Green dust-fixing agent and preparation method thereof

A green, cellulose ether-based technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of low dust-fixing efficiency of water sprinkling, complicated production process, and complex process, and achieve easy industrial production and large-scale promotion, Efficient capture and fixation, and efficient suppression of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

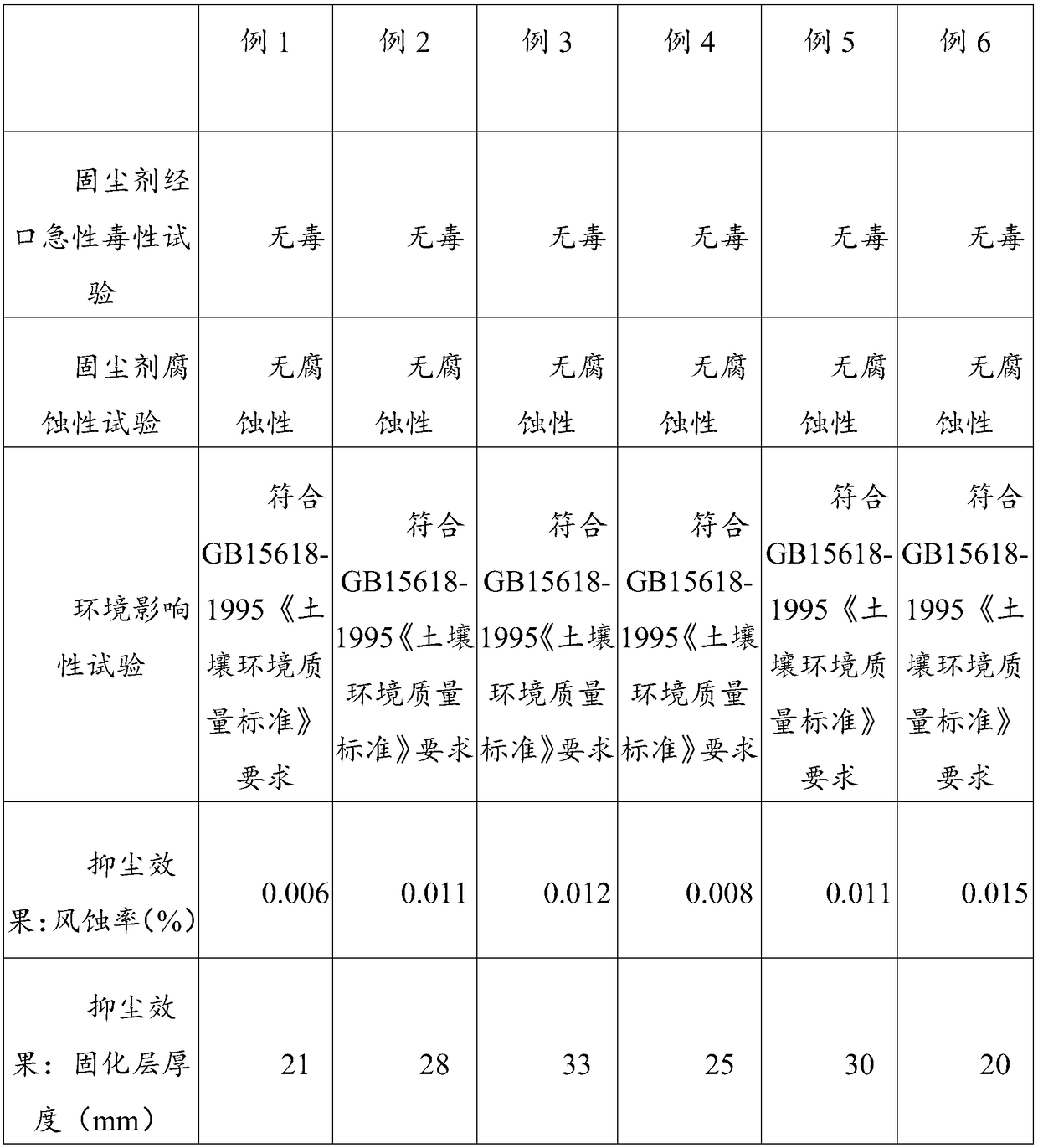

Embodiment 1

[0025] This embodiment provides a green dust-fixing agent. The raw material components include: 10 parts by weight of pregelatinized starch, 5 parts by weight of dextrin, 1 part by weight of xanthan gum, 10 parts by weight of carboxymethyl cellulose, and 10 parts by weight of sucrose , 500 parts by weight of water.

[0026] The green dust-fixing agent is prepared by the following method:

[0027] (1) Take pre-gelatinized starch, dextrin, xanthan gum, carboxymethyl cellulose, and sucrose in sequence and mix thoroughly to obtain a mixed powder; the average particle size of the pre-gelatinized starch is 0.15mm, and the viscosity is 400mpa·s; The DE value of dextrin is 17%, the solubility is 99.5%; the average particle size of xanthan gum is 0.11mm, the viscosity is 1650mpa s; the average particle size of carboxymethyl cellulose is 0.12mm, the viscosity is 800mpa s;

[0028] (2) Add water to the mixed powder, and stir at 15°C and 120rpm for 45min to make it fully mixed evenly to ...

Embodiment 2

[0030] This embodiment provides a green dust-fixing agent. The raw material components include: 60 parts by weight of pregelatinized starch, 5 parts by weight of dextrin, 5 parts by weight of xanthan gum, 5 parts by weight of hydroxypropyl methylcellulose, 80 parts by weight of sucrose parts by weight, 3000 parts by weight of water.

[0031] The green dust-fixing agent is prepared by the following method:

[0032] (1) Get pregelatinized starch, dextrin, xanthan gum, hydroxypropyl methylcellulose, sucrose successively, fully mix uniformly, obtain mixed powder; The average particle diameter of described pregelatinized starch is 0.15mm, The viscosity is 400mpa s; the DE value of dextrin is 17%, the solubility is 99.5%; the average particle size of xanthan gum is 0.11mm, the viscosity is 1650mpa s; the average particle size of hydroxypropyl methylcellulose is 0.14mm , the viscosity is 1300mpa s;

[0033] (2) Add water to the mixed powder, and stir at 60°C and 180rpm for 45min to...

Embodiment 3

[0035] This embodiment provides a green dust-fixing agent. The raw material components include: 30 parts by weight of pregelatinized starch, 10 parts by weight of dextrin, 1 part by weight of xanthan gum, 5 parts by weight of hydroxyethyl cellulose, and 20 parts by weight of sucrose , 1000 parts by weight of water.

[0036] The green dust-fixing agent is prepared by the following method:

[0037] (1) Get pregelatinized starch, dextrin, xanthan gum, hydroxyethyl cellulose, sucrose successively, fully mix uniformly, obtain mixed powder; The average particle diameter of described pregelatinized starch is 0.15mm, viscosity is 400mpa s; the DE value of dextrin is 17%, the solubility is 99.5%; the average particle diameter of xanthan gum is 0.11mm, the viscosity is 1650mpa s, the average particle diameter of hydroxyethyl cellulose is 0.12mm, the viscosity is 1500mpa s;

[0038] (2) Add water to the mixed powder, and stir at 120 rpm for 80 min at 45°C to make it fully mixed evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com