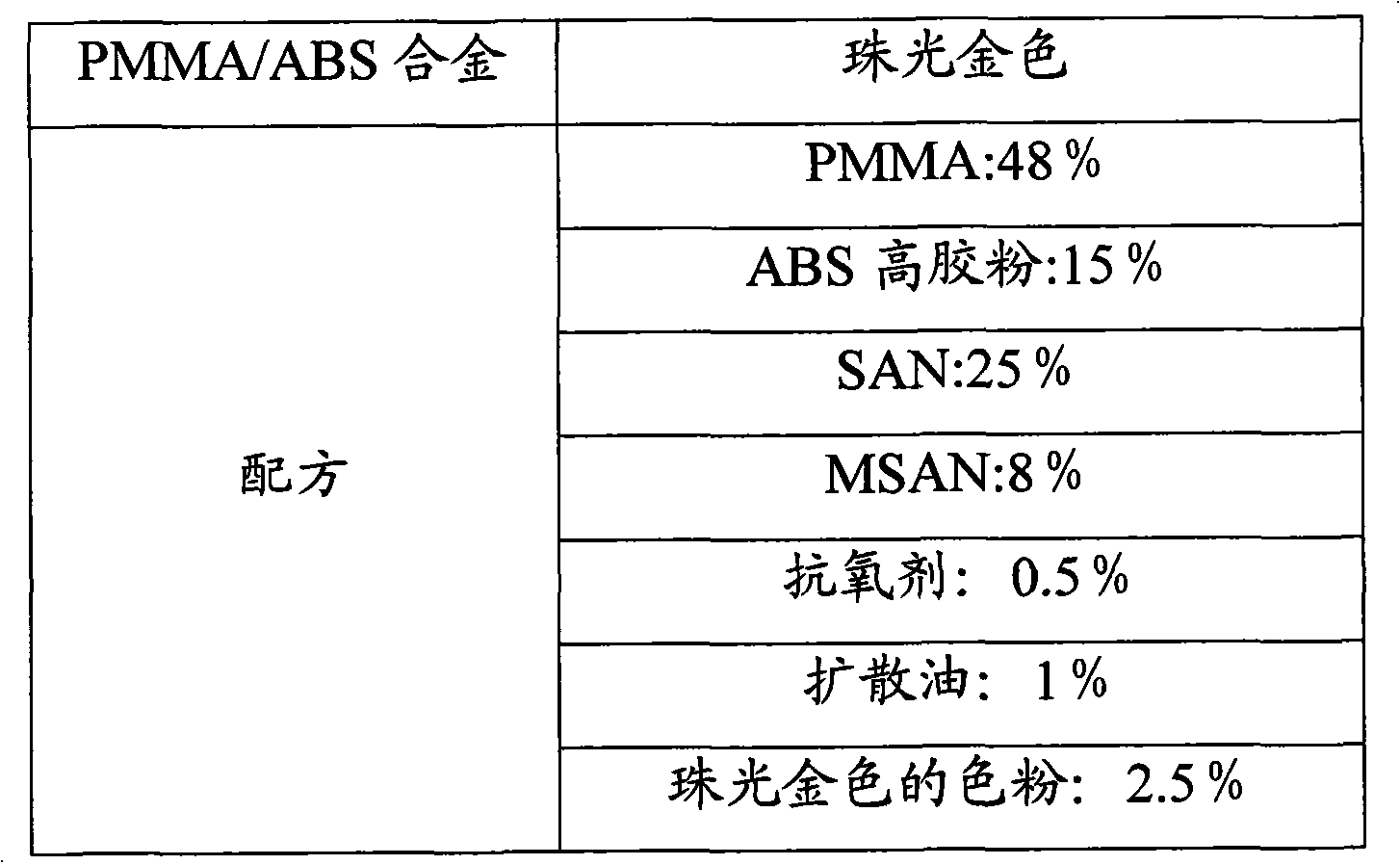

Pearlized gold toner and method for preparing PMMA/ABS alloy by using same

A golden and pearlescent technology, applied in the direction of pigment paste, etc., can solve the problem of painting on the surface of PMMA/ABS alloy, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

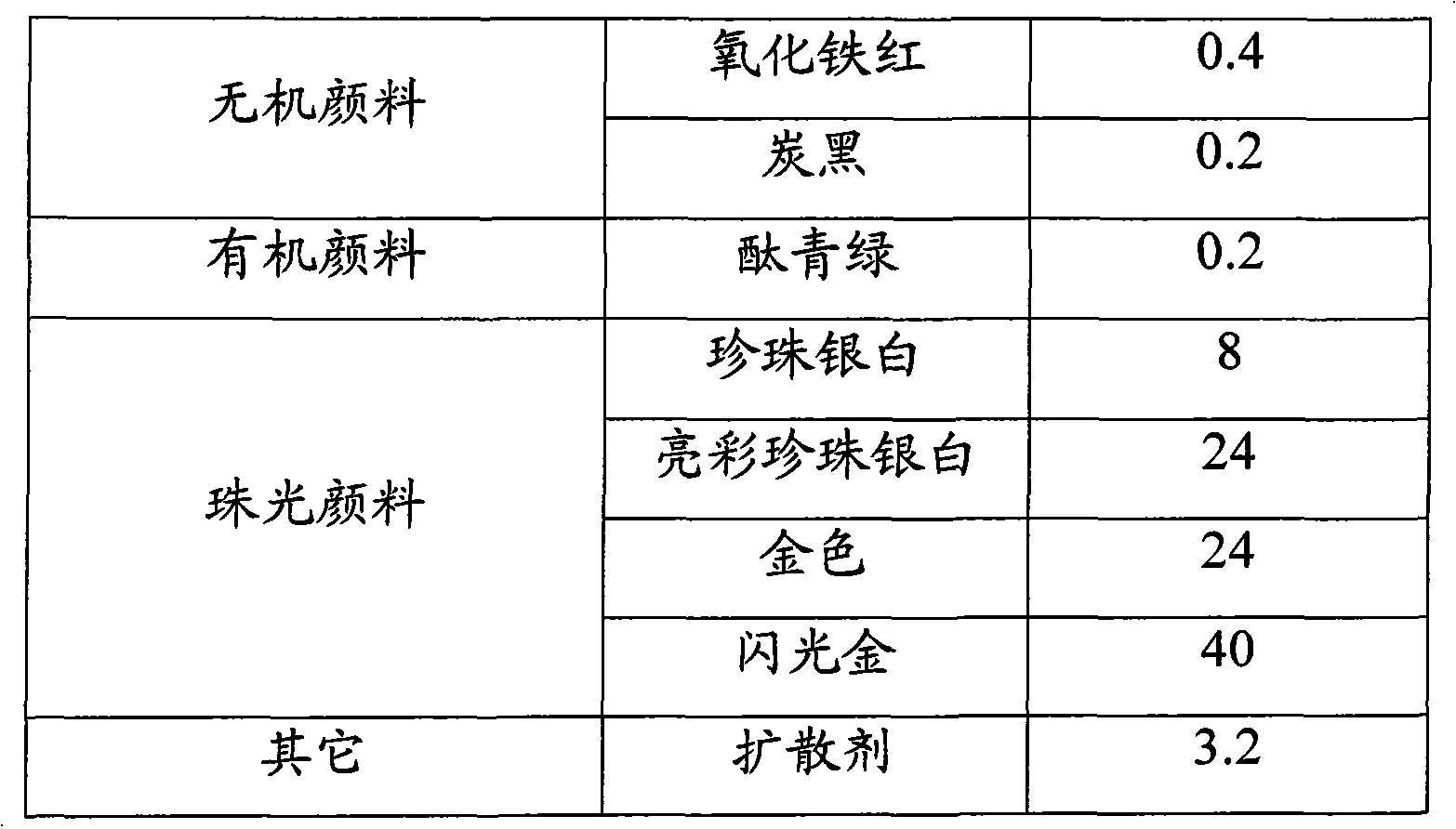

[0021] When preparing pearlescent gold color powder, the ratio of each component is: 0.05% iron oxide red; 0.05% carbon black; 0.05% phthalocyanine green; 2% pearl silver white; 36% bright color Pearl Silver; 36% Gold; 20% Glitter Gold; 5.85% Diffuser.

Embodiment 2

[0023] When preparing pearlescent gold color powder, the ratio of each component is: 0.2% iron oxide red; 0.1% carbon black; 0.1% phthalocyanine green; 4% pearl silver white; 32% bright color Pearl Silver; 34% Gold; 25% Glitter Gold; 4.6% Diffuser.

Embodiment 3

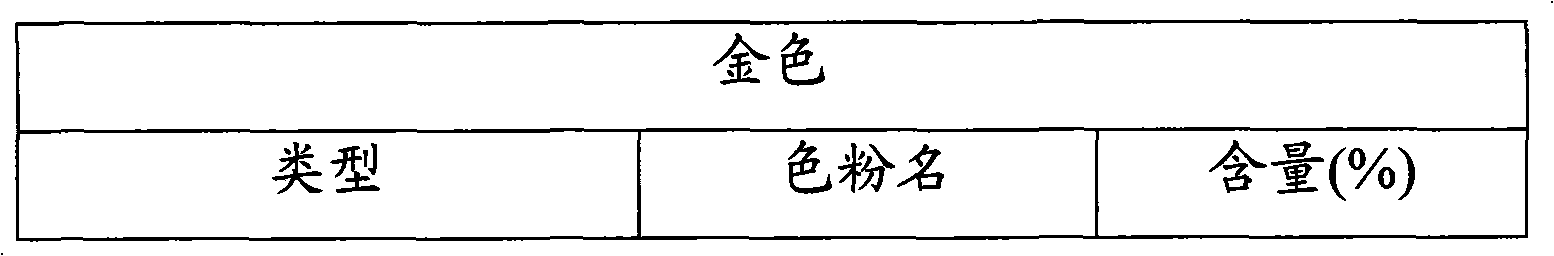

[0025] When preparing pearlescent gold color powder, the ratio of each component is: 0.4% iron oxide red; 0.2% carbon black; 0.2% phthalocyanine green; 8% pearl silver white; 24% bright color Pearl Silver; 24% Gold; 40% Glitter Gold; 3.2% Diffuser.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com