Weather-proof self-cleaning copper gold lacquer and preparation method thereof

A self-cleaning, copper-gold technology, applied in the field of coatings, can solve the problems of easy staining, poor weather resistance, etc., and achieve the effects of improving service life, uniform color, and avoiding cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

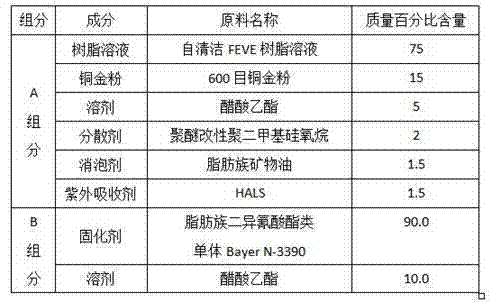

Embodiment 1

[0021]

[0022] Preparation:

[0023] (1) Mix and soak the copper and gold powder of component A with solvent for 30 minutes;

[0024] (2) Add the soaked copper and gold powder, solvent mixture and dispersant to 50% polyurethane resin solution, stir and disperse at high speed for 10 minutes;

[0025] (3) Slowly add defoamer, UV absorber and the remaining polyurethane resin solution while stirring, and continue stirring at high speed for 20 minutes after adding all of them to obtain a semi-finished product;

[0026] (4) Dilute the curing agent with the solvent in component B within half an hour before use, and fully mix and mature the semi-finished product at a ratio of 10:1 to make a finished product. The finished product must be used within 2 hours.

Embodiment 2

[0028]

[0029] Preparation:

[0030] (1) Mix and soak the copper and gold powder of component A with solvent for 40 minutes;

[0031] (2) Add soaked copper-gold powder, solvent mixture and dispersant to 60% polyurethane resin solution, stir and disperse at high speed for 15 minutes;

[0032] (3) Slowly add defoamer, UV absorber and the remaining polyurethane resin solution while stirring, and continue stirring at high speed for 20 minutes after adding all of them to obtain a semi-finished product;

[0033] (4) Dilute the curing agent with the solvent in component B within half an hour before use, and fully mix and mature the semi-finished product at a ratio of 11.5:1 to make a finished product. The finished product must be used within 2 hours.

Embodiment 3

[0035]

[0036] Preparation:

[0037] (1) Mix and soak the copper and gold powder of component A with solvent for 50 minutes;

[0038] (2) Add soaked copper-gold powder, solvent mixture and dispersant to 60% polyurethane resin solution, stir and disperse at high speed for 15 minutes;

[0039] (3) Slowly add defoamer, UV absorber and the remaining polyurethane resin solution while stirring, and continue stirring at high speed for 30 minutes after adding all of them to obtain a semi-finished product;

[0040] (4) Dilute the curing agent with the solvent in component B within half an hour before use, and fully mix and mature the semi-finished product at a ratio of 12:1 to make a finished product. The finished product must be used within 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com