Method for putting gold color on aluminum material

An aluminum and gold technology, used in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of peeling oxide film, long energization time, slow coloring speed, etc., to improve coloring speed and uniformity. , the effect of fast coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

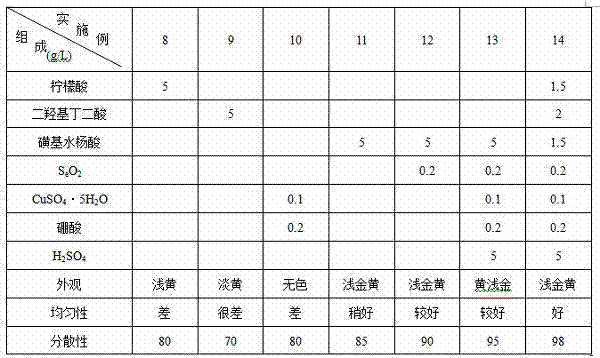

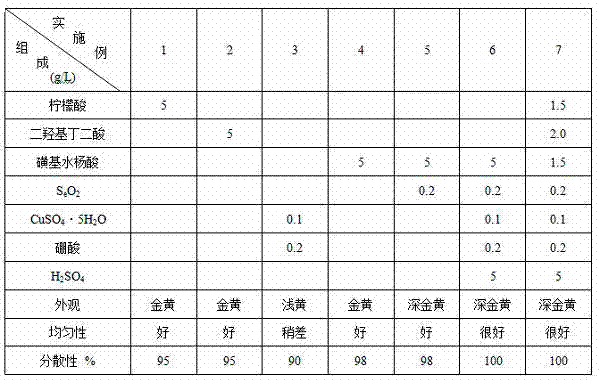

Embodiment 1~7

[0058] Film making: Set the area to 15cm 2 The 6063 aluminum alloy profile is first treated with a 5% acidic three-in-one treatment liquid degreasing film, washed with water, and then immersed in an electrolyte solution with a concentration of 160g / L sulfuric acid and kept at 22°C, with a current density of 1.2A / dm 2 DC anodizing for 30 minutes;

[0059] Modification treatment : Immerse the aluminum material washed with water after anodic oxidation treatment under the above conditions in the composition listed in Table 1, and keep it in the modifying solution at 20°C for 2 minutes;

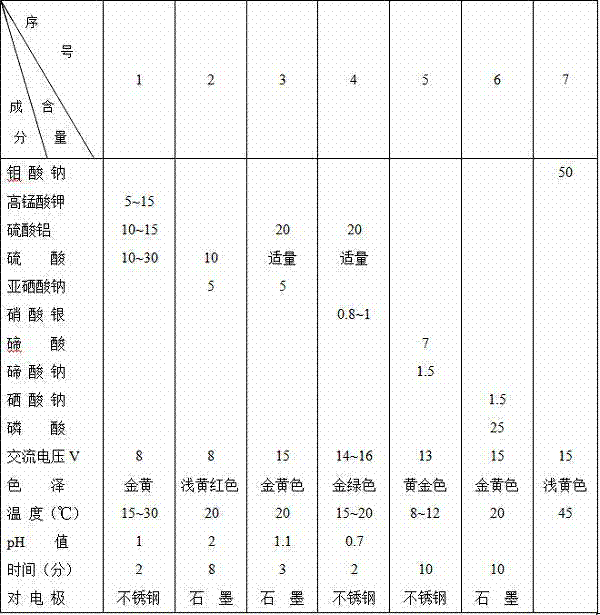

[0060] Coloring : Wash the modified aluminum material with water and immerse it in the 20°C treatment solution of potassium permanganate 3g / L and sulfuric acid 10g / L for 2 minutes. The electrolysis process parameters are AC voltage 15V and temperature 20°C;

[0061] All the above steps need to be washed with water. The final product is washed with water and dried in air.

[0062] Visually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com