Medical adhesive film

a technology of adhesive film and medical devices, applied in the field of medical devices, can solve the problems of inaccurate positioning, affecting rehabilitation, lowering the immune ability of the body, etc., and achieve the effects of accurate positioning, wide application, and reduced time for taking x-ray images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

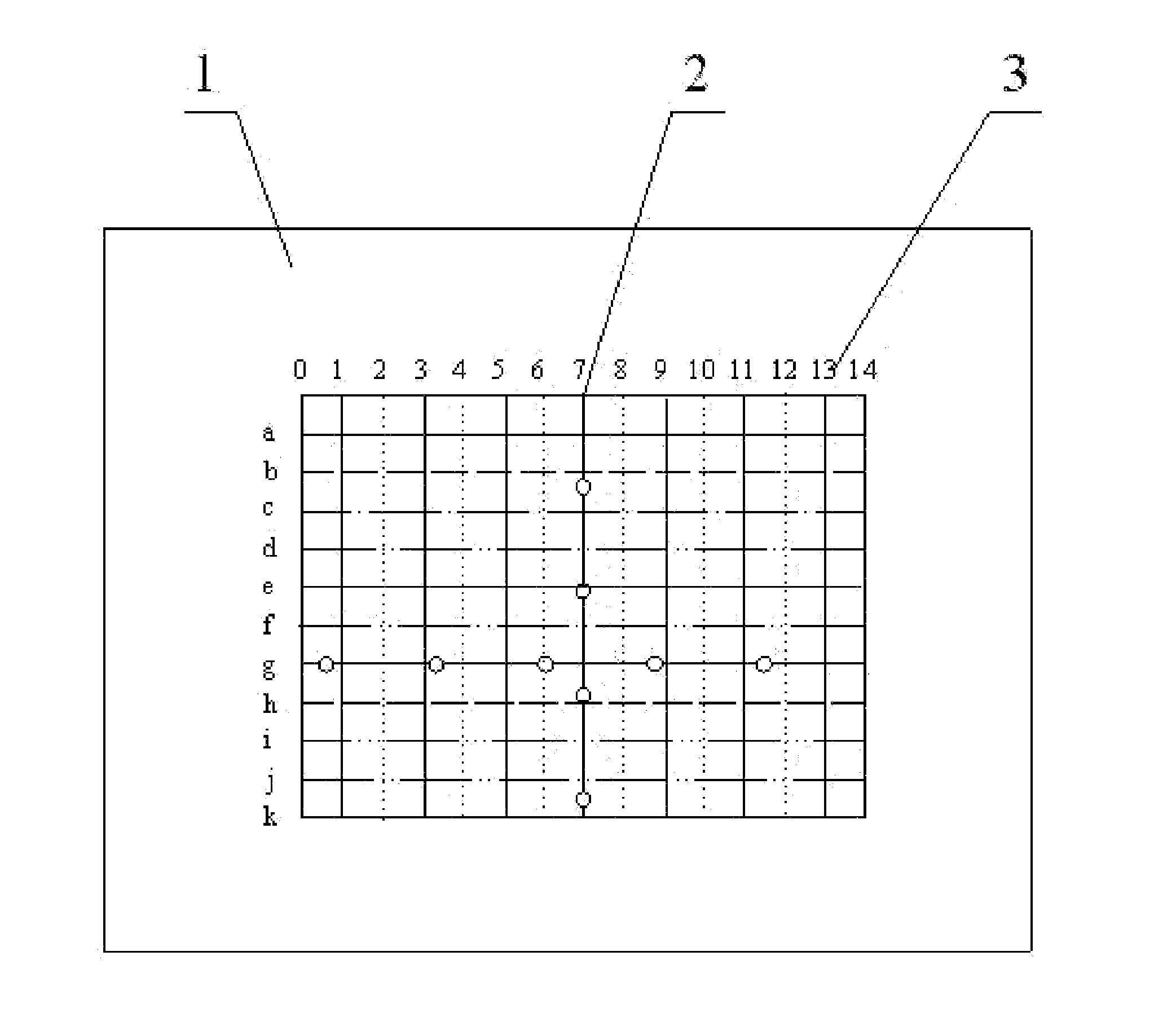

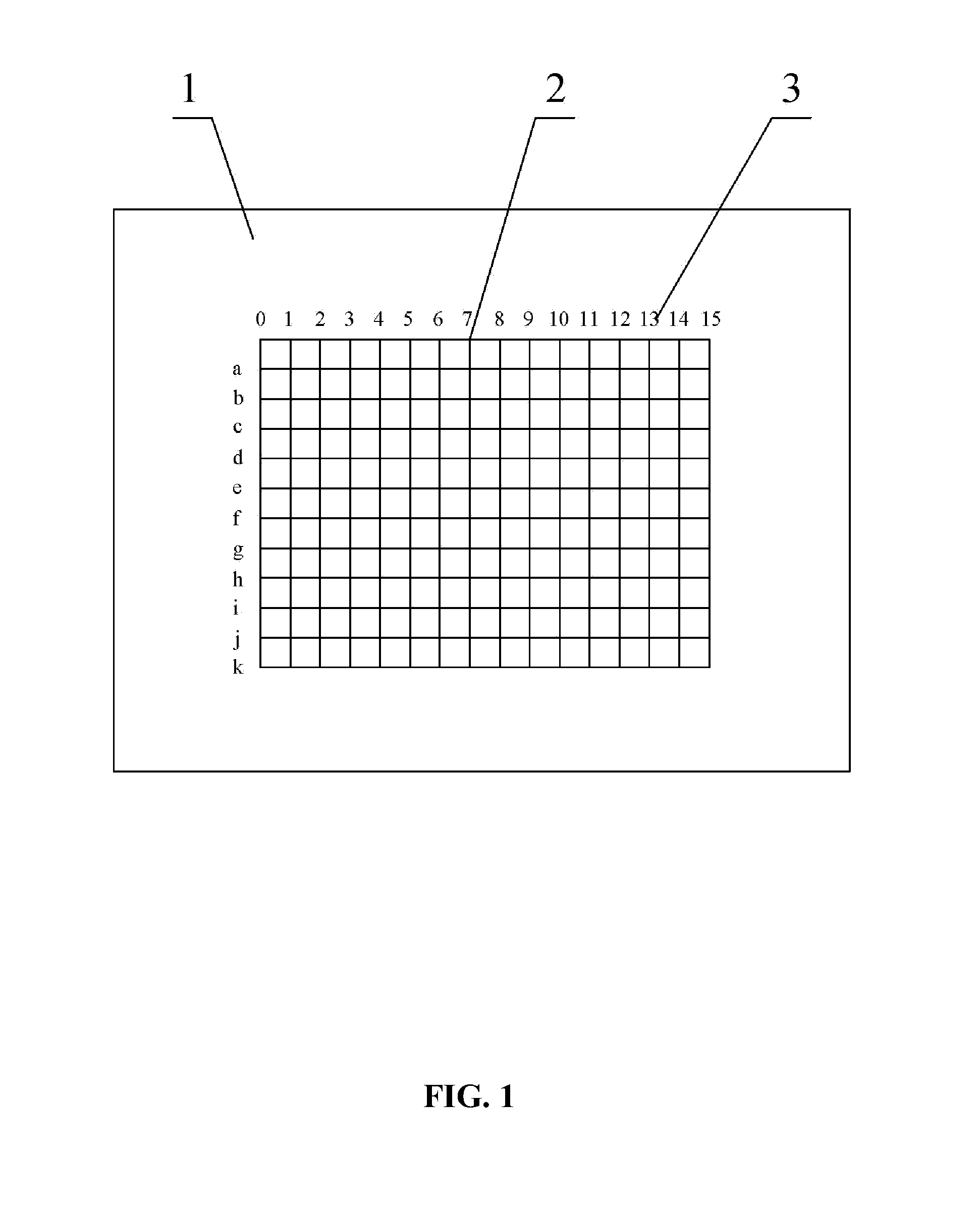

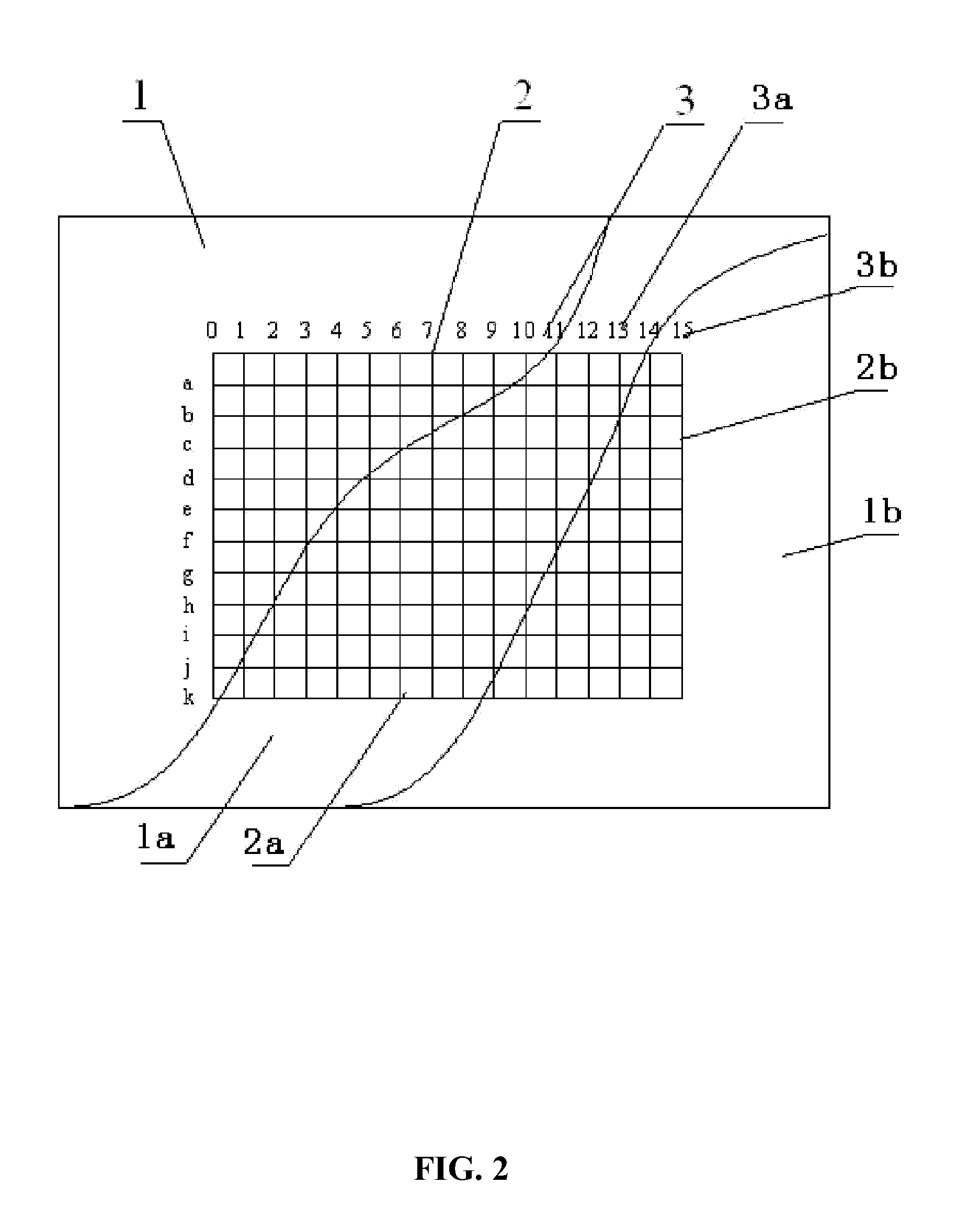

Grid-Type Adhesive Film: As Shown in FIGS. 1-3

[0037]The adhesive film comprises a plurality of layers of adhesive films. An upper surface of an uppermost adhesive film 1 is provided with a developing reference axis 2. A first inner adhesive film 1a, a second inner adhesive film 1b . . . are arranged beneath the uppermost adhesive film 1. Each of the inner adhesive films 1a, 1b . . . comprises an upper surface comprising a reference axis 2a, 2b . . . being the same as the developing reference axis arranged on the uppermost adhesive film. The uppermost reference axis 2 of the uppermost adhesive film superposes the reference axis 2a, 2b . . . arranged on each of the inner adhesive films. The reference axis 2, 2a, 2b . . . of each layer can be printed by a developing agent, or a non-developing agent. The developing reference axis 2 of the uppermost adhesive film 1 is provided with reference numbers 3. The inner adhesive films are also provided with reference numbers 3a, 3b . . . being t...

example 2

Point-Type Adhesive Film: As Shown in FIGS. 5-6

[0041]The adhesive film comprises a plurality of layers of adhesive films, what is different from Example 1 is that the reference axis of each adhesive film is formed by arranging points at equal intervals in vertical lines and transverse lines.

[0042]The points are circle points, square points, triangle points, trapezoid points, or heart-shape points.

[0043]The uppermost adhesive film is provided with the developing reference axis for the purpose of examination. The inner adhesive films are provided with the developing reference axis or the non-development axis according to different use: for examination purpose, the corresponding inner adhesive film is provided with the developing reference axis; and for radiotherapy purpose, the corresponding inner adhesive film is provided with the non-developing reference axis. The number of the layers of the inner adhesive films is between 1 and 3.

[0044]The method for using the adhesive film of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com