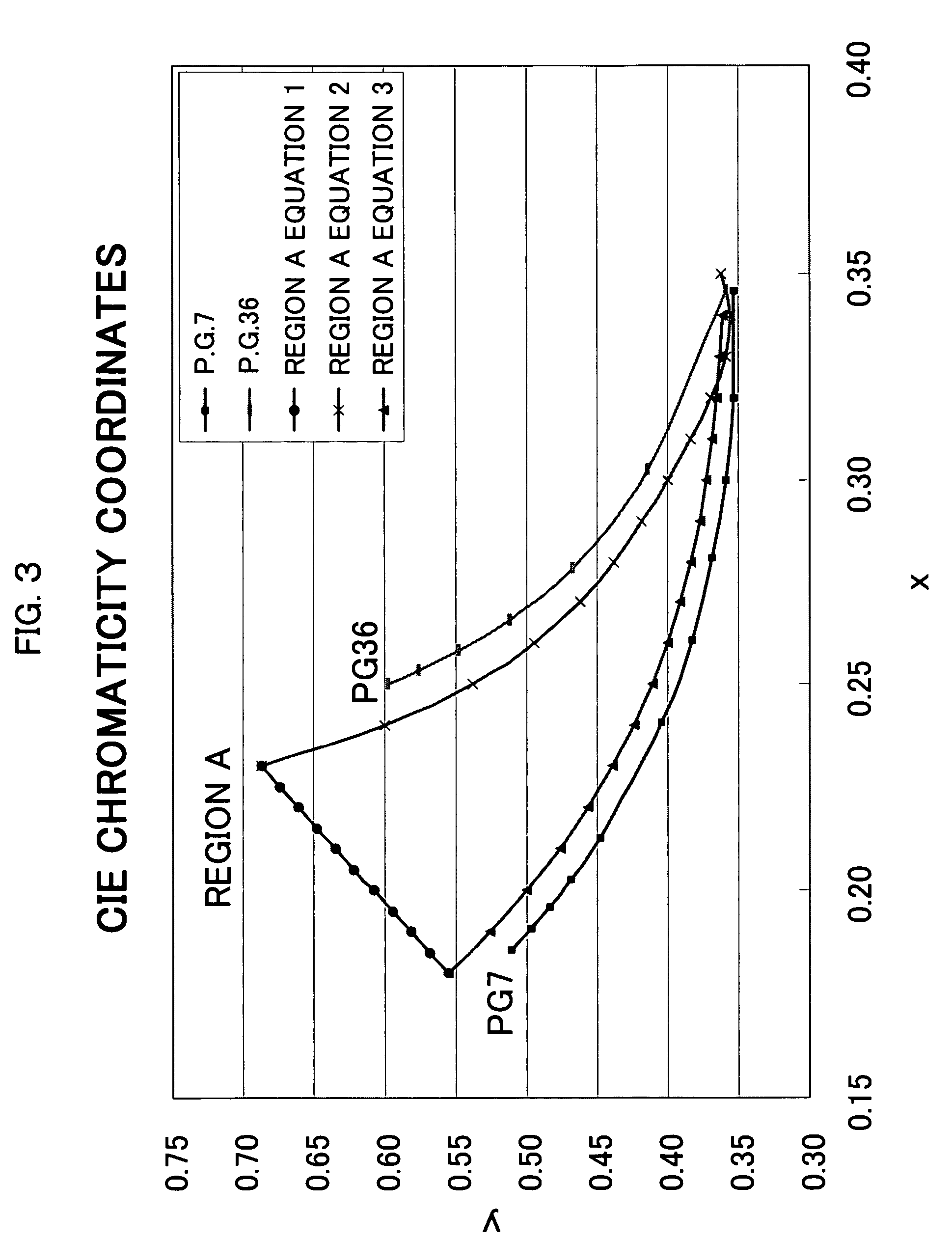

An object of the present invention is to provide a green pigment for a color filter, capable of displaying the chromaticity coordinates not to be displayed by the conventional green pigments, having the excellent color strength as a green color which is not excessively strong in a blue tinge, and a high transmittance, and moreover, to provide a photosensitive color composition, a pigment dispersion, a color filter and a liquid crystal panel, using the above-mentioned green pigment. In order to achieve the above-mentioned object, the present invention provides a green pigment for a color filter comprised of a phthalocyanine green pigment and capable of expressing a region of xy-chromaticity coordinate enclosed by predetermined equations 1, 2 and 3 defined by the XYZ color system of the CIE when the green pigment is solely subjected to colorimetry. Moreover, using the above-mentioned green pigment, it provides a photosensitive color composition capable of forming a color filter having a wide color reproduction range and a high transmittance. Furthermore, it provides a color filter having a wide color reproduction range and a high transmittance with a green pixel formed using the above-mentioned photosensitive color composition, and a liquid crystal panel using the color filter.

Owner:DAI NIPPON PRINTING CO LTD +1

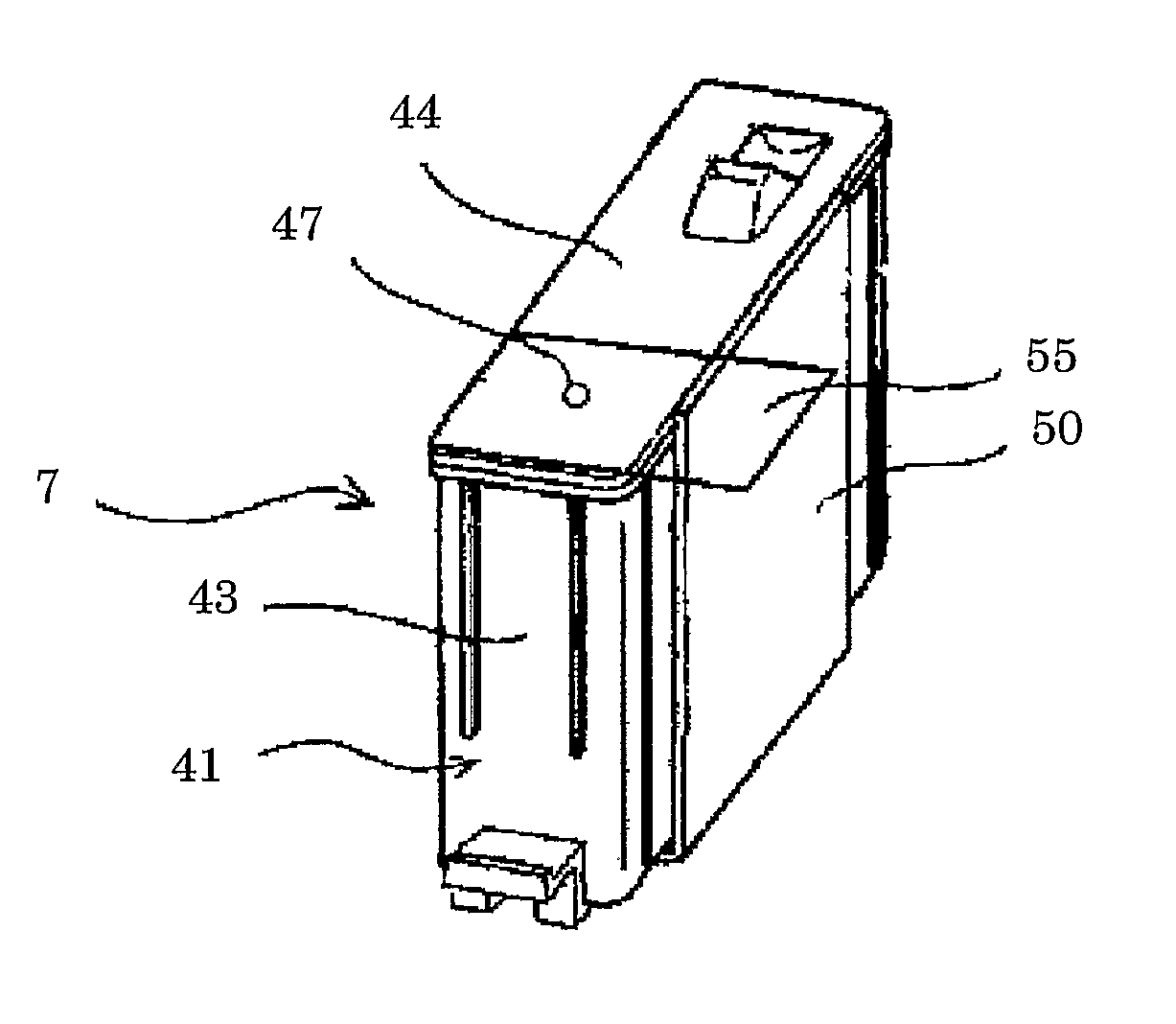

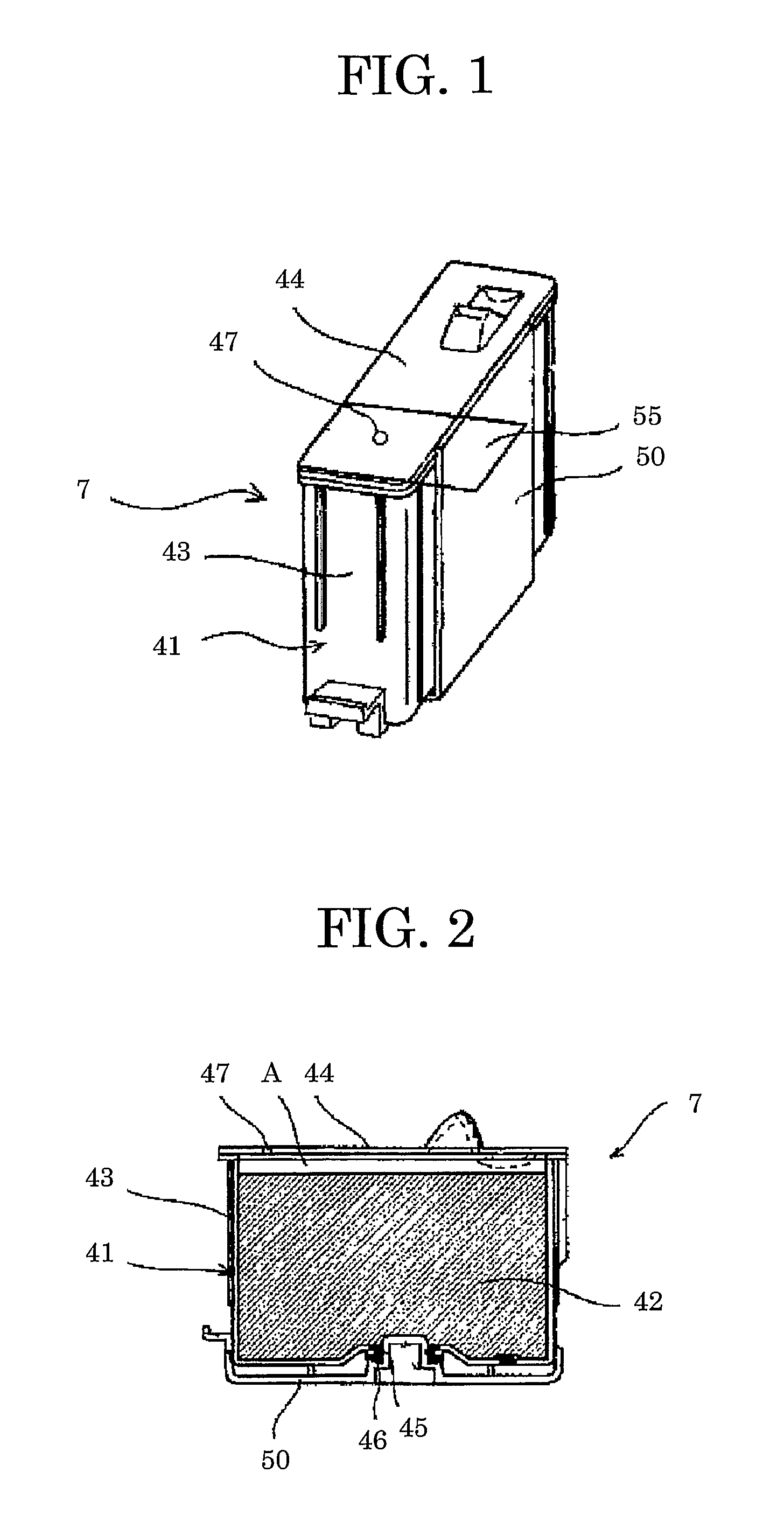

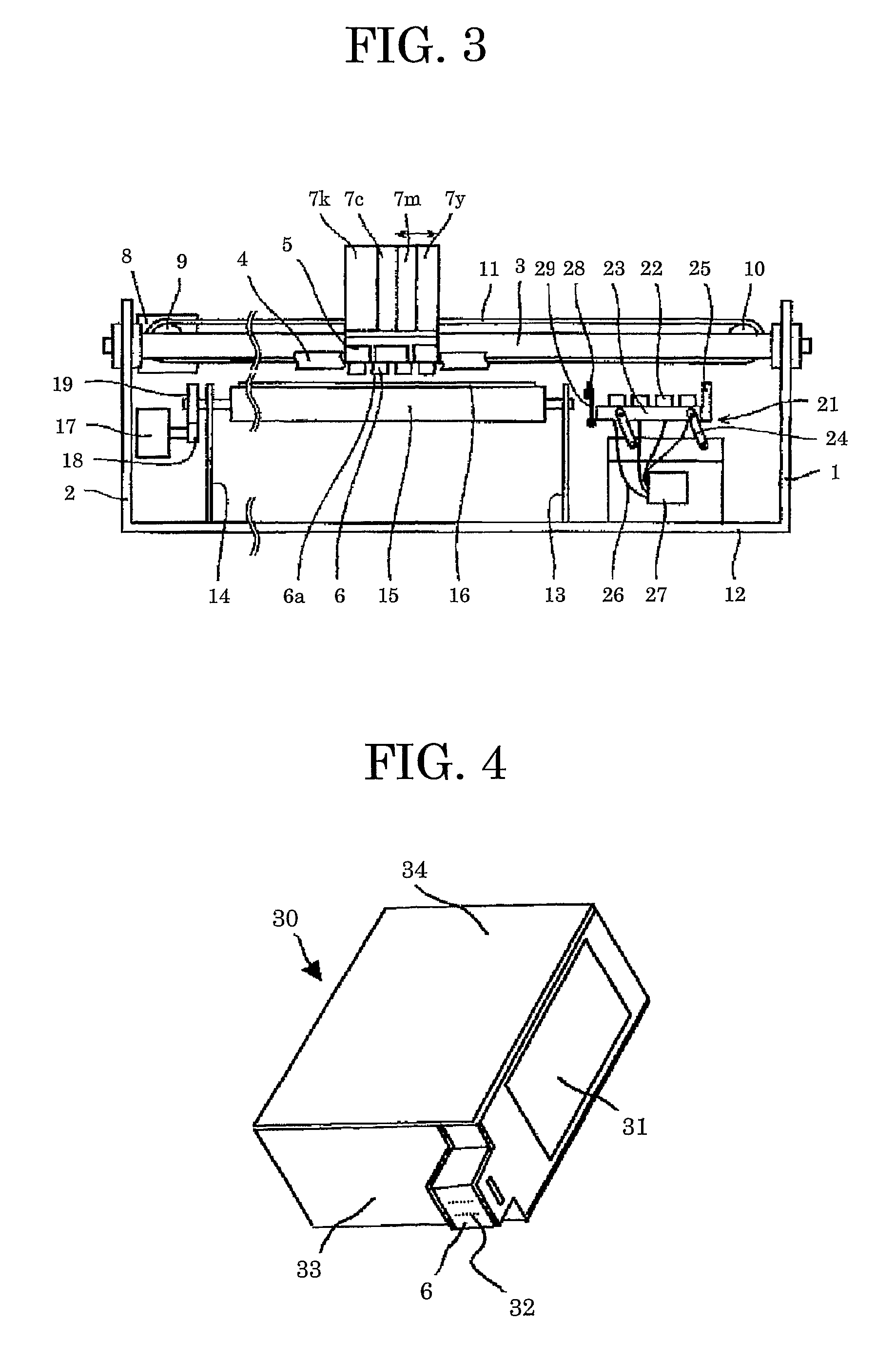

Recording ink, ink set, ink cartridge, ink record, inkjet recording apparatus and inkjet recording method

ActiveUS7977408B2Appropriate discharge stabilityGood colorOrganic chemistryMeasurement apparatus componentsEngineeringWater soluble

It is an object of the present invention to provide a recording ink which contains at least a pigment, a dispersant, a water-soluble solvent, a wetting agent and water, wherein the pigment contains at least one of diketopyrrolopyrrole red pigment and phthalocyanine green pigment in order to obtain a recording ink and ink set which excel in discharge stability with no head clogging during printing and can obtain high quality images with good color tone on the regular paper as well as on an exclusive recording paper; and ink cartridge, ink record, inkjet recording apparatus and inkjet recording method which utilize the recording ink and ink set respectively.

Owner:RICOH KK

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

Colored composition for color filters, color filter and liquid crystal display device

InactiveUS20070247565A1Increase contrastGood light fastnessDischarge tube luminescnet screensOptical filtersLiquid-crystal displayAnalytical chemistry

A cyan-colored composition for a color filter contains a phthalocyanine blue pigment comprising either of C.I. Pigment Blue 15:3 and C.I. Pigment Blue 15:4, or both, a phthalocyanine green pigment comprising C.I. Pigment Green 7, and a pigment carrier consisting of a transparent resin, a precursor of the resin or a mixture thereof. A color filter includes a red-colored filter segment, a green-colored filter segment, a blue-colored filter segment, and a cyan-colored filter segment or a yellow-colored filter segment.

Owner:TOPPAN PRINTING CO LTD

Recording ink, ink set, ink cartridge, ink record, inkjet recording apparatus and inkjet recording method

ActiveUS20090035468A1Appropriate discharge stabilityGood colorOrganic chemistryMeasurement apparatus componentsPigment dispersionPhthalocyanine

It is an object of the present invention to provide a recording ink which contains at least a pigment, a dispersant, a water-soluble solvent, a wetting agent and water, wherein the pigment contains at least one of diketopyrrolopyrrole red pigment and phthalocyanine green pigment in order to obtain a recording ink and ink set which excel in discharge stability with no head clogging during printing and can obtain high quality images with good color tone on the regular paper as well as on an exclusive recording paper; and ink cartridge, ink record, inkjet recording apparatus and inkjet recording method which utilize the recording ink and ink set respectively.

Owner:RICOH KK

Color masterbatch

The invention relates to color masterbatch. The color masterbatch is characterized by comprising, by weight, 75-85% of carriers, 5-6% of additives, 3-5% of dispersing agents, 2-3% of pearl powder, 1-2% of pigments, 1-2% of organic esters and 3-5% of paraffin, wherein the pigments comprise one or the mixture of phthalocyanine red, phthalocyanine blue, phthalocyanine green, sun-proof bright red, macromolecule red, macromolecule yellow, permanent yellow, permanent purple and azo red. The color masterbatch is the indispensable additive for colorization of plastic products, and for PVC products formed in an extrusion mode, the color masterbatch is assorted in variety and color, good in glossiness and high in controllability.

Owner:CHUZHOU HONGYUAN SPRAYING

Whisker material modified double-component color waterproof polyurethane coating and preparing process thereof

InactiveCN1451705AHigh strengthIncrease elasticityAntifouling/underwater paintsPaints with biocidesHigh resistanceCarboxylic salt

A dual-component water-proof color polyurethane paint modified by crystal whisker material is prepared through vacuumizing, dewatering and degassing polyether biol, adding diisocyanate, vacuumizing to obtain polyurethane elastomer A, vacuumizing and dewatering polyether triol, adding crystal whisker material, 3,3'-dichloro-4,4'-diaminodiphenyl methane, plasticizer, inorganic filler, the mixture of iron red or lemon yellow and phthalocyanine green, and metallic carboxylate as catalyst, stirring, vacuumizing to obtain polyurethane elastomer B, and proportional mixing A with B. Its advantages are high elasticity, elongation and adhesion, high resistance to corrosion and ageing, and no pollution.

Owner:HONGFU LAIYIN SCI & TECH DEV BEIJING

Whisker material modified polyurethane ground-paving material and preparation process thereof

The present invention provides a polyurethane floor paving material modified by whisker material and its preparation method. Said method includes the following steps: evacuating polyether dihydric alcohol, dewatering, deaerating, adding diisocyanate and evacuating, deaerating so as to obtain component A of polyurethane elastomer; evacuating polyether trihydric alcohol, dewatering, adding whisker material, 3,3'-dichloro-4,4'-diaminodiphenyl methane, plasticizer, ihorganic filler, iron red or lemon-yellow-phthalocyanine green mixed body and metal carboxylate catalyst, stirring them, mixing and evacuating, eliminating moisture so as to obtain component B or polyurethane elastomer; uninformly mixing the above-mentioned two components according to the ratio of 1:3-1:5.

Owner:HONGFU LAIYIN SCI & TECH DEV BEIJING

Fine clean production process of phthalocyanine green pigment

ActiveCN104804465AAvoid mutationEasy to operateOrganic chemistryPorphines/azaporphinesPhthalonitrileSide reaction

The invention discloses a fine clean production process of a phthalocyanine green pigment. The fine clean production process comprises the following steps: (1) phthalonitrile preparation; (2) copper source preparation; (3) solvent selection; (4) copper phthalocyanine obtaining; (5) phthalocyanine green crude product preparation; (6) phthalocyanine green refining; (7) finished phthalocyanine green preparation; (8) finished phthalocyanine green crystal form change. The phthalocyanine green pigment produced by the production process is clean, environment-friendly and less in side reaction; the coloring power, the brightness, the dispersibility, the transparence and other properties are finally improved; the production process is strong in operability, close in step combination and short in process time.

Owner:双乐颜料泰兴市有限公司

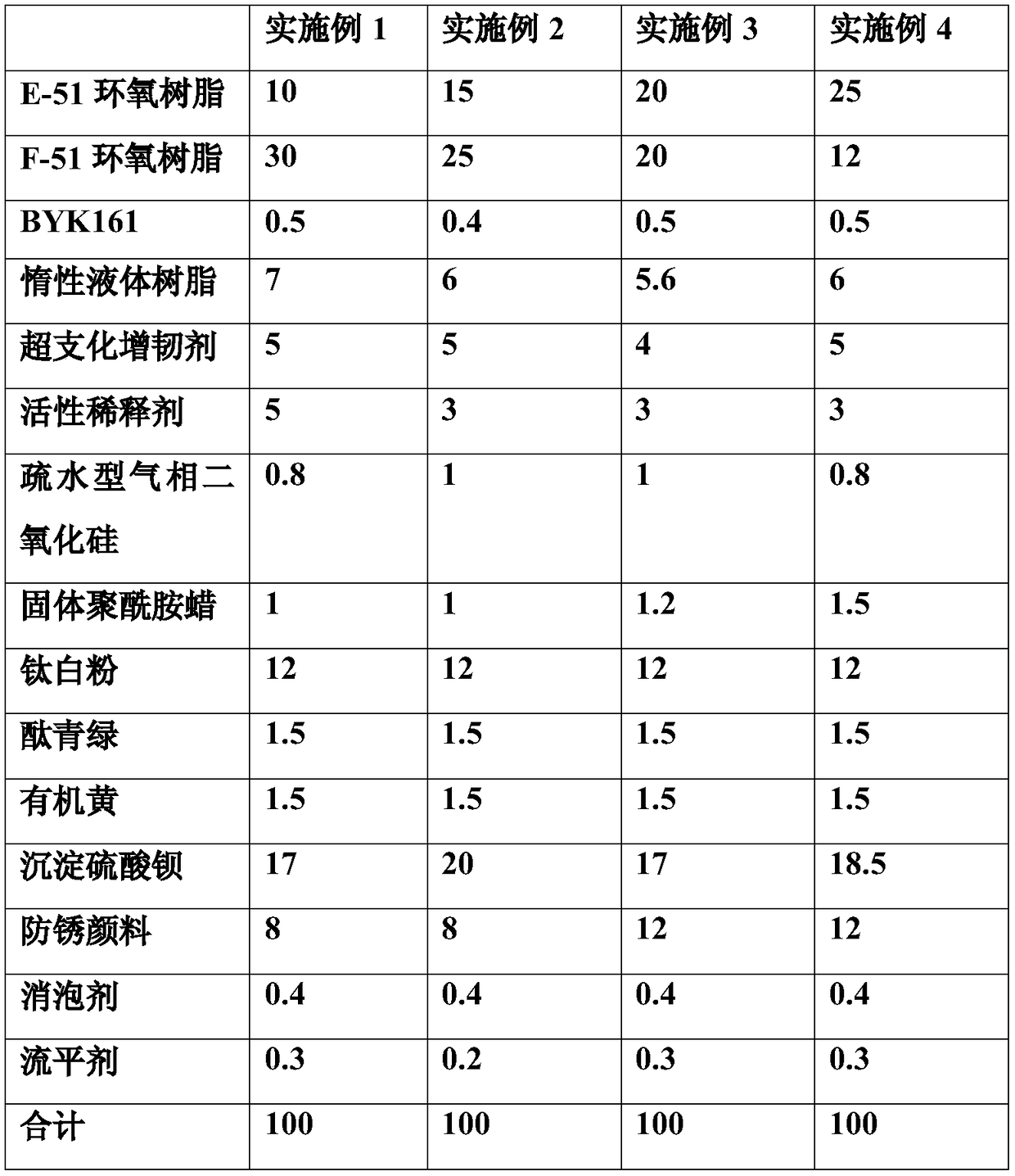

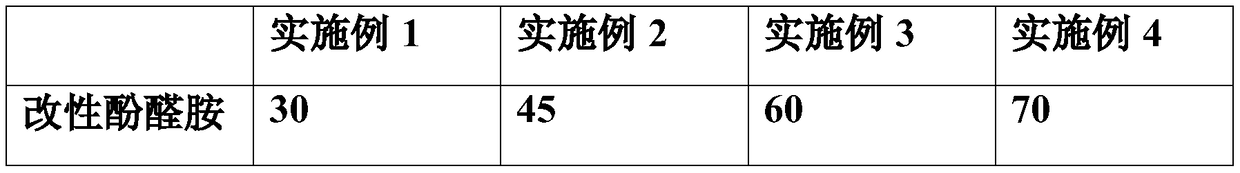

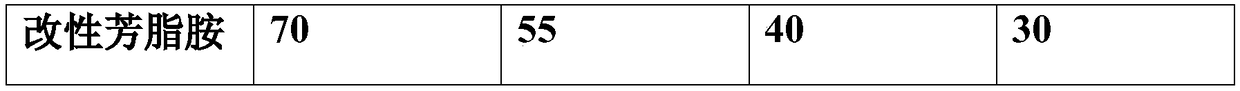

Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

InactiveCN109181477AGood chemical resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention discloses a solvent-free epoxy heavy anti-corrosion paint which is extruded and coated to the inner wall of a crude oil gathering pipeline. The paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-25 parts of E-51 epoxy resin, 12-30 parts of F-51 epoxy resin, 10-15 parts of titanium dioxide, 1-2 parts of phthalocyanine green, 1-2 parts of organic yellow, 1.5-3 parts of a thixotropic agent, 0.3-0.5 part of a wetting dispersant, 5-8 parts of inert liquid resin, 3-5 parts of an active diluting agent, 3-5 parts of a hyperbranched toughening agent, 15-20 parts of precipitated barium sulfate, 8-15 parts of anti-rust pigment, 0.3-0.5 part of a defoaming agent, 0.2-0.4 part of a flatting agent; the component B is prepared from 30-70 parts of modified phenolic amine curing agent and 70-30 parts of modified aromatic amine curing agent; and the mass ratio of the component A to the component B is(5-7):1. The solvent-free epoxy heavy anti-corrosion paint is applicable to gathering pipeline extruding and coating processes, the pipeline inner wall coating has excellent corrosion resistance and physical performance, the coating process can be reduced, the construction time can be saved, and the work efficiency can be improved.

Owner:石家庄市油漆厂

Liquid developer

A liquid developer of the present invention includes a toner particle and an insulating liquid, the toner particle including a resin and a pigment, the resin including a polyester resin, the pigment including a first pigment, a second pigment, and a third pigment, the first pigment being a carbon black, 10 to 25 mass % of the first pigment being included in the toner particle, the second pigment being nigrosine, 3 to 15 mass % of the second pigment being included in the toner particle, the third pigment being at least one organic pigment selected from a group consisting of a phthalocyanine blue pigment, a phthalocyanine green pigment, a carmine-based pigment, a naphthol-based pigment, a quinacridon-based pigment, an azo-based pigment, a benzimidazolone-based pigment, and an isoindoline-based pigment, 5 to 20 mass % of the third pigment being included in the toner particle.

Owner:KONICA MINOLTA INC

Colored oily fertilizer anticaking agent prepared from organic pigment and use thereof

The invention relates to a colored oily fertilizer anticaking agent prepared from an organic pigment and a use thereof. The colored oily fertilizer anticaking agent comprises, by mass, 0.5-2% of everbright fast red, everbright fast yellow G, phthalocyanine blue, phthalocyanine green or permanent heliotrope purple and 99.5-98% of an oily anticaking agent. The colored oily fertilizer anticaking agent is prepared through grinding and uniform mixing through a horizontal mill. The colored oily fertilizer anticaking agent is used for fertilizer coating. Through the colored oily fertilizer anticaking agent, the fertilizer produces corresponding red, yellow, blue, green or purple color. According to fertilizer products with different colors, the oily fertilizer anticaking agents with corresponding red, yellow, blue, green and purple color are provided so that interior and exterior of the fertilizer have the same color, color difference is avoided, decorative patterns are avoided, a masking capacity is good, a pump color is obtained, a bright and pure color is obtained, temperature and heat resistance is obtained, color fading is prevented and the color is not changed. The colored oily fertilizer anticaking agent can be used as a fertilizer type distinguishing and anti-counterfeiting label, a use cost is low and anticaking performances are good.

Owner:HUBEI FORBON TECH

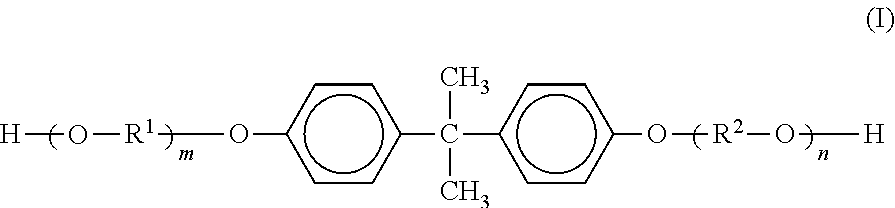

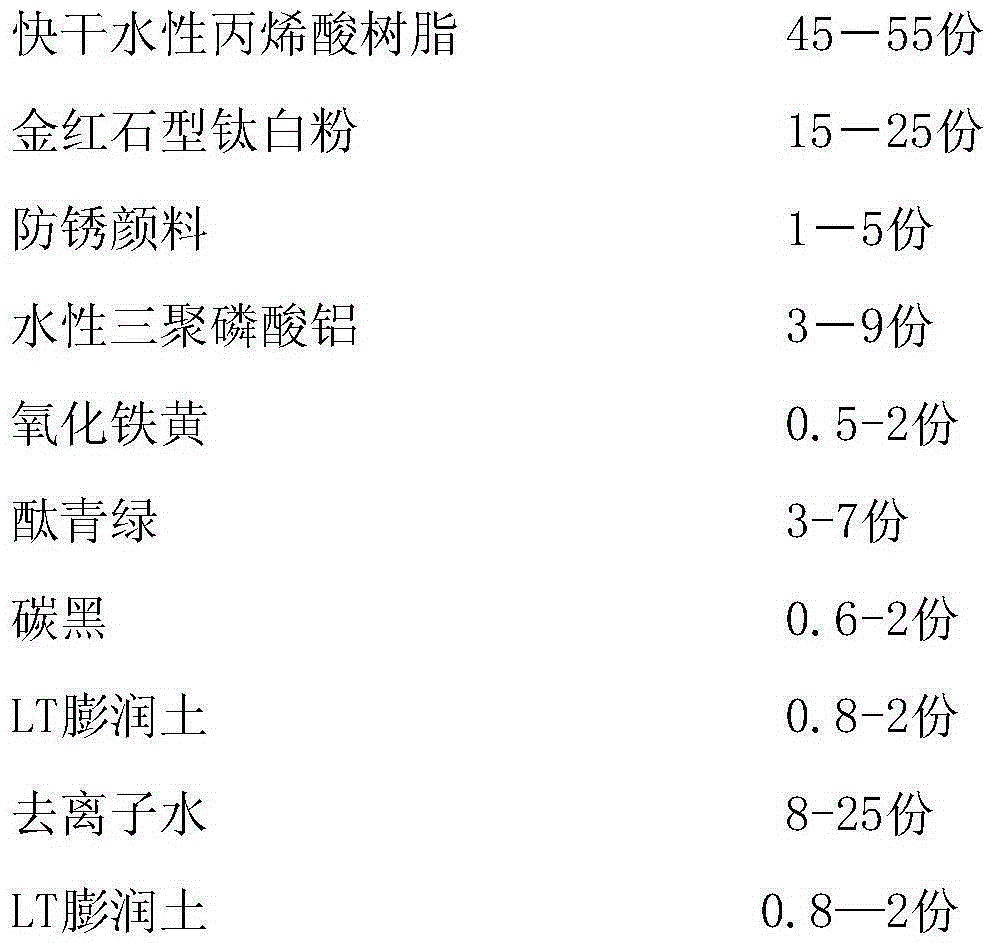

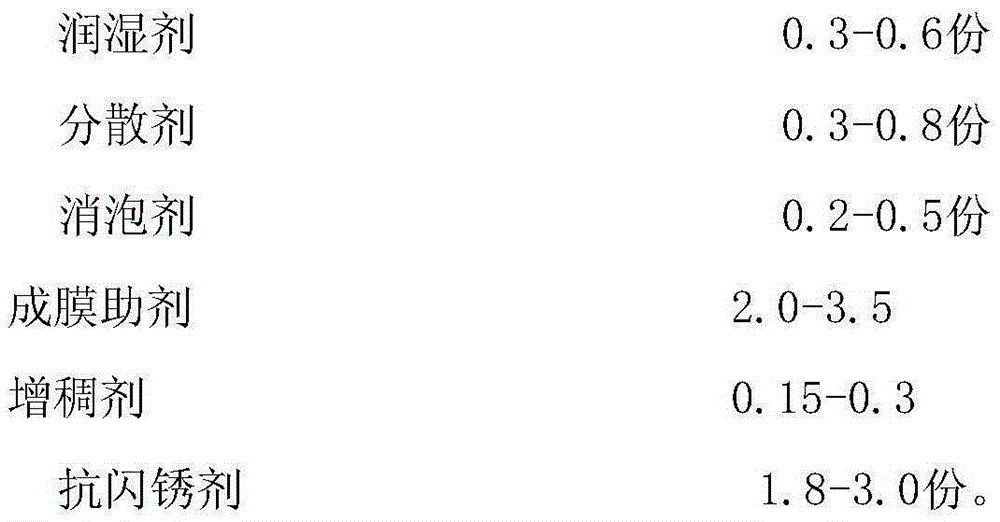

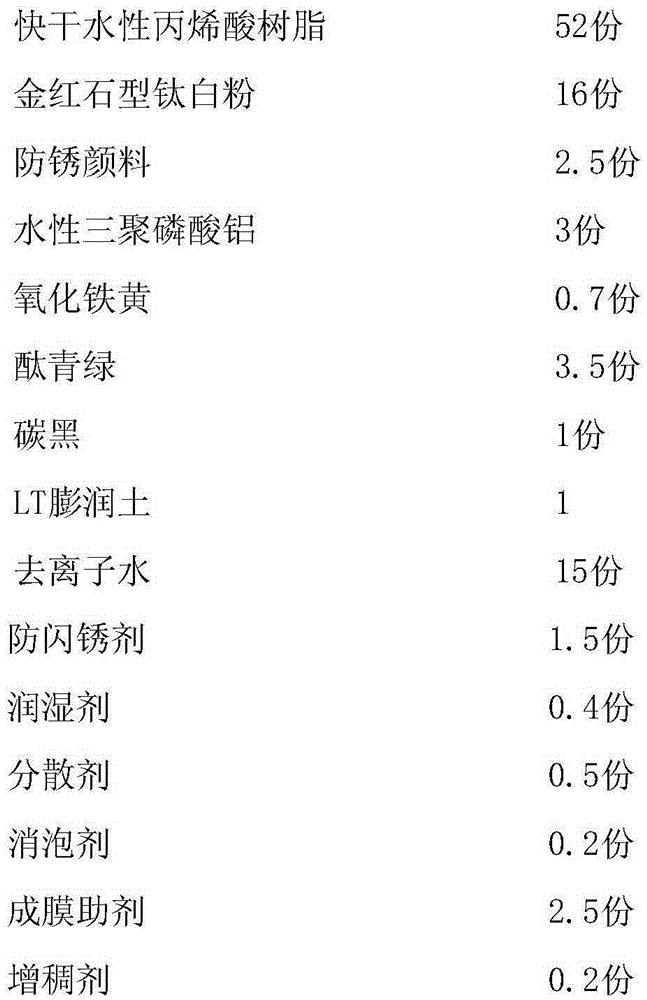

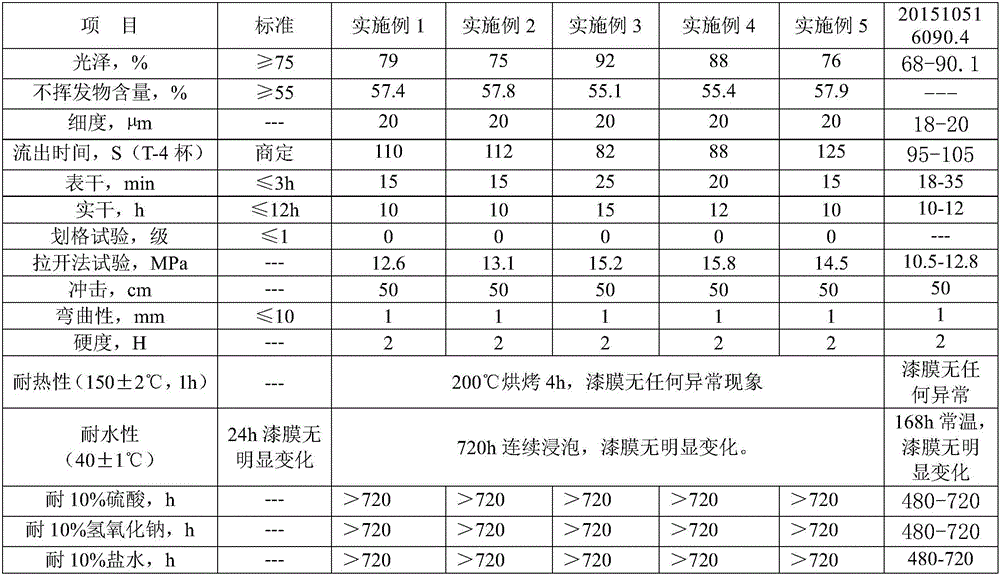

Water-based quick-drying primer-topcoat acrylic anti-corrosion paint and preparation method thereof

InactiveCN105331215AStrong weather resistanceStrong resistance to salt spray and corrosion resistanceAnti-corrosive paintsWater basedAcrylic resin

The invention discloses water-based quick-drying primer-topcoat acrylic anti-corrosion paint. The paint comprises water-based acrylic resin, rutile type titanium dioxide, water-based aluminium tripolyphosphate, an anti-rust pigment, LT bentonite, phthalocyanine green, iron oxide yellow, deionized water, carbon black and an aid; the deionized water, a wetting agent, a dispersing agent, a defoaming agent and a flash rusting resisting agent are added to a dispersing machine in the preset mass ratio, the rutile type titanium dioxide, the water-based aluminium tripolyphosphate, water-based zinc phosphate, the LT bentonite, the phthalocyanine green and the iron oxide yellow are added sequentially, the water-based acrylic resin is added and sent into a stirring kettle to be heated and dispersed at the high speed, and when the temperature in the kettle is 40 DEG C, a coalescing agent and a thickening agent are added for full mixing. The water-based quick-drying primer-topcoat acrylic anti-corrosion paint is safe and environment-friendly, physical, chemical and construction properties of the water-based quick-drying primer-topcoat acrylic anti-corrosion paint are obviously better than those of existing paint, surface drying is realized within 10 min without heating of a film, curing is realized within 2 h, and the paint is best applicable to high-yield production chain procedure process coating.

Owner:JIANGSU MARINE VICTORY COATING

Colored composition for color filters, color filter and liquid crystal display device

InactiveCN101004462AHigh luminous intensityOptical filtersNon-linear opticsLiquid-crystal displayAnalytical chemistry

The present invention relates to colored composition for color filters, color filter and liquid crystal display device. A cyan-colored composition for a color filter contains a phthalocyanine blue pigment comprising either of C.I. Pigment Blue 15:3 and C.I. Pigment Blue 15:4, or both, a phthalocyanine green pigment comprising C.I. Pigment Green 7, and a pigment carrier consisting of a transparent resin, a precursor of the resin or a mixture thereof. The color filter includes a red-colored filter segment, a green-colored filter segment, a blue-colored filter segment, and a cyan-colored filter segment or a yellow-colored filter segment.

Owner:TOYO INK SC HOLD CO LTD +1

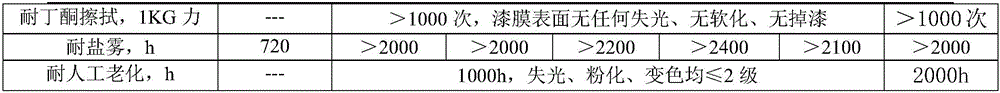

Waterborne undercoat-topcoat integrated paint applied to type-25 passenger trains

The invention provides a waterborne undercoat-topcoat integrated paint applied to type-25 passenger trains. The paint comprises a component A and a component B; the component A is prepared from waterborne hydroxy acrylic resin emulsion, waterborne organic silicon modified epoxy resin emulsion, waterborne chlorinated polypropylene emulsion, rutile titanium dioxide, phthalocyanine green, phthalocyanine blue, medium chrome yellow, carbon black, nano barium sulfate, surface treatment silicon powder, waterborne zinc phosphate, a waterborne dispersing agent, a waterborne foam inhibitor, a waterborne defoaming agent, a waterborne leveling agent, a surfactant, a neutralizing agent, a waterborne ultraviolet absorbing agent, waterborne polyamide wax slurry, a mould-proof bactericide, deionized water and a solubilizer; the component B is a hydrophilic isocyanate curing agent. The waterborne undercoat-topcoat integrated paint is high in drying speed, hardness and sagging resistance and excellent in chemical resistance, weatherability can reach 2000h or above, butanone resistance reaches 1000 times or above, and salt spray resistance reaches 2000h or above.

Owner:成都拜迪新材料有限公司

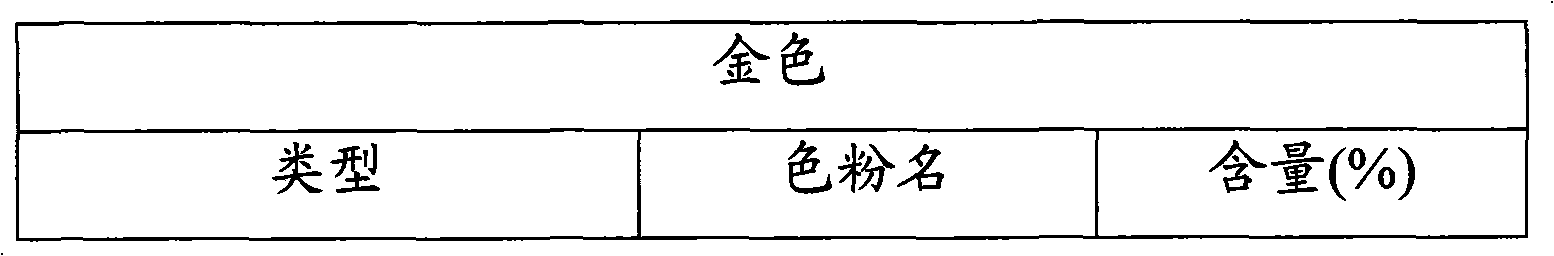

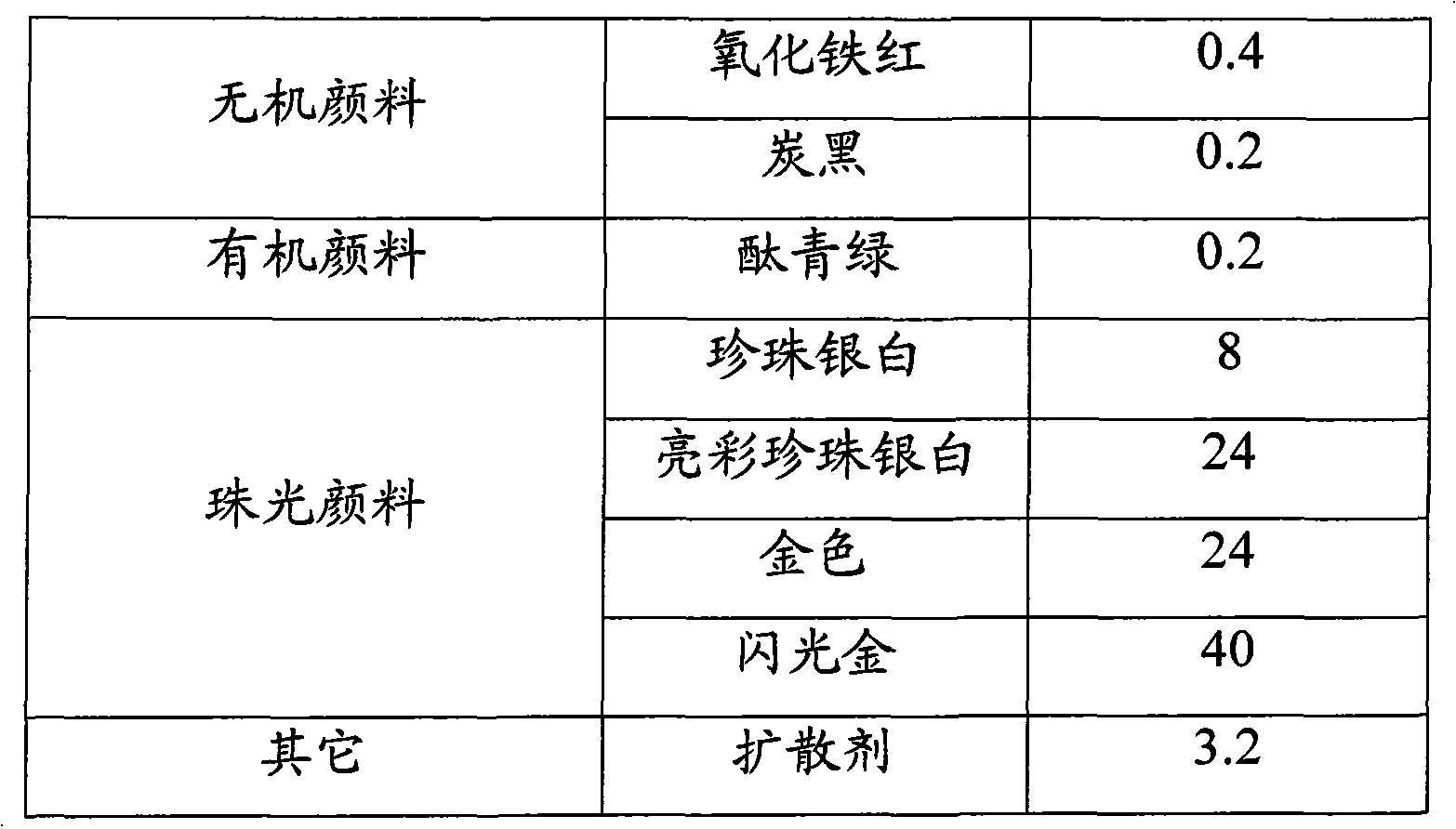

Pearlized gold toner and method for preparing PMMA/ABS alloy by using same

The invention is suitable for the technical field of thermoplastic resin alloys by high polymer material technology, and provides a pearlized gold toner and a method for preparing a PMMA / ABS alloy by using the same. The pearlized gold toner contains the following components in percentage by weight: 0.05 to 1 percent of iron oxide red, 0.05 to 1 percent of carbon black, 0.05 to 1 percent of phthalocyanine green, 2 to 16 percent of silver pearl, 5 to 40 percent of brilliant silver pearl, 5 to 40 percent of gold, 20 to 60 percent of glittery gold, and 1 to 6 percent of dispersing agent. In the invention, firstly, the pearlized gold toner is prepared, and secondly, the pearlized gold PMMA / ABS alloy is prepared by using the prepared pearlized gold toner; the surface of the alloy is free from paint spraying and coloring; and the alloy is formed only at a time, and has the advantages of energy conservation, never fading, environmental protection and the like.

Owner:惠州市沃特新材料有限公司

Scratching protecting paint printing process

ActiveCN102582298AReduce bad scratchesReduce labor costsInksOther printing apparatusEpoxyNumerical control

The invention belongs to the technical field of manufacture of photoelectron devices, and particularly relates to a pre-processing working procedure for glass of white panels. A layer of UV (ultraviolet) glass CNC (computerized numerical control) cutting protecting printing ink is in screen printing before cutting of a blank sheet. The UV glass CNC cutting protecting printing ink consists of substances including, by weight percentage, from 44 to 46% of epoxy resin, from 14 to 16% of barium sulfate, from 10 to 12% of talcum powder, from 0.5 to 1.5% of silicon dioxide, from 1 to 2% of phthalocyanine green, from 5 to 6% of photoinitiator, and from 20 to 22% of esters solvent. Glass is protected after a step A, printing ink on two surfaces of the glass is baked and dried thoroughly, and an original appearance effect of the glass is protected, and then steps including cutting, profiling, trimming, grooving, groove trimming, CNC, demolding, previous cleaning, strengthening, subsequent grinding and subsequent cleaning are realized successively.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Colored composition for color filters, color filter and liquid crystal display device

InactiveUS7804561B2Increase contrastGood light fastnessDischarge tube luminescnet screensOptical filtersLiquid-crystal displayAnalytical chemistry

A cyan-colored composition for a color filter contains a phthalocyanine blue pigment comprising either of C.I. Pigment Blue 15:3 and C.I. Pigment Blue 15:4, or both, a phthalocyanine green pigment comprising C.I. Pigment Green 7, and a pigment carrier consisting of a transparent resin, a precursor of the resin or a mixture thereof. A color filter includes a red-colored filter segment, a green-colored filter segment, a blue-colored filter segment, and a cyan-colored filter segment or a yellow-colored filter segment.

Owner:TOPPAN PRINTING CO LTD

Drag-reducing anti-fouling paint free of any copper antifouling agent and preparation method thereof

ActiveCN107286794AImprove adhesion strengthGood antifoulingAntifouling/underwater paintsRosin coatingsSilanesAnti-fouling paint

The invention provides a drag-reducing anti-fouling paint free of any copper antifouling agent and a preparation method thereof. The drag-reducing anti-fouling paint free of any copper antifouling agent uses silane polyacrylate resin with a degradable main chain as a main base material and a rosin derivative as an auxiliary base material; an antifouling agent having high antifouling activity to hard shell fouling organisms and an antifouling agent having high antifouling activity to botanical and microbial fouling organisms are compounded and used as the antifouling agent of the paint; composite zinc oxide obtained by mixing of zinc oxide with different particle sizes is used for adjusting the dissolving speed of a paint film; a variety of colors are obtained in virtue of usage of filling materials like talcum powder, iron oxide red, iron oxide black, iron oxide yellow, carbon black, toluidine red, phthalocyanine blue, phthalocyanine green and titanium dioxide and pigments; and the particle sizes of the used anti-fouling agents, filling materials and coloring pigments are all not more than 30 [mu]m. A paint film formed after drying of the paint has a smooth surface and excellent anti-fouling and drag-reducing performance. The invention further provides the preparation method for the drag-reducing anti-fouling paint. The preparation process is practical and has good application prospects.

Owner:XIAMEN SUNRUI SHIP COATING

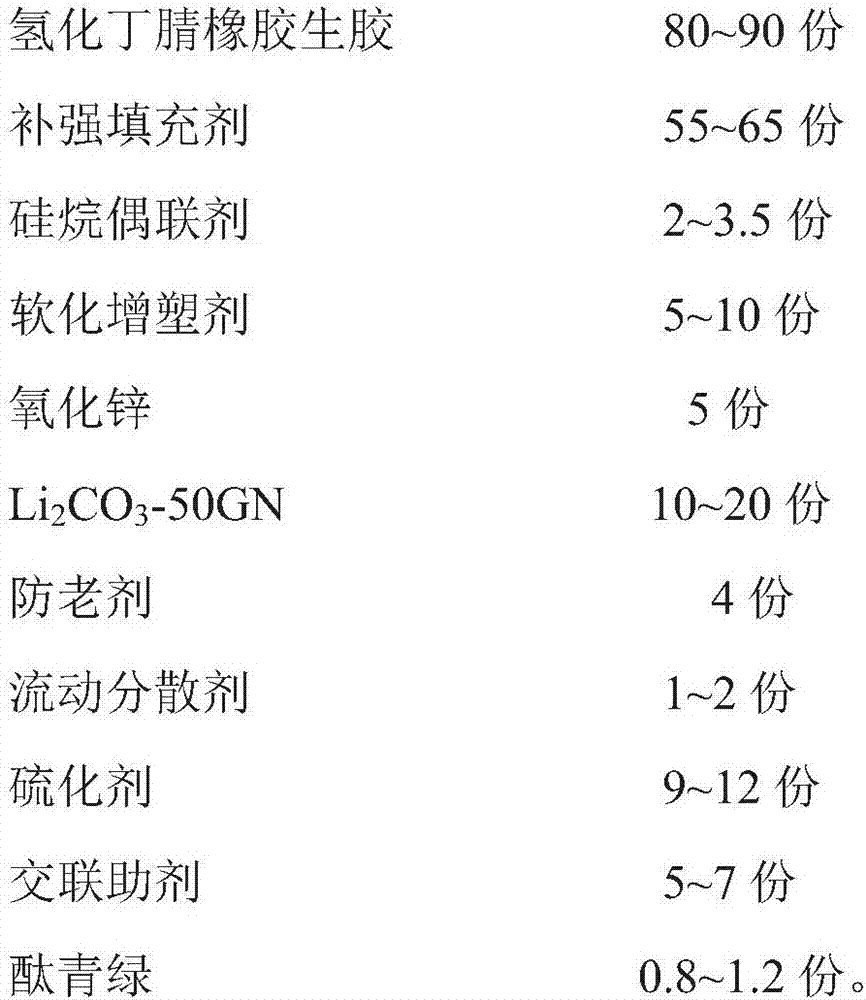

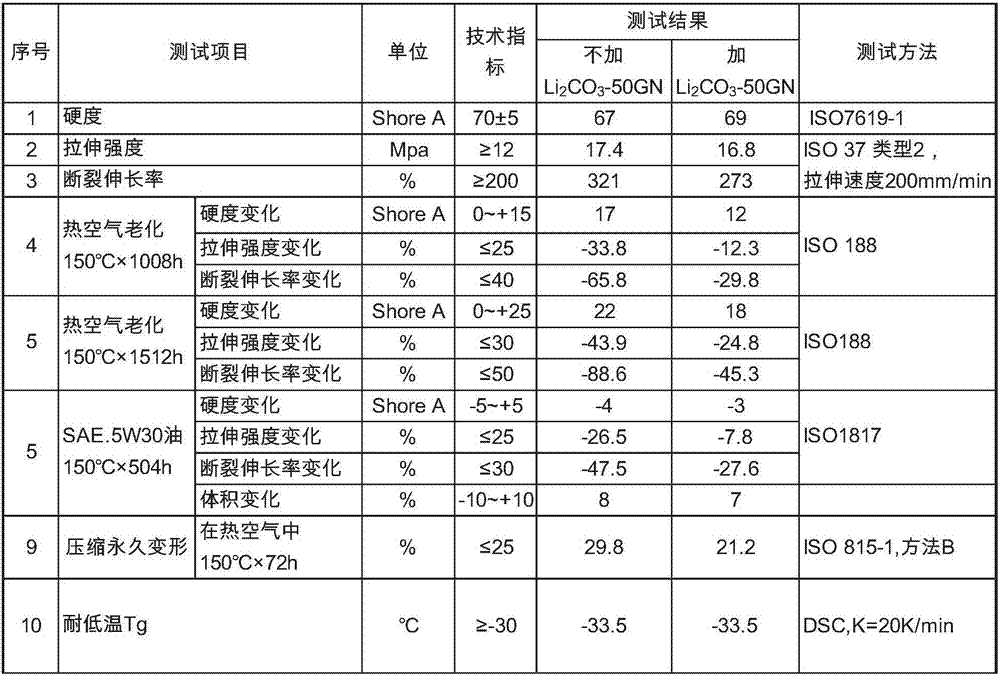

High temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and preparing method thereof

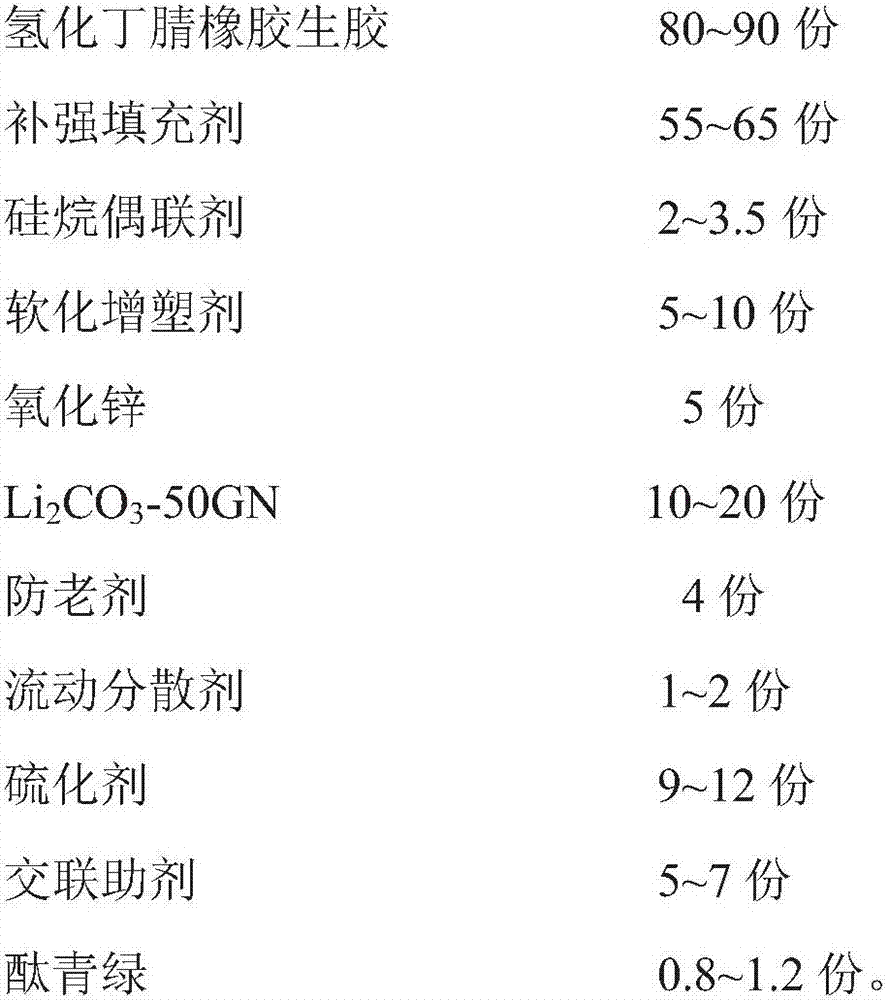

The invention discloses a high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material and a preparing method thereof, and belongs to the technical field of rubber. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material is prepared from, by weight, 80-90 parts of hydrogenated butadiene-acrylonitrile rubber crude rubber, 55-65 parts of reinforcing filler, 2-3.5 parts of silane coupling agent, 5-10 parts of softening plasticizer, 5 parts of zinc oxide, 10-20 parts of Li2CO3-50 GN, 4 parts of anti-aging agent, 1-2 parts of flowing dispersing agent, 9-12 parts of vulcanizing agent, 5-7 parts of crosslinking agent and 0.8-1.2 parts of phthalocyanine green. The high temperature resistant color hydrogenated butadiene-acrylonitrile rubber material has the advantages of being excellent in temperature resistant performance and oil resistant performance, resistant to low temperature, and low in compression deformation at the same time.

Owner:南京金三力高分子科技有限公司

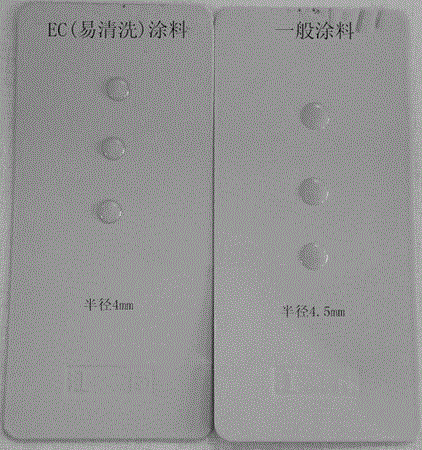

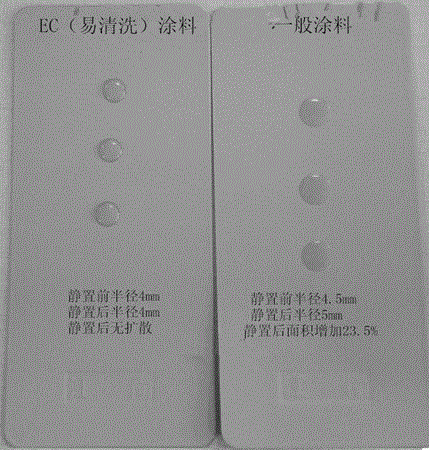

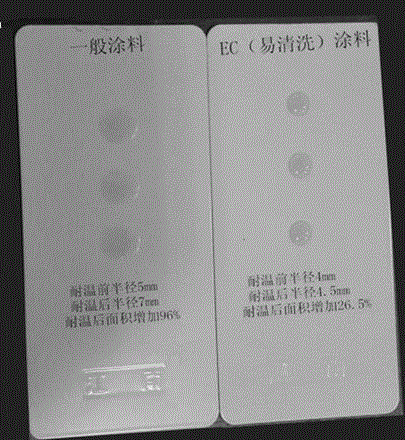

Easy-to-clean powder coating and production process for same

InactiveCN105482633AGood pollution resistanceEasy to cleanPowdery paintsEpoxy resin coatingsPolymer scienceBenzoin

The invention discloses an easy-to-clean powder coating, which is prepared from the following components in parts by weight: 28 to 32 pars of epoxy polyester, 26 to 30 parts of polyester resin, 1 to 1.5 parts of a leveling agent, 0.5 to 1 part of an optical brightener, 0.3 to 0.5 parts of benzoin, 10 to 13 parts of titanium dioxide, 1 to 1.5 parts of a matting agent, 32 to 18.4 parts of matting calcium, 0.8 to 1.5 parts of polytetrafluoroethylene wax, 0.2 to 0.5 parts of modified polyethylene wax, 0.02 to 0.03 parts of carbon black, 0.0003 to 0.0005 parts of phthalocyanine green and 0.05 to 0.07 parts of ferric yellow. The powder coating is free of any other polluting solvent, safe, environment-friendly, higher in decoration performance and pollution resistance and easy to clean.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Polymeric aluminum chloride flocculant preparation method using phthalocyanine green waste water

InactiveCN1544348AAchieve the purpose of useReduce pollutionWater/sewage treatment by ion-exchangeIron halidesAluminium chlorideLiquid product

A process for preparing polymerized aluminium chloride flocculating agent from phthalocyanine green waste water comprising, placing the type 335 weak alkaline anion exchange resin into adsorbing column, flowing dilute hydrochloric acid through the adsorbing column, rinsing the resin column with water or deionized water, processing the resin column by weak alkaline liquor, finally rinsing the adsorbing column with water or deionized water until water exhibits weak alkalinity, adjusting the pH of phthalocyanine green waste water, making it pass through the pretreated and transformed type 335 weak alkaline anion exchange resin column from normal temperature to 50 deg. C, and passing through another ion exchange resin adsorbing column, thus obtaining the phthalocyanine green waste water whose copper ion concentration meets second level standard. By concentrating the phthalocyanine green waste water treated by the resin under the condition of stirring and heating, adding in alkalinizing agents simultaneously for reaction, adjusting waste water till it exhibits weak acidity, continuously stirring and conducting heating reaction, the liquid product or solid end product can be obtained.

Owner:NANJING UNIV

Chlorinated rubber coating used for marine environment and production method

InactiveCN105315796AHigh glossEliminate Bubble ProblemsRubber derivative coatingsAnti-corrosive paintsEpoxyPolymer science

The invention relates to a chlorinated rubber coating used for a marine environment and a production method. The production method includes the steps of adding modified chlorinated rubber resin, modified hydrogenated bisphenol F-type epoxy resin and epoxidized soybean oil to a mixed solvent composed of dimethylbenzene and solvent oil, adding modified titanium dioxide, feldspar powder, talcum powder, silicon micro-powder, mica powder, phthalocyanine green, chrome yellow, polyamide wax, chlorinated paraffin, a hydroxyl triazine derivative and epoxy chloropropane and the like to the mixed solution, mixing, stirring and grinding the mixed solution to obtain the high-glossiness weather-resistant chlorinated rubber coating used for the marine environment. The marine environment can be uniformly stirred and directly used for coating surfaces. The coating allows construction at -20 DEG C, is excellent in storage stability, anti-ultraviolet light aging property, adhesive force, corrosion resistance of acids, alkalis and salts and sea water scouring resistance, and can be used for corrosion resistance of offshore structures such as ships, ocean platforms, docks and the like.

Owner:CNPC RES INST OF ENG TECH +2

Method for preparing plastic tray from three-layer composite film recycled material

The invention relates to a method for preparing a plastic tray from a three-layer composite film recycled material serving as a basic raw material. The method comprises the following steps of: taking 87 to 92 weight parts of three-layer composite film recycled material, 6 to 10 weight parts of butyl acrylate grafted linear low-density polyethylene (LLDPE-g-BA), 0.6 to 1.0 weight part of tris-(2,4-di-tert-butyl-pheny)phosphite, 0.4 to 0.7 weight part of tris(1,2,2,6,6-pentamethyl-4-piperidine)phosphite, 0.5 to 0.8 weight part of rutile type titanium dioxide and 0.3 to 0.5 weight part of phthalocyanine green, and performing crushing, drying, mixing, extrusion and injection molding. Compared with a wooden tray, the plastic tray prepared by the method has the characteristics of high compression strength, high stretchability, acid and alkali resistance, capacity of being easily washed and disinfected, no mildew and the like, and is suitable for the industries of machines, electronics, foods, clothing and the like.

Owner:FUJIAN NORMAL UNIV

High and low temperature type anti-corrosion viscoelastic body filler, and preparation method thereof

InactiveCN103709949ALiquidFunctionalNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterTectorial membrane

The invention discloses a high and low temperature type anti-corrosion viscoelastic body filler. The high and low temperature type anti-corrosion viscoelastic body filler is characterized by comprising a protective film, a viscoelastic body paste layer and an isolation film. The protective film is a polyethylene film; the isolation film is a polyester isolation film; and the viscoelastic body paste layer is composed of the following raw materials by mass: 33-36% of middle molecular weight polyisobutylene, 10.5-12.5% of low molecular weight polyisobutylene, 50-55% of precipitated barium sulphate, 1-1.5% of an antioxidant and 0.5-0.6% of phthalocyanine green. A preparation method of the high and low temperature type anti-corrosion viscoelastic body filler comprises the steps of kneading the raw materials to obtain daub; sending the daub into a reaction kettle for mixing; extruding by an extruder; coating on the isolation film; plying up the protective film; and rolling by a double-roller machine to obtain a product. The high and low temperature type anti-corrosion viscoelastic body filler is not restricted by the high and low temperatures, has self-repairing functions, is used as a sealing and filling anti-corrosion material for special-shaped pipes such as special-shaped steel elbows, bends, three-way gate valves and flanges, is environment-friendly and convenient for use, and has a good filling and sealing effect.

Owner:绵阳市振华长森科技有限公司

Green pigment for color filter, green pigment dispersion, photosensitive color composition, color filter, and liquid crystal panel

ActiveUS7781129B2High strengthPromote formationPhotosensitive materialsOptical filtersPhotopigmentPigment dispersion

Owner:DAI NIPPON PRINTING CO LTD +1

Strong anti-corrosion paint for ship and preparation method thereof

InactiveCN104293190AGuaranteed corrosion resistanceStrong anti-corrosion abilityWax coatingsAnti-corrosive paintsPolyvinyl alcoholPyrrolidinones

The invention discloses a strong anti-corrosion paint for a ship. The strong anti-corrosion paint is characterized by being prepared from the following raw materials in parts by weight: 6-9 parts of organic silicon resin, 3-5 parts of polyvinyl butyral, 10-13 parts of unsaturated polyester resin, 4-6 parts of trimethyl hexamethylenediamine, 1-2 parts of sodium petroleum sulfonate, 0.3-0.8 part of phthalocyanine green, 2-3 parts of light-weight magnesium chloride, 2-3 parts of zwieselite, 3-5 parts of wood wax oil, 0.5-1.0 part of rare earth chloride, 0.5-1.0 part of N-methyl pyrrolidinone, 1-3 parts of magnesium stearate, 0.2-0.5 part of cobaltous chloride, 43-47 parts of modified asphalt, 5-8 parts of modified waste resin sand, 2-3 parts of ammonium zinc sulfate, 6-9 parts of dimethyl benzene, 10-12 parts of butyl acetate and 5-7 parts of trichloroacetic acid. The strong anti-corrosion paint disclosed by the invention has the advantages that added polyvinyl butyral has very high anti-corrosion capacity and anti-rust capacity, high adhesive power and good water resistance; added zwieselite and sodium petroleum sulfonate have anti-corrosion and anti-rust effects, so that the anti-corrosion capacity of the paint is further ensured; the added wood wax oil has the effects of paint film surface hardness enhancement, water prevention, pollution prevention, abrasion resistance and rub resistance.

Owner:TIANCHANG YINHU PAINT

Process for producing high-grade phthalocyanine green pigment

The invention discloses a process for producing a high-grade phthalocyanine green pigment. The process comprises the following steps of: grinding crude pigment; adding an organic salt grinding aid in the grinding process; then, treating the ground pregrinding pigment by a solvent; and separating the aggregated large particles again, and crystallizing for properly growth and repair. During solvent treatment, the pH is adjusted as required, and a surface active agent can be added to improve the dispersivity of the pigment in the oil paint and the applicability in the ink slurry; and the derivative of phthalocyanine can be added to improve the flocculation stability and the luster. Compared with the traditional phthalocyanine green pigment, the phthalocyanine green pigment component is greatly enhanced in the aspects of brilliance, contrast and the like, not only can satisfy the application requirements of coatings, plastics, inks and other traditional industries, but also can satisfy the requirements of color filters used in liquid crystal displays.

Owner:LIWANG CHEM NANTONG

Urethane elastomer for sports field and its preparation method

InactiveCN1765950ARaw materials are easy to getReduce manufacturing costGround pavingsPolyurea/polyurethane coatingsPentachlorophenolPolyurethane elastomer

The invention relates to a polyurethane elastomer for stadium, which comprises: first constituent and second constituent by weight ratio as 1:2-1:4, and third constituent with percent as said constituents. Wherein, the first constituent is: methyl diphenylene diisocyanate, polyether diatomic alcohol, and montmorillonite; the second constituent is: polyether tribasic alcohol, 3,5-dichloro trifluoro methyl phenyl ethyl ether, chlorcosane, talcum powder, calcium oxide, calcium oxide or lemon yellow-phthalocyanine green mixture, and pentachlorophenol; the third constituent comprises: waste rubber particle and metal catalyst. Compared with prior art, this invention has low cost and good properties.

Owner:上海高分子材料研究开发中心 +1

Black Pigment Composition For Heat-Shielding Coating, Use Of Same, Heat-Shielding Coating Using Same And Use Of Same For Shading And Coating

InactiveUS20170044375A1Improve transmittanceCost advantageReflecting/signal paintsPolyester coatingsPhthalocyanineHue

Provided are a black pigment composition for heat-shielding coatings that has superior infrared radiation transmittance, approximates the hue of chromium-based black coatings not only in a dark color, but also in a light color as well and therefore facilitates hue adjustment when mixed with a chromatic coating, has superior weather resistance and is also advantageous in terms of cost, as well as a heat-shielding coating that uses the same, and a shading method. The black pigment composition for heat-shielding coatings contains, at least, a phthalocyanine blue pigment as a first pigment and a phthalocyanine green pigment as a second pigment, and further contains at least one other chromatic pigment, wherein, regarding the amounts in parts by weight of the phthalocyanine blue pigment as Mb, of the phthalocyanine green pigment as Mg, and of the total of the at least one other chromatic pigment as Mn,1.5<Mg / Mb<4.0, and2<Mb<2017<Mg<4045<Mn<63,are established.

Owner:CLARIANT INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com