A kind of electroforming liquid used in K gold electroforming process

An electroforming liquid and electroforming technology, applied in electroforming, electrolysis process, etc., can solve the problems of high processing cost, increased gold consumption, high product price, etc., and achieve three-dimensional and full shape, less gold consumption, and durable products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

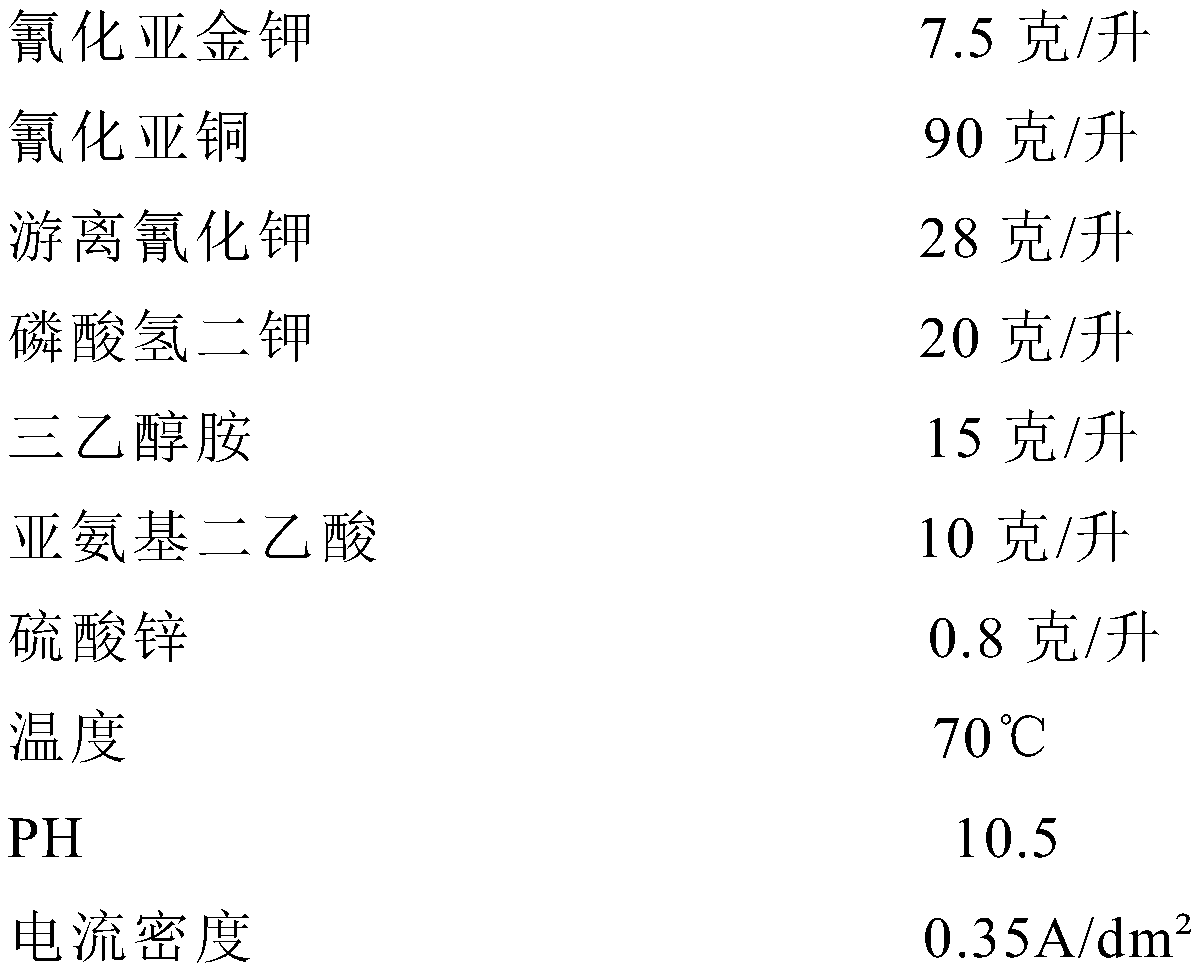

[0038] The formula of gold-copper binary K gold electroforming solution is as follows:

[0039]

[0040] According to the above formula as electroforming solution, the current density is 0.35A / dm 2 , The electroforming time is 16 hours, and the mirror K gold electroforming layer can be obtained with a thickness of 160 microns and a micro-Vickers hardness of 300HV. The mass fractions of the binary alloy are: gold 76%, copper 24%, and the color is bright rose gold.

Embodiment 2

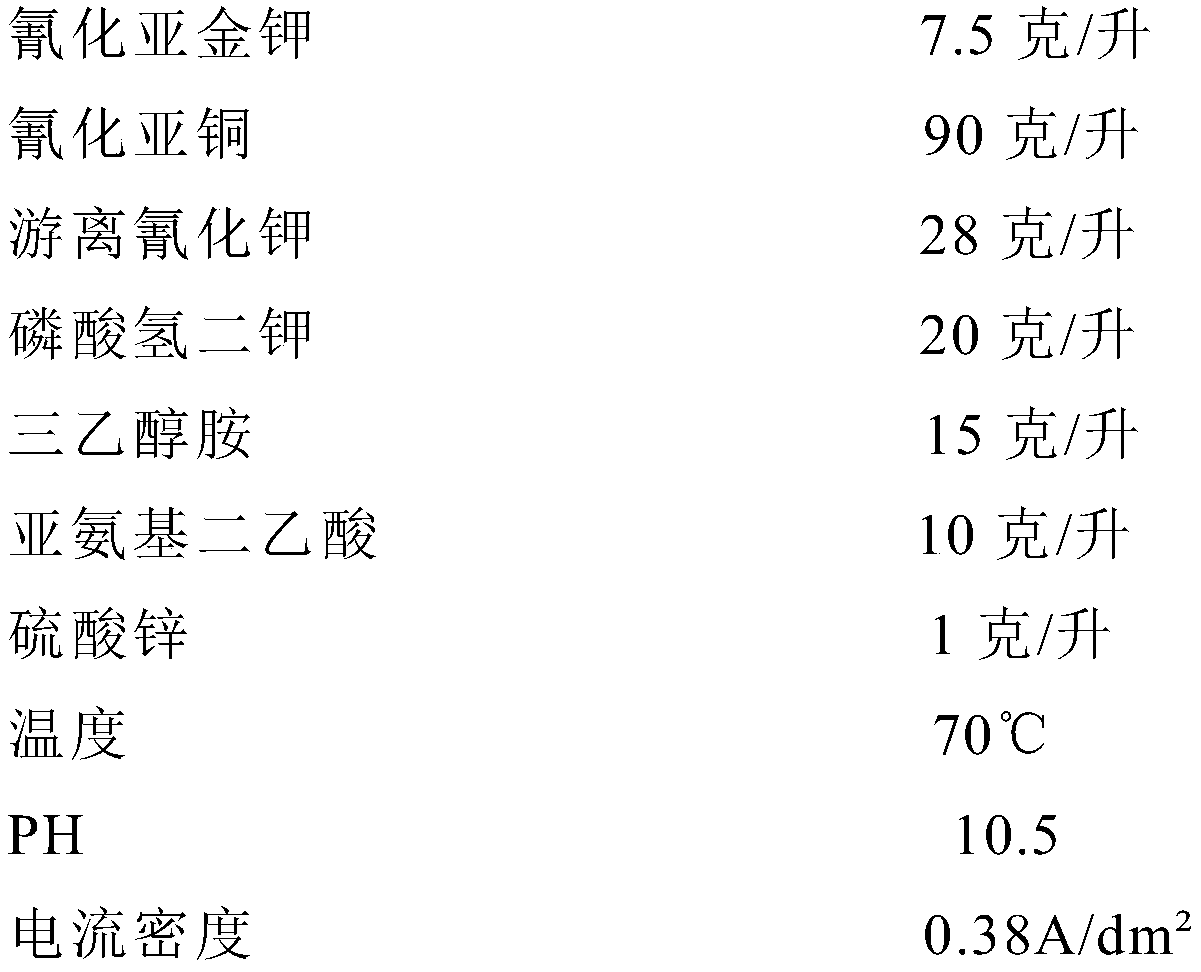

[0042] The formula of gold-copper binary K gold electroforming solution is as follows:

[0043]

[0044] According to the above formula as electroforming solution, the current density is 0.38A / dm 2 , The electroforming time is 16 hours, and the mirror K gold electroforming layer is obtained, the thickness is 160 microns, the micro-Vickers hardness is 360HV, the mass fractions of the ternary alloy are: gold 75.6%, copper 24.4%, and the color is bright rose gold.

Embodiment 3

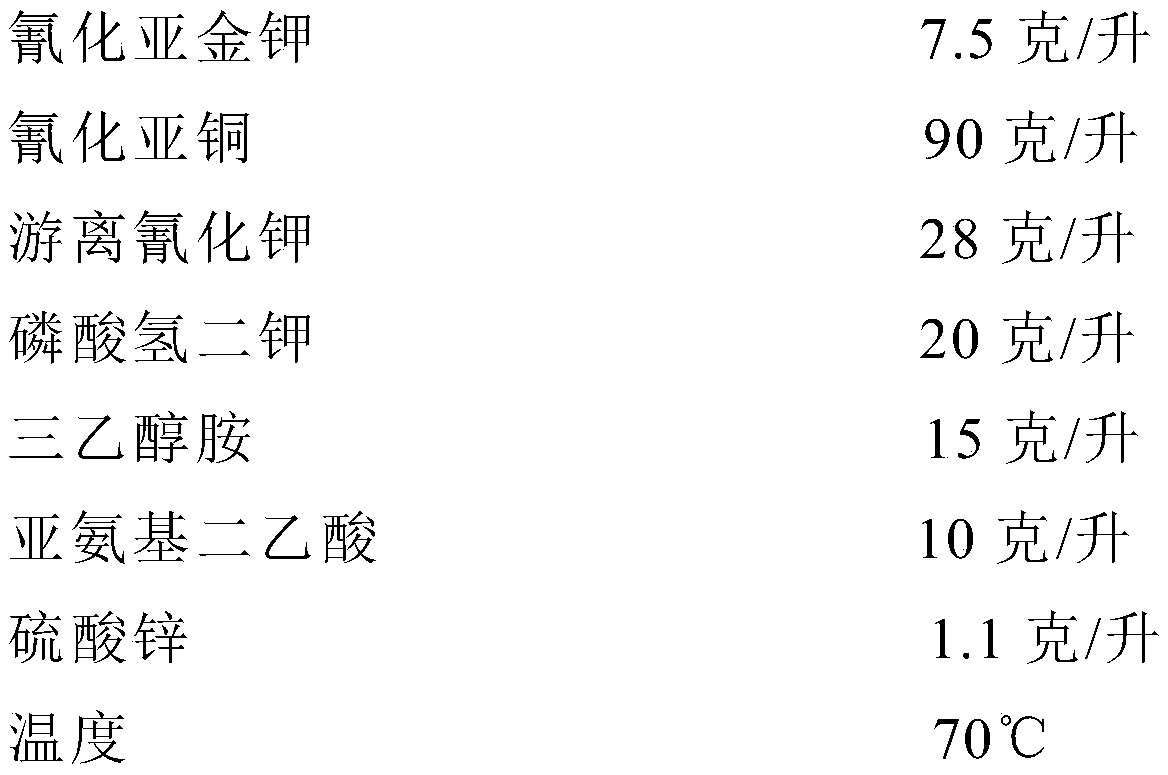

[0046] The formula of gold-copper binary K gold electroforming solution is as follows:

[0047]

[0048]

[0049] According to the above formula as electroforming solution, the current density is 0.46A / dm 2 , The electroforming time is 13.5 hours, and the mirror K gold electroforming layer can be obtained with a thickness of 165 microns and a micro-Vickers hardness of 369HV. The mass fractions of the binary alloy are: gold 59.5%, copper 40.5%, and the color is bright rose gold.

[0050] (4) Embodiment 4

[0051] The formula of gold-copper binary K gold electroforming solution is as follows:

[0052]

[0053] According to the above formula as electroforming solution, the current density is 0.49A / dm 2 , The electroforming time is 13.5 hours, and the mirror K gold electroforming layer can be obtained with a thickness of 165 microns and a micro-Vickers hardness of 368HV. The mass fractions of the binary alloy are: gold 58.8%, copper 41.2%, and the color is bright rose g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com