Patents

Literature

90results about How to "Simple environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

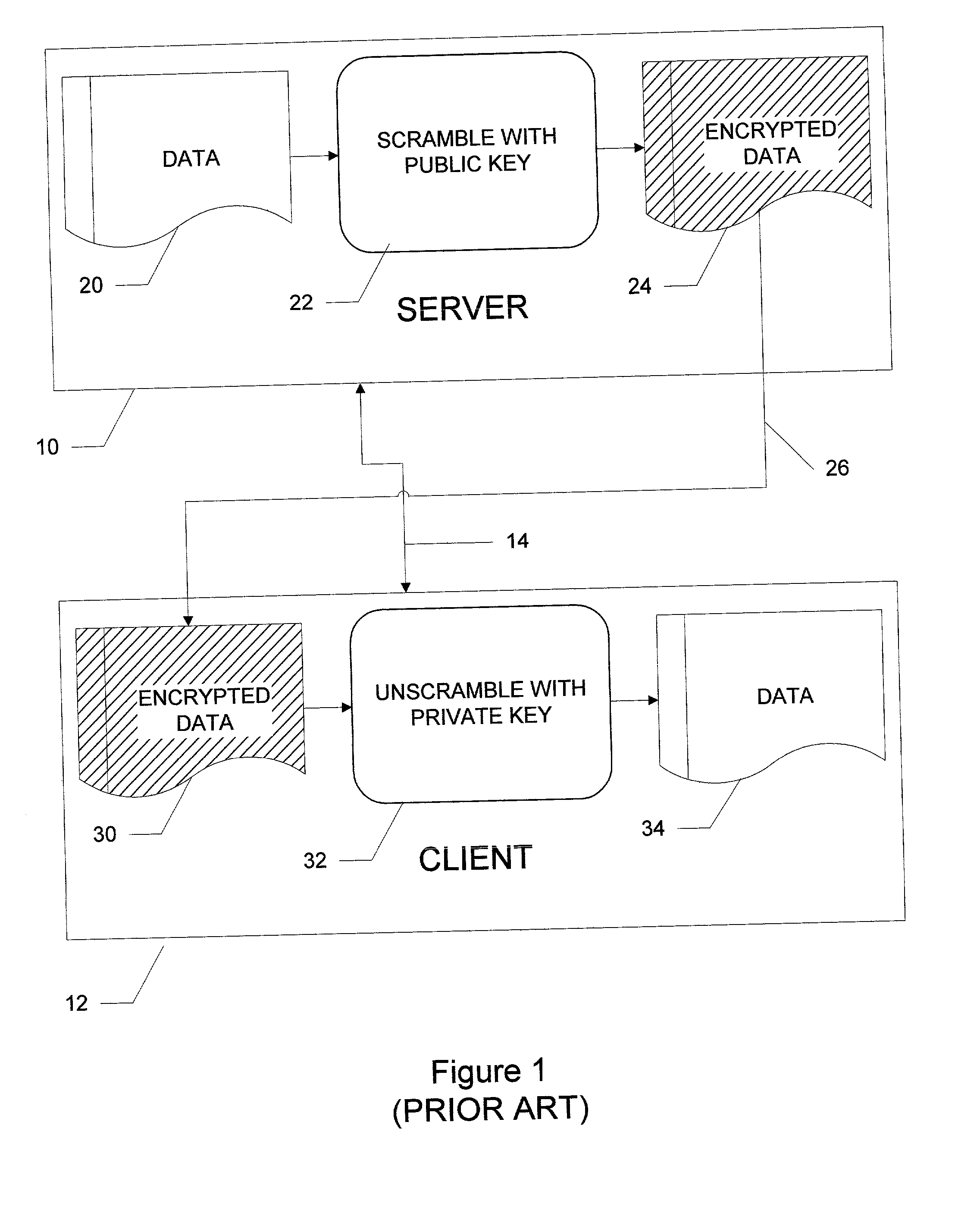

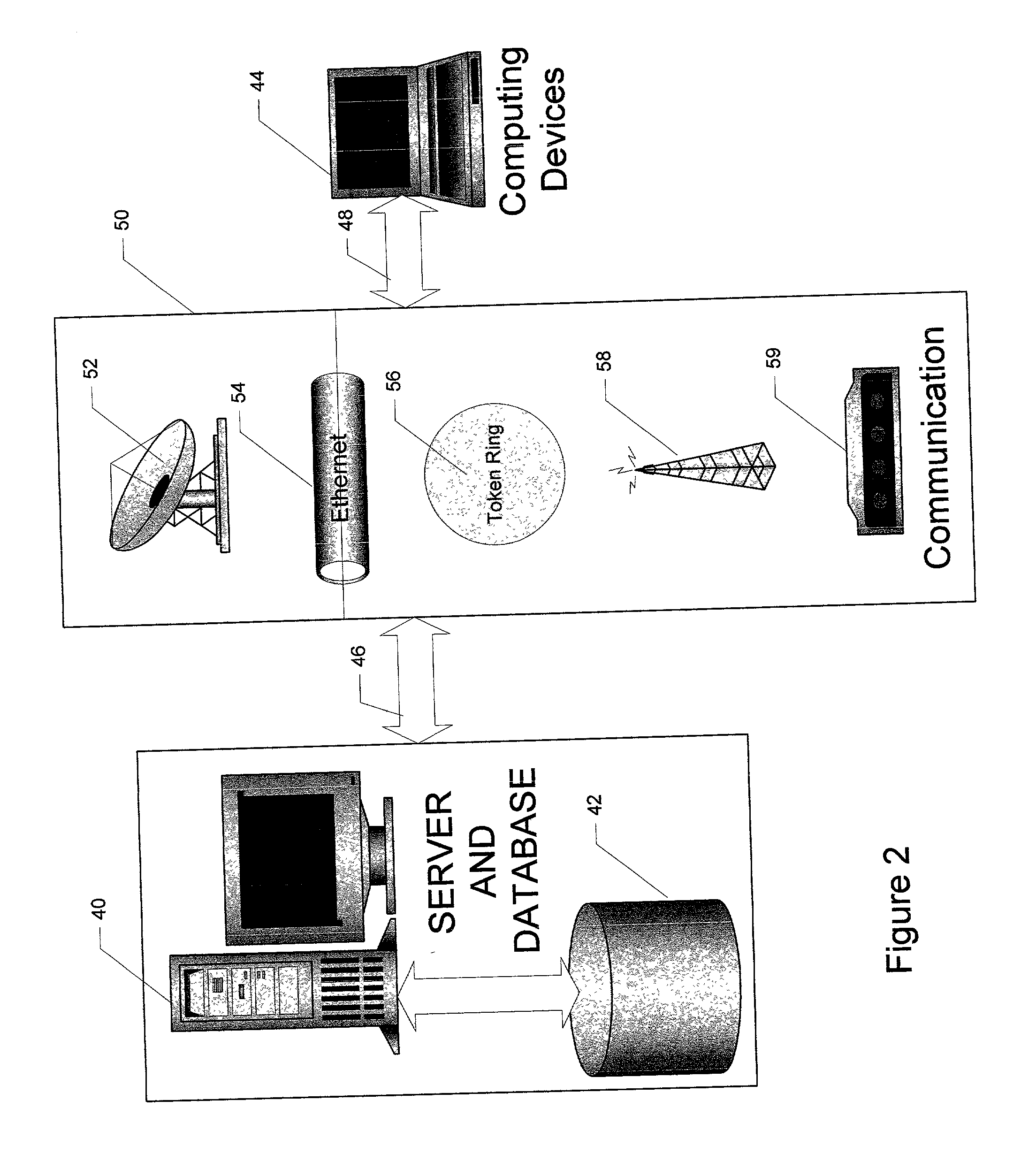

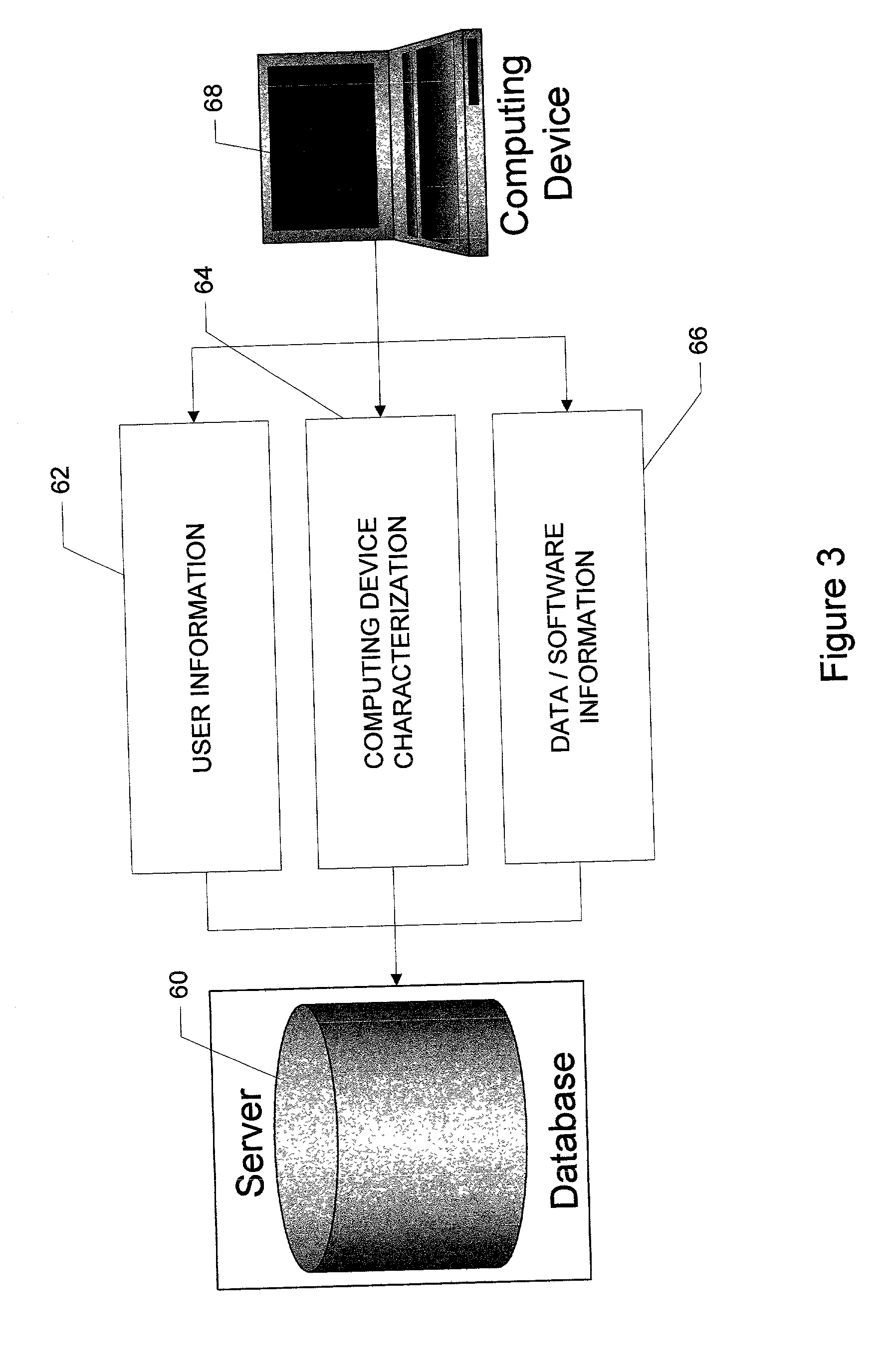

Digital data and software security protection

InactiveUS20010034846A1Prevents illegal installation and useAvoid installationDigital data processing detailsUnauthorized memory use protectionDigital dataIntellectual property

The present invention provides for a system method of preserving digital intellectual property data and software security utilizing a network by removing a random chunk of data from executable code and only delivering the proper chunk, size and location upon successful authentication of the user, the computing device environment and previous registration history.

Owner:BEERY PETER

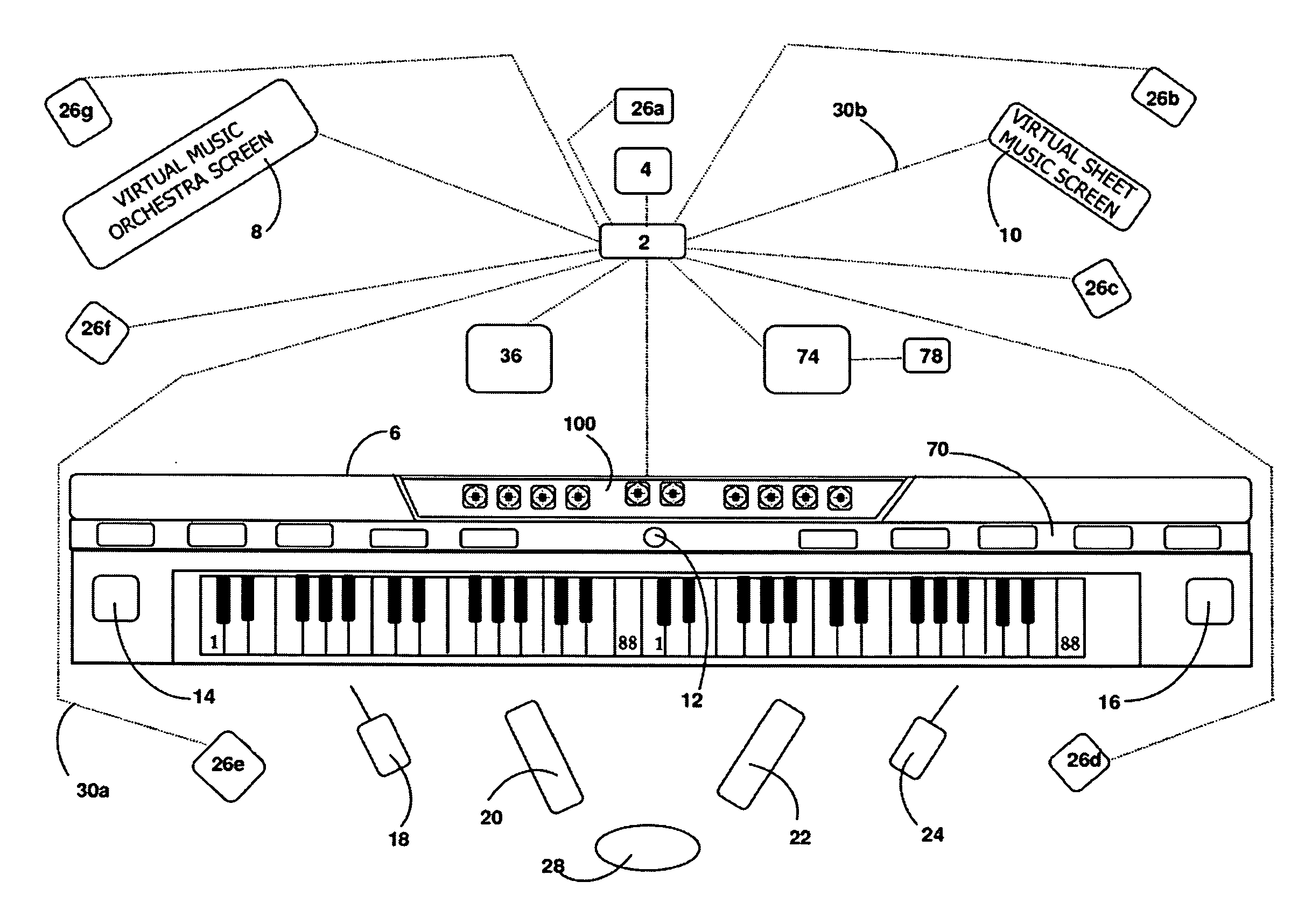

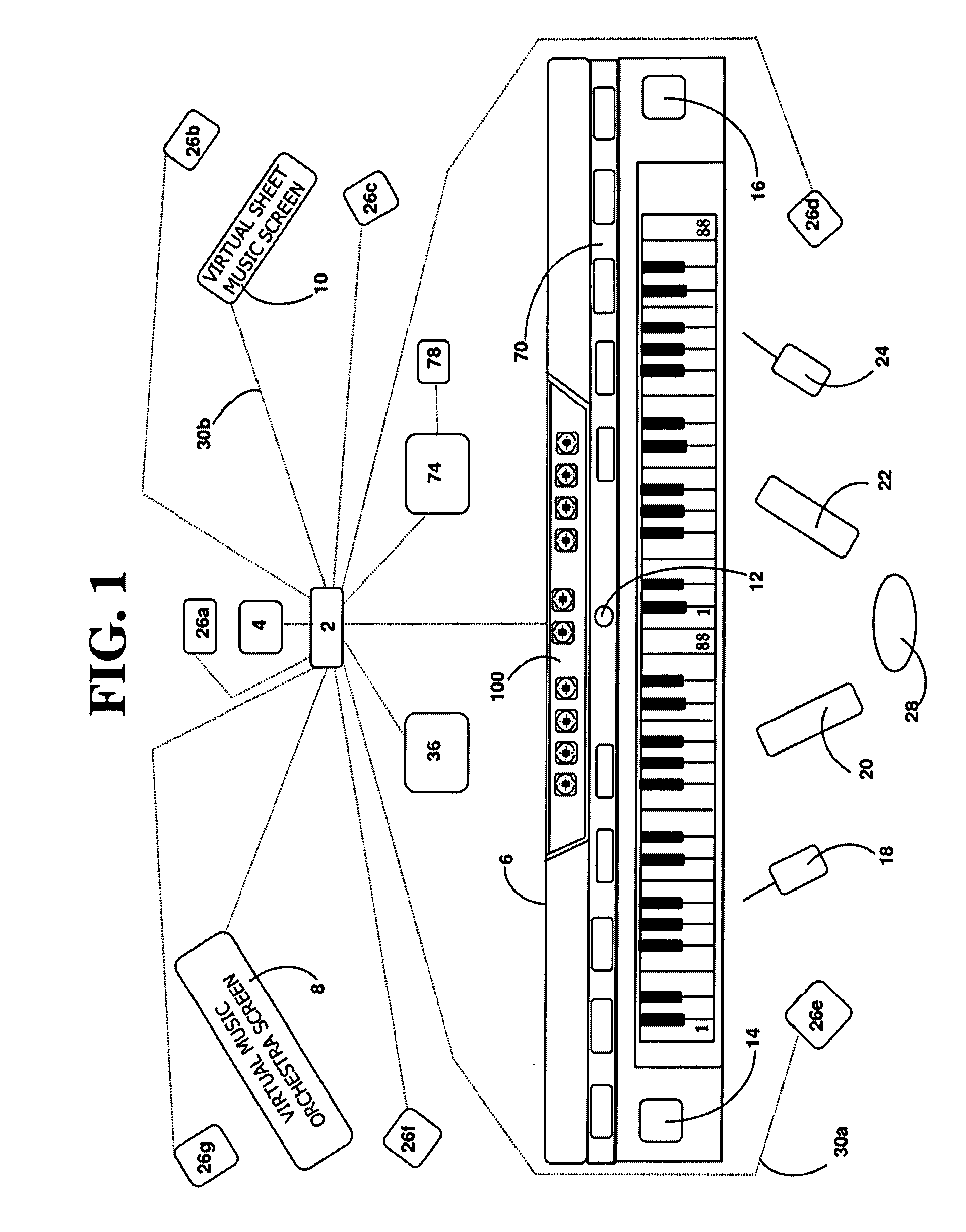

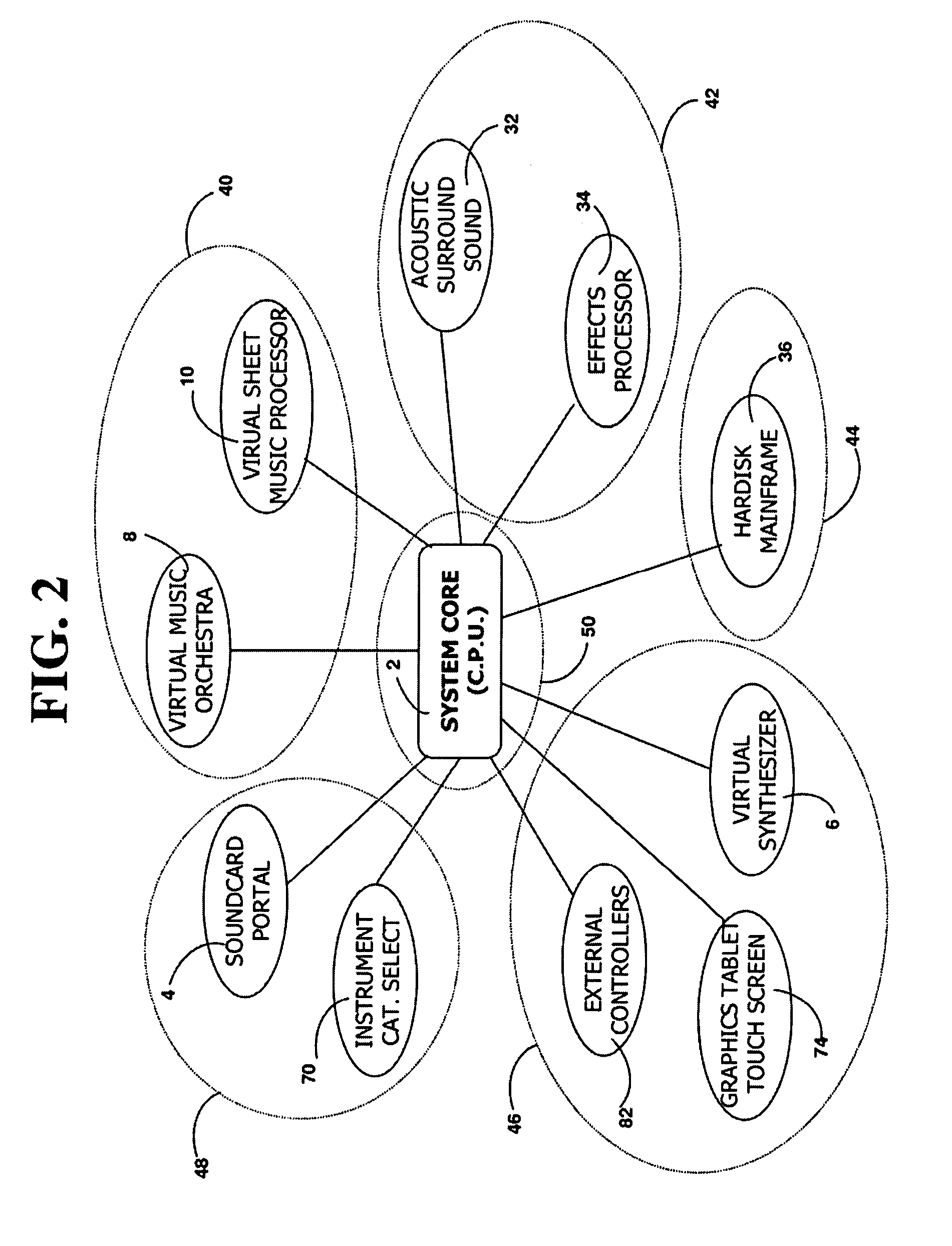

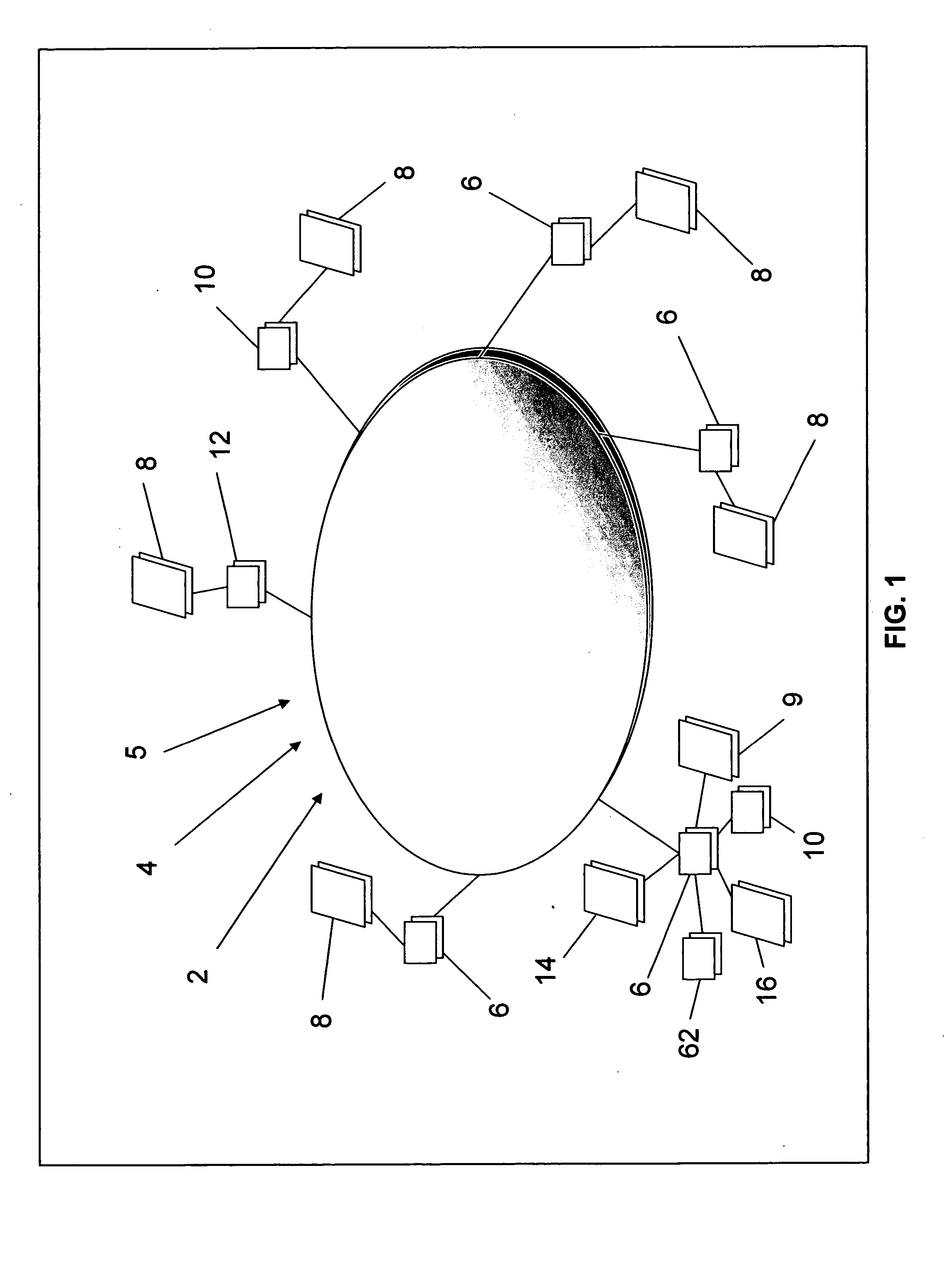

Virtual Reality Composer Platform System

InactiveUS20090114079A1Simple environmentElectrophonic musical instrumentsMusicInput/outputVirtual reality

A virtual reality composer platform and system (VRCPS) includes a plurality of user input / output devices and signal input / output controllers interfaced to a central processing unit complete with plurality of memory means, a butterfly morpheus musical instrument with plurality of manual input means each with a first unique visible indicia interfaced to said central processing unit, a plurality of finger adapters each with a second unique visible indicia donned on respective fingers and at least one custom butterfly morpheus music notation computer interface. The system is particularly suited for composing music for self-learning and teaching for all types of musical instruments for optimal virtual reality multimedia experience. The VRCPS platform and concepts disclosed are vari-dimensional acoustic environments, which are equally suited to all types of electronic learning and composing systems, game systems and computers. It is suitable for all levels of Do-It-Yourself learning from learning Beginners to Virtuoso Levels.

Owner:EGAN MARK PATRICK

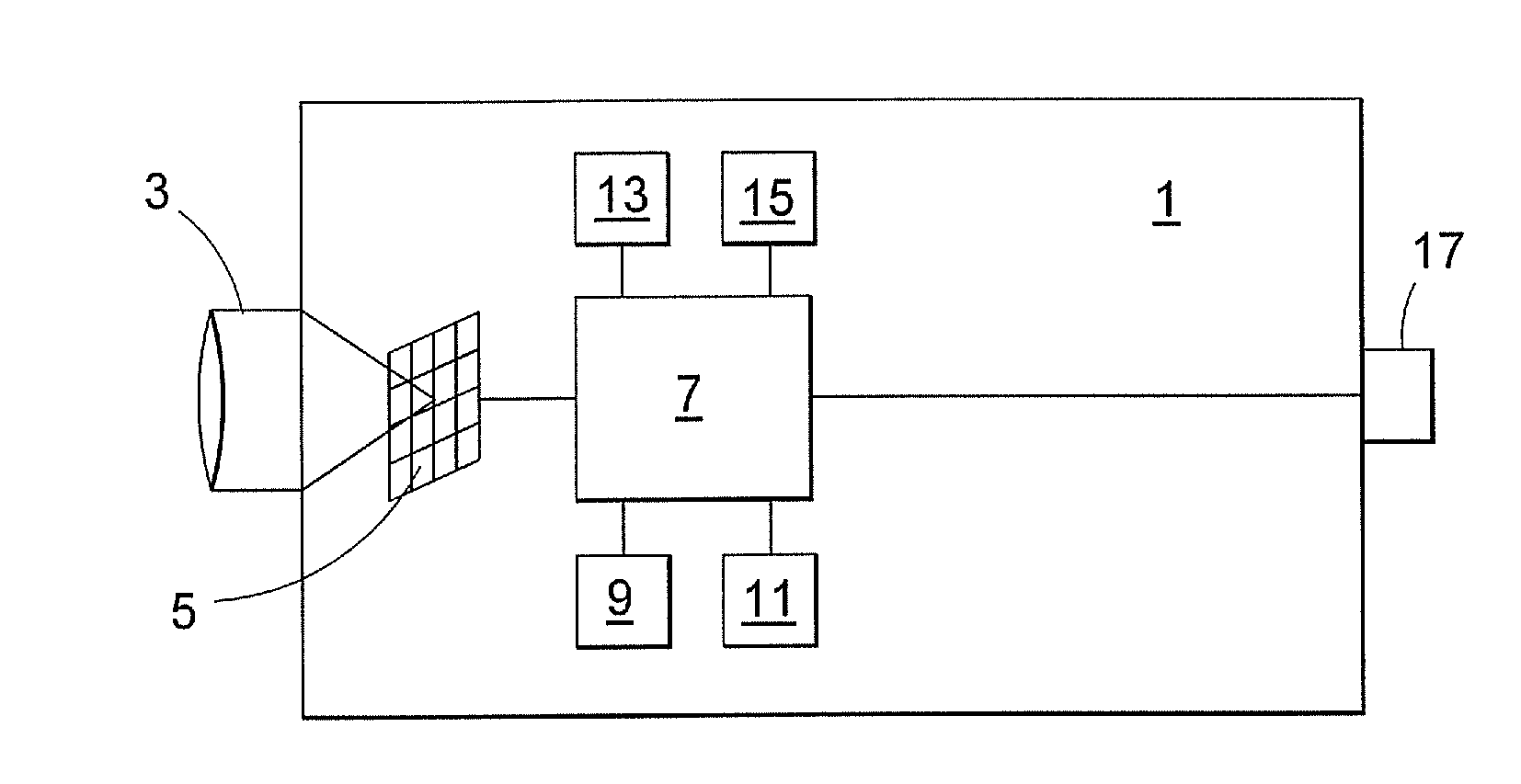

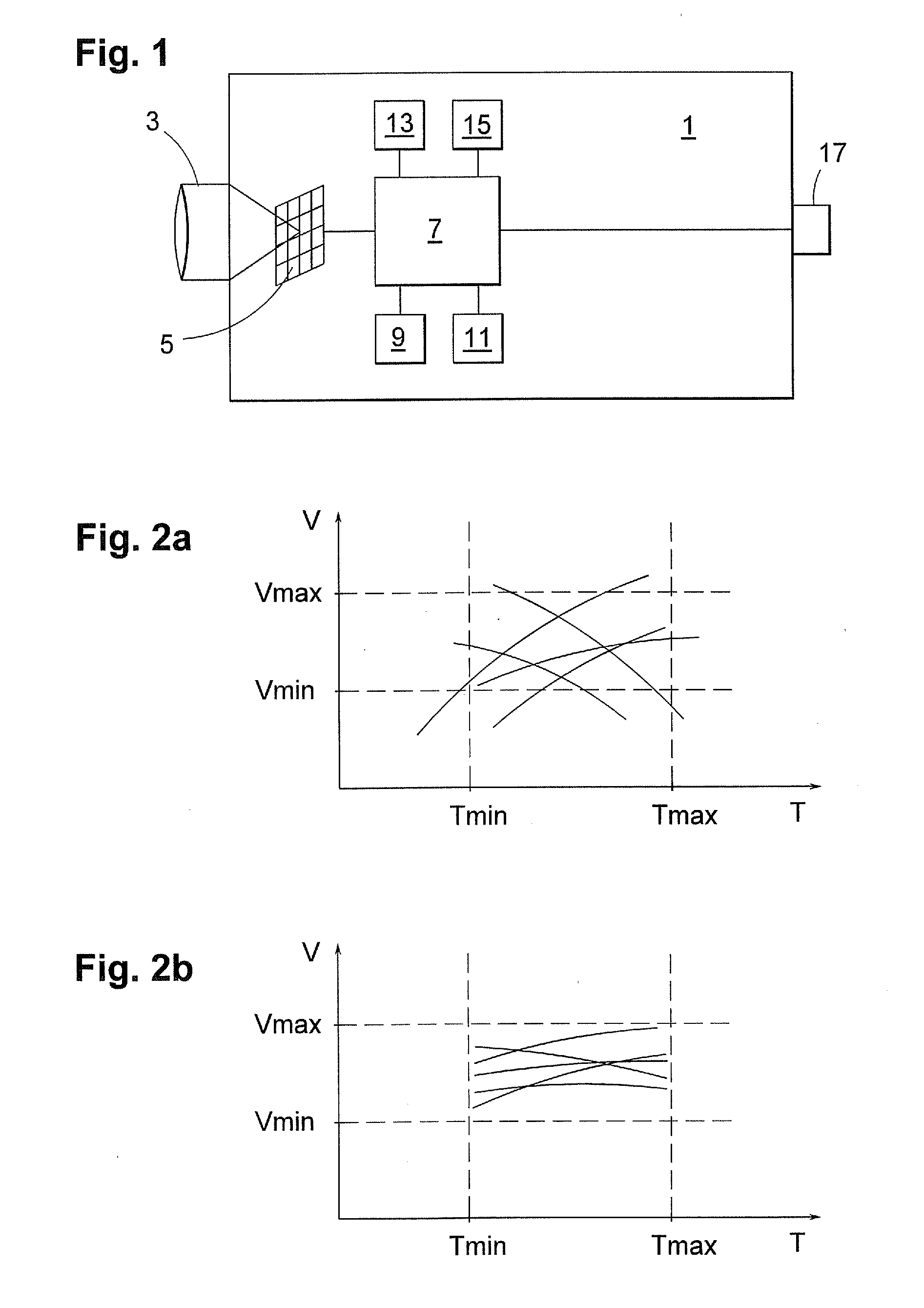

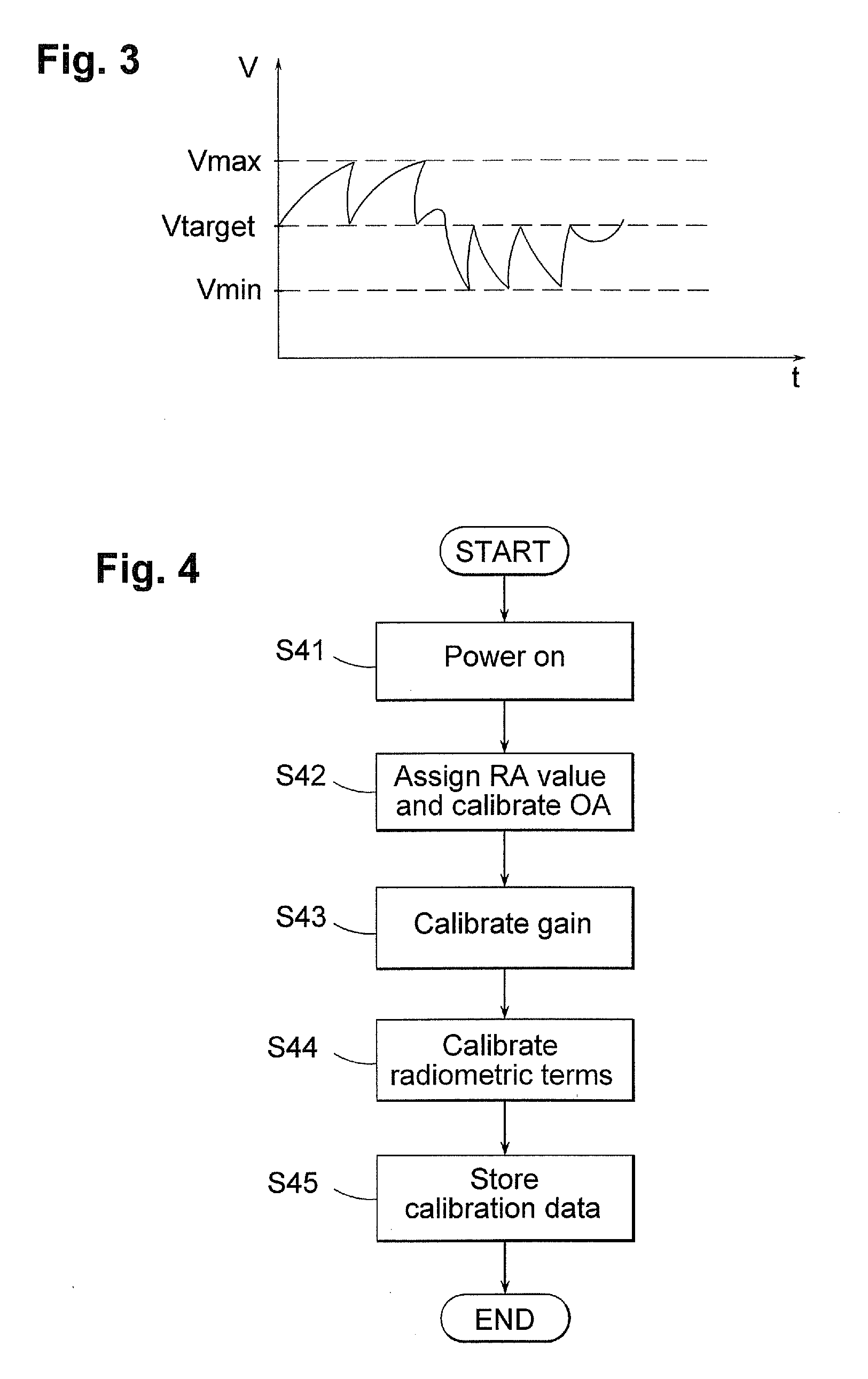

Ir camera and method for use with ir camera

InactiveUS20090273675A1Simple manufacturing processFocal plane array stableTelevision system detailsColor television detailsComputer scienceIr camera

An infrared camera is arranged to compensate for temperature variations of the camera byRecording the output signal of each pixel of the detector during a shutter operation Using the recorded signal from each pixel to update a temperature offset map stored in the camera to ensure uniform signal levels at different camera temperatures, Said code means being arranged to perform the following steps during operation of the camera:save at least a first temperature offset map during a first shutter operation at a first temperature and a second temperature offset map during a second shutter operation at a second temperaturefit the data from the at least first and second offset maps to a curveusing the curve to compensate for variations in signal output caused by temperature variations.

Owner:FLIR SYST AB

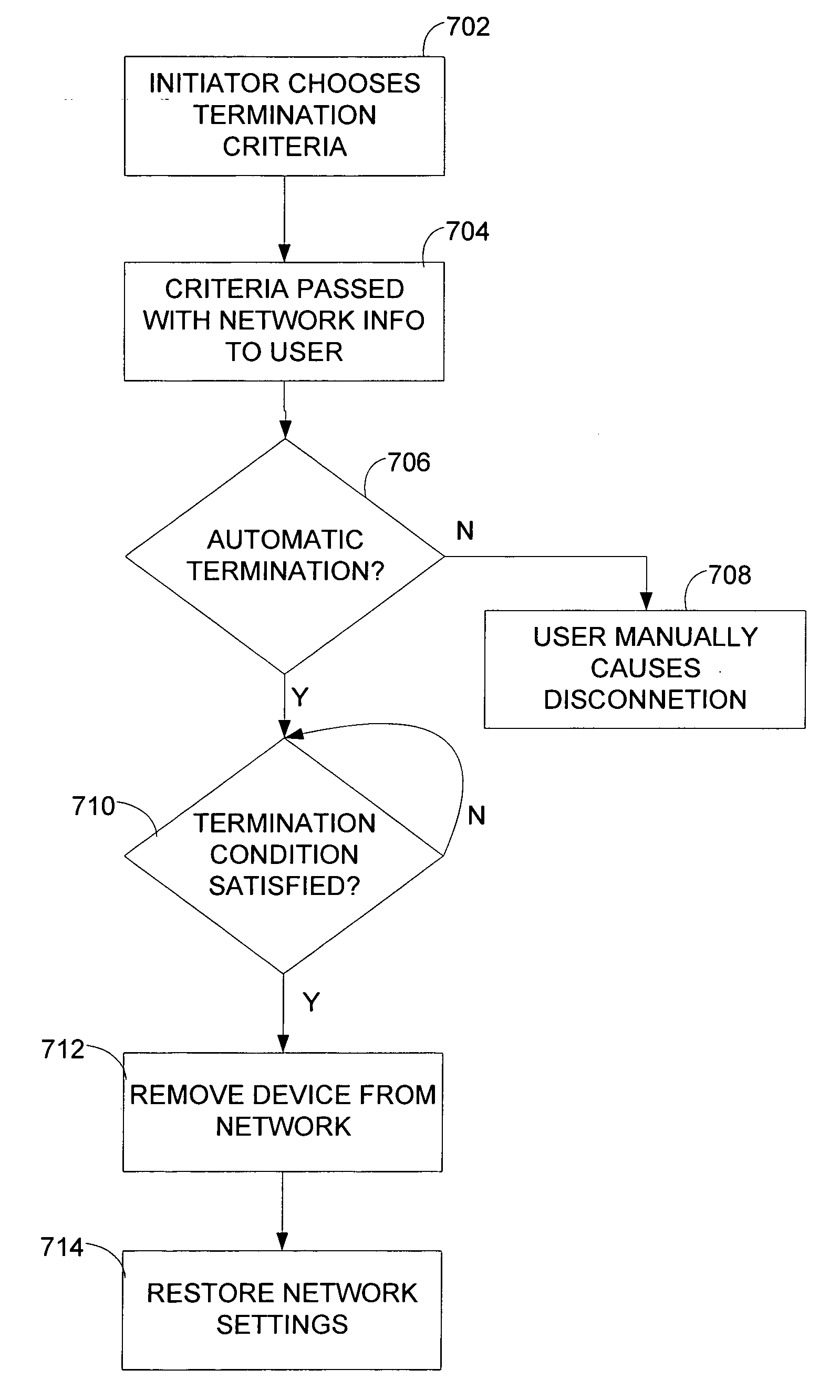

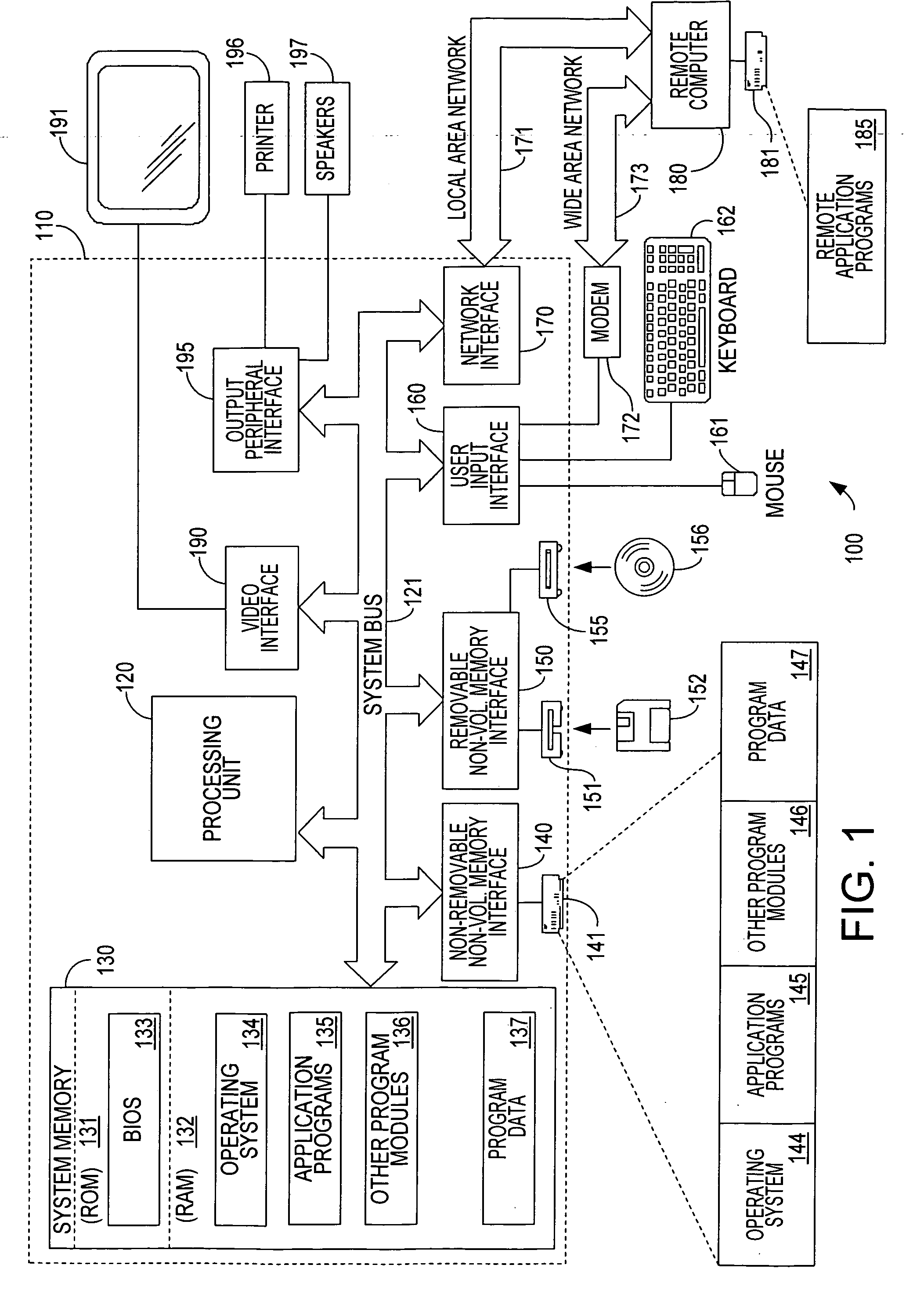

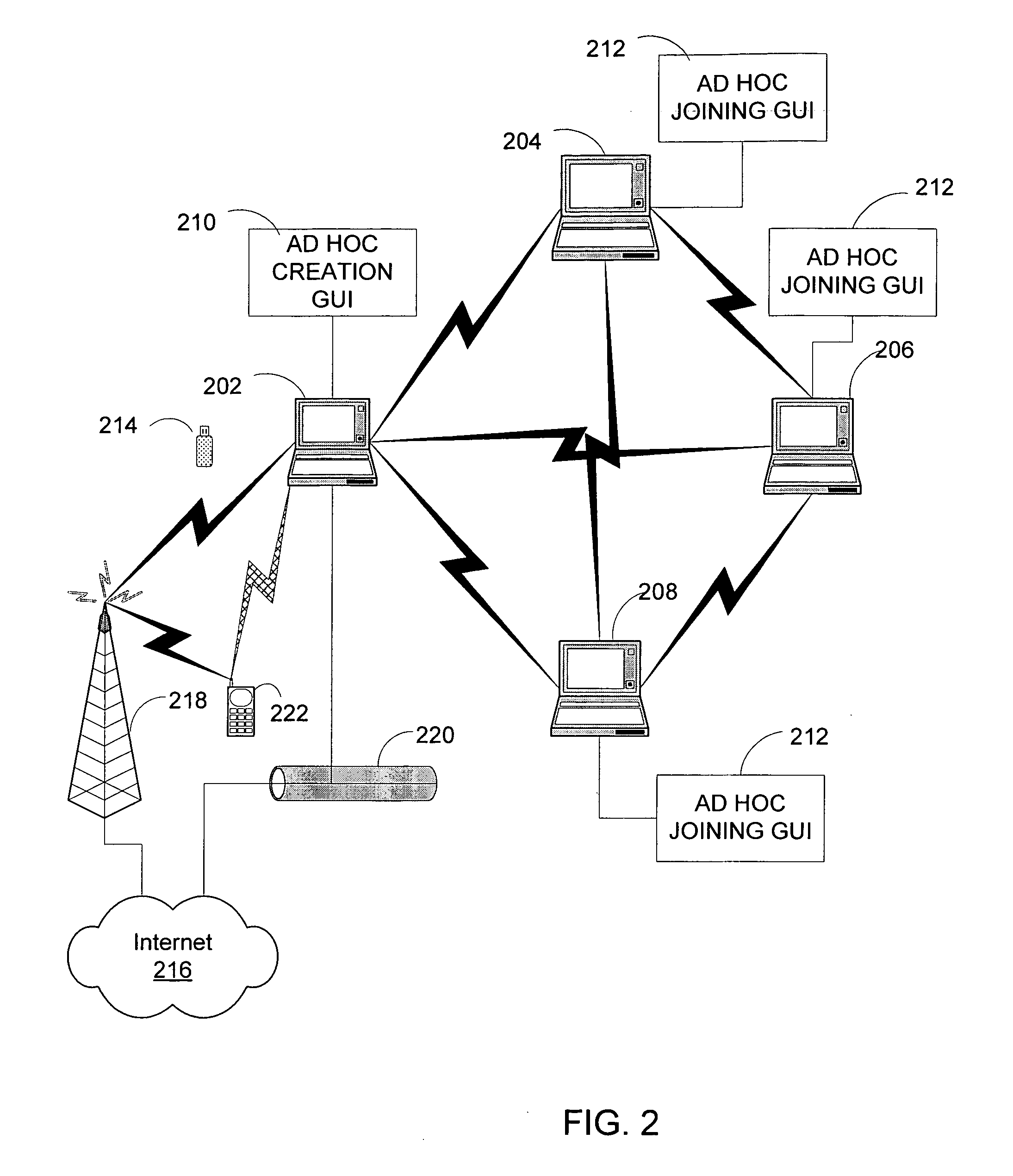

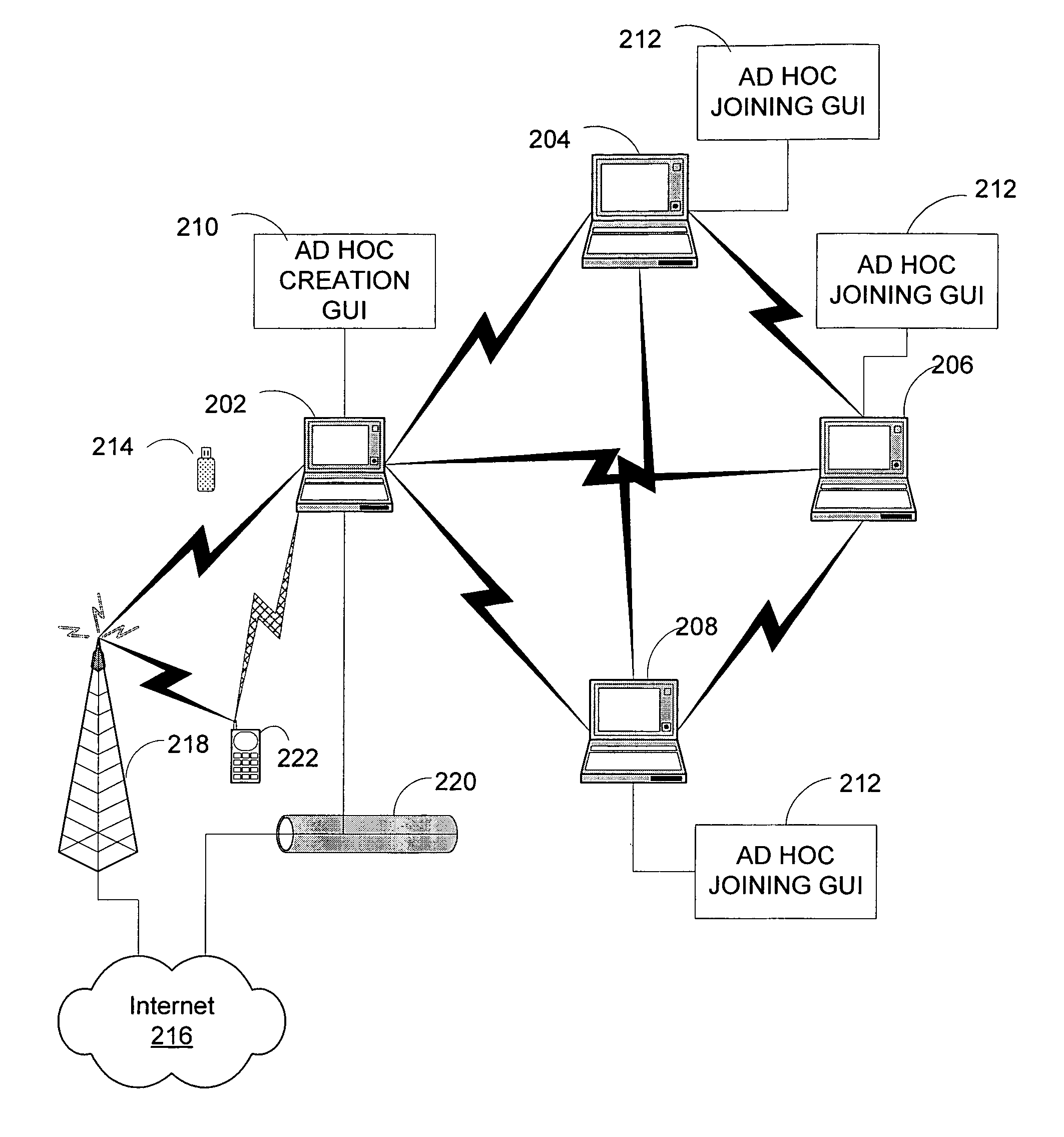

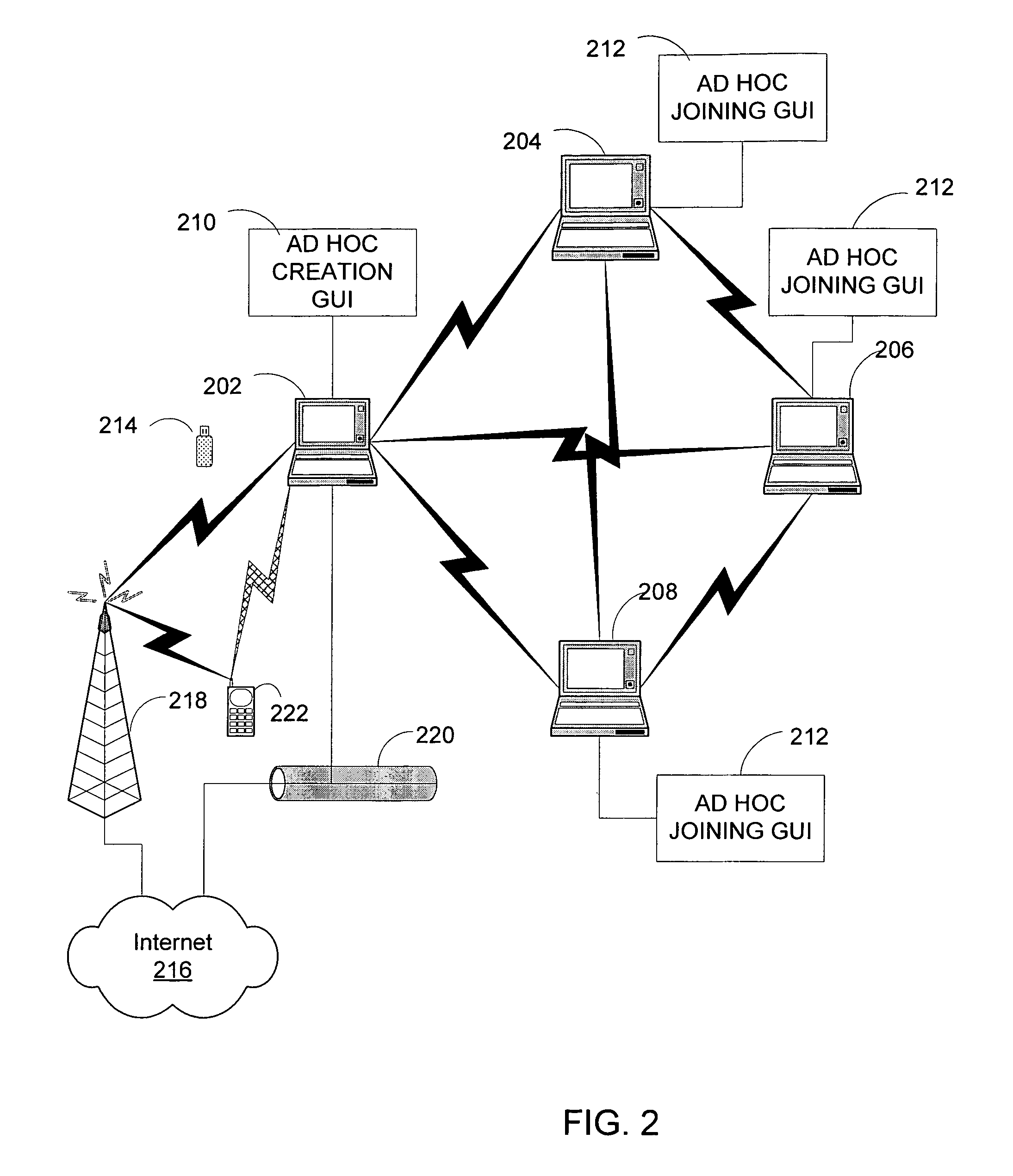

Simplified creation and termination of an ad hoc wireless network with internet connection sharing

ActiveUS20060221915A1Easily create and maintain ad hoc networkQuick SetupNetwork topologiesData switching by path configurationGraphicsGraphical user interface

Methods and systems are described for simplified creation of, connection to, and termination from an ad hoc wireless network. Graphical user interfaces are used to guide users though creation and joining ad hoc network. The option to share one user's Internet connection with the entire ad hoc network is also described. The ad hoc networks described can provide some managed services traditionally unavailable in ad hoc networks, such as IP address assignment and name resolution services. The ad hoc networks can be created with termination criteria, such that a computer's connection to the ad hoc network is automatically terminated and previous network configuration settings are restored when one or a combination of termination criteria are met.

Owner:MICROSOFT TECH LICENSING LLC

Spray dried emulsifier compositions, methods for their preparation, and their use in oil-based drilling fluid compositions

ActiveUS20070167333A1Reduce transportation costReduce shipping costsTransportation and packagingFluid removalSolventChemistry

Spray dried emulsifier compositions are described, which have desirable emulsifying and wetting characteristics. Among other advantages, the solid particulate emulsifier compositions greatly reduce transportation costs and simplify the logistics and environmental concerns associated with shipping large volumes of solvent-containing liquids. The emulsifier comprises (1) a carboxylic acid terminated fatty amine condensate or (2) a modified tall oil or (3) a blend of (1) and (2) that is converted to its alkali or alkaline earth metal salt and spray dried.

Owner:INGEVITY SOUTH CAROLINA

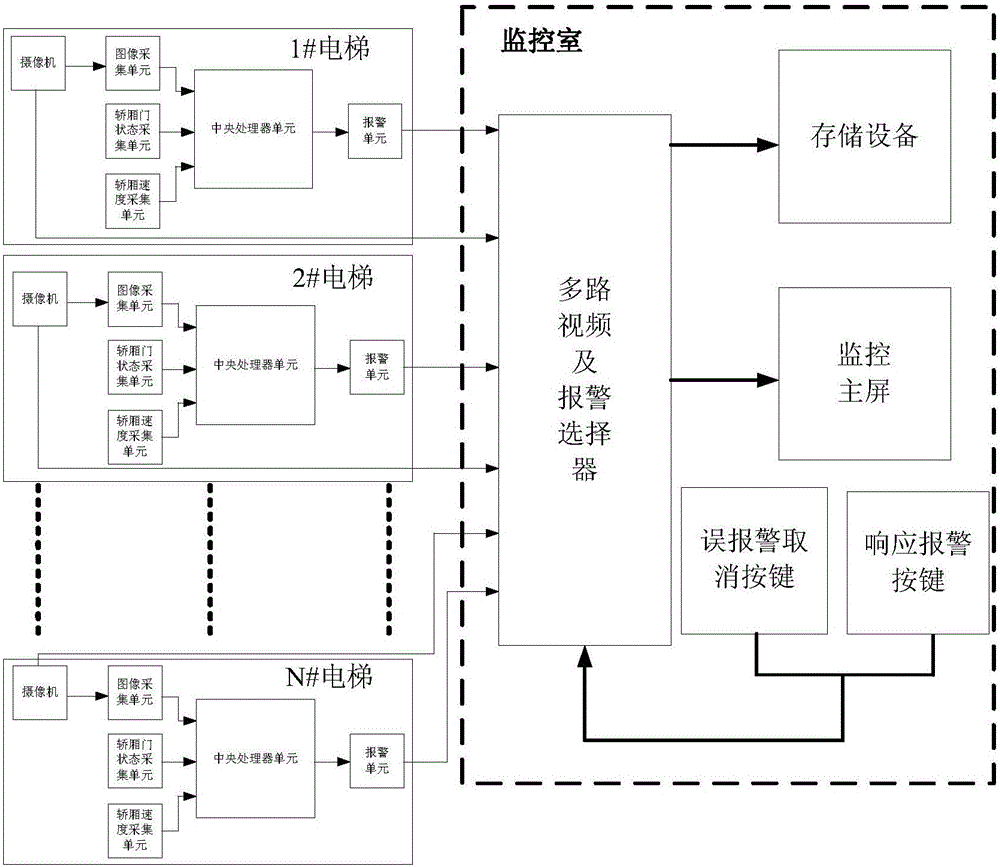

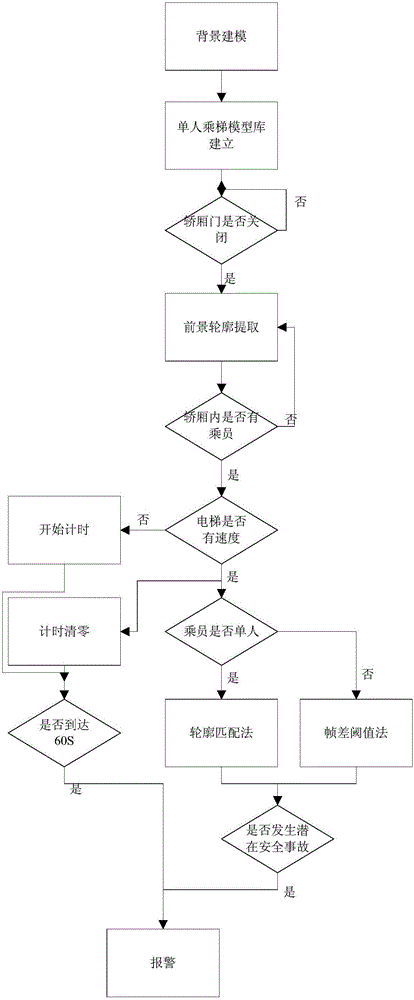

Elevator passenger comprehensive safety intelligent monitoring method based on machine vision

ActiveCN106241533ASimple environmentFast video analysisCharacter and pattern recognitionElevatorsCommunication AnalysisTemplate matching

The invention provides a comprehensive safety intelligent monitoring method capable of effectively and quickly judging if such abnormal activities as trapping, falling and violence are generated in a car to timely and accurately give an alarm so as to effectively relieve the burden of monitoring staff. The comprehensive safety intelligent monitoring method specifically comprises the following steps: an image shot by a camera with a fixed position is used as a background model; a differential image is obtained through a difference between a present video frame and the background model by a background subtracting method; the binarization processing is performed for the differential image according to a binarization formula; then, the noise is removed through a morphology filtering algorithm; finally, the area communication analysis is performed for the noise removing result; the edge profile of the binarized image is extracted by a Canny operator; and the extracted foreground profile is compared with a human body image template library by a template matching algorithm to judge if one or more persons are in the car and if the abnormal activities are generated to trigger warning.

Owner:XIAN SPECIAL EQUIP INSPECTION INST

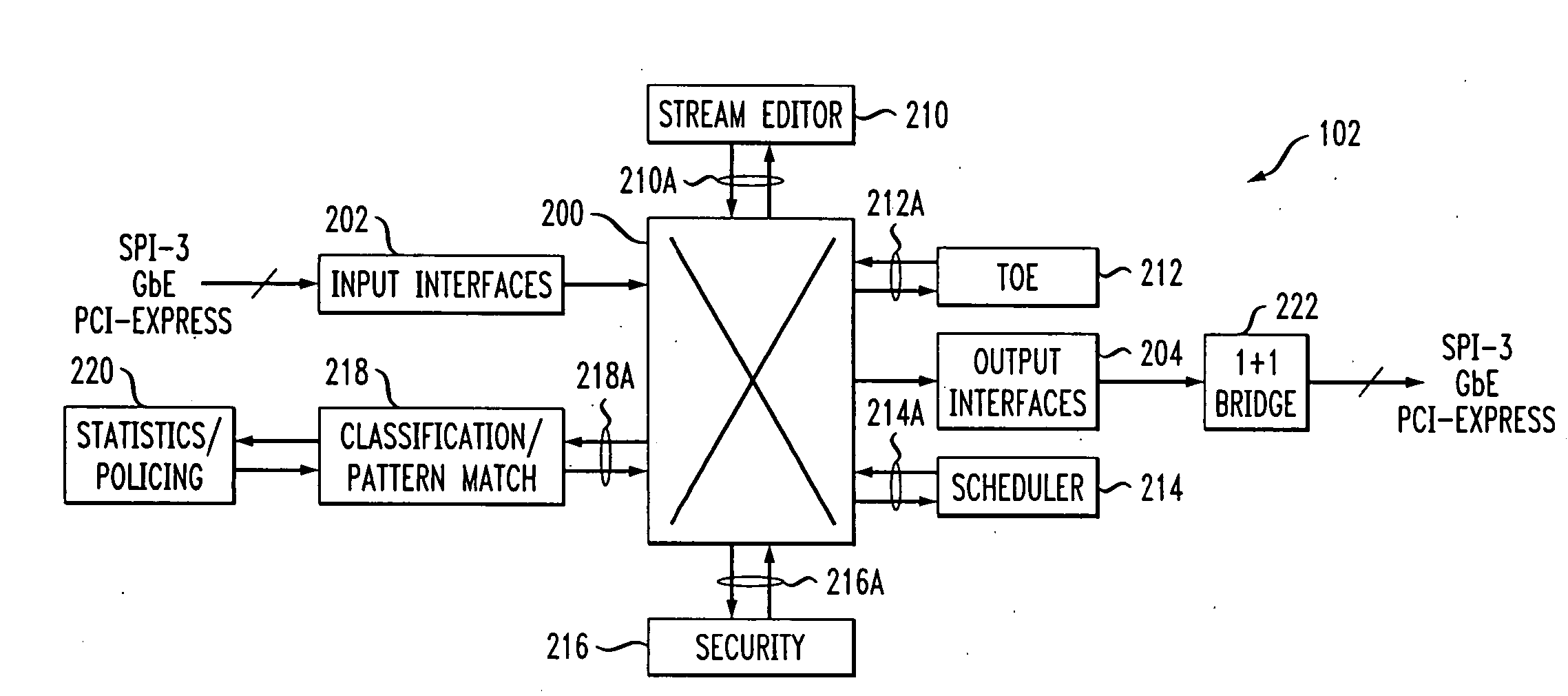

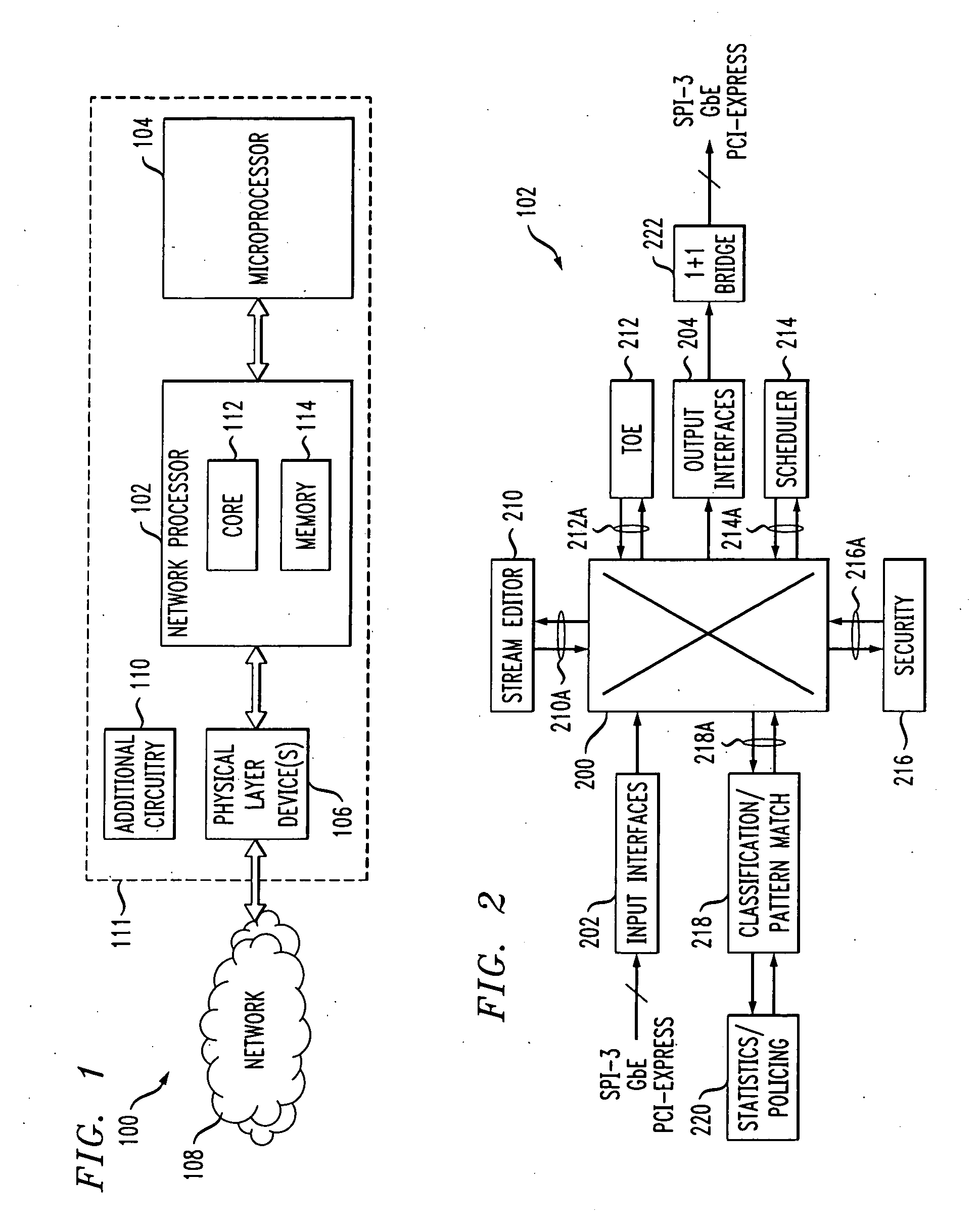

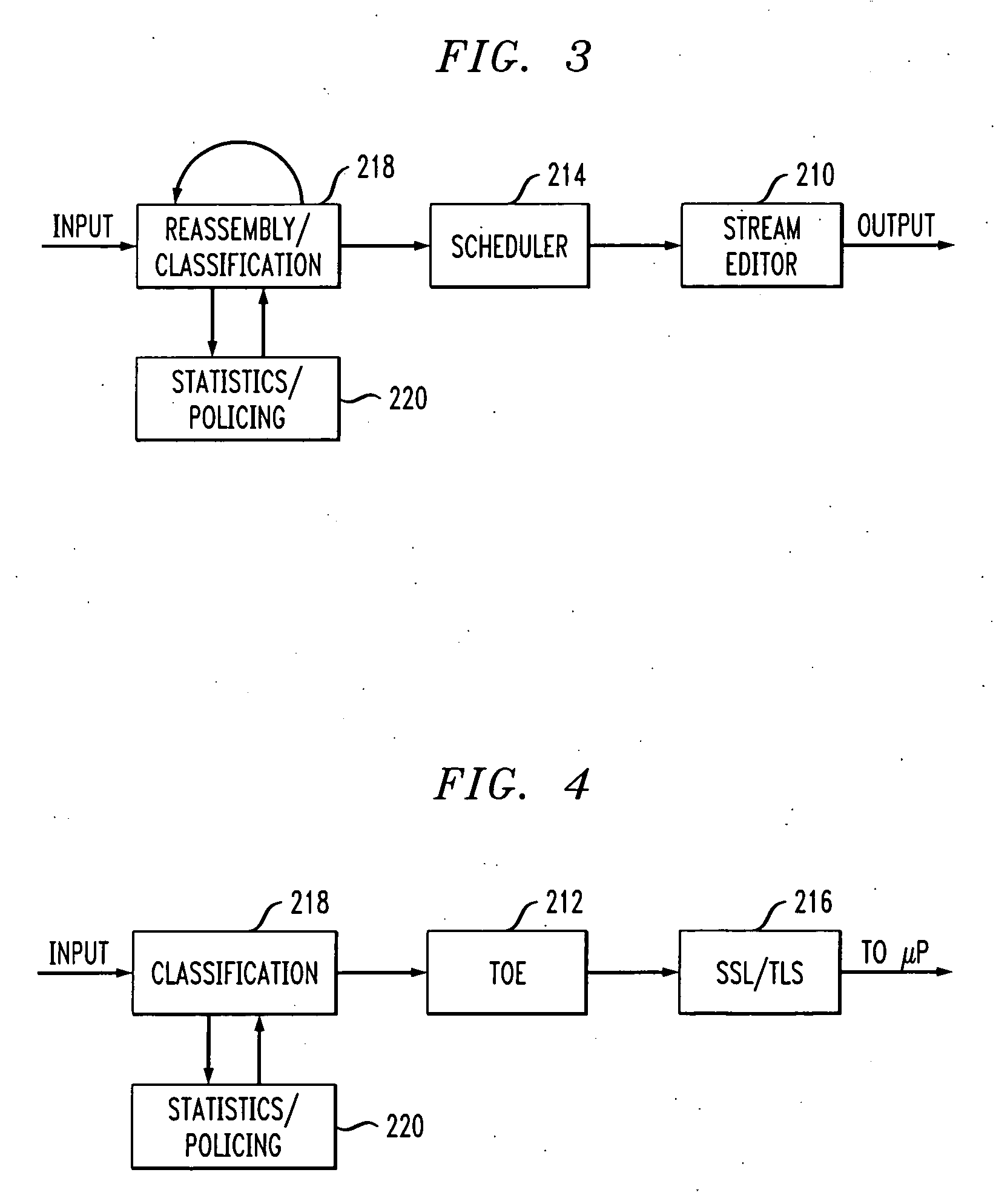

Switch-based network processor

ActiveUS20070230475A1Adversely impacting packet processing performanceSimple environmentData switching by path configurationParallel computingProcessing element

A network processor comprises an input interface, an output interface, a switch coupled between the input and output interfaces, and a plurality of processing elements coupled to respective bidirectional ports of the switch. Such processing elements include, in an illustrative embodiment, a scheduler, a security engine, a classification engine, a stream editor, etc. Information associated with a given packet received via the input interface is sequentially processed through multiple ones of the processing elements in a serial processing order based on switching operations of the switch. In the illustrative embodiment, the switch can permit any desired interconnection of the various processing elements so as to achieve a particular packet processing flow appropriate for a given application.

Owner:TAHOE RES LTD

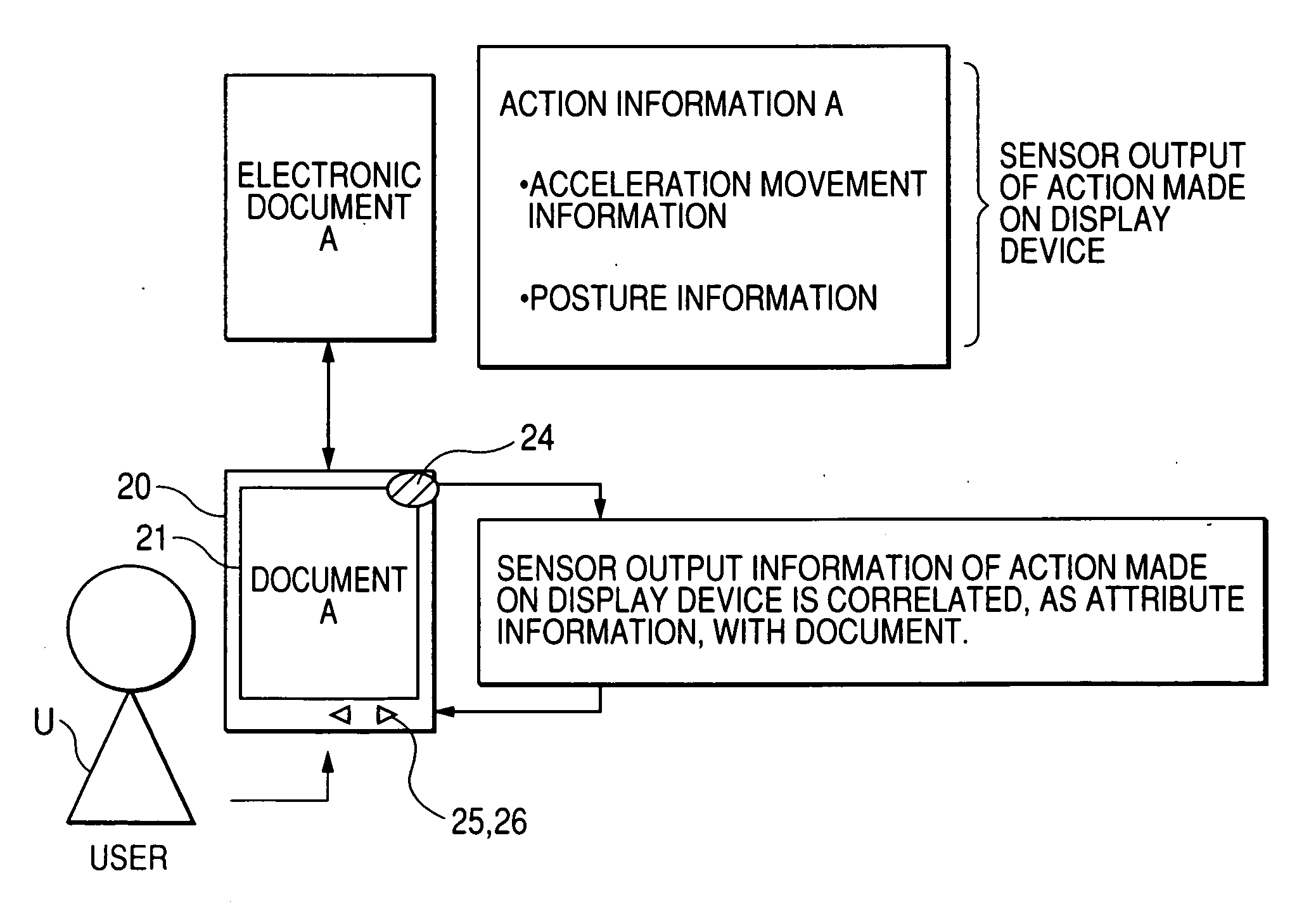

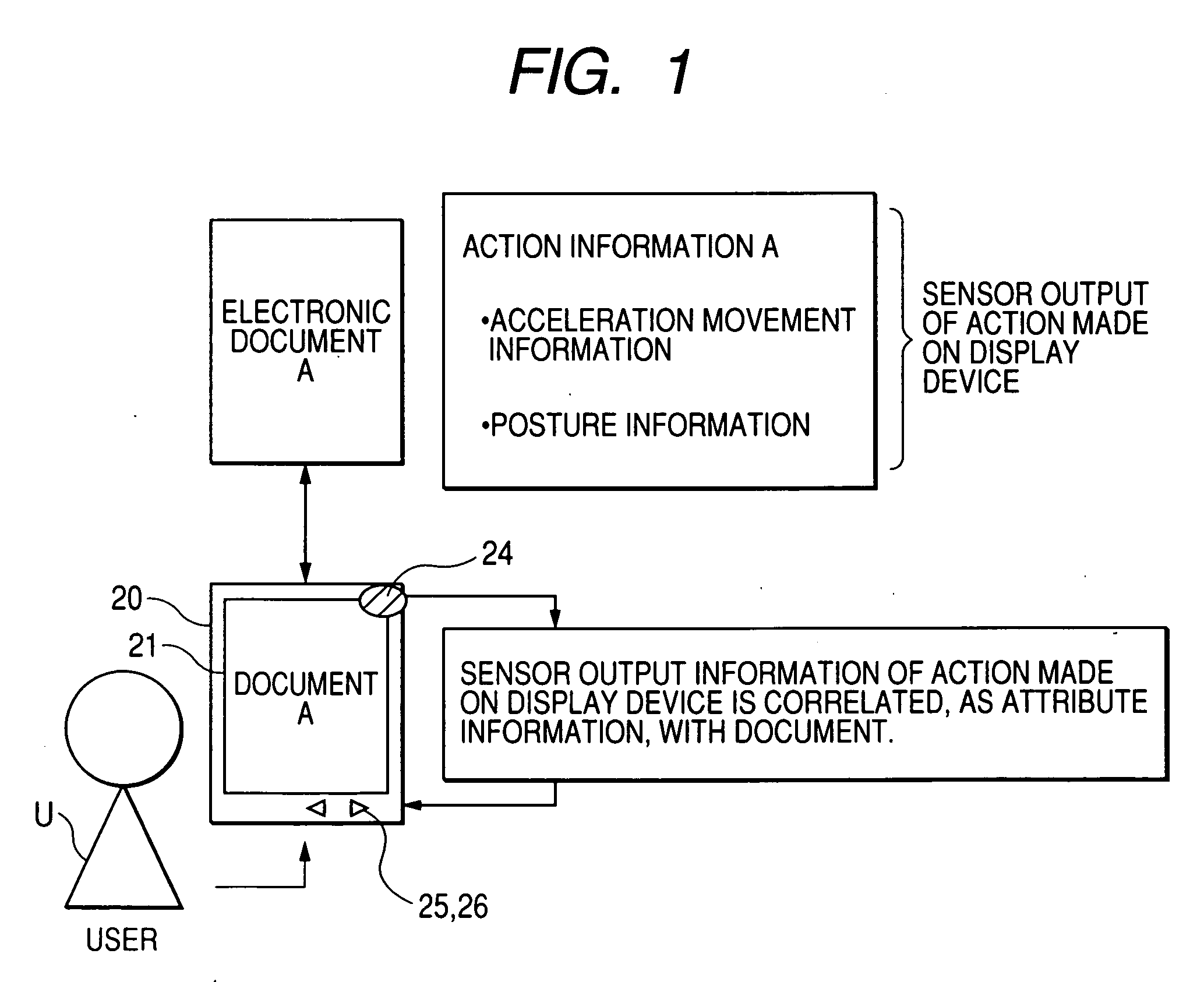

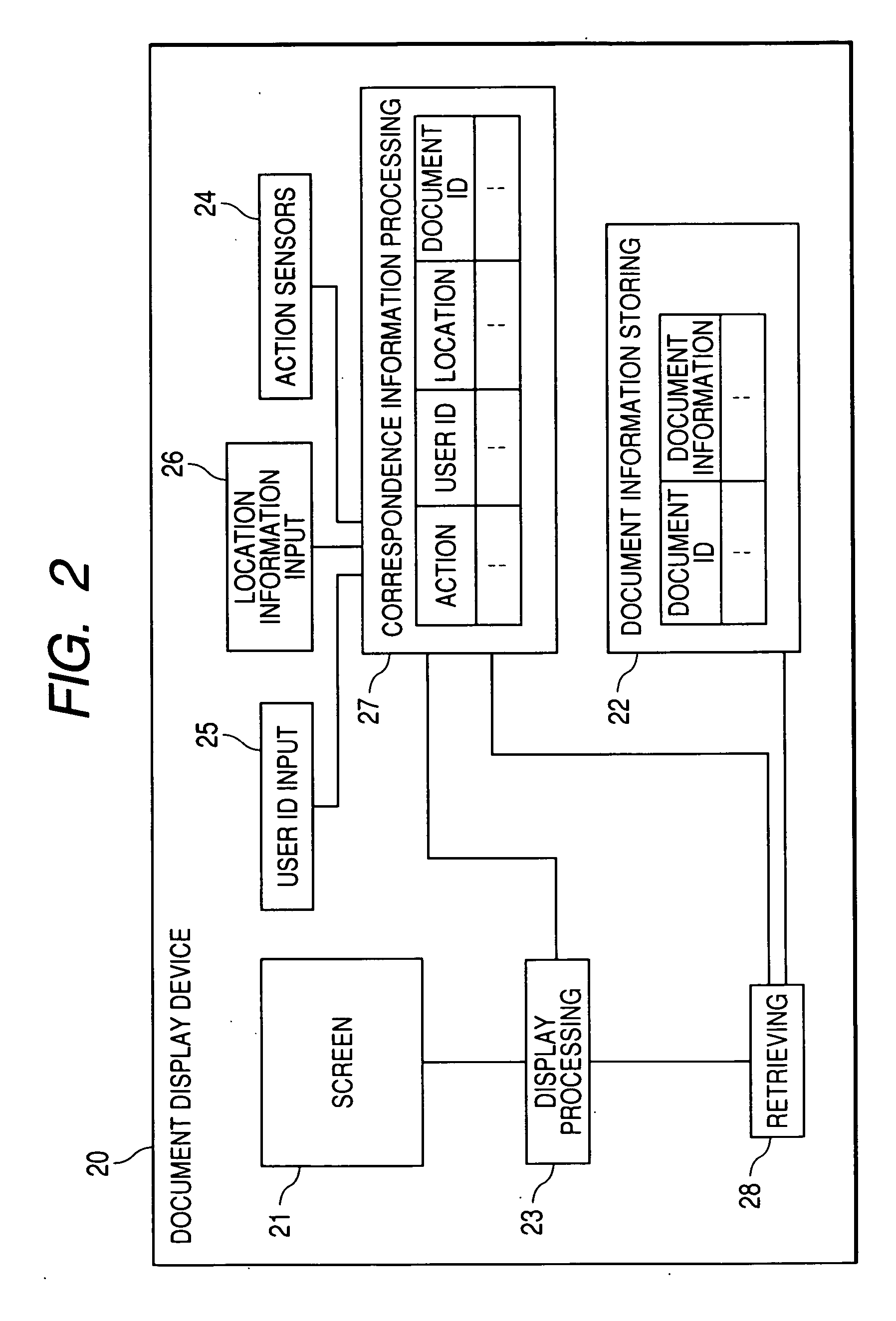

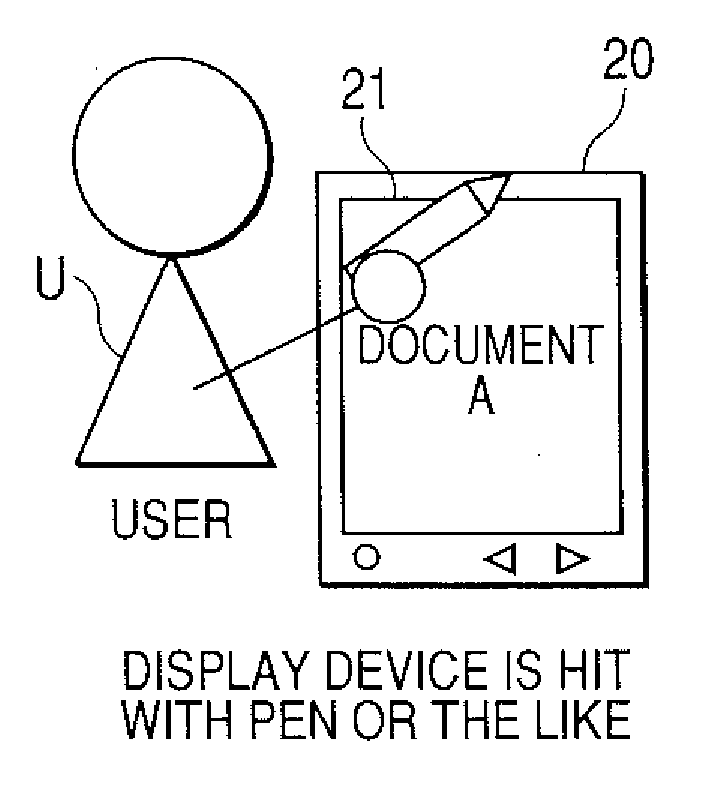

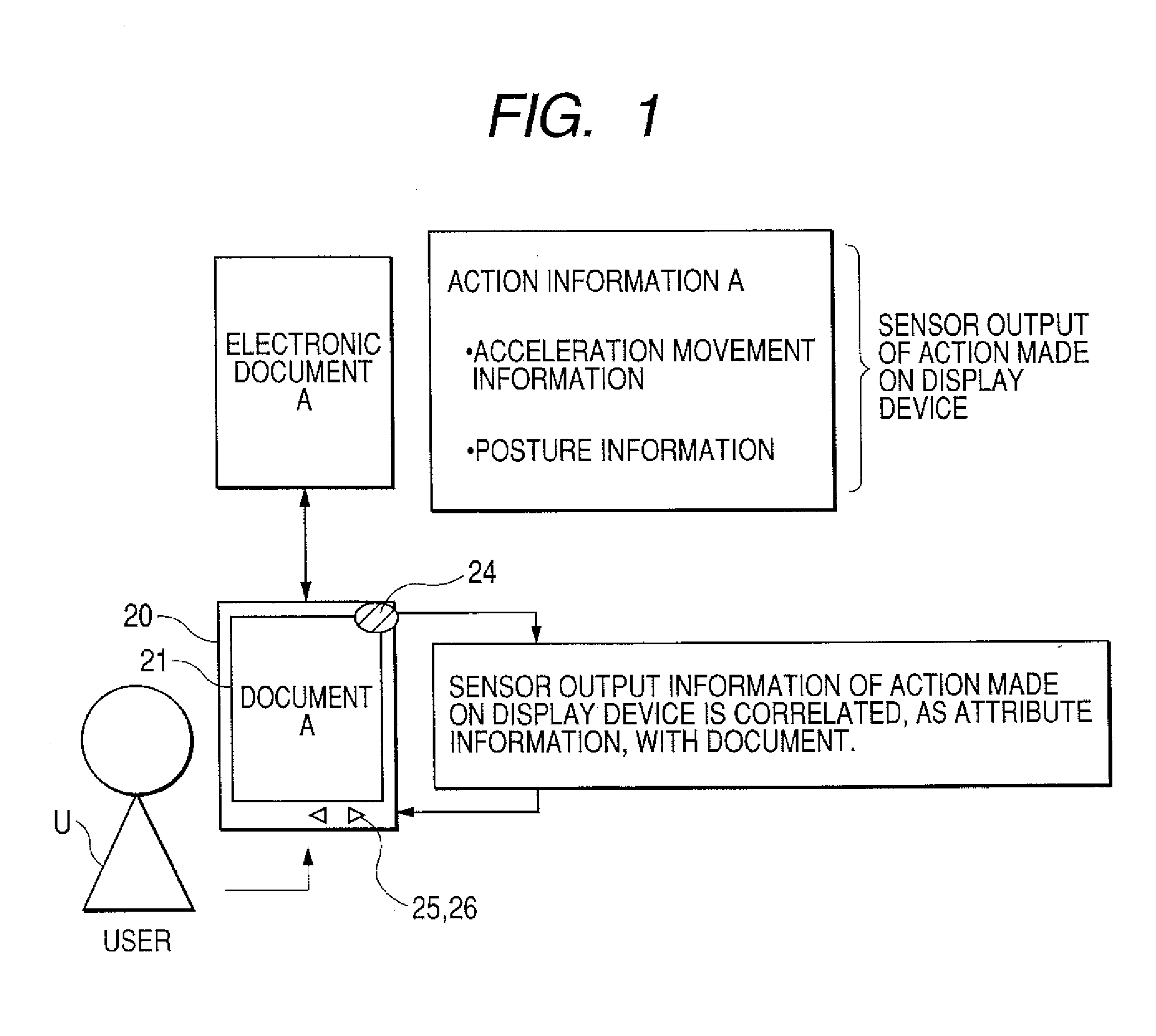

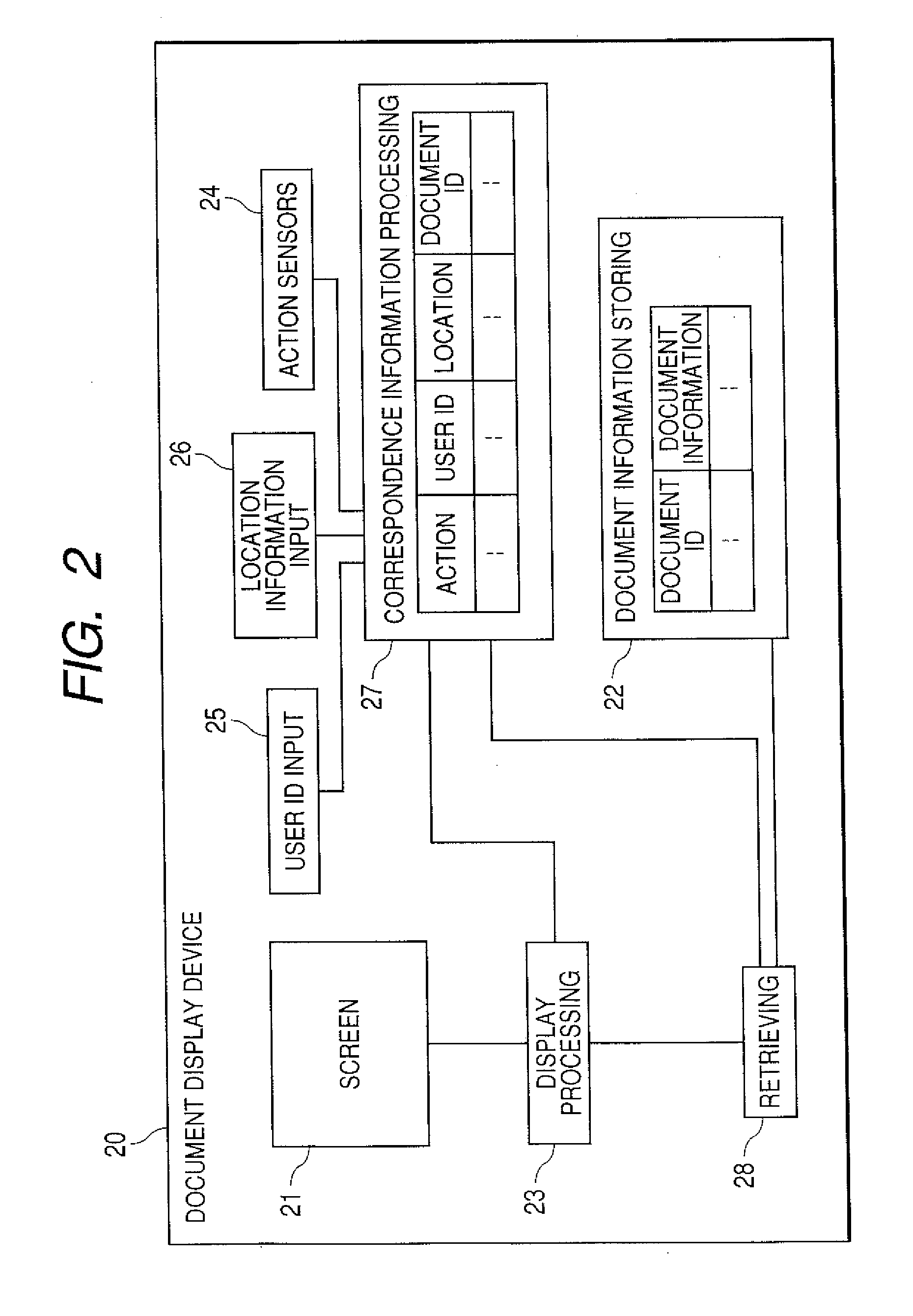

Document processing system

InactiveUS20060242556A1Avoid difficult choicesSimple environmentDigital data processing detailsSpecial data processing applicationsInformation processingDisplay device

A document display device for displaying a document on a screen on the basis of document information, includes: a sensor for detecting an action made on the document display device; a document information storing means for holding the document information of documents to be displayed on the screen; and a correspondence information processing means for storing information of an action detected by the sensor in a state that a document is displayed on the screen in such a manner that it is correlated with document information of the document being displayed on the screen.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Simplified creation and termination of an ad hoc wireless network with internet connection sharing

ActiveUS7616588B2Easy creation and maintenanceQuick SetupNetwork topologiesData switching by path configurationWireless mesh networkIp address

Methods and systems are described for simplified creation of, connection to, and termination from an ad hoc wireless network. Graphical user interfaces are used to guide users though creation and joining ad hoc network. The option to share one user's Internet connection with the entire ad hoc network is also described. The ad hoc networks described can provide some managed services traditionally unavailable in ad hoc networks, such as IP address assignment and name resolution services. The ad hoc networks can be created with termination criteria, such that a computer's connection to the ad hoc network is automatically terminated and previous network configuration settings are restored when one or a combination of termination criteria are met.

Owner:MICROSOFT TECH LICENSING LLC

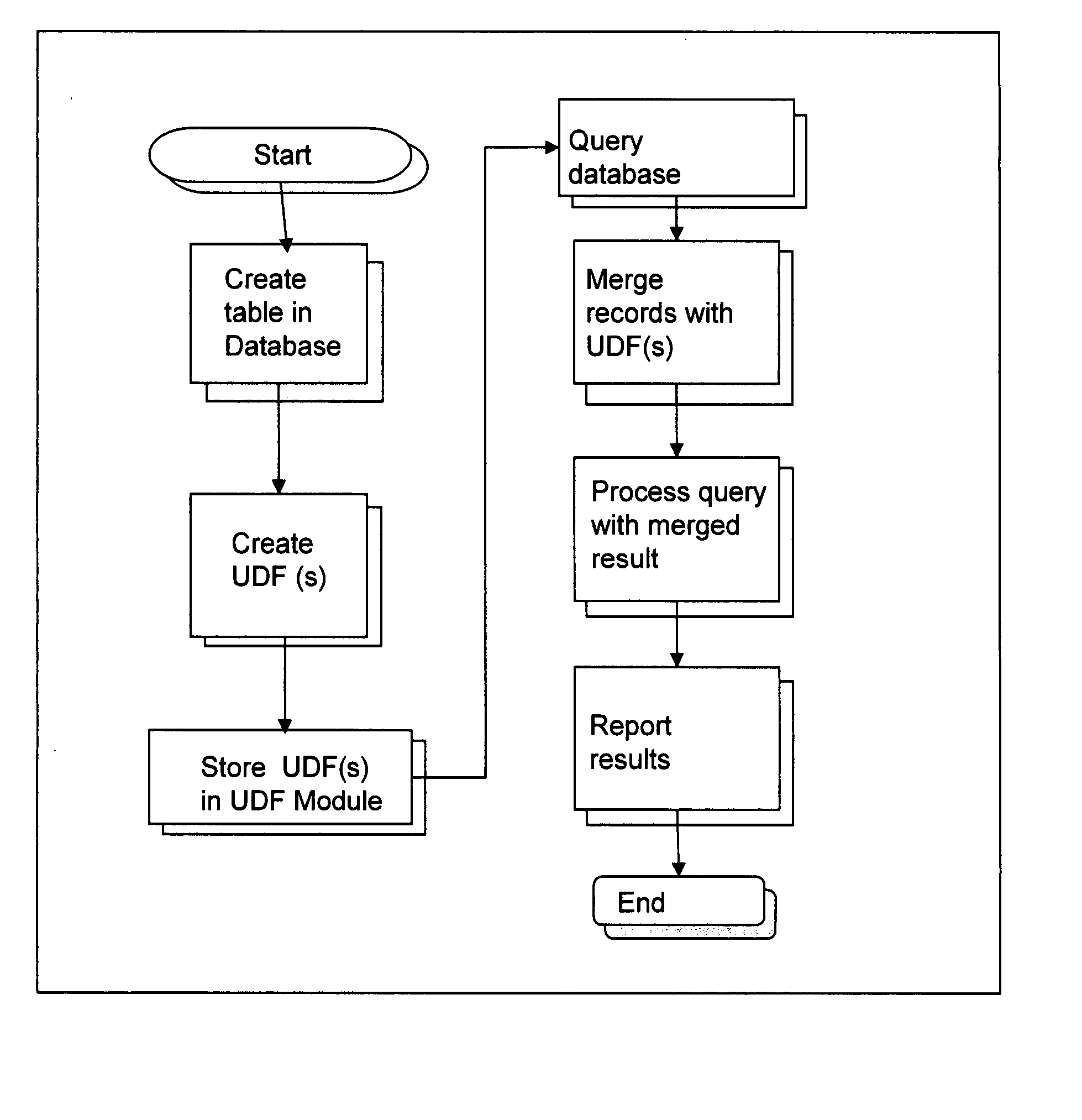

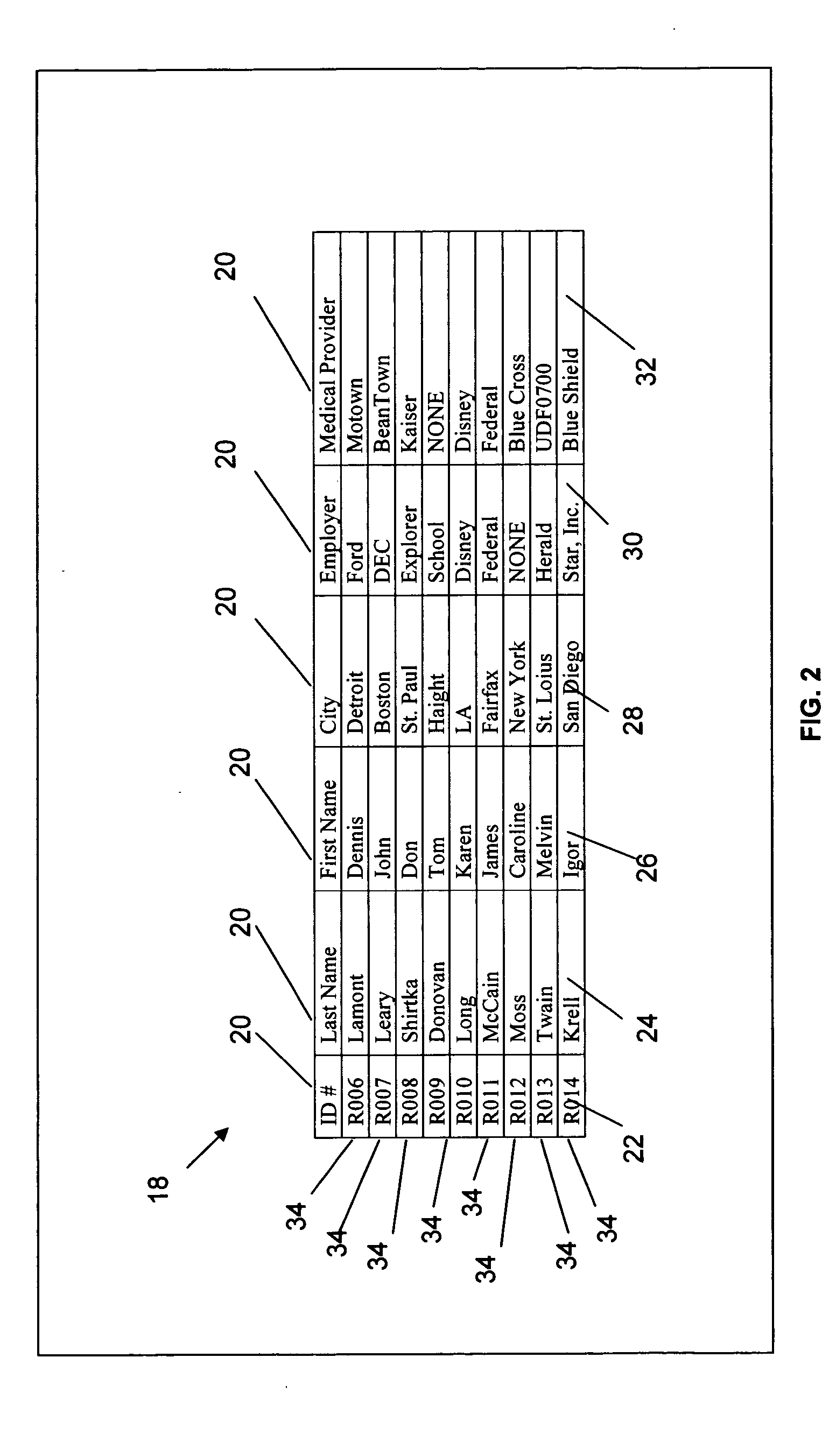

Method and system for generating, associating and employing user-defined fields in a relational database within an information technology system

InactiveUS20050080820A1Simple environmentDigital data information retrievalSpecial data processing applicationsRelational databaseUser defined

A system and method for creating and employing user-defined fields with an information technology system is provided. An exemplary computational system has a relational database and relational database management software program. The method of the present invention enables the creation of a user-defined field that may be associated with one or more records of one or more tables of a database of the computational system. Data may be appended to records without changing the schema of the table.

Owner:KOPPEL CARL ARNOLD +1

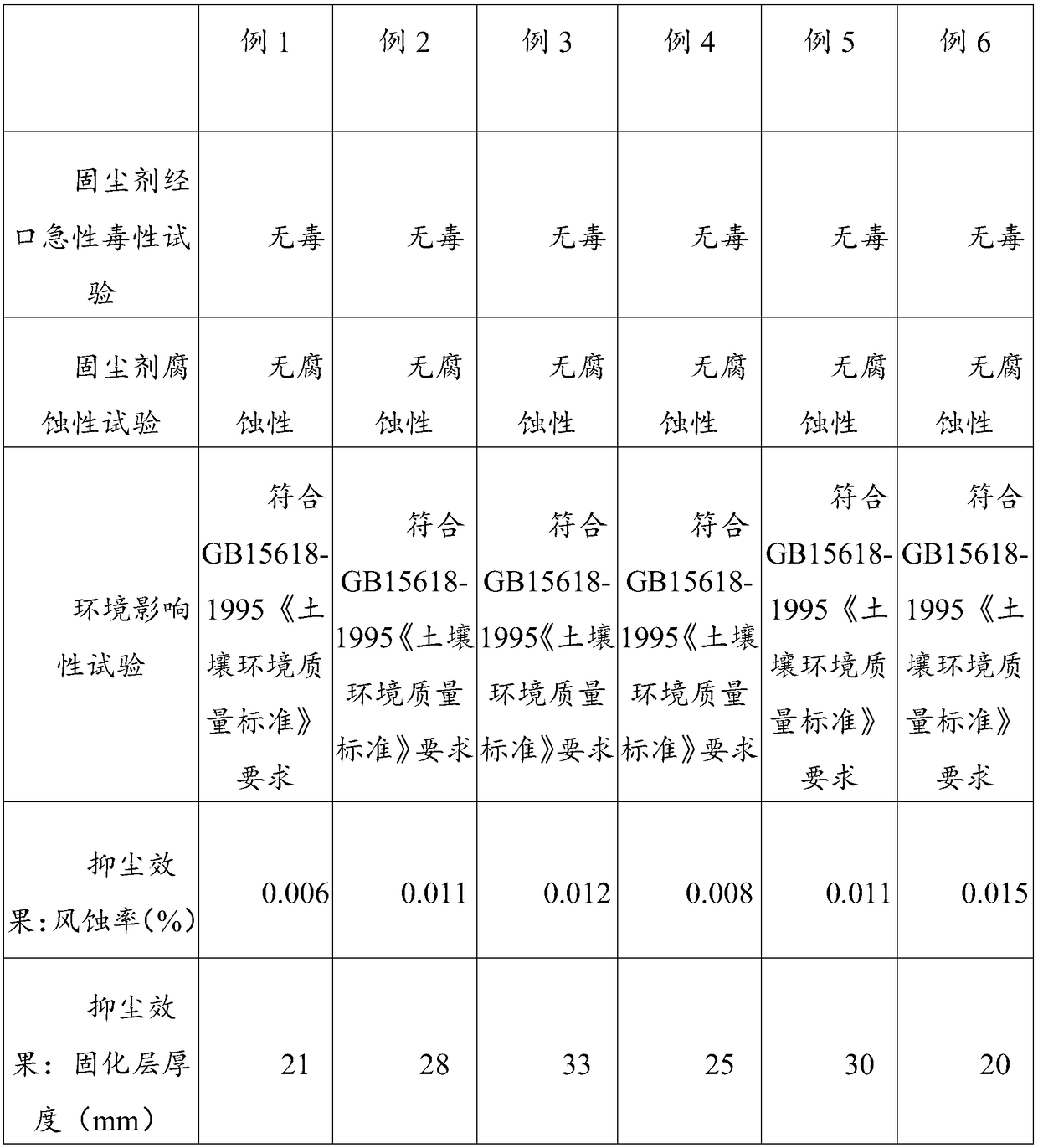

Green dust-fixing agent and preparation method thereof

The invention relates to a green dust-fixing agent and a preparation method thereof. The green dust-fixing agent is prepared by using pregelatinized starch, dextrin, xanthan gum, cellulose ether derivatives, sucrose and water as raw materials with a proper weight ratio. A compounded mixture of pregelatinized starch, dextrin, xanthan gum and cellulose ether derivatives is used as a main binder, andsucrose is used as an auxiliary binder, the colloidal properties of the plant polysaccharide is fully utilized, a stable multi-point cross-linked network structure is formed between dust and soil particles, efficient capture and fixation of dust and soil can be realized, dust-fixing effect is good, long dust-fixing period is long, and the agent has certain erosion resistance; the product is green, safe, environmentally friendly, and non-polluting, and cannot not cause secondary pollution; the method has the advantages of simple construction and convenient operation, and can meet the needs ofdifferent dust-fixing environments such as building site construction, mine and industrial manufacturing; the preparation cost is low, the preparation process is simple, and the method are suitable for industrial production and scale promotion.

Owner:北京英华高科技环保有限公司

Fermenting production method of cordycepin

ActiveCN102559815AIncrease productionReduce pollutionMicroorganism based processesFermentationBiotechnologyBacterial strain

The invention discloses a fermenting production method of cordycepin, and the method comprises the following steps of: transplanting activated bacterial strain cordyceps militaris into a fermentation tank filled with a fermentation culture medium, wherein the fermentation temperature is 25-28 DEG C, and the stirring rotation speed is 150-180rpm (revolutions per minute); feeding sodium hydroxide solution and hydrochloric acid to control the pH value of fermentation liquor at 5.5-6.0; and when a carbon source is completely consumed, reducing the stirring rotation speed to be 60-80 rpm, and replenishing a water solution containing glucose and adenosine into the fermentation tank by means of intermittent feeding, wherein the whole fermentation time is 200-280 hours. According to the fermenting production method, the pH value of the fermentation process is controlled, and the energy sources and the cordycepin precursor are timely replenished, so that the fermentation process can be kept under an optimum environment, and the fermenting production method is good for the growth of thallus, and good for the transplantation of metabolic flux, therefore, the cordycepin yield can be finally up to 10.0g / L, the production efficiency reaches 0.25g / L / d, and the method is simple in process, lower in environment pollution, convenient to operate, and high in cordycepin yield.

Owner:JIANGSU FANGSHIYUANLVE SCI & TECH CONSULTING CO LTD

Solid invert emulsion drilling fluid additives, methods of preparation and use in oil-based drilling fluids

ActiveUS20160298015A1Desirable performance characteristicEliminate performance disadvantageDrilling compositionFood additiveEmulsion

Solid free-flowing powdered drilling fluid additives compositions having desirable emulsifying, wetting and other performance characteristics are described. Their method of preparation and their use in oil-based drilling fluid compositions are described. The manufacturing process comprises of contacting (spraying or mixing) different types of liquid invert emulsion additives individually at elevated temperature with a blend of inert fillers in specific proportions and of particular particle size in a blender for a specified time. The solid powdered additives thus obtained are controlled pulverized to obtain the final particle size which does not alter the performance of each individual additive. The solid invert emulsion additives obtained are added to drilling fluid compositions yielding drilling muds with improved performance. Solid powdered additives compositions greatly reduce transportation costs and simplify the logistics and environmental concerns associated with shipping large volumes of solvent-containing liquids and overcome the pour point issues associated with liquid additives.

Owner:GUMPRO DRILLING FLUID PVT

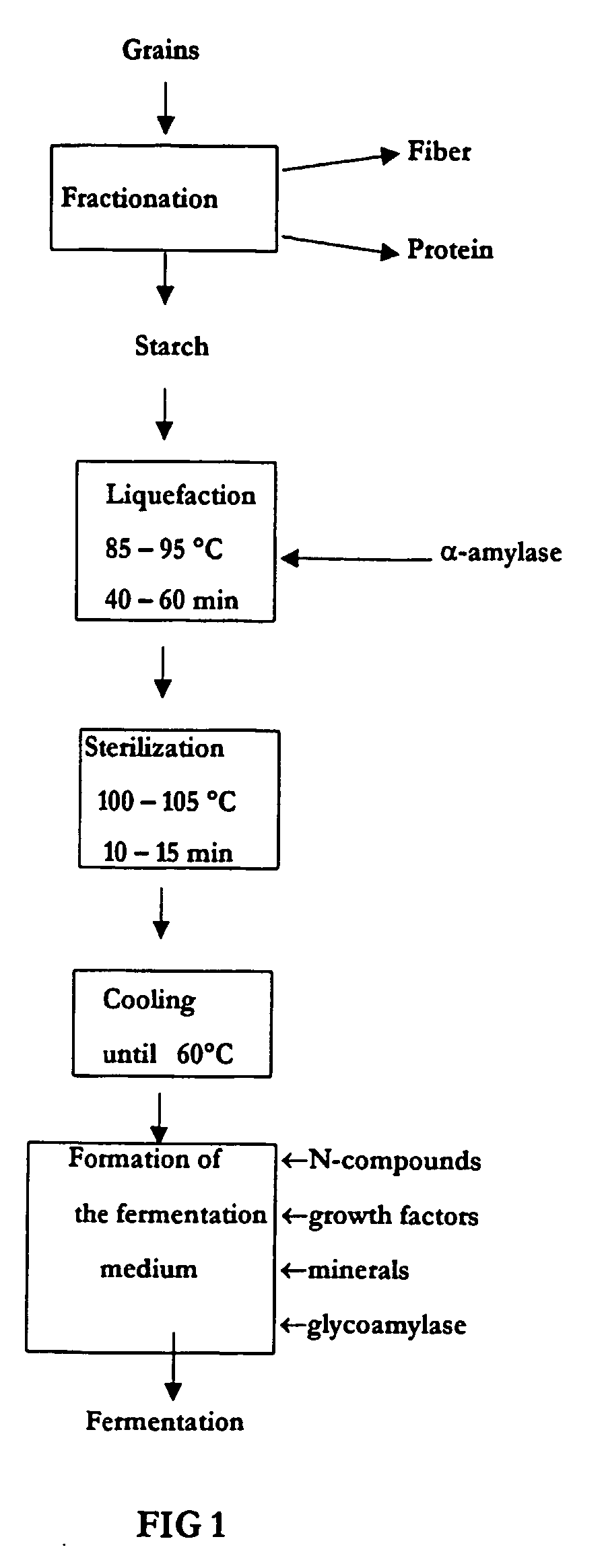

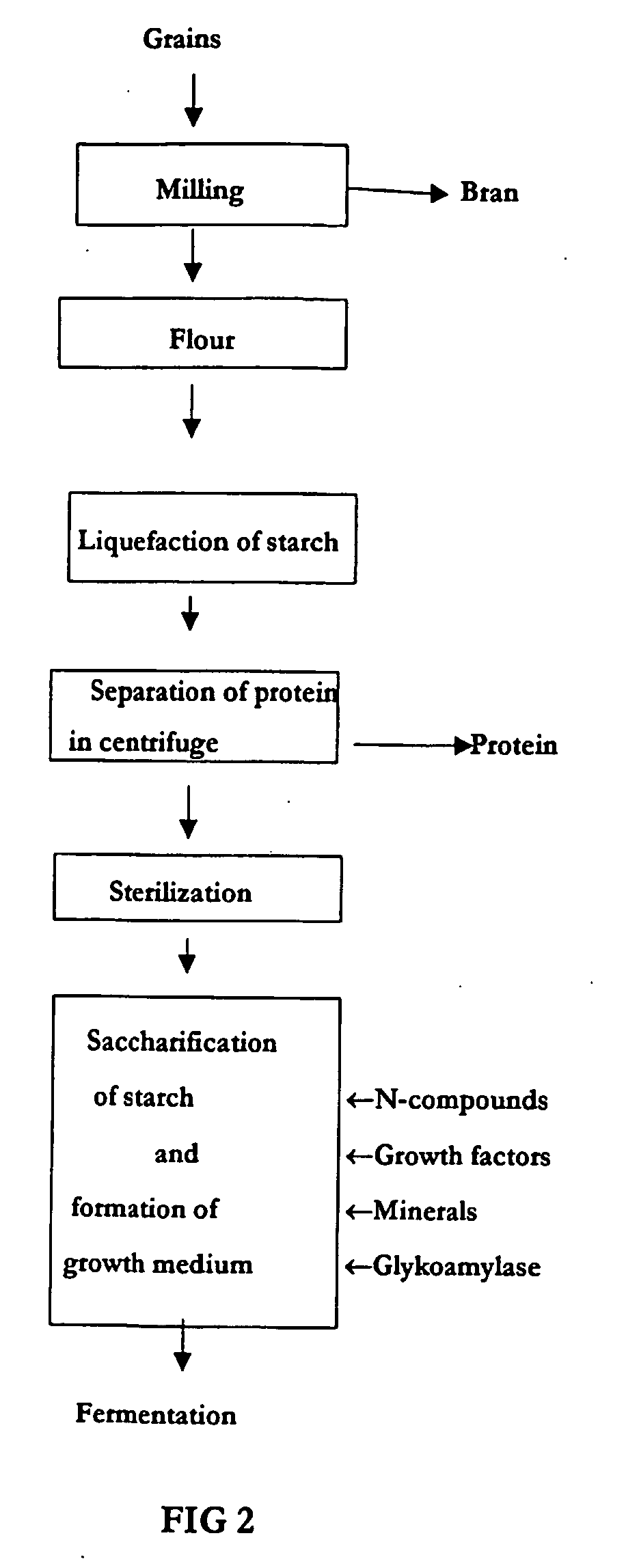

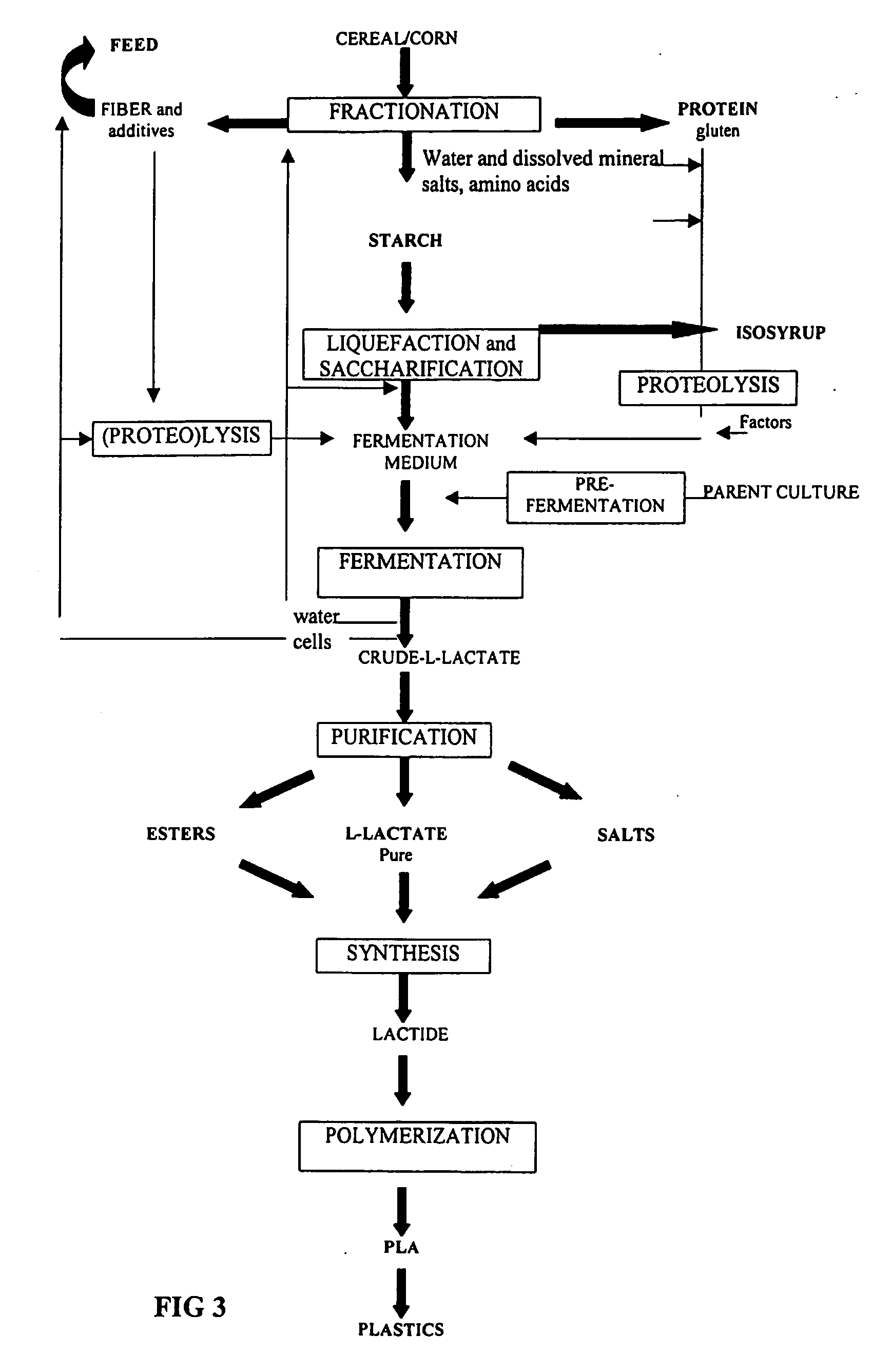

Method of production of biodegradable lactic acid polymers and the use of lactic acid polymers produced using such a method

InactiveUS20060154350A1Reduce shareSave resourcesFermentationFood preparationPolymer scienceFermentation

The invention relates to the use of lactic acid and its esters produced upon microbiological fermentation of organic substances, particularly cereal starch, for producing biodegradable lactic acid polymers and use of the biodegradable polymer produced using such a technique. The areas of application of the invention include food processing and chemical technology. The fields of usage of the invention include the production of starch, phytoprotein, lactic acid and its derivatives, including its salts, esters and biodegradable polymer (PLA).

Owner:MAILTEC

Lubricant additives for water based drilling fluid

ActiveUS20190136112A1Good dispersionImprove the lubrication effectConstructionsFlushingWater basedIon

The invention relates to powdered lubricants for water based drilling fluids. Conventional liquid lubricants containing particularly divalent ions have the tendency to grease out. The powdered lubricants have excellent dispersion properties and hence do not grease out, when added to the drilling mud in the concentrations, preferably of the order of about 3% or less. The powdered lubricant is a combination of inert fillers with fatty acids that are essentially free from fatty acid esters and metal soaps and have organic acids containing C10-C24 alkyl groups fatty acids. The improved lubricating properties of the drilling muds result in greatly increased life of the rotary drilling bits and marked reduction in torque required to rotate the bit. Solid powdered additives compositions greatly reduce transportation costs and simplify the logistics and environmental concerns associated with shipping large volumes of liquids and overcome the pour point issues associated with liquid additives.

Owner:GUMPRO DRILLING FLUID PVT

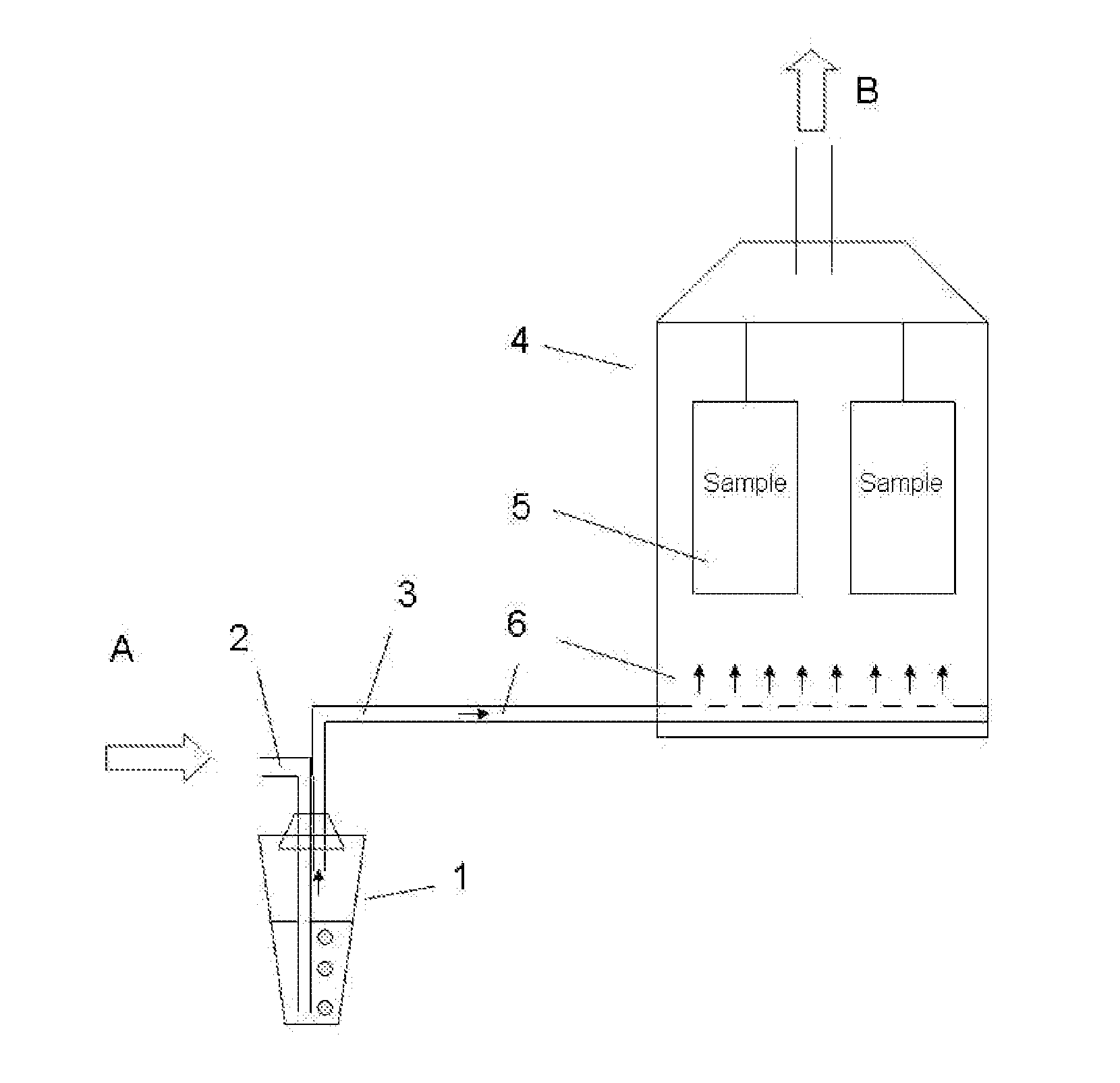

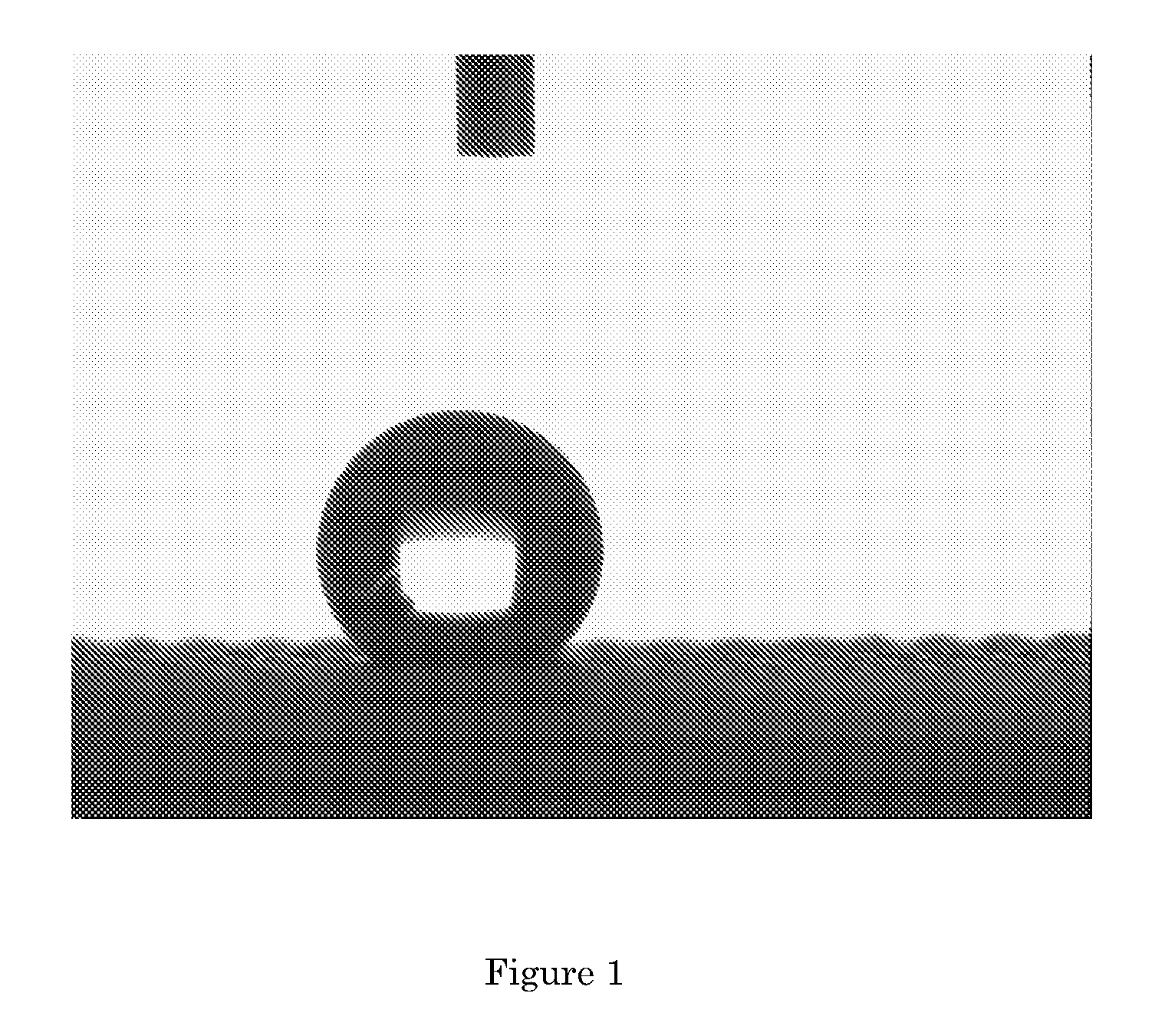

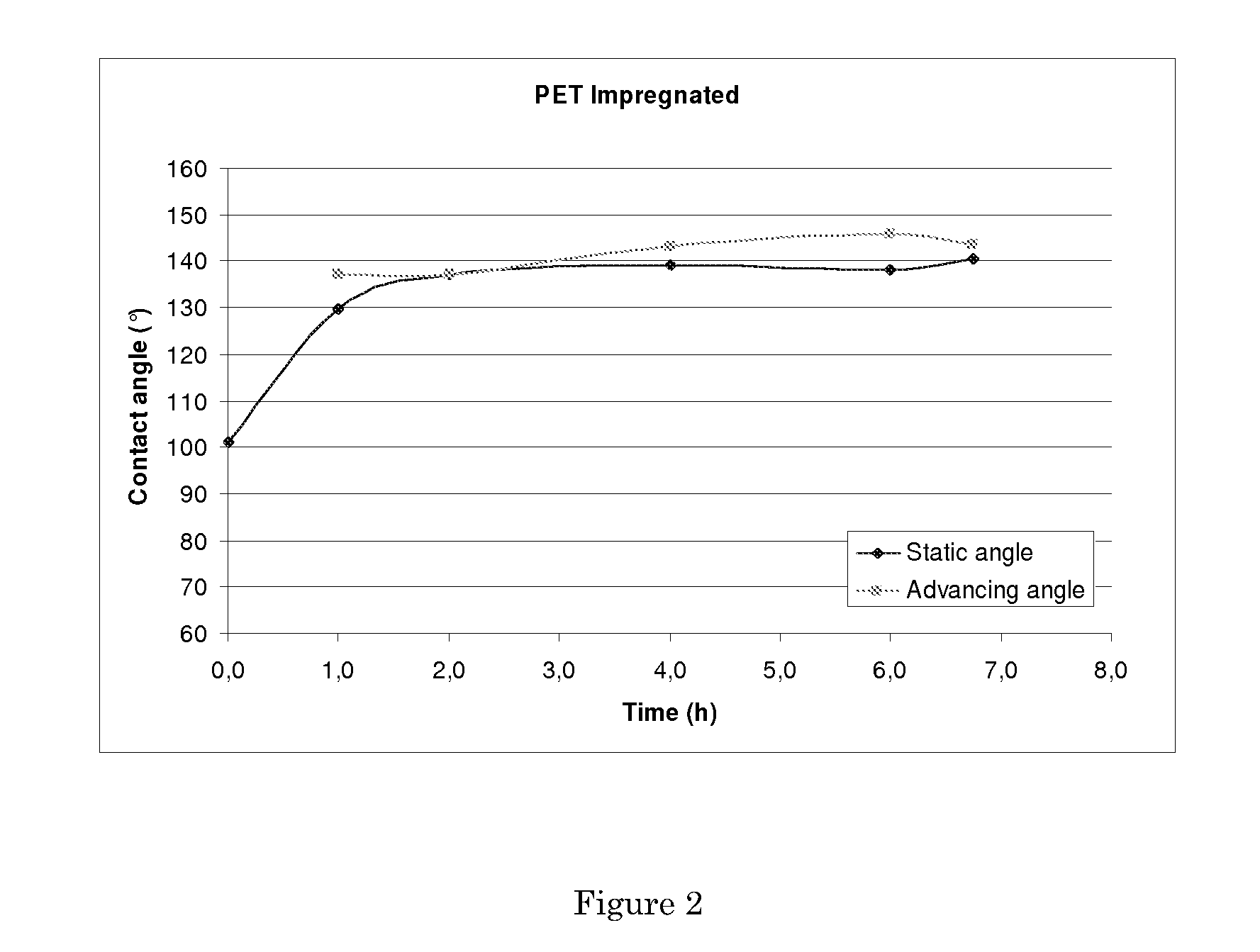

Hydrophobic surface finish and method of application

InactiveUS20100267303A1Simple environmentFibre treatmentSynthetic resin layered productsSuperhydrophobeSurface finish

The present invention relates to a method for hydrophobization of a fabric surface comprising providing a stream of a substantially anhydrous gas, passing said gas over or through a substantially anhydrous liquid of an alkylsilane, preferably a fluorinated alkylsilane to provide an alkylsilane, preferably a fluorinated alkylsilane vapor and bringing said vapor in contact with the fabric surface, thereby allowing the optionally fluorinated alkylsilane to bind covalently to the fabric surfaced. The present invention further relates to a fabric comprising a superhydrophobic surface finish prepared by a method of the invention and to a device for carrying out the method of the invention.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

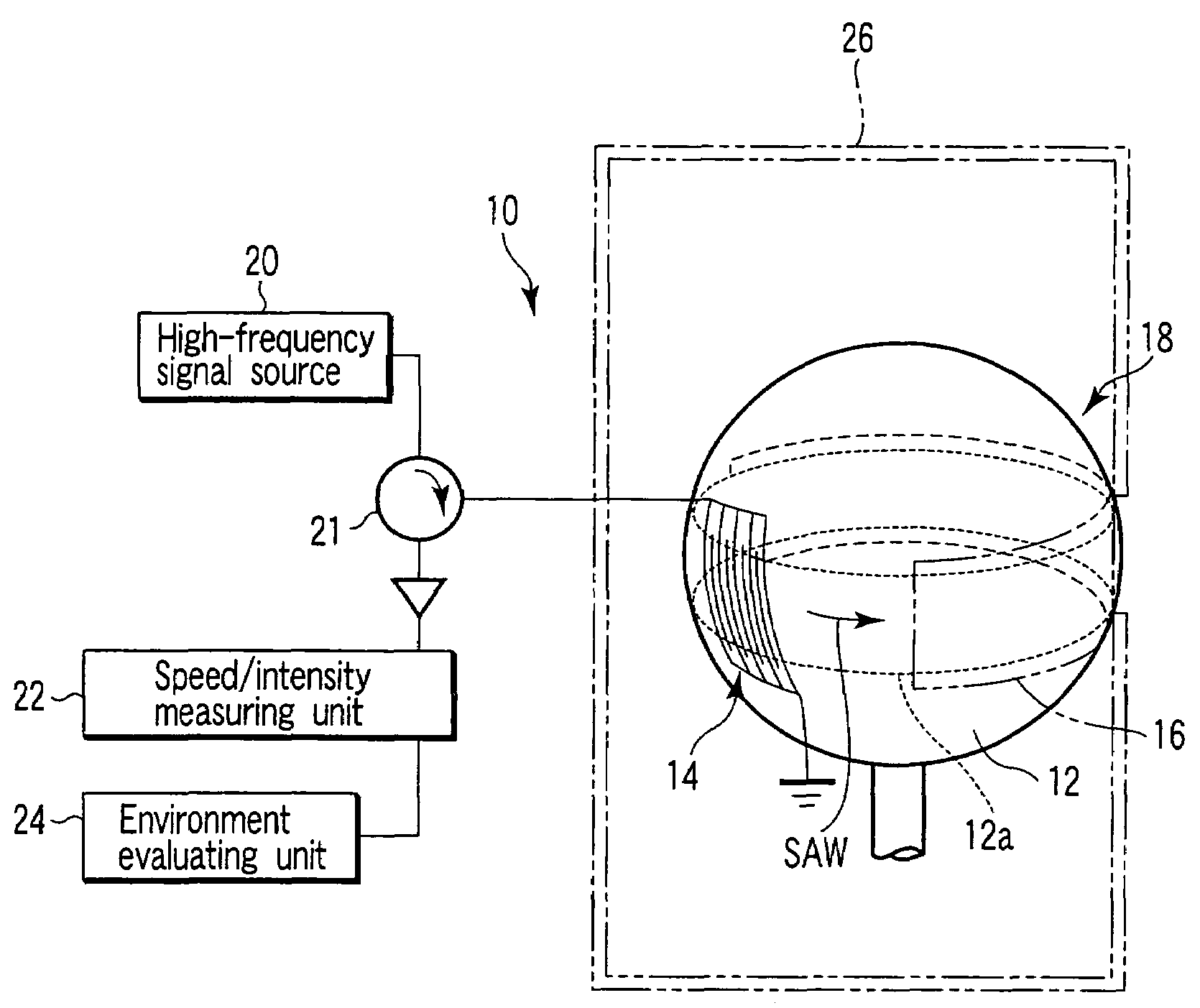

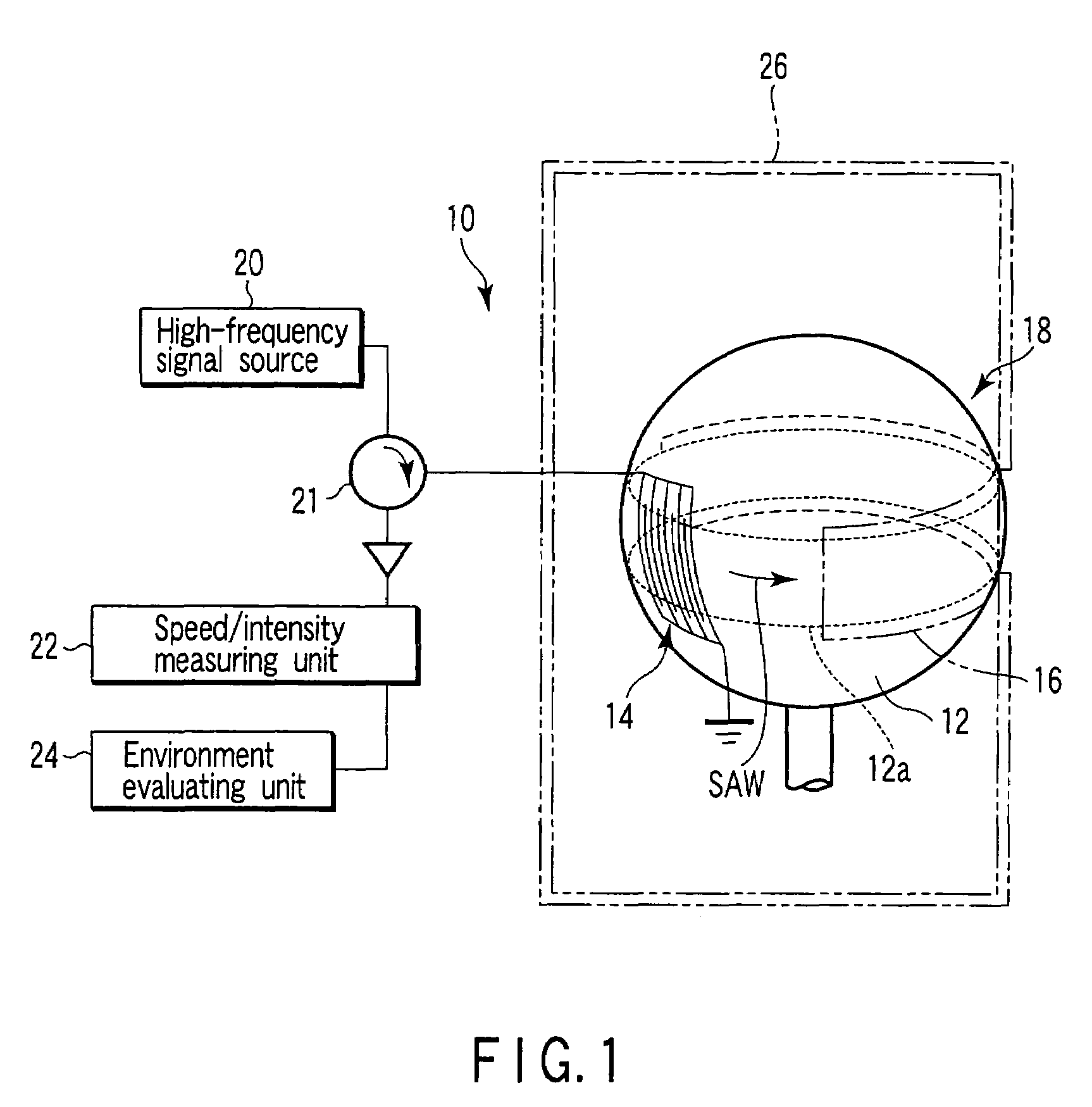

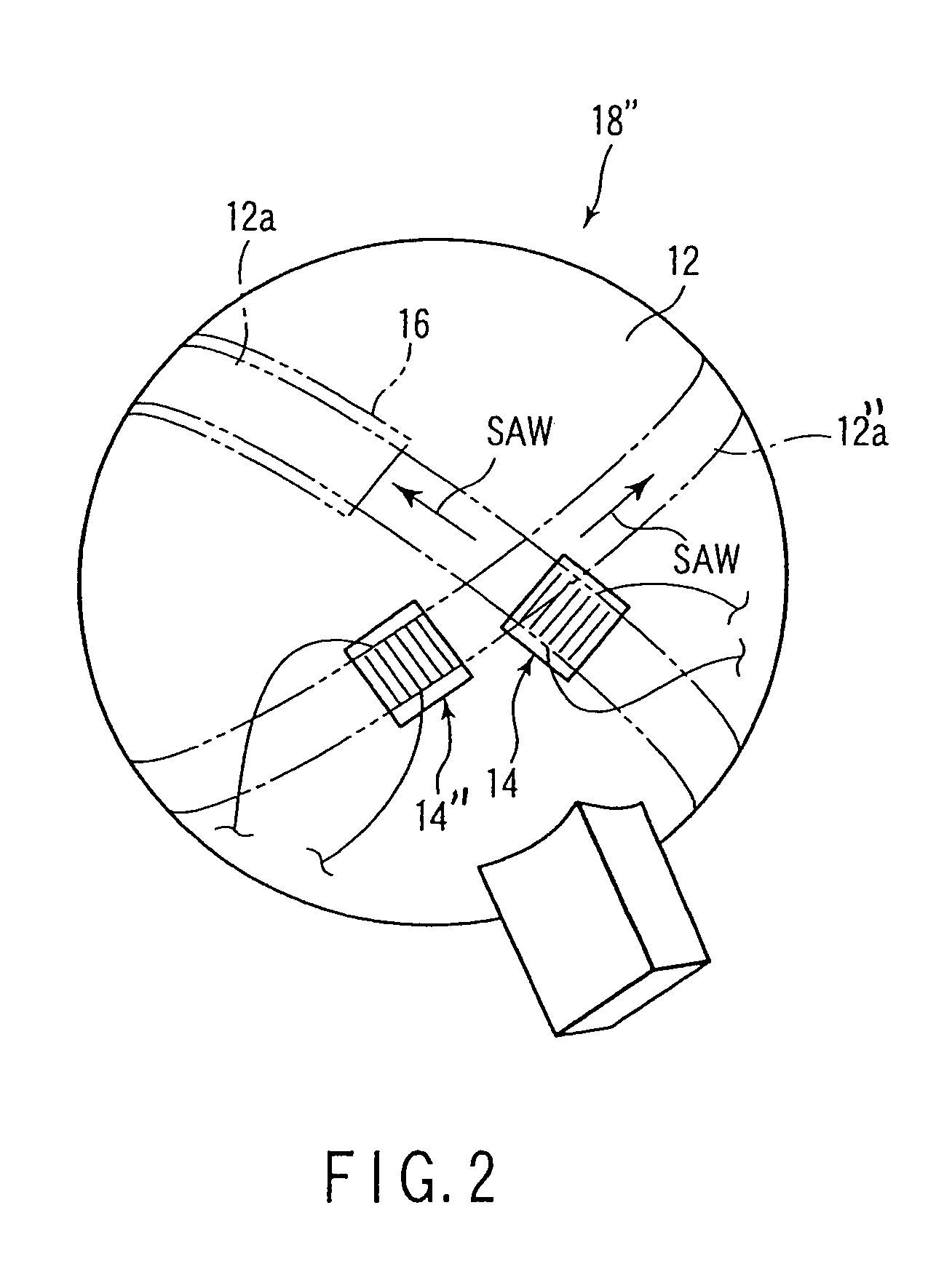

Environment difference detector

ActiveUS7647814B2Quickly and highly accurately measuredLonger propagation distanceVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesSurface acoustic wave sensorUltimate tensile strength

An environment difference detector includes an elastic surface wave element equipped with a substrate including a surface having an annular surface acoustic wave circulating path, a surface acoustic wave exciting / receiving unit exciting a surface acoustic wave along the circular path and receiving the circulated surface acoustic wave, and a sensitive film disposed on the circular path to change an elastic nature in accordance with a change in an adjacent environment, a speed / intensity measuring unit measuring a circulating speed and intensity of the surface acoustic wave from an electric signal generated by the unit when the unit receives the circulating surface acoustic wave, and an environment evaluation unit evaluating an environment adjacent to the sensitive film from at least one of the circulating speed and the intensity measured by the unit.

Owner:YAMANAKA KAZUSHI +1

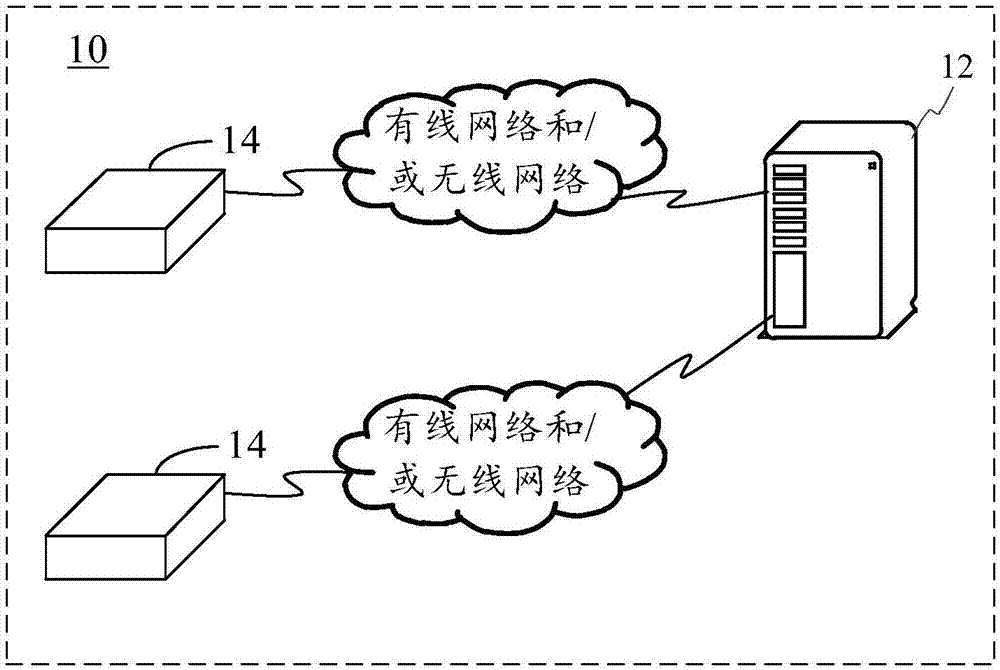

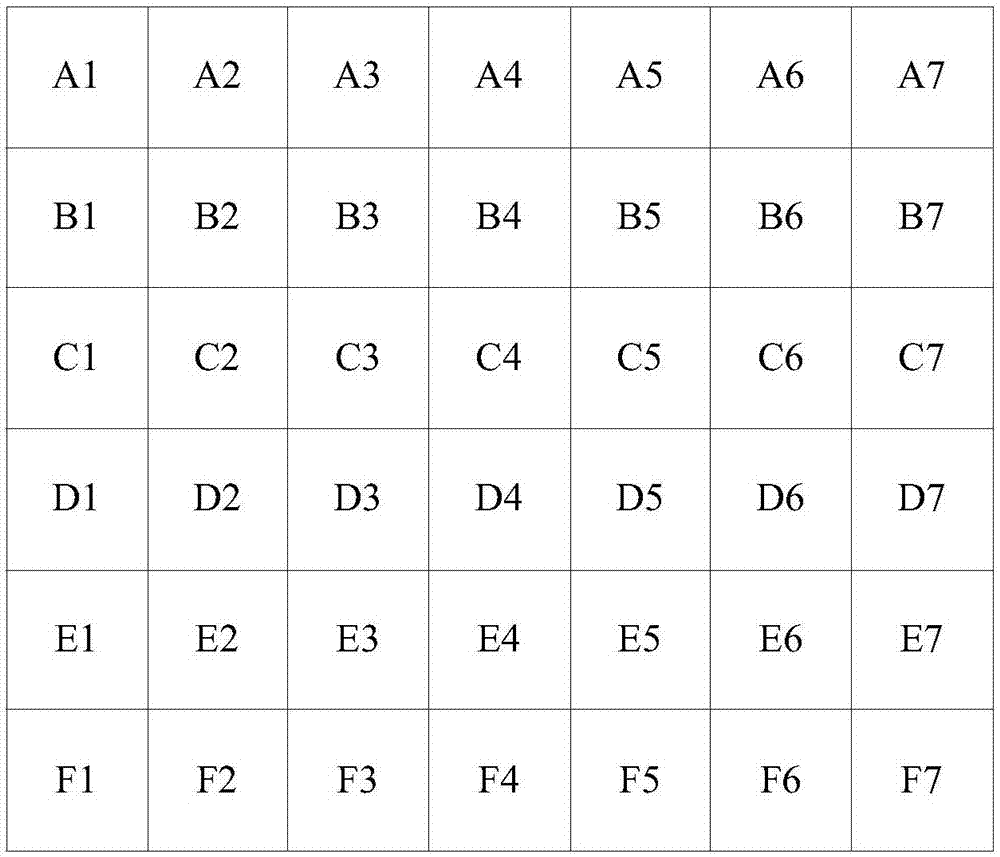

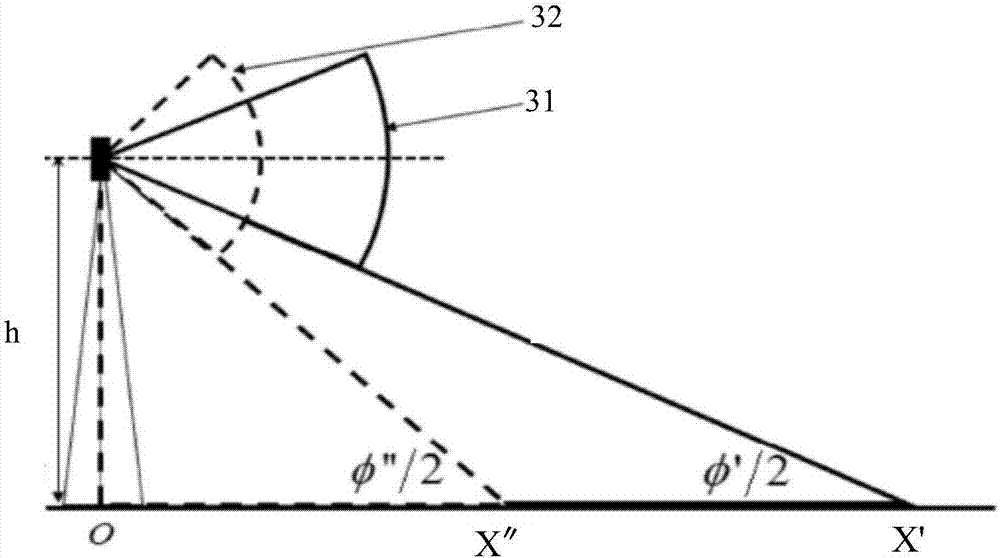

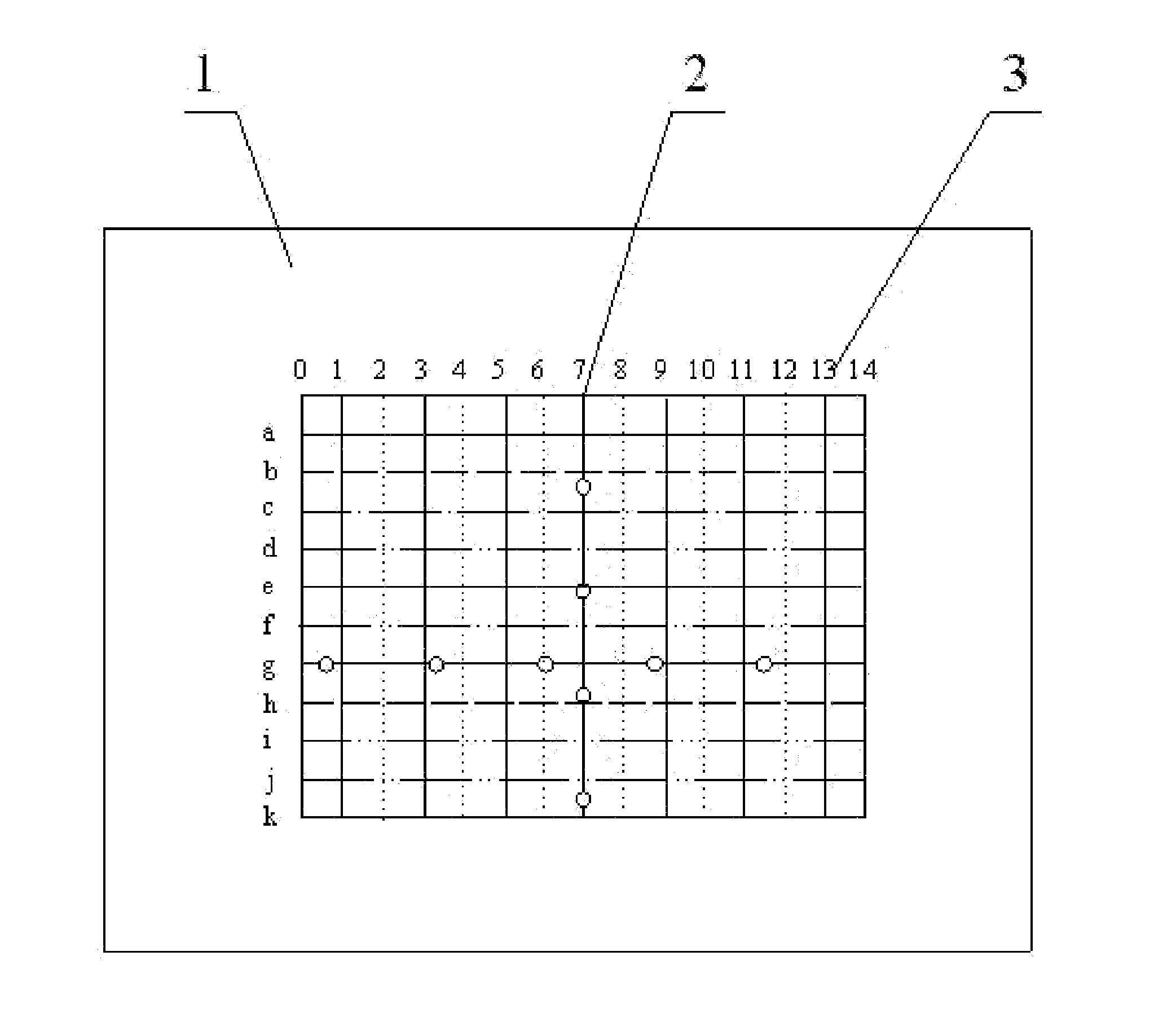

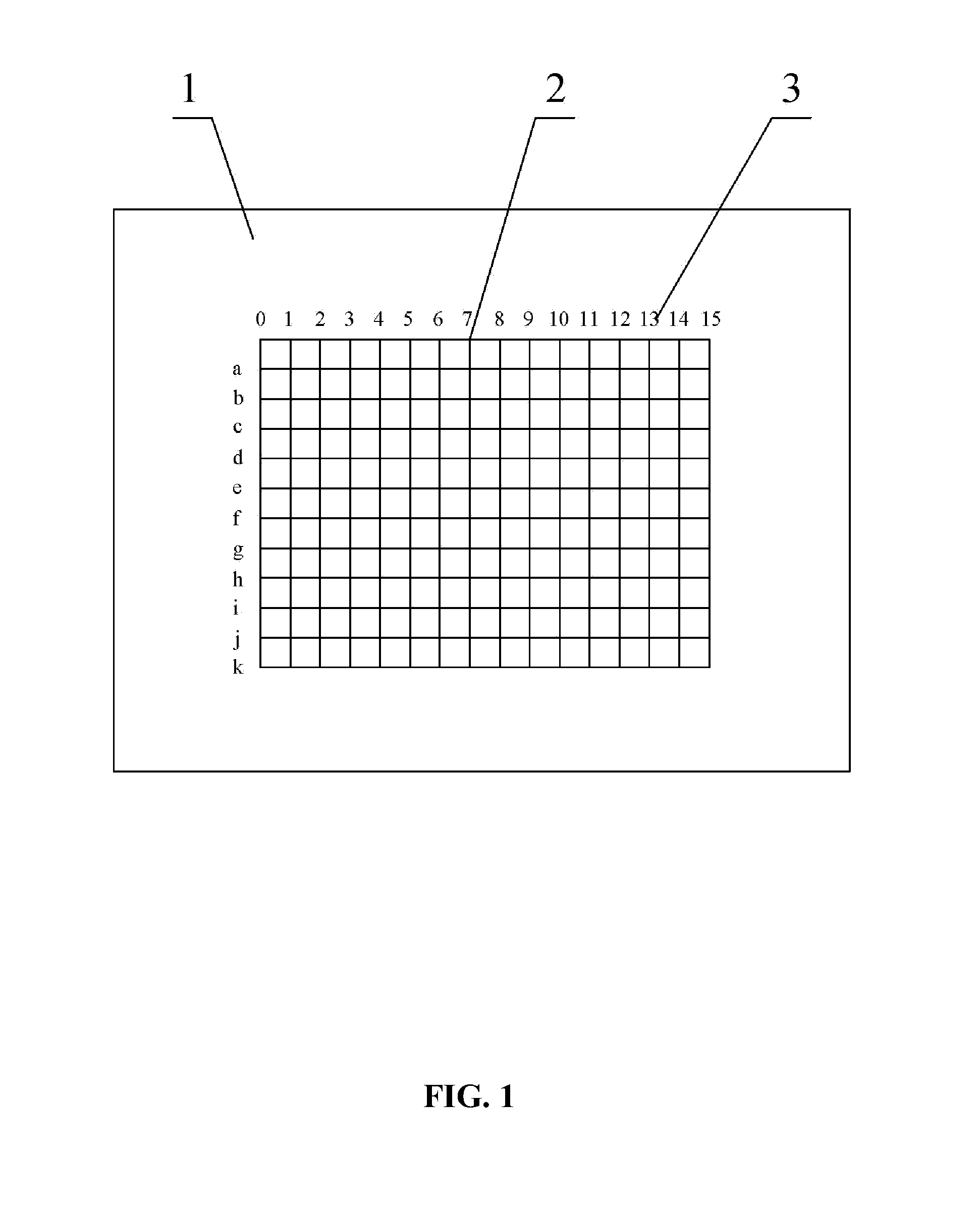

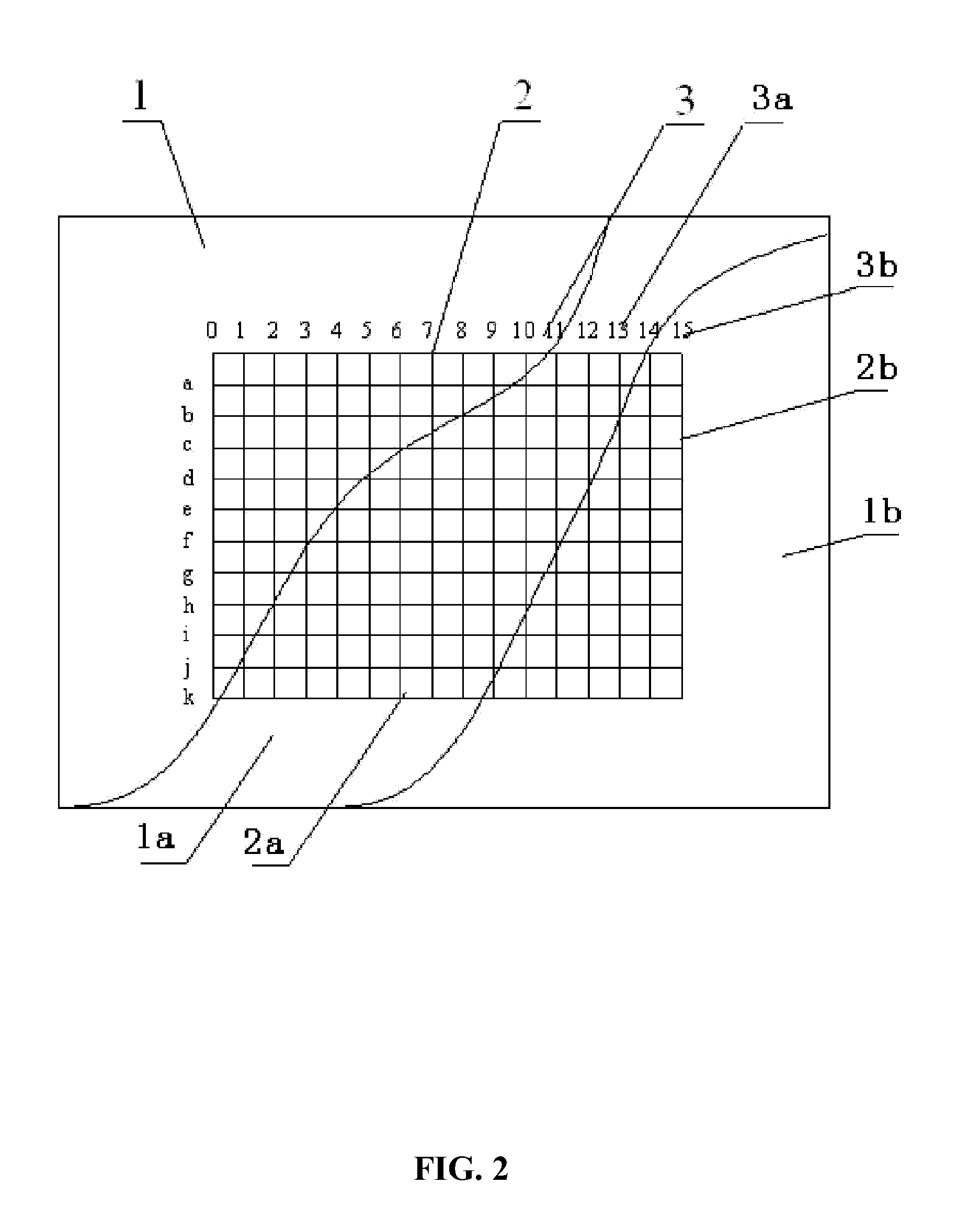

Positioning system, indoor positioning method, server and storage medium

ActiveCN107995683ASignal strength is accurateGuaranteed accuracyUsing reradiationWireless communicationDirectional antennaComputer module

The disclosure discloses a positioning system, an indoor positioning method, a server and a storage medium, belonging to the technical field of positioning. The positioning system comprises a positioning server and n acquisition modules in a target area; wherein the target area comprises n cell grids, and the n cell grids and the n acquisition modules have a one-to-one correspondence; the acquisition module comprises a directional antenna and a wireless probe connected with the directional antenna, and each wireless probe is connected with the positioning server through a wired network and / ora wireless network. According to the embodiment of the disclosure, the target area is divided into n cell grids, and the acquisition module in each cell grid is used to collect wireless signals in thecell grid; because the environment in one cell grid is relatively simple, so the multipath transmission phenomenon is not easy to appear; therefore, the signal intensity of the wireless signal collected by the acquisition module is more accurate, so that the accuracy of the positioning based on the signal strength of the subsequent positioning server is ensured, and the positioning accuracy is greatly improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

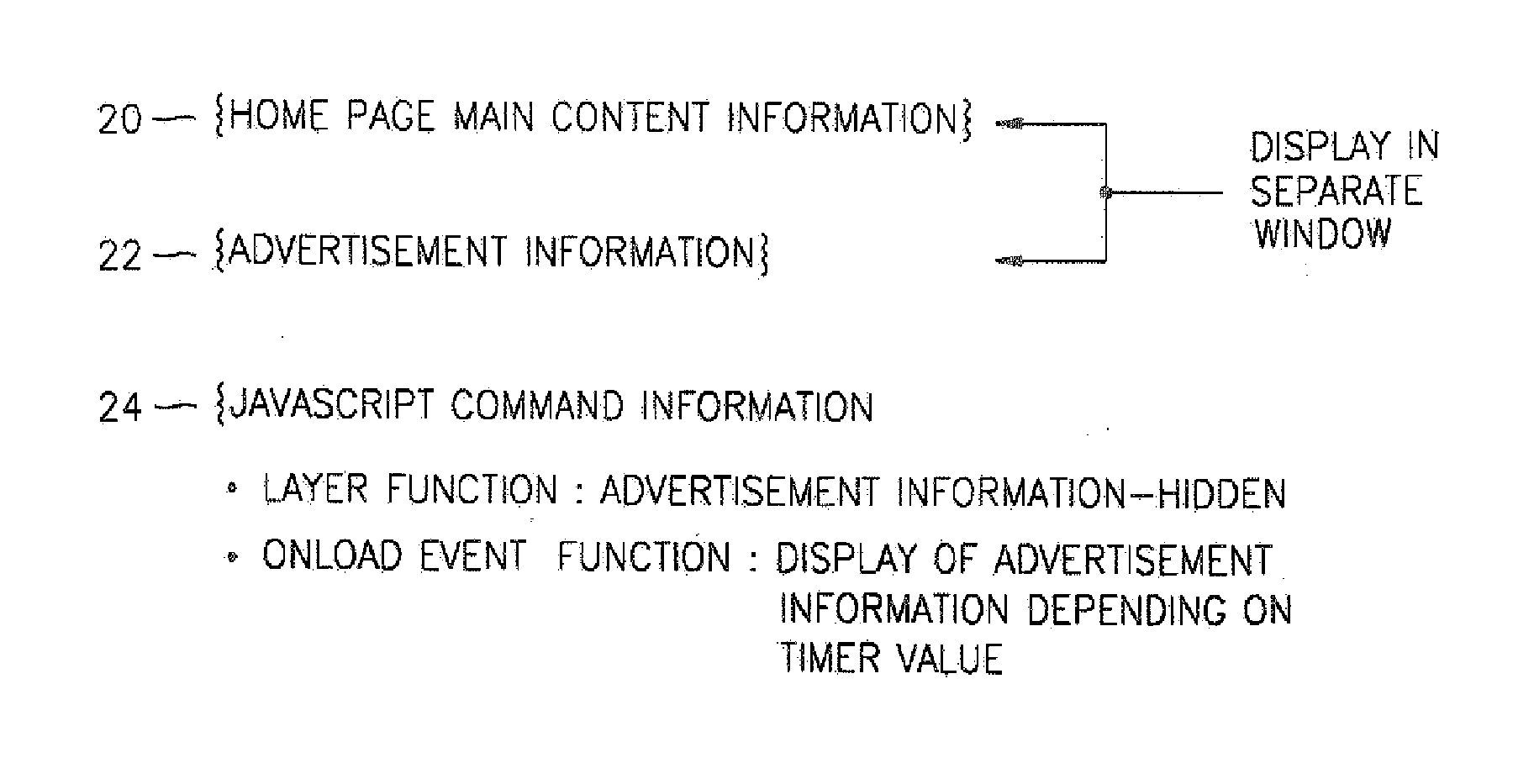

Home page advertising method

InactiveUS20070016480A1Attention of userSimple environmentAdvertisementsSpecial data processing applicationsOperational systemHome page

A home page advertising method is provided. The home page advertising method for transmitting home page data, including advertisement information, from a server to a client computer, wherein the server computer and client computers are interconnected through a network, includes the step of transmitting home page data, including one or more program codes that perform a predetermined layer function for displaying home page main content information and advertisement information on a home page screen in a separate window, wherein the program codes are written using a predetermined object-oriented programming language for implementing a predetermined multi-platform application within an operating system of the client computer. The home page advertising method reduces the complexity of a home page screen due to the presence of advertisement screens, while still effectively attracting the user's attention.

Owner:SAMSUNG ELECTRONICS CO LTD

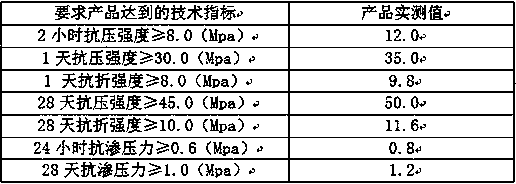

Production method of high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar

The invention discloses a production method of high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar. Raw materials of the high-strength non-vibrated environmental-friendly smooth facing fabricated part mortar comprises limestone machine-made sand, limestone powder, early-strength sulphoaluminate cement, ordinary silicate cement, composite coupling agent, water reducing agent, dispersible emulsion powder, cellulose ether, starch ether, sodium tetraborate, lithium carbonate, antifoaming agent and high-strength fiber. According to the production method, the intrinsic defect of the crisp and hard performance of the mortar is overcome, the anti-cracking and anti-leakage performance of the mortar is improved, hollowing is reduced, the bonding force is improved,the mortar is more suitable for mechanical construction and has the advantages of low addition amount and high cost performance, and the rigidity of the mortar is improved; the problems are solved that the mortar is dry and is not easily scraped, the bonding strength is low, hollowing and falling phenomena are easily caused, the shrinkage amount is large, and the surface is easily cracked; the anti-freezing, anti-leakage and water-resistant performance of the mortar is improved, and the mortar has the advantages of being high in compressive strength, fracture resistance and leakage resistance,high in strength, non-vibrated, environmentally friendly and smooth.

Owner:GUANGXI HENGXIAN HENGFENG BUILDING MATERIAL

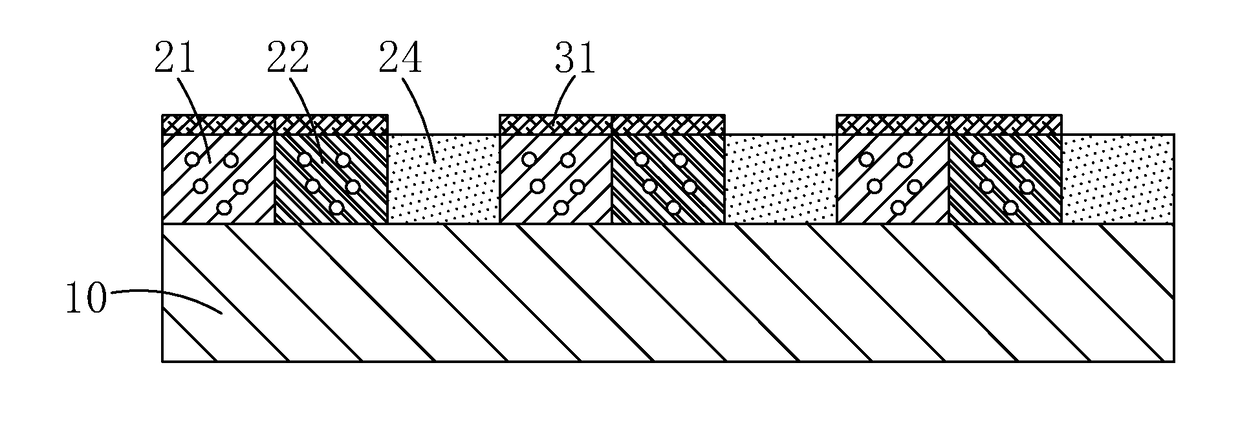

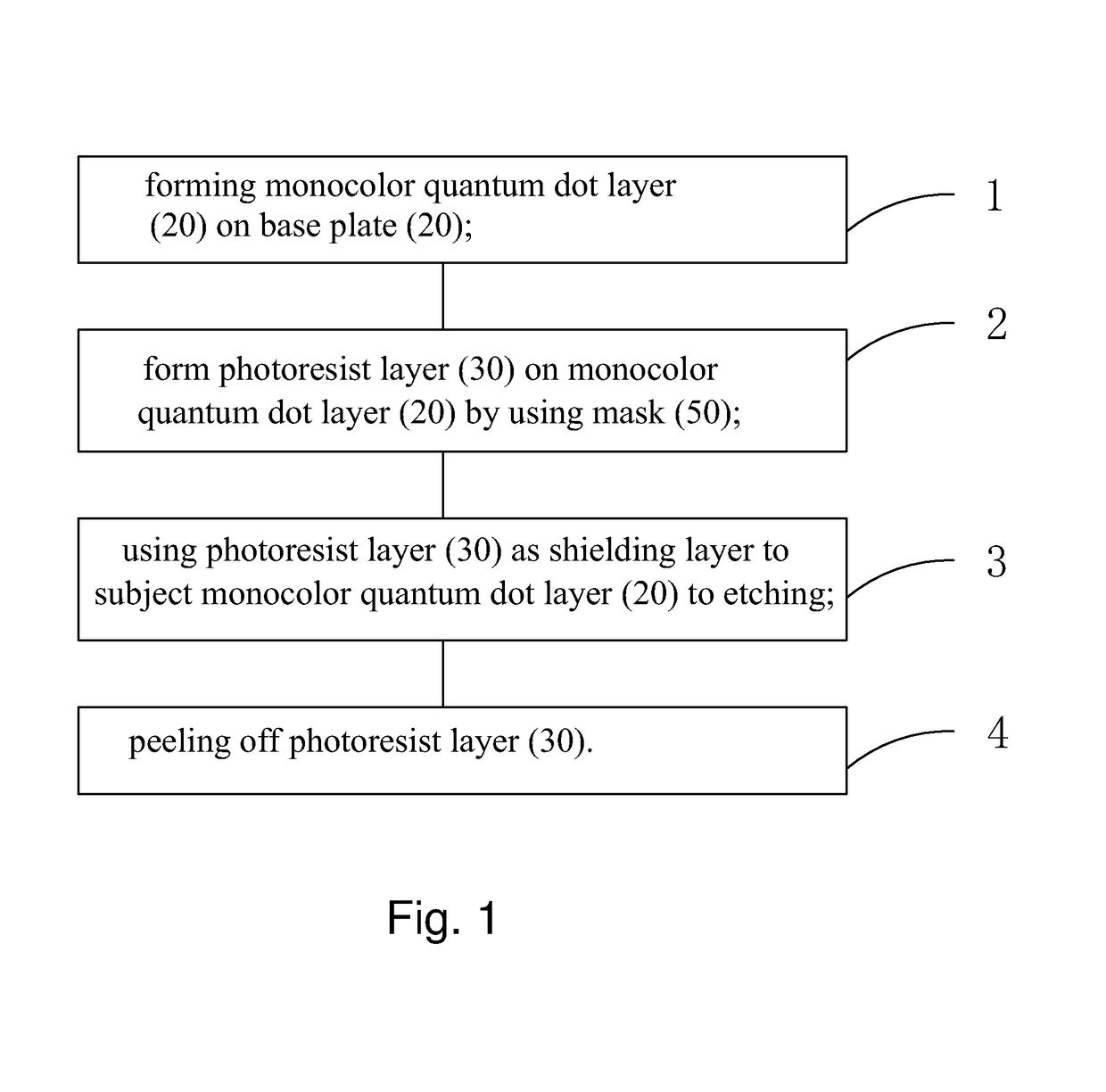

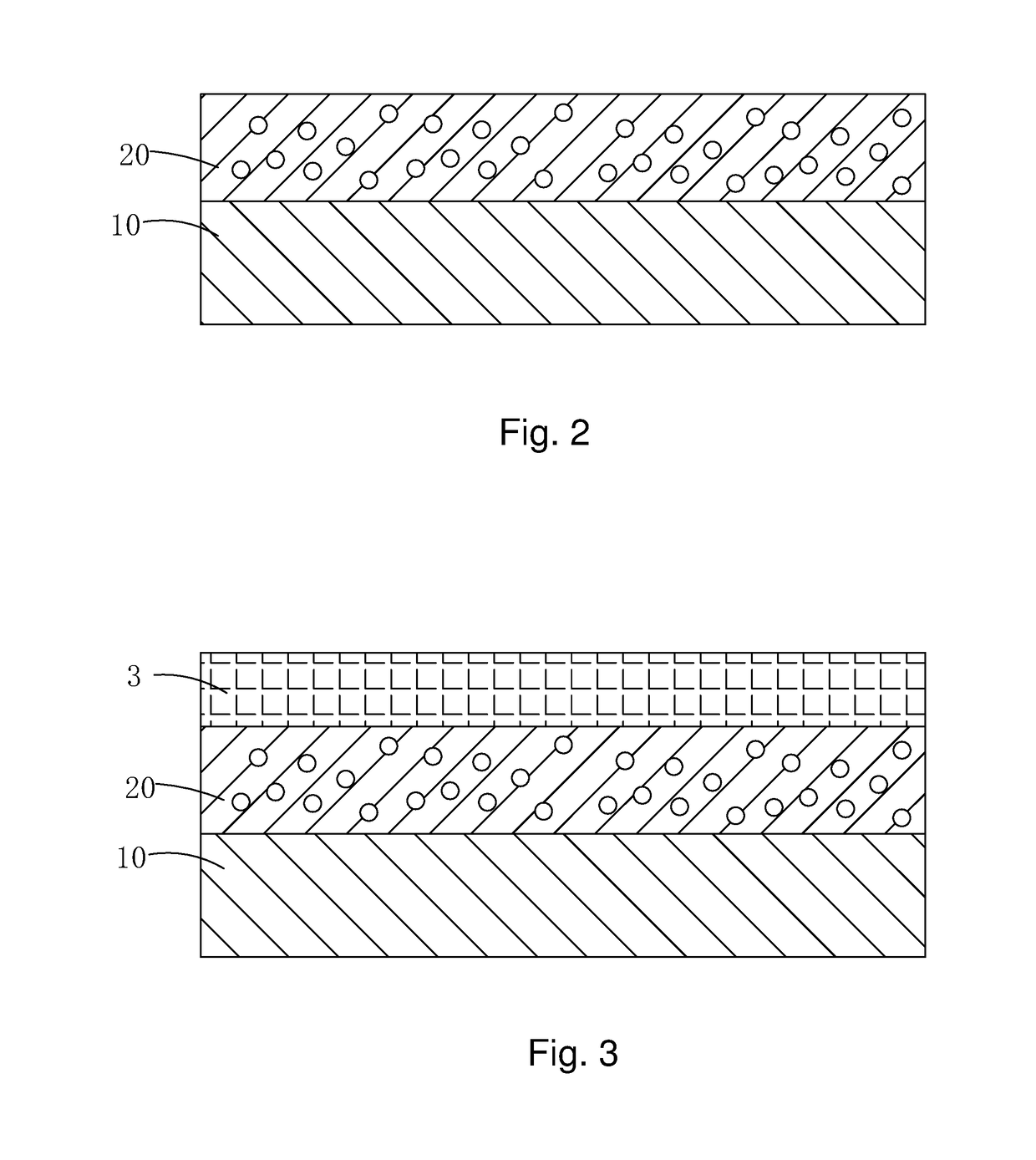

Method for patterning quantum dot layer and method for manufacturing quantum dot color filter

InactiveUS20170254934A1Simplify surface chemical environmentImprove luminous efficiencyOptical filtersSemiconductor/solid-state device manufacturingImage resolutionColor gel

The present invention provides a method for patterning a quantum dot layer and a method for manufacturing a quantum dot color filter. The method for patterning a quantum dot layer according to the present invention uses a photoresist layer having a patterned structure as a shielding layer to subject a monocolor quantum dot layer to etching to form a patterned quantum dot layer. The method simplifies the constituent components for making a quantum dot paste that is used to form a quantum dot layer and simplifying a surface chemical environment of the quantum dots to thereby increasing light emission efficiency of the quantum dot. Further, the method may manufacture a fine quantum dot pattern, greatly improving the resolution of the patterned quantum dot layer. The method for manufacturing a quantum dot color filter according to the present invention is applied to manufacturing a quantum dot color filter on the basis of the above-described method for patterning a quantum dot layer and the quantum dot color filter so manufactured has a fine quantum dot pattern, the light emission efficiency of the quantum dots being high to thereby effectively improve the resolution and backlighting utilization of a display device.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

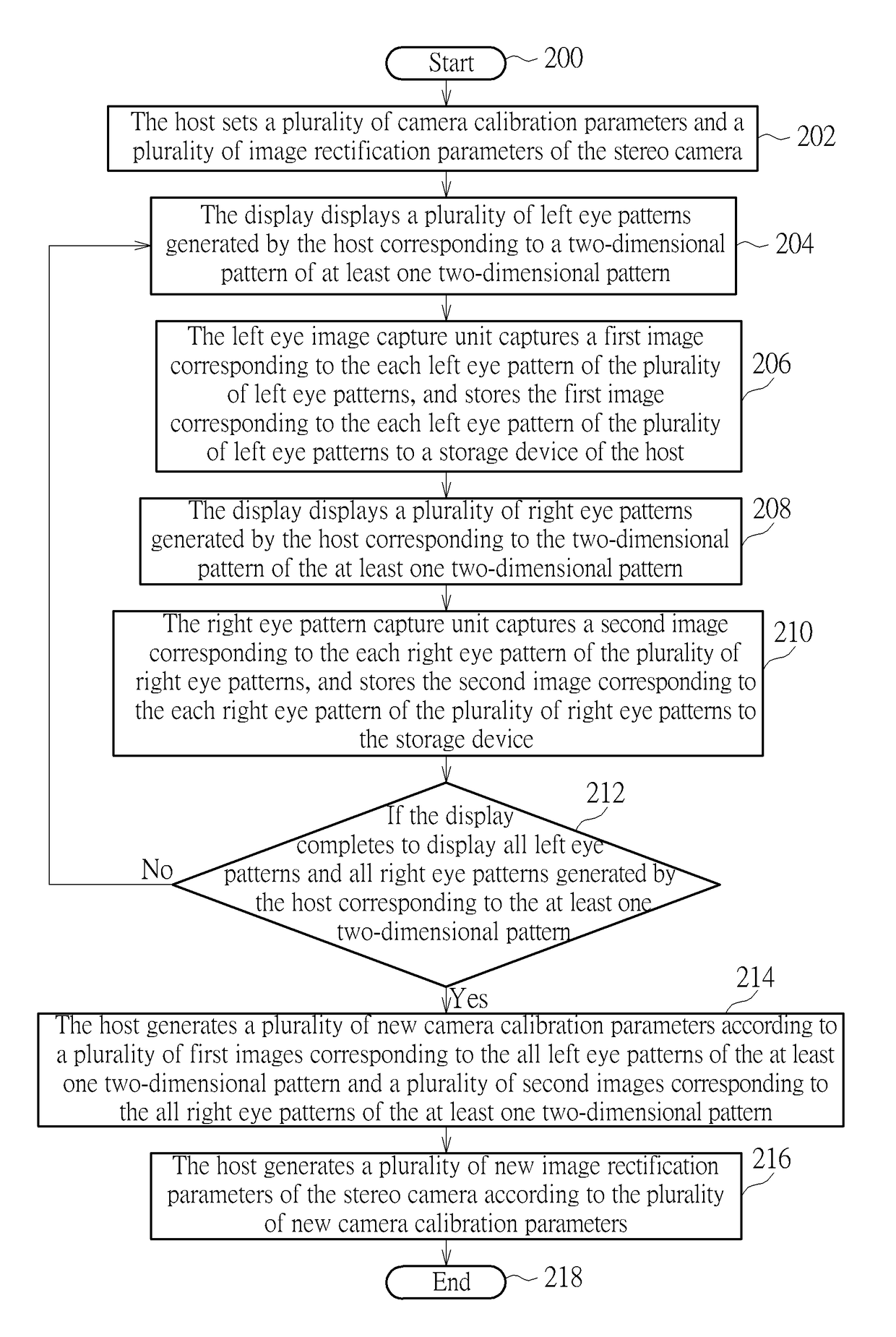

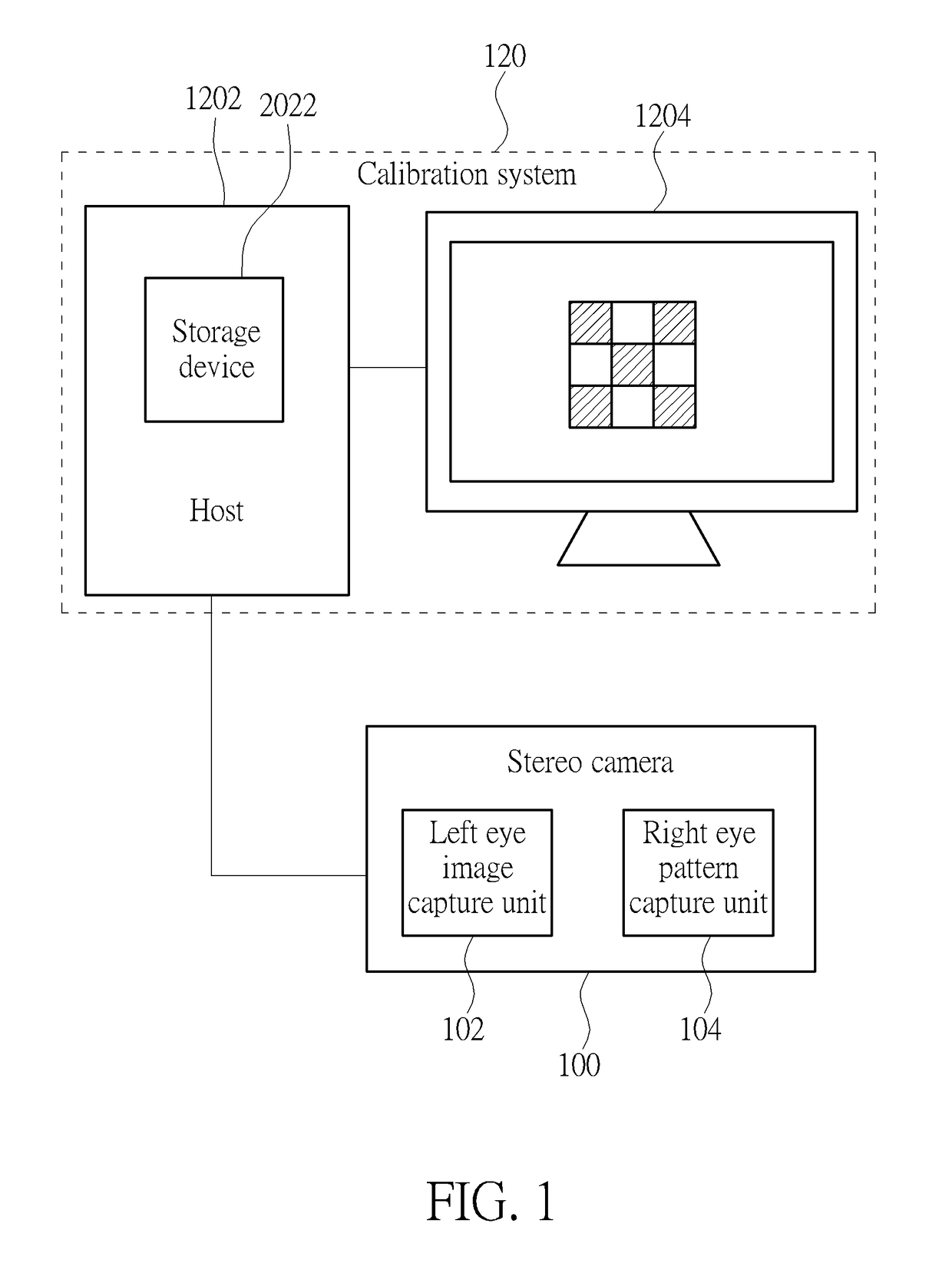

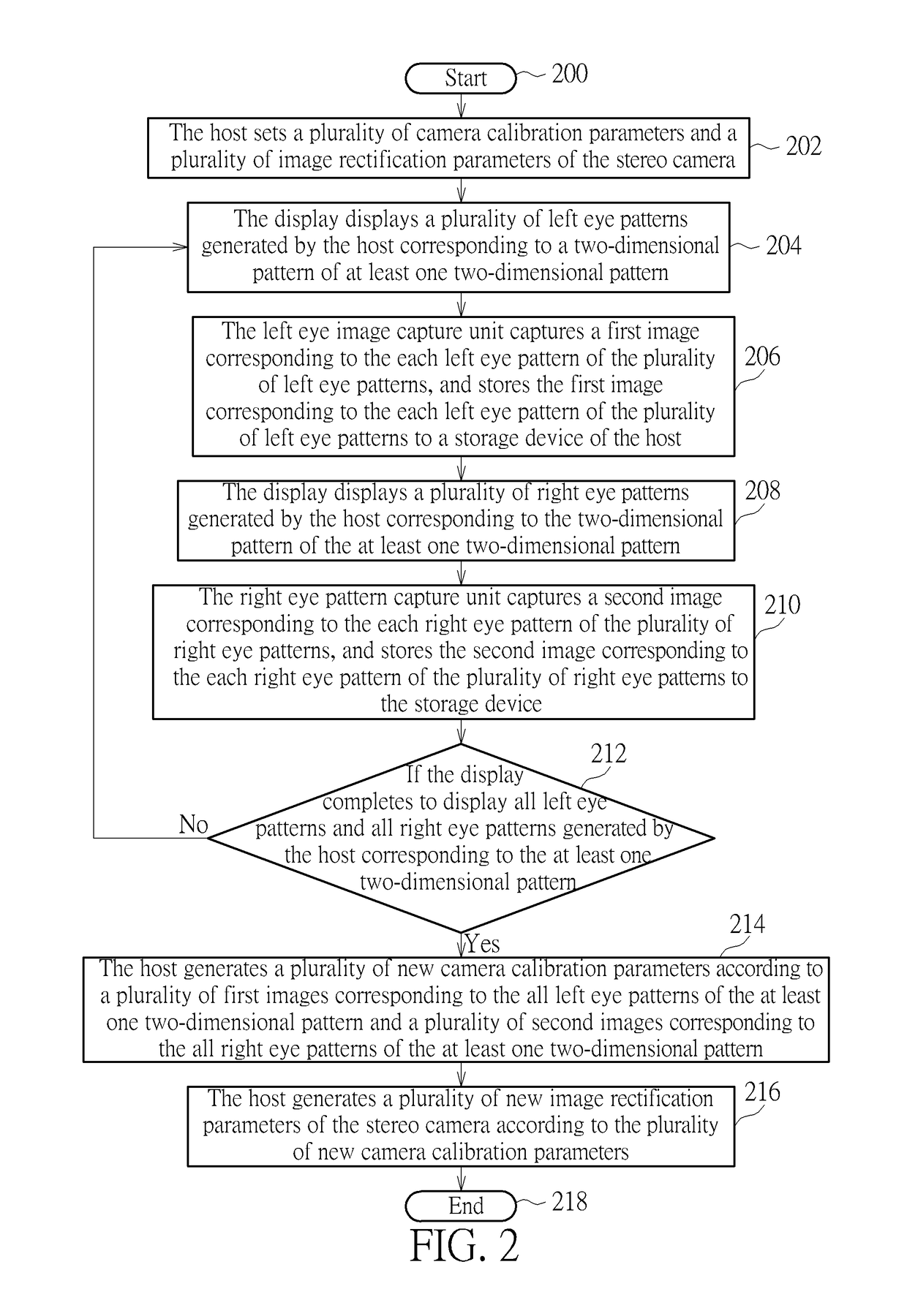

Calibration system of a stereo camera and calibration method of a stereo camera

ActiveUS9628778B2Simple environmentReduce verification timeImage analysisSteroscopic systemsStereo cameraImage capture

A calibration method of a stereo camera includes optionally setting a plurality of camera calibration parameters and a plurality of image rectification parameters of the stereo camera; executing an image capture step on at least one left eye pattern and at least one right eye pattern corresponding to each two-dimensional image of at least one two-dimensional image; generating a plurality of new camera calibration parameters according to a plurality of first images corresponding to all left eye patterns corresponding to the at least one two-dimensional image and a plurality of second images corresponding to all right eye patterns corresponding to the at least one two-dimensional image; and generating a plurality of new image rectification parameters of the stereo camera according to the plurality of new camera calibration parameters.

Owner:EYS3D MICROELECTRONICS CO

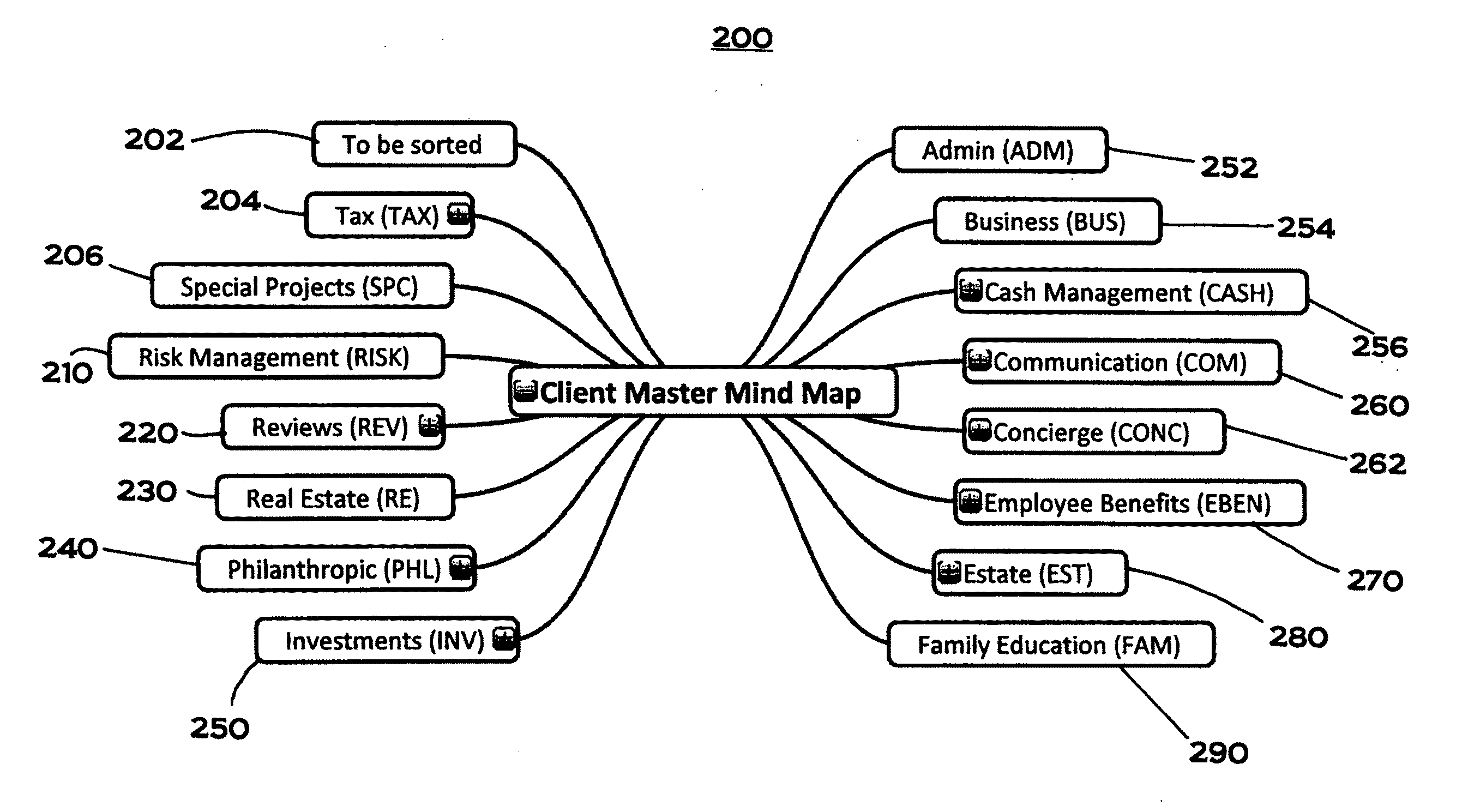

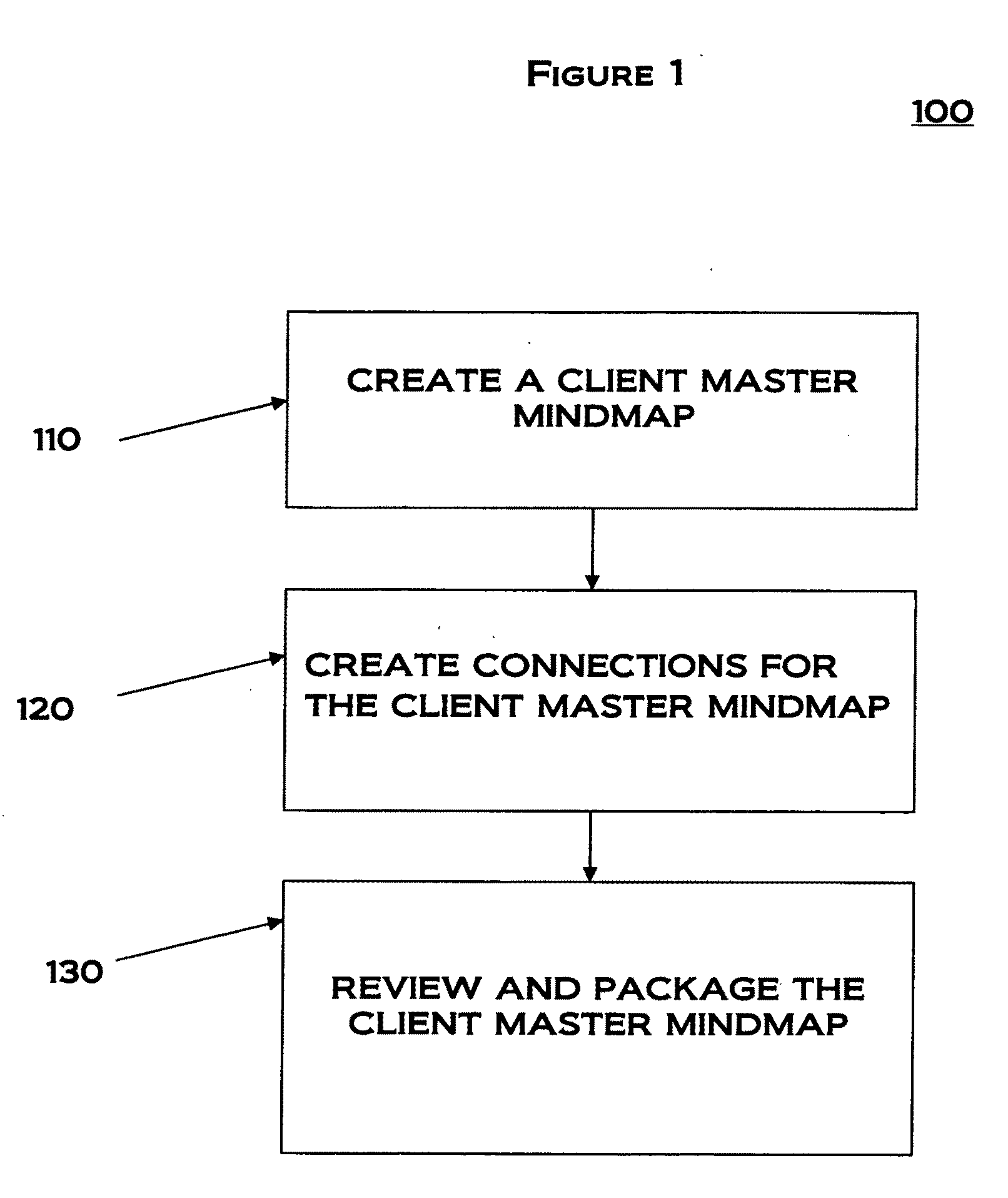

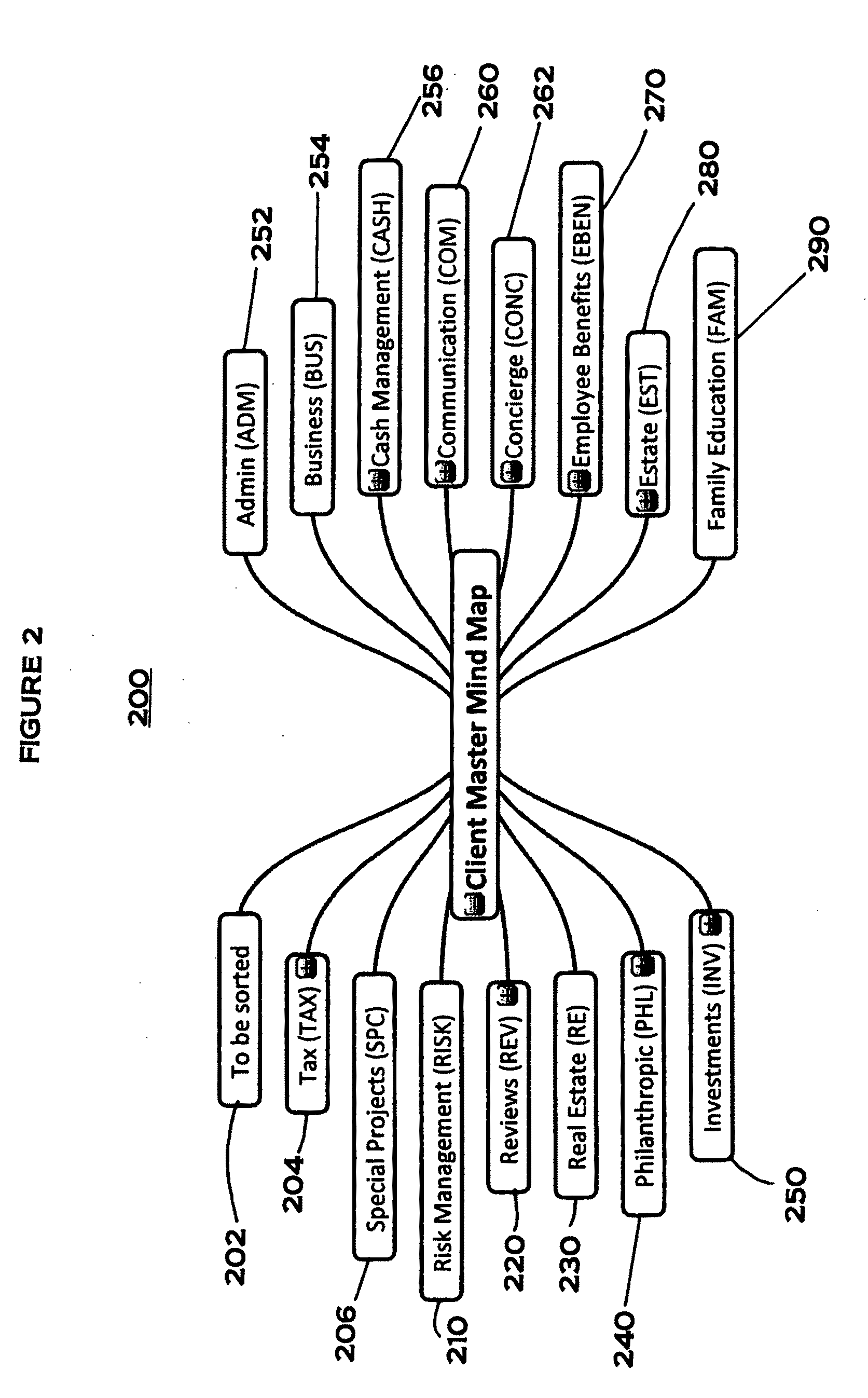

Mindmap Illustrator

ActiveUS20110167329A1Simple processAvoid normal workOffice automationSpecial data processing applicationsCustomer relationship managementDocumentation

Owner:KLABEN GARY W

Spray dried emulsifier compositions, methods for their preparation, and their use in oil-based drilling fluid compositions

ActiveUS8258084B2Reduce shipping costsSimple environmentTransportation and packagingFluid removalParticulatesAlkaline earth metal

Spray dried emulsifier compositions are described, which have desirable emulsifying and wetting characteristics. Among other advantages, the solid particulate emulsifier compositions greatly reduce transportation costs and simplify the logistics and environmental concerns associated with shipping large volumes of solvent-containing liquids. The emulsifier comprises (1) a carboxylic acid terminated fatty amine condensate or (2) a modified tall oil or (3) a blend of (1) and (2) that is converted to its alkali or alkaline earth metal salt and spray dried.

Owner:INGEVITY SOUTH CAROLINA

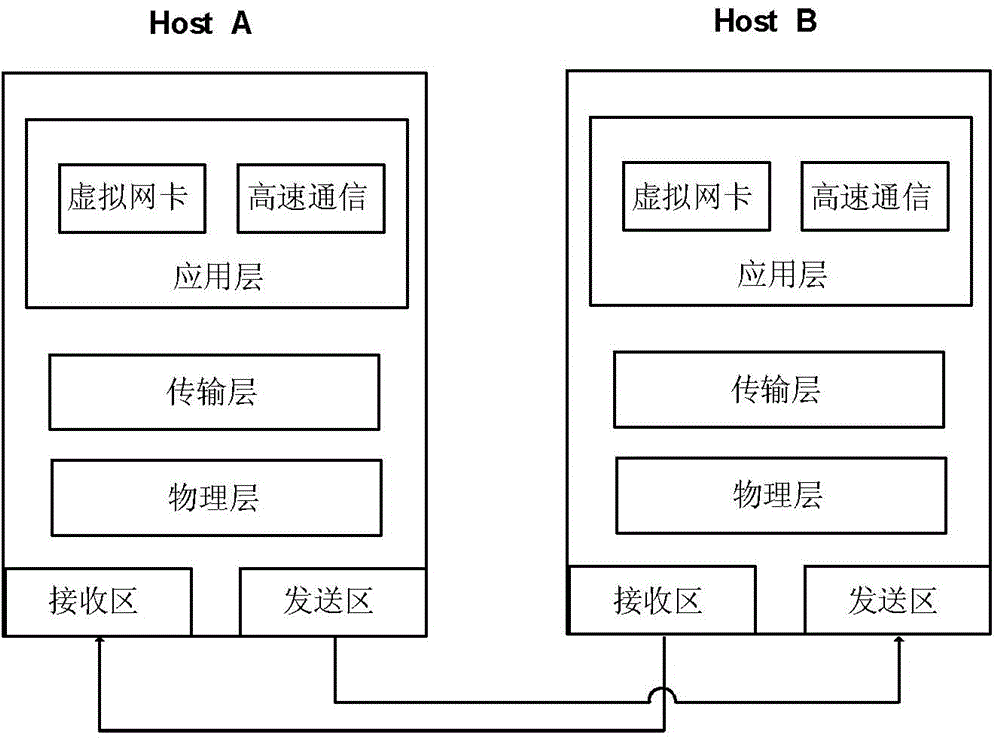

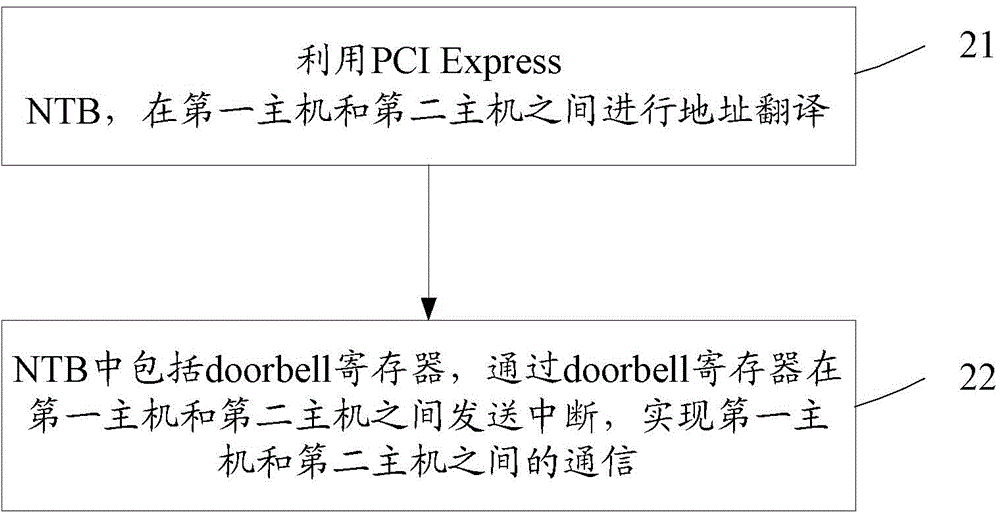

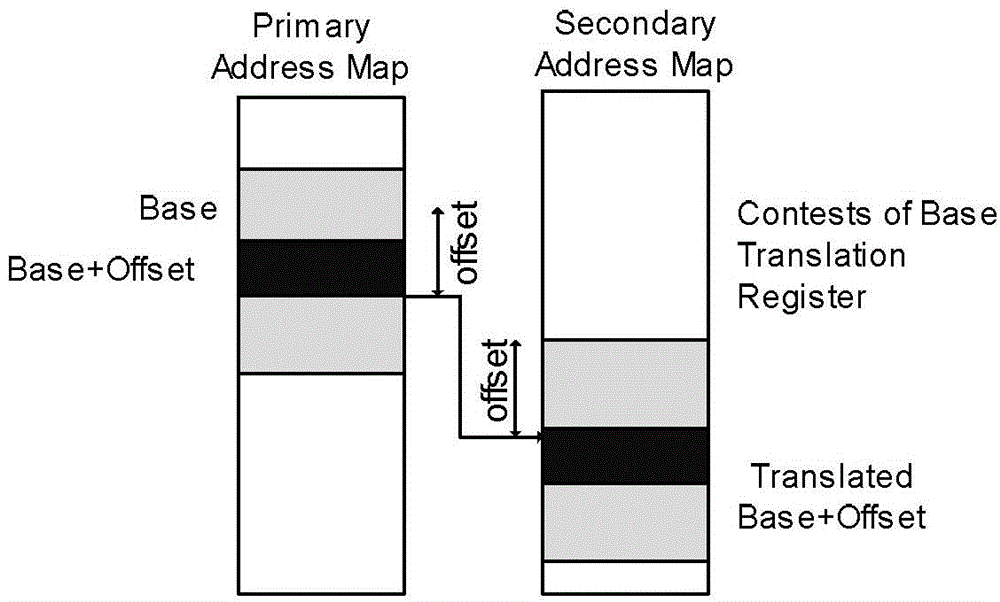

Communication method and system between double controls

ActiveCN104486365ASimple environmentShort transmission distanceTransmissionElectric digital data processingDoorbellPCI Express

The invention provides a communication method between double controls. The method comprises carrying out address translation between a first host and a second host based on PCI Express NTB, the NTB comprising a doorbell register; and sending interrupt between the first host and the second host through the doorbell register to realize communication between the first host and the second host. The communication method and system are suitable to be used between the first host of a local system and the second host of a far-end system, can simplify protocols, and can guarantee safety and reliability of data.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

Document Processing System

InactiveUS20120117464A1Avoid difficult choicesSimple environmentDigital data processing detailsSpecial data processing applicationsInformation processingDisplay device

Owner:FUJIFILM BUSINESS INNOVATION CORP

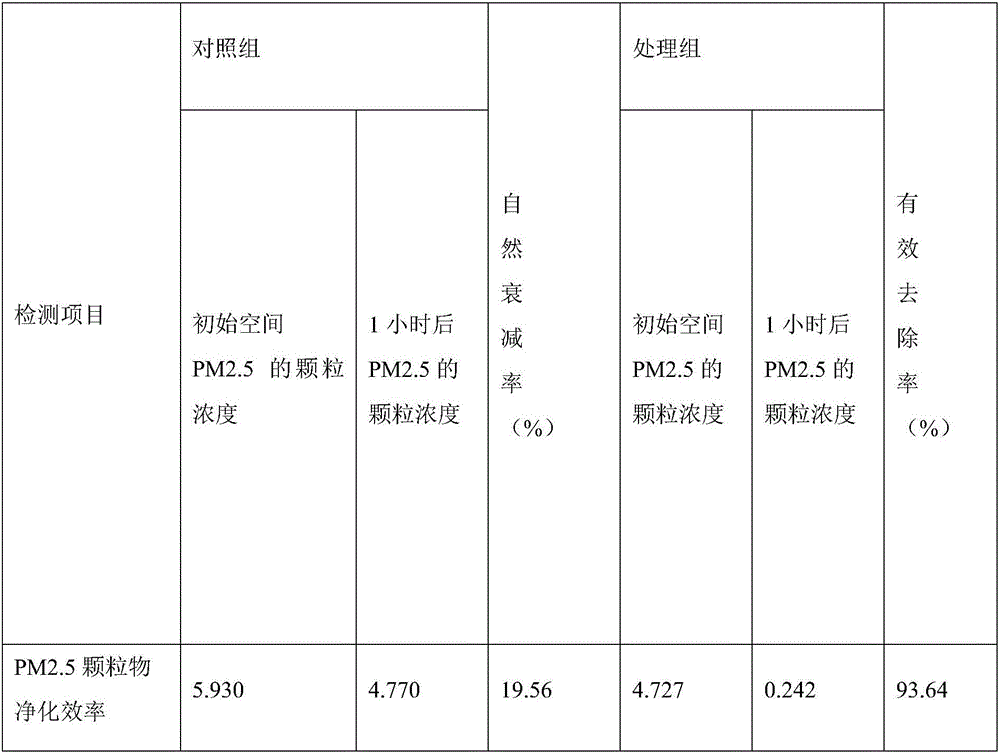

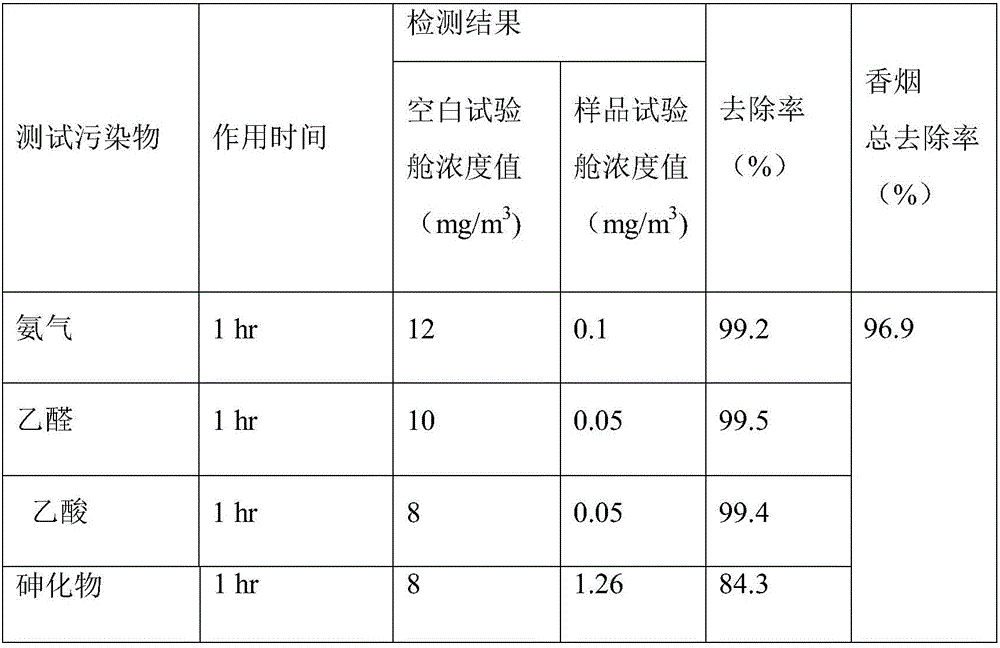

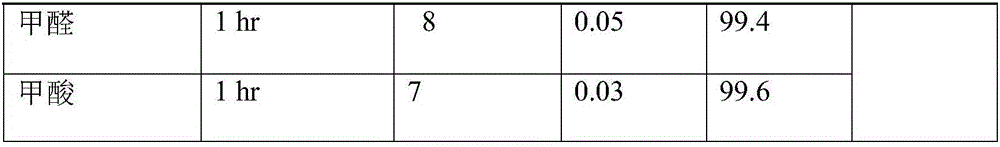

Composite air purifying agent for purifying cigarette smoke

InactiveCN106000304AGood purification effectImprove aerodynamic performanceGas treatmentOther chemical processesBiological activationVacuum drying

The invention discloses a composite air purifying agent for purifying cigarette smoke. The composite air purifying agent is prepared by the steps: firstly, carrying out high temperature calcination activation of natural zeolite for 2-8 hours at the temperature of 400-800 DEG C, to obtain modified zeolite; placing the modified zeolite in a saturated potassium permanganate solution, immersing for 24 hours in a brown closed reactor at room temperature, after the impregnation is completed, taking out, vacuum-drying at the temperature of 80 DEG C, naturally cooling to obtain potassium permanganate-supported zeolite, and carrying out sealed light-shielding preservation; and evenly mixing 20-30 mesh activated carbon and the potassium permanganate-supported zeolite, to obtain the composite air purifying agent. The air purifying agent can effectively remove 99.9% of indoor cigarette smell and micro-particles, improves the purification effect of an air purifier, improves the indoor environment, avoids damage of secondhand smoke, and provides a healthy and comfortable environment for the family.

Owner:SOLVE AIR HEFEI

Medical adhesive film

InactiveUS20130295345A1Precise positioningWide applicationSurgical adhesivesDecorative surface effectsAdhesiveEngineering

Owner:WUHAN VSD MEDICAL SCI & TECH CO LTD

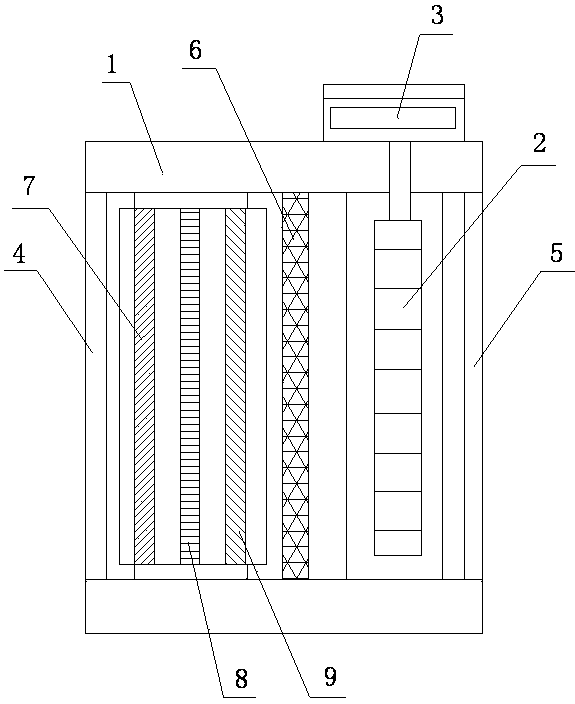

Intelligent air purifier

InactiveCN103405969AImprove air qualitySmall volumnDispersed particle filtrationIndoor air qualityEngineering

The invention discloses an intelligent air purifier comprising a purifier shell, a centrifugal fan, a filter and an intelligent regulation controller, wherein an air inlet is formed in one side of the purifier shell while an air outlet is formed in the other side of the purifier shell, the centrifugal fan is close to the air outlet, the filter is close to the air inlet, a silencer is arranged between the filter and the centrifugal fan, and the intelligent regulation controller controls the centrifugal fan to operate and is fixed outside the purifier shell. The intelligent air purifier has the advantages of simple structure, convenience in operation and high intelligent degree. The filter is used for purifying air, and thus the indoor air quality is improved greatly. By virtue of the silencer, the sound of the purifier is lowered greatly, and thus a quiet environment is created for people.

Owner:俞舒洋

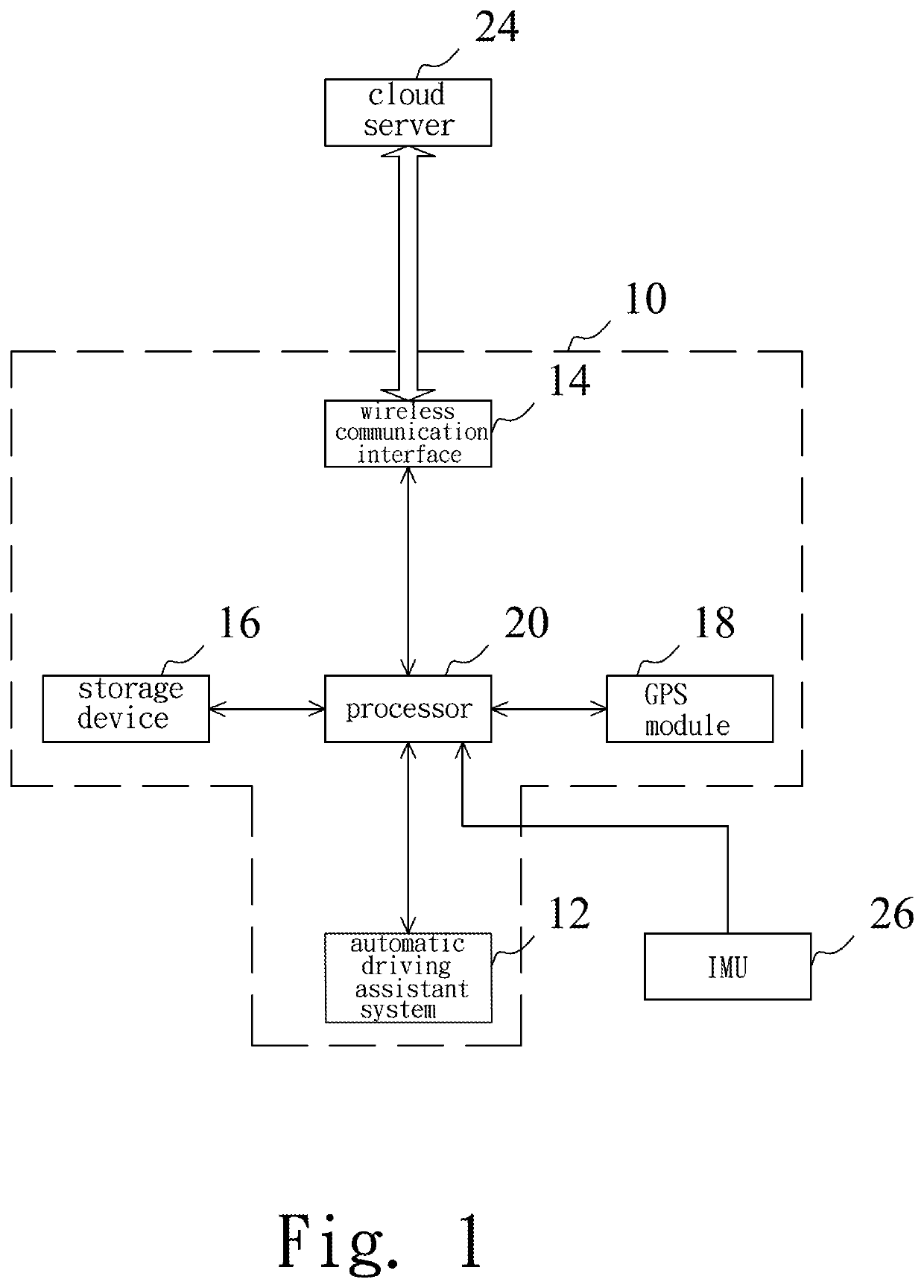

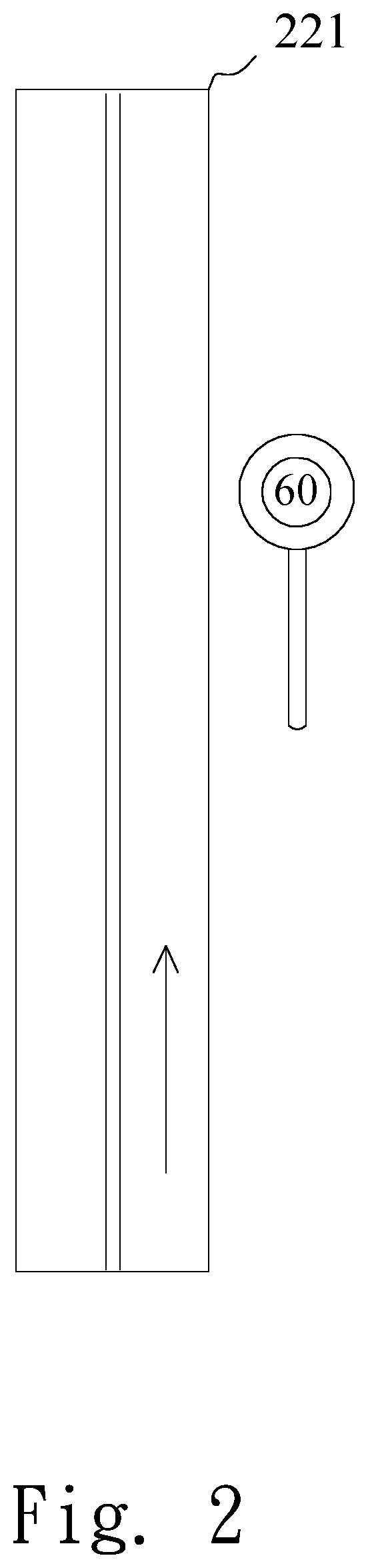

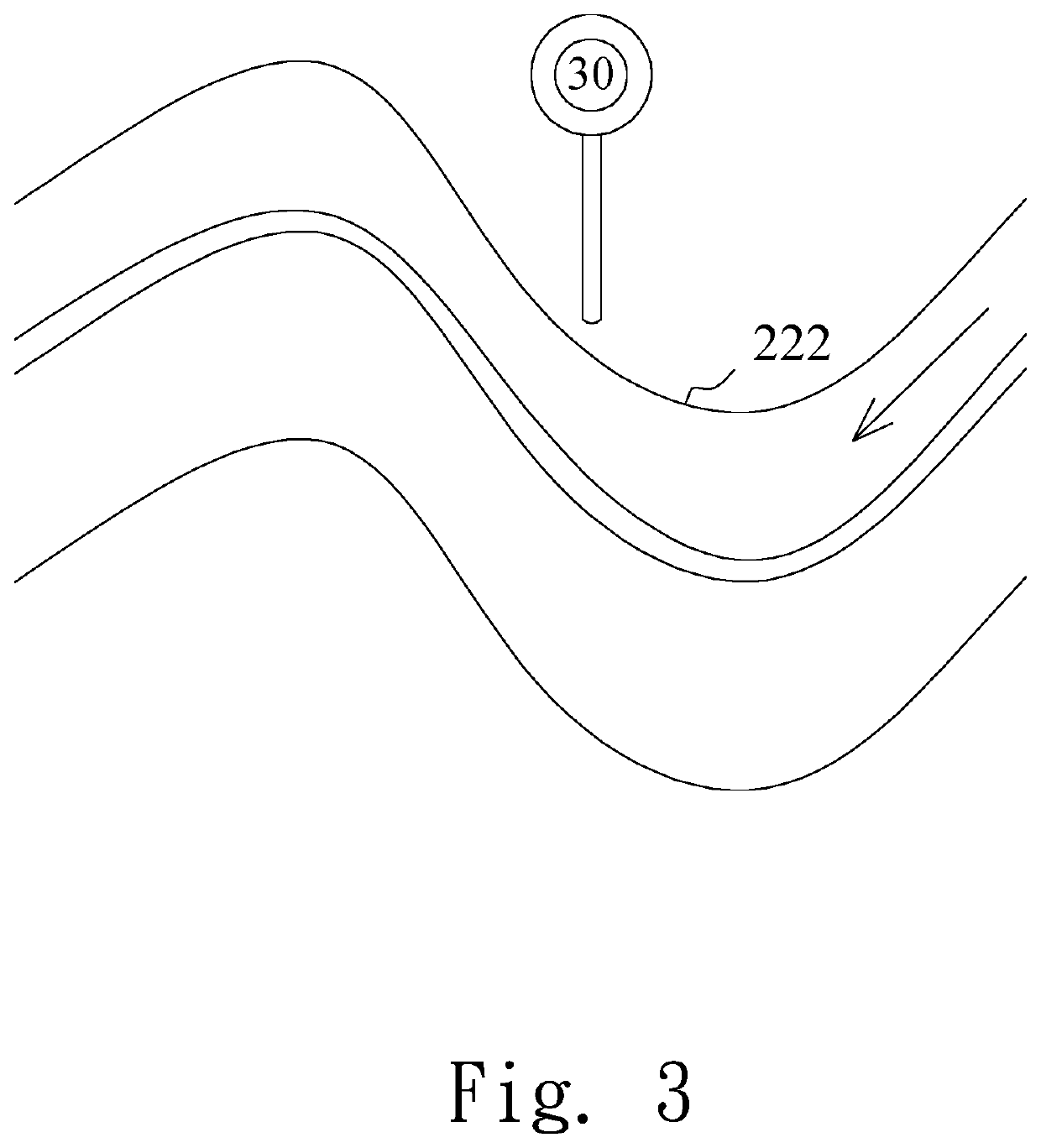

Dynamic graphic information classification device and method

ActiveUS20200201899A1Reduce data volumeSimple environmentInstruments for road network navigationStill image data clustering/classificationCommunication interfaceGraphics

A dynamic graphic information classification device which is installed in a vehicle and comprises at least one automatic driving assistant system, a wireless communication interface, a storage device, a GPS module, and a processor. The wireless communication interface is connected with a cloud server where a high definition map and 3D point cloud map information are stored. The GPS module acquires position coordinates of the vehicle from an electronic map. The storage device stores at least one of at least one road curvature and at least one crossroads feature of a road environment of a predetermined driving path of the vehicle. The processor classifies the map information to be downloaded according to at least one of at least one road curvature and at least one crossroads feature and an automatic driving level of the automatic driving assistant system, whereby to reduce the time for download.

Owner:AUTOMOTIVE RES & TESTING CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com