Patents

Literature

32results about How to "Meet the needs of the masses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

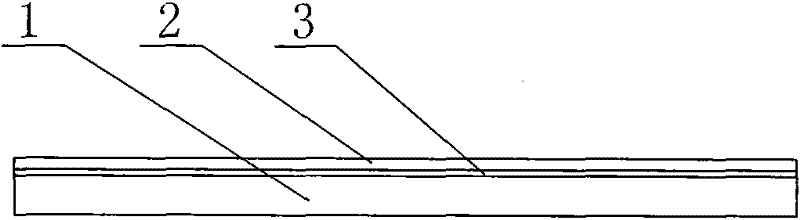

Double-sided metal clad plate and manufacturing method thereof

InactiveCN101513785ALuxurious decorative effectHigh-grade decorative effectLamination ancillary operationsSpecial ornamental structuresNonferrous metalFlexural strength

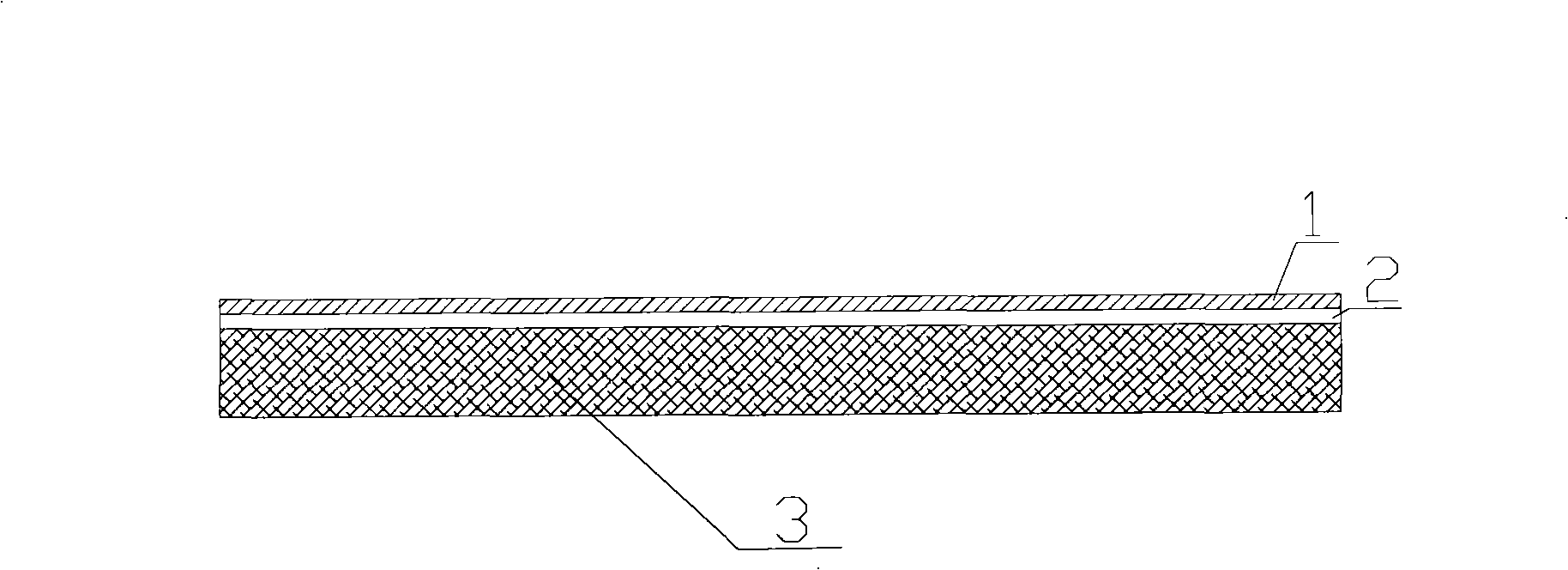

The invention discloses a double-sided metal clad plate and a manufacturing method thereof. The double-sided metal clad plate is jointly formed by a panel, a substrate and high polymer material in an intermediate layer. The panel chooses a nonferrous metal foil with the thickness of 0.05-1.5mm or a plate as a plane material, the material of which can be red copper, brass, titanium or stainless steel. The substate chooses a common metal plate with the thickness of 0.1mm-3mm as a base material, the material of which can be galvanized steel or antirust aluminum. The high polymer material can be used as an alite paste. A thin nonferrous metal and a thick common metal plate, the middle of which is lined with the higher polymer material, are made into the double-sided metal clad plate by the lamination technique. The metal clad plate has enough shearing strength and bending strength and is a new material which can be further processed by the cold-bending molding technique. The invention has simple manufacturing process and novel structure, is in line with the processing requirement and uses different materials for synthesizing advanced composite material to replace former precious nonferrous metals, thus greatly reducing the cost.

Owner:上海鑫型金属复合材料有限公司

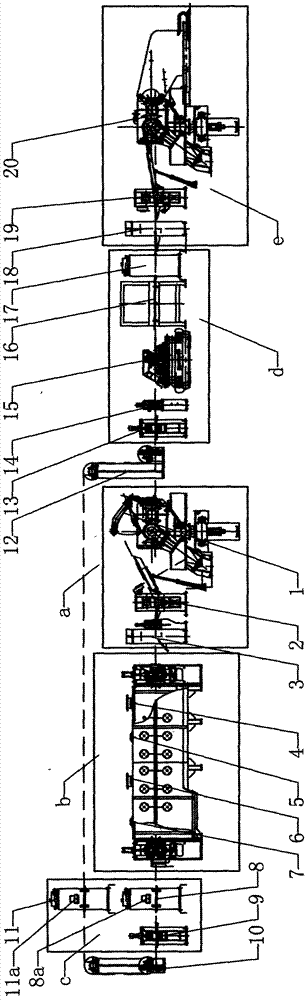

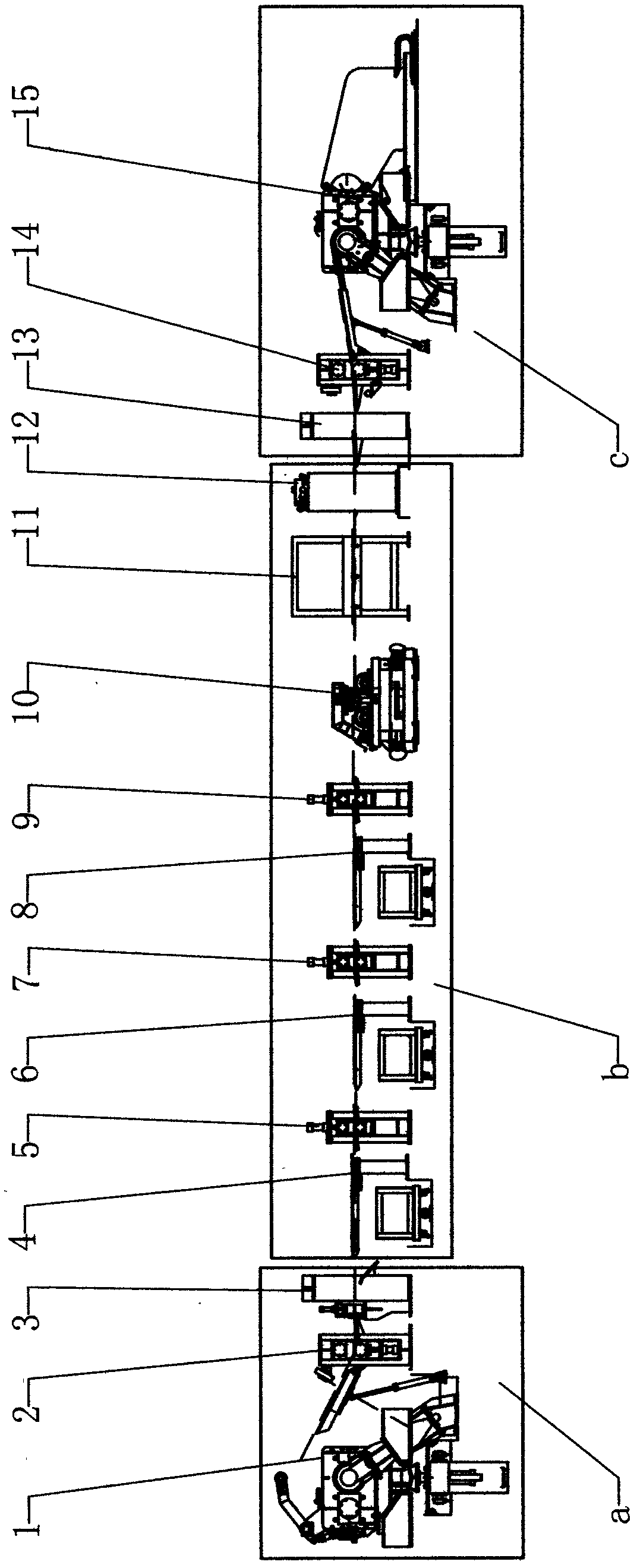

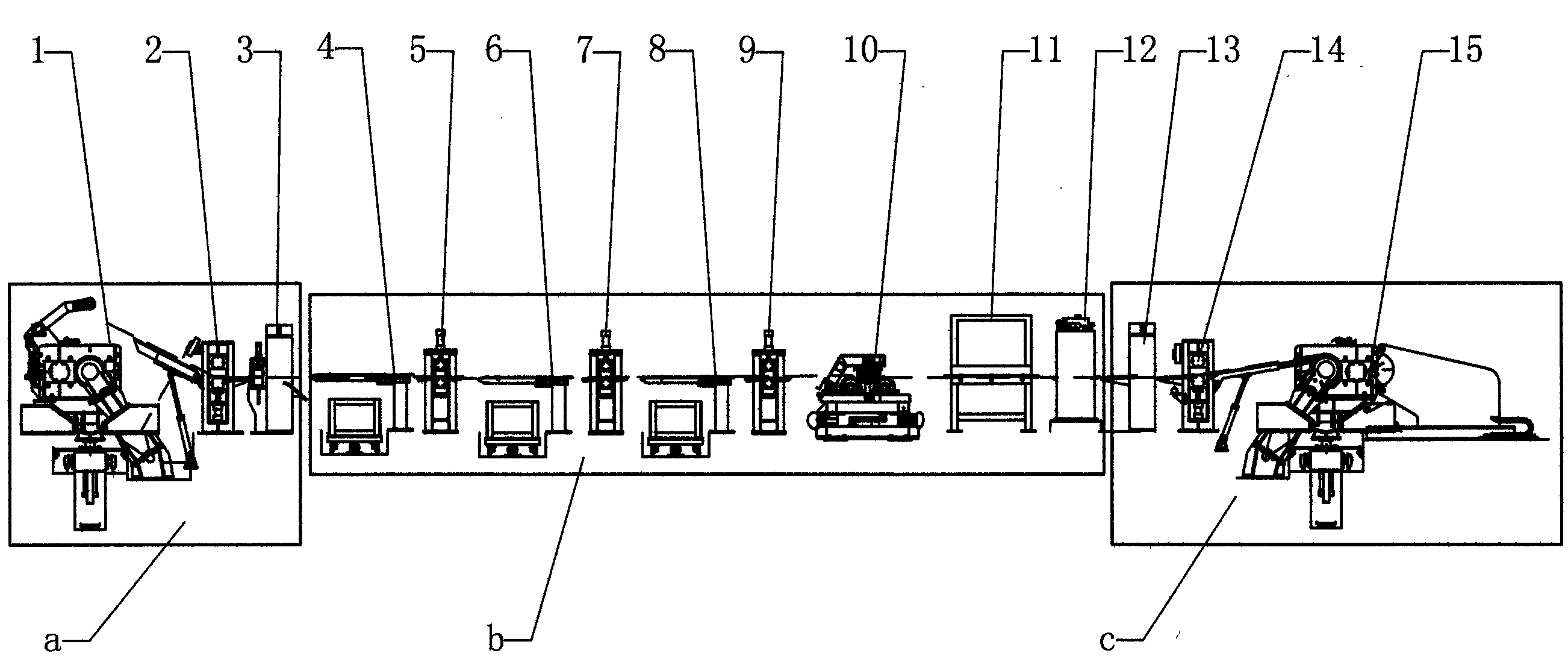

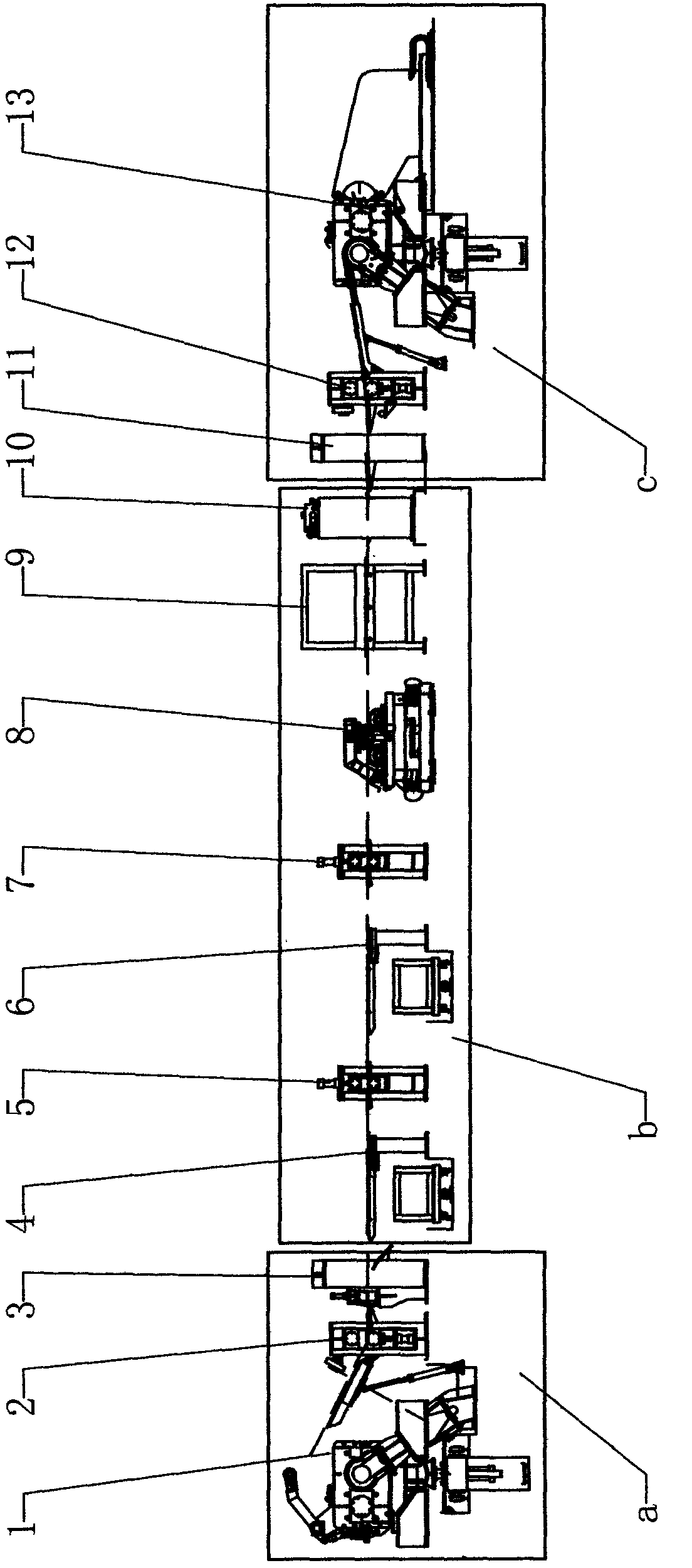

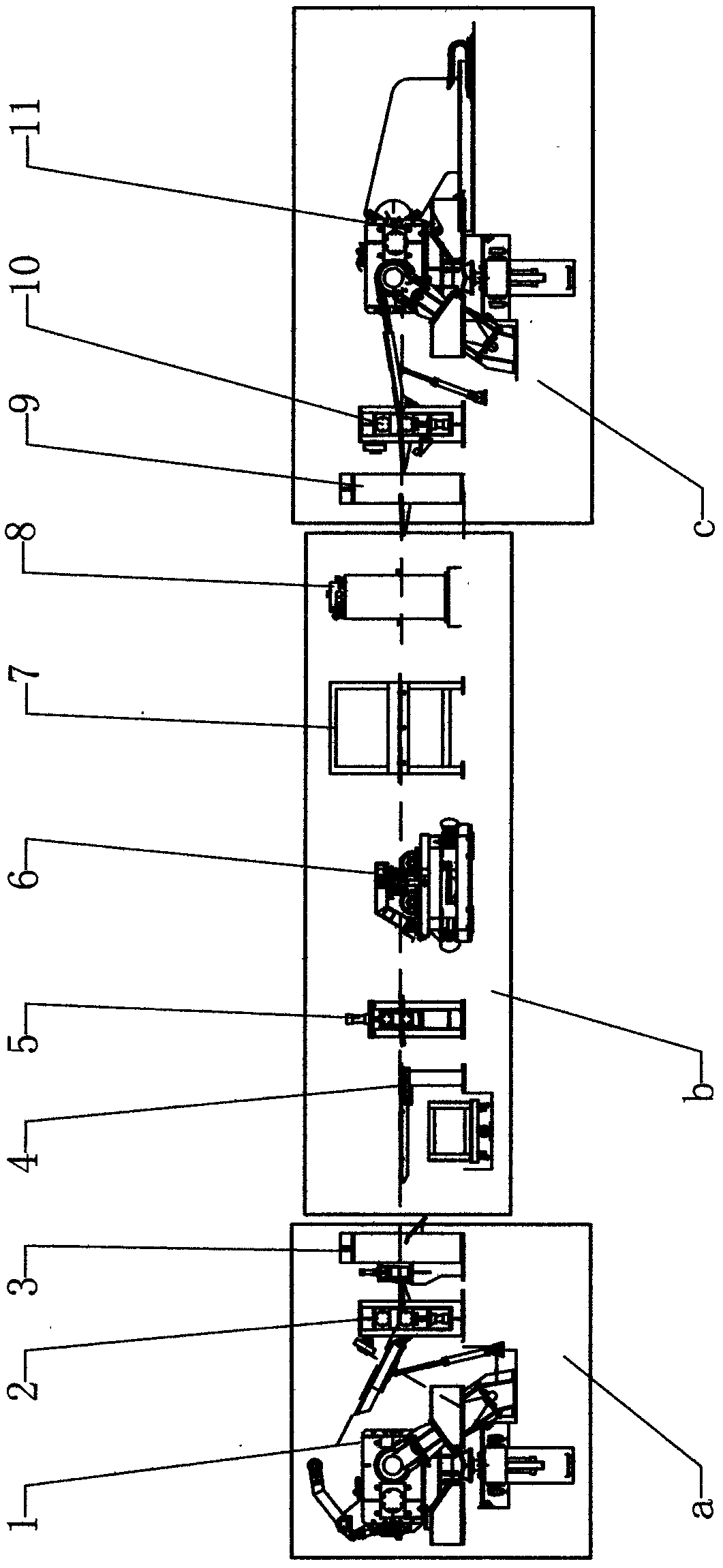

Production line of plasma spraying iron, magnesium, aluminum and zinc composite boards

InactiveCN102582151AImprove bindingEasy to manufactureMolten spray coatingMetal layered productsProduction lineNonferrous metal

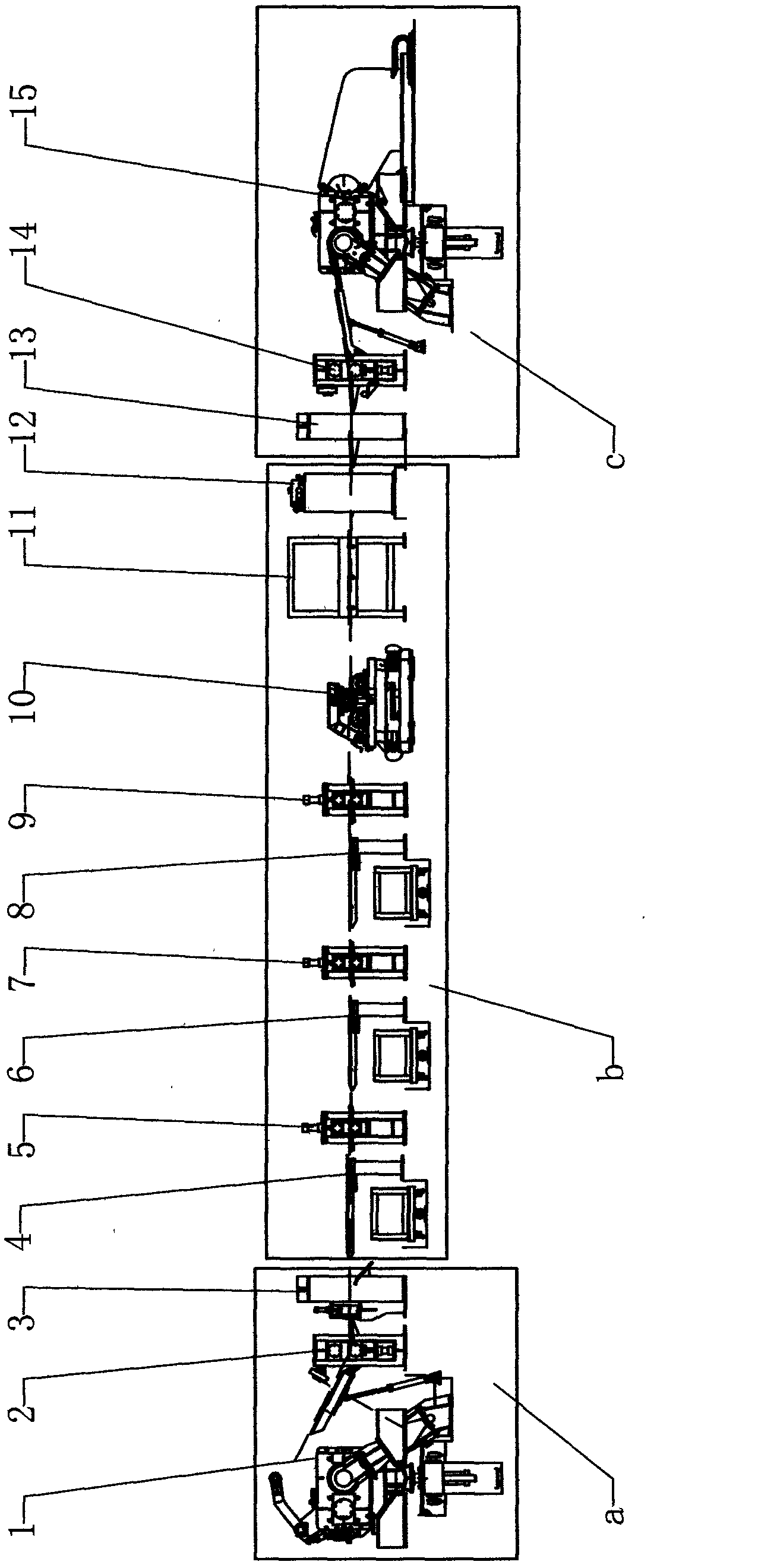

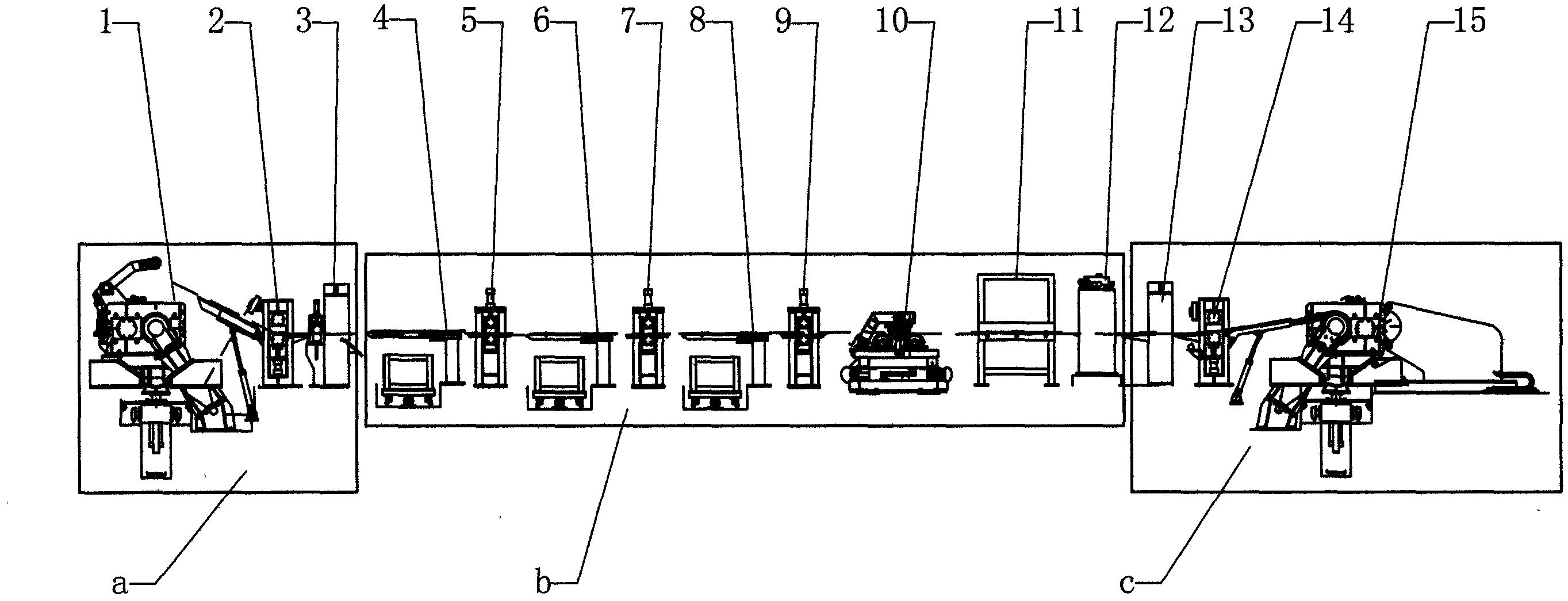

A production line of plasma spraying iron, magnesium, aluminum and zinc composite boards comprises an uncoiler, an entry pinch and an entry shear arranged on the production line entry portion; a three roller rectification machine and a detection platform arranged on the production line processing portion; and an export shear, an export pinch and a coiler arranged on the production line export portion. The production line is characterized by further comprising a plasma magnesium spraying machine, a first cold-rolling mill, a plasma aluminum spraying machine, a second cold-rolling mill, a plasma zinc spraying machine, a third cold-rolling mill and an electrostatic oiler arranged on the production line processing portion. The production line solves existing problems, and particularly provides a production line using ultrasonic flame spraying machines for compositing magnesium, aluminum and zinc on iron plates; and as produced iron, magnesium, aluminum and zinc composite boards substitute for scarce nonferrous metals, consumption of valuable nonferrous metals is reduced. Therefore, the production line has the advantages of being energy saving and environment friendly, convenient to process, good in decoration effect, low in cost and the like.

Owner:王宝根

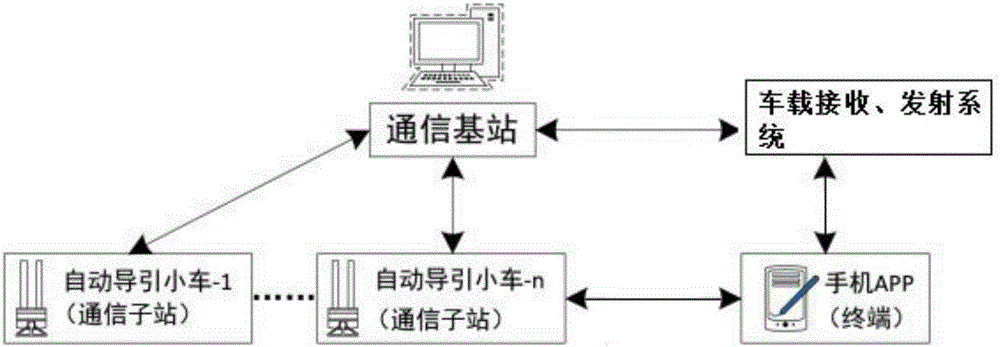

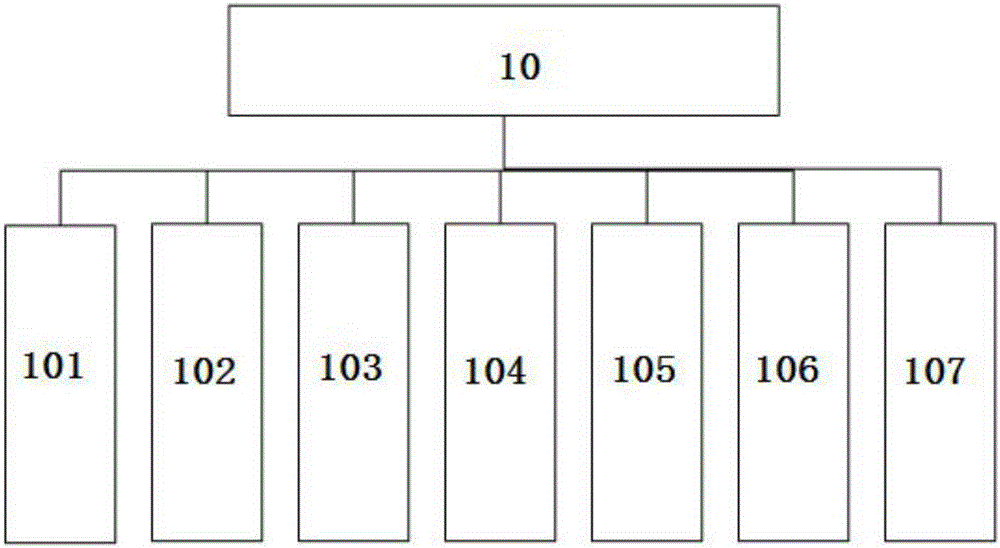

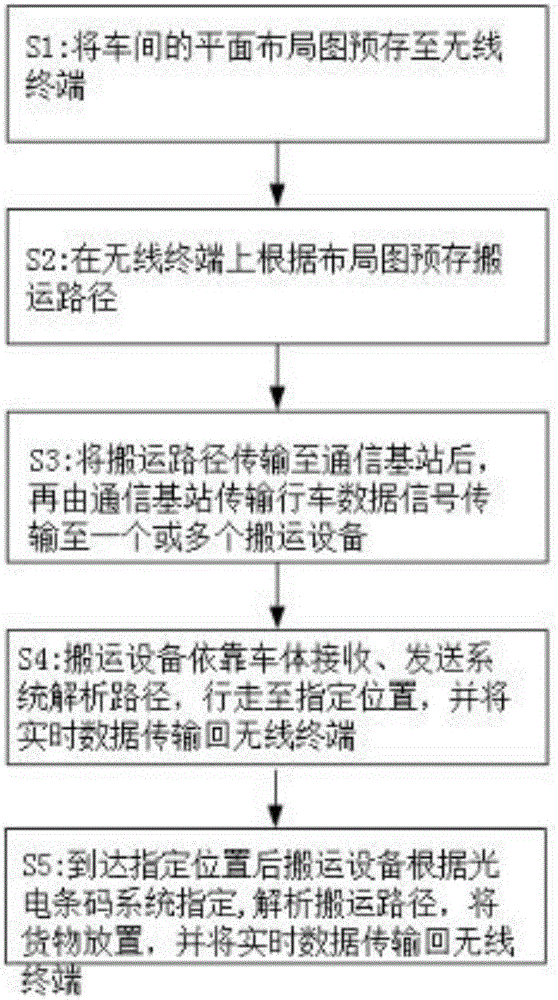

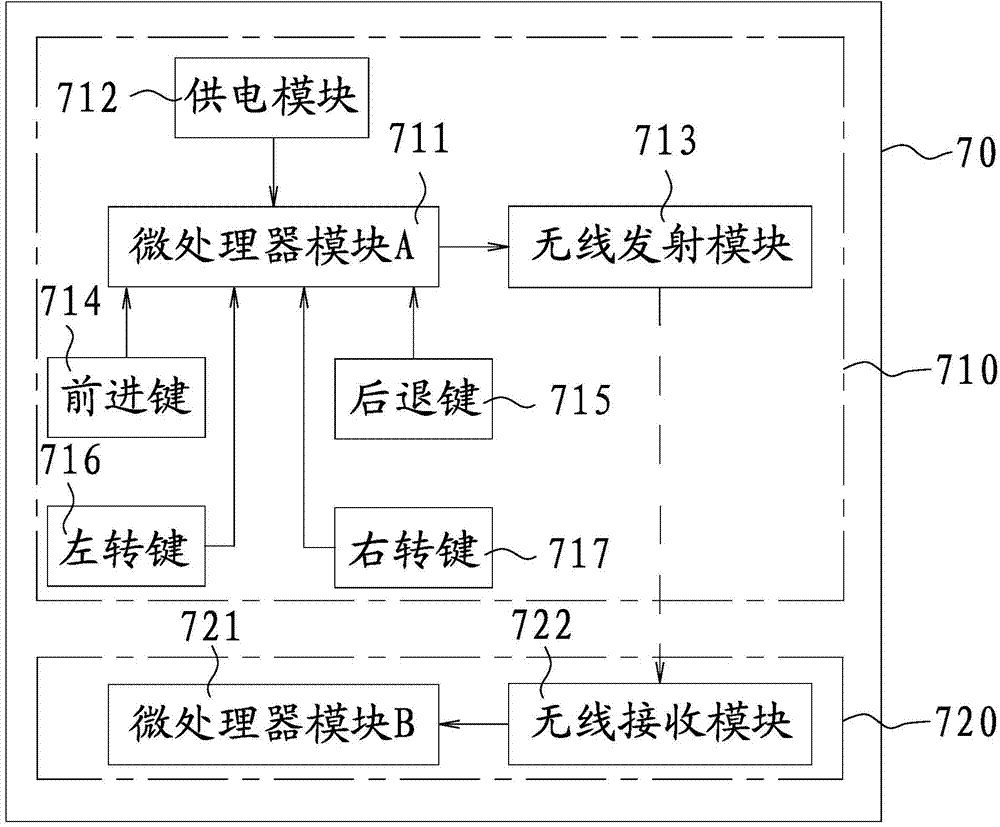

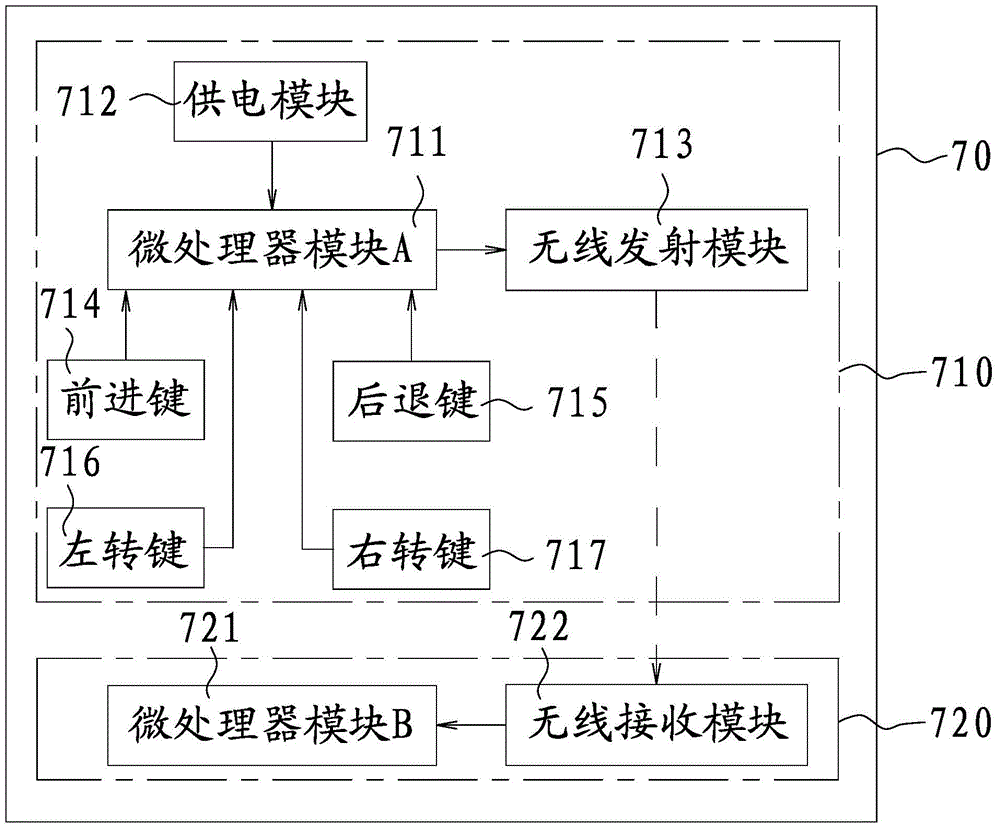

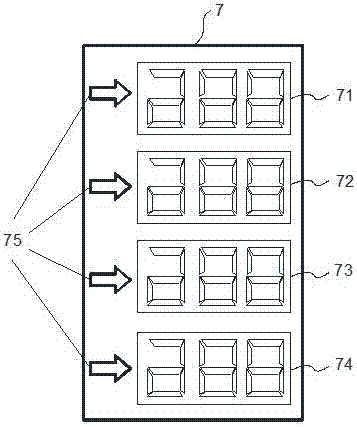

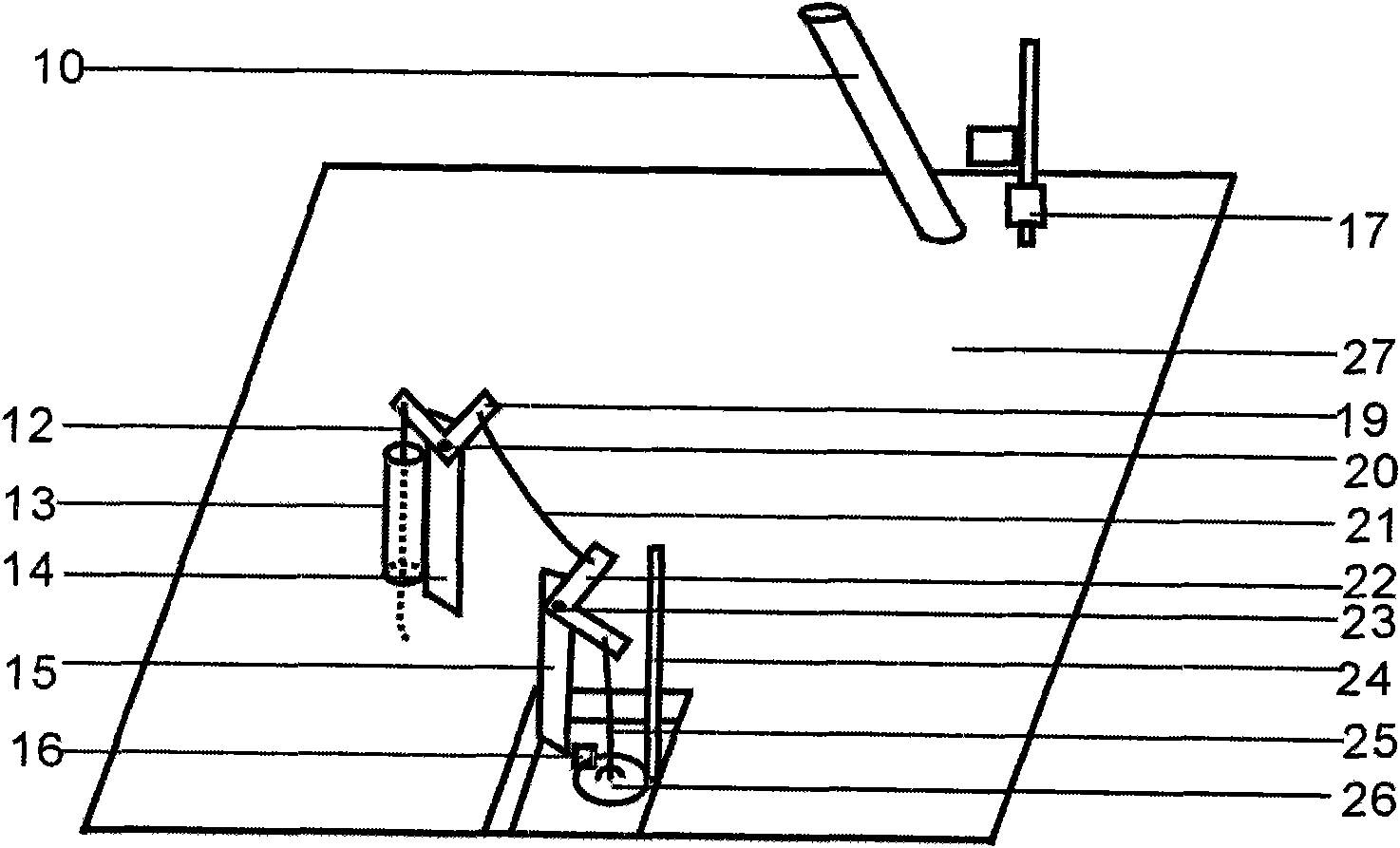

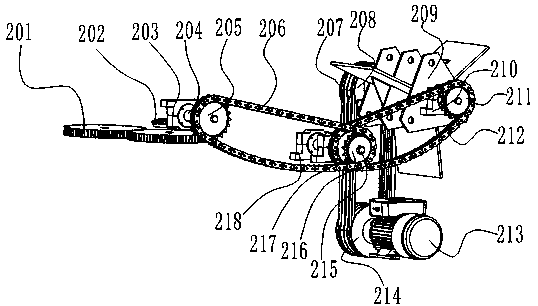

Automatic guidance control system and control method based on wireless terminal

InactiveCN106292661ALow costMeet the needs of the massesPosition/course control in two dimensionsPosition/direction controlAutomatic train controlBarcode

The invention provides an automatic guidance control system and control method based on a wireless terminal. The automatic guidance control system is characterized by comprising a wireless location system, a photoelectric barcode location system and a transfer device. The wireless location system can control fuzzy location of the transfer device, and the photoelectric barcode location system can control accurate location of the transfer device. The automatic guidance control system based on the wireless terminal can perform fuzzy location through the wireless location system and can perform accurate location through the photoelectric barcode system, so that the cost is low, the popular requirement is met, and the accurate location with high cost is avoided. Furthermore, the two control systems of wireless location and photoelectric barcodes are combined, the control system is simplified, and the application range is improved. The automatic guidance control system is flexible to use, can be matched with various tools and clamps to be used together and is obvious in functionality.

Owner:JIASNGSU GAOKE LOGISTICS TECH CO LTD

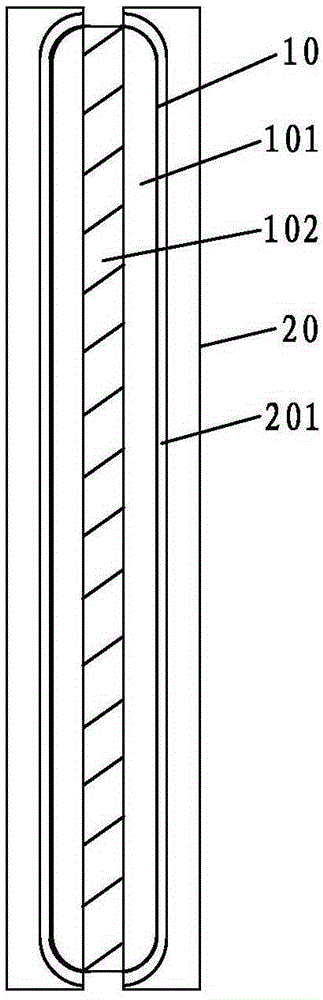

Double-sided metal composite panel

InactiveCN102259446ATo achieve the effect of decorationMaintain decorative effectMetal layered productsPolymer substrateThin layer

The double-sided metal composite board includes a substrate, a panel, an adhesive substrate, and a polymer PVC material adhesive layer for the panel. The panel adopts a thin layer, and the thickness of the substrate is greater than that of the panel. The substrate is made of conventional metal materials, such as steel plate or alloy aluminum, which can provide sufficient strength for the panel; the panel is made of non-ferrous metal foil or metal plate, such as brass, copper, etc., and the decoration can be achieved with less material. The effect of decoration; the adhesive layer is made of polymer PVC material, which plays the role of firmly bonding the substrate and the panel. The beneficial effect of the present invention is that it is easy to manufacture, uses less precious metal materials to compound with ordinary metal steel plates and aluminum plates, retains the decorative effect of metal materials, and combines the strength of ordinary metal steel plates and aluminum plates to make the overall decorative effect It is better, has a longer service life, reduces production costs, and meets the needs of popularization.

Owner:WUXI MEIYU METAL COMPOSITE NEW MATERIALS

Preparation technology of high-strength cup paper

InactiveCN105696405AHigh strengthReduce usageReinforcing agents additionInorganic compound additionChemical industryPulp treatment

The invention relates to the technical field of chemical industry, and particularly relates to a preparation technology of paper cup raw paper. The paper cup technology includes seven technological processes of pulp material proportioning, paper pulp preparation, impurity removal, pulping treatment, paper compositing, squeezing and finished product obtaining; the production and processing method of the paper enables the prepared paper to prevent water and oil and have high strength, and at the same time, the use amount of the wood pulp is greatly reduced; compared with a conventional paper preparation method, the method can make the use amount of the wood pulp reduced by half, and has the advantages of low consumption of the wood pulp, low cost and environmental protection; moreover, the high-strength cup paper prepared by the preparation technology meets the popular demand, has the advantages of wide material sources and simple preparation method, also can be used for second time, and responses to calls of the nation on resource-saving and environment-friendly country construction; and the cup paper can be applicable in various business fields and thousands-of-households resident houses.

Owner:安庆市芊芊科技包装股份有限公司

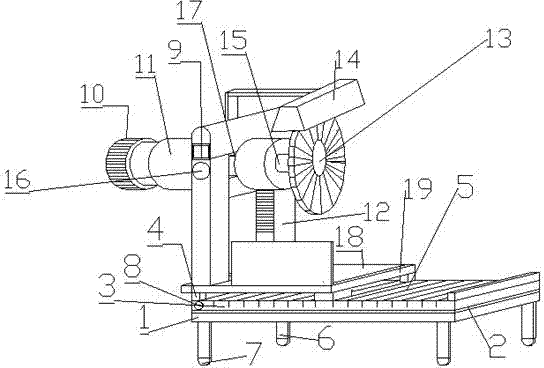

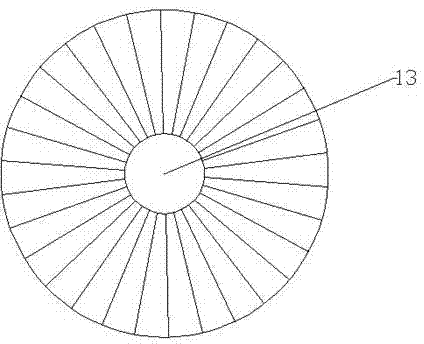

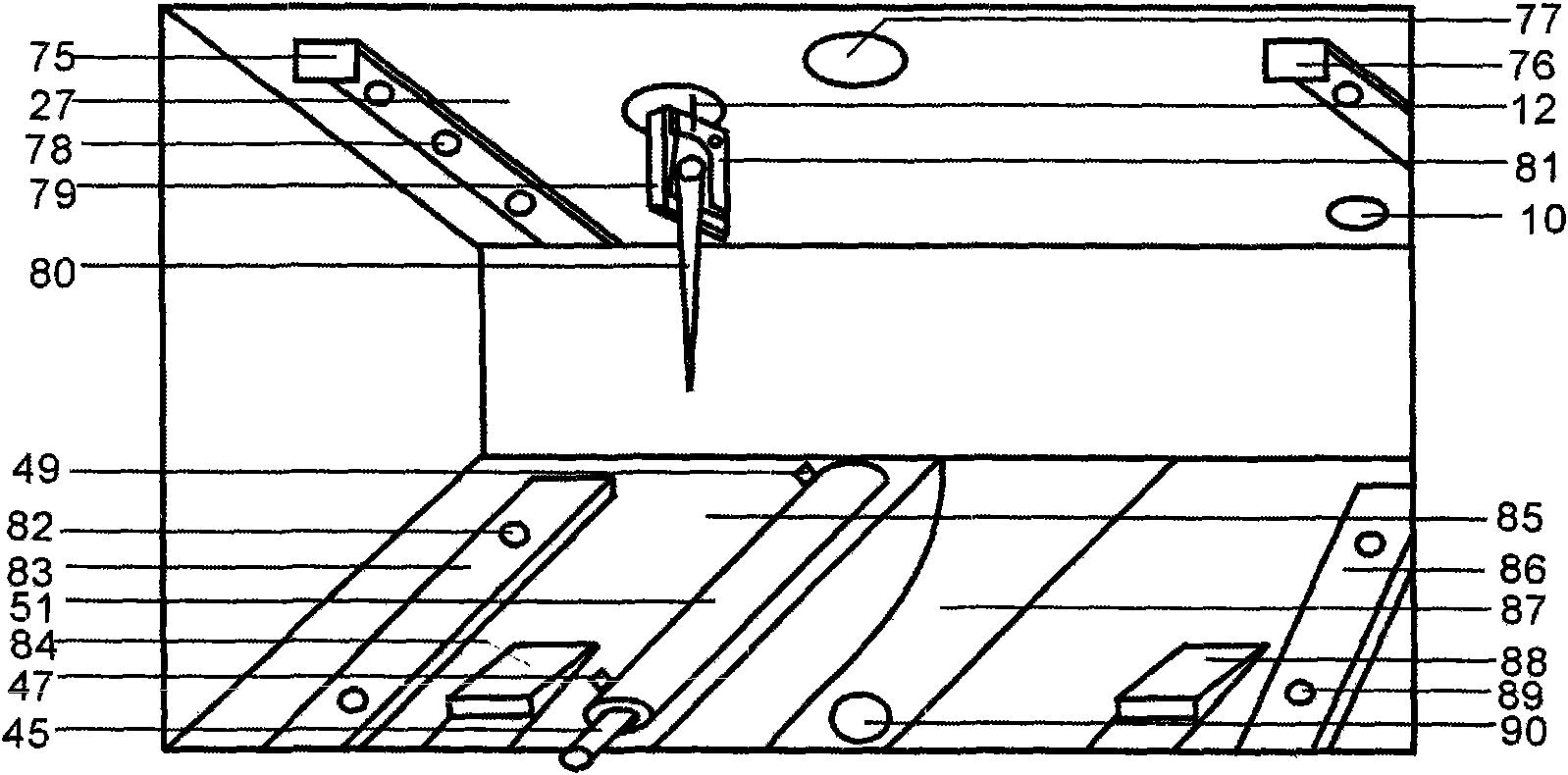

Small cutting and grinding two-purpose machine

InactiveCN104723111ALight structureLow priceOther manufacturing equipments/toolsSurface layerEngineering

A small cutting and grinding two-purpose machine comprises a base, a laminate board, a grinding device, a motor, a saw web, a motor distance adjuster, a workbench base and a movable table top. A machine body and the base are arranged on the top and the bottom of the laminate board respectively. Stand columns are closely fixed to the bottom of the base, sliding wheels are arranged at the bottoms of the stand columns, a blocking device and a guide rail are arranged on the top and an inner cavity of the machine body respectively, the workbench base is arranged on the top of the guide rail, the movable table top is arranged on the surface layer of the workbench base, a vertical plate is arranged on the top of the movable table top, and a switch and the motor distance adjuster are arranged on the left side of the top of the vertical plate. The small cutting and grinding two-purpose machine meets the public requirement, carrying and placing are facilitated for people through the telescopic folded design of the stand columns and the sliding wheels, the small cutting and grinding two-purpose machine can be suitable for various materials through a speed changing device which is installed on the motor and can be controlled, the application range of the small cutting and grinding two-purpose machine is enlarged, positioning cutting and grinding are provided for people through scales on the vertical plate and the machine body, and different operation modes are provided for people through the both-way mode switch.

Owner:鲁奎

Heat-clearing chufa and honey powder and preparation method thereof

InactiveCN104982774AHeat-clearing and detoxifyingWith skin care and beautyFood ingredient functionsFood preparationWater ChestnutsToxic material

The invention discloses heat-clearing chufa and honey powder and a preparation method thereof. The heat-cleaning chufa and honey powder comprises honey, water chestnut starch, pawpaw, white radish, kudzu vine root powder, cordyceps flowers, spirulina, mulberry leaf buds, flaxseed powder, momordica grosvenori flowers, honeysuckle, dendrobium officinale and the like. The heat-cleaning chufa and honey powder and the preparation method thereof have the advantages that the heat-clearing chufa and honey powder has the health-care functions of clearing away heat and toxic materials, protecting and beautifying skin, clearing liver to improve vision, cooling blood, promoting the secretion of saliva or body fluid, increasing the production of urine, relaxing the bowels, resolving dampness, eliminating phlegm, moistening the lungs to arrest couch, helping digestion to remove flatulency, helping users to lose weight and reduce fat, tonifying the spleen, stimulating appetite and the like, and the heat-clearing chufa and honey powder also has natural fragrance of flowers and fruits, is rich and smooth in taste, has agreeable sweetness and unique flavor, and can meet the needs of the public.

Owner:WUHU HYK FOOD CO LTD

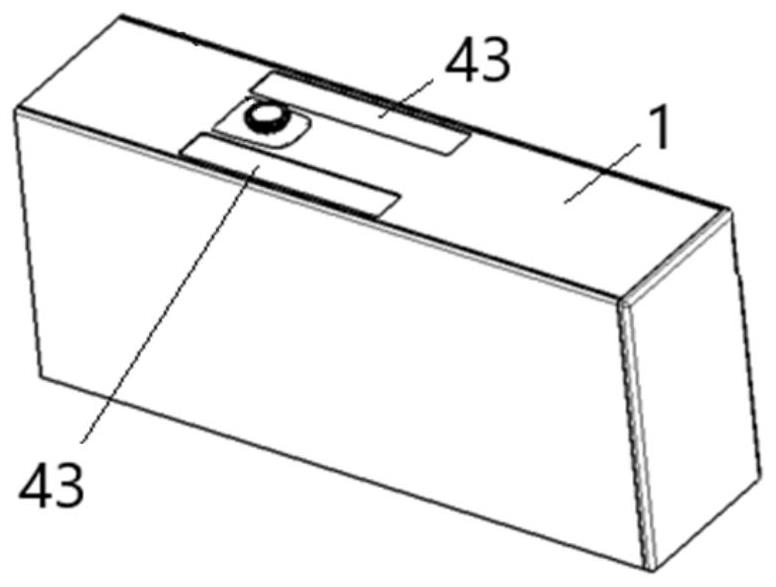

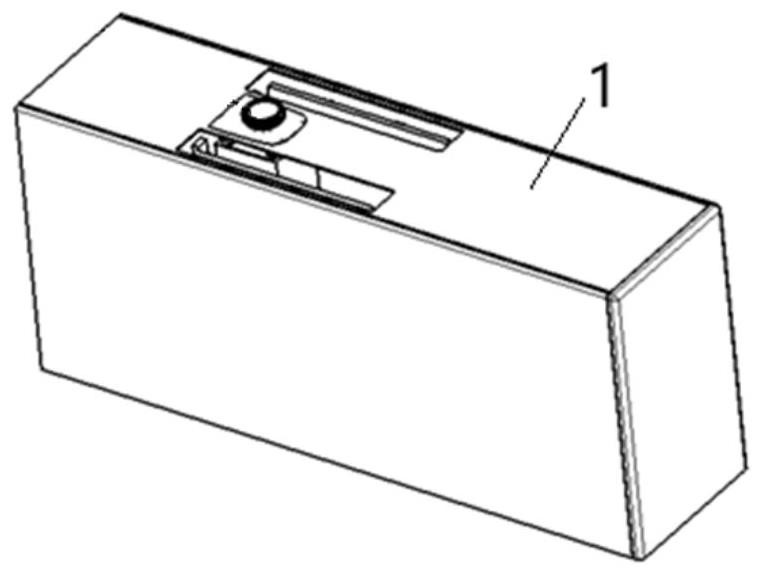

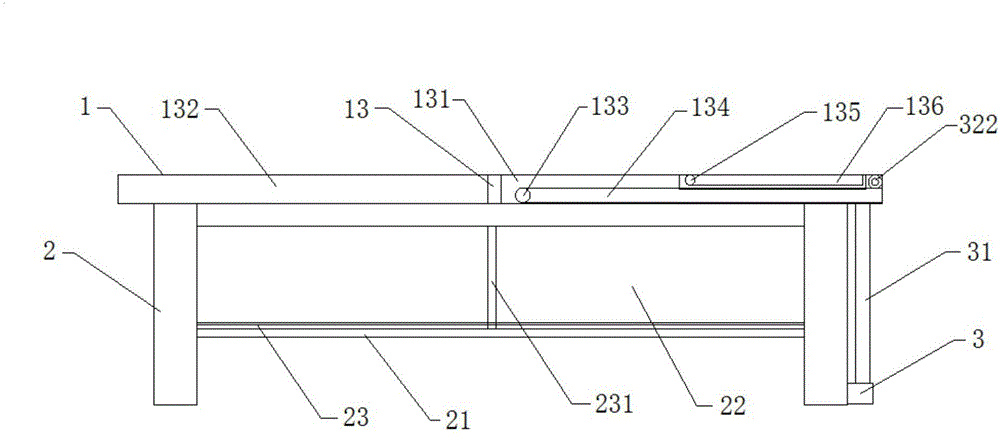

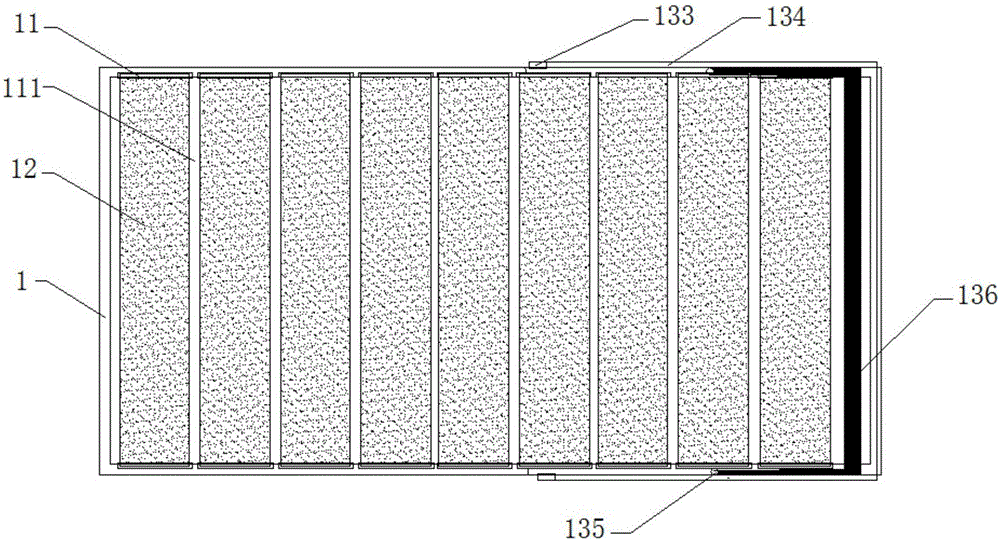

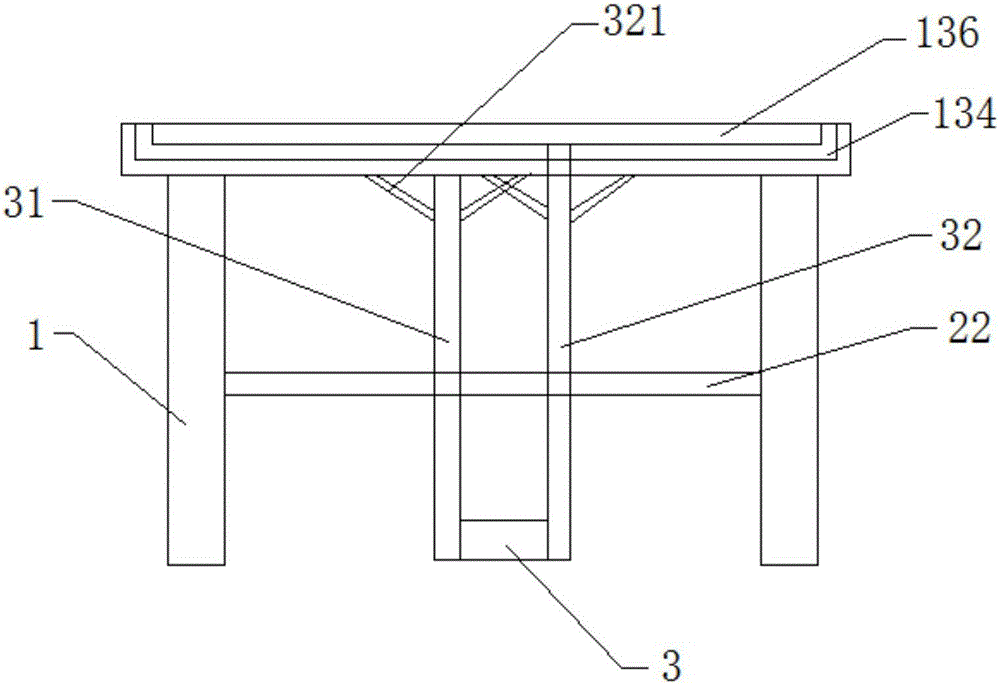

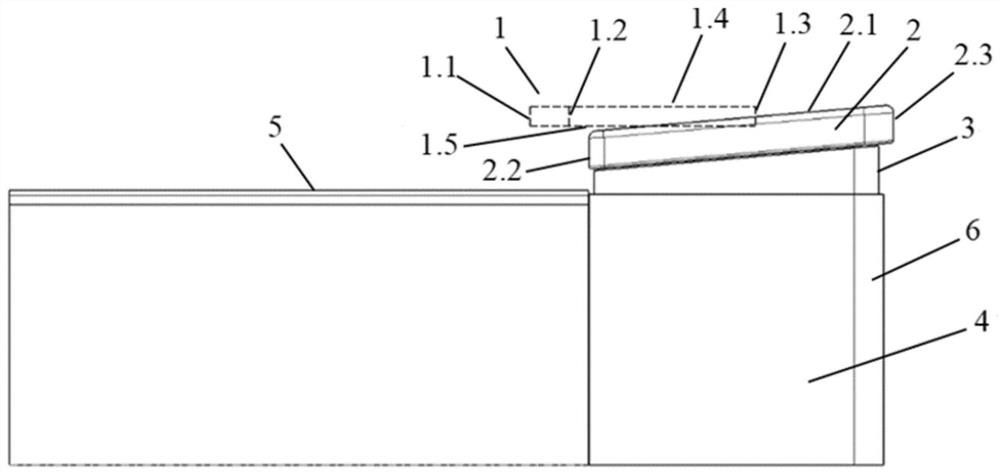

Auxiliary instrument panel structure with small table board

ActiveCN114043872AEliminate fatigueMeet the needs of the massesVehicle arrangementsDashboard fitting arrangementsStructural engineeringMechanical engineering

The invention discloses an auxiliary instrument panel structure with a small table board, and relates to the technical field of automobile interiors. The auxiliary instrument panel structure comprises an auxiliary instrument panel; two parallel outer side sliding rails are arranged on the bottom surface of the small table plate, and hinge holes are formed in the two ends of the inner side edges perpendicular to the two outer side sliding rails respectively; the two outer side support assemblies are each provided with a hinge pin shaft capable of ascending and descending, and the hinge pin shafts are hinged to the hinge holes. Y-shaped supporting branches capable of ascending and descending are arranged on the two inner side support assemblies correspondingly, and supporting rolling wheels are arranged on the tops of the Y-shaped supporting branches and located in the outer side sliding rails; a sensing control assembly collects body type information of a user and outputs a control instruction to control the action of the inner and outer side support assembly. The height position of the small table board can be automatically adjusted according to drivers and passengers of different body types, the mobile phone containing plate, the pen box and the table lamp are arranged on the small table plate so that the user can conveniently use the small table plate, the functions are complete, and the drivers and passengers of different body types and different use requirements can obtain the best use experience.

Owner:DONGFENG MOTOR GRP

Flavor vegetable-pork product and preparation method thereof

The invention discloses a flavor vegetable-pork product, which contains the following raw materials: pork, carrots and other vegetables, and caraway, spring onion, ginger slice, cornstarch, Chinese prickly ash particles, anise, cooking wine, colza oil, chili powder, cinnamon, refined salt, white sugar, aromatic vinegar, sauce, ground pepper, tangerine peel and dried hawthorns. The flavor vegetable-pork product is balanced in meat and vegetables, abundant in nutrients, and popular in taste. The invention further provides a preparation method of the flavor vegetable-pork product. The preparation method comprises the following steps: firstly pickling pork, then stirring together with vegetables into stuffing, then putting into a mold with cartoon character shape and fixing and forming, finally baking to be cooked, cooling, sterilizing, and performing vacuum packaging, and thus obtaining the product. The pork product prepared by adopting the preparation method is safe to eat, good in mouth feeling, abundant and interesting in appearance, and easy to chew and digest, thus being a healthy and nutritional food suitable for both the old and the children.

Owner:合肥慧明瀚生态农业科技有限公司

Medical nursing bed for operation

InactiveCN106214395AEasy to operateImprove comfortNursing bedsAmbulance serviceHydraulic cylinderEngineering

The invention discloses a medical nursing bed for operation. The nursing bed comprises a nursing bed body, supporting columns and a hydraulic cylinder, wherein the supporting columns are arranged at four corners of the nursing bed body; multiple groups of grooves are oppositely formed in the inner side of the nursing bed body; an assembly plate is arranged on the nursing bed body through the grooves; a pin roll is arranged at the joint between a bed board I and a rotating shaft; a body supporting plate is arranged by virtue of the pin roll, the bottom of the body supporting plate is movably connected with the output end of the hydraulic cylinder through a hydraulic rod; a head supporting plate is arranged in the middle of the bed board I through the pin roll; and the bottom of the head supporting plate is movably connected with the output end of the hydraulic cylinder through a hydraulic rod II. The medical nursing bed for operation is simple in structure and low in manufacture cost, so that the corresponding market commercial price is reduced, and the comfortable feeling of a patient can be ensured, the popular requirement can be met, and the sale quantity of the medical nursing bed can be increased.

Owner:泉州市知产茂业工业设计有限公司

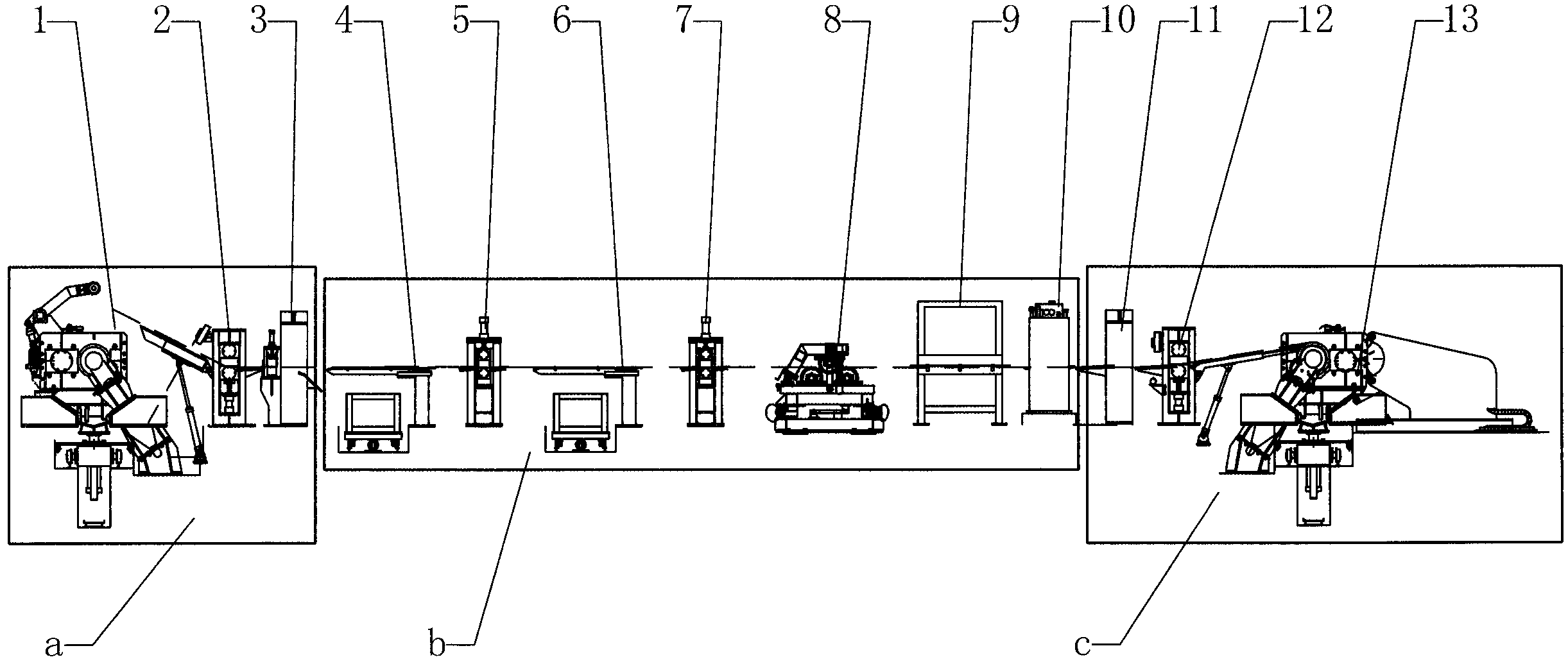

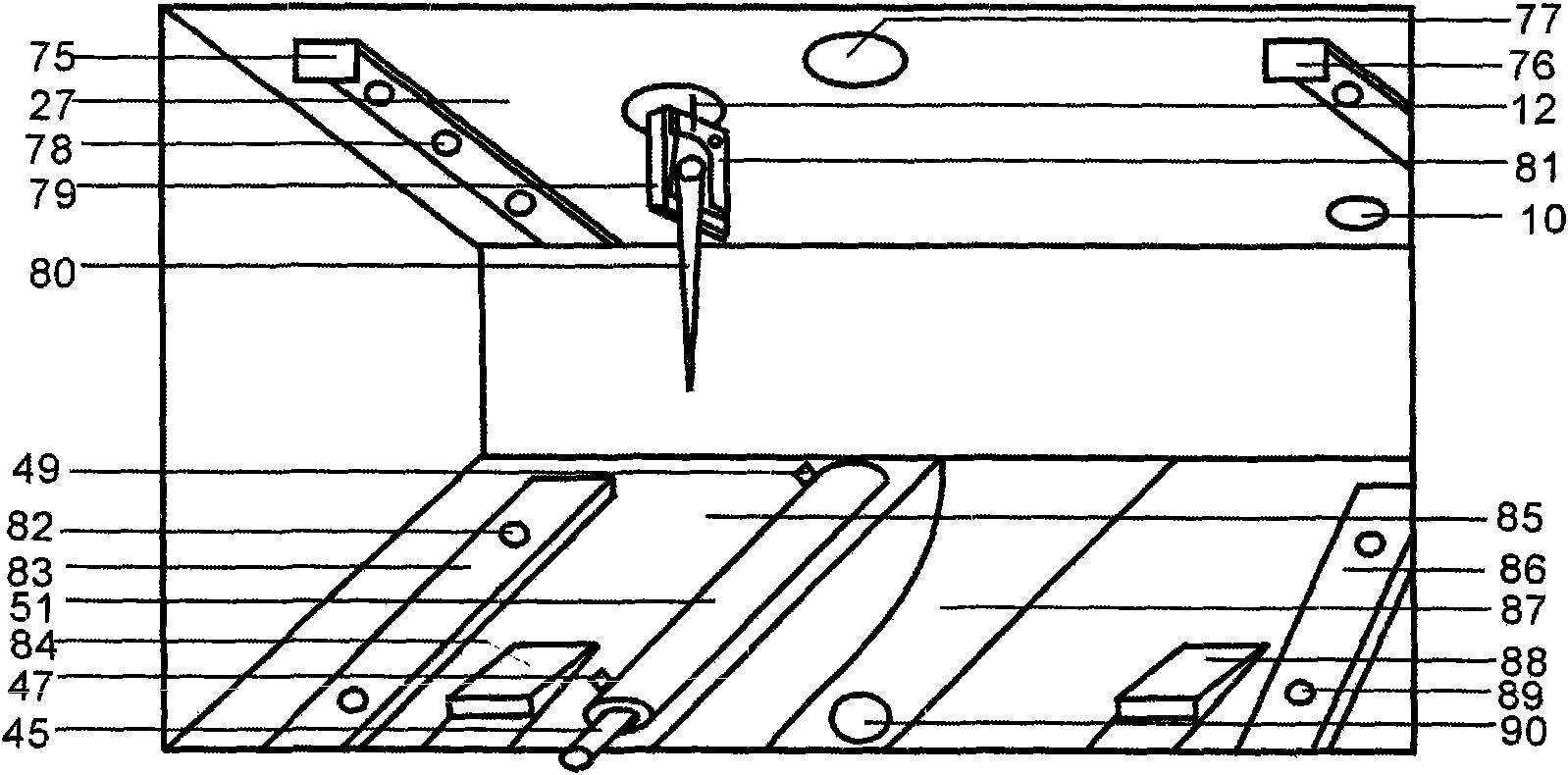

Double-sided aluminium multilayer metal composite plate and production line thereof

InactiveCN102848633AImprove bindingEasy to manufactureMolten spray coatingMetal layered productsEngineeringComposite plate

A double-sided aluminium multilayer metal composite plate and a production line thereof. The production line comprises an uncoiler, an inlet pinch, and inlet scissors disposed at an inlet part of the production line, a three-roller rectification machine and a detection bench disposed at a processing part of the production line, outlet scissors, an outlet pinch and a coiler disposed at an outlet part; the production line is characterized in that the production line also comprises a passivation part which comprises an ultrasonic cleaner, a first clear water cleaner, a passivation machine, and a second clear water cleaner, and comprises a front side high-frequency heating spray coater, a first cold rolling machine, a reverse side high-frequency heating spray coater, a second cold rolling machine, a double-sided aluminium cold pressing welder, and a static oiling machine disposed at the processing part. The invention solves current problems, provides a production line for compounding copper or zinc and aluminium powder on an iron plate by high-frequency heating and spraying technology; the produced iron copper aluminium composite plate or iron zinc aluminium composite plate can substitute non ferrous metal in shortage, reduce the consumption of precious non ferrous metal, and has the characteristics of energy saving, environmental protection, convenient processing, good decorative effect, low cost, and the like.

Owner:王宝根

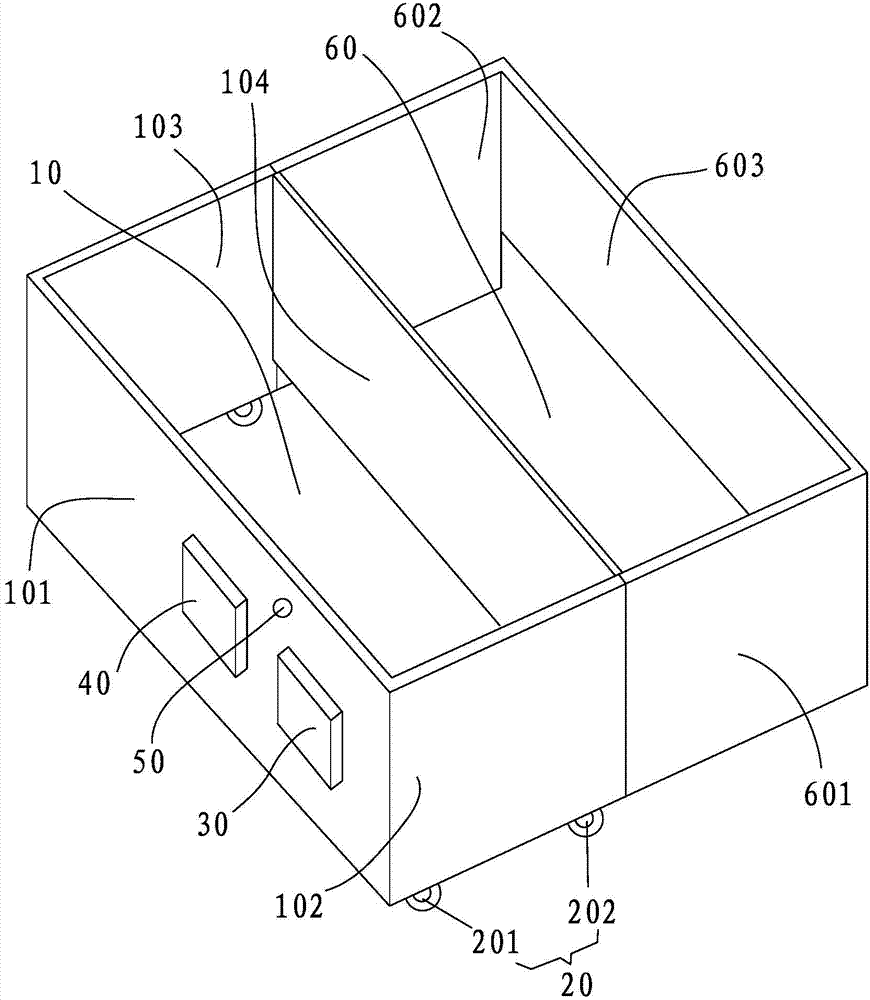

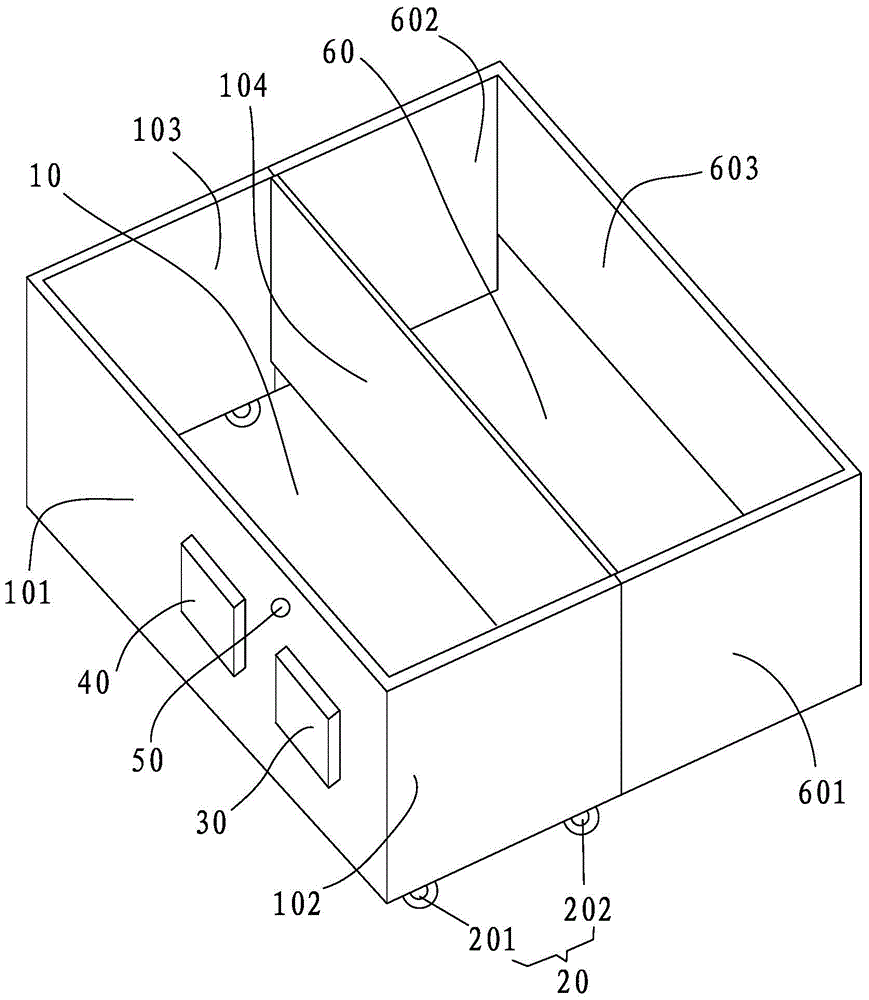

Efficient ground paving and levelling machine

InactiveCN103938842APaving speed is fastGood flatnessBuilding constructionsRoads maintainenceMultiple functionControl switch

The invention discloses an efficient ground paving and levelling machine. The efficient ground paving and levelling machine comprises a first containing cavity, idler wheels, a motor, a power supply, a control switch and a second containing cavity. The first containing cavity is defined by a front panel A, a left side plate A, a right side plate A and a rear panel A in an enclosing mode, openings are formed in the upper end and the lower end of the first containing cavity, the bottom of the front panel A, the bottom of the left side plate A and the bottom of the right side plate A are flush with one another, and the bottom of the rear panel A is slightly higher than the bottom of the front panel A, the bottom of the left side plate A and the bottom of the right side plate A. The number of the idler wheels is four, the four idler wheels include two universal wheels and two directional wheels, the two universal wheels are arranged at the front end of the first containing cavity, and the two directional wheels are arranged at the rear end of the first containing cavity. Through the efficient ground paving and levelling machine, the ground can be paved and leveled fast, the paving speed is high, the smoothness is good, and the efficient ground paving and levelling machine is particularly suitable for paving and levelling ground with floor tiles requiring to be laid. The efficient ground paving and levelling machine can be used for automatically plastering the back faces of the floor tiles and really shows the multiple functions.

Owner:冼日声

High-strength pouring cup paper preparation technology

InactiveCN105507057AHigh strengthReduce usageDrinking vesselsPaper-making machinesHigh intensityMaterials science

The invention discloses a high-strength pouring cup paper preparation technology and relates to the technical field of chemical engineering. The preparation technology comprises seven technology processes of preparing material, preparing paper pulp, removing impurities, pulping, composting paper, squeezing and finishing products. By the use of the manufacturing and processing method, the paper is waterproof and oil-resistant and has high strength; wood pulp use amount can be greatly reduced; compared with a paper preparation method in the prior art, the wood pulp use amount can be reduced by a half, so wood pulp loss can be reduced, cost is lowered and the environment is protected; the high-strength pouring cup manufactured by the preparation technology meets demands of the public; the pouring cup can be made from wide material and simple methods and can be reused; the high-strength pouring cup paper preparation technology responses to a call for the construction of resource-saving and environment-friendly nation; and the pouring cup is suitable for various business fields and all households.

Owner:ANQING SHENGHUA PAPER PACKAGING

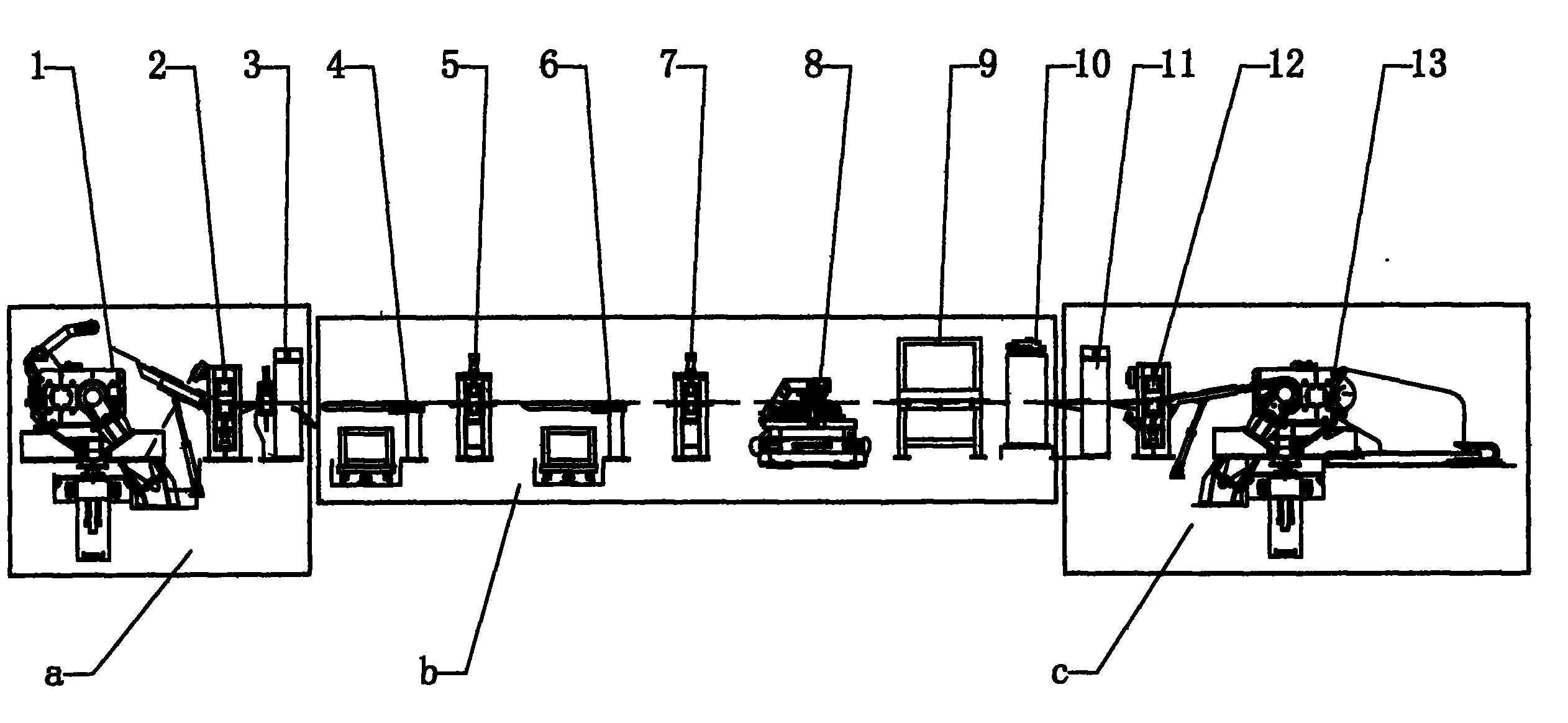

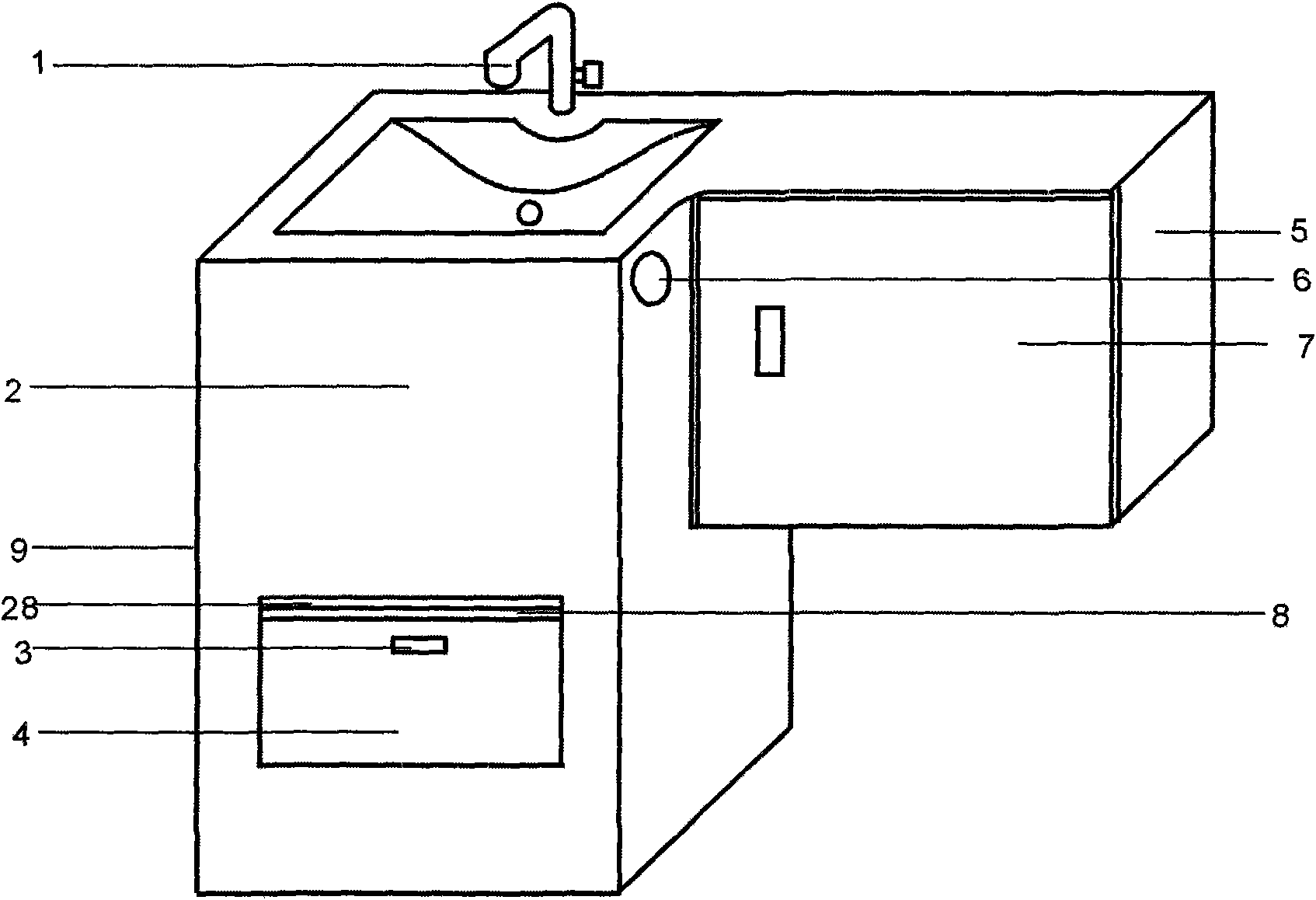

Production line for hypersonic flame spraying iron copper aluminum zinc composite boards

InactiveCN102582154AImprove bindingEasy to manufactureMolten spray coatingMetal layered productsProduction lineNonferrous metal

A production line for hypersonic flame spraying iron copper aluminum zinc composite boards comprises an uncoiler, an inlet pincher, an inlet shear, a three-roller deviation rectifying machine, a detecting platform, an outlet shear, an outlet pincher and a recoiler, wherein the uncoiler, the inlet pinch and the inlet shear are arranged on an inlet portion of the production line; the three-roller deviation rectifying machine and the detecting platform are arranged on a processing portion of the production line; and the outlet shear, the outlet pinch and the recoiler are arranged on an outlet portion of the production line. The production line for hypersonic flame spraying iron copper aluminum zinc composite boards is characterized by further comprising a hypersonic flame copper spraying coater, a first cold rolling mill, a hypersonic flame aluminum spraying coater, a second cold rolling mill, a hypersonic flame zinc spraying coater, a third cold rolling mill and an electrostatic oiler, which are arranged on the processing portion of production line. The production line for hypersonic flame spraying iron copper aluminum zinc composite boards solves the existing problems by providing a production line on which hypersonic flame spraying coaters are used for copper aluminum zinc composition on an iron plate so that non-ferrous metals in short supply are replaced with produced iron copper aluminum zinc composite boards, and the consumption of valuable non-ferrous metals is reduced. The iron copper aluminum zinc composite boards have the advantages of being energy-saving, environment-friendly, convenient to process, good in decorative effect, low in cost and the like.

Owner:王宝根

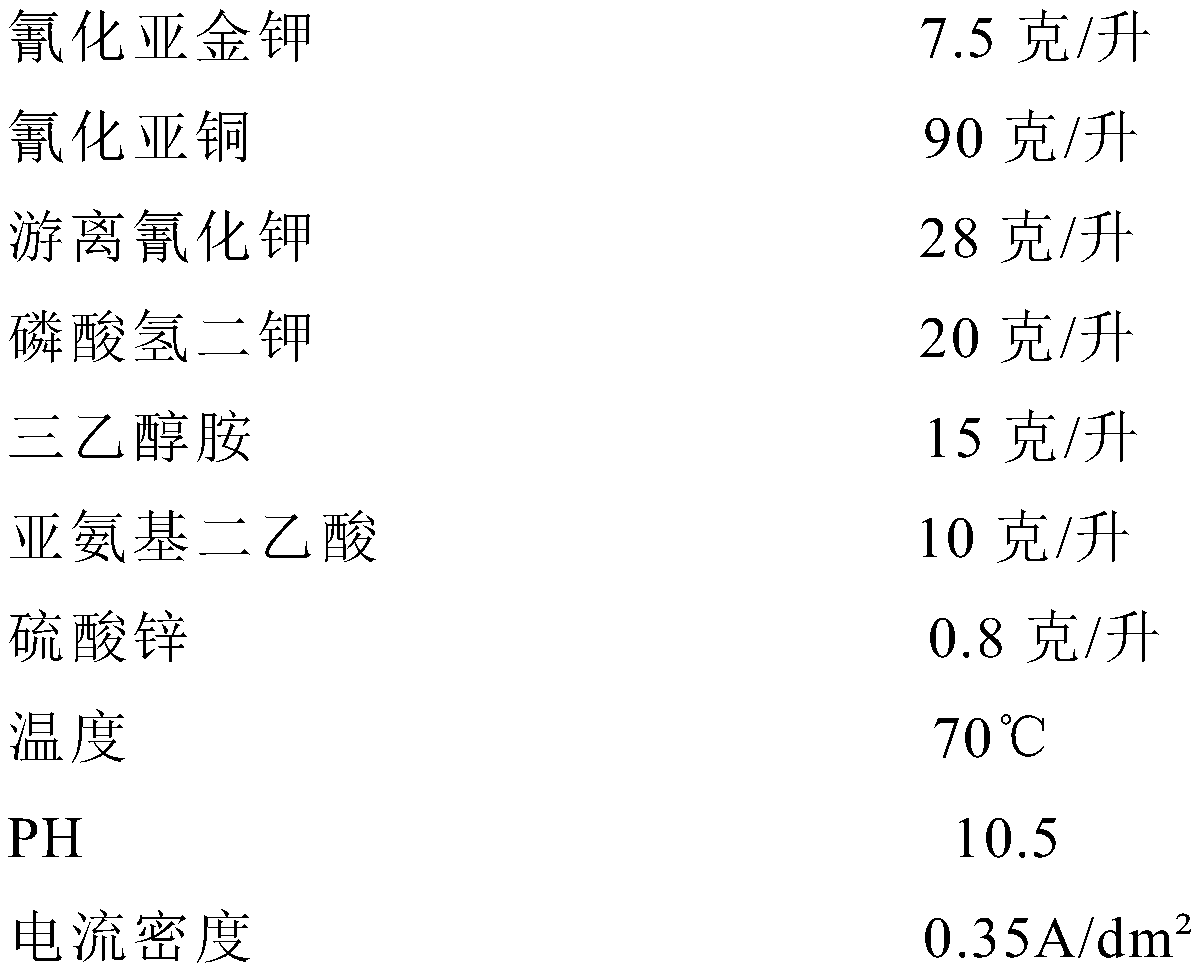

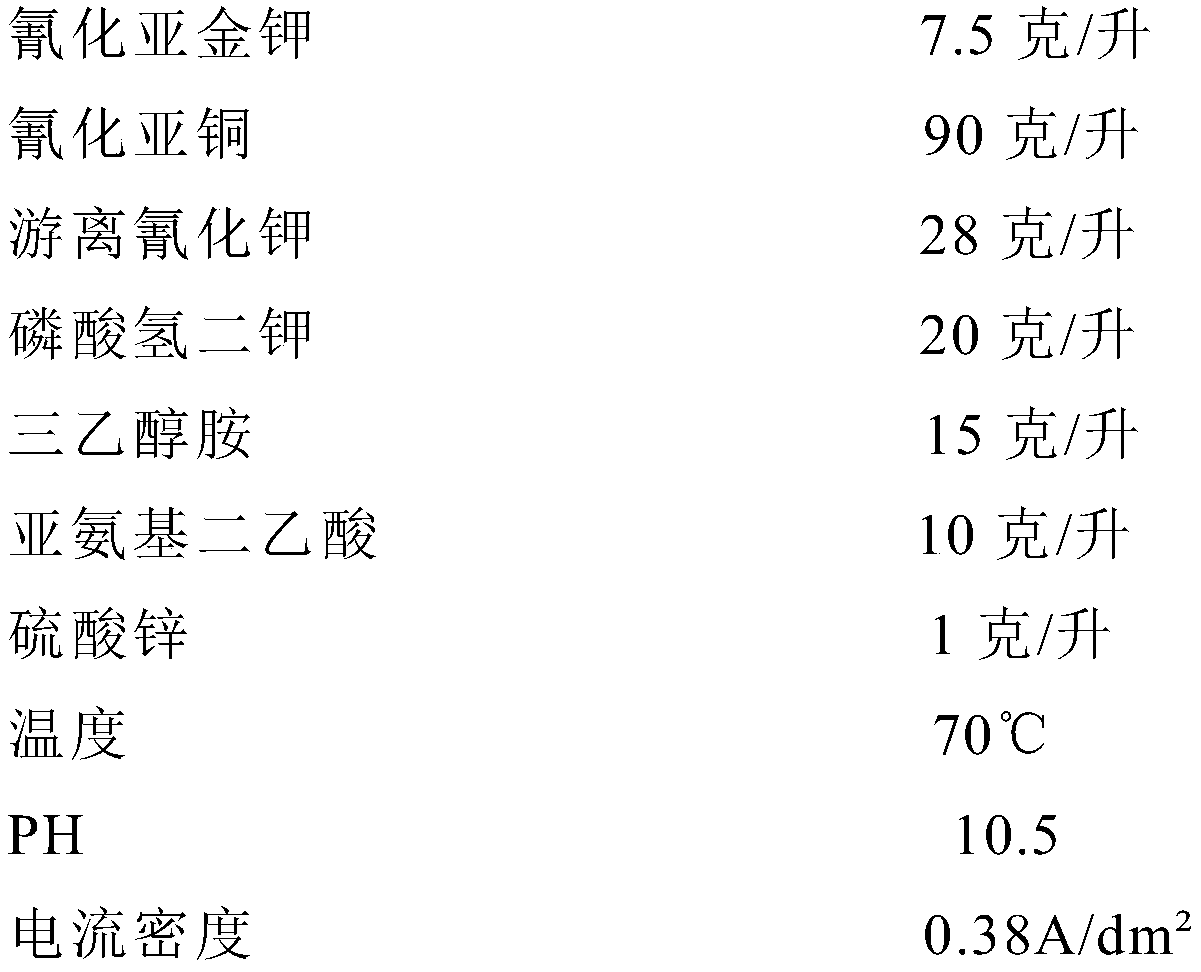

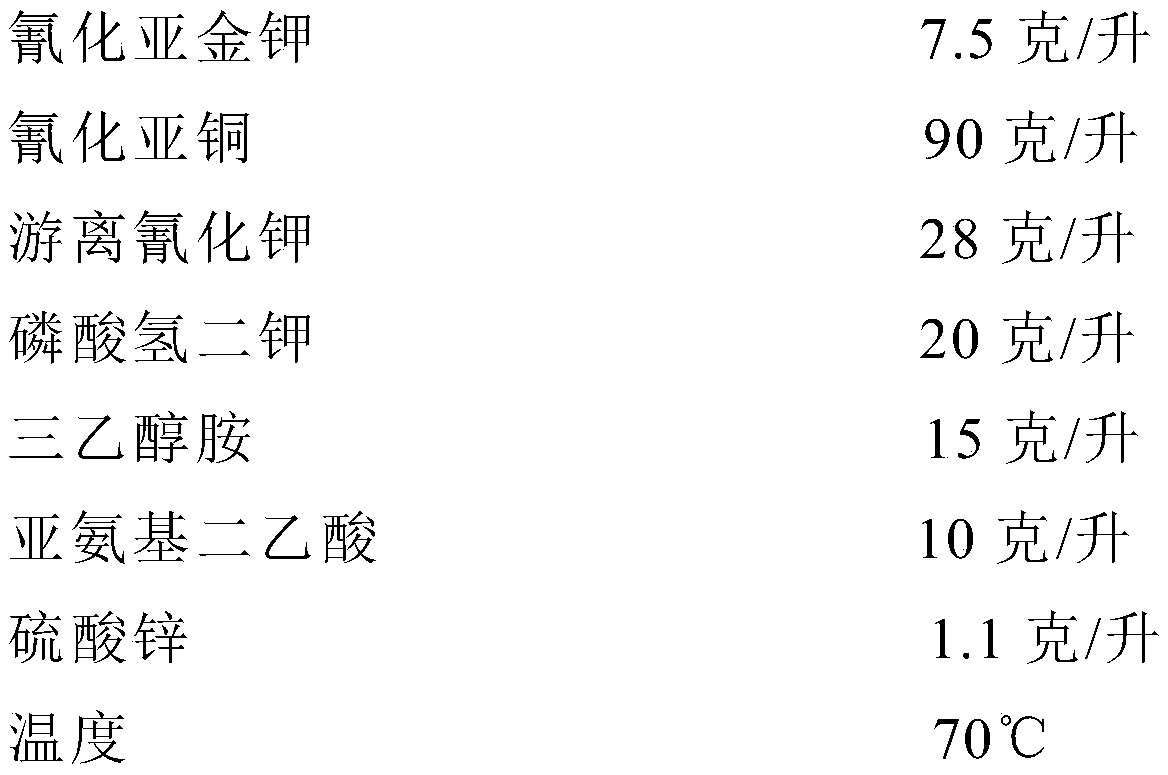

A kind of electroforming liquid used in K gold electroforming process

InactiveCN109778245BImprove performanceReduce weightElectroforming processesPotassium cyanideDipotassium phosphate

The invention relates to electroforming liquid for a K gold electroforming process. The electroforming liquid comprises the following main components with one liter of solution as unit: 4-10 g / l of potassium aurous cyanide, 50-100 g / l of cuprous cyanide, 18-35 g / l of free potassium cyanide, 1-50 g of triethanolamine and 1-30 g / l of iminodiacetic acid as auxiliary complexing agents, 0.2-4 g / l of zinc sulfate as hardening agents, 10-30 g / l of dipotassium phosphate as buffering agents; the electroforming liquid for the K gold electroforming process is prepared through the components, and K gold products are electroformed; K gold is prepared through a gold and copper binary alloy electroforming process; the K gold electroforming liquid with stable performances is used for preparing hollow K gold products with low weights, high hardness, bright rose gold colors and bright and smooth surfaces; and the products have the advantages of low gold consumption, durability, three-dimensional and full shapes and low cost.

Owner:深圳市昊扬电铸技术开发有限公司

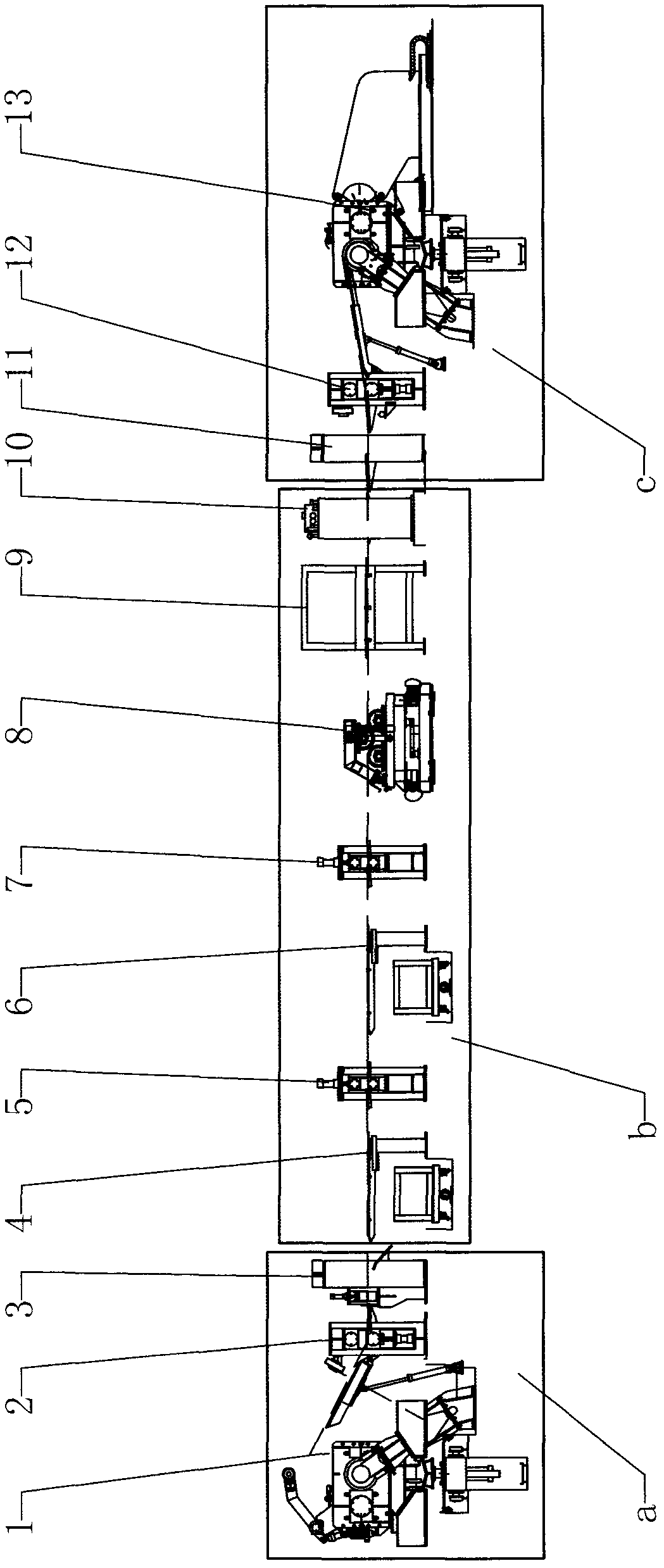

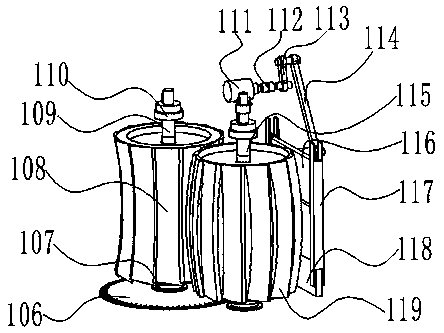

Plasma spraying iron-copper-zinc composite plate production line

InactiveCN102586717AImprove bindingEasy to manufactureMolten spray coatingMetal layered productsProduction lineNonferrous metal

A plasma spraying iron-copper-zinc composite plate production line comprises an uncoiler, an inlet clamping feeding device, inlet scissors, a three-roller rectification machine, a detection table, outlet scissors, an outlet clamping feeding device and a coiler, wherein the uncoiler, the inlet clamping feeding device and the inlet scissors are arranged on an inlet portion of the production line, the three-roller rectification machine and the detection table are arranged on a processing portion of the production line, and the outlet scissors, the outlet clamping feeding device and the coiler are arranged on an outlet portion of the production line. The plasma spraying iron-copper-zinc composite plate production line is characterized by further comprising a plasma copper sprayer, a first cold-rolling mill, a plasma zinc sprayer, a second cold-rolling mill and an electrostatic oil coating machine which are all arranged on the processing portion of the production line, wherein the plasma copper sprayer is arranged behind the inlet scissors, and the first cold-rolling mill is arranged behind the plasma copper sprayer. The plasma spraying iron-copper-zinc composite plate production line solves the existing problem, can compound copper and zinc on an iron plate by using the plasma sprayers and has the advantages of being energy-saving, environment-friendly, convenient to process, good in decoration effect, low in cost and the like, and an iron-copper-zinc composite plate produced by the production line replaces scarce nonferrous metals, so that consumption of valuable nonferrous metals is reduced.

Owner:王宝根

Supersonic flame spraying iron aluminum and zinc composite board production line

InactiveCN102586720AImprove bindingEasy to manufactureMolten spray coatingMetal layered productsProduction linePulp and paper industry

The invention relates to a supersonic flame spraying iron aluminum and zinc composite board production line, which comprises an uncoiling machine, an inlet clamping and conveying device, an inlet shear, a three-roll deviation correcting machine, a detection table, an outlet shear, an outlet clamping and conveying device and a coiling machine, wherein the uncoiling machine, the inlet clamping and conveying device and the inlet shear are arranged at an inlet part of the production line, the three-roll deviation correcting machine and the detection table are arranged at a processing part of the production line, and the outlet shear, the outlet clamping and conveying device and the coiling machine are arranged at an outlet part of the production line. The production line is characterized by also comprising a supersonic flame aluminum spraying machine, a first cold rolling machine, a supersonic flame zinc spraying machine, a second cold rolling machine and a static oil coating machine which are arranged at the processing part of the production line, wherein the supersonic flame aluminum spraying machine is arranged behind the inlet shear, and the first cold rolling machine is arranged behind the supersonic flame zinc spraying machine. The invention solves the problems in the prior art and provides the production line for compounding aluminum or zinc on iron boards by using the supersonic flame spraying machine, the produced iron aluminum and zinc composite boards replace non-ferrous metals in short supply, the consumption of noble non-ferrous metals is reduced, and the production line has the characteristics that the energy is saved, the environment is protected, the processing is convenient, the decoration effect is good, the cost is low, and the like.

Owner:王宝根

Double-side metal composite plate

InactiveCN103331962AEasy to makeGood decorative effectMetal layered productsSteel platesPrecious metal

The invention discloses a double-side metal composite plate. The double-side metal composite plate comprises a face plate, a basal plate and a bonding layer, wherein the face plate and the basal plate are arranged at the outer layer; the bonding layer is configured to be a middle layer; the thickness of the basal plate is greater than the thickness of the face plate. The double-side metal composite plate disclosed by the invention is convenient to manufacture; through compositing less noble metal material with an ordinary steel plate, a decorative effect of the original noble metal material is maintained and the strength of the ordinary steel plate is integrated, so that the total decorative effect can be excellent, the service life is long, the production cost is reduced, and the need of the popularity is met.

Owner:WUXI MEIYU METAL COMPOSITE NEW MATERIALS

Efficient floor paving and leveling machine

InactiveCN103938842BSpeed up pavingImprove paving qualityBuilding constructionsRoads maintainenceArchitectural engineeringControl switch

The invention discloses an efficient ground paving and levelling machine. The efficient ground paving and levelling machine comprises a first containing cavity, idler wheels, a motor, a power supply, a control switch and a second containing cavity. The first containing cavity is defined by a front panel A, a left side plate A, a right side plate A and a rear panel A in an enclosing mode, openings are formed in the upper end and the lower end of the first containing cavity, the bottom of the front panel A, the bottom of the left side plate A and the bottom of the right side plate A are flush with one another, and the bottom of the rear panel A is slightly higher than the bottom of the front panel A, the bottom of the left side plate A and the bottom of the right side plate A. The number of the idler wheels is four, the four idler wheels include two universal wheels and two directional wheels, the two universal wheels are arranged at the front end of the first containing cavity, and the two directional wheels are arranged at the rear end of the first containing cavity. Through the efficient ground paving and levelling machine, the ground can be paved and leveled fast, the paving speed is high, the smoothness is good, and the efficient ground paving and levelling machine is particularly suitable for paving and levelling ground with floor tiles requiring to be laid. The efficient ground paving and levelling machine can be used for automatically plastering the back faces of the floor tiles and really shows the multiple functions.

Owner:冼日声

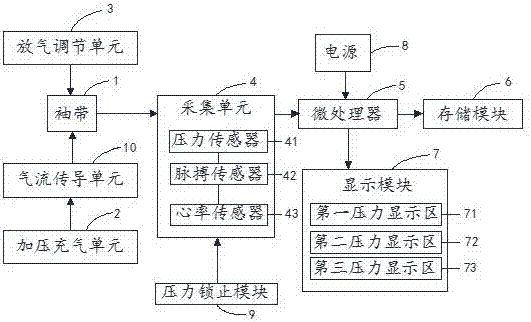

Sphygmomanometer

The invention discloses a sphygmomanometer. The sphygmomanometer comprises a cuff, a pressurizing and inflating unit, a deflating and adjusting unit, an acquiring unit, a storage module, a microprocessor, a power supply, a pressure locking module and a display module, wherein the acquiring unit comprises a pressure sensor and a pulse sensor, the pressure sensor is used for acquiring pressure in the cuff and transmitting a pressure signal to the microprocessor; the pulse sensor is used for detecting pulse wave and determining initial pressure of heartbeat every time; when the pressure locking module is pushed, the pressure sensor acquires an initial pressure value of the heartbeat at present; the microprocessor is used for transmitting initial pressure values, which are acquired by the pressure sensor, of pressure and heartbeat and transmitting the initial pressure values to the storage module; and a pressure value is calculated by analysis. By the sphygmomanometer, the pressure value can be accurately measured in an inflating and compressing process; by pressure locking and heart rate measurement, functions are powerful; the structure is simple; and the sphygmomanometer caters for detection habits of a user.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

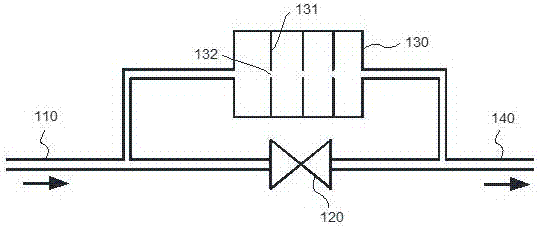

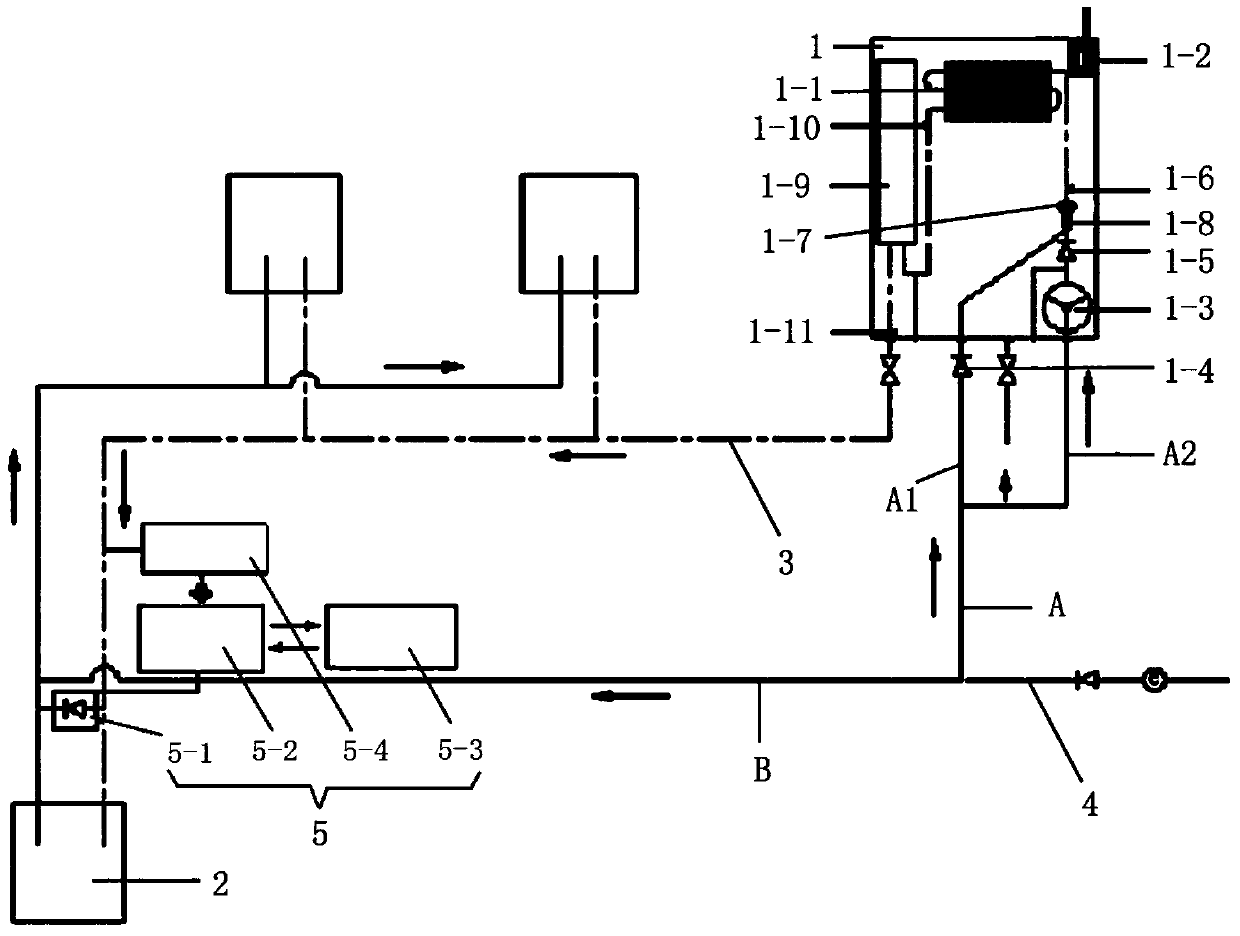

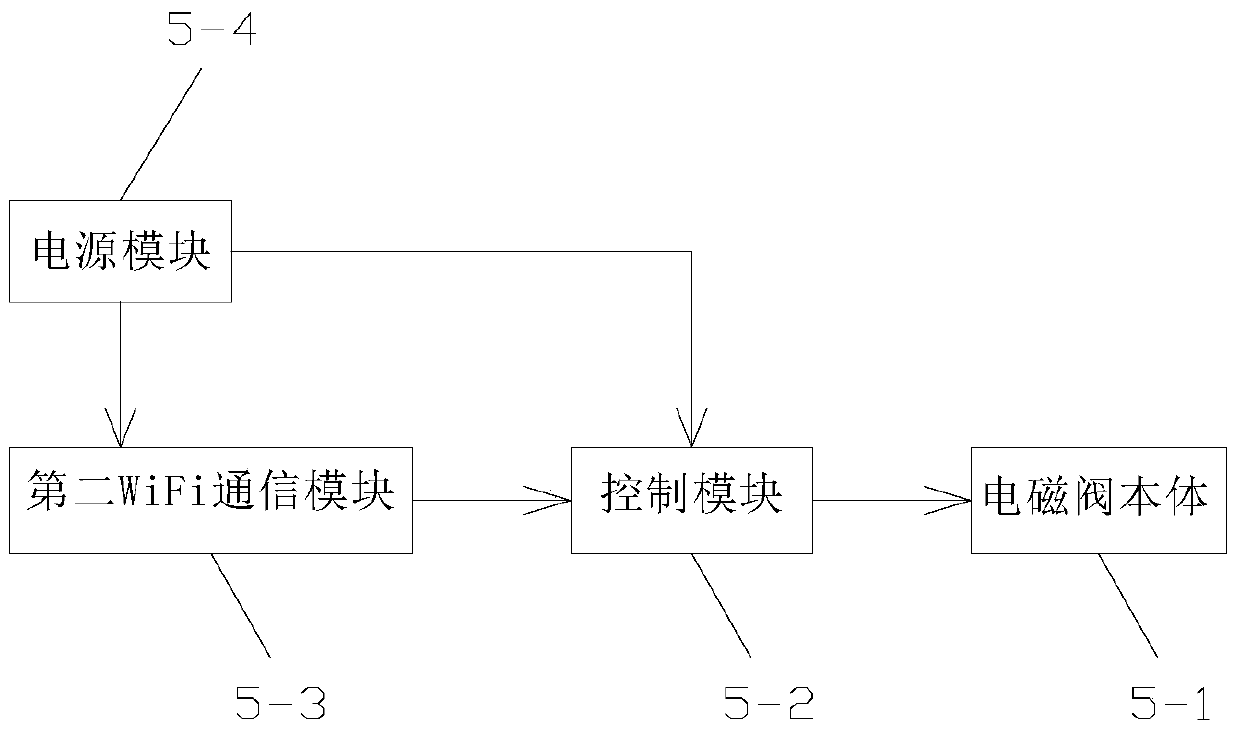

An instant-on and instant-heating gas water heater circulation pipeline control system

ActiveCN105805952BSolve the self-starting phenomenonEasy to useWater heatersControl systemWater flow

The invention discloses an instant heating gas water heater circulating pipeline control system. The system comprises a gas water heater body, a plurality of water consuming points, a hot water pipeline and a cold water pipeline. The cold water pipeline is divided into two paths A and B through a valve. The path A is connected with the gas water heater body to supply cold water to the gas water heater body. The path B is connected with the water consuming points to supply cold water to the water consuming points. The hot water pipeline is connected between the gas water heater body and the water consuming points to supply hot water to the water consuming points. The system is characterized in that an electronic control one-way valve is further arranged between the hot water pipeline at the farthest water consuming point and the path B of cold water pipeline; and when the electronic control one-way valve is turned on, water flows from the hot water pipeline to the path B of cold water pipeline. When the electronic control one-way valve is turned on, part of the cold water pipeline serves as a return water pipeline, and the instant heating function of the gas water heater is achieved. Fundamentally, the hot water pipeline and the cold water pipeline are relatively reliably independent, so that the problem that water heater self-starting caused by water utilization is thoroughly solved.

Owner:GUANGDONG MACRO GAS APPLIANCE

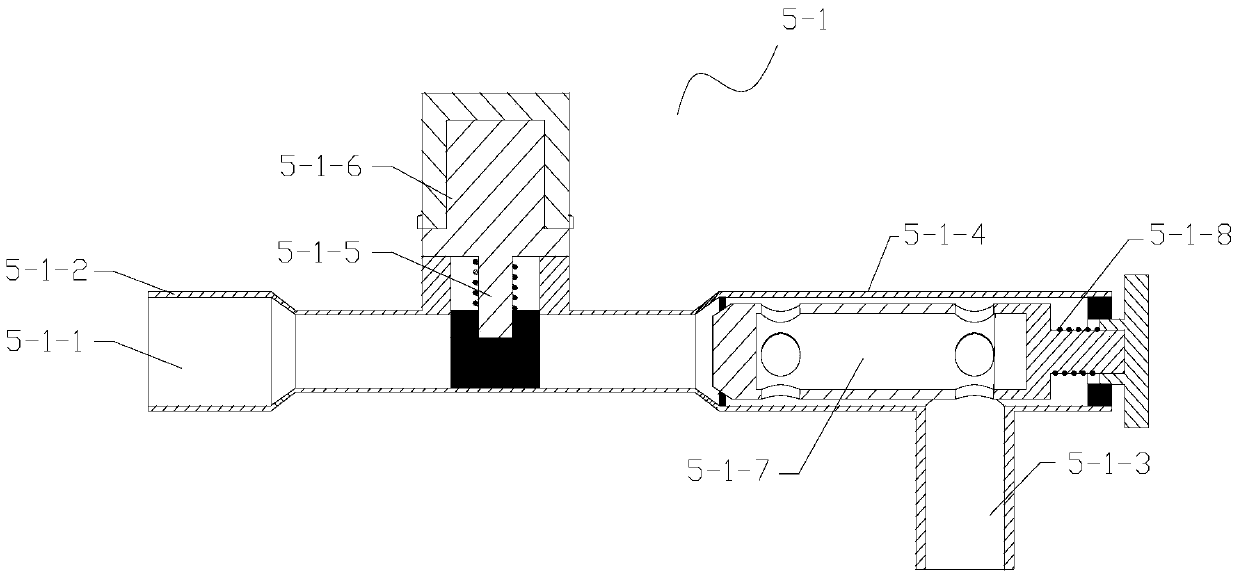

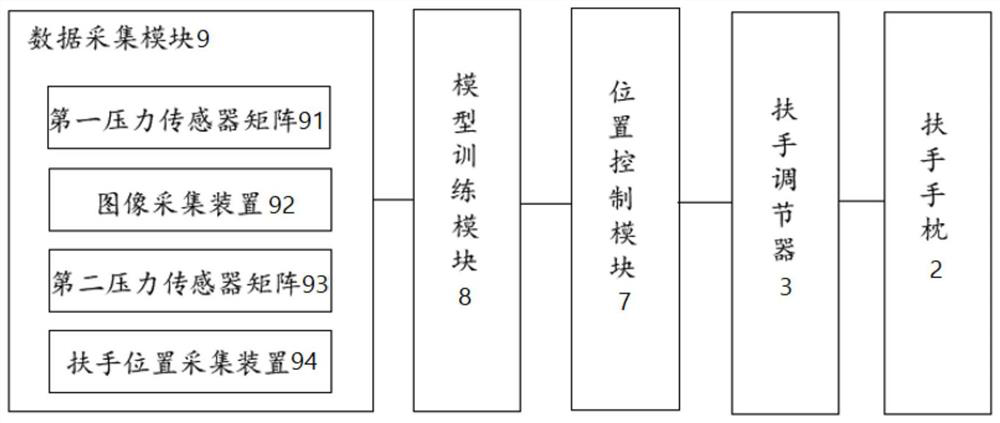

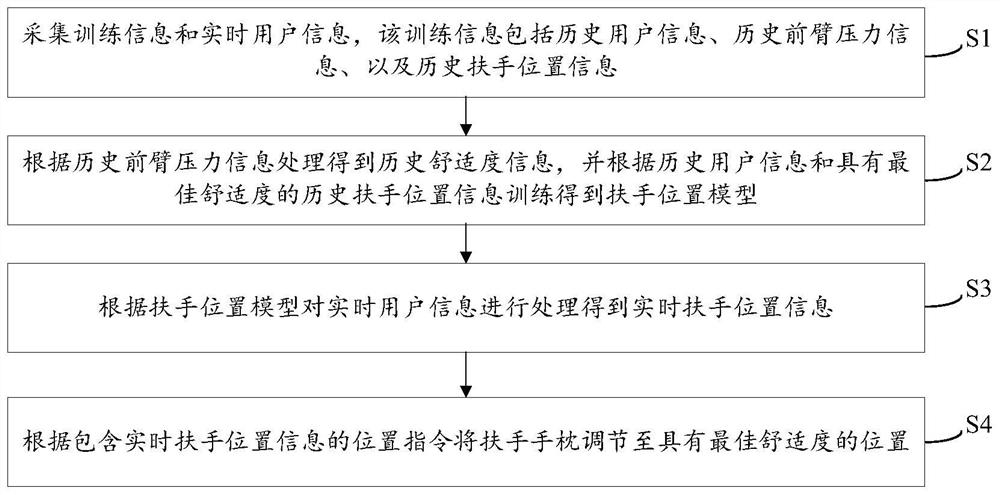

Automobile automatic armrest and armrest adjusting method

ActiveCN114043913AGood for healthEliminate fatigueArm restsElectric/fluid circuitPhysical medicine and rehabilitationDriver/operator

The invention discloses an automobile automatic armrest and an armrest adjusting method, and relates to the technical field of automobile armrests, and the method comprises the steps that a control device collects historical forearm pressure information, historical user information and historical armrest position information, and historical comfort information is obtained through processing according to the historical forearm pressure information; a handrail position model is obtained through training according to the historical user information and the historical handrail position information with the best comfort level, and the control device further collects real-time user information and inputs the real-time user information into the handrail position model to obtain real-time handrail position information; and an armrest adjuster adjusts the armrest hand pillow to the position with the best comfort degree according to the position instruction containing the real-time armrest position information, wherein the best comfort degree means that the attaching area of the forearm of the driver and the armrest hand pillow is the largest, and the pressure on the armrest hand pillow is the most uniform. The position of the armrest can be automatically adjusted according to different drivers, so that the most comfortable state can be achieved when the forearms of the different drivers are put on the armrest pillow.

Owner:DONGFENG MOTOR GRP

Production line for hypersonic flame aluminium powder fusion iron composite boards

InactiveCN102582156AGood iron binding abilityImprove bindingMolten spray coatingMetal layered productsProduction lineNonferrous metal

A production line for hypersonic flame aluminium powder fusion iron composite boards comprises an uncoiler, an inlet pinch, an inlet shear, a three-roller deviation rectifying machine, a detecting platform, an outlet shear, an outlet pinch and a recoiler, wherein the ncoiler, the inlet pinch and the inlet shear are arranged on an inlet portion of the production line; the three-roller deviation rectifying machine and the detecting platform are arranged on a processing portion of the production line; and the outlet shear, the outlet pinch and the recoiler are arranged on an oulet portion of the production line. The production line for hypersonic flame aluminium powder fusion iron composite boards is characterized by further comprising a hypersonic flame aluminium spraying coater, a cold rolling mill and an electrostatic oiler, wherein the hypersonic flame aluminium spraying coater is arranged behind the input shear, and the cold rolling mill is arranged behind the hypersonic flame aluminium spraying coater. The production line for hypersonic flame aluminium powder fusion iron composite boards solves the existing problems by providing a production line on which hypersonic flame spraying coaters are used for composition of aluminium powder on an iron plate so that non-ferrous metals in short supply are replaced with produced aluminium powder fusion iron composite boards, the consumption of valuable non-ferrous metals is reduced. The aluminium powder fusion iron composite boards have the advantages of being energy-saving, environment-friendly, and good in decorative effect, low in cost and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

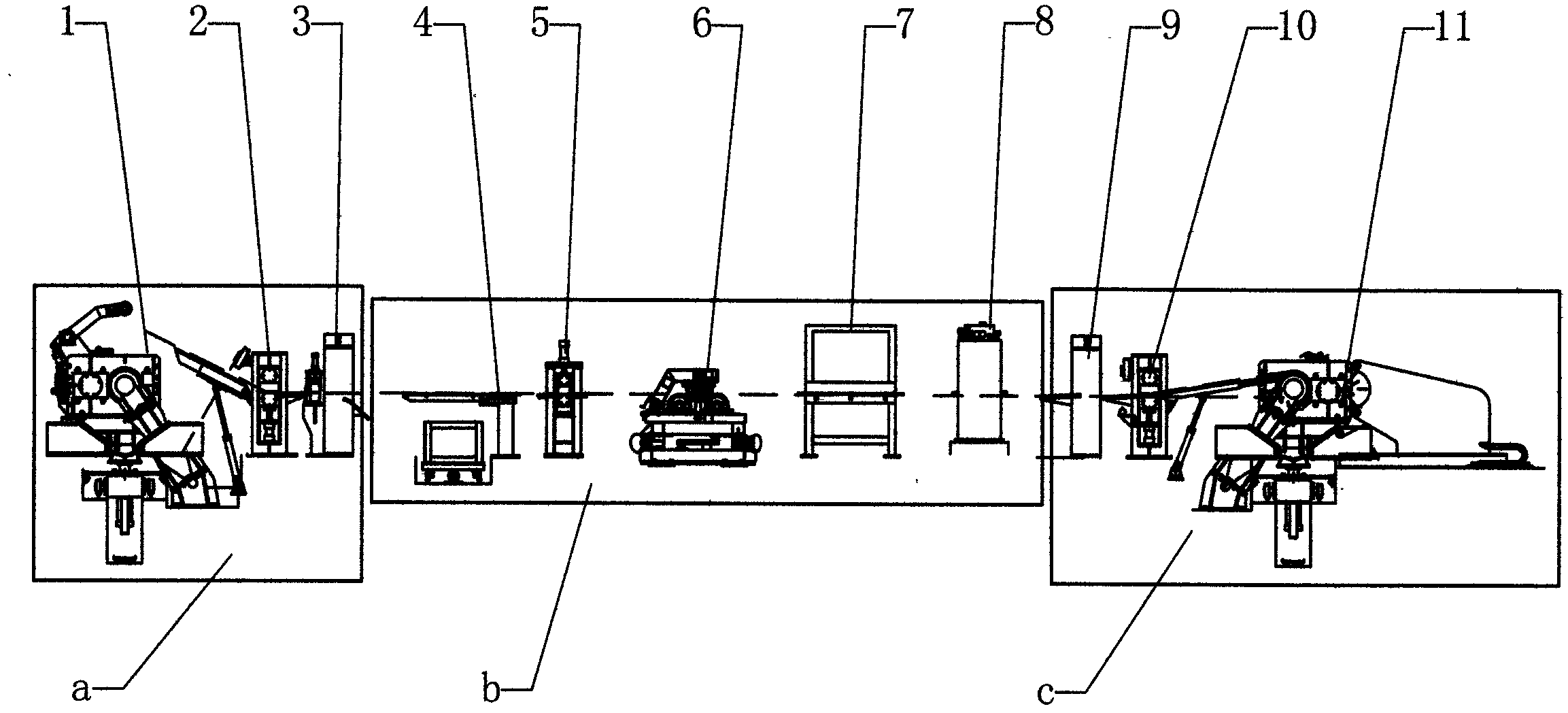

Automatically invisible water-saving closestool

InactiveCN101614037AIncrease activity spaceThe overall environment is simpleWater resource protectionWater closetsAutomatic controlControl function

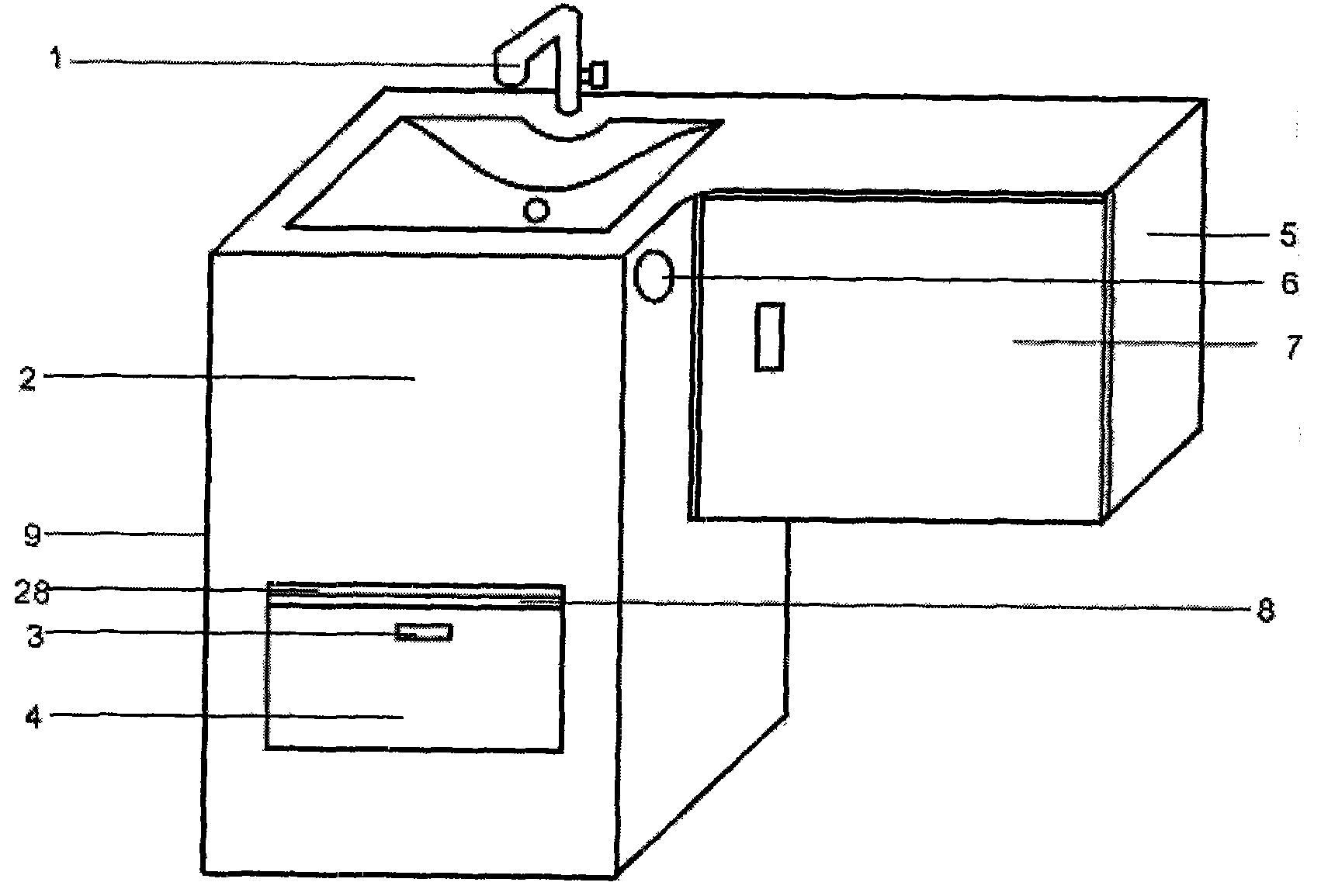

The invention relates to an automatically invisible water-saving closestool, comprising a body, wherein, a water tap and a water tank are installed on the body; a stool channel is installed in the body, is positioned under the water tank and is moveably connected with a hydraulic cylinder shaft in a hydraulic cylinder; acted by the hydraulic cylinder shaft, the stool channel is in withdrawable connection with the body; the hydraulic cylinder is connected with a hydraulic valve which is connected with a tap-water pipe, and a button with a control function is arranged on the hydraulic valve and is installed on the surface of the body; and a drain hole is arranged on a bottom plate of the water tank and is in seal connection with a flashing valve, a travel switch is fixedly connected at the lower end face of the bottom plate of the water tank and is connected with the flashing valve by a tightening wire, a travel strip is moveably connected on the travel switch, and a contact block is fixedly installed on the stool channel and contacts the travel strip on the position thereof. The closestool of the invention combines a washbasin with a closestool, the stool channel can be automatically invisible, and the closestool of the invention has the function of automatic flushing control, and is convenient, sanitary, water-saving and shapely.

Owner:彭明奎

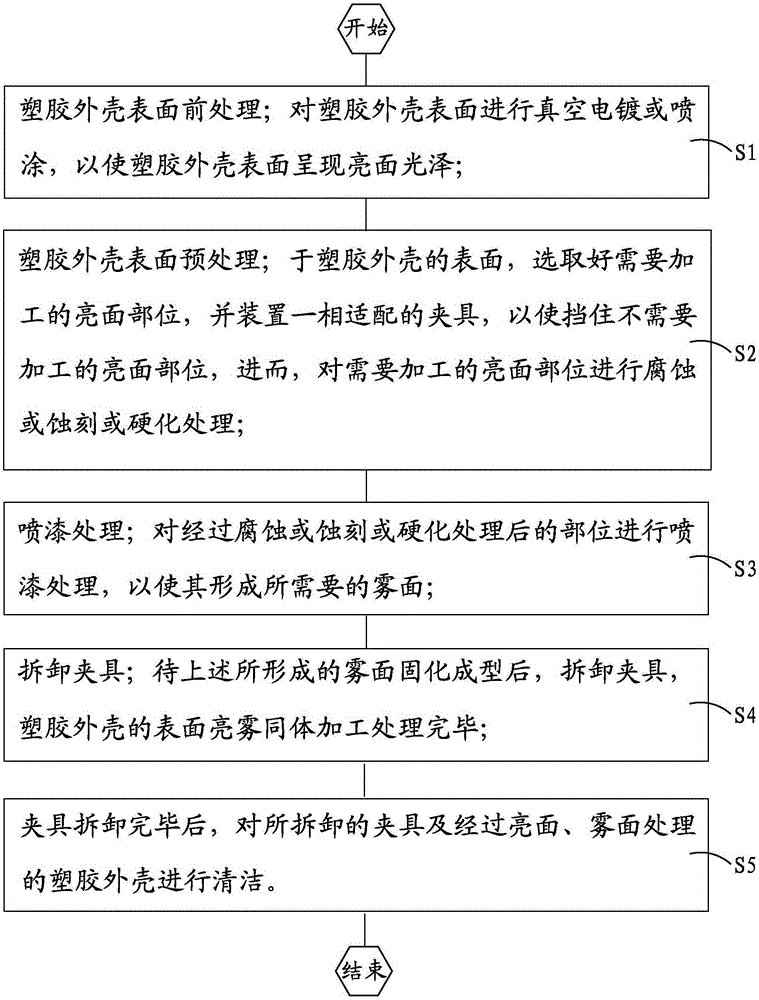

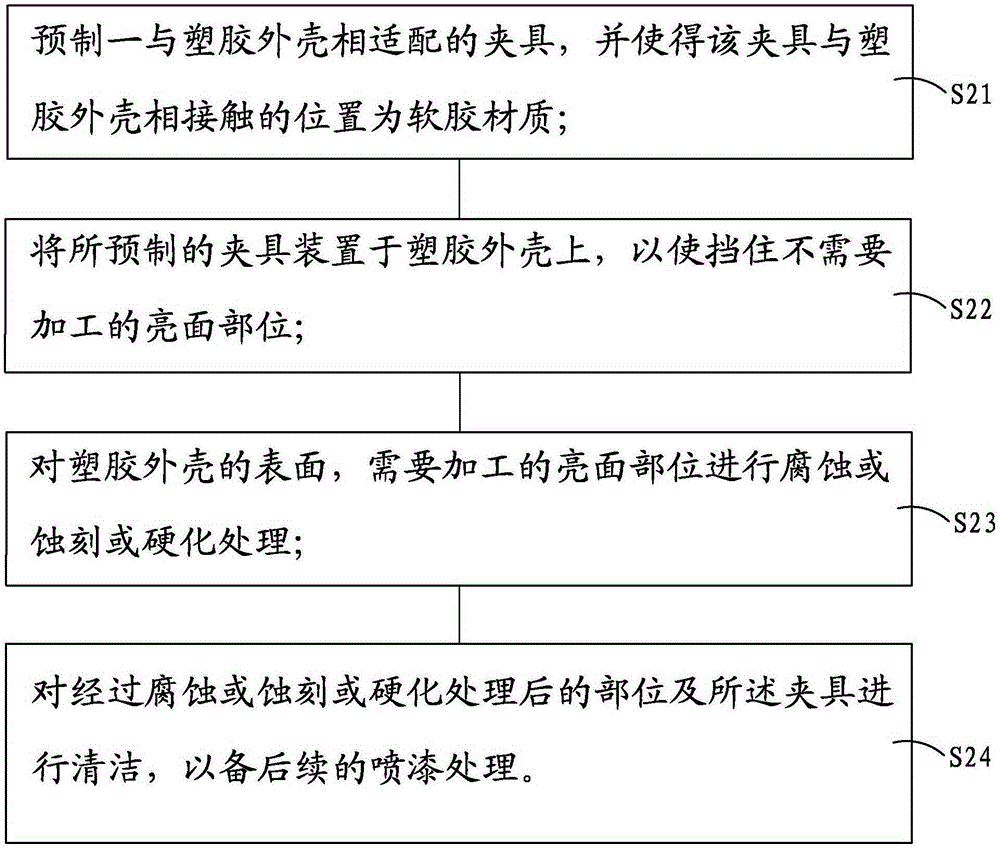

Realize the processing technology of bright fog on the surface of plastic shell

InactiveCN104014468BMeet the needs of the massesReduce manufacturing costSpecial surfacesCoatingsMechanical engineeringLight effects

The invention discloses a processing technique for realizing the homogeneity of bright fog on the surface of a plastic shell; it comprises the following steps: S1, pre-treating the surface of the plastic shell; performing vacuum electroplating or spraying on the surface of the plastic shell, so that the surface of the plastic shell presents bright gloss ; S2, surface pretreatment of the plastic shell; on the surface of the plastic shell, select the bright surface parts that need to be processed, and install a suitable fixture to block the bright surface parts that do not need to be processed, and then, the parts that need to be processed Corrosion, etching or hardening treatment on the bright surface; S3, painting treatment; painting treatment on the parts after corrosion, etching or hardening treatment; S4, dismantling the fixture; after the fog surface formed above is cured and formed, disassemble the fixture; The invention provides a processing technology for realizing the homogeneous bright mist on the surface of the plastic shell, so that the effect of homogeneous bright mist can also be realized on the surface of the plastic shell, and the processing technology is simple, the operation is quick and convenient, and the production cost is low.

Owner:POLIMAX BIODEGRADABLE PLANT FIBER MFG

Peony black tea

The present invention discloses peony black tea. The peony black tea is characterized by comprising the following raw materials in parts by weight: 60-100 parts of black tea, 10-20 parts of peony fragrant honey, 5-10 parts of strawberry fragrant honey, 5-10 parts of honey, 10-15 parts of sugar water and 120-180 parts of ice blocks. The manufactured peony black tea is low in costs and unique in flavor, has taste different from taste of existing fruit tea and can meet popularization demands.

Owner:龙里县泽洋生态科技有限公司

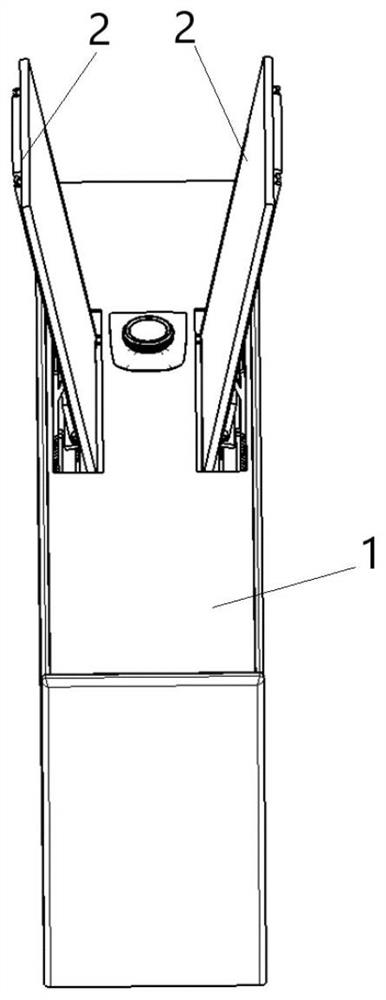

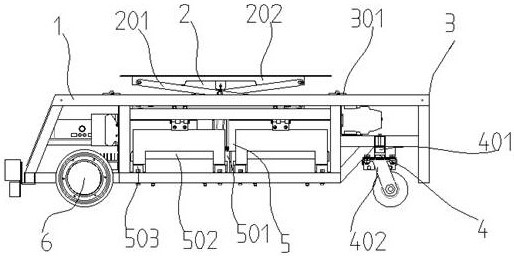

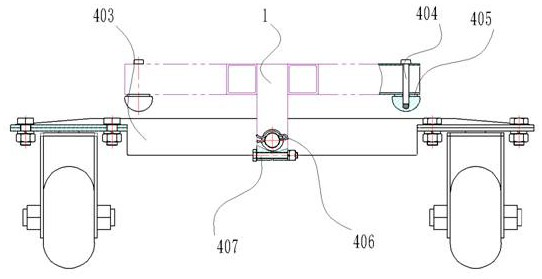

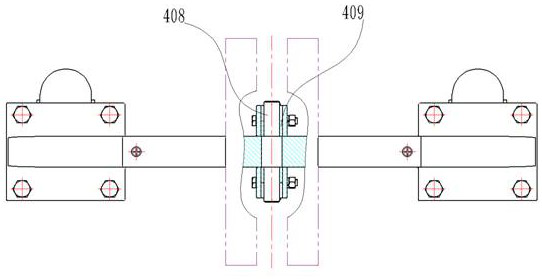

Special intelligent logistics vehicle for workshop

PendingCN113895246AGuaranteed to passSimple structurePropulsion by batteries/cellsElectric vehicle charging technologyVehicle frameSplit pin

The invention provides an intelligent logistics vehicle special for a workshop. The intelligent logistics vehicle comprises a vehicle frame, a lifting device, a vehicle shell, a rear axle assembly, a battery positioning device and a hub servo motor. The logistics vehicle is characterized in that the vehicle frame is formed by cutting and welding 30*30 square tubes. The lifting device is composed of a lower plate, a threaded shaft, a supporting rod, a sleeve, an electric push rod and an upper plate. The vehicle shell is composed of a main shell body, a front door, a rear door, a side door and hinges. The rear axle assembly is composed of rubber universal wheels, a rear axle, a rear axle hinge shaft, a sliding bearing, a limiting buffer block, a limiting adjusting screw, a limiting adjusting gasket and a spring cotter pin. The battery positioning device is composed of a roller strip, a baffle I and a baffle II. The hub servo motor is rigidly connected to the front portion of the vehicle frame, a battery bin and the lifting device are installed in the middle of the vehicle frame, and the rear axle assembly is hinged to the tail of the vehicle frame. The device solves the problems that an existing logistics vehicle special for a workshop is low in efficiency, large in turning radius and insufficient in trafficability.

Owner:HEBEI AGRICULTURAL UNIV.

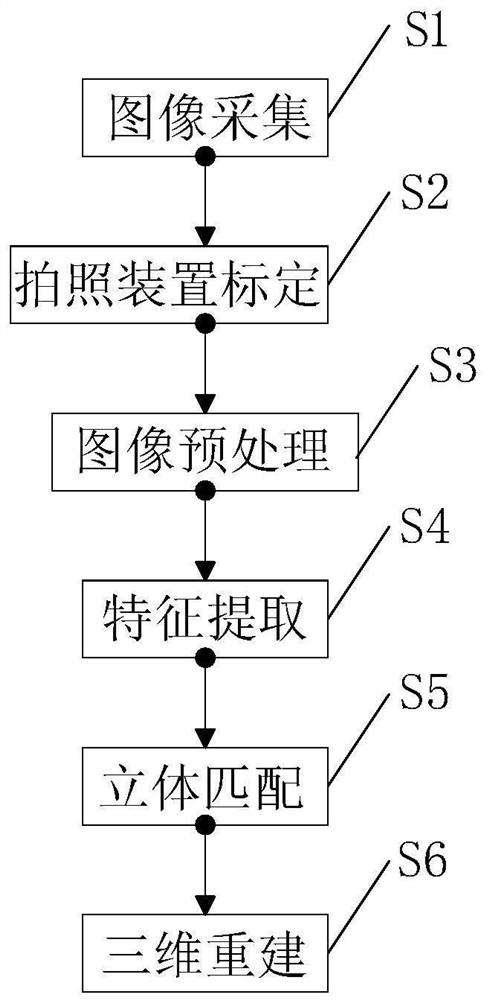

A 3D modeling method and system based on image sequence

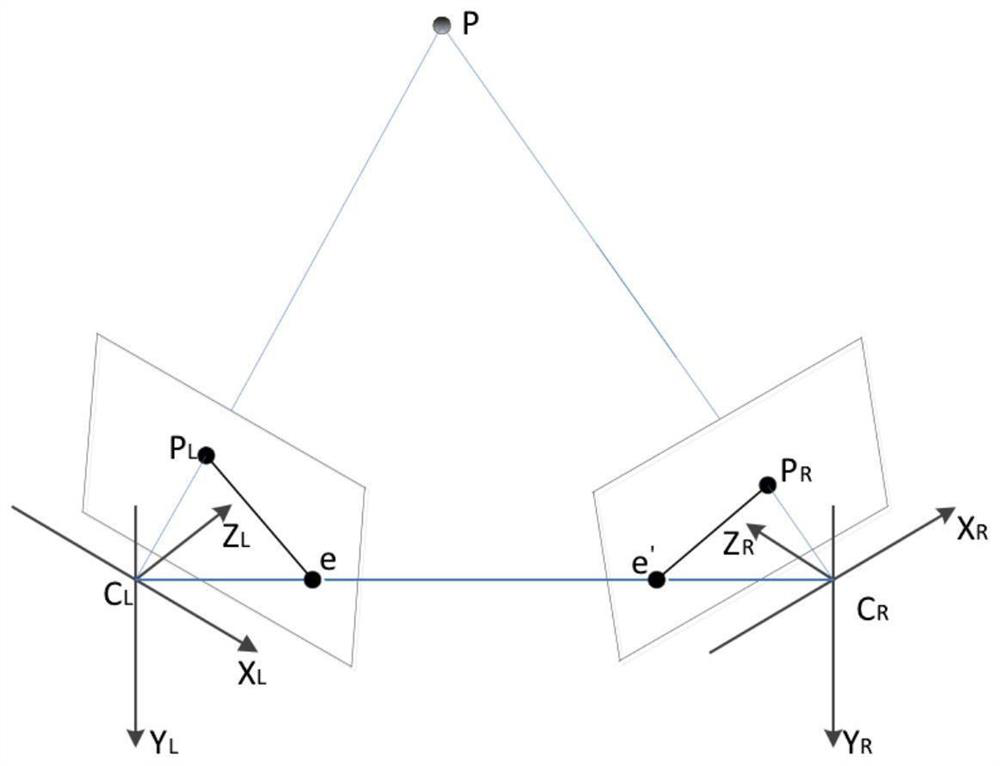

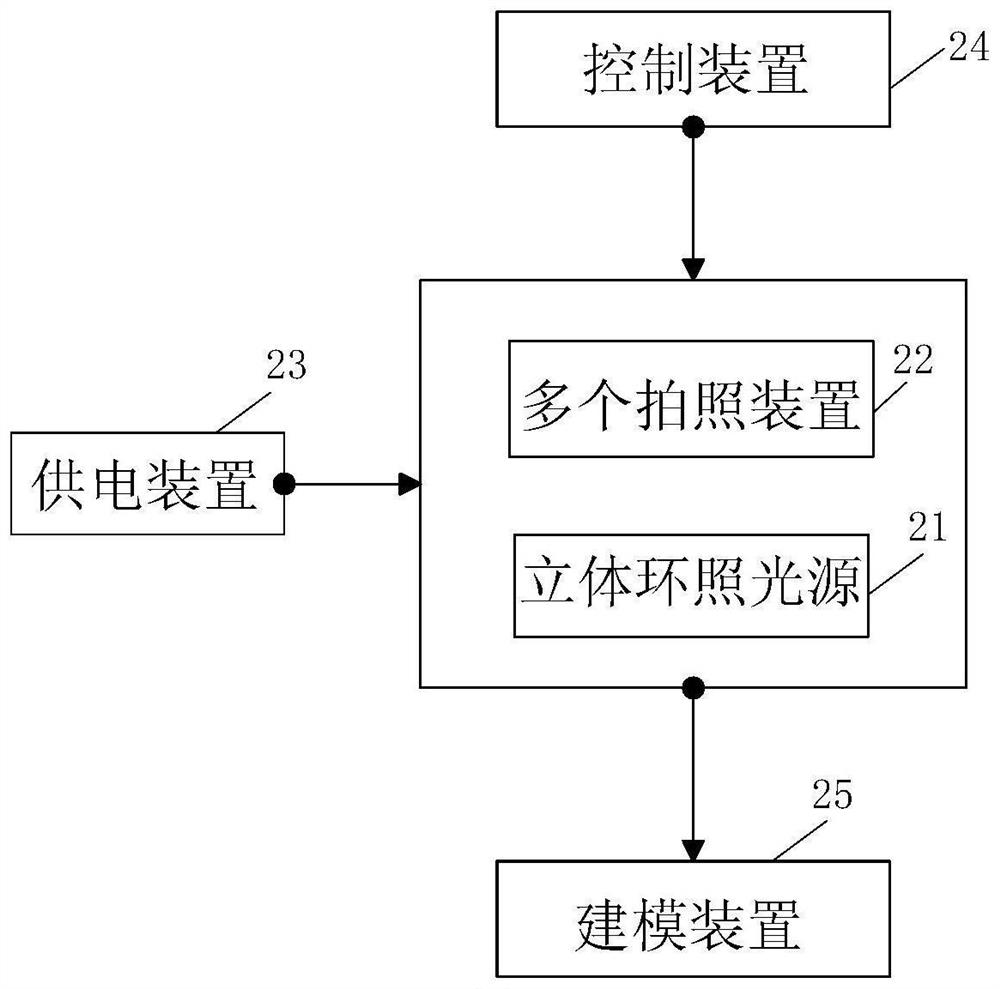

ActiveCN109242898BEasy to operateMeet the needs of the massesImage enhancementDetails involving processing stepsStereo matchingThree-dimensional space

Owner:FANTAWILD DIGITAL FILM

Automatically invisible water-saving closestool

InactiveCN101614037BIncrease activity spaceSimple environmentWater resource protectionWater closetsHydraulic cylinderWater saving

Owner:彭明奎

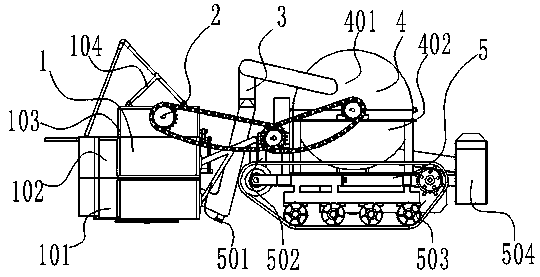

Raspberry stubble flattening and crushing integrated machine with special-shaped conveying rollers

PendingCN110149946AEffective involvementHigh stubble efficiencyPlant waste comminutingGearingCouplingAgricultural engineering

The invention provides a raspberry stubble flattening and crushing integrated machine with special-shaped conveying rollers. The machine comprises a stubble flattening device, a transmission system, an air duct device, a crushing device and a chassis, and is characterized in that the stubble flattening device consists of a lower shell chassis, a lower shell upper disc, an upper shell, a push rod,a circular saw disc, a bearing end cover, a left shaft, bearings, motors, a coupling, a crank, a connecting rod, a right shaft, a moving knife, a slideway, a fixed knife and special-shaped rollers, wherein the transmission system consists of cylindrical gears, bevel gears, shafts, chains, chain wheels, belts, belt wheels, crushing transmission frames and the like; the air duct device is connectedwith the stubble flattening device; the crushing device is connected with the tail end of the air duct device; the chassis is connected with the crushing device; the stubble flattening device is connected with a lever; and the tail end is connected with a collecting box. The device solves the problems of stubble flattening and crushing of picked raspberry branches.

Owner:HEBEI AGRICULTURAL UNIV.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com