Pearlescent pigment having 999-pure gold effect and preparation method thereof

A technology of pearlescent pigments and pure gold, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of unsatisfactory jewelry manufacturers, insufficient brightness, high production cost, etc., and achieve bright luster and golden purity High, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

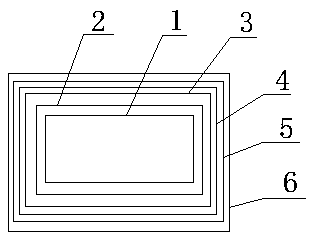

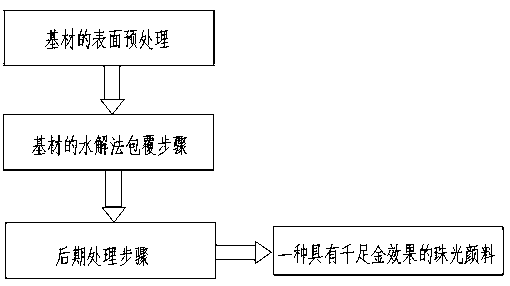

[0020] The invention discloses a pearlescent pigment with a pure gold effect, which comprises a base material, the base material is natural mica, synthetic mica or glass flakes, and the base material is coated with a first composite layer, a second composite layer, The third composite layer, the fourth composite layer and the fifth composite layer, the first composite layer is composed of tin protochloride, magnesium chloride and zinc chloride, and the second composite layer is titanium tetrachloride and nickel chloride mixed with tin tetrachloride, the third composite layer is made of titanium tetrachloride and ferric chloride, the fourth composite layer is made of silicon dioxide or alumina, and the fifth composite layer is made of four Titanium chloride and ferric chloride are mixed, the thickness of the substrate is 50nm-3000nm, the particle size is 2-1000μm, a method for preparing a pearlescent pigment with a pure gold effect, the preparation method includes the surface of...

Embodiment 2

[0022] The invention discloses a pearlescent pigment with a pure gold effect, which comprises a base material, the base material is natural mica, synthetic mica or glass flakes, and the base material is coated with a first composite layer, a second composite layer, The third composite layer, the fourth composite layer and the fifth composite layer, the first composite layer is composed of tin protochloride, magnesium chloride and zinc chloride, and the second composite layer is titanium tetrachloride and nickel chloride mixed with tin tetrachloride, the third composite layer is made of titanium tetrachloride and ferric chloride, the fourth composite layer is made of silicon dioxide or alumina, and the fifth composite layer is made of four Titanium chloride and ferric chloride are mixed, the thickness of the substrate is 60nm-2000nm, the particle size is 5-900μm, a method for preparing a pearlescent pigment with a pure gold effect, the preparation method includes the surface of ...

Embodiment 3

[0024] The invention discloses a pearlescent pigment with a pure gold effect, which comprises a base material, the base material is natural mica, synthetic mica or glass flakes, and the base material is coated with a first composite layer, a second composite layer, The third composite layer, the fourth composite layer and the fifth composite layer, the first composite layer is composed of tin protochloride, magnesium chloride and zinc chloride, and the second composite layer is titanium tetrachloride and nickel chloride mixed with tin tetrachloride, the third composite layer is made of titanium tetrachloride and ferric chloride, the fourth composite layer is made of silicon dioxide or alumina, and the fifth composite layer is made of four Titanium chloride and ferric chloride are mixed, the thickness of the substrate is 60nm-2000nm, the particle size is 5-900μm, a method for preparing a pearlescent pigment with a pure gold effect, the preparation method includes the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com