Patents

Literature

67 results about "Gold color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold or golden is a yellowish orange color, that is a bit like the color of the metal gold.

Metallized colored transparent laminating film

A multilayer laminate is disclosed. The base layer is a transparent colored layer made of OPS, PET, polypropylene, polyester, or a similar material. The base layer is then metallized by a vacuum process to provide a metallized sheet or film. A second sheet or film is then laminated over the metallized layer. The laminating sheet or film is transparent and may be either clear or have a desired color so that a metallized color is seen on both sides of the sheet. If a colored laminated layer is selected then a different color is seen on each side of the sheet. The sheet may then be converted into a thermoformed tray. The use of a colored laminating sheet provides colors such as gold and metallized blue previously not available at reasonable costs.

Owner:REYNOLDS FOOD PACKAGING CANADA INC

Amber-colored Polyester Film with Particular Suitability for Metallization and Steel-lamination

ActiveUS20080318073A1Cost-effective processGood appearanceLiquid surface applicatorsCovering/liningsPolyesterNanometre

The present invention relates to a biaxially oriented polyester film, whicha) has a base layer B, which includes a yellow dye and a red dye,b) has, on each side of the base layer B, at least one layer (A or C) which includes, based on the weight of layer A or C, less than 0.01% by weight of the yellow dye and less than 0.01% by weight of the red dye, andc) the film has one absorption maximum lying at from 400 to 500 nm in the UV / visible spectrum from 400 to 800 nm.Preferred dyes are anthraquinone dyes and perinone dyes; the polyester is preferably PET. After metallization or lamination, the film has a gold appearance, and is a suitable packaging material.

Owner:MITSUBISHI POLYESTER FILM

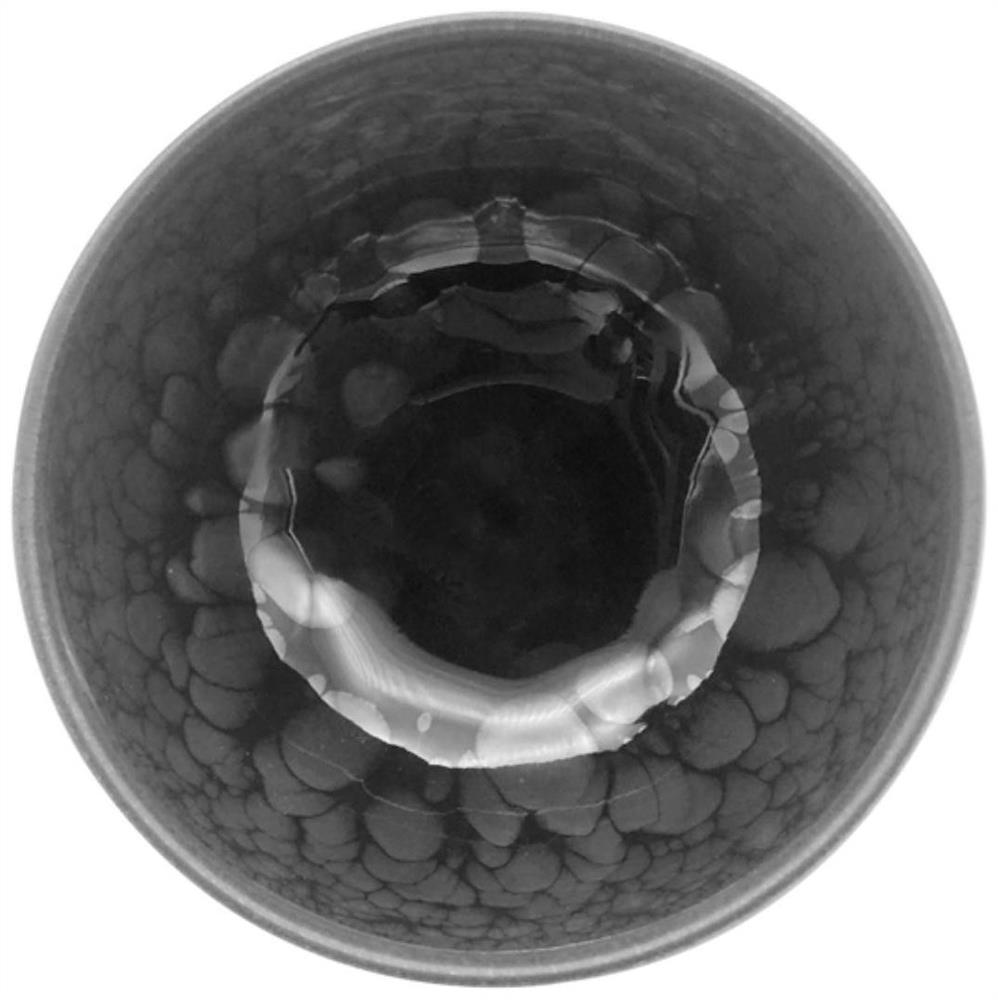

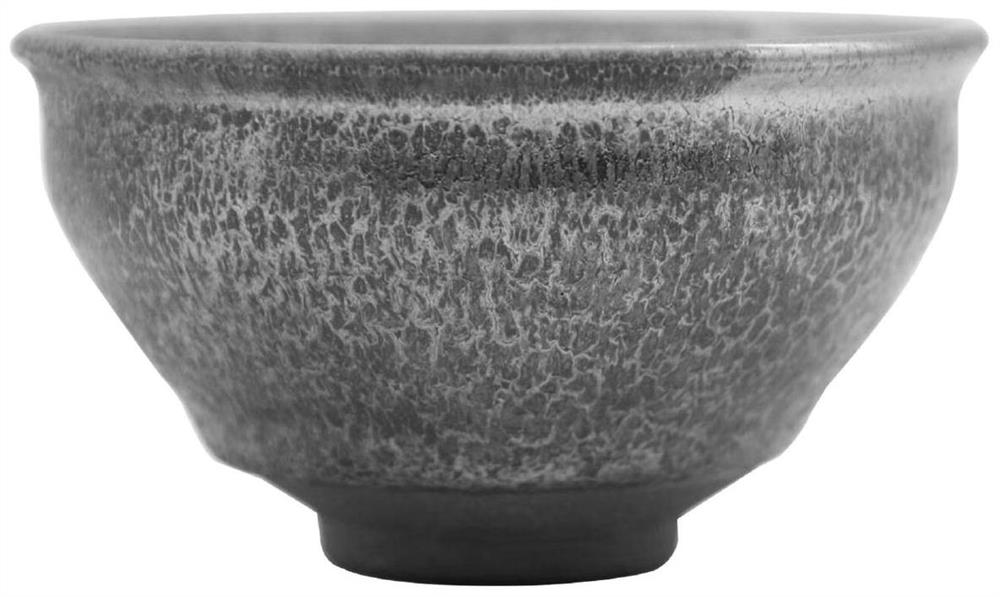

High temperature transmutation star glazed ceramic glaze and preparation technology of high temperature transmutation star glazed ceramic

PendingCN109179997AUnique artistic beauty and spiritual feelingPromotes crystallization and spot formationCeramic materials productionClaywaresBone ashCeramic glaze

The invention relates to the field of ceramic products and manufacturing processes, in particular to a high temperature transmutation star glazed ceramic glaze and a preparation technology of high temperature transmutation star glazed ceramic. The invention is characterized in that the glaze comprises the following ingredients (by weight): 35-40 parts of feldspar, 5-8 parts of kaolin, 2-5 parts oflimestone, 10-15 parts of talc, 15-20 parts of quartz, 5-8 parts of bone ash and 5-8 parts of industrial iron red powder. The high temperature transmutation star glazed ceramic produced by using thehigh temperature transmutation star glazed ceramic glaze is different from traditional transmutation glaze as follows: the black base is completely covered with golden color, etc. on the surface suchthat the ceramic is archaized but not ancient, is creative on the basis of forefathers, is gold-like and silver-like, is a very magic and varied porcelain, and has unique artistic beauty and spiritualfeeling; the glaze has high viscosity at high temperature, and is easy to form bubbles during firing, which helps enrich iron and precipitate crystals; and spots are evenly spread on the glaze.

Owner:FUJIAN DEHUA HONGFANG CERAMIC CO LTD

Reduced metal transmutation glaze, ceramic product prepared from same and preparation method

The invention relates to a reduced metal transmutation glaze, a ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramic. The reduced metal transmutation glaze comprises components in parts by mass as follows: 30-40 parts of nepheline-syenite, 4-7 parts of kyanite, 8-12 parts of barium carbonate, 22-27 parts of a frit, 14-17 parts of quartz, 7-12 parts of kaolin, 2-7 parts of calcium carbonate, 2-4 parts of cerium oxide, 28-32 parts of manganese oxide, 3-4 parts of copper oxide and 1-2 parts of nickel oxide, wherein the frit comprises components in parts by mass as follows: 48-52 parts of borax, 23-27 parts of quartz, 3-7 parts of kaolin, 13-17 parts of calcium carbonate and 3-7 parts of potassium carbonate. The reduced metal transmutation glaze ceramic product has reddish brown ground coat on the surface, gold spots flush with the glaze surface are formed on the glaze coat, and the color of the glaze is pure, bright and dazzling.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

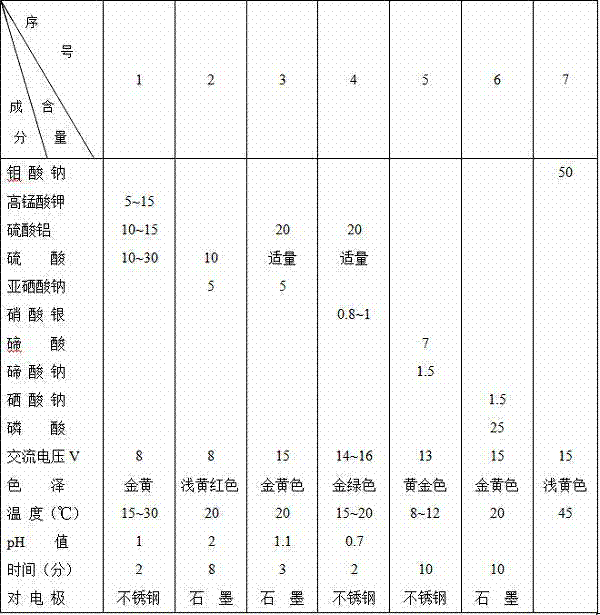

Method for putting gold color on aluminum material

ActiveCN102808208AFast coloringImprove uniformitySurface reaction electrolytic coatingElectrochemical responseElectrolysis

The invention belongs to the field of metal surface treatment and particularly relates to a technology for putting a K gold color (referring to 24K gold color) on the surface of an aluminum material. A method for putting the gold color on the aluminum material comprises the following steps of: placing the aluminum material on which an anode oxidation film is prepared in specific modified solutionfor dipping to enable the porous surface of the oxidation film to be adsorbed with a layer of substances which can realize chemical reaction and can promote electrochemical reaction, and then dippingor conducting electrolytic treatment in acidic solution of coloring additive to obtain a gold color film layer with pure and even color. A composition used in the method is stable and has long service life, the reject rate of the treated aluminum material is extremely low, and the problems of low coloring speed, unstable quality and high cost are ideally solved.

Owner:GUANGDONG HAOMEI ALUMINUM

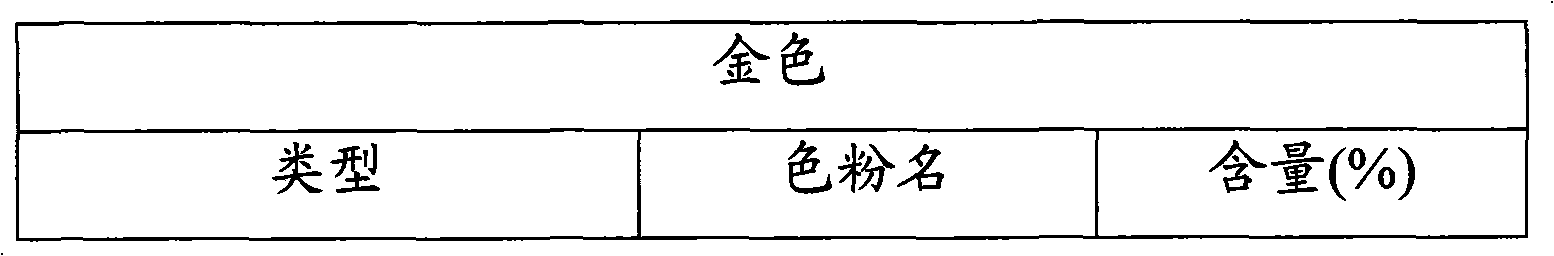

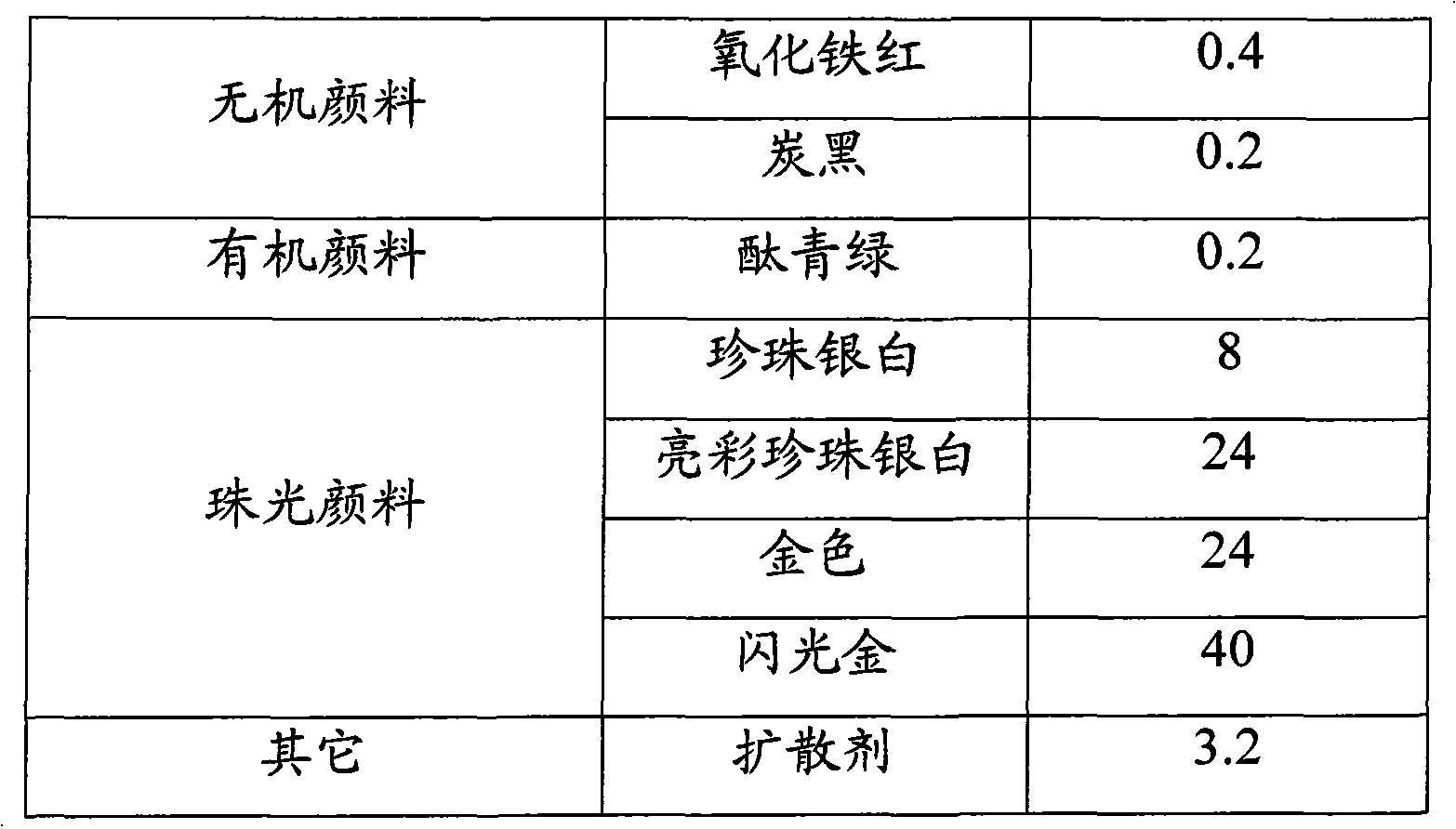

Pearlized gold toner and method for preparing PMMA/ABS alloy by using same

The invention is suitable for the technical field of thermoplastic resin alloys by high polymer material technology, and provides a pearlized gold toner and a method for preparing a PMMA / ABS alloy by using the same. The pearlized gold toner contains the following components in percentage by weight: 0.05 to 1 percent of iron oxide red, 0.05 to 1 percent of carbon black, 0.05 to 1 percent of phthalocyanine green, 2 to 16 percent of silver pearl, 5 to 40 percent of brilliant silver pearl, 5 to 40 percent of gold, 20 to 60 percent of glittery gold, and 1 to 6 percent of dispersing agent. In the invention, firstly, the pearlized gold toner is prepared, and secondly, the pearlized gold PMMA / ABS alloy is prepared by using the prepared pearlized gold toner; the surface of the alloy is free from paint spraying and coloring; and the alloy is formed only at a time, and has the advantages of energy conservation, never fading, environmental protection and the like.

Owner:惠州市沃特新材料有限公司

Colored gold oil drop cup building and firing process

The invention discloses a colored gold oil drop cup building and firing process. The process comprises the following steps: preparing a green body, main body glaze slip and mouth edge glaze slip, applying the mouth edge glaze slip to the mouth edge of the green body, carrying out pre-sintering, applying the main body glaze slip to the pre-sintered green body, putting the glazed and air-dried greenbody into an electric kiln, and implementing roasting, cooling and discharging. The fired colored gold oil drop built cup has the advantages that oil drop stripes and hair are generated on the glazesurface, the oil drop stripes and hair are generated at the same time, the single type of traditional oil drops and rabbit hair is broken through, different stripe effects are shown, and meanwhile, part of oil drops are in a semi-crystalline state (partially transparent) and have the beauty of glittering and glittering. The glaze surface is of a color mainly comprising purple gold and silver blue,and the color saturation is high.

Owner:福建省开河窑建盏文化发展有限公司

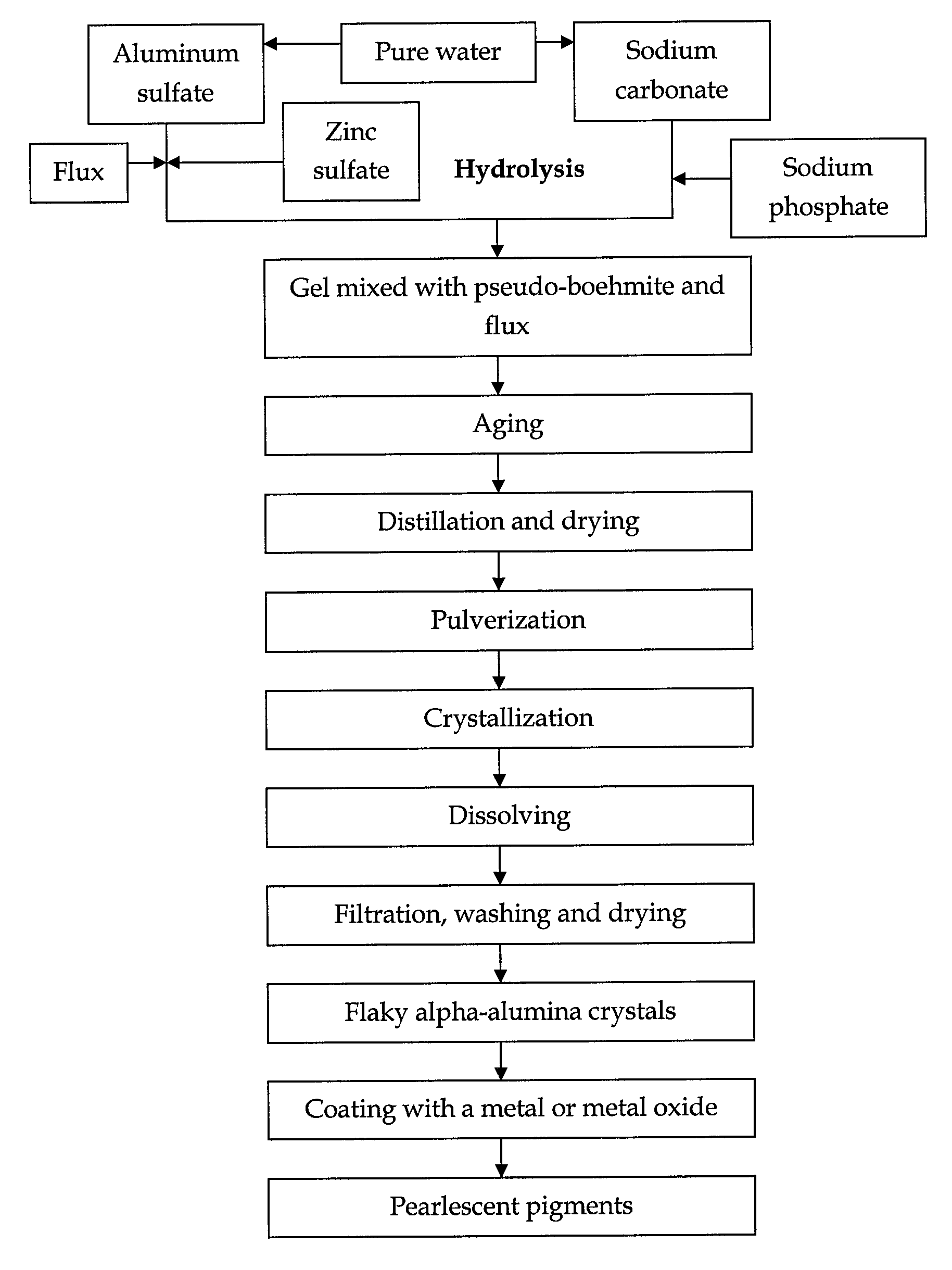

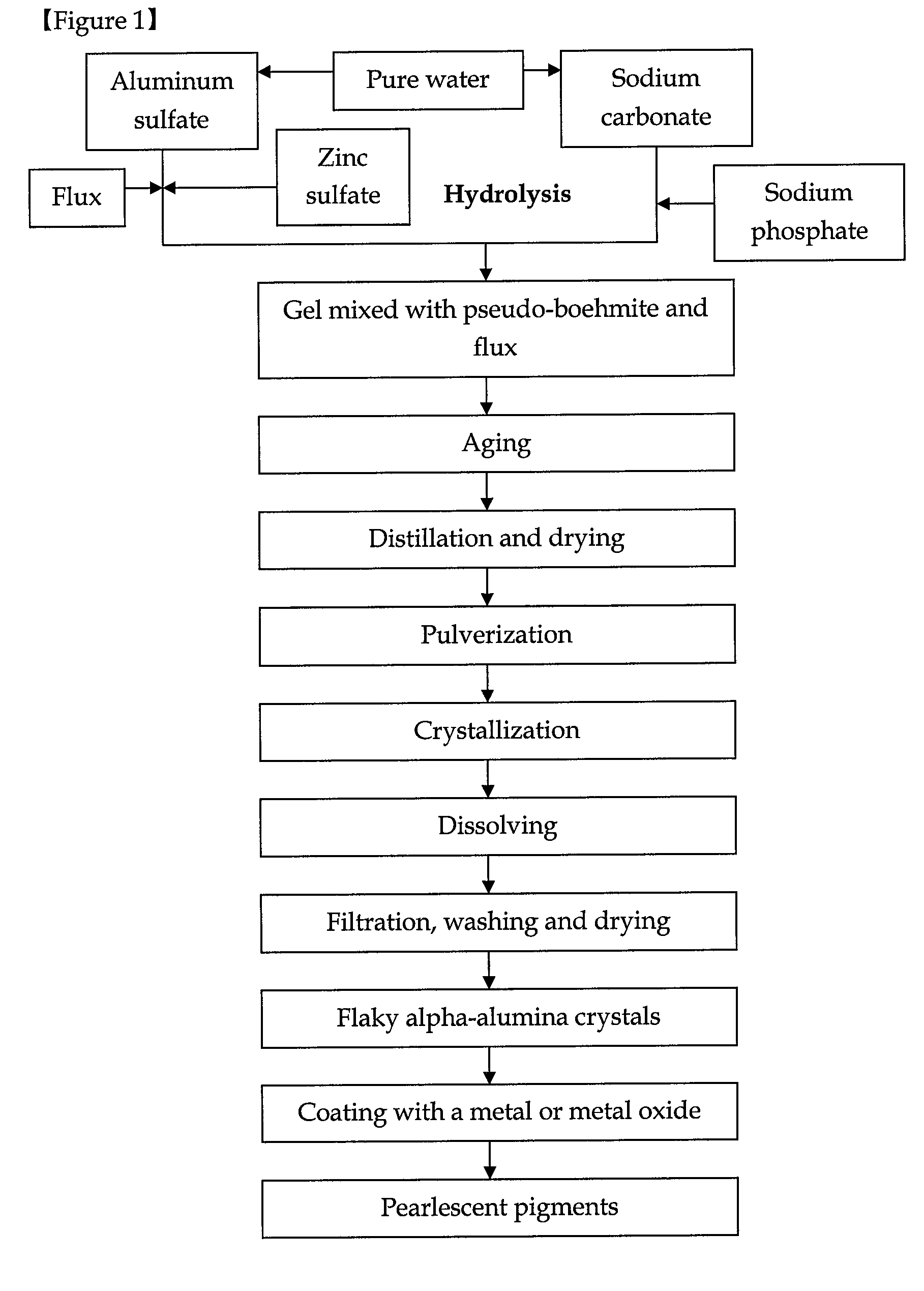

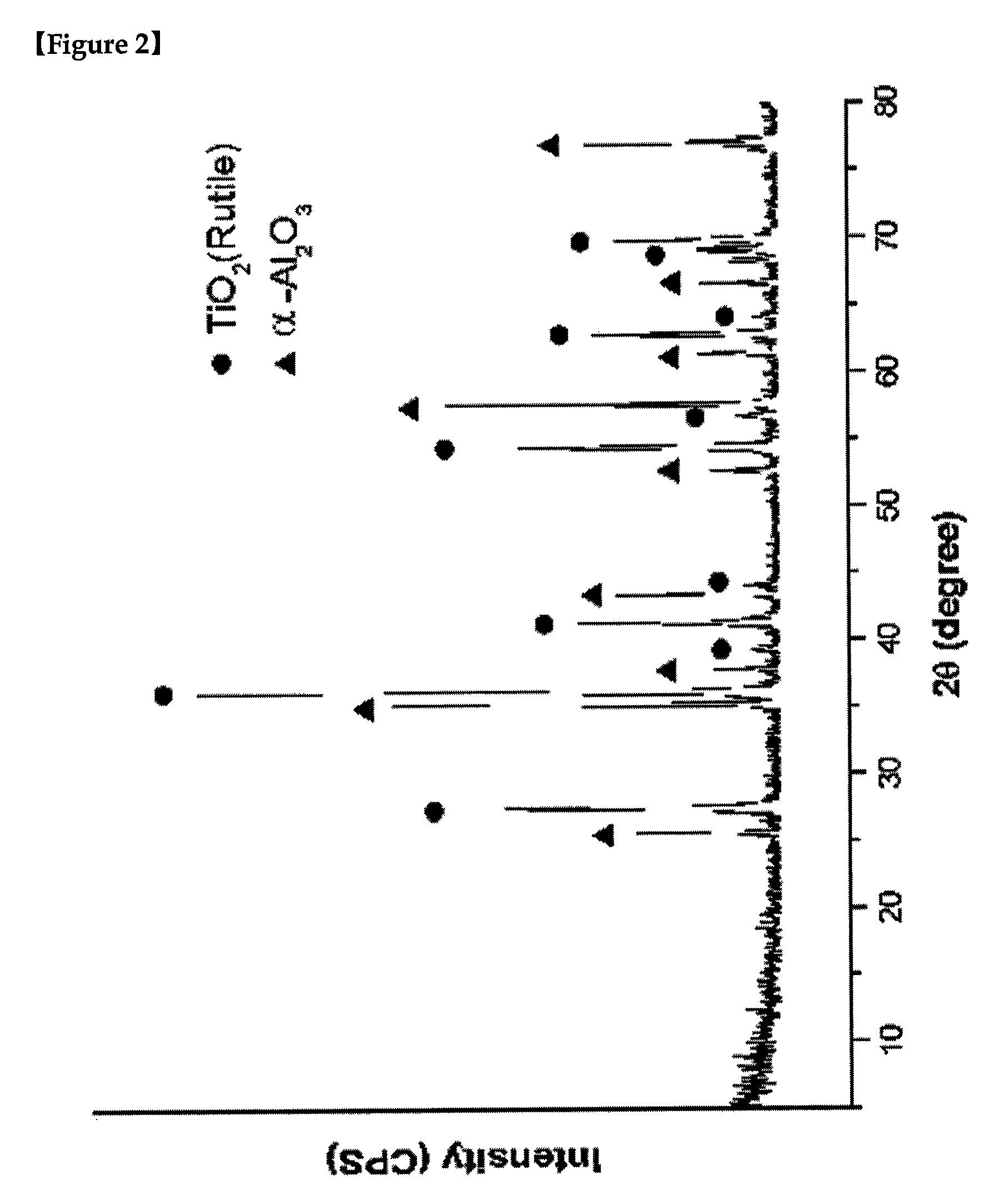

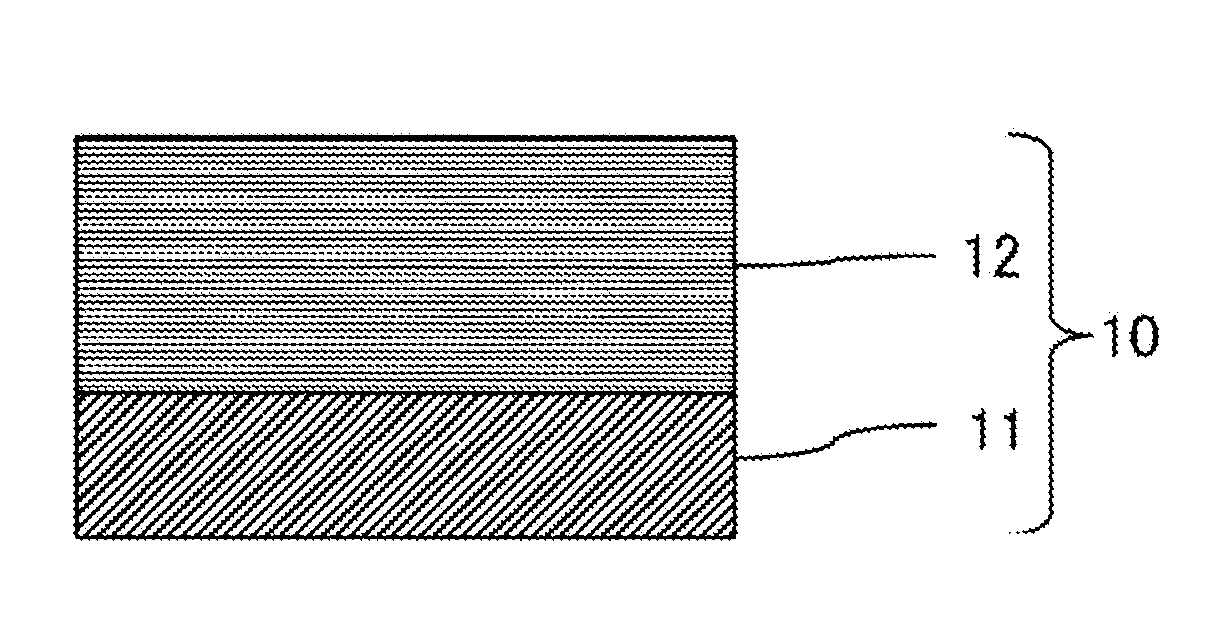

Pearlescent pigments with large aspect ratio and a method of their preparation

ActiveUS8287636B2High glossOvercome problemsPigment preparation by wet methodsZinc compoundsCrystallographyInterference color

The present invention relates to a pearlescent pigment with large aspect ratio and a method of their preparation, and particularly to pearlescent pigments prepared by coating a metal or metal precursor on the flaky alpha-alumina crystals obtained by using an aluminum precursor aqueous solution and a zinc precursor aqueous solution as main ingredients. The crystals herein has an average particle thickness of 0.5 μm or less, an average particle diameter of 15 μm or higher and a large aspect ratio of 50 or higher, thereby being superior in gloss. The crystals show metal colors and interference colors of silver, gold, red, purple, blue and green.

Owner:KOREA RES INST OF CHEM TECH +1

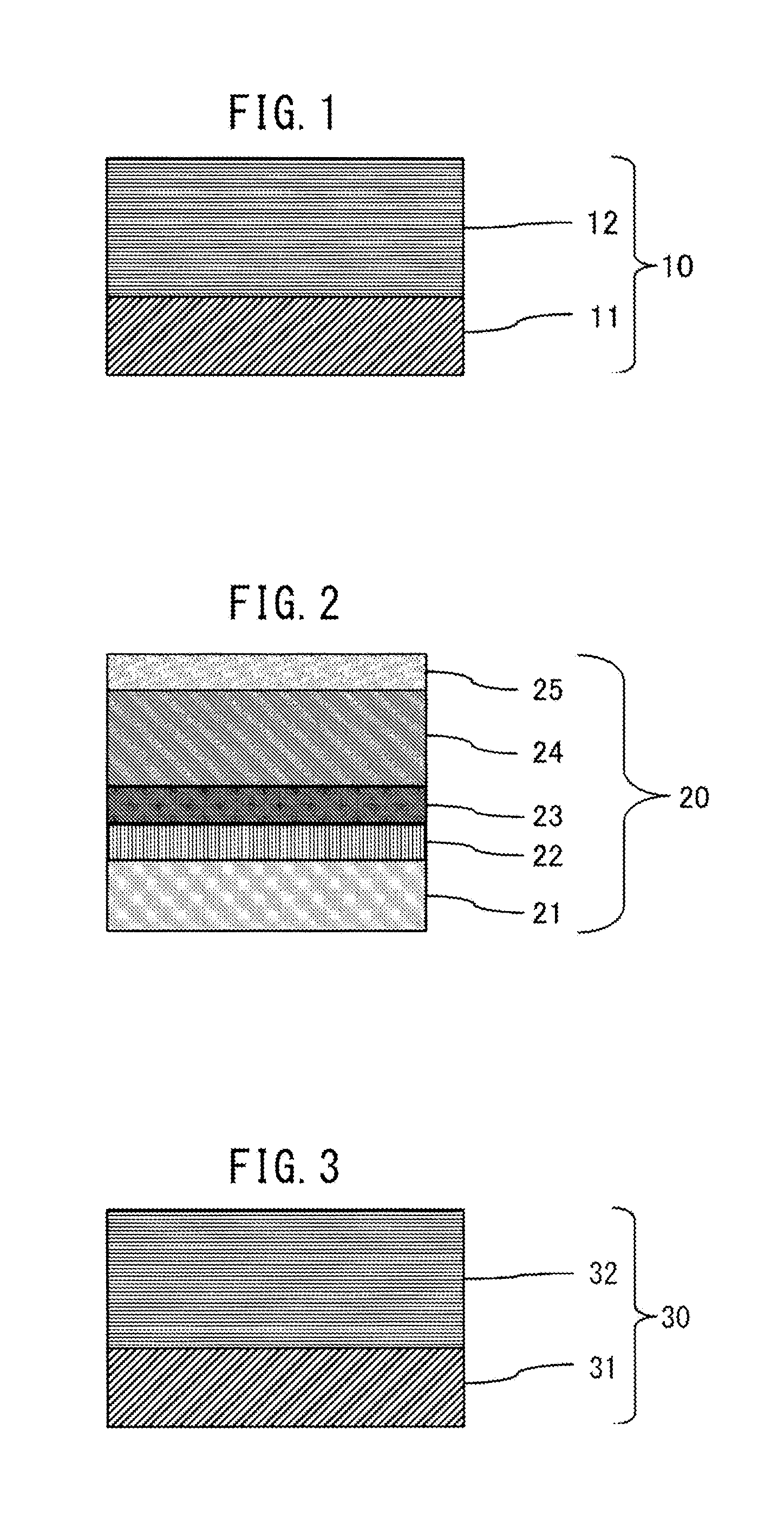

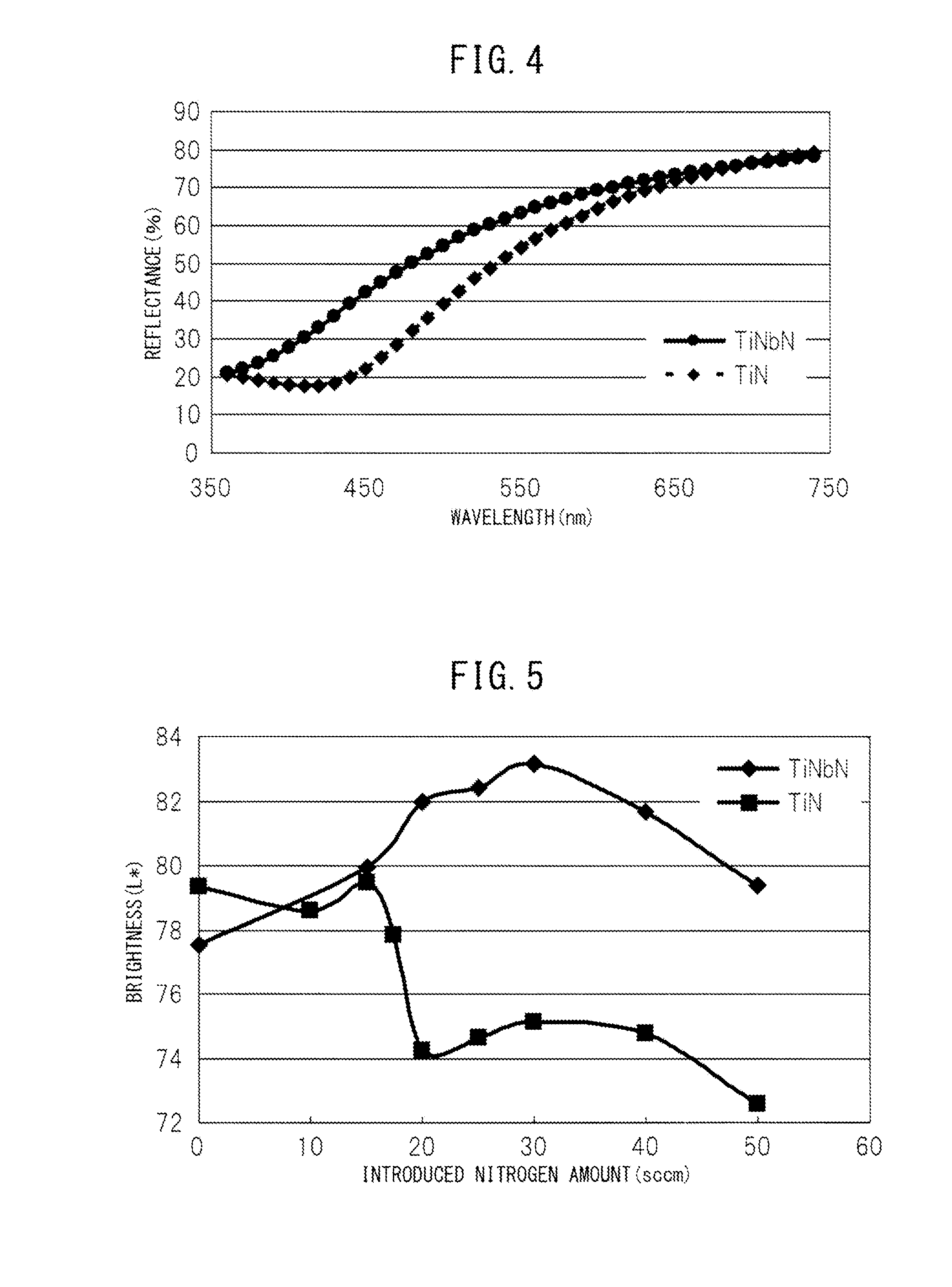

Golden rigid decorative member

ActiveUS20150044453A1Deterioration of appearance qualityIncrease brightnessNitrogen compoundsVacuum evaporation coatingAlloyGold color

A golden rigid decorative member in which scratch resistance and abrasion resistance are significantly improved and deterioration of appearance quality due to a flaw, abrasion, or the like is suppressed, and which has a pale color with a high quality feel is stably provided. A single layer or several layers of a coating including a reaction compound of an alloy of Ti and one or two or more metals selected from Nb, Ta, and V, and of one or two non-metallic elements mainly including nitrogen and selected from carbon and oxygen are stacked on a base.

Owner:CITIZEN WATCH CO LTD

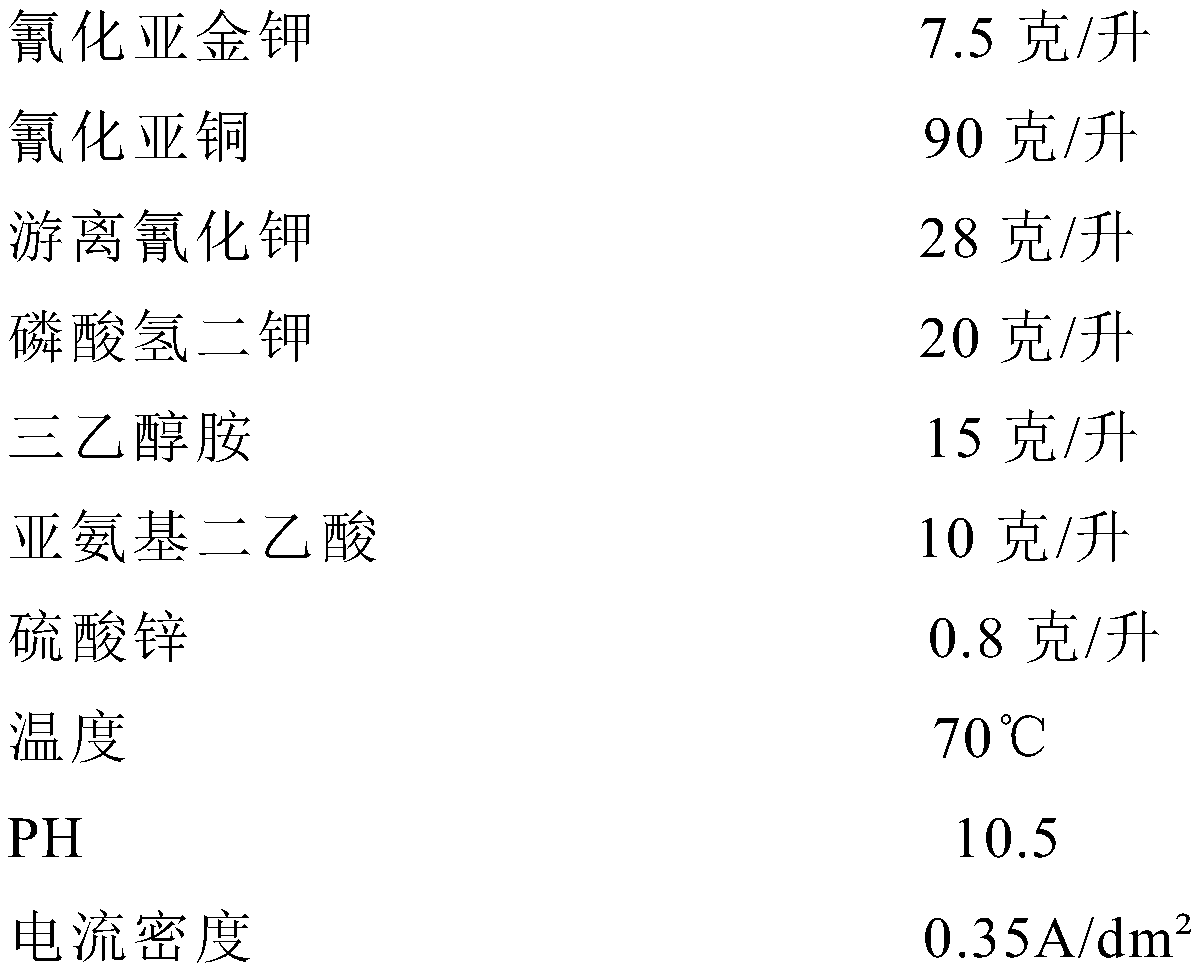

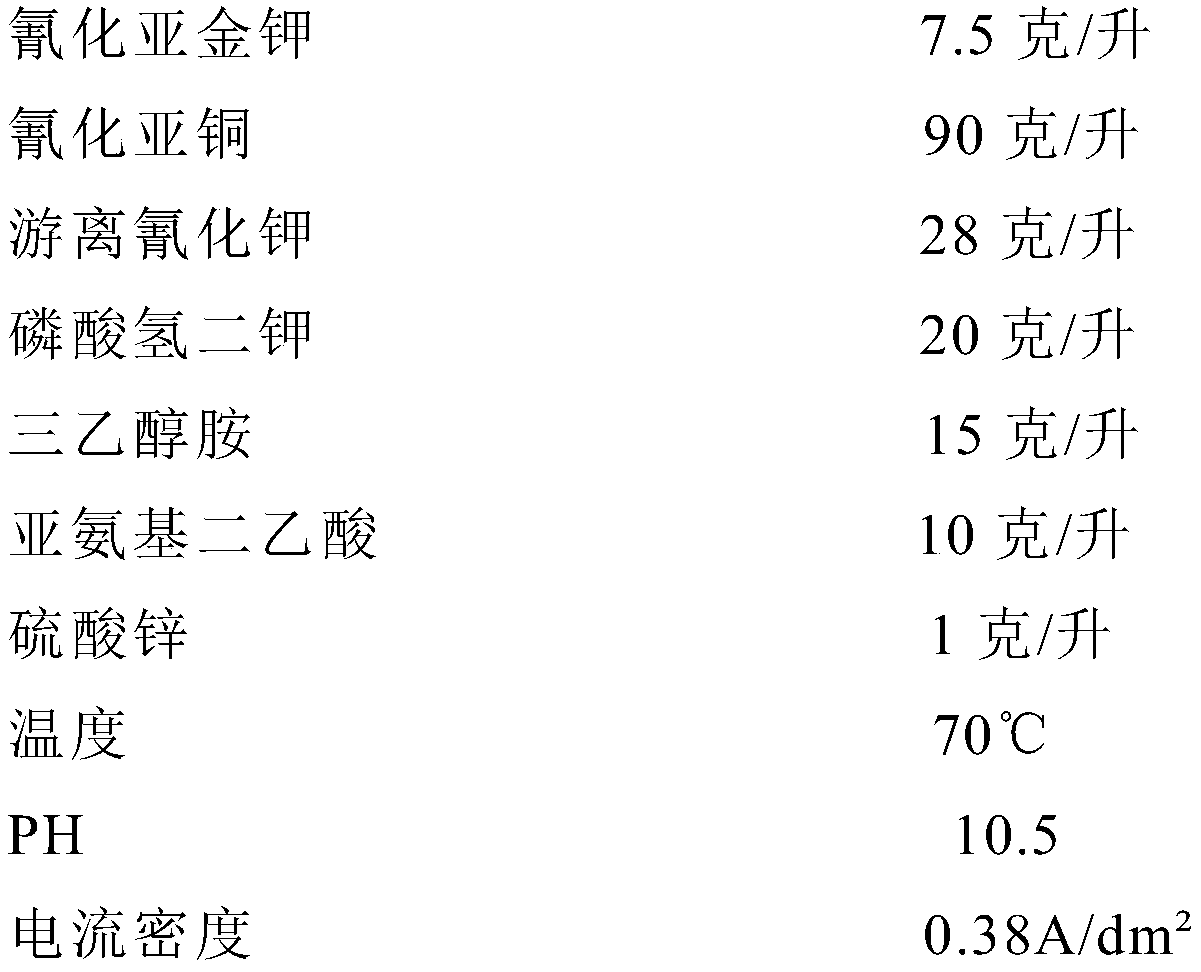

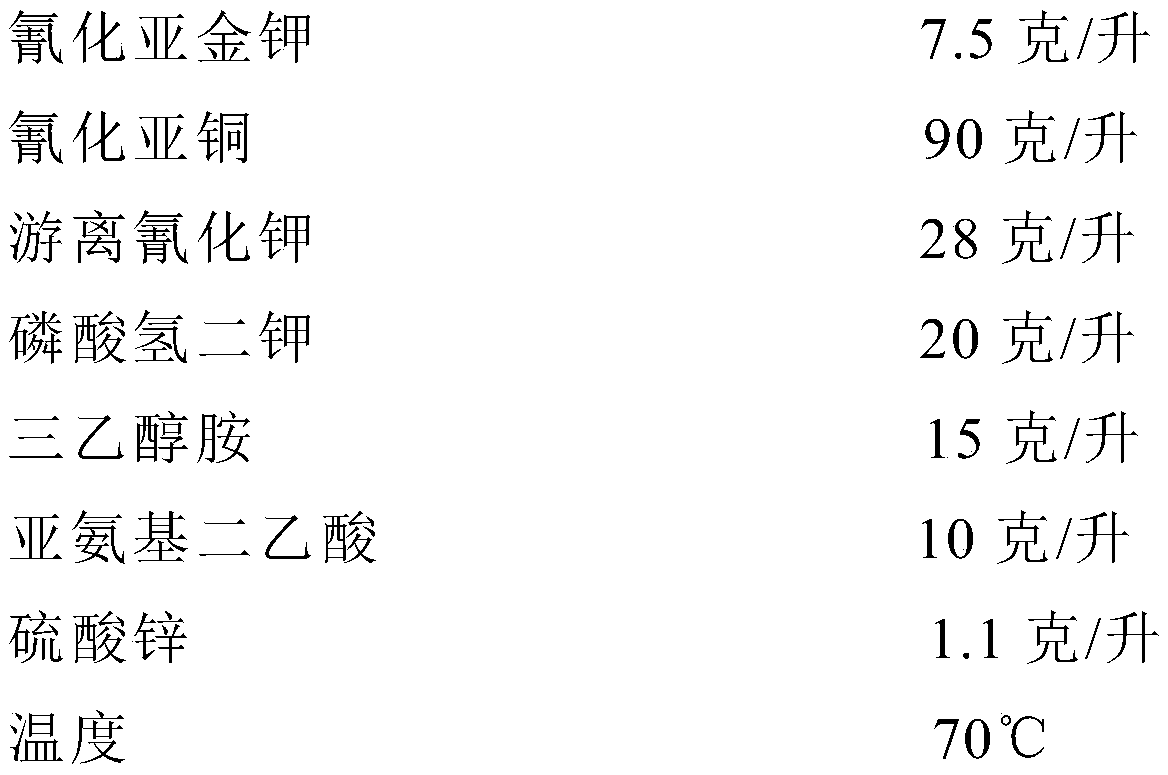

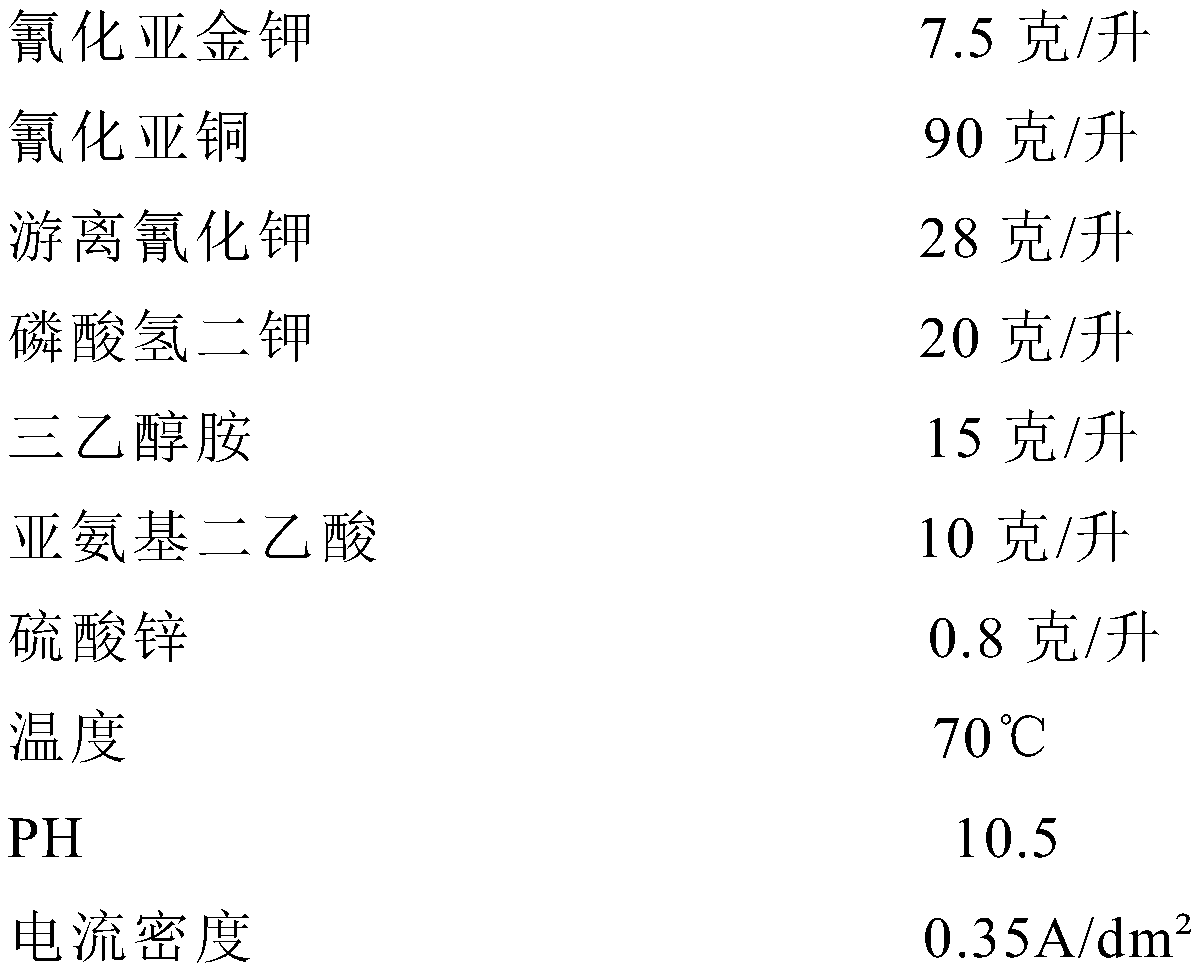

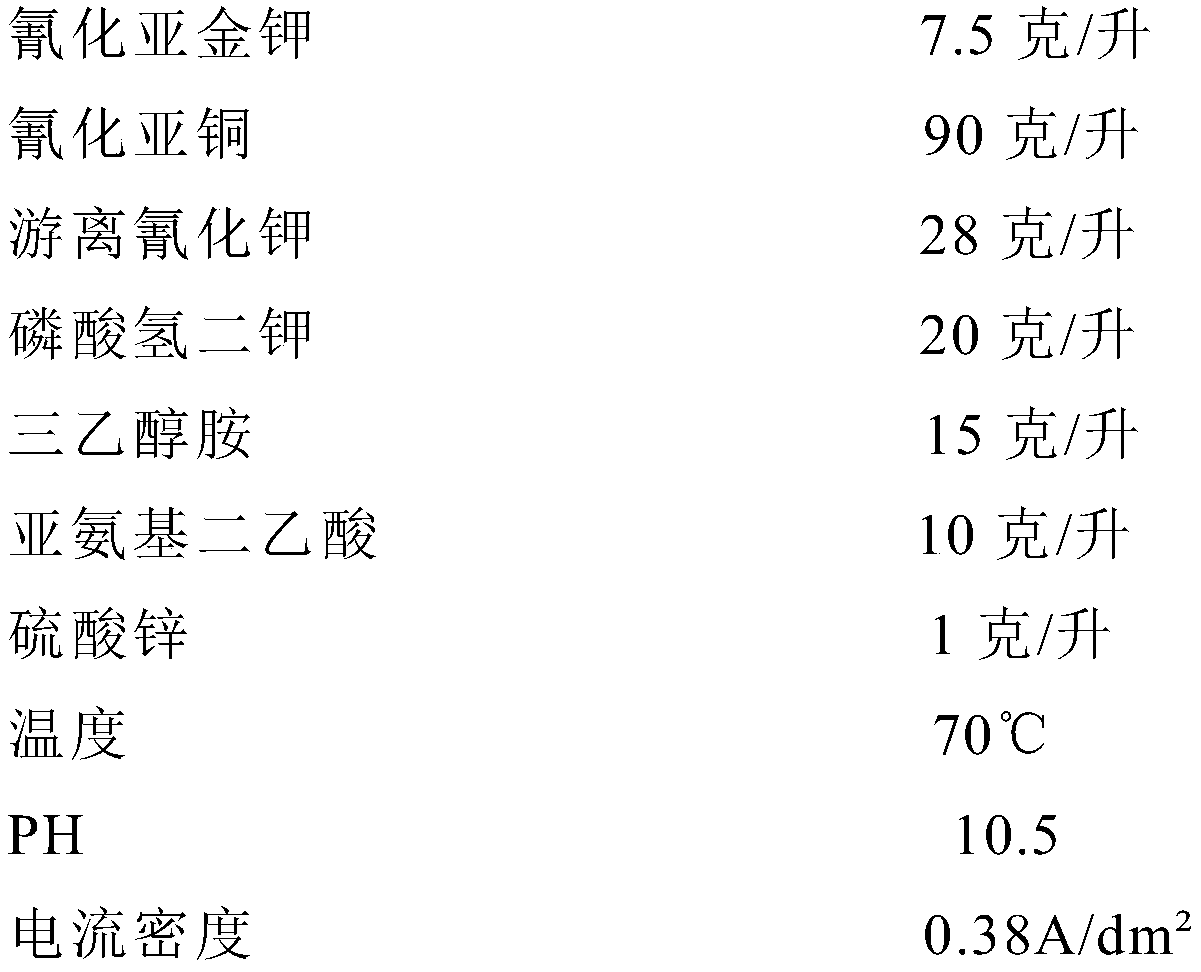

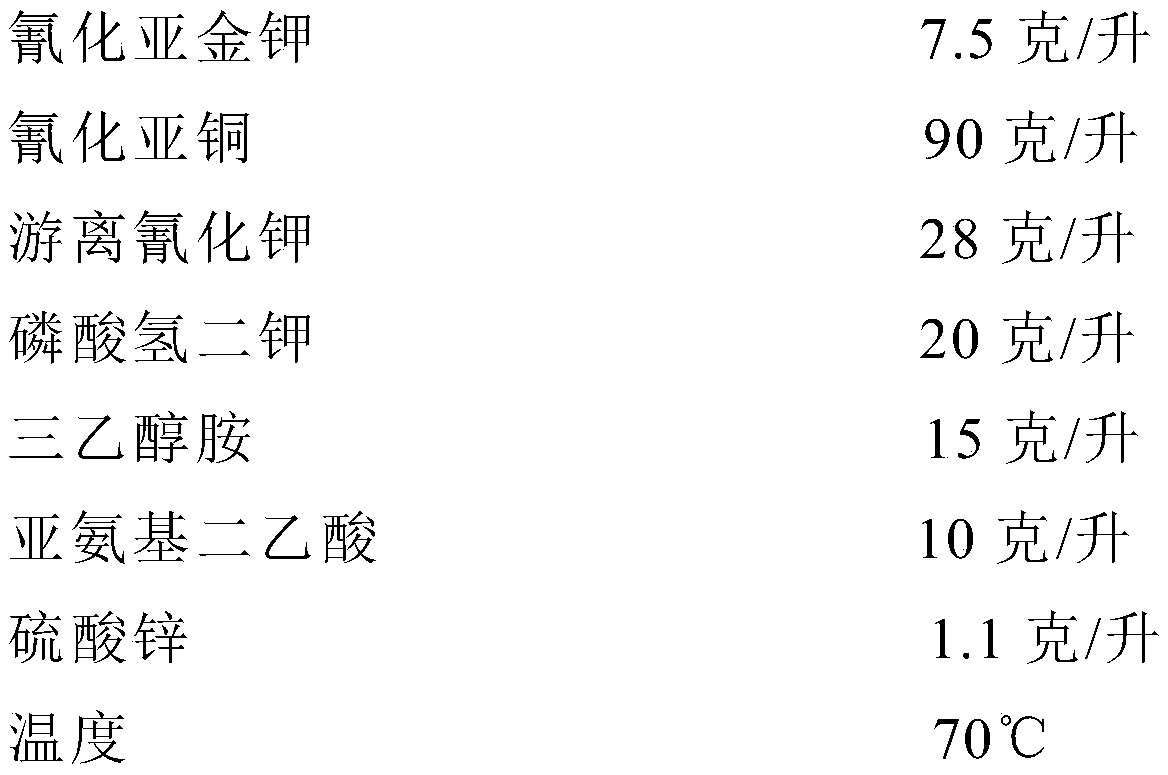

Electroforming liquid for K gold electroforming process

InactiveCN109778245AImprove performanceReduce weightElectroforming processesPotassium cyanidePotassium

The invention relates to electroforming liquid for a K gold electroforming process. The electroforming liquid comprises the following main components with one liter of solution as unit: 4-10 g / l of potassium aurous cyanide, 50-100 g / l of cuprous cyanide, 18-35 g / l of free potassium cyanide, 1-50 g of triethanolamine and 1-30 g / l of iminodiacetic acid as auxiliary complexing agents, 0.2-4 g / l of zinc sulfate as hardening agents, 10-30 g / l of dipotassium phosphate as buffering agents; the electroforming liquid for the K gold electroforming process is prepared through the components, and K gold products are electroformed; K gold is prepared through a gold and copper binary alloy electroforming process; the K gold electroforming liquid with stable performances is used for preparing hollow K gold products with low weights, high hardness, bright rose gold colors and bright and smooth surfaces; and the products have the advantages of low gold consumption, durability, three-dimensional and full shapes and low cost.

Owner:深圳市昊扬电铸技术开发有限公司

Firing method for Jianzhan with colored ground coat, colored oil drops and gold edge

The invention provides a firing method for Jianzhan with a colored ground coat, colored oil drops and a gold edge. The firing method comprises the following steps: preparing a green body raw materialand a glaze, carrying out throwing molding on the green body raw material, then successively conducting fettling, heating and glazing, putting a glazed and air-dried green body into a kiln, conductingroasting, performing natural cooling, and taking the prepared Jianzhan out of the kiln. Technological processes such as a formula, a firing atmosphere and a temperature curve are clear in the invention; the firing method is easy to control, good in stability and high in yield; the sintered Jianzhan has the and glossy gold edge; the ground coat is has a color varying with light rays; the Jianzhanhas vertical hair which have flowing light color and partly hidden and partly visible; oil drops which are different in size and changing in color emerge on the surface of the Jianzhan, and look likestars gathering into groups in the sky; and the Jianzhan has extremely high artistic value and appreciation value.

Owner:南平市曜变陶瓷研究院

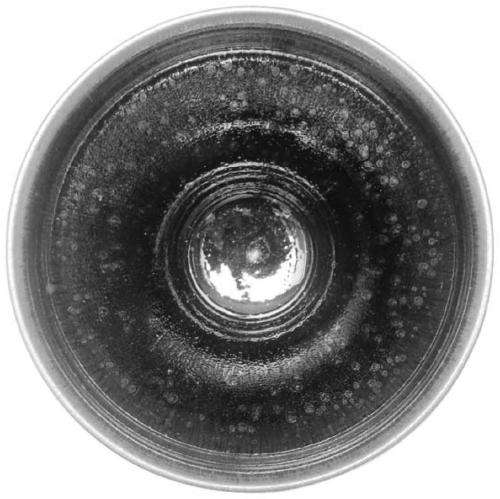

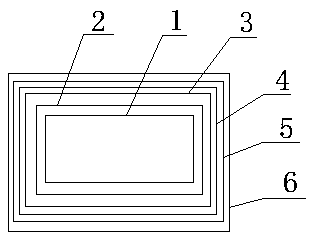

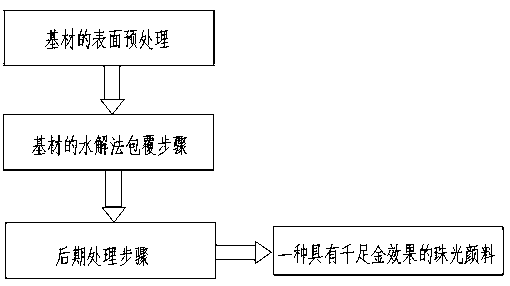

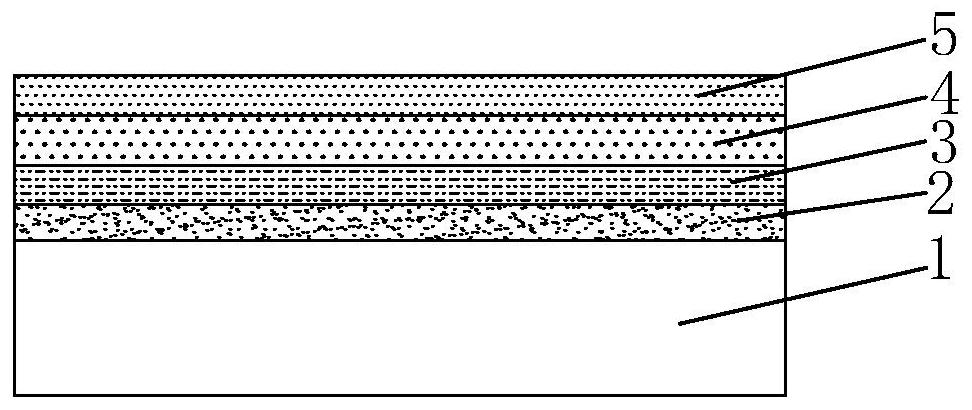

Pearlescent pigment having 999-pure gold effect and preparation method thereof

InactiveCN108690377ABright lusterHigh purity goldInorganic pigment treatmentWeather resistanceChloride

The invention discloses a pearlescent pigment having 999-pure gold effect and a preparation method thereof. The pearlescent pigment includes a base material, which is successively coated with a firstcomposite layer, a second composite layer, a third composite layer, a fourth composite layer and a fifth composite layer; wherein the first composite layer is formed by mixing stannous chloride, magnesium chloride and zinc chloride; the second composite layer is formed by mixing titanium tetrachloride, nickel chloride and stannic chloride; the third composite layer is formed by mixing titanium tetrachloride and ferric chloride; the fourth composite layer is formed by silicon dioxide or alumina; the fifth composite layer is formed by mixing titanium tetrachloride and ferric chloride. The preparation method includes steps of: surface pretreatment of the base material, hydrolytic coating of the base material, and post-treatment. The pearlescent pigment has a bright color, is high in purity ofgolden color, is good in glossiness, weather resistance and dispersibility, is low in cost, is simple in preparation method, and is convenient to use.

Owner:JIANGSU BEILIDE NOVEL MATERIALS

Preparation process of raw ore gold oil drop Jianzhan teacup

The invention discloses a preparation process of a raw ore gold oil drop Jianzhan teacup, which comprises the following steps of: preparing a green body and glaze slip, glazing, roasting the glazed and air-dried green body in an electric kiln, and discharging the finished product from the kiln after roasting. According to the raw ore gold oil drop Jianzhan teacup obtained through firing, gold oildrop spots are distributed on the blue-black ground color, the metallic luster is obvious, the teacup has flowing light and color and is sparkling, and different color visual effects can be generatedunder various light sources; and meanwhile, the golden oil drops do not protrude out of the surface and are integrated with the glaze surface, the surface is flat, smooth and fine, and color changingand blackening caused by external influences in the using process are not likely to happen.

Owner:张浩

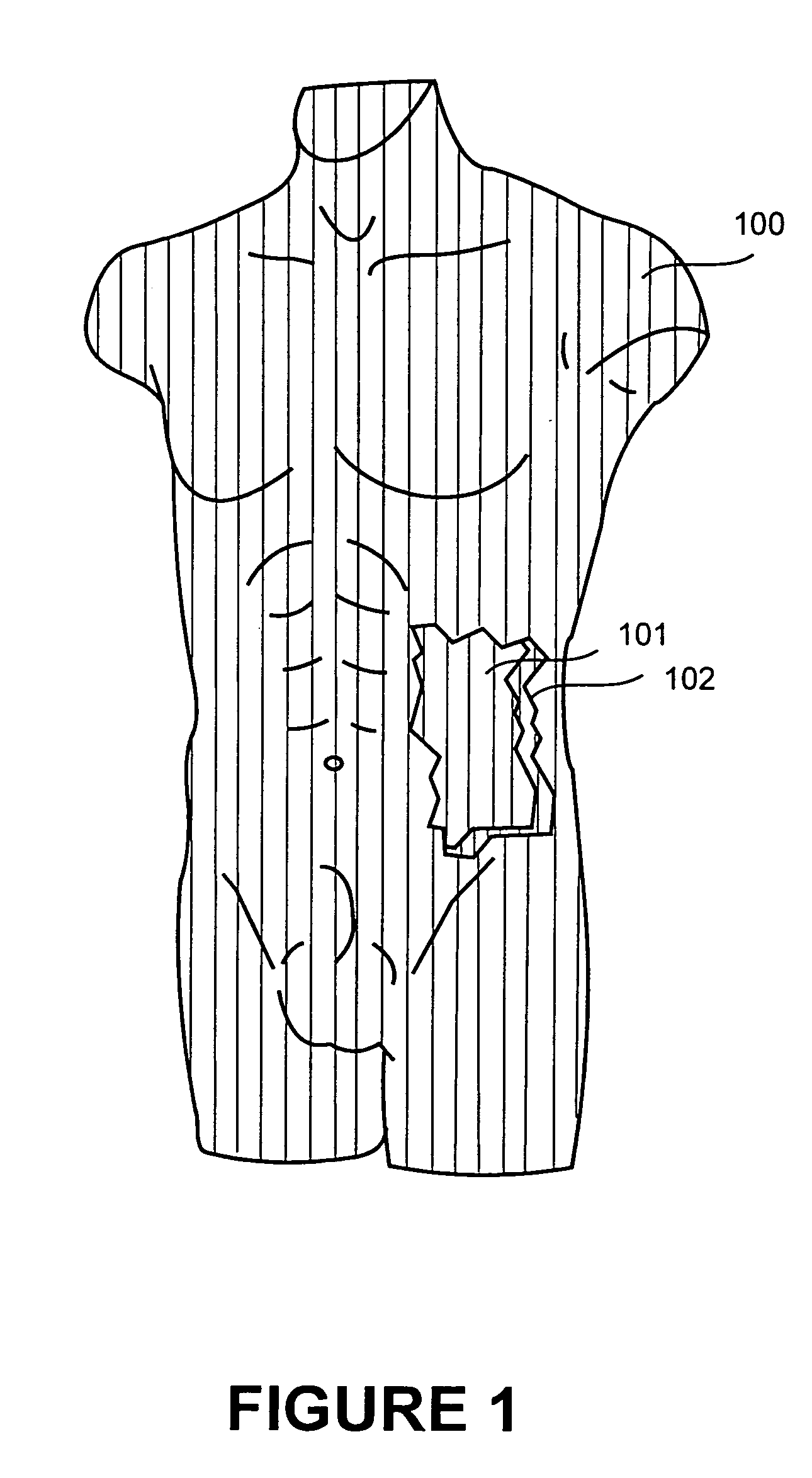

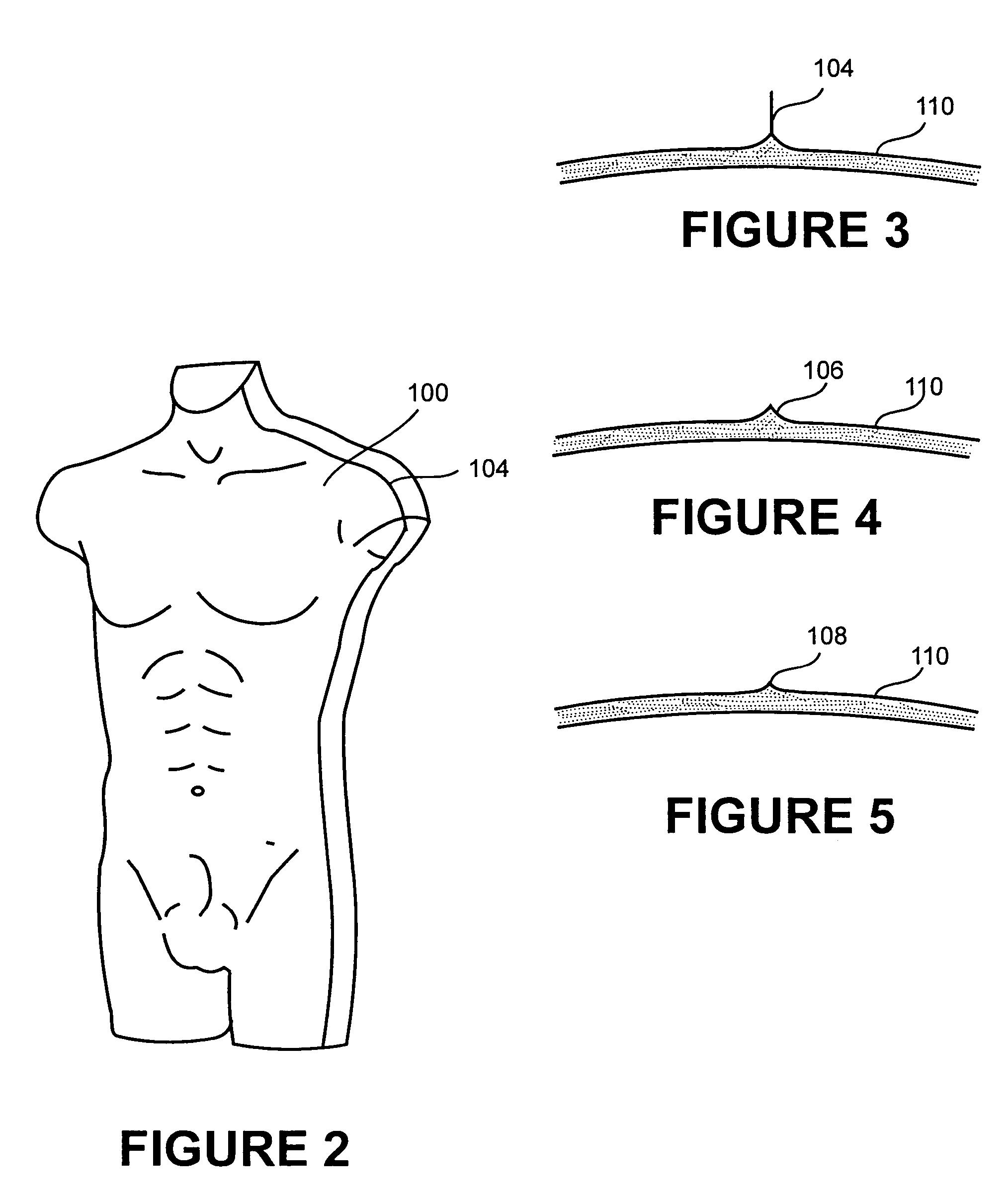

Molded display forms

InactiveUS20050184422A1Allowing in durabilityAllowing efficiency in processingCeramic shaping apparatusDomestic articlesResistEngineering

Methods of making a molded display form (i.e. a mannequin) or other article are provided, of an elastomeric material having a pigment and / or dye mixed therein, said form having a selected uniform color throughout the thickness of said material. Any desirable color may be selected, e.g., skin color (to approximate that of any race) grey, tan, red, blue, yellow, metallic colors such as gold and silver, and mixtures thereof. White and black molded articles are also provided herein. The processes of this invention are especially suitable for producing articles having a uniform color throughout without streaking. The forms of this invention are non-brittle, resist burning, and stand up well to high temperatures. If they are scraped or chipped, the uniform color of the material throughout will make the injury less noticeable. The material is also soft enough that seam lines may eliminated by buffing with synthetic pads, and because of the uniform color of the material, there is no need to paint over the buffed surface.

Owner:FUSION SPECIALTIES

Kitchen cabinet door sheet with gilding layer and manufacturing method of kitchen cabinet door sheet

InactiveCN105415800AStrong adhesionNot easy to fall offLamination ancillary operationsLaminationLacquerSurface cleaning

The invention discloses a kitchen cabinet door sheet with a gilding layer. The kitchen cabinet door sheet comprises a kitchen cabinet door sheet body. Gold foil adheres to part of or all of the outer surface of the kitchen cabinet door sheet body. The golden color which is most popular currently is applied to a kitchen cabinet for the first time, and the requirements of customers pursuing fashion and individuality can be met. Meanwhile, through the characteristics that the chemical property of gold is very stable and gold is not prone to oxidation, gold is used for the kitchen cabinet door sheet, disengagement is not likely to happen, glossiness is high, artistic value and appreciation value are achieved, it can be guaranteed that the spraying effect of gold is consistent, the influence of time passage on the spraying effect is low, cost is low, and the service life of the door sheet is prolonged. A gilding method is simple, the needed product can be obtained after surface cleaning, transparent primer spraying, colored paint spraying, raw lacquer brushing, gilding, finish paint spraying and polishing, the finally-obtained door sheet is fewer in flaw, high in glossiness and abrasion resistance and washable, the gold foil is not prone to disengagement, the requirements of the customers are met, and the service life of the product is prolonged.

Owner:ZBOM HOME COLLECTION CO LTD

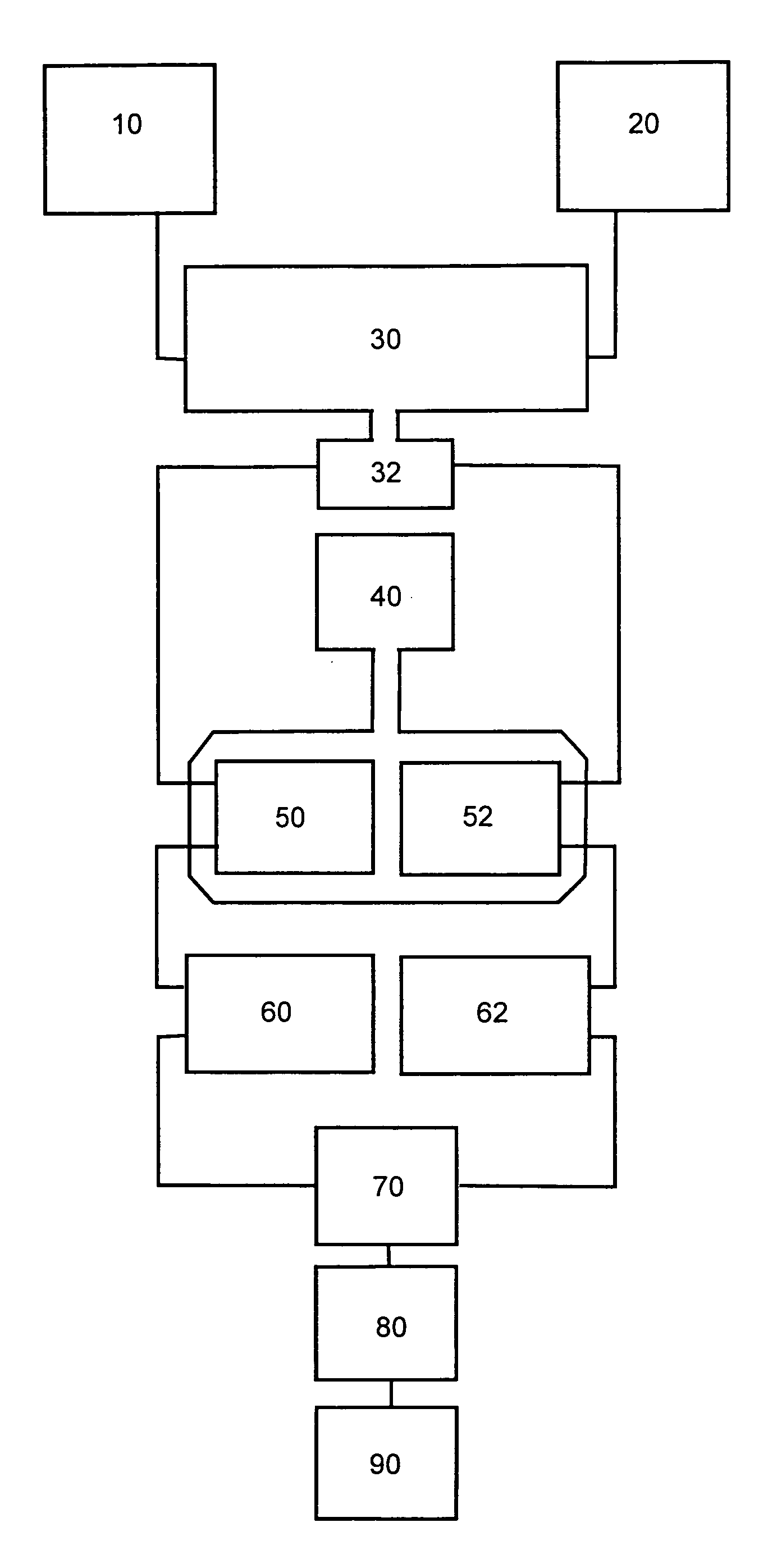

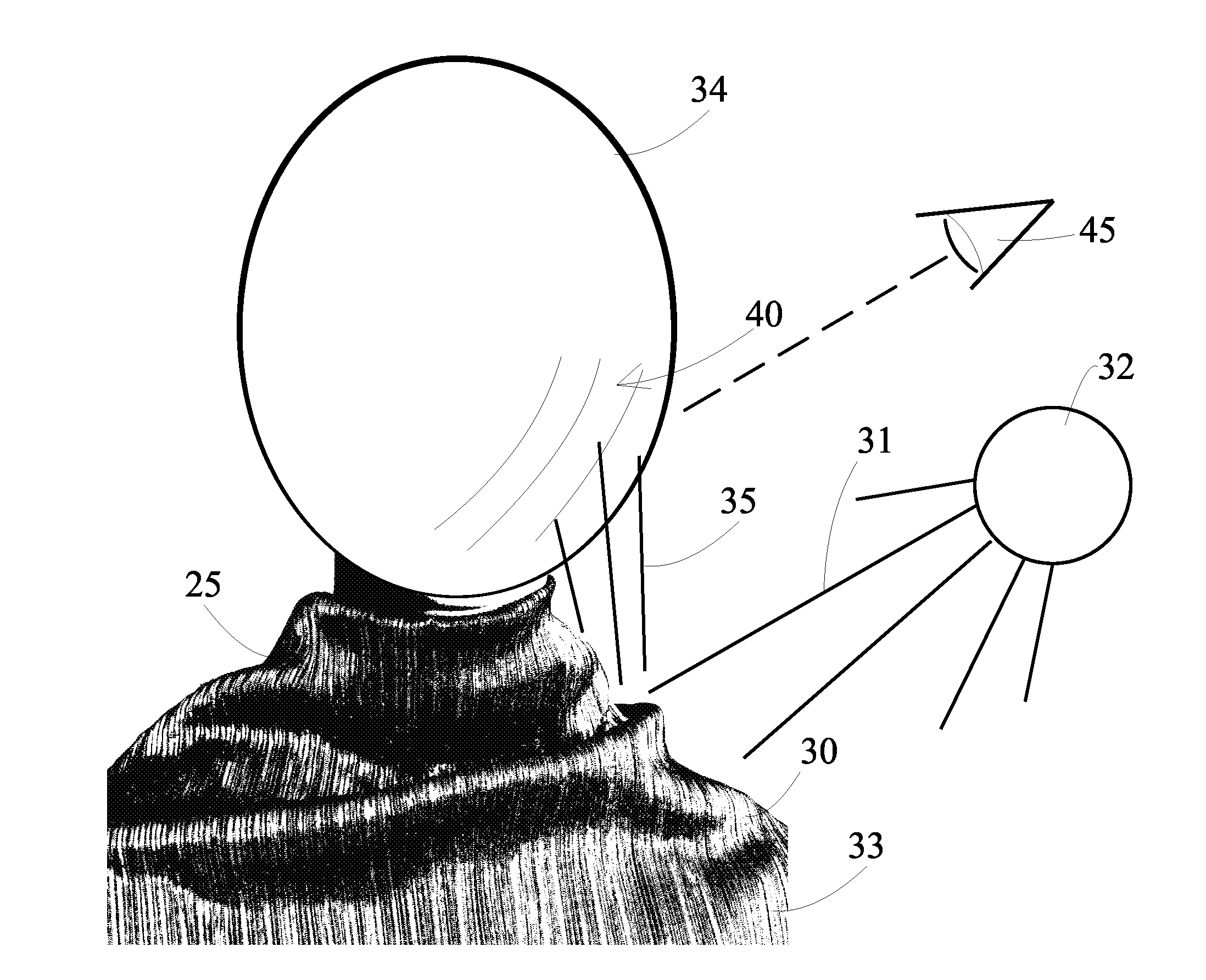

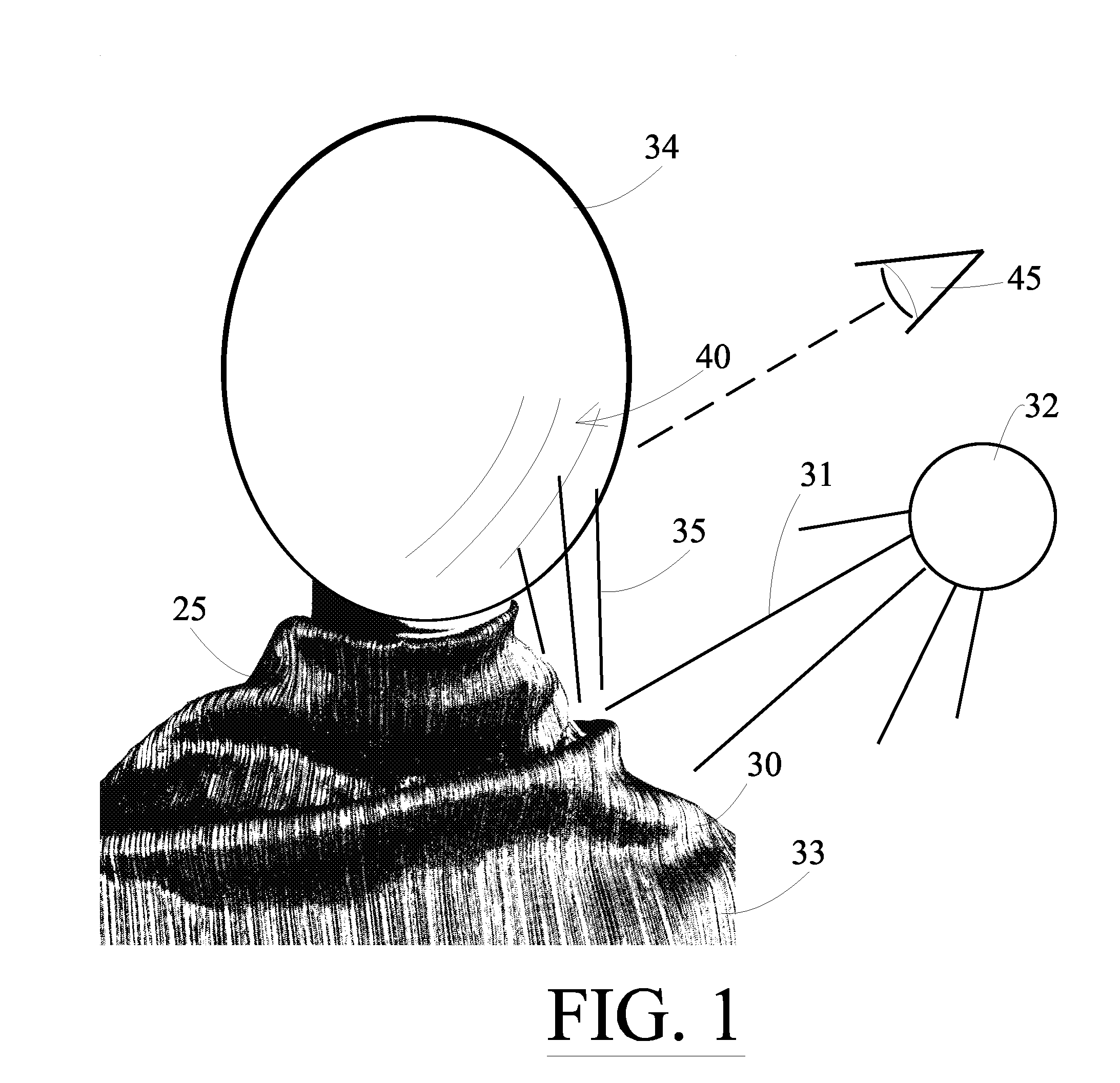

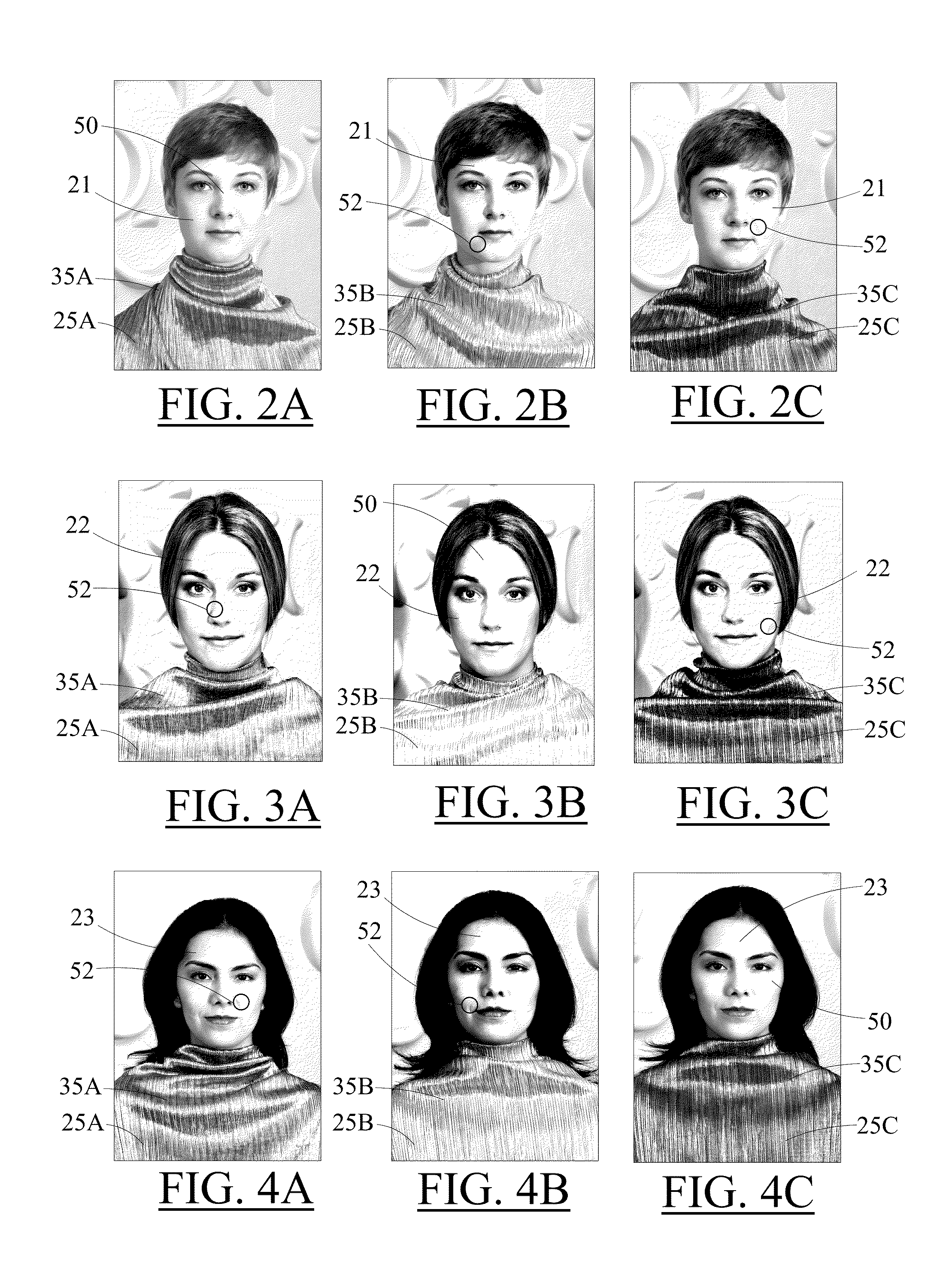

System and method of a personal enhancing color selection

A personal enhancing color selection system and method, in which a selected reflective material, preferably in the form of a fabric or woven drape, is placed near the face or skin surface of a subject person. The selected reflective material has a metallic sheen when reflecting an ambient light source. The selected reflective fabric material is either a silver-hued material, a copper-hued material, or a gold-hued material. The incident light from the ambient light source imparts a reflected light onto the skin surface, with the copper material imparting a copper toned reflected light, the silver-hued material imparting silver toned reflected light, and the gold material imparting a gold toned reflected light. A visual determination of an aesthetically appealing augmentation to the skin surface is made, to recommend haircoloring, clothing colors and makeup selections that will likewise produce a positively enhanced appearance of the subject person of the color analysis.

Owner:SPEARING THIA

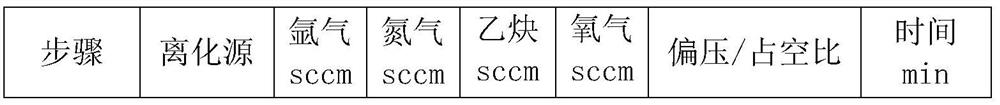

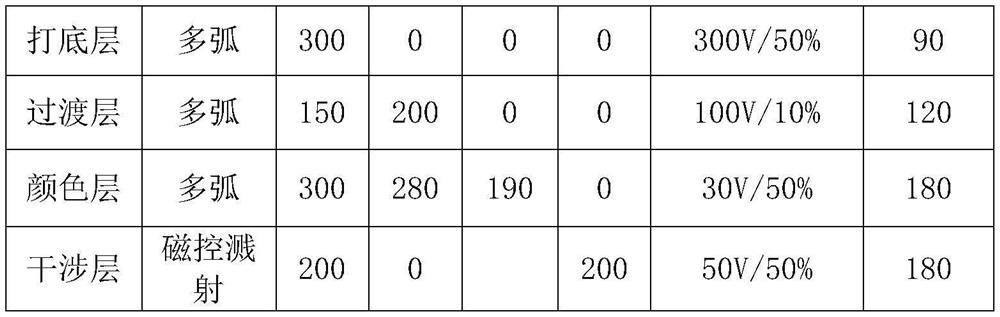

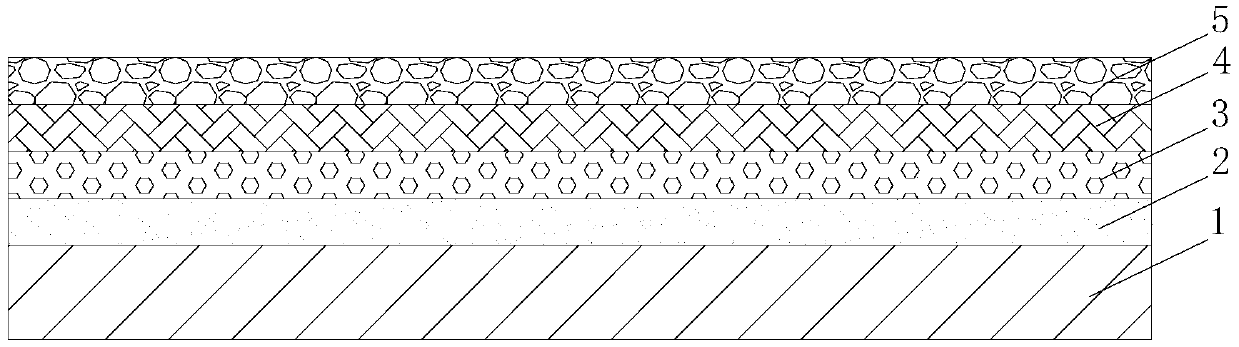

Red copper golden PVD decorative film and preparation method thereof

PendingCN113930721ASolve high rednessSolve high hardnessVacuum evaporation coatingSputtering coatingMetal coatingPhysical chemistry

The invention discloses a red copper golden PVD decorative film and a preparation method thereof. The preparation method comprises the following steps: preparing a base layer on the surface of a substrate; preparing at least one transition layer on the base layer; preparing a color layer on the transition layer; and preparing an interference layer on the color layer so as to generate light interference, respectively increasing the color a value and the color b value after light reflected by the color layer passes through the interference layer, and enabling the surface of the substrate to present the red copper golden color. The film is high in color a value, good in color uniformity and good in wear resistance, and solves the problems of high redness and high hardness which cannot be realized by a conventional PVD metal coating technology.

Owner:JOMOO KITCHEN & BATHROOM

Golden effect pigment and production technology thereof

ActiveCN102675931BStrong color densitySimple processInorganic pigment treatmentTin dioxidePhotopigment

Owner:四川万圣通精密机械制造有限公司

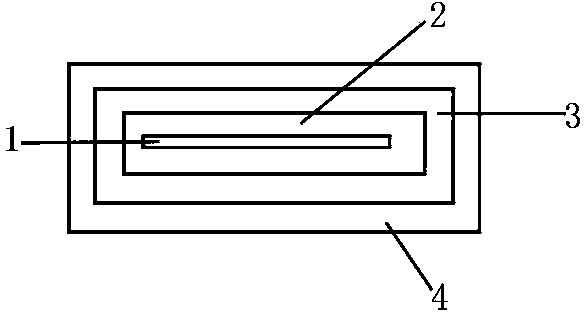

Gravure lipophilic golden ink and preparation method thereof

The invention provides gravure lipophilic golden ink and a preparation method thereof. The ink is prepared from the following components in parts by weight: 6-8 parts of yellow pigment, 8-13 parts of electroplated silver, 25-30 parts of lipophilic polyurethane resin liquid, 2-5 parts of ketone-aldehyde resin, 1-5 parts of auxiliary and 39-50 parts of mixed solvent. According to the gravure lipophilic golden ink and the preparation method thereof, each index can reach the specified standard, and compared with ink prepared from bronze powder, the gravure lipophilic golden ink has the advantages of excellent metal effect and storage stability.

Owner:肇庆信合油墨科技有限公司

Rose gold color system adjusting and testing coating technology by replacing gold target

InactiveCN111057995AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingTitaniumSputter deposition

The invention discloses a rose gold color system adjusting and testing coating technology by replacing a gold target, and relates to the technical field of vacuum coating. The technology is characterized in that a Cr priming layer is prepared on the surface of a substrate through a vacuum magnetron sputtering deposition technology, so that the binding force of a matrix and a film layer is enhanced; a TiCrN transition layer is generated on the surface of a first Cr priming layer, so that the continuity of the film layer is kept; on the basis of the second TiCrN transition layer, coating is carried out through the vacuum magnetron sputtering deposition technology to obtain a TiN transition layer, so that the uniformity of the color of the film layer is improved; and through the vacuum magnetron sputtering deposition technology, nitrogen, acetylene and a titanium target are combined on the surface of the third TiN transition layer so as to carry out coating to obtain a TiCN color layer, so that the surface of a product is rose gold. According to the technology, all the prepared layers of films can achieve different functions and the color transition function, the processing cost is reduced, the practicability is high, the cost performance is high, the appearance decoration performance of a workpiece is greatly improved through the color progression of the film layers, and the application prospect is wide.

Owner:SHANGHAI ZICHUANG COATING TECH

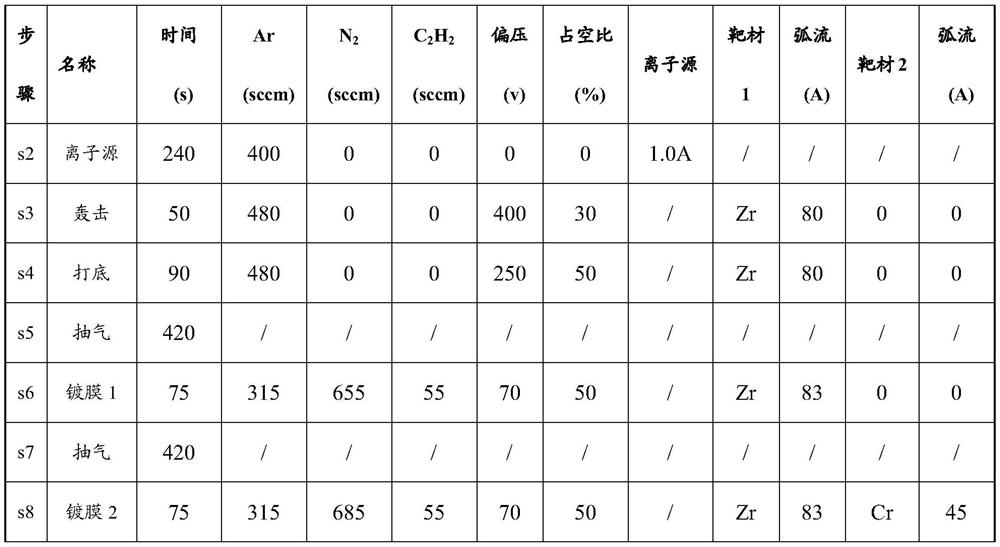

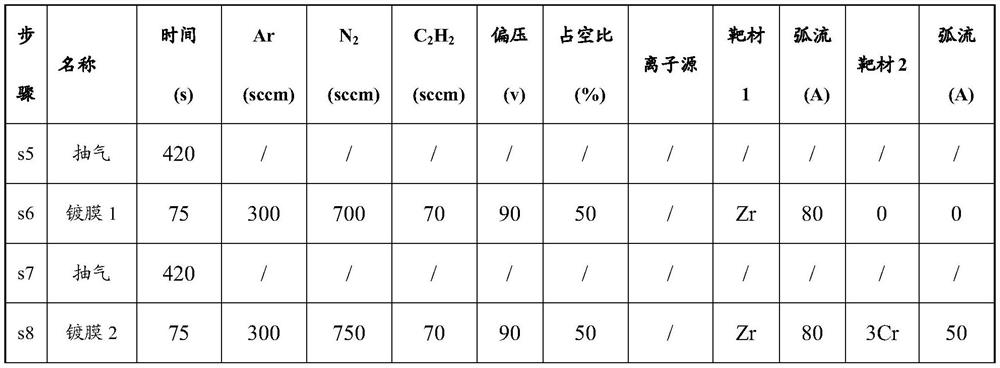

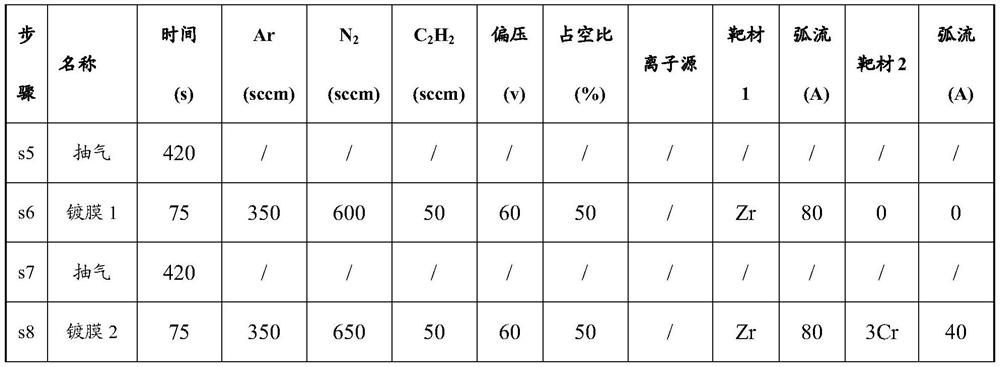

Preparation method of gold-imitating coating

ActiveCN113025967AUniform colorStable color valueVacuum evaporation coatingSputtering coatingFilm baseSurface cleaning

The invention provides a preparation method of a gold-imitating coating. The preparation method comprises the following steps that (1), surface cleaning treatment is conducted on a to-be-plated part; (2), plasma etching treatment is conducted on the to-be-plated part by adopting a gas ion source under the protection of inert gas; (3), under the protection of the inert gas, the treated to-be-plated part is subjected to bombardment treatment through high-energy particles of zirconium, and a zirconium ion semi-permeable layer is attached to the surface of the to-be-plated part; (4), a zirconium metal film base layer is deposited on the surface of the treated to-be-plated part by adopting a magnetic control multi-arc method and using a zirconium target material; (5), depositing is conducted on the surface of the treated to-be-plated part by adopting the magnetic control multi-arc method and using the zirconium target material to obtain a first film layer; and (6), depositing is continuously conducted on the surface of the first film layer of the to-be-plated part by adopting the magnetic control multi-arc method and using the zirconium target material and a chromium target material to obtain a second film layer, so that a zirconium carbonitride and chromium carbonitride mixed coating is obtained. By means of the method, the golden yellow product with the uniform color and the stable color value can be obtained, the repeatability of the method is good, and stable batch production can be achieved.

Owner:NANCHANG KOHLER

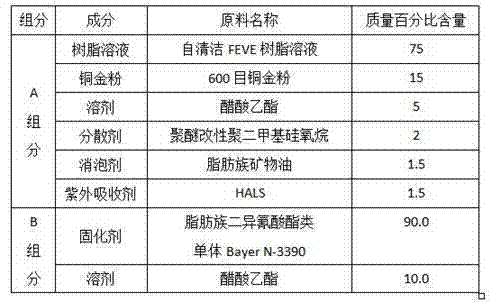

Weather-proof self-cleaning copper gold lacquer and preparation method thereof

InactiveCN102952435AImprove the decorative effectLong-term decorativePaints with free metalsLacquerMaterial resources

The invention discloses a weather-proof self-cleaning copper gold lacquer which comprises a component A and a component B, wherein the ratio of the component A to the component B in parts by weight is (10-12.5):1, the component A comprises 65-75wt% of resin solution, 15-25wt% of bronze powder, 5-10wt% of solvent, 2-5wt% of dispersing agent, 1-3wt% of defoaming agent and 1-3 wt% of ultraviolet absorbent; and the component B comprises the ingredients of 50-90 wt% of curing agent and 10-50wt% of solvent. The invention also discloses a preparation method of the weather-proof self-cleaning copper gold lacquer. During the use, the component A and the component B are mixed uniformly according to a proportion and are cured so that coating construction can be carried out. The weather-proof self-cleaning copper gold lacquer related in the invention can be used in protection and appearance decoration of outdoor buildings, sculptures and the like, has a long-term gold color and a metal texture, does not need to be frequently cleaned in a coating service process so that manpower and material resources are saved, and provides the convenience for corrosion-prevention and decoration industries.

Owner:CHINA NAT ELECTRIC APP RES INST

Process for UV printing of golden or silver patterns and application thereof

ActiveCN113022186AEffective adhesionGood glazing effectDuplicating/marking methodsInksMoisture resistanceSilver color

The invention provides a process for UV printing of golden or silver patterns and application thereof. The process specifically comprises the following steps of S1, printing a bottom layer; S2, powdering treatment; S3, powder removal treatment; and S4, carrying out gloss oil sealing treatment. According to the process for UV printing of the golden or silver patterns, viscous ink and non-viscous light ink are adopted to be alternately and mutually matched for use, gold and silver pearl powder can be effectively adhered, the glossiness is high, the color persistence is long, the light resistance and the heat-proof and moisture-proof performance are excellent, and the texture grade of a product can be improved.

Owner:广州市宝墨光固化科技有限公司

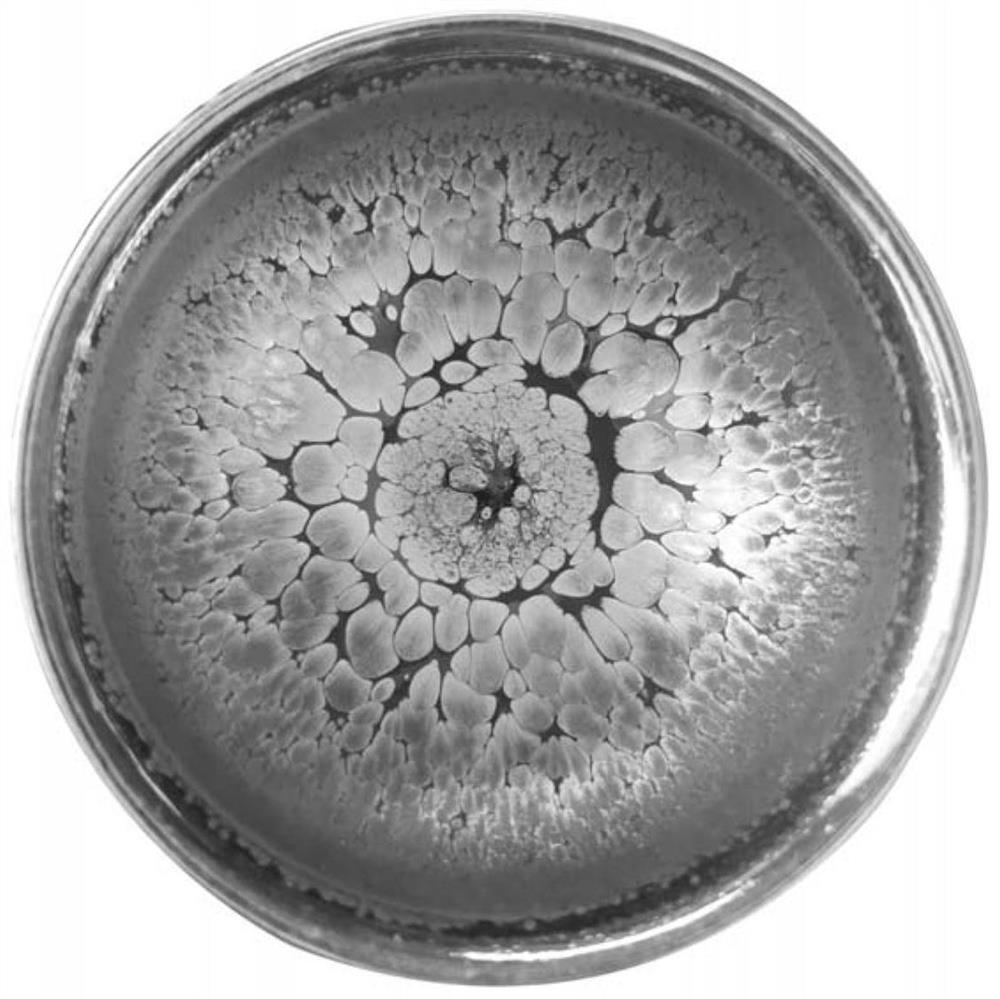

Preparation process of mosaic gold hare's fur cup

A preparation process of a mosaic gold hare's fur cup is disclosed. The preparation process comprises the following steps: preparing a green body raw material and glaze slip; carrying out throwing molding, fettling, biscuiting and cooling on the green body raw material to obtain a green body; glazing; putting the glazed and air-dried green body into an electric kiln for roasting. The ground colorof a glaze surface of the mosaic gold hare's fur cup prepared by the process is jade green, and the glaze bottom is moist and smooth and is like mild and clear beautiful jade; meanwhile, glaze crystallization is thorough, crystals are high in three-dimensional sense, oil drops are clear in gradation, upper oil drops are fine and dense, lower oil drops are large and full, the oil drops are coloredgolden, specifically, the oil drops are golden yellow, yellowish violet, bluish violet and purplish red from outside to inside, the colors are gradually transited to be rich and dazzling, and the artistic aesthetic feeling is very high.

Owner:张有兴

A kind of electroforming liquid used in K gold electroforming process

InactiveCN109778245BImprove performanceReduce weightElectroforming processesPotassium cyanideDipotassium phosphate

The invention relates to electroforming liquid for a K gold electroforming process. The electroforming liquid comprises the following main components with one liter of solution as unit: 4-10 g / l of potassium aurous cyanide, 50-100 g / l of cuprous cyanide, 18-35 g / l of free potassium cyanide, 1-50 g of triethanolamine and 1-30 g / l of iminodiacetic acid as auxiliary complexing agents, 0.2-4 g / l of zinc sulfate as hardening agents, 10-30 g / l of dipotassium phosphate as buffering agents; the electroforming liquid for the K gold electroforming process is prepared through the components, and K gold products are electroformed; K gold is prepared through a gold and copper binary alloy electroforming process; the K gold electroforming liquid with stable performances is used for preparing hollow K gold products with low weights, high hardness, bright rose gold colors and bright and smooth surfaces; and the products have the advantages of low gold consumption, durability, three-dimensional and full shapes and low cost.

Owner:深圳市昊扬电铸技术开发有限公司

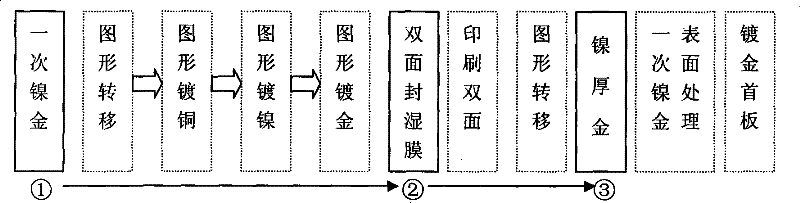

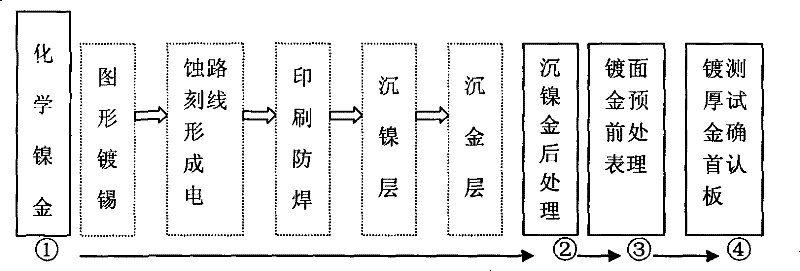

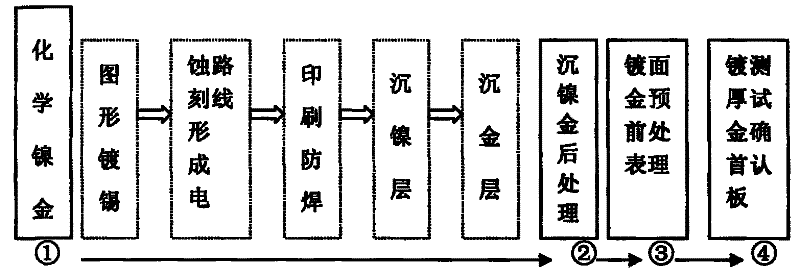

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427BNo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

Iridescent Jianzhan firing process

The invention discloses an iridescent Jianzhan firing process which comprises the following steps: preparing a green body and glaze slip; glazing by adopting internal oscillation and external immersion methods, not glazing the outer bottom of the green body, and airing after glazing; and putting the glazed and air-dried green body into an electric kiln for roasting, naturally cooling, and taking out of the kiln. The technological processes such as the formula, the temperature curve and the kiln atmosphere of the Jianzhan blank glaze are clear and easy to control, the stability is good, and the rate of finished products is high. According to the fired iridescent Jianzhan, the glaze surface is covered with the colorful oil drop stripes with rose gold as the main color, the oil drop stripes are full and dense, the gold thread boundary is clear, iridescent light is changed in the sun, and extremely high artistic value and appreciation value are achieved.

Owner:福建南平市建窑陶瓷研究所

Thermal transfer-printing method for gold stamping

The invention discloses a thermal transfer-printing method for gold stamping. The thermal transfer-printing method comprises the following steps: preparing a pattern and a substrate to be printed, printing an ink absorbing coating, printing an adhesive layer, spreading powder, removing powder, heating and curing, and transfer-stamping. A release film used by the method disclosed by the invention is equipped with a metal electroplated coating which can have metal luster such as gold color or silver color; while the pattern subjected to thermal transfer-printing needs metal luster effect, the ink absorbing coating and the adhesive layer are printed on the gold-stamping release film, so that the adhesive layer and the metal electroplated coating are adhered together; during transfer-stamping,a contact area between the metal electroplated coating and the adhesive layer is transfer-stamped onto a target material, and a non-contact area of the metal electroplated coating and the adhesive layer is still kept on a release film, so that the pattern to be subjected to gold stamping is stamped on the target materials such as cloth through a thermal transfer-printing way, and thus, the thermal transfer-printing method is simple to operate, is good in effect and is low in cost.

Owner:TAOTECH DIGITAL TECH

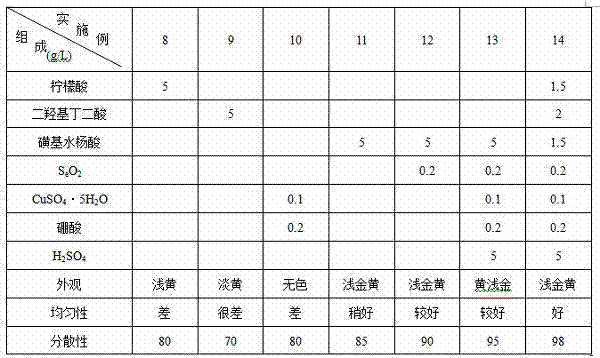

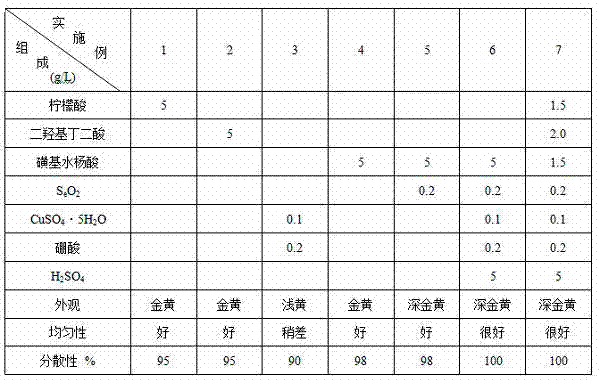

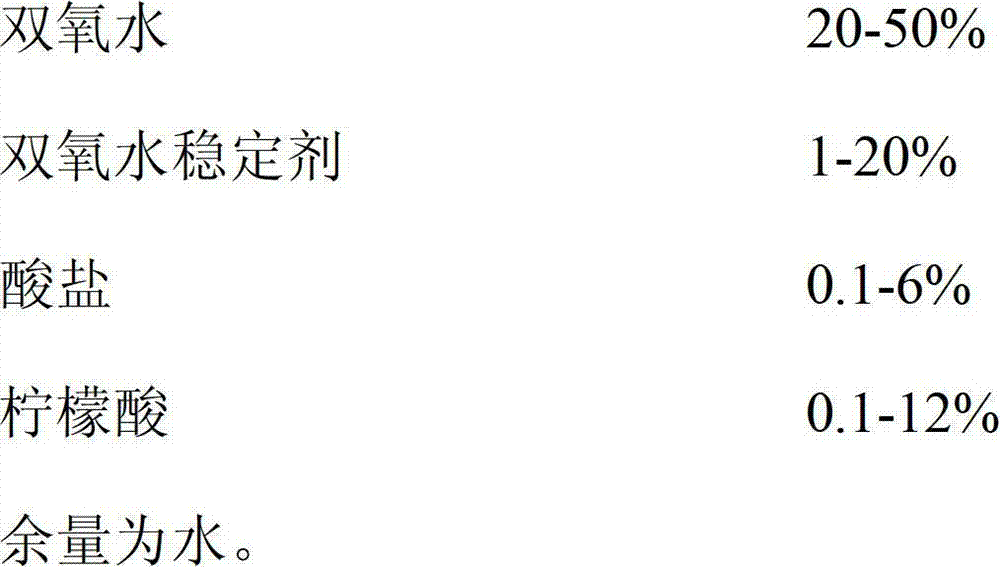

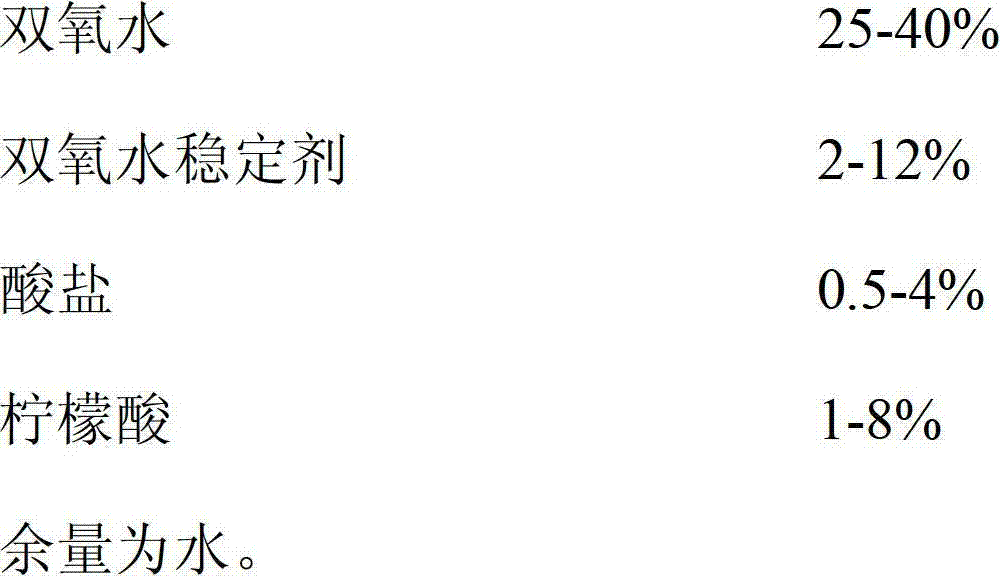

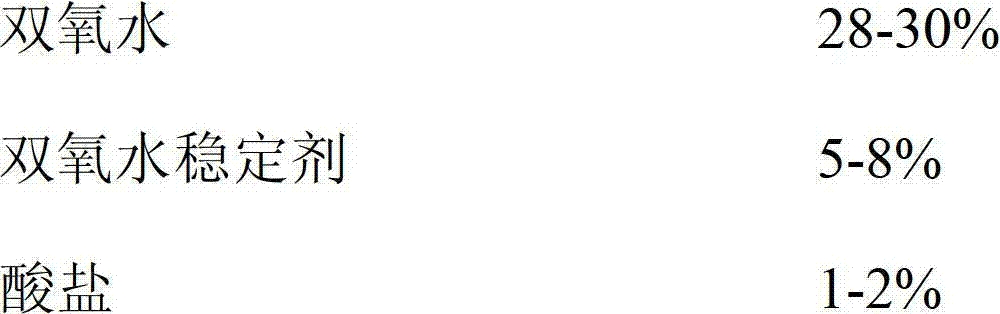

Brass gold color dyeing solution and preparation method thereof as well as method for dyeing gold color on brass

The invention relates to a brass gold color dyeing solution comprising the following components in weight percentage of 20-50% of hydrogen peroxide, 1-20% of hydrogen peroxide stabilizing agent, 0.1-6% of acidic salt, 0.1-12% of citric acid and the balance being water. The preparation method of the brass gold color dyeing solution comprises the following steps of: adding water which is 20-80% of a formula amount; then sequentially adding the citric acid, the acidic salt, the hydrogen peroxide stabilizing agent and the hydrogen peroxide by agitating; and finally adding water which is the balance of the formula amount and agitating for at least 5 minutes, and packaging to obtain a product. The invention further relates to a method for dyeing a gold color on a brass by using the brass gold color dyeing solution, which sequentially comprises the following steps of: pre-treating and dying the gold color by utilizing the brass gold color dyeing solution; and drying and closing. The method disclosed by the invention can be used for machining hardware accessories. The method for dyeing the gold color is toxin-free and pollution-free, reduces the loss of resources and the pollution to an environment, and can achieve the effects of 18K and 24K gold colors.

Owner:DONGGUAN DONGHUI TRADE

Amber-colored polyester film with particular suitability for metallization and steel-lamination

ActiveUS7670687B2Good lookingPromote resultsLiquid surface applicatorsCovering/liningsPolyesterAnthraquinones

The present invention relates to a biaxially oriented polyester film, whicha) has a base layer B, which includes a yellow dye and a red dye,b) has, on each side of the base layer B, at least one layer (A or C) which includes, based on the weight of layer A or C, less than 0.01% by weight of the yellow dye and less than 0.01% by weight of the red dye, andc) the film has one absorption maximum lying at from 400 to 500 nm in the UV / visible spectrum from 400 to 800 nm.Preferred dyes are anthraquinone dyes and perinone dyes; the polyester is preferably PET. After metallization or lamination, the film has a gold appearance, and is a suitable packaging material.

Owner:MITSUBISHI POLYESTER FILM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com