Golden effect pigment and production technology thereof

An effect pigment and production process technology, applied in the field of inorganic pigments, can solve the problems of complex production process, difficult to stabilize control, poor color concentration of golden effect pigments, etc., and achieve the effect of simple process, easy control, and large market economic value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

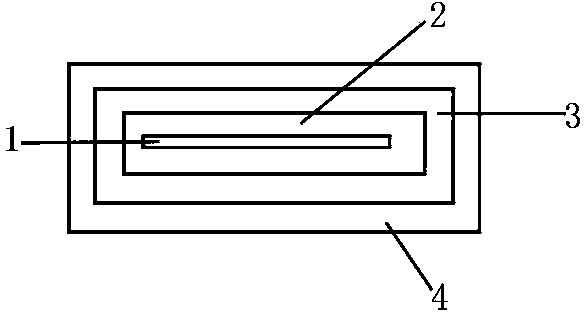

Image

Examples

Embodiment 1

[0031] Put the synthetic mica flakes into deionized water to make a suspension with a solid-to-liquid mass ratio of 1: (5-50), and then carry out the following three layers of metal oxide coating in sequence: the first layer, use inorganic acid Adjust the pH value of the above suspension to 1.6-2.5, and add TiCl with a concentration of 10%-30% 4 solution with a concentration of 50% SnCl 4 The solution was mixed well, and slowly added to the above suspension, TiCl 4 solution with SnCl 4 The volume ratio of the solution is (30-150):1. At the same time, the pH value of the process is adjusted with an inorganic base to keep it stable. The reaction temperature is controlled at 70-85°C. The total coating optical thickness is controlled at 150-170nm; the second layer, FeCl is added to the above reaction system 3 with AlCl 3 A mixed solution in which FeCl 3 Solution concentration is 50-120g / L, AlCl 3 Solution concentration is 100-300g / L, FeCl 3 with AlCl 3 The volume ratio o...

Embodiment 2

[0034] Take 50g of synthetic mica powder with a thickness of 10 microns and put it into deionized water to make a solid-liquid

[0035] The suspension ratio is 1:6, and then the first layer of metal oxide coating is started. The pH value of the above suspension is adjusted to 2.2 with hydrochloric acid, and the concentration of 20% TiCl 4 solution with a concentration of 50% SnCl 4 The solution is mixed well and evenly, the volume ratio is 50:1, and slowly added to the above suspension. At the same time, adjust the pH value of the process with NaOH solution to keep it stable at 2.2. The reaction temperature was controlled at 70°C. The optical thickness is controlled at 180nm.

[0036] For the second layer, add a mixed solution of 50g / L FeCl3 solution and 300g / LAlCl3 to the above reaction system, the volume ratio is 80:1, the pH value of the reaction system is controlled at 3.3, and the reaction temperature is controlled at 90°C. The optical thickness is controlled at 250nm...

example 3

[0040] Take 60g of synthetic mica powder with a thickness of 10 microns and a particle size of 555 microns to make a solid-liquid mass ratio of 1:

[0041] 50 suspension.

[0042] In the first layer, the pH value of the above suspension was adjusted to 2.0 with hydrochloric acid, and the concentration of 16% TiCl 4 solution with a concentration of 50% SnCl 4The solution is thoroughly mixed and the volume ratio is 100:1, slowly added to the above suspension. At the same time, adjust the pH value of the process with NaOH solution to keep it stable at 2.0. The reaction temperature was controlled at 75°C. The optical thickness is controlled at 150nm.

[0043] For the second layer, add a mixed solution of 50g / L FeCl3 solution and 300g / LAlCl3 to the above reaction system, the volume ratio is 100:1, the pH value of the reaction system is controlled at 3.3, and the reaction temperature is controlled at 90°C. The optical thickness is controlled at 230nm.

[0044] In the third lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com